Page 1

1

CONTENTS

General Description 2

Specifications 3

Gimbal Unit Assembly and Installation 4

Portable Unit Assembly and Installation 10

Operation 14

Menu Functions 16

Using the Zoom modes 19

Understanding the Colors 20

Typical Indications 21

Frequently Asked Questions 24

Maintenance 25

Troubleshooting 26

Other Vexilar Products 27

Optional Transducers 30

Service and Support 32

Founded in 1960, Vexilar, Inc. has a long

history of bringing revolutionary

technology to the sport fishing industry.

Some of the Vexilar firsts include: the first

liquid crystal display, the first fish alarm,

the first three color display, the first CRT and straight line

paper graphs, and the first split-screen zoom flasher for the

sport fisherman.

CLC-200 Operation Manual

Page 2

2

GENERAL DESCRIPTION

The five-color CLC-200 is a compact and light-weight

liquid crystal depth sounder. It indicates depth, shows

changes in bottom content, and conditions. It can also

discriminate between large underwater targets, such as

fish, and smaller targets such as bait fish and plankton.

The unit transmits bursts of high frequency pulses which

are converted from electrical to mechanical energy by the

transducer. These "sound" pulses radiate from the

transducer downward and are reflected back up to the

transducer where the energy is converted back to

electrical signals. The CLC-200 then processes these

signals and displays them.

The graphic display is accomplished by activating

individual or groups of multi-colored pixels, or dots, on

the LCD. The first vertical column of pixels, on the right

edge of the display, shows the most current information.

This column is then moved to the next place, to the left, as

soon as a new column is

ready. This process is

repeated continually to make

up the graphic display. Thus

what you see on the display

is a brief history of what the

boat just went over. The CLC200 also displays the depth as

an easy to read digital

number on the right side of

the display.

Page 3

3

• Operating Voltage:

• Current Draw:

• Power Output:

• Frequency:

• Beam Angle:

• Resolution:

• Sounding Rate:

• Display Size:

• Display Colors

• Background Color

• Temperature Range

8 - 17 VDC (12 Volts Nominal)

83 mA

400 Watts (Peak to Peak)

200 kHz

12˚

(Gimbal) / 22˚

(Boundary Waters)

192 x 160 Pixels

410/min. Max

2 3/4" x 2 1/4"

Black, Red, Green, Yellow, White

Selectable White or Black

30 - 100 Degrees F

SPECIFICATIONS

• Depth Ranges:

0-20', 0-30', 0-50', 0-75', 0-100', 0-125',

0-150', 0-200', 0-250’, and 0-300'.

CLC-200 Gimbal version (Left)

CLC-200TM - Transom transducer

CLC-200PK - Puck style transducer

CLC-200BW Boundary Waters

portable version (Right)

Page 4

4

UNIT ASSEMBLY (Gimbal Version)

You will need to

find a place to mount

the CLC-200 that will

make it easy to view

and reach. You must

provide the unit with

power and mount the

transducer in an effective location.

MOUNTING THE UNIT

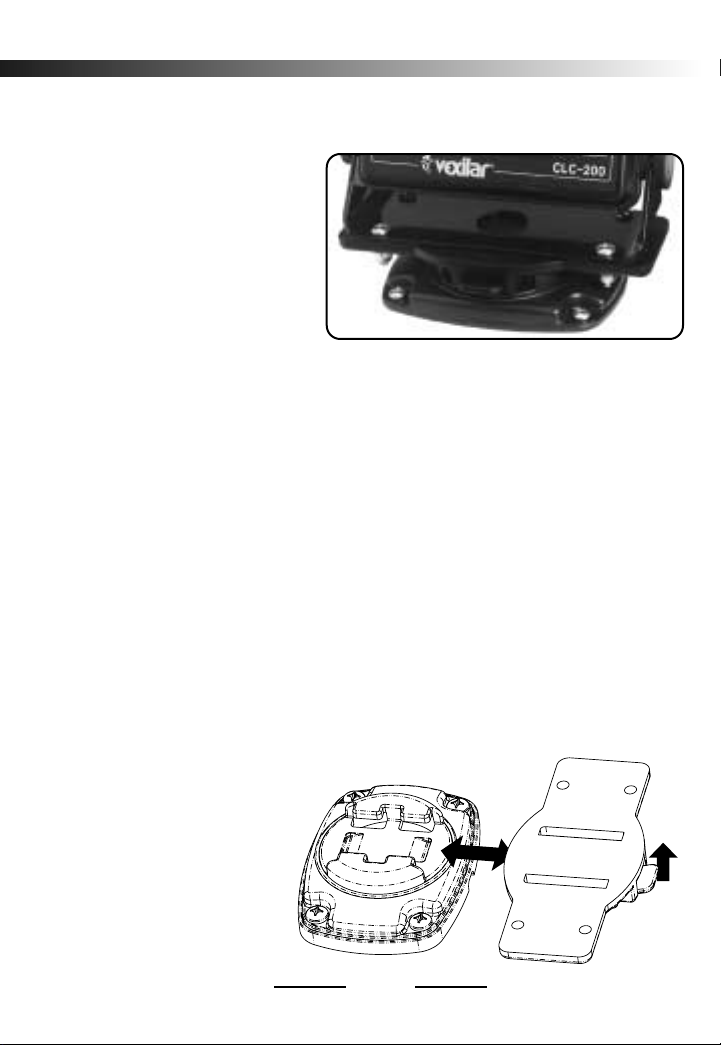

Attach the CLC-200 to the ProMount™ bracket system.

First, remove the platform by lifting the tab and pulling it

forward, as in figure 4. Use the supplied hardware with

locking washers to securely attach your unit to the removable platform section. Be sure you mount the unit to the

ProMount

™ platform so that the “lift” tab is facing forward.

You are now ready to locate the permanent base. First

look for a flat area for mounting. If you are going to drill

holes in your dash or deck to run cables, make sure you

spend a little time to place the holes in the right spot before

beginning. Allow for

plenty of movement

for your electronics

and cables. If you are

drilling a large hole

to accommodate the

cable connectors, you

may want to position

Lift

Pull

Figure 4

Page 5

5

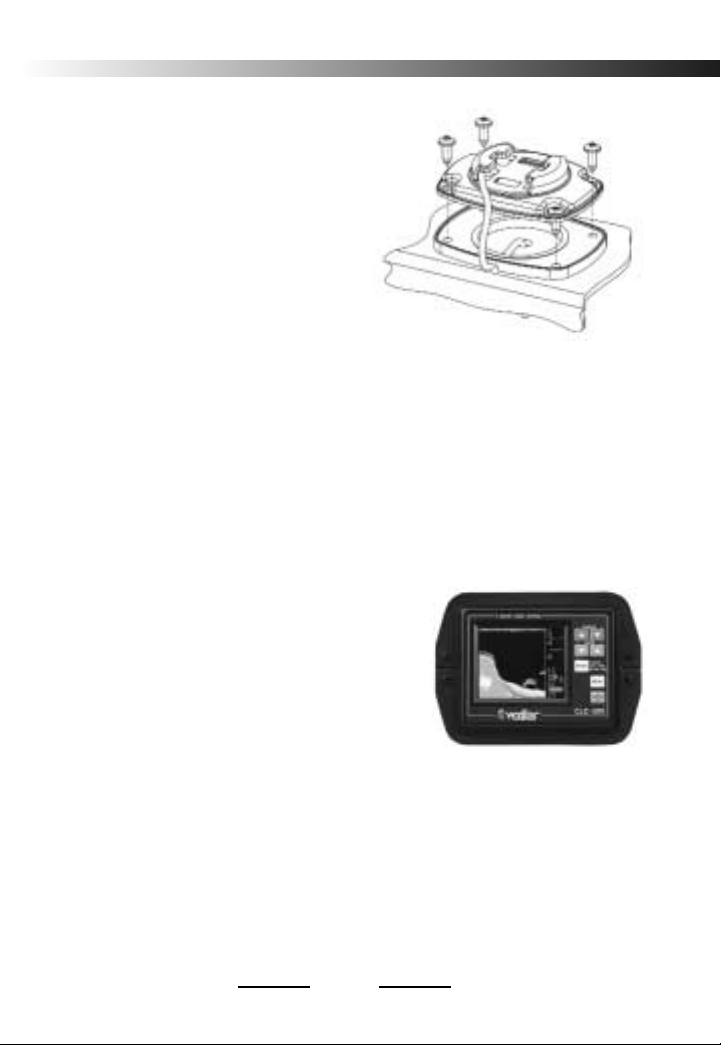

your base directly over the hole

using the hole cover spacer

gasket. Be sure to run cables out

the back side of the spacer

gasket which has the pre-cut

groove. (See figure 5 )

Now mark the center of each

of the four holes with a fine point

marker or center punch. Pre-drill

the mounting holes using a 1/8" drill bit and use the

supplied mounting screws. DO NOT OVERTIGHTEN THE

SCREWS.

When reattaching the ProMount platform (unit attached)

to the mounted base, slide it back into position until you

hear a loud“click”. This confirms it is locked into place.

IN-DASH MOUNTING

The CLC-200 can be mounted in

the dash of your boat using the

optional In-Dash Mounting Kit (part#

IDK001). This kit will contain the

necessary hardware and instructions

to complete the installation.

CONNECTING POWER

Plug the 2 pin connector into the back of the unit. Find

the closest source of 12 volts and route the cord to it. Keep

the cord away from sharp metal edges and avoid tight

places where the cord may get crushed. Connect the white

Figure 5

CLC-200 In-Dash

Kit #IDK001

Page 6

wire to positive and the black wire to negative. If the cord

provided is not long enough, more can be added. Use 18

gauge wire minimum. Install the included 1 amp in-line

fuse, placed in the positive line, as close to the power source

as possible, to protect against shorts in the wiring.

ASSEMBLING THE TRANSOM STYLE

TRANSDUCER

Locate the transducer, and bracket hardware. This

includes;

1 - Transducer

2 - Angle Brackets

4 - Bracket Screws

2 - Bracket Plates

4 - Nuts

4 - Mounting Screws

Attach the bracket to the transducer as shown in Figure

7. The flanges of the bracket normally point outward, away

from the transducer. If mounting space is tight, you can

reverse the angle brackets and face the flanges inward.

TRANSOM TRANSDUCER INSTALLATION

When choosing an area to mount the transducer, keep

in mind that you need clear water flow across the face of

the transducer to insure a clear reading at all speeds. Try

to stay away from rivets, ribs, or strakes that would be just

in front of the transducer. They can disturb the water and

scramble the reading.

6

Page 7

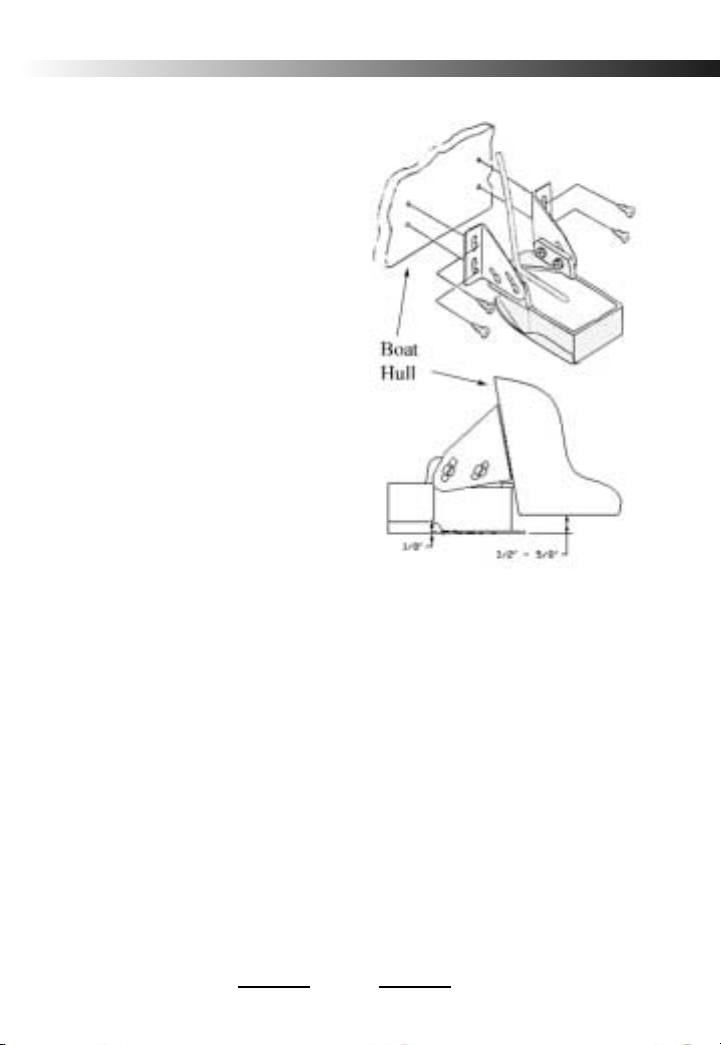

With the mounting bracket

attached to the transducer,

hold it up to the boat where

you are planning to mount it.

Mark the holes on the transom,

or mounting plate, so that

when the bottom of the

transducer is flush with the

bottom of the boat the holes are

located at the bottom of the

bracket slots. This gives you

room to "fine tune" the position

of the transducer and optimize

your reading after you've put

the boat in the water. Ideally,

the transducer should be just

under the bottom of the boat.

However, you may need to

lower it 1/2” to 5/8” to get a clear reading at top speed.

Drill out the holes and tighten the bracket to the hull

securely. Be sure to seal any holes drilled into the transom

with silicone to prevent water from leaking into the boat.

Give the transducer a slight tilt downward so that the back

is about 1/8” lower than the front. Tighten the bracket

screws and nuts securely. Run the transducer cord up to

the unit. Plug the transducer connector into the back of the

unit and screw the retaining ring down snugly.

7

Figure 7

Page 8

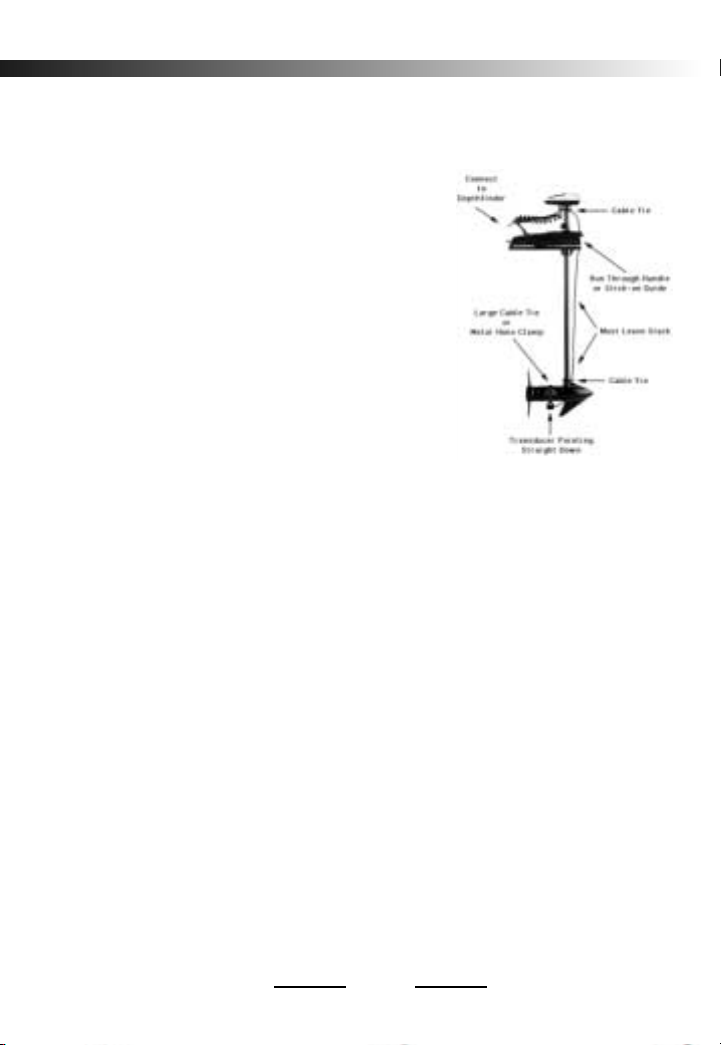

PUCK TRANSDUCER MOUNTING

To attach a Puck style transducer to a trolling

motor use the large cable tie

provided. Notice the slots in the

transducer for this purpose. Locate

the transducer on the bottom of the

lower unit (figure 8). Run the cable

up the shaft using smaller cable ties

to hold it in position. Make sure that

the motions of the trolling motor will

not damage the cable. Plug the transducer connector into the back of the

unit and screw the retaining ring down tight.

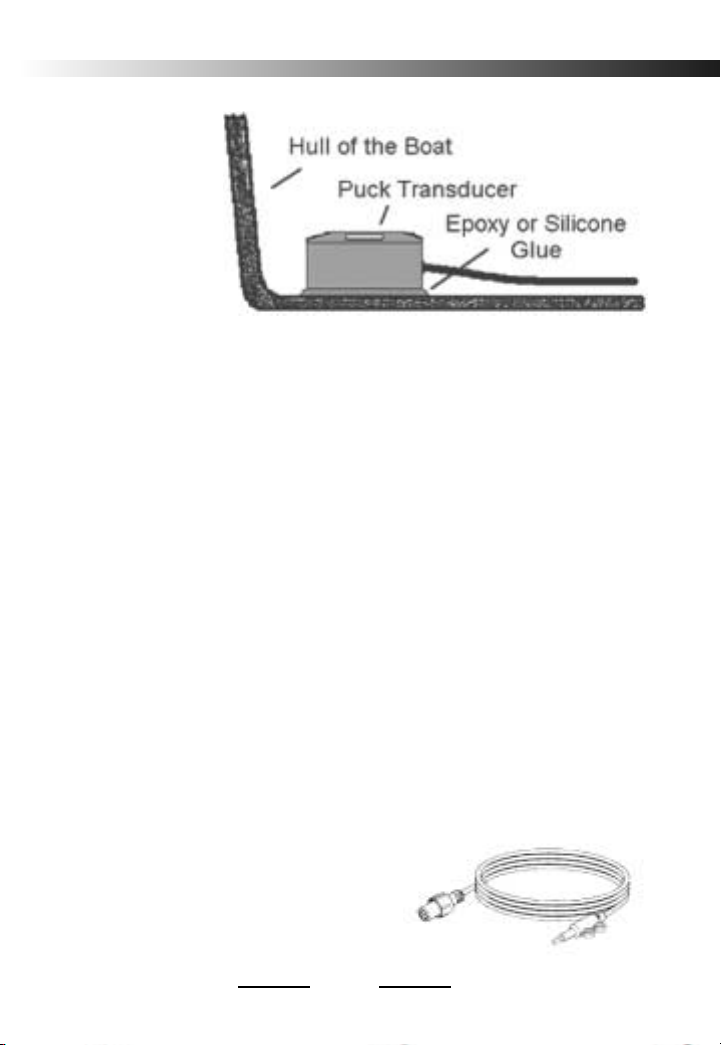

IN-HULL MOUNTING

Puck transducers can also be mounted in-hull. This

method gives high-speed reading without the worry of

having a transducer hanging on the back of the boat to get

damaged. Finding the best location for the transducer before

installation is critical. Choose a flat smooth spot near the

center of the bilge and near the back of the boat. Be sure to

make a "test run" before you permanently install the

transducer to make sure that you can get a good reading

through your hull at all speeds. When the boat is in the

water, put about a half inch of water in the bilge and hold

the transducer in the intended location. Move the it around

until you get the best reading. Mark the spot.

To install the transducer, first clean the spot of mud and

oil. Using an epoxy* or silicone glue, make a puddle, about

8

Figure 8

Page 9

the same size as

the transducer,

on the inside of

the hull. Place

the transducer in

the glue and

press it down

firmly, gently

twisting it back and forth, making sure that there are no air

bubbles in the glue between the transducer and the hull. It

is important that you let the glue dry completely before

turning the unit on.

* If your hull is aluminum, use silicone. This material will flex with

the hull at high speeds and in rough water.

9

OPTIONAL TEMPERATURE SENSOR

To install the optional temperature sensor (part# TP0002)

use the supplied mounting screws to secure the probe to

boat transom. Alternately, you can use a plastic cable tie or

wire twist tie to secure it to existing hardware. The probe

should be in the water, but not below the hull line.

Route the cable up to the unit just as you ran the

transducer cable. Remove the plastic protective cap from

the temperature sensor jack on the back of the unit. Be sure

to keep it for future use. Plug the 8

pin connector into the CLC-200.

When you turn the unit on, the

temperature reading will appear on

the screen automatically.

TP0002

Page 10

10

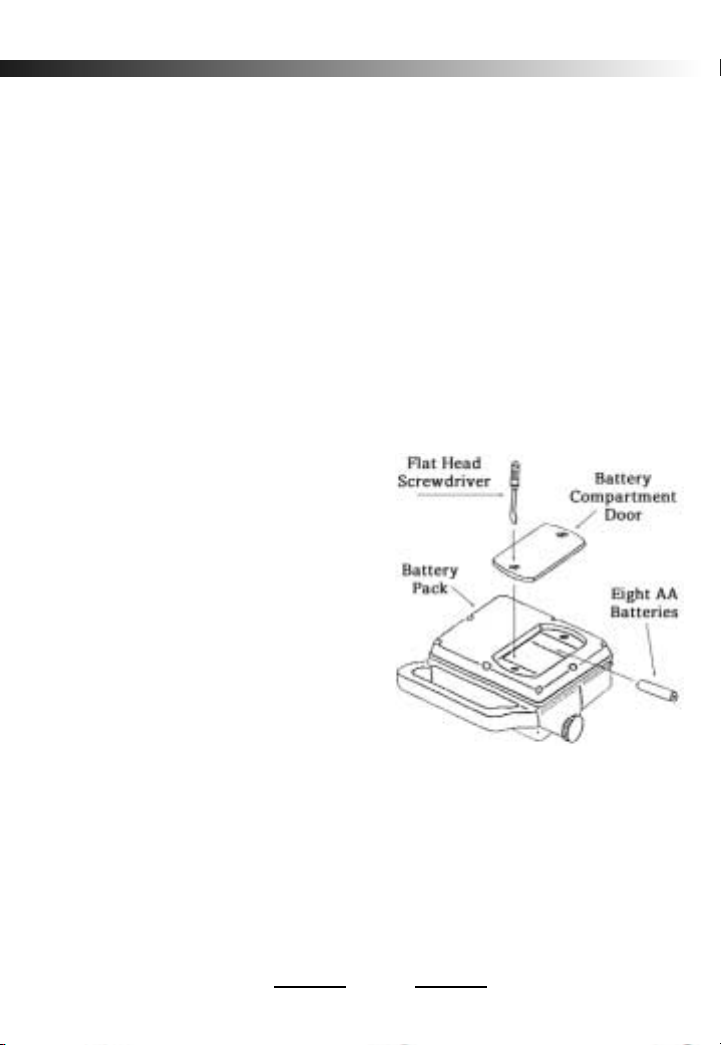

UNIT ASSEMBLY (Portable Version)

Remove the gimbal knobs from the unit and then

remove the rubber washers from the knobs. Set the battery

pack down on a table top and place the unit, face down,

inside with the top of the unit opposite the battery pack

handle. Place one gimbal knob on each side of the unit.

Place the metal ends of the carry strap over each knob with

the bend pointing outward, away from the threads. Put a

flat rubber washer onto each of the threaded shafts to hold

the strap ends in place. Install the knobs into the unit,

through the battery pack. Tighten both slightly.

INSTALLING THE

BATTERIES

Turn the unit over to

access the battery compartment door (figure 11).

Unscrew the two retaining

screws and remove the compartment door. Install eight

AA

ALKALINE batteries (not

included) by following the

imprinted guides in the battery compartment. Replace the

compartment door and tighten the screws back into place.

Plug the power cord from the battery pack into the

CLC-200 and tighten snugly.

Note— The battery compartment is not sealed. After use in a wet

environment, remove the batteries and leave the compartment open.

This allows it to dry and minimize any corrosion that may develop.

Figure 11

Page 11

ASSEMBLING THE TRANSDUCER

Locate the transducer and bracket assembly. This

includes:

1 - Transducer

1 - Metal Bracket

1 - Suction Cup

1 - Short Panhead Screw

2 - Short Machine Screws

2 - Nuts

2 - Washers

1 - Safety rope

The suction cup installs using the single short screw.

Attach it to the hole in the flat bracket as shown in figure

12. Now locate the transducer and the remaining hardware.

Install the transducer onto the bracket as shown. Install the

two short screws through the transducer slots and into the

bracket holes. Place the washers and then the nuts onto the

screws and tighten

securely. Finally,

install the safety rope.

Tie a knot in the rope

and run it through

the upper hole in the

bracket until the knot

stops at the hole. You

will tie the other end

to the boat.

11

Figure 12

Page 12

12

TRANSDUCER MOUNTING

The suction cup bracket assembly is designed to be

mounted on the side of a canoe or kayak. However, it can

also be attached to the transom (back) of a normal fishing

boat.

Wet the suction cup and press the assembly onto the

surface of the hull in the area where you are going the attach

it. Slide the assembly up or down until the transducer is

completely in the water. You may want to bend the

bracket so that the transducer is not pointing off at an angle.

Ideally, it should point straight down when your boat is

normally loaded.

Tie the end of the safety rope to the boat. Leave as

little slack in the rope as you can. If the suction cup lets

loose, the rope can save your transducer and depth sounder

from being lost.

If you’ll be mounting to a flat

transom and you wish to get clear

readings while the boat is moving at

faster speeds, you may want to

purchase the optional Tri-Cup

bracket (part# BK0061) shown in figure 13.

IN-HULL MOUNTING

This method, gluing the transducer to the hull, gets similar results as if you were mounting the transducer externally, only there is no transducer on the outside of the boat

to get damaged by impact or tangled in weeds or fishing

line. This method works well for most types of single layer

Figure 13

Page 13

13

hull materials, including aluminum. However, the transducer is not easily removed

after installation.

Finding the best location

for the transducer before

installation is critical. Choose

a flat smooth spot near the

center of the hull and near the back of the boat. It is a good

idea to make a "test run" before you permanently install

the transducer to make sure that you can indeed get a

reading through your hull at all speeds. When the boat is

in the water, put about a half inch of water in the bottom

of the boat and hold the transducer in the intended

location. Move the transducer around until you get the best

reading. Mark the spot.

To install the transducer, first clean the spot of mud and

oil. Using an epoxy* or silicone glue, make a puddle, about

the same size as the transducer, on the inside of the hull.

Place the transducer in the glue. Press it down firmly,

gently twisting it back and forth, making sure that there

are no air bubbles in the glue between the transducer and

the hull. It is important that you let the glue dry completely

before turning the unit on.

* If your hull is aluminum, use silicone. This material will flex with

the hull at high speeds and in rough water.

Page 14

14

OPERATION

The CLC-200’s control panel contains the basic controls

you need to operate the unit. For example, Range controls

how deep the unit will read and Gain controls how much

signal will be displayed on the screen. This section describes

in detail the controls of the CLC-200.

ON/POWER/OFF

This turns the CLC-200 ON and OFF. If you choose to

modify any of the control features, your settings will be

saved in memory when the unit is turned off or disconnected from power. When you turn it on again, the unit

will operate the same way as it did when you last used it.

RANGE CONTROL

The two red buttons at the top of the control panel set

the depth range when the Auto Range Mode is off. Pressing

the (1) button changes the range to the next shallowest

range. Pressing the (2) button changes the range to the

next deeper range.

GAIN CONTROL

The two green buttons control the CLC-200’s gain level

when the Auto Gain Mode (located in the menu controls)

is set to off. Pressing the

(3) decreases the gain level

and

(4) button increases the gain level.

Page 15

MODE

During Normal Operation - The Mode button cycles

through the three different types of views; Normal, Auto

Zoom, and Bottom Lock. Zoom modes will be described

in a coming section.

While in the Menu - The Mode button is used to

toggle between menu choices. The Menu choices will be

described in the next section.

MENU

Pressing the MENU button opens the menu page.

Pressing it again will go back to the normal view. Each item

in the menu will be explained in the next section.

15

Page 16

16

MENU FUNCTIONS

Press the MENU button to enter the CLC-200’s menu

page. To select a feature item, press the (1) or the (2)

button to move the curser and highlight the desired item.

CONTRAST

Contrast controls the overall lightness or darkness of

the display. Press the (4) button or the (3) to increase

or decrease the display contrast to your preference. Contrast

adjustments should only be required after large changes in

ambient light or if you switch COLOR modes (see COLOR).

SWEEP

Sweep controls how fast the image moves across the

screen. There are 4 sweep speeds, plus STOP. The current

sweep speed is displayed as a series of red arrows on the

right side of the display. Four arrows showing indicates

the fastest sweep speed. Press the

(4) button or the

(3) to increase or decrease the sweep speed to your

preference. The sweep speed should roughly match the

speed of the boat. When in doubt, use the fastest sweep

speed setting.

AUTO_R

AUTO_R controls the CLC-200’s Automatic Range

Control feature. When set to ON, the unit will

automatically change the range to the optimal setting. To

Page 17

select whether this feature is ON or OFF, highlight the item

and press the MODE button on the control panel. In general, you will want to use the Automatic Range Control

feature. However, there may be times when you want to

lock a range setting or switch to a deeper range; for instance,

if you want to see the second echo of the bottom.

AUTO_G

AUTO_G controls the CLC-200’s Automatic Gain

Control feature. To select whether this feature is ON or OFF,

highlight the item and press the MODE button on the

control panel. When set to ON, the unit will

automatically adjust the gain level for optimal performance.

Keep the feature set to ON for normal operation. You can

set it to OFF if you want to change the gain setting to see

more or less detail.

F_ALARM

F_ALARM turns the CLC-200’s fish alarm feature on

and off. To select whether this feature is ON or OFF,

highlight the item and press the MODE button on the

control panel. When set to ON, an alarm will sound each

time the unit sees a substantial target separated from the

bottom. The fish alarm makes a series of short beeps.

17

Page 18

18

B_ALARM

B_ALARM controls the Bottom Alarm feature. To select

whether this feature is ON or OFF, highlight the item and

press the MODE button on the control panel. When this

item is ON and highlighted, you can press the

(4)

button or the

(3) to increase or decrease the minimum

depth at which the alarm will sound. The bottom alarm

makes a series of long beeps.

TEMP_ADJ

TEMP_ADJ is used to calibrate the optional

temperature sensor. Normally, this setting does not need

to be changed, but it allows for adjustment if necessary.

D_UNIT

D_UNIT is used to switch the depth unit between Feet

and Meters.

RESET

Use this feature to trouble shoot problems or to get back

to a "known state”. Highlight the RESET item and then

press the MODE button to reset all items to the initial

factory settings.

Page 19

19

USING THE ZOOM MODES

The CLC-200 offers three different types of depth views,

Standard, Auto Zoom, and Bottom Lock. Pressing the Mode

button on the front panel cycles through the different

settings.

Standard - This view is the normal depth view. It shows

the entire water column from the surface to the bottom.

This view shows the maximum amount of history, as it uses

the entire width of the graphical view screen.

Auto Zoom - This view splits the graphical screen into

two parts. The right side shows the the Standard view. the

left side shows a magnified view of the bottom of the

current depth range. This view allows for an increased

ability to see small structure and depth changes. It also

makes targets very close to the bottom much easier to see.

Bottom Lock - This mode also splits the screen into two

parts and works much the same as the Auto Zoom feature.

However, Bottom Lock identifies the bottom signal and

“locks” it into position on the zoom display. Adepth scale

appears in this mode.The bottom will always line up with

the zero mark. The numbered foot marks shown are feet,

or meters, away from the bottom. This mode can be very

useful when trying to see fish and structure near the

bottom when in heavy waves or over quick changes in

depth.

Page 20

20

UNDERSTANDING THE COLORS

The CLC-200’s color LCD display gives you much more

information that a normal single color unit. The 5 different

display colors of the CLC-200 represent five different

levels of sonar signal strength. This is very useful for

helping you determine bottom content, target size and

target position. In addition, the CLC-200 offers two

different color modes. MODE 1 shows a light background

and MODE 2 show a black background.

SIGNAL MODE 1 MODE 2

Echo 1 (Strongest) Black Red

Echo 2 Red Yellow

Echo 3 Green Green

Echo 4 Blue White

Echo 5 (Weakest) Yellow Blue

Background White Black

Page 21

21

TYPICAL INDICATIONS

If the AUTO_R AND AUTO_G modes are set to on, the

CLC-200 will find bottom and adjust the gain for the best

view automatically. This can take just a short moment or a

few minutes, depending on the depth and conditions. As

soon as the bottom begins to sweep across the screen in the

graphical view, the digital readout of the depth will appear

in the information view.

You can determine the general hardness of the bottom

by looking at the color content and width of the bottom

signal. Generally, harder bottoms will contain the stronger

echo colors and be of a fairly narrow width. Softer bottoms

will contain weaker echo colors and have a wider overall

width.

Figure 16

Surface Line

Bottom

Fish

Current

Depth

Depth Scale

Scroll Rate

Gain

Level

Battery

Power

0 - 100 %

AutoRange (on)

AutoGain

(off)

Page 22

22

SEEING FISH

Fish will appear as distinctive targets above or very

close to the bottom signal. The colors will help you

identify fish from floating debris. If the target appears large

in size and contains stronger echo colors, you can assume

it's something significant, like a fish. If the target appears

smaller or broken up and contains weaker echo colors, you

can assume it is bait fish or floating debris. However,

sometimes this can indicate a fish away from the boat, in

the outer area of the transducer cone area.

SURFACE CLUTTER

The line of information going across the top of the

display represents the surface of the water. This line can

get quite wide at times, due to surface clutter. Tiny marine

life, such as algae or plankton, can be responsible for this.

Choppy or rough waters can also be a cause as tiny air

bubbles are forced down under the surface. Surface

clutter has little effect on the performance of the unit.

HIGH SPEED OPERATION

The CLC-200 can read depths at almost any boat speed.

Due to the limited speed of the display, the displayed

bottom may be some distance behind you, depending on

how fast the boat is traveling. Once the boat starts to plane,

turbulence will develop behind the transom. If your

transducer is poorly mounted, the unit will lose the

Page 23

23

bottom at a certain boat speed. This is due to all of the air

bubbles in the turbulent water. Readjustment of the

transducer mounting should solve this problem.

SHALLOW WATER OPERATION

When the CLC-200 is in the AUTO mode, it

automatically senses the bottoms depth and tries to keep

the best view at all times. Although the display may not

show it, the CLC-200 is monitoring basic sonar signals such

as the bottoms second echo and various target's signal

strengths. This way it can maintain the optimum gain level,

automatically, for you.

In very shallow water (less than 3 feet) the unit can get

"over-welmed". In this condition the unit can show

erroneous information. The graphic display will become

overly cluttered and the digital numbers on the display can

read depths that are much deeper than reality. These depths

are actually multiple echoes of the real bottom. It is

important to use caution when navigating in shallow

waters. Use common sense. Don't rely solely on your

depth finder.

It often helps to turn off the automatic range and gain

features and manually set the range to the shallowest

setting and the gain to a low level. If the digital depth

reading doesn't seem right, it is probably a multiple of the

correct depth. Use the graphic display as a better reference.

Page 24

24

FREQUENTLY ASKED

QUESTIONS

Q - Can the CLC-200 be used for Ice Fishing?

A - Yes, but it’s performance may be very limited. LCD

depth sounders in general do not work well for ice fishing.

The type of display has significant speed and temperature

limits as opposed to flasher depth sounders which are more

popular for ice fishing.

Q - Why doesn’t the CLC-200 have a backlight for night

use?

A - This unit incorporates a reflective type of color LCD.

This technology uses ambient light to illuminate the

pixels. Backlighting will not work, front lighting is required.

The unit can be used at night, although the user must

provide adequate front lighting.

Q - Can I convert my Portable CLC to a gimbal version or

convert my gimbal version to a portable?

A - Yes, simply contact Vexilar for the conversion kit

required (see page 32).

Page 25

MAINTENANCE

Maintenance for the Boundary Waters CLC-200 is very

simple. There, simply, is not that much to maintain. Because

of this, problems can sneak up on you if you're not careful.

The unit should be removed whenever the boat is

parked to guard against theft. Don't store it in a place that

may fill with water.

Power connections need constant checking. Corrosion

can develop and cause intermittent or loss of operation.

Spray the power connector pins and battery compartment

contacts with silicone to prevent this. Remove the

batteries before you put the unit away for storage.

The transducer should be checked for scratches and

cracks which can reduce the units sensitivity. Cuts or breaks

in the cord should be repaired as soon as possible so

corrosion doesn't attack the wire. Periodically clean the face

of the transducer with a mild soap An oily film can

develop which will cause weak readings.

Clean the face of the unit with a mild soap and a clean

soft towel. Don't submerge the unit when cleaning.

25

Page 26

26

Possible Cause

TROUBLE SHOOTING

Unit is turned on, but there is no

display.

Battery voltage may be too low.

The unit will show no display if

the voltage is below 8.5 volts.

Unit will not turn on.

Check for proper battery polarity and that you have fully

charged, working batteries.

Unit runs well for a short time,

then the unit quits.

Bad battery. Check voltage indicator on display to insure you

have power remaining.

Unit runs and shows display

light, but does not read depth.

Transducer is not plugged in or

not in contact with the water.

Unit works, but needs high gain

to see bottom or targets.

Transducer is not aimed correctly or needs to be cleaned.

Unit works, but has too many

lines on the display. Can't tell

what is what.

Many air bubbles or very small

targets in the water.

Unit works well when sitting

still or at slow trolling speeds,

but loses reading when the boat

speeds up.

Improper transducer installation

or adjustment. There is a loss of

clear water flow across the face

of the transducer when the boat

reaches a certain speed.

Unit works, but shows noise

when the engine is started or the

electric trolling motor is turned

on.

Improper ground or missing

ground in electrical system.

Defective engine or trolling

motor.

Unit turns on, but the display is

very dim or does not appear.

Outside temperature is too

warm or too cool.

Symptom

Page 27

OTHER VEXILAR PRODUCTS

The Edge

The Edge, model LC-507, is the ulti-

mate LCD depth sounder. It’s unique

design incorporates two transducers

running at the same time. The split

screen view is like having two different

depth finders built into one unit.

The LPS-1 Handheld

The LPS-1 Handheld depth find-

er is perfect for finding the right spot.

Whether you’re canoeing, ice-fishing, or scuba diving. A push of the button display the depth

as an easy to read digital number for ten second before

shutting itself off. Runs on 1 9 volt battery.

The FL-18 Color Flasher

The FL-18 is the ultimate is flasher

technology. It has features such as splitscreen zoom, a low power mode for shallow water, and a super bright display.

The FL-18 Pro Pack is the unit to own for

ice fishing. It incorporates a 7.2 amp/hr

battery, easy to use charger, battery status indicator all

housed in a compact Porta-case designed to fit in the

bottom of a standard 5 gallon bucket.

27

Page 28

28

BATTERY STATUS INDICATOR

The Vexilar Battery Status Indicator

works with all 12 volt batteries and can

be permanently mounted or used as a

portable unit. It monitors your battery

constantly as it is discharging and

charging. Battery charge status is indicated with highly visible colored LED

lights.

12 VOLT SEALED LEAD ACID BATTERY

WITH CHARGER

This Vexilar Battery was designed

for sportsmen on the go, with rugged

construction and design features that

make it ideal for summer and winter

use. With a near "bulletproof"

charger, this system packs enough power to run your

equipment for hours, and for years to come.

Page 29

P-160 CARRYING CASE

The unique Vexilar Flasher Carrying

Case holds your FL-18, CLC-200, or

other manufacturer's sonar or GPS. It

has space for your transducer, a

rechargeable battery, and the Vexilar

Battery Status Indicator. The round base

is just the right size to fit down inside a

standard 5 gallon bucket.

104 DEPTHERM

The fishing odds are on your side

when you use DEPTHERM. It tells you

quickly and accurately what temperatures

are below your boat and it also tells you

the temperature at a specific depth. If your

DEPTHERM indicates that the water temp

is wrong for the species you're after, you

can quickly move.

29

Page 30

30

OPTIONAL TRANSDUCERS

HIGH SPEED TRANSDUCERS

TB0044

19 Degree Transom Mount High

Speed Transducer. Comes with the

Mounting Bracket and 25 Feet of Cable.

TB0030

9 Degree Transom Mount High Speed Transducer.

Comes with the Mounting Bracket and 25 Feet of Cable.

TB0045

Dual Beam 9/19 Degree Transom Mount High Speed

Transducer. Comes with the Mounting Bracket and 25 Feet

of Cable. Built-In Switch Box must be Mounted within 3

Feet of the Depth Finder.

TB0084

12 Degree Transom Mount High Speed Transducer.

Comes with the Mounting Bracket and 25 Feet of Cable.

BK0044

Optional Suction Cup Mount for all of the above High

Speed Transducers. Dual suction cups for extra holding

power.

Page 31

PUCK STYLE TRANSDUCERS

TB0023

1” 19 Degree Puck Transducer. For

Mounting on a Electric Trolling Motor,

In-Hull Mounting, Portable Use, or Ice

Fishing. Comes with 25 Feet of Cable.

BK0023

Optional Suction Cup Mount for TB0023.

TB0027

2” 9 Degree Puck Transducer. For Mounting on a Electric

Trolling Motor, In-Hull Mounting, Portable Use, or Ice

Fishing. Comes with 25 Feet of Cable.

TB0032

2”Dual Beam 9/19 Degree Puck Transducer. For

Mounting on a Electric Trolling Motor, In-Hull Mounting,

Portable Use, or Ice Fishing. Comes with 25 Feet of Cable.

Built-In Switch Box must be Mounted within 3 Feet of the

Depth Finder.

TB0087

2” 12 Degree Puck Transducer. For Mounting on a

Electric Trolling Motor, In-Hull Mounting, Portable Use, or

Ice Fishing. Comes with 25 Feet of Cable.

31

Page 32

32

SERVICE AND SUPPORT

If you find that you need help or want to order

accessories, feel free to contact us. Please have ready the

model number and, if possible, the serial number of your

product. If you’re having problems, be sure to read the

Trouble Shooting sections first.

Address

Vexilar, Inc.

200 W. 88th St.

Minneapolis, MN, 55420-2752

Telephone

(952) 884-5291 (8 am to 5 pm M-F Central Time)

Fax

(952) 884-5292

Web Site

www.vexilar.com

Email

service@vexilar.com

Loading...

Loading...