VEXILAR EDGE LC-507 Operation Manual

1

Contents

General Description 2

Specifications 4

Installation 5

Operation 11

Menu Functions 15

Typical Indications 20

Maintenance 28

Trouble Shooting 29

Other Products 30

Replacement Parts 32

Service and Support 33

Founded in 1965, Vexilar, Inc. has a

long history of bringing revolutionary

technology to the sport fishing industry. Just some of the Vexilar

firsts include: the first liquid crystal display, the first fish alarm, the

first three color display, and the first CRT and straight line paper

graphs, for the sport fisherman.

Edge LC-507 Operation Manual

2

General Description

The Edge 507 is like having two depth sounders in one. The features are designed to give the angler the best sonar for any situation. The split screen dual frequency design allows you to compar e

one view with the other to help you gain much more information

about what is below.

The dual frequency feature gives an you incredible advantage.

The Low frequency, 107 kHz, beam provides a wide cone with allot

of sensitivity. This allows you to see fish, as true arcs, as they pass

under the boat. Also, it allows you to see br eaks and structur e of f to

the sides of you. The high frequency beam, 400 kHz, is an excellent

compliment. It gives you a precise narrow beam for locating fish

and sharp edges of structure that are dir ectly under the boat. Using

3

these two beams together will allow you to locate fish, identify bottom conditions, and even control your boat better. Imagine following a weed line using the Edge. Simply keep the weeds within the

wide beam, but outside the narrow beam.

The Edge is very easy to use. All of the important control features are right on the front panel. Range, gain, auto/manual, and

clean line controls are only one button away. There are even separate controls for each screen.With three feature presets you can quickly add or change any of the features to meet the new conditions.

Imagine fishing with preset #1, with all features set for slow tr olling

along a sharp break. Then you decide to move to a new spot. Hit

the preset button to move you to the next feature setup, #2, that you

have programmed for high speed operation (super fast sweep and

higher gain). Now, down the lake you have found something interesting. Move to the next feature setup, #3, that you have programmed

for intense structure and fish finding (slower sweep speed, multiple echo view, fish alarm, and hard bottom alarm). Want your original settings back? Hit the preset button to get you back to setup #1

again. Internal memory backup insures that all feature selection will

be saved when the unit is shut off or disconnected from power.

The incredible features of the Edge ar e br ought to life by a beautifully detailed LCD. The 320 x 240 multi level pixel display is near

paper graph standards. Visibility on the brightest days and the darkest nights is unbelievable. The contrast control is right on the front

panel.

In addition to the innovative features, the Edge is a very high

quality device. It comes with the best warranty and product support in the industry. W ith 2 year warranty coverage and quality service and support you are sure to get the most out of the Edge. Got

a question or concern? One phone call is all it takes to quickly talk

to a technician who can help with anything you should need.

4

• Operating Voltage:

• Current Draw:

• Power Output:

• Frequency:

• Beam Angle:

• Resolution:

• Sounding Rate:

• Display Size:

• Dimensions:

• Weight:

10 - 16 Volts (12 Volts Nominal)

500mA (800 mA w/Backlight On)

1600 Watts (Peak to Peak) 200 Watts (RMS)

107 Khz & 400 Khz

38˚ & 10˚

320 x 240 Pixels

1800/Min. Maximum

5” x 3 1/2"

9.2"H x 8.9"W x 3"D

3.1 Lbs. (Unit Only)

SPECIFICATIONS

• Depth Ranges:

0-5', 0-10', 0-12’, 0-15', 0-20', 0-25’, 0-30', 0-35’, 0-40', 0-50', 0-60',

0-70’, 0-80’, 0-100’, 0-120', 0-150', 0-200'

LC-507 CONNECTIONS

5

INSTALLATION

You will need to find a place to mount the LC-507 that will make

it easy to view and reach. You must provide the unit with power

and mount the transducer and sensor assembly in an effective location.

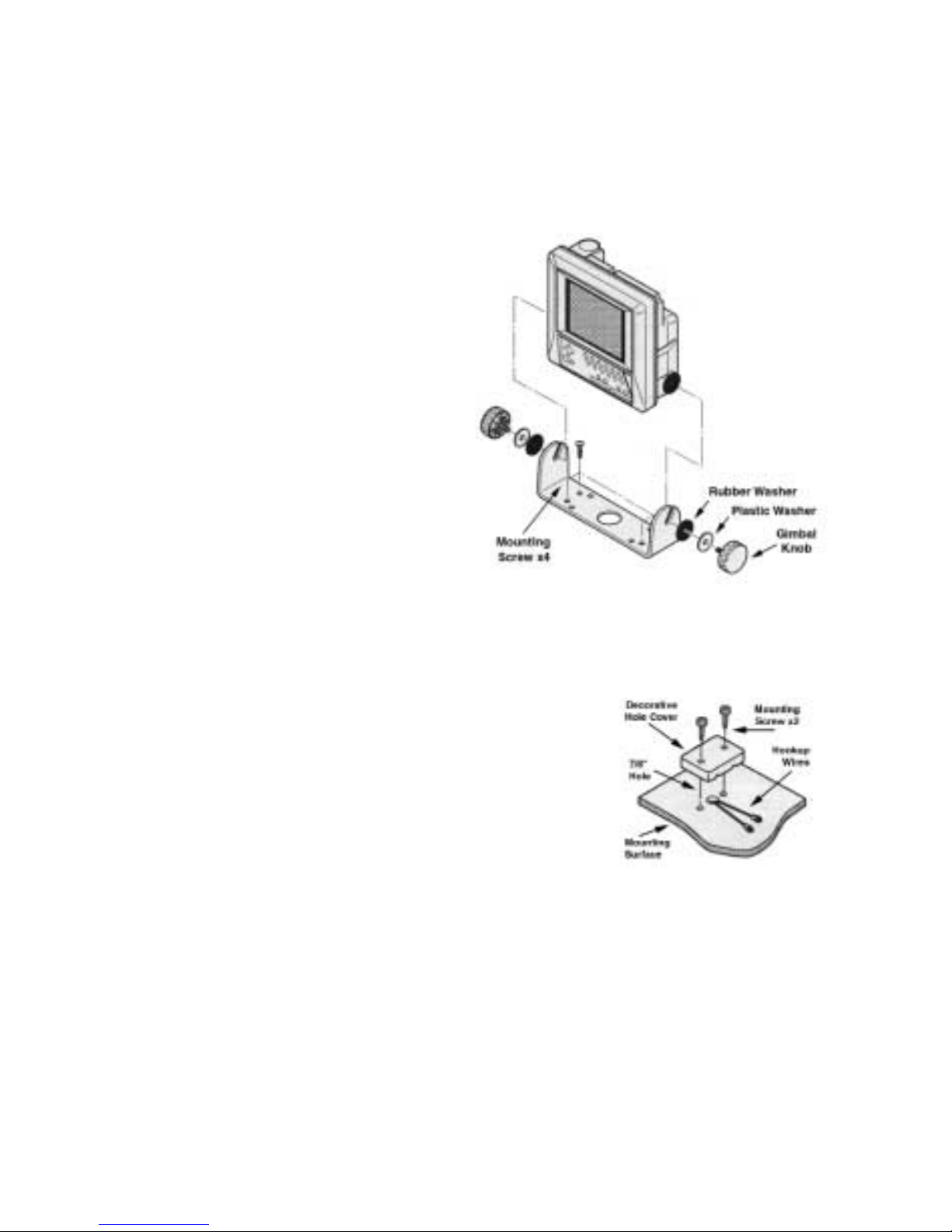

MOUNTING THE UNIT

Find a convenient place to

mount the unit. This may include

a boat seat, deck, dash, or a

portable case. Make sure that

there is plenty of room for the

unit to tilt freely without the

cables binding or stretching

behind the unit. Once you have

found the spot, remove the unit

from the gimbal bracket and

securely attach the bracket to the mounting surface. The screws pr ovided are for wood/carpet or dash mounting applications. An

optional removable swivel bracket is available. See page 32.

Note - ADecorative Wire Cover has been

included to help make your rigging job look

good. Use this to cover up the large hole you’ll

need to drill to fit the connector through.

CONNECTING THE POWER

Plug the 2 pin connector into the back of the unit. Find the closest source of 12 volts and route the cord to it. Keep the cord away

from sharp metal edges and avoid tight places where the cor d may

get crushed. Connect the white wire to positive and the black wire

to negative. If the cord provided is not long enough, more can be

added. Use 18 gauge wire minimum. Install the included 2 amp inline fuse, placed in the positive line, as close to the power source as

possible, to protect against shorts in the wiring.

6

MOUNTING THE TRANSDUCERS

Before you mount the transducers, you need to decide which

method is best for you and your boat. Your options are transom

mounted, in-hull mounted, trolling motor mounted, or portable.

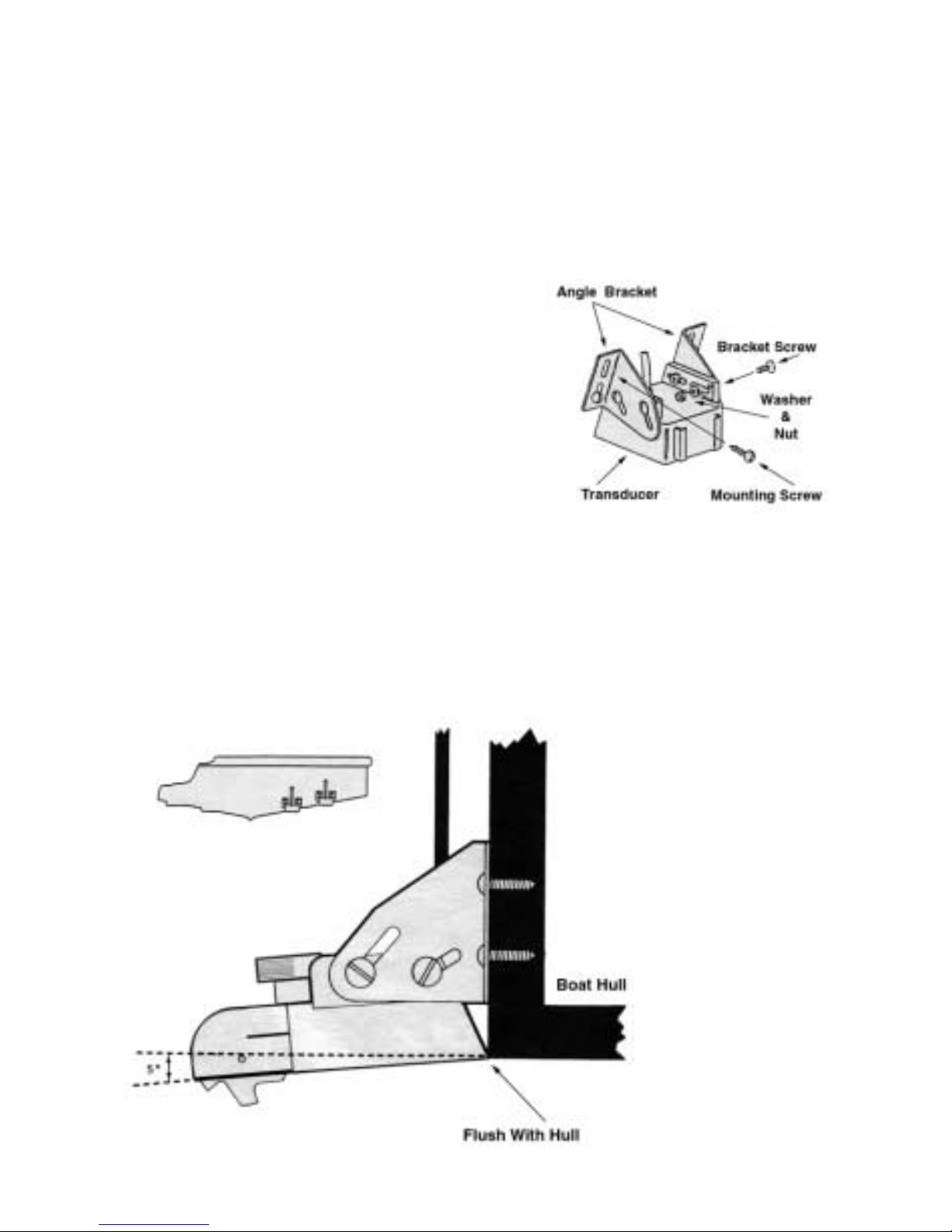

TRANSOM MOUNTING

Locate the transducers, and bracket

hardware. Each transducer has a mounting bracket assembly which includes;

2 Angle Brackets

4 Bracket Screws

4 Washers

4 Nuts

4 Mounting Screws

Attach the bracket to the transducer as shown in Figure 5. The

flanges of the bracket normally point outward, away from the transducer. If mounting space is tight, you can reverse the angle brackets and face the flanges inward.

Locate a spot

for each transducer similar to

the one in figure

6. Keep in mind

that you need

clear water flow

across the face of

the transducers

to insure a clear

reading at all

speeds. Stay

away from rivets,

ribs, or strakes

that would be

Figure 5

Figure 6

Figure 5

7

just in front of the transducers. They will disturb the water and

scramble the reading. The 107 kHz transducer is more susceptible

to this effect than the 400 kHz transducer, so it is a good idea to place

it closer to the center of the transom.

FOR EACH TRANSDUCER, FOLLOW THESE

INSTRUCTIONS TO OBTAIN A PROPER

INSTALLATION.

After you attach the mounting bracket to the transducer, hold it

up to the boat where you are planning to mount it (see figure 6).

Mark the four holes on the transom, or mounting plate, so that when

the bottom of the transducer is flush with the bottom of the boat the

holes are located at the bottom of the bracket slots. This gives you

room to "fine tune" the position of the transducer and optimize your

reading after you've put the boat back in the water. Drill out the

holes and install the transducer bracket assembly. T ighten the scr ews

down securely. Be sure to seal any holes drilled into the transom

with silicone to prevent water from leaking into the boat.

Route the transducer cord up to the unit taking the same care as

you did when you routed the power cord. Make sure that the cord

is restrained and not allowed to flop around in the wind. This can

cause stress on the wire inside the cable, and possible breakage. Plug

the transducer connector into the back of the unit and screw the

retaining ring down tight.

After you have put the boat back in the water confirm that you

can maintain a bottom reading at all boat speeds. If not, loosen the

bracket screws and tilt the transducer some more. Keep the front

edge flush with the boat, but drop the back edge down a little more.

If changing this angle several times does not clear up the reading,

loosen the mounting screws and slide the transducer down, slightly. Repeat these adjustments until you get a clear reading. Make sure

that all mounting screws are tight. Finally, fill any gap between the

transducer and the hull with silicone to prevent a rooster tail from

shooting up behind the boat.

8

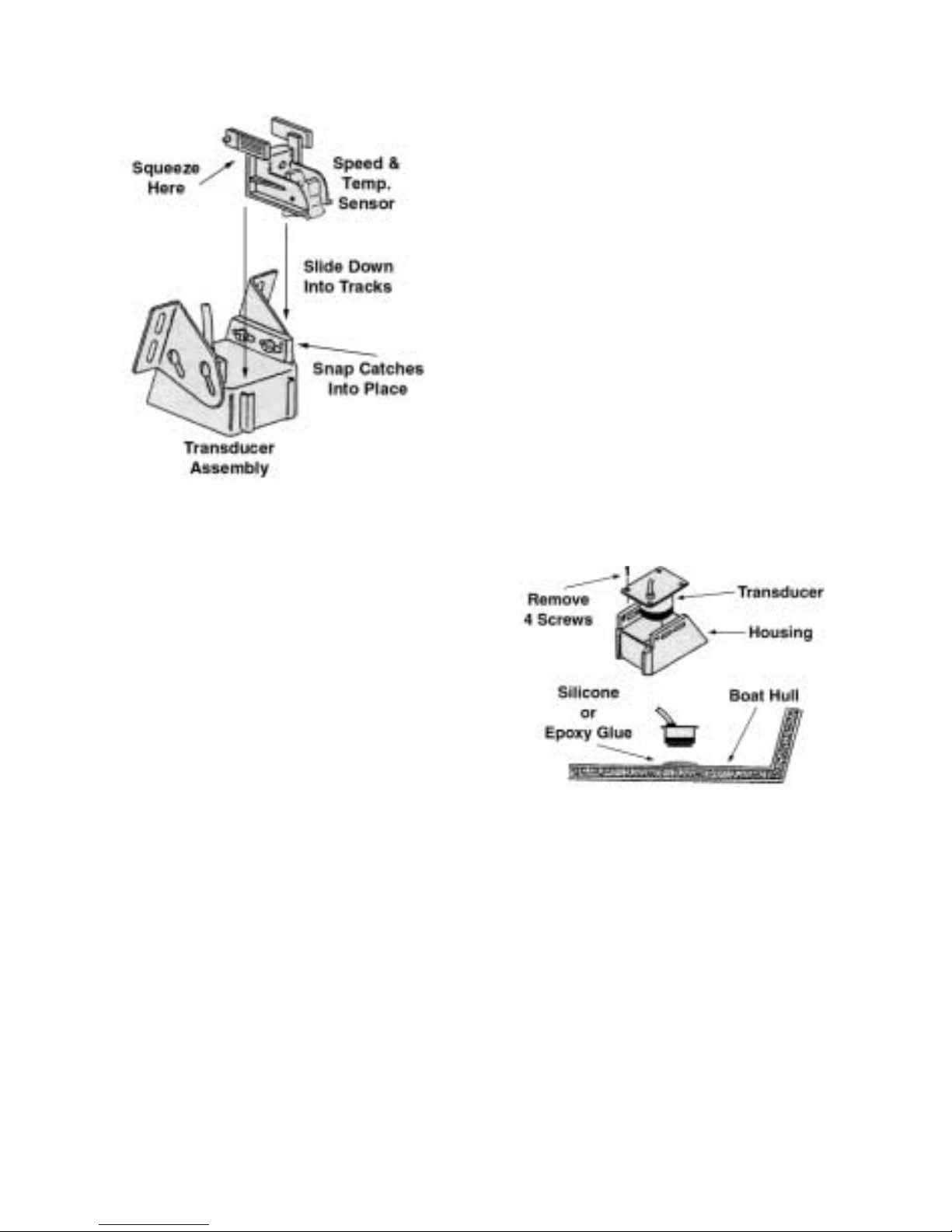

ATTACHING THE SENSOR

ASSEMBLY

The speed and temperature sensor assembly attaches to either transducer as shown. Pinch, or squeeze,

together the tabs at the top of the sensor and slide the assembly down into

the tracks on the back of the transducer. Push it down until it stops, and

then, push the tabs back, outward,

until the catches snap into the holes

on the transducer.

CAUTION - It is a good idea to

restrain the speed wheel from spinning

freely while trailering the boat. Damage may result because there is no

water to lubricate the wheel bearings. Arubber band works good for this.

IN-HULL MOUNTING

Finding the best location for the

transducers before mounting is critical. Choose a flat smooth spot near the

center of the bilge and near the back

of the boat. It is a good idea to make

a "test run" before you permanently

install each transducer. This makes sure that you can,

indeed, get a reading through your hull, and when the boat is on

plane. Put about a half inch of water in the bilge and hold the transducers in the intended location. Move the transducers around until

you get the best reading. Mark the spot.

Remove each transducer from its housing as shown in figure 8.

To install, clean the spot of mud and oil. Using an epoxy or silicone

glue, make a puddle about the same diameter as the transducer on

the hull. Place the transducer in the glue. Press it down firmly, gently twisting it back and forth, making sure that there ar e no air bubbles in the glue between the transducer and the hull. Let the glue

dry completely before turning the unit on.

Figure 7

Figure 8

9

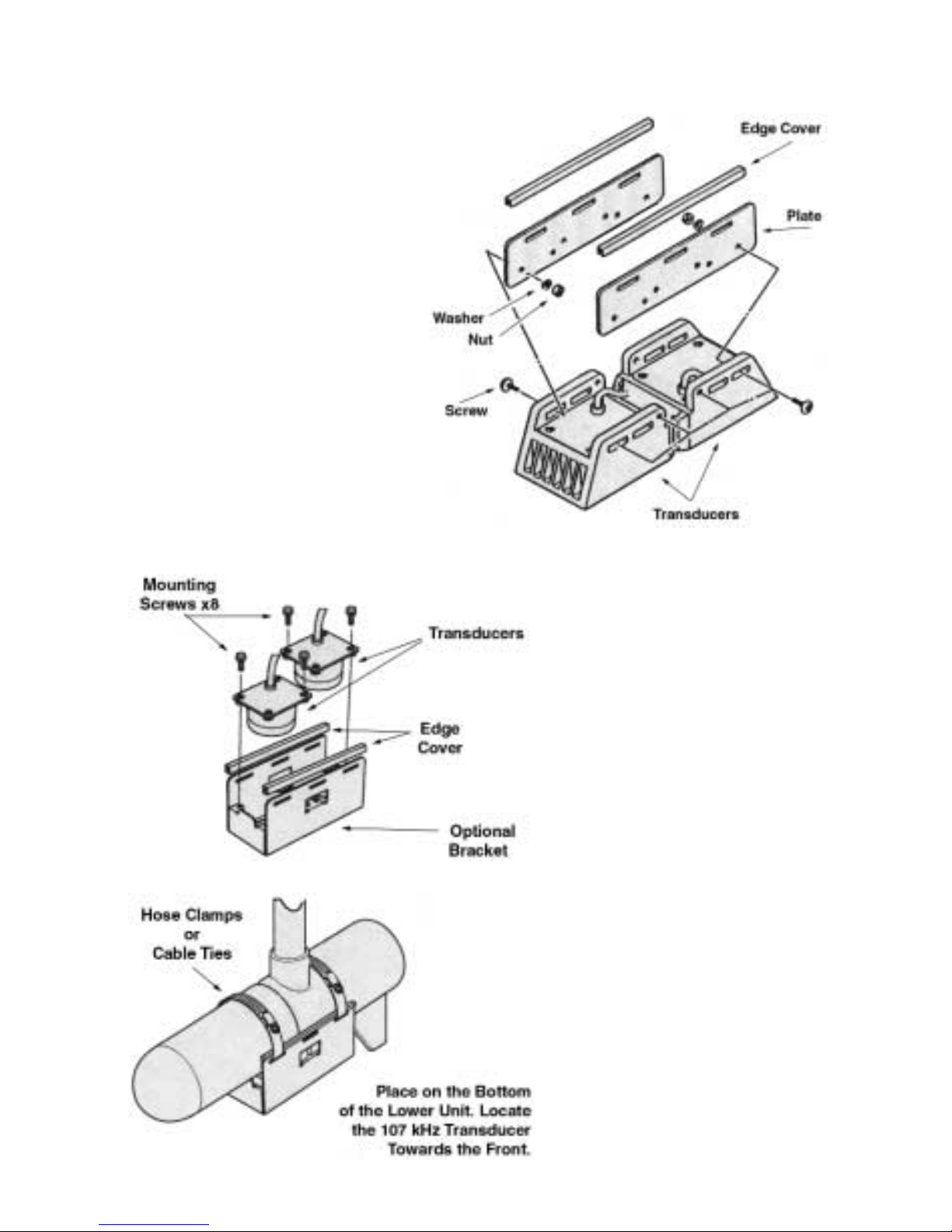

TROLLING MOTOR MOUNTING

Install the bracket assembly onto the transducers. Set

the two transducers down on

a flat surface, back to back.

Install the bracket assembly

as shown in figure 9. Use the

two included large cable ties

to attach the transducer to the

electric trolling motors lower

unit. Using the slots in the

transducer bracket, run the

ties through them and

around the motors lower

unit. Locate the transducers

on the bottom of the lower unit as in figure 10. Locate the 107 kHz

towards the front of the

motor. This transducer is

more susceptible to noise,

so keep it further away

from the propeller

Run the cables up the

shaft using smaller cable

ties to hold it in position.

Make sure that the cables

will not be damaged by the

movement of the trolling

motor. Plug the transducer

connectors into the back of

the unit and tighten the

retaining rings.

There is an optional one

piece mounting bracket,

part #TMB003. This bracket is more compact and

durable than the standard.

Figure 9

Figure 10

10

SENSOR MOUNTING

If you mount the transducers inside the hull of the boat or on an

electric trolling motor (described on page 8) you will need to use

the provided sensor mounting bracket, instead of the transducer, to

mount the speed and temperature sensor.

Snap the sensor assembly into the

mounting bracket as shown in figure 11.

Hold the assembly up to the boat at the bottom of the transom. Stay away from rivets,

ribs, or strakes that would be just in front of

the sensor, as they can affect your speed

reading. Mark the two holes on the transom, or mounting plate, so

that when the bottom of the sensor is flush with the bottom of the

boat the holes are located at the bottom of the bracket slots. The bottom of the speed wheel should be below the transom line.

Locate the two mounting screws and drill the appropriate sized

holes in the transom. Install the sensor assembly and tighten it down

securely. Don’t forget to seal the holes with silicone to prevent leakage.

CAUTION - It is a good idea to restrain the speed wheel from spinning freely while trailering the boat. Damage may result because ther e is

no water to lubricate the wheel bearings. Arubber band works good for

this.

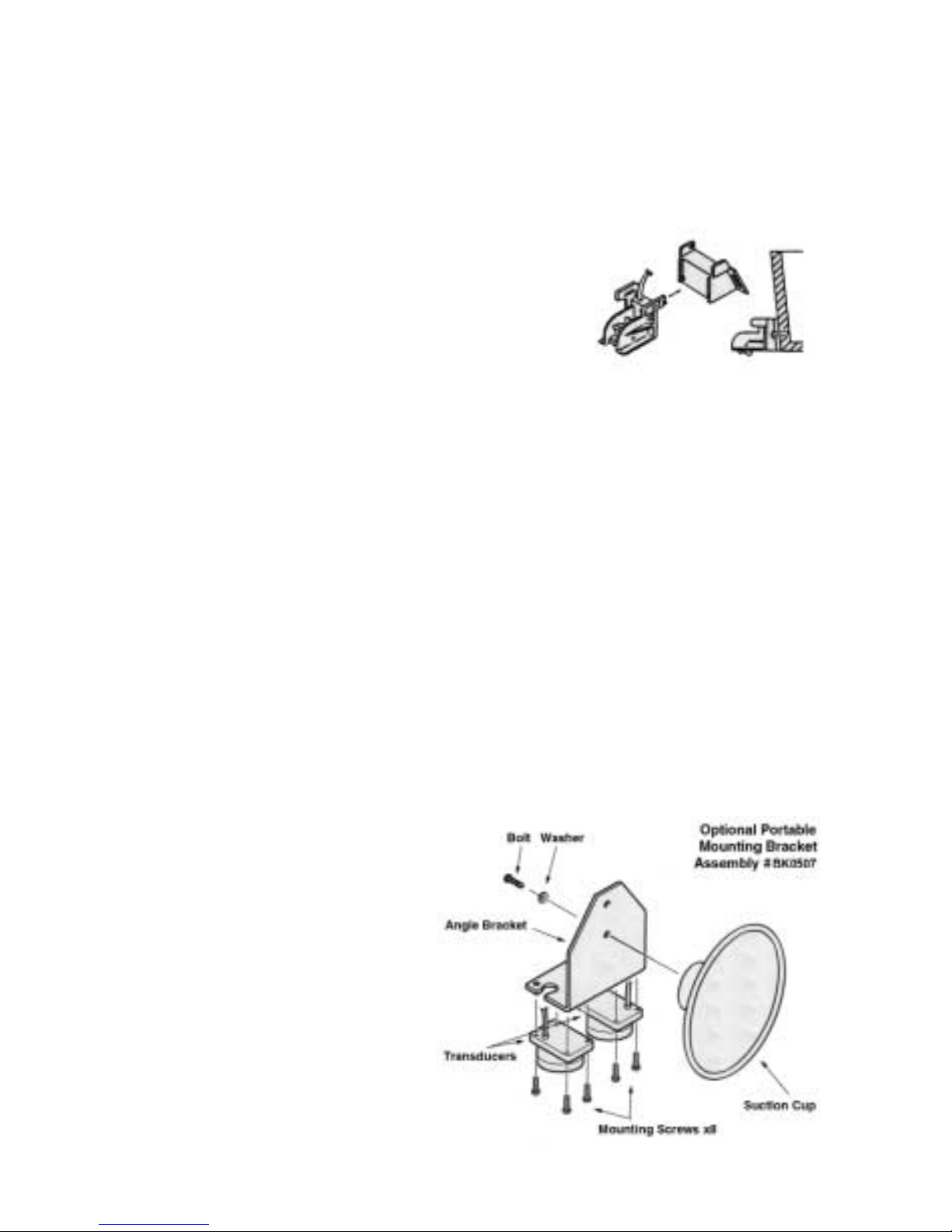

PORTABLE MOUNTING

An optional suction cup

bracket can be used to temporarily attach the transducers to the transom or side of

the boat. The cup should be

placed in a location where it

will not be torn off when the

boat goes high speed. The

optional BK0507 suction cup

mounting bracket works well

for this application.

Figure 11

Figure 12

11

OPERATION

The LC-507 is a sophisticated depth sounder, yet very easy to

operate. All of the main sonar controls are right on the front panel.

There are even seperate contr ols for each beam. Figur e 13 shows the

control panel of the unit.

Figure 13

TURNING THE UNIT ON

Once the unit is connected to power you can turn it on.

Press the ON/OFF button. You will hear a series of short

beeps before the display shows up. To turn the unit off, press

this button again. All of your feature and menu settings will automatically be saved in memory. When you turn the unit on again,

these settings will be restored.

USING THE BUILT-IN SIMULATOR

When learning the operation of the unit, it may be helpful to activate the internal simulator. This will play a short program, on the

display, that will simulate a real world situation. You can experiment with all of the panel controls and menu functions and see the

results on the display.

To turn the simulator on, first make sure the unit is off. Now,

press the ON/OFF button and hold it in. You will hear the normal

series of beeps, followed by up to three more sets of beeps, about

three seconds later. Release the button after the last beep and the

simulator will start. There are three different programs. Each time

you start the simulator, a different program will start.

Loading...

Loading...