Vexar C36EMW-RC, C36EMW-RBC, C36EMW-RPLC Owners & Installation Manual

For more information, visit www.desatech.com

SAVE THIS BOOK

This book is valuable. In addition to instructing you

on how to install and maintain your appliance, it also

contains information that will enable you to obtain replacement parts or accessory items when needed. Keep

it with your other important papers.

This replace is approved for use as a wood burning

replace or for use with a vented gas log approved to

ANS Z21.60, Z21.84 or RGA 2-72 standards or for use

with a vent-free gas log heater approved to ANS Z21.11.2

standard. A vent-free log can only be installed in an aftermarket (completion of sale, not for purpose of resale

from the manufacturer), permanently located, manufactured (mobile) home, where not prohibited by local

codes. Approved hood must be installed when using a

vent-free gas log heater (see Accessories, page 18).

This rebox meets the construction and safety standards of H.U.D. for application in mobile homes when

installed according to these instructions.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

36" CIRCULATING LOUVERED FIREBOX

OWNER’S INSTALLATION MANUAL

C36EMW-RC with Brushed

Brass Finish Bi-fold Doors

C36EMW-RBC with Black

Finish Bi-fold Doors

C36EMW-RPLC with Platinum

Finish Bi-fold Doors

Includes Manual

Control Fan System

and Combustion

Air Kit

O-TL REPORT # 114-F-20-4

www.desatech.com

124558-01A2

TABLE OF CONTENTS

Safety .................................................................. 2

Specications ...................................................... 3

Fireplace Installation............................................ 3

Venting Installation .............................................. 6

Optional Gas Line Installation............................ 13

Finishing Fireplace ............................................ 15

Operation and Maintenance Guidelines ............ 15

Replacement Parts ............................................ 17

Technical Service............................................... 17

Accessories ....................................................... 18

SAFETY

CAUTION: The structural

integrity of the mobile home

oor and ceiling/roof must be

maintained.

WARNING: Do not install a

replace insert in this box unless

the manufacturer's instructions

with the insert specically state

this replace has been tested for

use with the insert.

FOR YOUR SAFETY

• Do not store or use gasoline

or any other ammable vapors

or liquids in the vicinity of this

or any other appliance.

• Due to high temperatures, the

appliance should be located

out of trafc and away from

furniture and draperies.

• Do not place clothing or other

ammable materials on or near

the appliance.

• Never leave children unattended when a re is burning

in the replace.

This replace is not intended to

be used as a substitute for a furnace to heat an entire home. Use

for supplemental heat only.

This wood burning fireplace

complies with the UL 127 standard as a FACTORY BUILT FIREPLACE and is listed and tested

by OMNI Test Laboratories.

WARNING: Improper installation, adjustment, alteration,

service or maintenance can

cause injury, property damage or

loss of life. Refer to this manual

for assistance or additional in-

formation. Consult a qualied

installer or local distributor.

IMPORTANT: Check HUD requirements before installing this

replace.

The C36EMW Series is specically designed

for use in manufactured mobile homes. These

replaces include a manual control fan system, combustion air kit and bi-fold doors.

Before beginning the installation of the

fireplace, read these instructions through

completely.

• This Style Crest replace and its components are safe when installed according

to this installation manual. Unless you use

Style Crest approved components, which

have been designed and tested for the

replace system, you may cause a re

hazard.

• The Style Crest warranty will be voided by

and Style Crest disclaims any responsibility for the following actions.

a. Modication of the replace, compo-

nents, doors, blower, fans, air inlet

system and damper control.

b. Use of any component part not manu-

factured or approved by Style Crest

in combination with a Style Crest

replace system.

Proper installation is the most important step

in ensuring safe and continuous operation of

the replace. Consult the local building codes

as to the particular requirements concerned

with the installation of all factory built replaces. Although grounding may not be required

by code, the manufacturer recommends it.

www.desatech.com

124558-01A 3

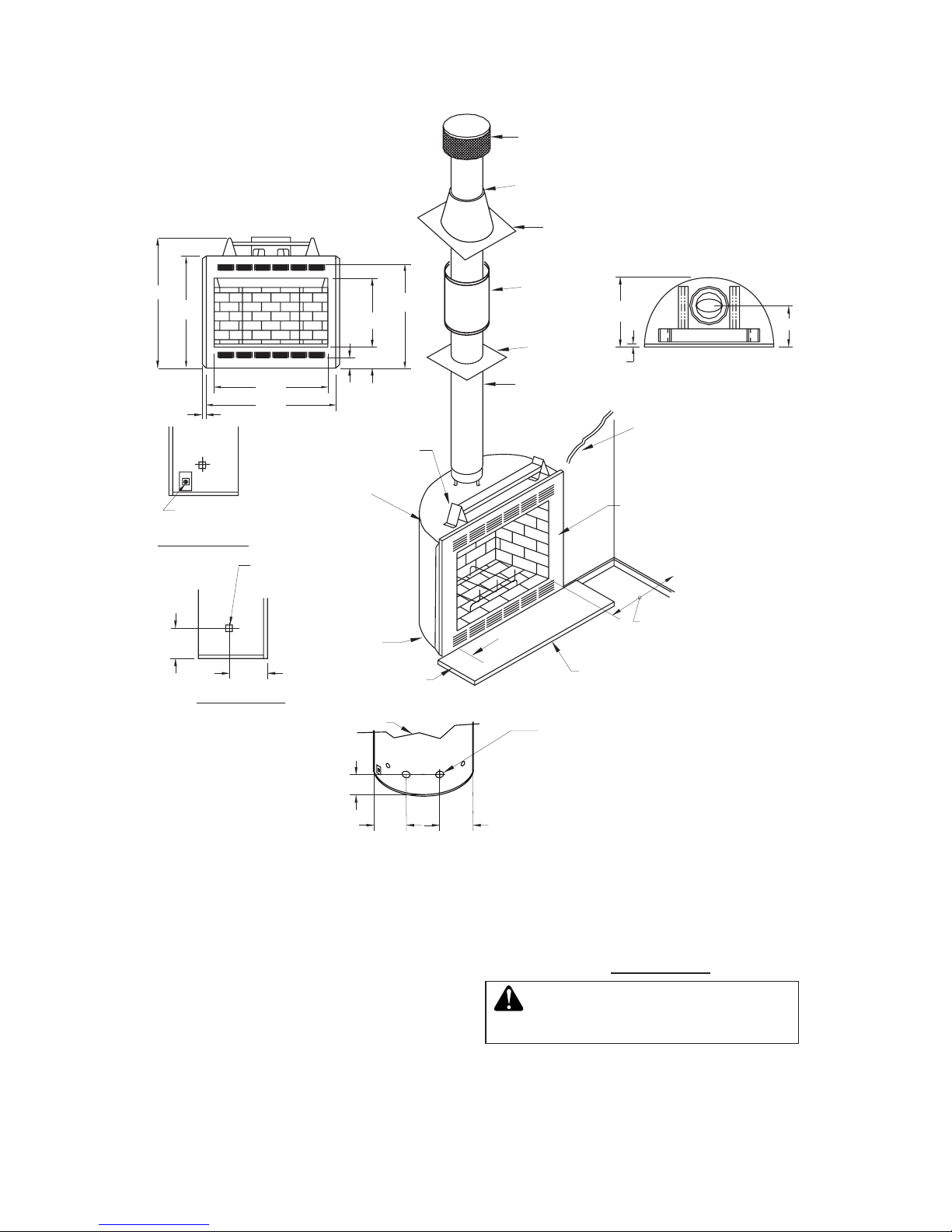

SPECIFICATIONS

42"

36

1

/4"

33

1

/4"

22

1

/8"

6

3

/4"

7

3

/4"

9

3

/8"

3"

36"

41"

1"

J-Box

Access

RH SIDE VIEW

LH SIDE VIEW

Gas Line Conduit

Sleeve (Both Sides)

1/2" Air Space

Back and Sides

0" To T o p

Spacer

Round To p T e rmination

Storm Collar

Flashing

Firestop

1" Airspace

To Combustible

Materials

Combustible

Wall Board

No Combustible

Material On Face

Not Less Than 14"

To Perpendicular

Sidewall

Hearth Extension

52" x 16"

0" To

Bottom

8" Each

Side

221/16"

5/8"

13"

Rear View

of Fireplace

Opening for

Outside Air

Firestop

Thimble

91/2"

14"

14"

FIREPLACE INSTALLATION

SELECTING LOCATION

To determine the safest and most efcient

location for the replace, you must take into

consideration the following guidelines:

1. The location must allow for proper clear-

ances (see Figures 1 and 2, page 4).

2. Consider a location where the heat output

will not be affected by drafts, air conditioning ducts, windows or doors.

3. A location that avoids the cutting of

joists or roof rafters will make installation

easier.

4. An outside air kit is available with this

replace (see Outside Air Kit on page 6).

WARNING: Do not install this

appliance in a bedroom.

www.desatech.com

124558-01A4

MINIMUM CLEARANCE TO

COMBUSTIBLES

Back and sides of replace 1/2" minimum*

Floor** 0" minimum

Wall to front of replace 36" minimum

Perpendicular wall to opening 14" minimum

Top spacers 0" minimum

Mantel clearances see Mantels,

page 15

Chimney outer pipe surfaces 1" minimum

* Not required at nailing anges

** See step 2 of Framing, page 5

WARNING: Do not pack required air spaces with insulation

or other materials.

Minimum/Maximum Chimney Height

Minimum height ofthe chimney, measured

from base of replace to ue gas outlet of

termination, is 14 feet* for straight ue or a

ue with one elbow set. Maximum distance

between elbows is 2 feet.

13" Min.

Maintain 1/2" Air Space

Between Framing

and Fireplace

43

5

/8"

Min.

41 3/4" Min.

61

11/16" Min.

Figure 2 - Corner Installation

FIREPLACE INSTALLATION

Continued

Maximum height of any system is 40 feet.*

This measurement includes replace, chimney sections and height of termination assembly at level of ue gas outlet (see Figure 3).

*For manufactured home application, minimum

height is 11' for straight ue or ue with one elbow

set. Maximum height of any system is 20'.

Figure 3 - Standard and Alternate

Venting Installation

Effective Height of

T e rmination Cap

Effective Height of

Termination Cap

Effective Height of

T e rmination Cap

RT-8DM

RT-8DM

RT-8DM

14' Min.

Height

2' Max

Pipe Length

30E-8DM

11 ' for

Manufactured

Home

Application

14' Min.

Height

11 ' for

Manufactured

Home

Application

40' Max.

Height

20' for

Manufactured

Home

Application

Effective Height of

Te rmination Cap

RT-8DM

30E-8DM

40' Max.

Height

20' for

Manufactured

Home

Application

Standard

Installation

Alternate

Installation

Alternate

Installation

42 1/4"

41

3

/4"

22

5

/8"

10"

Figure 1 - Framing Dimensions

www.desatech.com

124558-01A 5

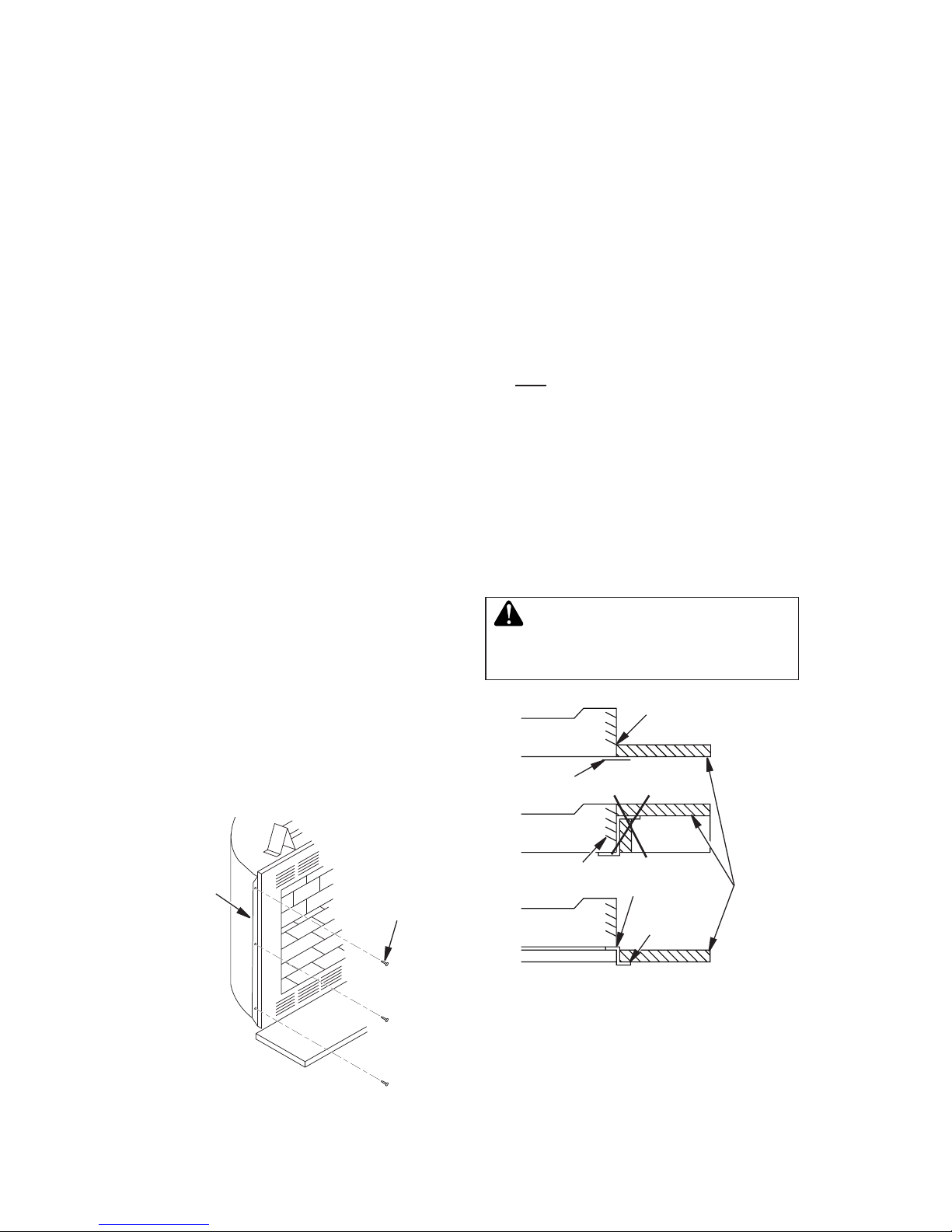

Figure 4 - Nailing Flanges

Screw

or Nail

Nailing

Flange

FIREPLACE INSTALLATION

Continued

Figure 5 - Hearth Extension

Seal Gap

Fireplace

Front

Ember

Protector

Ember

Protector

Seal Gap

Hearth

Extension

FRAMING

1. Frame opening for replace using dimensions shown in Figures 1 and 2.

2. If replace is to be installed directly on

carpeting, tile (other than ceramic) or any

combustible material other than wood

ooring, replace must be installed on a

metal or wood panel extending full width

and depth of replace. (It is acceptable to

cover two outside ends or columns of top

louver panel leaving four center columns

open).

3. Set replace directly in front of this opening and slide unit back until nailing anges

touch side framing.

4. Check level of replace and shim with

sheet metal if necessary.

5. Before securing replace to prepared framing, metal ember protector (provided) must

be placed between hearth extension (not

supplied) and under bottom front edge of

replace to protect against glowing embers

falling through. If replace is to be installed

on a raised platform, a Z-type ember protector (not supplied) must be fabricated to

t your required platform height. Ember

protector should extend under replace

a minimum of 1

1

/2". The ember protector

should be made of metal material.

6. Using screws or nails, secure replace to

framing through anges located on sides

of replace (see Figure 4).

HEARTH EXTENSION

A hearth extension projecting a minimum of

16" in front of and a minimum of 8" beyond

each side of the replace opening is required

to protect combustible oor construction in

front of the replace. Use an equal material

which meets the following specications: a

layer of noncombustible, inorganic material

having a thermal conductivity of K=0.84 BTU

IN/FT, HR. F (or less) at 1" thick. For example,

if the material selected has a K factor of 0.25,

such as glass ber, the following formula

would apply:

0.25 x 1.0" = 0.30" thickness required

0.84

Thermal conductivity "K" of materials can be

obtained from the manufacturer or supplier of

the noncombustible material. If the hearth extension is to be covered, use noncombustible

material such as tile, slate, brick, concrete,

metal, glass, marble, stone, etc. Provide

a means to prevent hearth extension from

shifting and seal gap between replace frame

and hearth extension with a noncombustible

material (see Figure 5).

WARNING: Hearth extension

is to be installed only as shown

in Figure 5.

Fireplace Front

Elevated

Raised

Hearth

DO NOT Block Louvers

NO

www.desatech.com

124558-01A6

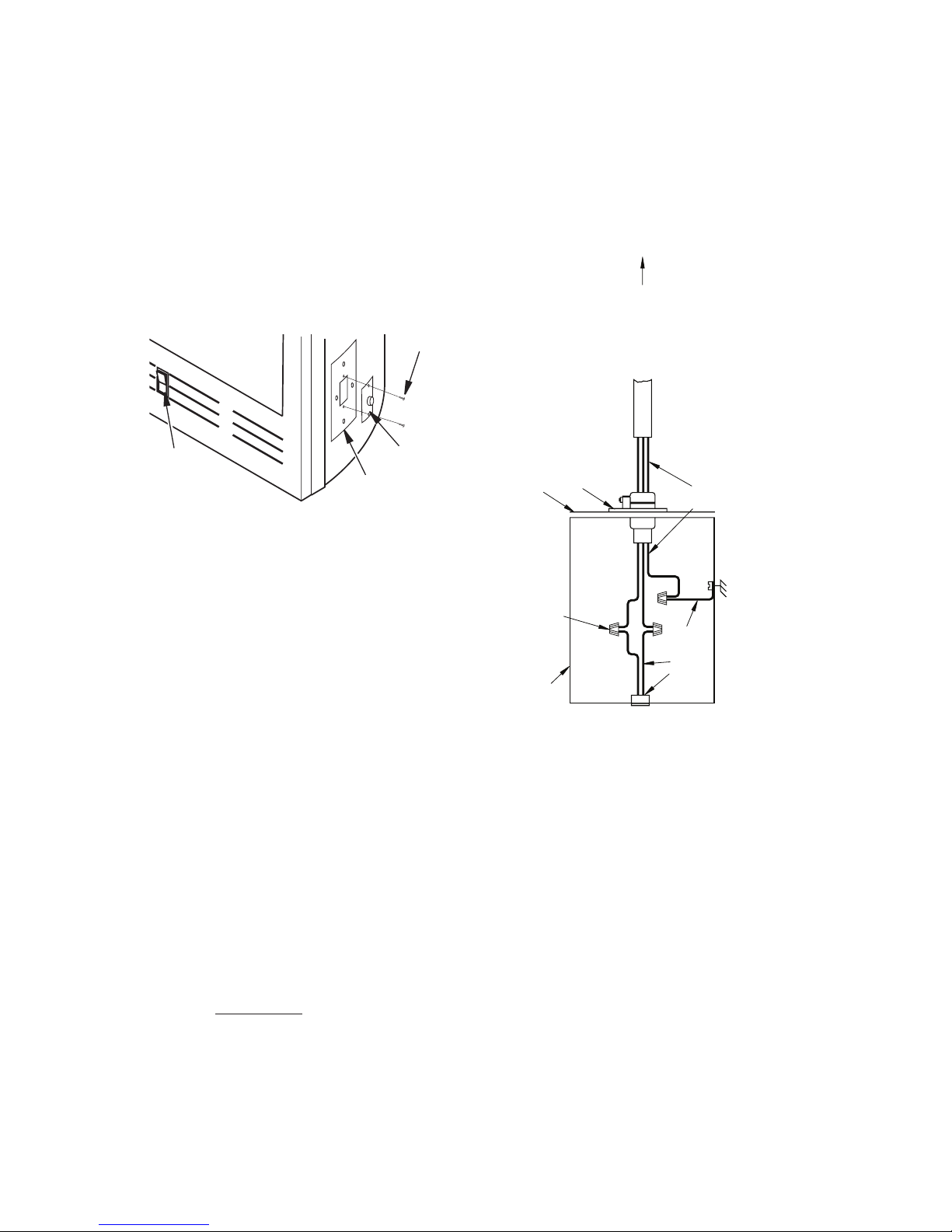

Figure 7 - Fan Kit Wiring Diagram

OF FIREPLACE

OUTER WRAPPER

TO

POWER SOURCE

ELECTRICAL

COVER PLATE

AND STRAIN RELIEF

POWER SOURCE

WIRING (NOT SUPPLIED)

FIREPLACE

(NOT SUPPLIED)

WIRE NUT (3x)

HOUSING

PRE-WIRED

RECEPTACLE

AND GROUND

CHASSIS

GROUND

FIREPLACE INSTALLATION

Continued

Electrical

Cover Plate

Rocker

Switch

Strain

Relief

Figure 6 - Fan Kit BK2 Electrical Cover

FAN KIT ASSEMBLY (BK2)

A fan kit assembly is preinstalled in this

replace. Use of blowers or fans other than

model BK2 voids warranty. Fan is operated by

pressing rocker switch located at lower right

hand corner of replace face. Fan kit electrical connections are made through electrical

cover plate located on side of replace as

shown in Figure 6.

Screws

Fan Kit Wiring Instructions

1. Loosen strain relief by turning plastic screw

counterclockwise.

2. Remove electrical cover plate (with strain

relief) from replace by removing two sheet

metal screws .

3. Slide power source wiring through strain

relief opening and electrical cover plate

and make all necessary connections

4. Place all wiring connections into electric

housing as shown in Figure 7.

5. Secure electrical cover plate with screws

previously removed.

6. Tighten strain relief plastic screw

Note: Electrical housing and cover plate have

sharp edges. Wear protective gloves.

VENTING INSTALLATION

OUTSIDE AIR KIT

Installation of an outside air kit should be

completed during the rough framing of

replace due to nature of its location. The

supplied ex duct measures approximately

10" compressed and up to approximately 36"

extended. Outside combustion air is accessed

through mobile home oor using air kit model

AK6E or a side wall using air kit model AK6WE (see Accessories on page 18).

Installer may choose either left or right side

mounting to allow for proper wall/rafter

clearances.

For AK6-WE Only: Construct a 4.5" x 4.5"

framing or opening on exterior wall (see

Figure 8, page 7).

For AK6E Only: The outside air vent is installed through a ventilated crawl space (see

Figure 9, page 7).

Loading...

Loading...