Vexar CD32M-B Owner's Operation And Installation Manual

DIRECT VENT FIREPLACE

OWNER’S OPERATION AND INSTALLATION MANUAL

O-TL REPORT # 114-F-06-5

MODEL CD32M-B

WARNING: If the information in this manual is not

followed exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

— Installation and service must be performed by a quali-

ed installer, service agency or the gas supplier.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

For more information, visit www.desatech.com

Introduction .......................................................... 3

Selecting Location ............................................... 3

Safety .................................................................. 4

Local Codes......................................................... 5

Product Features ................................................. 6

Pre-Installation Preparation .................................. 6

Installation ........................................................... 9

Burner Flame Adjustment .................................. 23

Operation ........................................................... 24

SAVE THIS BOOK

This book is valuable. In addition to instructing you on how to install and

maintain your appliance, it also contains information that will enable you to

obtain replacement parts or optional accessory items when needed. Keep

it with your other important papers.

WARNING: Improper installation, adjustment, al-

Gas Conversion ................................................. 26

Specications .................................................... 27

Troubleshooting ................................................. 28

Replacement Parts ............................................ 29

Service Hints ..................................................... 29

Technical Service............................................... 29

Accessories ....................................................... 29

Parts .................................................................. 30

Limited Two Year Warranty ..................Back Cover

teration, service or maintenance can cause injury or

property damage. Refer to this manual for correct installation and operational procedures. For assistance

or additional information consult a qualied installer,

service agency or the gas supplier.

TABLE OF CONTENTS

WARNING: This direct vent gas replace is intended

for use with natural or propane/LP gas only. Do not attempt to burn any solid fuels in this appliance.

This replace is manufactured for Stylecrest Inc. under

the Vexar brand name by DESA Heating, LLC.

This replace may be installed as an OEM installation

in a manufactured (mobile) home and must be installed

in accordance with the manufacturers instructions and

the Manufactured Home Construction and Safety Stan-

dard, Title 24 CFR, Part 3280 in the United States or the

Mobile Home Standard, CAN/CSA Z240 MH Series, in

Canada. This replace is only for use with the type(s)

of gas indicated on the rating plate. A conversion kit is

supplied with the replace.

www.desatech.com

124433-01A2

INTRODUCTION

WARNING: This product contains and/or generates chemicals

known to the State of California

to cause cancer or birth defects

or other reproductive harm.

Models CD32M-B is a heat circulating gravity

direct vent replaces with sealed combustion

chamber. These replaces use millivolt gas

control valve and millivolt ignition system.

These fireplaces are convertible with the

standard setup as natural gas. Conversion

may be performed by the OEM mobile home

builder or by a qualied service person on-

site. If you are uncertain as to what gas your

unit is equipped for, please check the rating

plate located inside of the appliance opening

or consult your mobile home supplier or your

local distributor of Style Crest, Inc. products.

NOTICE: Check local building

codes for area requirements before installing this appliance.

BEFORE YOU BEGIN

Before beginning the installation of your

appliance, read these instructions through

completely.

This Style Crest, Inc. replace and its components are safe when installed according

to this installation manual and operated as

recommended. Unless you use Style Crest,

Inc. components designed and tested for

this replace system, YOU MAY CAUSE A

SAFETY HAZARD!

The Style Crest, Inc. warranty will be voided

by, and Style Crest, Inc. disclaims any responsibility for the following actions:

A) Modication to the replace, components,

doors, blower, fans or vent system.

B) Use of any component part not manu-

factured or approved by Style Crest, Inc.

in combination with a Style Crest, Inc.

replace system.

Proper installation is the most important step

in ensuring safe and continuous operation

of the replace. Consult the local building

codes as to the part icular require ments

concerned with the installation of all factory

built replaces. This replace, when installed,

must be electrically grounded in accordance

with local codes or in the absence of local

codes, with the National Electrical Code,

ANSI/NFPA 70.

The installation must conform with local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1. This

appliance complies with ANSI Z21.88.

SELECTING LOCATION

To determine the safest and most efcient

location for your replace, consider the fol-

lowing guidelines:

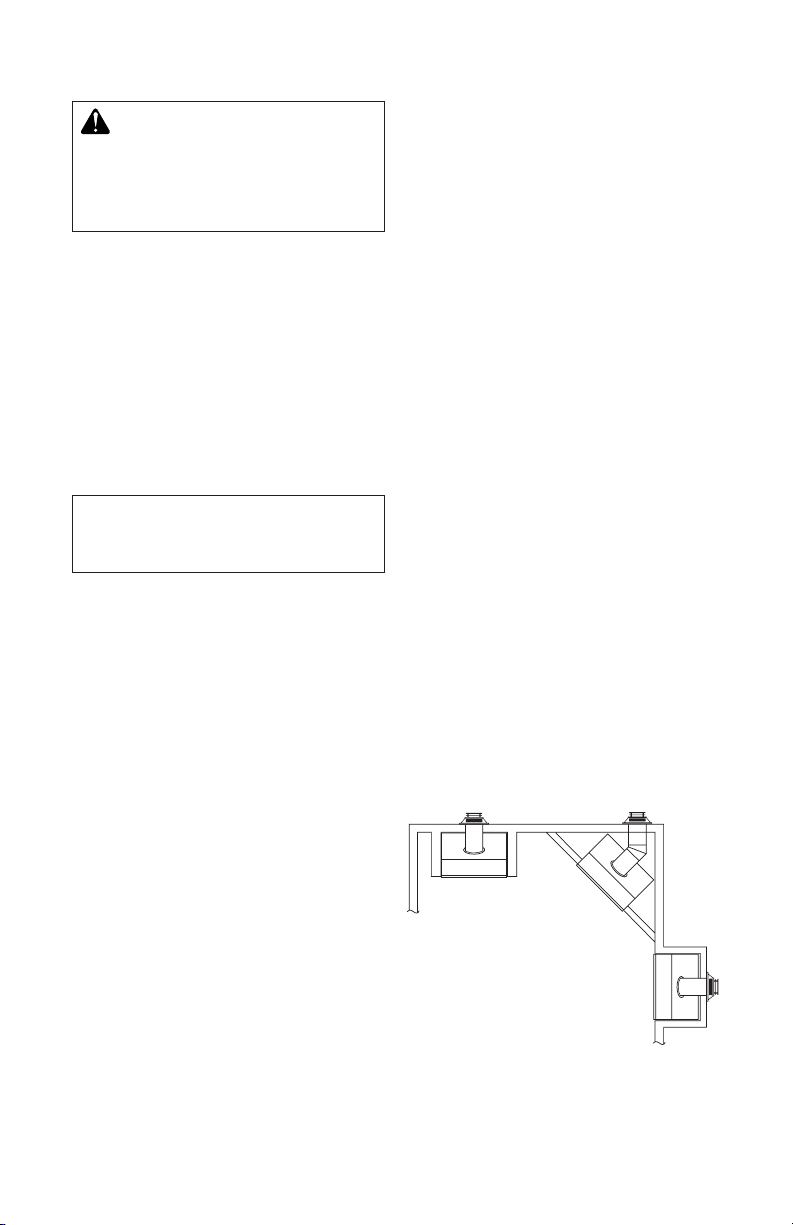

1. The location must allow for proper clearances (see Figure 1).

• Flush installation is recommended where

living space is limited.

• Projected installation may be ideal for

a new addition to an existing nished

wall.

• Corner installation makes use of a space

that may not normally be used and pro-

vides a wider and more efcient range

for radiant heat transfer.

2. Consider a location where the replace

would not be affected by drafts, air conditioning ducts, windows or doors.

124433-01A 3

www.desatech.com

3. A location that avoids the cutting of joists

or roof rafters makes ventilation installation easier.

FULL

PROJECTION

Figure 1 - Common Fireplace Locations

CORNER

INSTALLATION

FLUSH

INSTALLATION

SELECTING LOCATION

Continued

In selecting a location, the following precautions must be observed:

• Do not connect this appliance to a chimney system used for solid fuel burning

replace.

• Due to high temperatures, do not locate

this appliance in high trafc areas or near

furniture and draperies.

• Never obstruct openings of the appliance or

ow of ventilation air. Keep control compart-

ments accessible.

SAFETY

• Do not locate appliance close to where

gasoline or other ammable liquids may be

stored. The appliance must be kept clear

and free from combustible materials.

• Do not use this appliance if any part has

been under water. Immediately contact a

local service technician to examine the

appliance and to replace any part(s) of the

control ignition system and other related

components that have been submerged

under water.

DANGER: Carbon monoxide

poisoning may lead to death!

This replace must be installed by the O.E.M.

builder or by a qualied (certied or licensed)

service person. It has a sealed gas combustion chamber that uses a coaxial pipe (pipe

within a pipe and having the same center)

venting system. It brings in fresh air for combustion through the outer pipe and combustion gases are exhausted through the inner

pipe. If the glass door assembly and venting

pipe are not properly seated, connected and

sealed, carbon monoxide leakage (spillage)

can occur.

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning resemble the

u, with headaches, dizziness or nausea. If

you have these signs, the replace may not

be working properly. Get fresh air at once!

Have replace serviced. Some people are

more affected by carbon monoxide than others. These include pregnant women, people

with heart or lung disease or anemia, those

under the inuence of alcohol and those at

high altitudes.

Propane/LP and Natural Gas: Propane/LP

and natural gas are odorless. An odor-making

agent is added to the gas. The odor helps you

detect a gas leak. However, the odor added to

the gas can fade. Gas may be present even

though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this replace.

WARNING: Any change to

this replace or it’s controls can

be dangerous. Do not modify

this replace under any circumstances. Any parts removed for

servicing must be replaced prior

to operating replace.

WARNING: Do not use a blower insert, heat exchanger insert

or other accessory not approved

for use with this replace.

WARNING: This appliance

is only for use with the type of

gas indicated on the rating plate.

This appliance is not convertible

for use with other gases unless

a certied kit is used.

WARNING: Do not allow fans

to blow directly into the replace.

Avoid any drafts that alter burner

ame patterns.

Due to high temperatures, the

appliance should be located out

of trafc and away from furniture

and draperies.

www.desatech.com

124433-01A4

SAFETY

Continued

Do not place clothing or other

ammable material on or near

the appliance. Never place any

objects on the appliance.

Do not use this replace to cook

food or burn paper or other ammable material.

This replace reaches high temperatures. Keep children and

adults away from hot surface to

avoid burns or clothing ignition.

Fireplace will remain hot for a

time after shutdown. Allow surface to cool before touching.

Carefully supervise young chil-

dren when they are in the room

with replace.

Keep the area around your

replace clear of combustible

materials, gasoline and other

ammable vapor or liquids. Do

not run replace where these

are used or stored.

1. For propane/LP replace, do not place

propane/LP supply tank(s) inside any

structure. Locate propan e/LP supp ly

tank(s) outdoors. To prevent performance

problems, do not use propane/LP fuel tank

of less than 100 lbs. capacity.

2. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not

use any phone in your building

• immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier's instructions

• if you cannot reach you gas supplier, call

the re department.

3. Never install the replace

• in a recreational vehicle

• in windy or drafty areas where curtains or

other combustible (ammable) objects can

make contact with the replace front

• in high trafc areas

4. Turn fireplace off and let cool before

servicing, installing or repairing. Only a

qualied service person should install,

service or repair this replace. Have replace inspected annually by a qualied

service person.

5. You must keep control compartments,

burners and circulating air passages

clean. More frequent cleaning may be

needed due to excessive lint and dust

from carpeting, bedding material, etc.

Turn off the gas valve and pilot light before

cleaning replace.

6. Have venting system inspected annually by

a qualied service person. If needed, have

venting system cleaned or repaired.

7. Do not use any solid fuels (wood, coal,

paper, cardboard, etc.) in this replace.

Use only the gas type indicated on re-

place nameplate.

8. This appliance, when installed, must be

electrically grounded in accordance with

local codes or, in the absence of local

codes, with the National Electrical Code,

ANSI/NFPA 70.

9. Do not use replace if any part has been

exposed to or under water. Immediately

call a qualied service person to arrange

for replacement of the unit.

10. Do not operate replace if any log is

broken.

11. Do not operate replace with glass door

removed, cracked or broken.

12. Provide adequate clearances around air

openings.

LOCAL CODES

Install and use replace with care. Follow all

local codes. In the absence to local codes,

use the current National Fuel Gas Code ANSI

Z223.1/NFPA 54* (USA) or the current CSAB149.1 Installation Code (Canada).

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

124433-01A 5

www.desatech.com

PRODUCT FEATURES

C

B

A

D

E

F

G

T o p of Louver Opening

3

2

1

4

5

6

7

Wa ll

These are a few facts that can help you under-

stand and enjoy your direct-vent replace:

• The venting system may be routed to the

outside of your home in several ways. It

may vent through the roof (vertical) or it

may vent to an outside/exterior wall (hori-

zontal). The vent pipe installation is very

important to allow for proper operation.

You must follow the venting instructions

very carefully for either vertical or horizontal

applications.

• This replace may be installed in any room

of your house provided all local codes and

these installation instructions are followed.

• A piezo ignitor and ceramic electrode create spark to ignite the pilot light. It does not

require any matches, batteries or any other

sources of ignition to light the pilot.

• Each time you turn on your replace, you

PRE-INSTALLATION PREPARATION

CAUTION: Do not block

required air spaces with insulation or any other material. Do not

obstruct the effective opening

of the appliance with any type

of facing material.

CLEARANCES TO COMBUSTIBLES

Minimum clearances to combustibles for the

replace are:

• Back and Sides of Fireplace . . . . . . . . 0"

• Floor . . . . . . . . . . . . . . . . . . . . . . . . . . 0"

• Perpendicular Wall . . . . . . . . . . . . . . . 6"

• Front . . . . . . . . . . . . . . . . . . . . . . . . . 36"

• Top of Standoffs .................. 0"

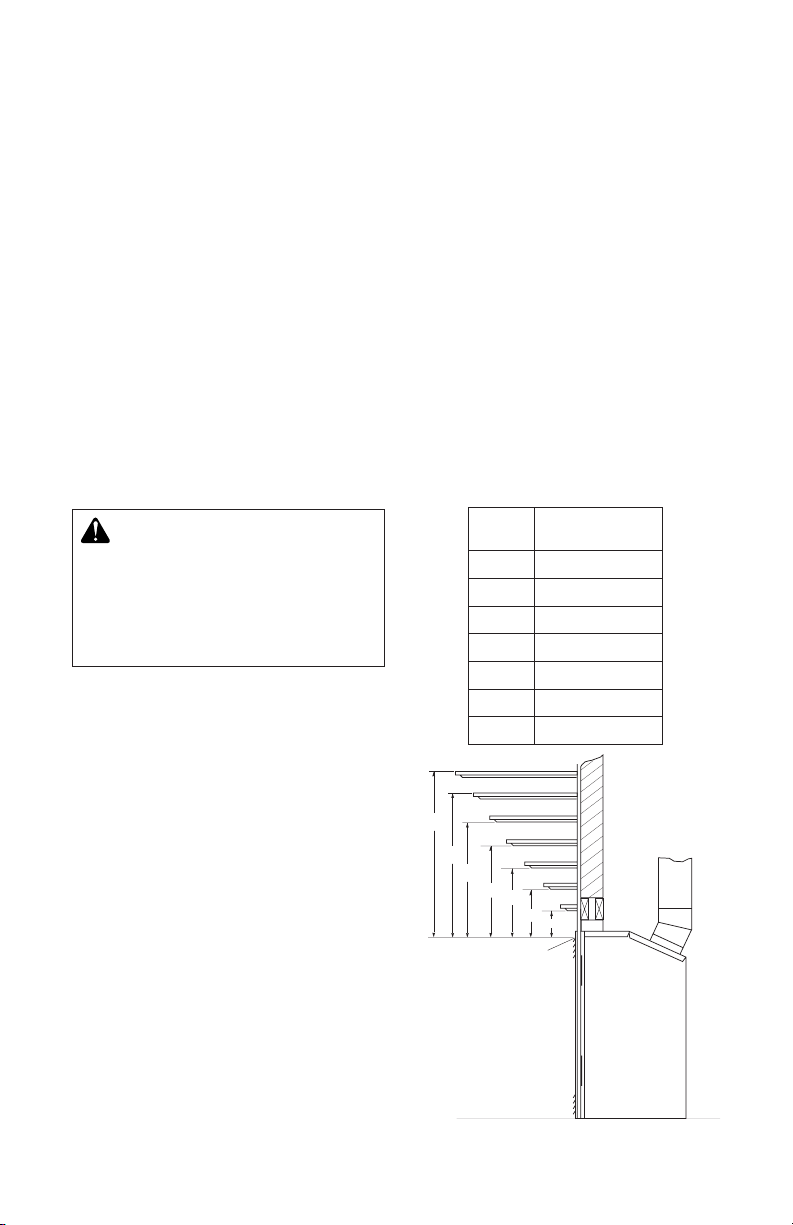

MANTEL CLEARANCES

Woodwork, such as wood trims, mantles

and other combustible materials should be

placed within the required clearance speci-

ed in Figure 2.

may notice some amount of condensation

on the inside of the replace glass. This

is normal and will disappear after 10-20

minutes of operation.

• Your d irect-vent gas firepla ce system

(replace and venting) is a balanced and

sealed gas operating unit. It requires approximately 10-20 minutes of operating

time before the ame pattern stabilizes.

• This replace is equipped with a millivolt

gas control system that does not require

electricity to operate. A piezo ignitor is

provided to light the pilot without using

matches or lighters.

• This model can accept an optional circulating air blower when 120 VAC connection is

supplied. If you plan to install an optional

blower, do not forget to wire the replace

outlet when framing.

Mantel

Depth

Mantel From Top

of Opening

(1) 14" (A) 16"

(2) 12" (B) 14"

(3) 10" (C) 12"

(4) 8" (D) 10"

(5) 6" (E) 8"

(6) 4" (F) 6"

(7) 2" (G) 4"

Figure 2 - Mantel Clearances

www.desatech.com

124433-01A6

PRE-INSTALLATION PREPARATION

A

B

E

F

G

H

D

C

Nailing Tabs

Continued

VENT TERMINATION CLEARANCES

Final position of your replace depends on

location of the vent termination in relation to

clearances that must be observed as shown

in Figure 5 on page 8.

The vent system serves as the “chimney” as

well as combustion air supply (air intake).

The horizontal run must have a rise of 1/4"

(0.6 cm) for every 12" (30.48 cm) of horizon-

tal run towards the termination. Maximum

horizontal run depends on vertical rise from

replace adapter collar to vent termination

(see table below).

VERTICAL HORIZONTAL

0 to 1 ft (30.48 cm)

1 ft (30.48 cm) to 4 ft (121.92 cm)

2 ft (60.96 cm) to 8 ft (243.84 cm)

3 ft (91.44 cm) to 12 ft (365.76 cm)

4 ft (121.92 cm) to 16 ft (487.68 cm)

5 ft (152.40 cm) to 15 ft (457.20 cm)

6 ft (182.88 cm) to 14 ft (426.72 cm)

7 ft (213.36 cm) to 13 ft (396.24 cm)

8 ft (243.84 cm) to 12 ft (365.76 cm)

WARNING: Never allow the

vent to run downward as this

may cause excessive temperatures which could cause a re.

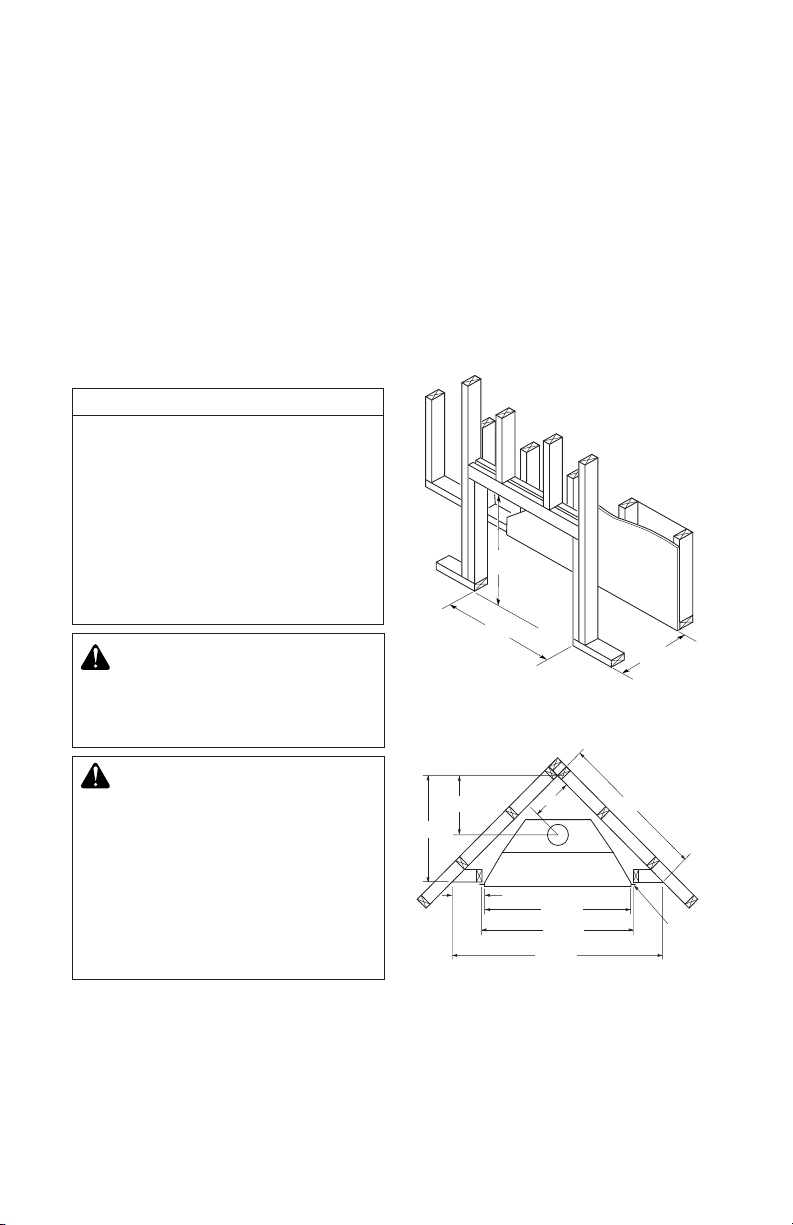

FRAMING

Once the nal location has been determined,

observing height clearances for vent termination, you may construct framing using dimensions shown in Figures 3 and 4, depending on

your installation.

If the appliance is to be installed directly on

carpeting, tile (other than ceramic) or any

combustible material other than wood ooring, appliance must be installed on a metal

or wood panel extending full width and depth

of the appliance.

323/8"

345/8"

19"

Figure 3 - Framing Dimension

WARNING: Horizontal sec-

tions of this vent system require

a minimum clearance of 2" from

28 1/2"

13 5/8"

9 1/2"

39 3/8"

the top of the pipe and 1" minimum to the sides and bottom.

Vertical sections of this system

require a minimum of 1" clearance to combustible materials

on all sides of the pipe.

124433-01A 7

www.desatech.com

97/8"

343/8"

345/8"

541/8"

Figure 4 - Corner Installation

Nailing

Tabs

Fixed

Closed

Openable

Fixed

Closed

V

V

V

V

V

V

V

V

X

X

V

X

G

G

J

F

B

B

K

N

H

I

A

N

E

L

D

B

M

A

C

B

V

V

A

G

G

B

TERMINATION CAP

AIR SUPPLY INLET

GAS METERRESTRICTED AREA

(TERMINATION PROHIBITED)

A = clearance above grade, veranda, porch, deck, or

balcony [*12" (30.5 cm) minimum]

B = clearance to window or door that may be opened

[6" (15 cm) min. for 10,000 Btu or less; 9" (23 cm) in US

if between 10,000 and 50,000, 12" (30 cm) in Canada

if between 10,000 and 100,000; 12" (30 cm) in US if

greater than 50,000, 36" (91 cm) in Canada if greater

than 100,000]

C = clearance to permanently closed window

[minimum 12" (30.5 cm) recommended to prevent

condensation on window]

D = vertical clearance to ventilated soffit located above the

terminal within a horizontal distance of 24" (61 cm) from

the center-line of the terminal [18" (45.7 cm) minimum]

E = clearance to unventilated soffit [12" (30.5 cm) minimum]

F = clearance to outside corner (see below)

G = clearance to inside corner (see below)

H = *not to be installed above a meter/regulator assembly

within 36" (91.4 cm) horizontally from the center line

of the regulator

I = clearance to service regulator vent outlet [*72" (182.9 cm)

minimum]

J = clearance to non-mechanical air supply inlet to building

or the combustion air inlet to any other fireplace

[6" (15 cm) min. for 10,000 Btu or less; 9" (23 cm) in US

if between 10,000 and 50,000, 12" (30 cm) in Canada

if between 10,000 and 100,000; 12" (30 cm) in US if

greater than 50,000, 36" (91 cm) in Canada if greater

than 100,000]

K = clearance to a mechanical air supply inlet [*In Canada,

6 ft. (1.83m) minimum; In US 3 ft. (91 cm) above if within

10 ft. (3 m) horizontally]

L = † clearance above paved side-walk or a paved driveway

located on public property [*84" (213.3 cm) minimum]

M = clearance under veranda, porch, deck

[*12" (30.5 cm) minimum ‡]

N = clearance above a roof shall extend a minimum of

24" (61 cm) above the highest point when it passes

through the roof surface and any other obstruction within

a horizontal distance of 18" (45.7 cm)

† vent shall not terminate directly above a side-walk or paved driveway which is located between two

single family dwellings and serves both dwellings*

‡ only permitted if veranda, porch, deck or balconey is fully open on a minimum of 2 sides beneath the floor*

* as specified in CAN/CSA B149 (.1 or .2) Installation Codes (1991) for Canada and U.S.A.

Note: Local codes or regulations may require different clearances

A = 6" (15.2 cm)

Inside Corner

V

B

E

V

B = 6" (15.2 cm)

C = Maximum depth of 48" (121.9 cm)

for recessed location

D = Minimum width for back wall of

recessed location Combustible - 38" (965 mm)

Noncombustible - 24" (61 cm)

E = Clearance from corner in

recessed location Combustible - 6" (15.2 cm)

Noncombustible - 2" (5.1 cm)

Outside Corner Recessed Location

G

H

G = 12" (30.5 cm) minimum clearance

Balcony with No Side Wall

V

J

Combustible &

Noncombustible

H = 24" (61 cm)

J = 20" (50.8 cm)

Balcony with Perpendicular Side Wall

C

D

C

Termination Clearances for Buildings with Combustible and Noncombustible Exteriors

Openable

PRE-INSTALLATION PREPARATION

Continued

Figure 5 - Minimum Clearances for Vent Terminations

www.desatech.com

124433-01A8

INSTALLATION

WARNING: Read all instruc-

tions completely and thoroughly

before attempting installation.

Failure to do so could result in

serious injury, property damage or loss of life. Operation of

improperly installed and maintained venting system could

result in serious injury, property

damage or loss of life.

NOTICE: Failure to follow these in-

structions will void the warranty.

VENTING INSTALLATION

PRECAUTIONS

Consult local building codes before beginning

installation. Installer must make sure to select

proper vent system for installation. Before

installing vent kit, installer must read this replace manual and vent kit instructions.

Only a qualied service person should install

venting system. The installer must follow

these safety rules:

• Wear gl oves an d s afety glasse s f or

protection

• Use extreme caution when using ladders

or when on roof tops

• Be aware of electrical wiring locations in

walls and ceilings

The following actions will void the warranty

on your venting system:

• Installation of any damaged venting component

• Unauthorized modification of the venting

system

• Installation of any component part not

manufactured or approved for use with the

replace.

• Installation other than as instructed by

these instructions

NOTICE: All Style Crest, Inc.

direct vent replaces only approved 5/8" pipe components

and terminations.

WARNING: This gas replace

and vent assembly must be

vented directly to the outside. The

venting system must NEVER be

attached to a chimney serving a

separate solid fuel burning appliance. Each gas appliance must

use a separate vent system. Do

not use common vent systems.

WARNING: Horizontal sec-

tions of this vent system require

a minimum clearance of 2" from

the top of the pipe and 1" minimum to the sides and bottom.

Vertical sections of this system

require a minimum of 1" clearance to combustible materials

on all sides of the pipe.

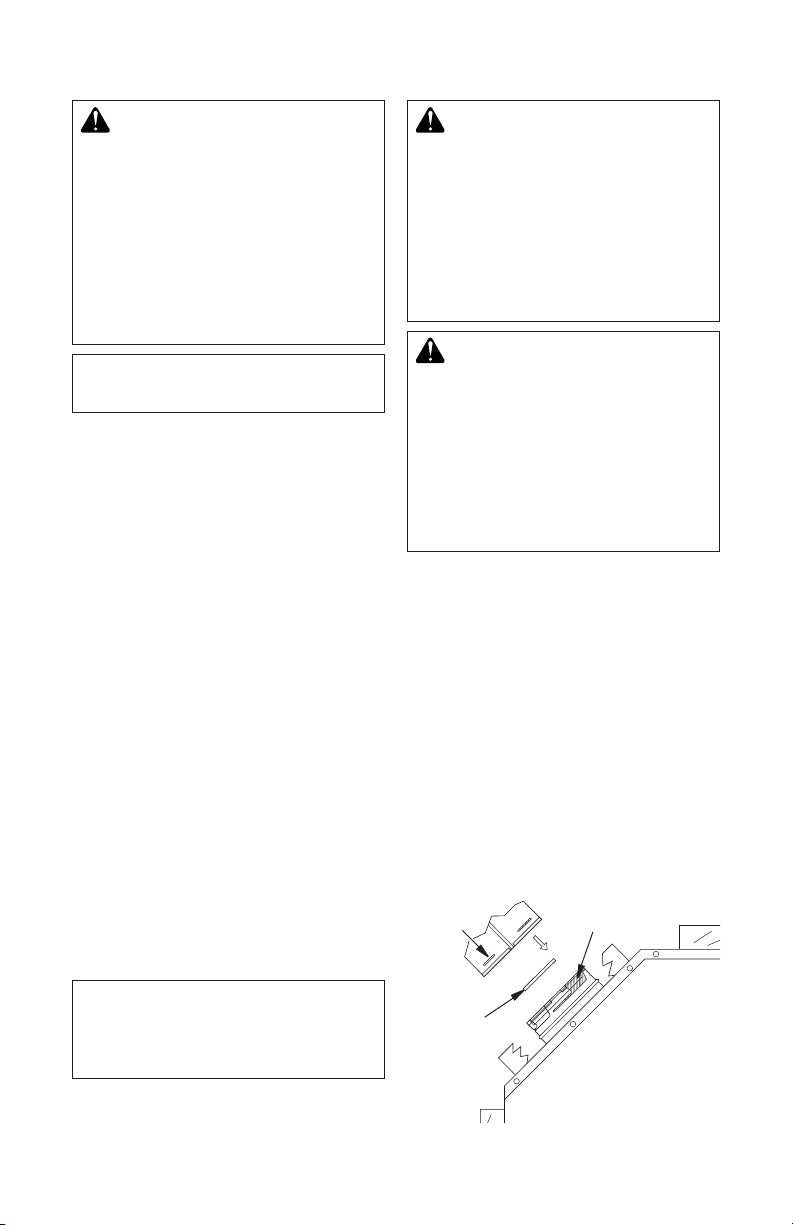

VENTING INSTALLATION

1. Install elbow to replace collar adapter

located on back of the unit at a 45° angle.

Slide elbow over collar and twist to lock.

Check to insure proper connection (see

Figure 6).

2. Continue to install remainder of pipe for

desired installation. Make sure each section is twist-locked securely.

3. When installation of vent pipe is complete,

in stall vent termination. Depending on

location of your replace, you will vent

vertically or horizontally.

4. Allow 1" of pipe to protrude from internal

wall, depending on wall thickness. See

Figure 7, page 10.

Female

Locking

Lugs

Vertical Flue

Restrictor

(For Vertical

Venting

Application)

Male Locking

Lugs

Figure 6 - Venting Installation

124433-01A 9

www.desatech.com

INSTALLATION

Continued

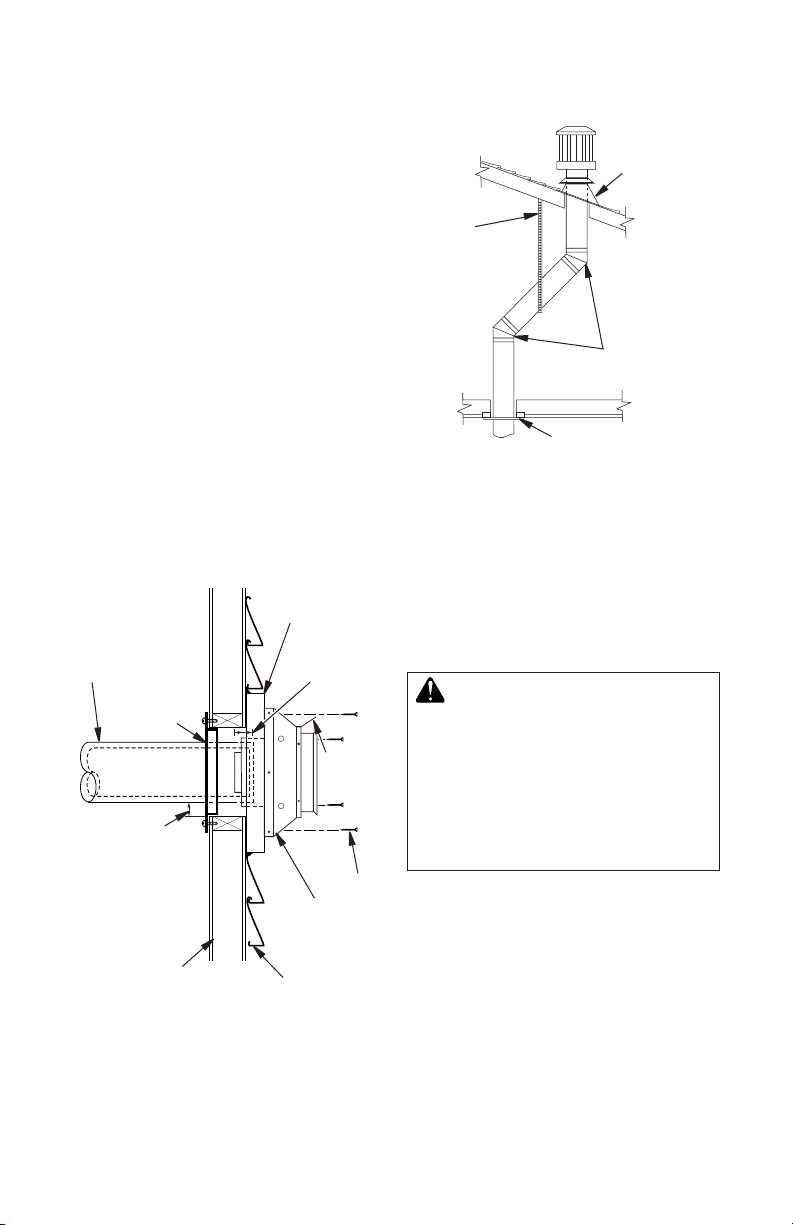

5. For horizontal installation, an optional

siding standoff may be installed between

vent cap and exterior wall. Secure horizontal vent cap to standoff. Secure standoff/

vent cap assembly to wall (see Figure 7).

Do not seal termination to vent pipe. Vent

termination must be removable for service

pipe inspection.

6. For vertical installation, a vertical termination is available. A vertical ue restrictor must be installed into inner collar of

replace as shown in Figure 6, page 9.

When installing a length of pipe for vertical

termination that is over 3 ft., support pipe

every 3 ft. using metal wall straps. Vertical

to horizontal pipe must be kept at a 1 ft. to

4 ft. ratio with a maximum run of no more

than 20 ft.

If an offset is necessary in attic to avoid

obstruction, it is important to support vent

pipe every 3 ft. to avoid excessive stress

on elbows and possible separation (see

Figure 8).

Siding Standoff

(Optional)

Direct vent

Pipe

Wall Firestop

Maintain 1"

Minimum

Air Space

Around Outer

Pipe when

Penetrating a

Wall

10 3/4" x 10 3/4"

Framed Opening

Figure 7 - Vent Termination (Horizontal)

Minimum Pipe

Overlap 1 1/4"

Deector

Shield

Screws

Horizontal

Termination

(Vent Cap)

Exterior Wall

with Vinyl

Siding

Roof

Flashing

Wall

Strap

45° Elbows

Ceiling Firestop

Figure 8 - Vertical Termination with

Offset and Wall Strap

Horizontal Termination Congurations

Figures 9 through 13, page 11 show different

congurations and alternatives for venting

with hor izont al termin ation. Each figure

includes a chart with critical minimum and

maximum dimensions which MUST be met.

IMPORTANT: Remember that a horizontal

run of venting must have a 1/4" rise for every

12" of run toward termination.

WARNING: Never run vent

downward as this may cause

excessive temperatures which

could cause a re. Operation of

improperly installed and maintained venting system could

result in serious injury, property

damage or loss of life.

www.desatech.com

124433-01A10

Loading...

Loading...