Vetus DIESEL VH4.65, VH4.80 Operation Manual

VH4.65

VH4.80

Operation manual

VD01079

VH4.80

1

Operation manual

Please enter the serial numbers here.

These numbers should be quoted when inquiring about Customer

Service, Repairs or Spare Parts (see page 6).

We reserve the right to make any changes without previous

notice.

Serial numbers

Engine serial number Vetus:

Hyundai:

Gearbox serial number:

VH4.65

VH4.80

350102.01 (STM4994)

Please read and observe the information given in this operation

manual. This will enable you to avoid accidents, preserve the

manufacturer’s warranty and maintain the engine in peak operating condition.

For the Guarantee Conditions, see the Vetus Diesel Service and

Warrantee Manual.

This engine has been built exclusively for the application specified in the scope of supply and is to be used only for the intended purpose. Any use exceeding that scope is considered to be

contrary to the intended purpose. The manufacturer will not not

assume responsibility for any damage resulting therefrom. The

risks involved are to be borne by the user.

Use in accordance with the intended purpose also implies compliance with the conditions laid down by the manufacturer for

operation, maintenance and servicing. The engine should only

be operated, maintained and serviced by persons which are

familiar with the former and the hazards involved.

The relevant accident prevention guidelines and other generally accepted safety and industrial hygiene regulations must be

observed.

Unauthorized engine modifications will invalidate any liability

claims against the manufacturer for resultant damage.

Manipulations of the injection and regulating system may also

influence the performance of the engine, and its emissions.

Adherence to legislation on pollution cannot be guaranteed

under such conditions.

2

Serial numbers 1

1 Introduction 4

2 Engine description

General 6

Identification of engine parts 8

Control panels 10

3 Use

General guidelines 12

First commissioning 13

Running-in 16

Starting 17

(Pre-heating) 18

Cruising 20

Stopping 22

4 Routine maintenance

Introduction 23

Maintenance schedule 24

5 Maintenance

Checking the oil level 25

Checking the coolant level 26

Checking and cleaning the

raw water strainer 27

Draining water from the water

separator/fuel filter 28

(Bleeding) 29

Battery, cables and cable

connections 30

Changing the oil 32

Checking the gearbox oil level 34

Changing the gearbox oil 35

Replacing the fuel filter 36

Cleaning fuel lift pump 37

Checking the V-belts 38

Checking flexible engine mounts 40

Checking hose connections 40

Checking fastenings 40

Checking valve clearance 41

Checking the raw water pump 44

Coolant replacement 46

Cleaning the heat exchanger 48

Checking engine rpm 51

6 Winter lay-up

Winter storage procedure 52

Recommissioning after winter

storage 55

7 Troubleshooting 58

8 Technical Data 64

9 Operating media

Lubrication Oil 66

Fuel 67

Coolant 68

10 Wiring Diagrams 69

11 Overall Dimensions 72

3

Contents

4

Dear Customer,

Vetus diesel engines are designed both for pleasure and commercial craft. Consequently, a wide range of variants are offered

to meet the requirements of specific cases.

Your engine is appropriately equipped for your vessel, which

means that not necessarily all components described in this

manual are mounted to your engine.

We have endeavoured to highlight any differences so that you

will able to locate the operating and maintenance instructions

relevant to your engine quickly and easily.

Please read this manual before starting your engine and always

observe the operating and maintenance instructions.

We are available to help with any additional inquiries.

Sincerely, VETUS N.V.

Introduction

5

Safety measures

Introduction

All safety instructions in this manual are designated by the accompanying symbol. Please

follow them carefully.

Pass the safety instructions to other persons operating the

engine as well.

General regulations and laws for safety and accident prevention

must also be observed.

• Never attempt to touch moving parts when the engine is running.

• Never touch hot parts of the engine, and keep flammable

materials well away from the engine.

• Always stop the engine before checking or adjusting components.

• Always stop the engine before checking or topping up the

coolant or oil.

• Never open cap on top of header tank when the engine is at

operating temperature.

• Always carry out maintenance safely by only using tools well

matched in size.

6

Engine data tag

The vetus engine serial number and performance data are printed on the engine

data tag.

Model and engine serial number must be

given when ordering spare parts.

Engine data tag location

The vetus engine data tag is attached to

the valve cover.

Engine serial number

The HyuNdai engine serial number is

stamped at the indicated spot.

Engine description

General

VH480---A

D4BB1207830

A

4000 59 80

200001

ø88 MM

VD00232 VD01080 VD01081

7

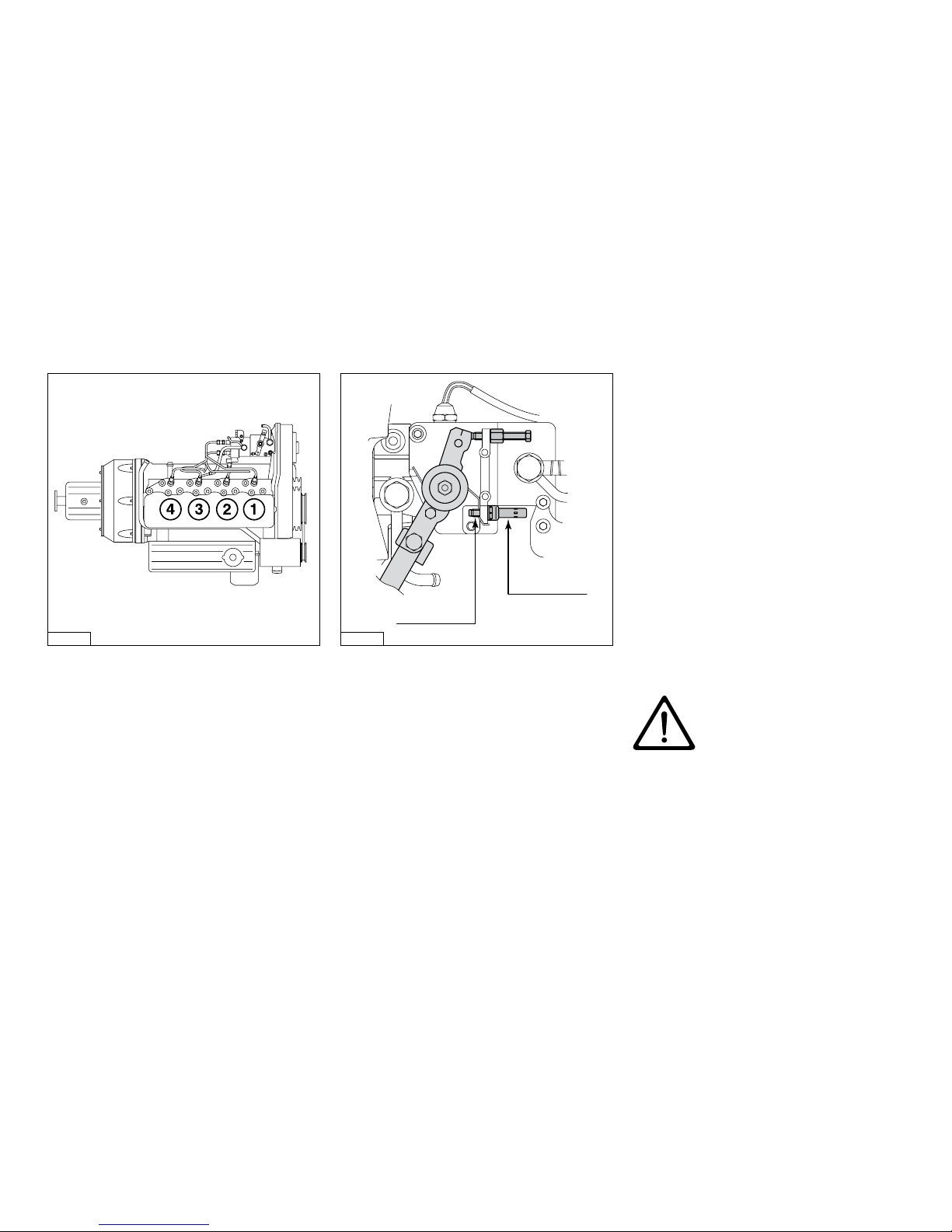

Cylinder numbering

Cylinders are numbered consecutively,

beginning at the front end.

Fuel pump seal

The manufacturer shall not be held liable

for damages resulting from adjustments

made to the fuel injection pump.

The maximum engine speed adjustment

screw has been sealed to prevent this.

Adjustments to the fuel

pump are to be carried out

by authorized Vetus-Service

specialists only.

General

Engine description

VD00230

Lead seal

Maximum rpm

adjustment screw

VD00229

Port-side

Starboard

8

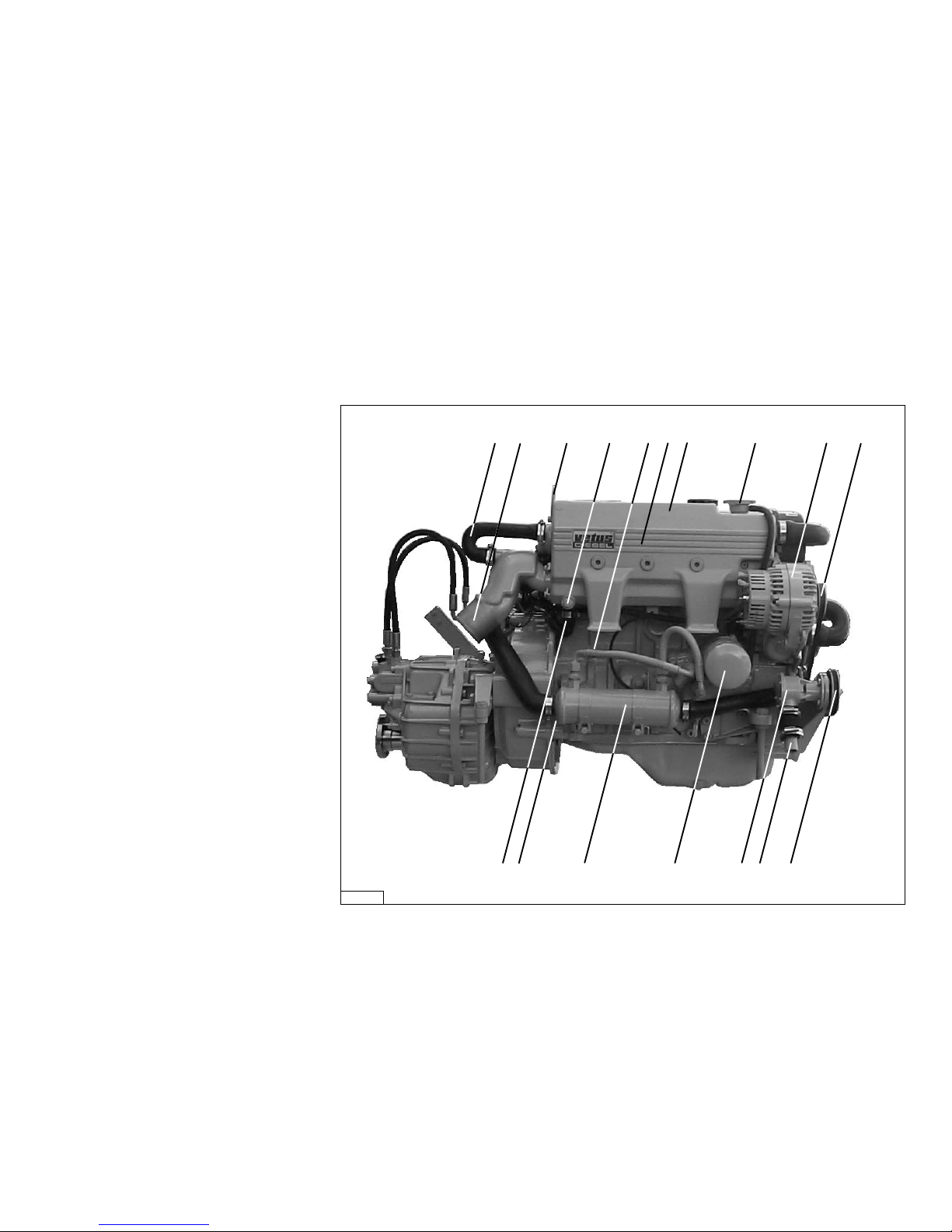

1 Airvent connection

2 Exhaust injection bend

VH4.65: ø 60 mm

VH4.80: ø 75 mm

3 Lifting eye

4, 5 Cooling system drain plug

6 Heat exchanger

7 Expansion tank

8 Filler cap for cooling system

9 Alternator

10 V-belt alternator/ coolant pump

11 V-belt raw water pump

12 Raw water inlet ø 25 mm

13 Raw water pump

14 Oil filter

15 Oil cooler

16 Raw water drain plug

17 Calorifier connection, engine ‘IN’

(ø 22 mm)

18 Connection for throttle push-pull

cable

19 Cooling system air bleed nipple

20 Temp. switch coolant

Engine description

Identification of engine parts

Starboard

1 2 3 4 5 6 7 8 9 10

11121314151617

VD01105

VH4.80

9

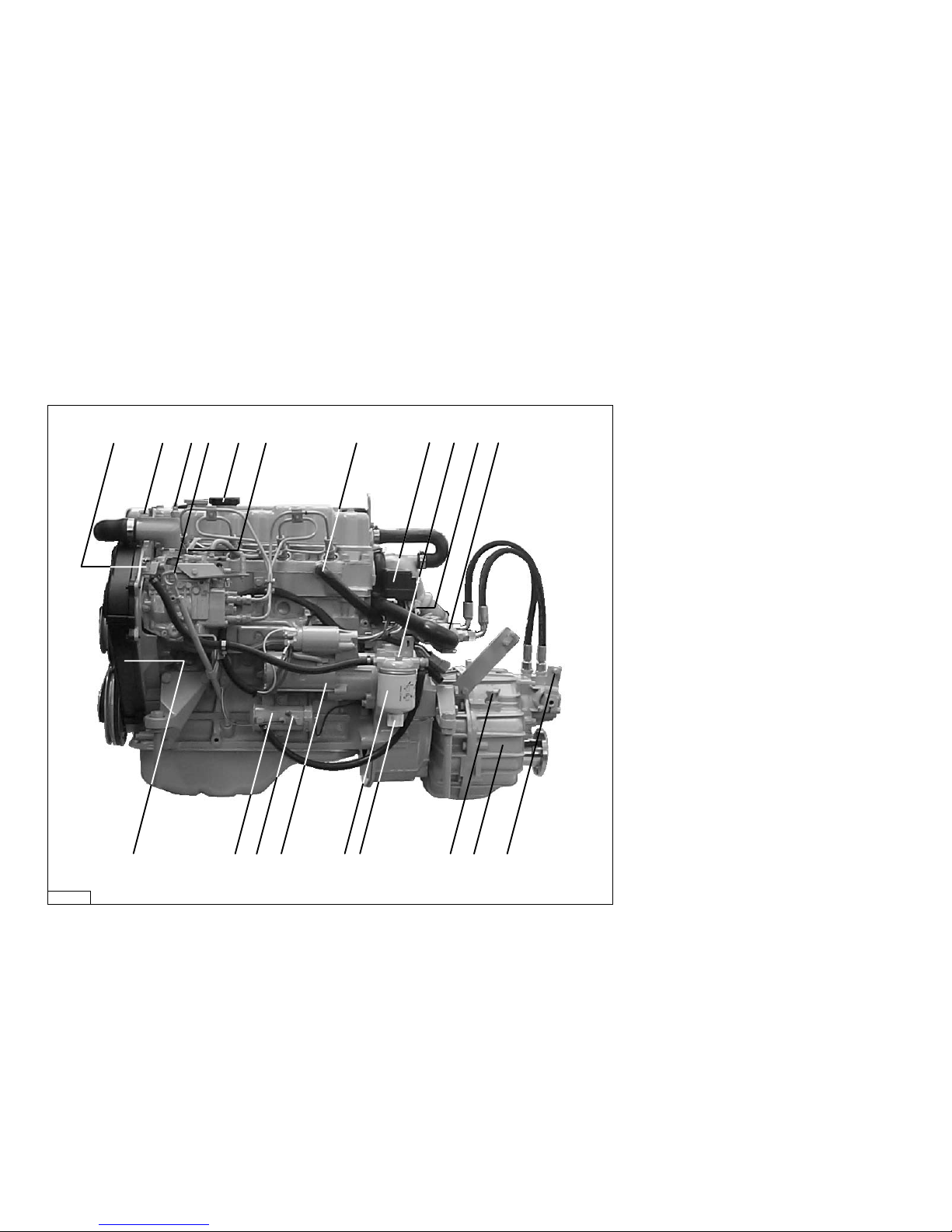

21 Oil dipstick

22 Oil filler cap

23 Fuel return pipe connection

ø 8 mm

24 Calorifier connection, engine ‘OUT’

(ø 17 mm)

25 Electrical system connection box

26 Water separator/fuel filter air bleed

nipple

27 Fuse

28 Gearbox lube oil cooler

29 Connection for gearbox push-pull

cable

30 Gearbox

31 Gearbox filler cap/ oil dipstick

32 Water separator/ fuel filter drain

plug

33 Water separator/ fuel filter

34 Starter motor

35 Fuel supply pipe connection

ø 8 mm

36 Fuel lift pump

37 Distribution cover

Identification of engine parts

Port-side

Engine description

19 20 21 22 23 24 26 27 28

293031323334353637

18 25

VD01106

VH4.80

10

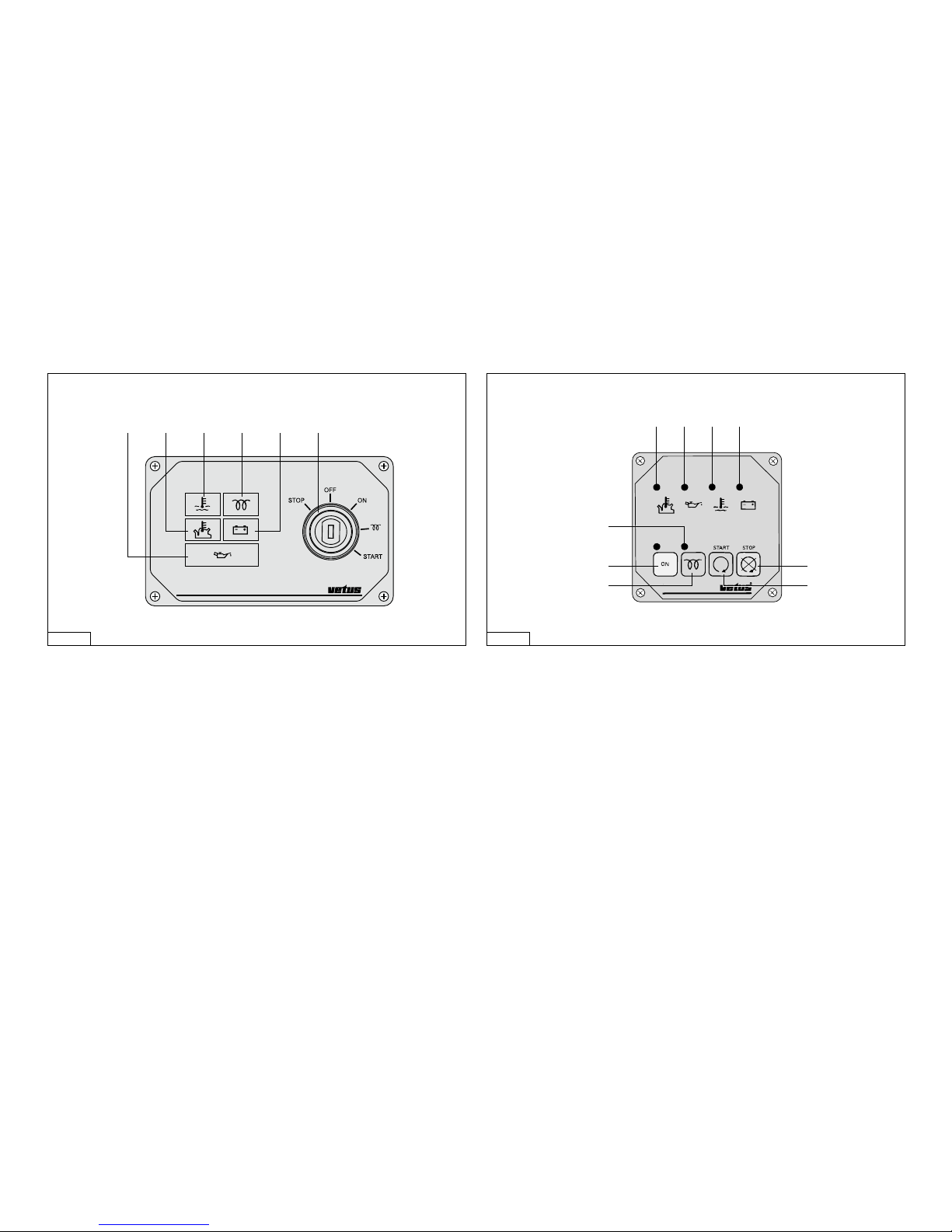

Basic panel (model 22)

Fly-bridge panel (excl. voltmeter, model 21)

Extended panel (model 34)

Engine description

Control panels

5

3

7

8

6

4

9

1 2

VD00103

5

3

7

8

6

4

9

1 210

11

VD00104

11

Sailingboat panel (model 10) Push button panel (model 00)

Control panels

Engine description

1 Tachometer/Operating hours counter

2 Voltmeter

3 Starter pre-heat switch/lock

4 Warning light high raw water temperature

5 Warning light low oil pressure

6 Warning light high coolant temperature

7 Warning light battery charging

8 Indicator light pre-heating

9 Warning light gearbox low oil pressure *

10 Temperature gauge, coolant

11 Oil pressure gauge

12 On push button switch

13 Pre-heating push button switch

14 Starter push button switch

15 Stop push button switch

*) This is an option, not fitted as standard.

5

3

7

8

6

4

VD00102 VD00101

4 5 6 7

8

12

13

15

14

12

General guidelines for use

Implementing the following recommendations will result in longer

life and better performance and more economical operation of

your engine.

• Carry out the maintenance described regularly, including the

‘Daily procedures before starting’.

• Use anti-freeze in the engine coolant all year long, this helps

prevent corrosion as well as protecting against frost damage.

For specifications see page 68.

• Never run the engine without a thermostat.

• Use a good quality lubricating oil. For specifications see page

66.

• Use a good quality diesel fuel that is free of water and other

pollutants.

• Always stop the engine immediately if one of the warning

lamps for oil pressure, high coolant temperature, high raw

water temperature or battery charging lights up.

Use

General guidelines

13

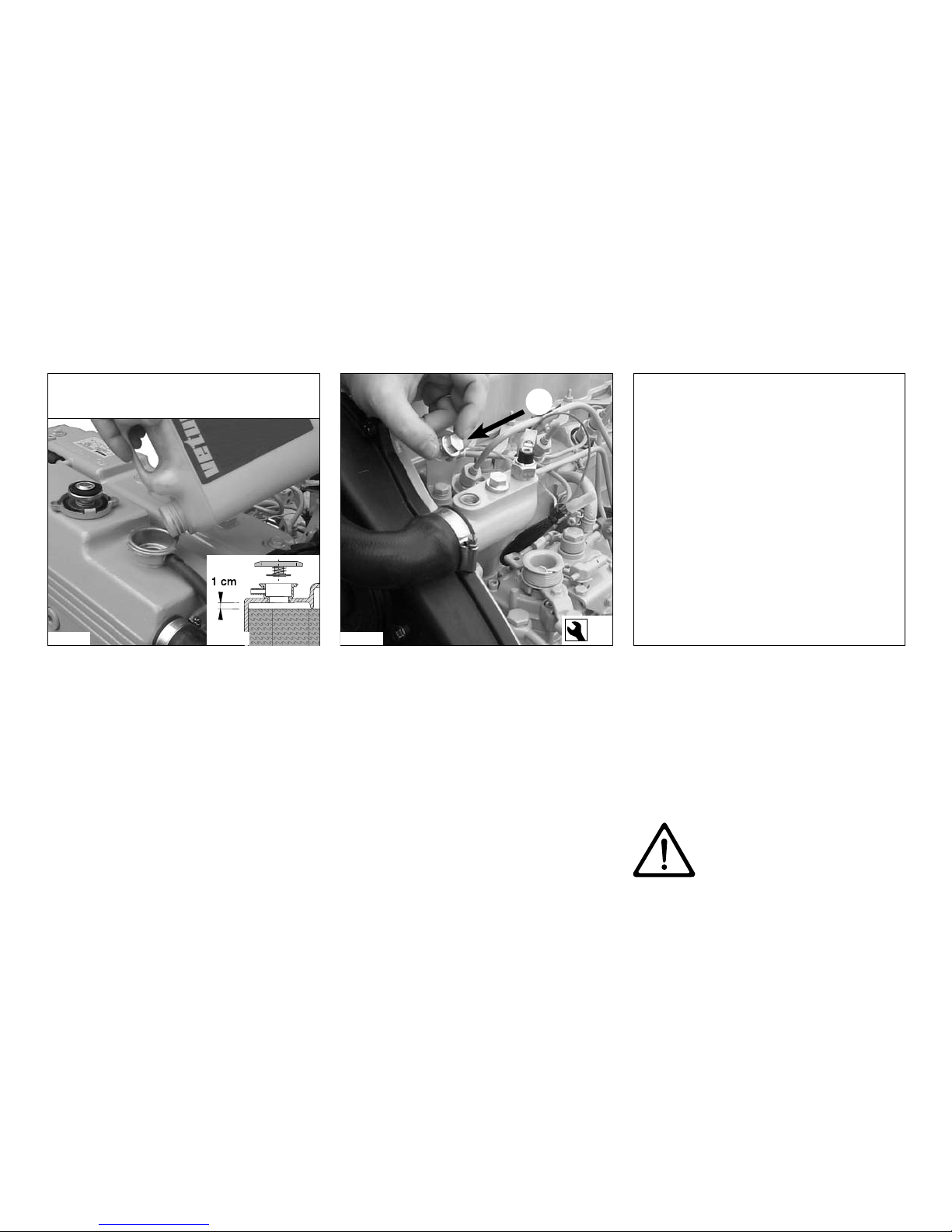

Commissioning the engine

Before starting the engine for the first time,

the following procedures must be carried

out:

Filling with engine oil

As a rule engines are delivered empty of

oil.

Fill the engine with oil through the filler

neck on top of the valve cover, for quantity

and specification see page 66.

Check the oil level with the dipstick, see

page 25.

First commissioning

Use

Engine Oil

4.9 litres (1.1 UKgal) 15W40

API: CD, CE or CF4

CCMC: D4, D5

For example:

- Vetus Marine Inboard Diesel Motor

Oil

- Shell Super Diesel T

OIL

VD01082

Filling gearbox with oil

Fill the gearbox with oil.

Check the oil level with the dipstick, see

page 34.

ZF Hurth:

model HBW250 : 0,75 litres ATF*)

(ZF25M) (1.3 UKpt)

model HBW250A : 0,8 litres ATF*)

(ZF25MA) (1.4 UKpt)

model HSW250A : 1,8 litres ATF*)

(ZF25A) (3.2 UKpt)

model HSW250H : 2,5 litres ATF*)

(ZF25) (4.4 UKpt)

*) ATF: Automatic Transmission Fluid

type A, Suffix A.

Technodrive:

model TMC260 : 1,2 litres ATF*)

(2.1 UKpt)

model TM345H : 1,6 litres Engine oil

(2.8 UKpt) SAE 20W40-CD

model TM345A : 1,6 litres Engine oil

(2.8 UKpt) SAE 20W40-CD

*) ATF: Automatic Transmission Fluid

type A, Suffix A.

First commissioning

Use

14

OIL

VD01100

Vetus engines are normally equipped

with ZF-Hurth or Technodrive gearboxes.

In case your engine is equipped with

another brand of gearbox follow the

instructions given in the supplied owners manual.

15

Filling the cooling system

Remove the cap of the filler neck on the

top of the heat exchanger housing.

Remove plug A, so that air can escape

from the cooling system.

Fill the cooling system. Replace plug A as

soon as coolant flows out.

Use a mixture of 40% antifreeze (ethyleneglycol based) and 60% tap water or use a

special coolant.

For specifications see page 68.

The level of the coolant must be approx.

1 cm (3/8”) below the lower edge of the

filler neck.

Bleeding will take place automatically during filling!

Replace the filler cap.

After the engine has run for the first time

and has reached operating temperature

and has cooled down again to ambient

temperature, check the coolant level in the

heat exchanger housing.

If necessary, add coolant.

Use

First commissioning

Water Heater

If a water heater is connected to the

engine and this heater is positioned

above the upper side of the engine

then bleeding of the heater will not

take place automatically! Fill the heater

separately to bleed the cooling system

completely.

Never fill the cooling system

with sea water or brackish

water.

A

13

VD01083 VD00144

(3/8”)

VD01084

Coolant

quantity :

7.1 litres (1.6 UKgal)

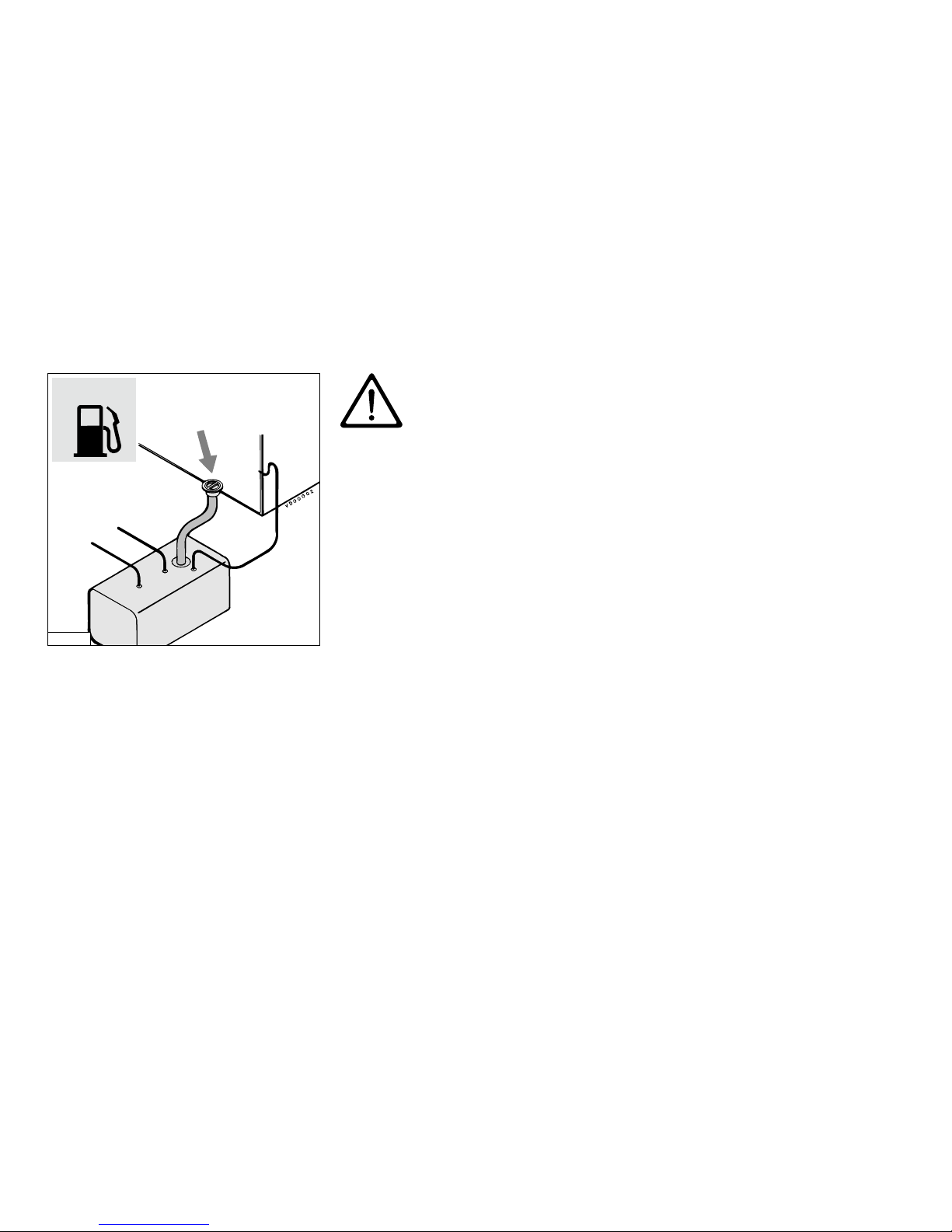

Fuel

Ensure that the fuel tank is filled with

diesel fuel.

Use only clean, water-free, commercial

approved diesel fuel.

For fuel grade see page 67.

Bleed the fuel system, see page 29.

Other preparations

• Check battery and cable connections.

• Start the engine, see page 17, and let it

run for about 10 minutes without load.

Check the engine and all connections

(fuel, cooling water and exhaust) for

leaks.

Running-in

In order to ensure a long life for your

engine, please observe the following for

the first 50 operating hours:

• Allow the engine to reach operating

temperature before applying a load.

• Avoid fast acceleration.

• Do not allow the engine to run faster

than 3/4 of maximum RPM.

First commissioning

Running-in

Use

16

FUEL

VD00002

Never fill the fuel tank while

the engine is running.

Do not spill fuel. Prevent

unnecessary pollution.

17

After repair work:

Check that all guards have been replaced

and that all tools have been removed from

the engine.

When starting with pre-heating, do not use

any other substance (e.g. injection with

‘Easy Start’). Doing so could result in an

accident.

Preparation starting

Before starting the engine, always check

that the control lever(s) is (are) in the neutral position.

Never start the engine with

the fuel injection pump

removed.

Disconnect battery.

Set the control lever to ‘half throttle’ without engaging the gearbox.

Use

Starting

Before starting, alWays check the following points:

• Engine oil level.

• Coolant level.

• Sea cock open.

• Main switch ‘oN’.

• Gearbox in ‘Neutral’ position.

neutral

gearbox

forward

half throttle,

gearbox not engaged

gearbox

reverse

reverse

throttle

forward

throttle

VD00111 VD00112

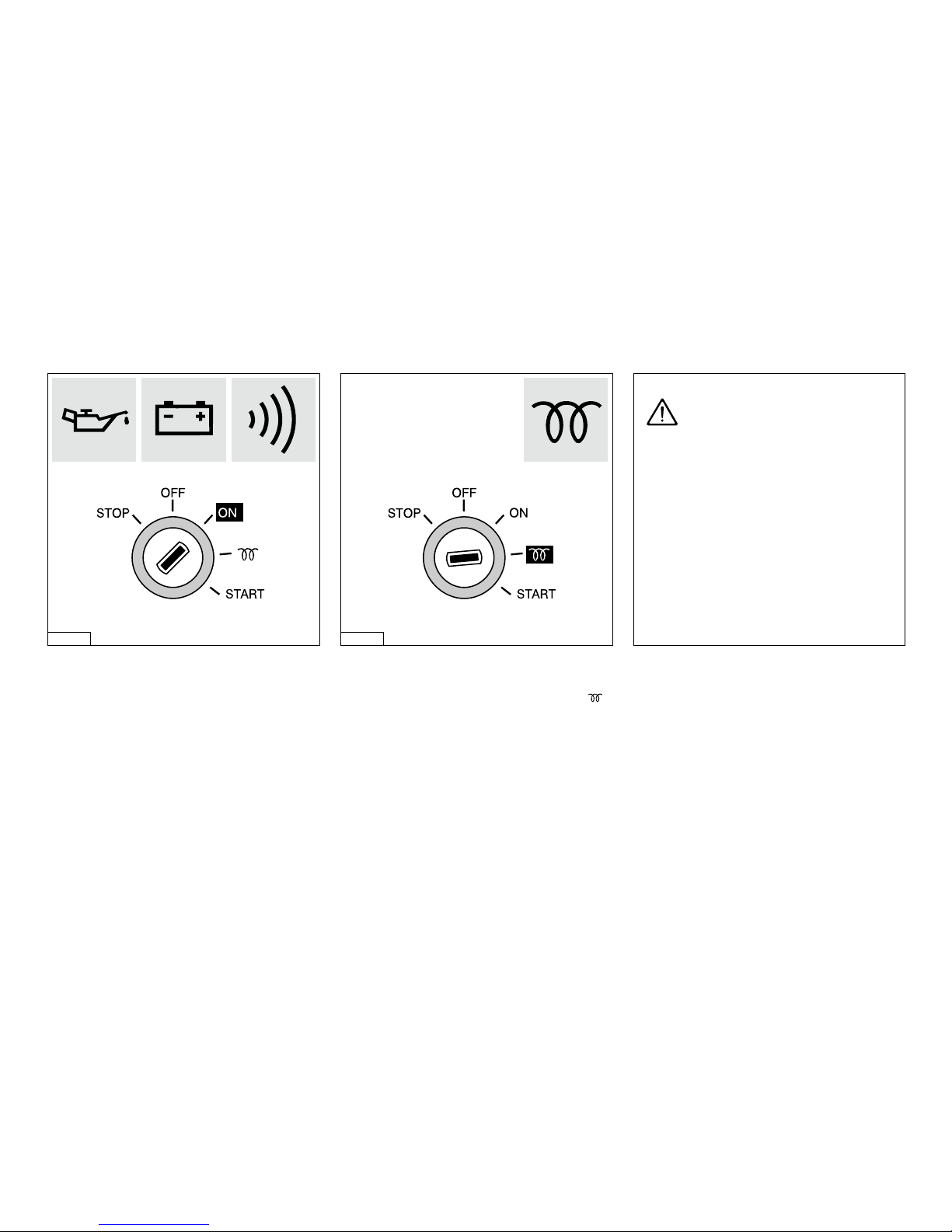

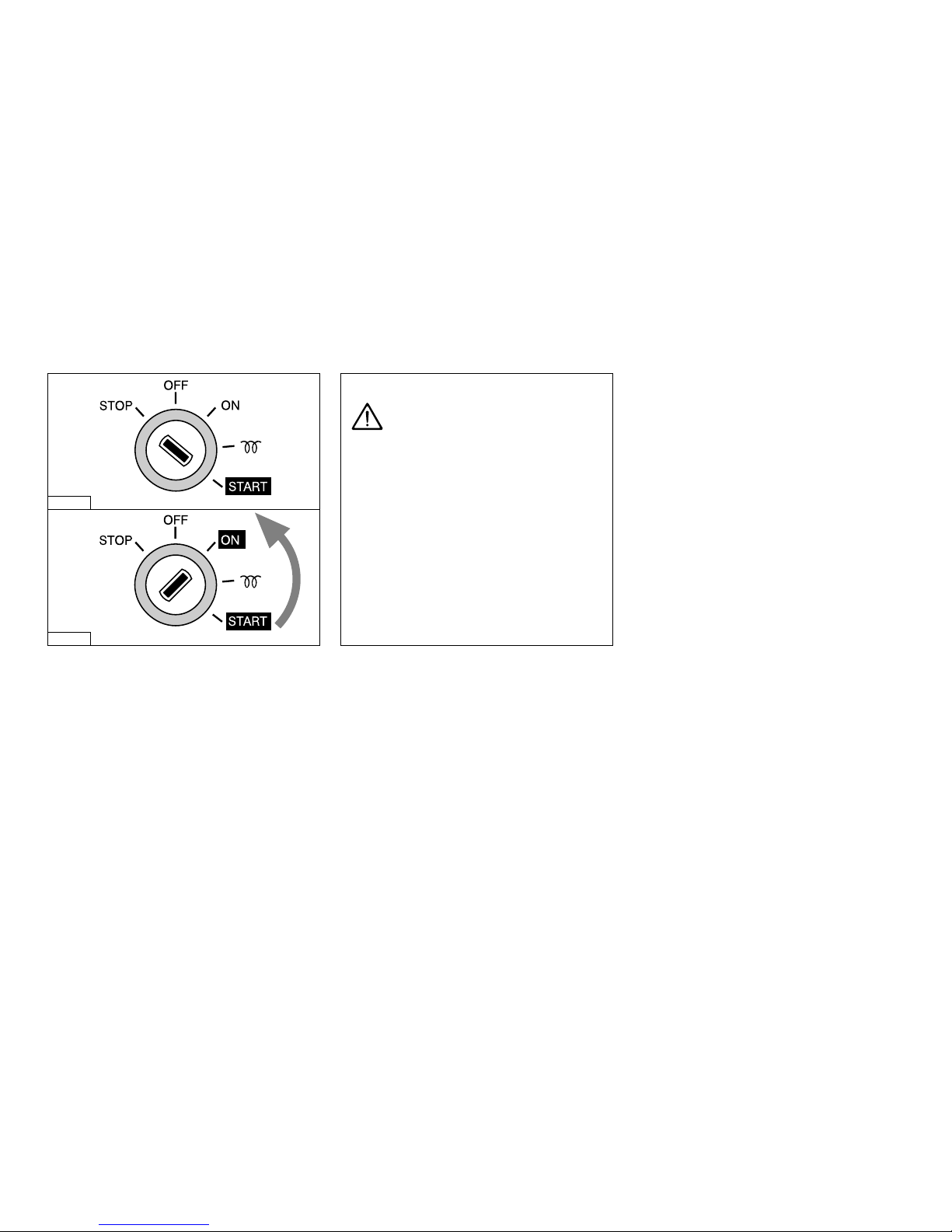

Turn the start key on the instrument panel

clock-wise; the warning lights for oil pressure and alternator will now light up and

the alarm buzzer will sound.

Pre-heating

Turn the key further clockwise to the ‘ ’

position; only the pre-heating indicator light will be lit now.

Hold the key in this position for about 2

seconds.

Starting

Use

18

VD00107 VD00108

WarNiNg

To prevent the glow plugs

from burning out, never exceed the

stated maximum pre-heating time.

Maximum pre-heating time is 3

seconds.

19

Starting

Now turn the key further to the ‘start’

position.

Release the key as soon as the engine

fires (the key will return to the ‘oN’ position) and throttle back.

Leave the key in this position while the

engine is running.

Check that the indicator lights for oil pressure and alternator are off. Cooling water

should now flow out of the exhaust; if this

is not the case, stop the engine immediately. Before submitting the engine to full

load it should be brought up to operating

temperature as quickly as possible by

running at 3/4 of maximum revs. Never

turn the main switch off while the engine

is running.

Use

Starting

WarNiNg

Release the key if the engine does

not fire within 10 seconds. Wait until

the starter motor has stopped running

completely before turning the key to

the ‘start’ position again. Never allow

the starter motor to run for more than

30 seconds consecutively.

VD00109

VD00110

The instrument panel is provided with the

following instruments (Depending of the

type of panel, see page 10 and 11).

WarNiNg

Never turn the key to the ‘start’ position

while the engine is running.

Doing so will damage the starter motor.

20

When the engine reaches operational temperature, exhaust gases should be colourless or light-blue. (In the winter, the low

temperatures will turn the exhaust emissions white.)

If black smoke is emitted from the exhaust,

this indicates that combustion is incomplete.

If white smoke is emitted, this indicates

combustion of oil forced up.

Tachometer

Indicating the number of revolutions per

minute of the engine.

Avoid idling for more than 10 minutes.

Also the number of running hours is indicated.

Idling speed,

VH4.65 : 850 rpm

VH4.80 : 850 rpm

Voltmeter

Indicating the battery voltage.

When the engine is running, the battery

voltage should be between 12 and 14

Volts.

With the engine stopped and the start key

in the first position, the voltmeter should

indicate 12 Volts.

Cruising

Use

VD00577 VD00578

21

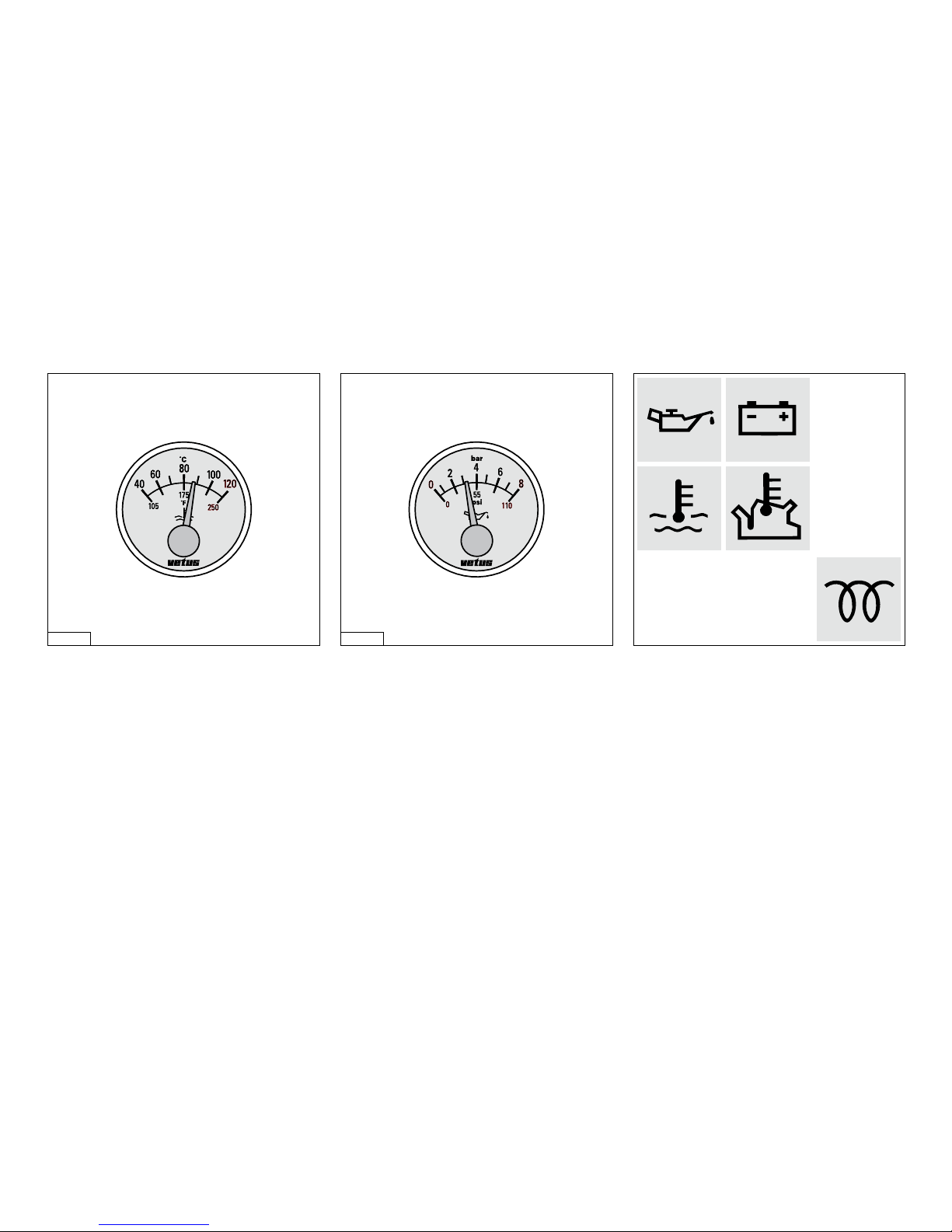

Temperature gauge

Indicating the temperature of the internal

cooling system.

The operating temperature is 76˚C - 85˚C.

In case the engine is overheated: turn off

the engine and establish the cause, see

fault finding table, page 59 .. 63.

Oil pressure gauge

With the engine at operating temperature,

the oil pressure is:

When idling: at least 0.8 bar (6 psi).

In case the oil pressure is too low: turn off

the engine and establish the cause, see

fault finding table, page 59 .. 63.

Warning lights

None of the five warning lights should light

up while the engine is running. Oil pressure, battery charging and temperature

indicator lights are all connected to an

alarm buzzer. If this alarm buzzer sounds

while running, stop tHe eNgiNe immedi-

ately!

Cruising

VD00663 VD00664

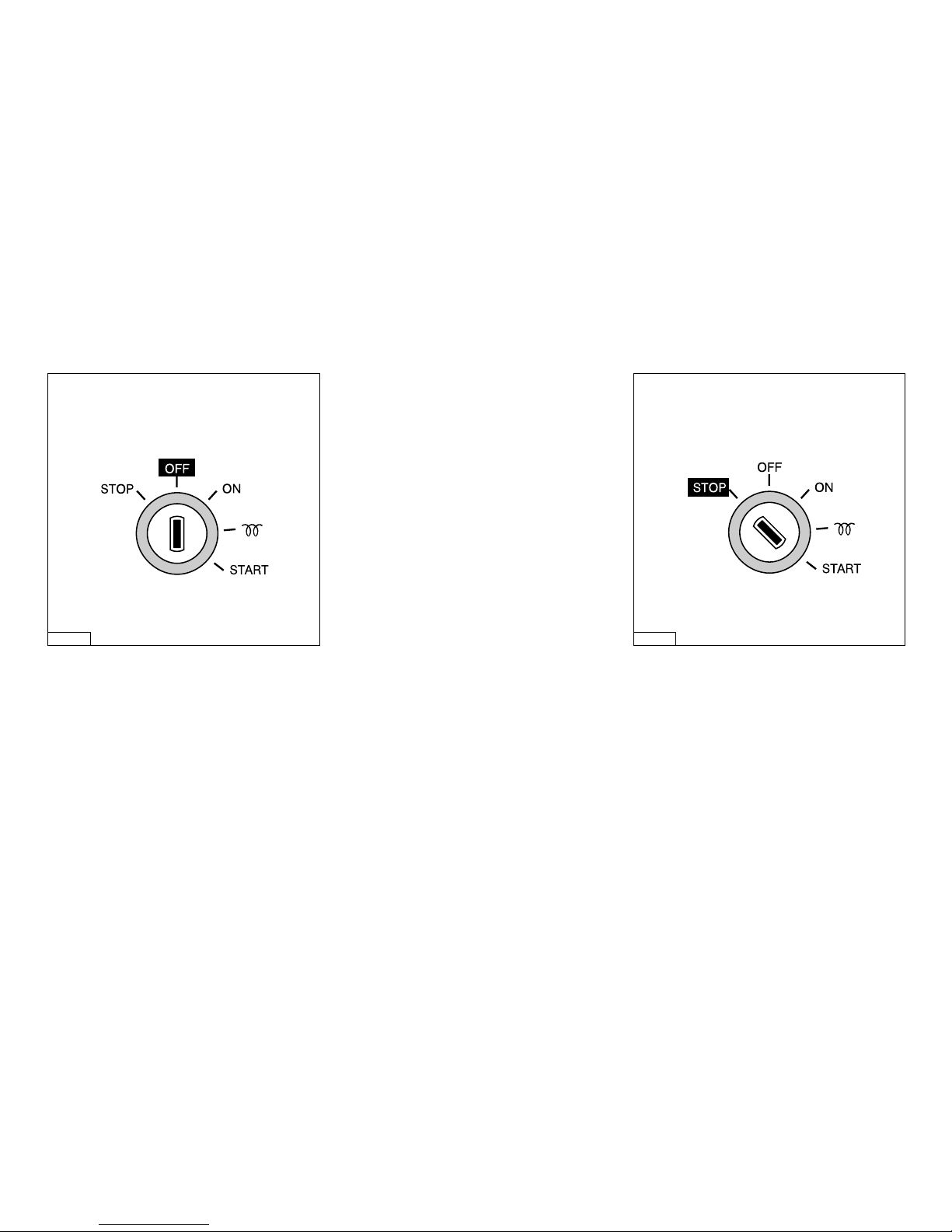

Stopping

Reduce engine speed to idle and shift the

gearbox to ‘Neutral’. Turn the key to the

left to the ‘off’ position.

If the engine is not to be used for some

time, it is recommended that the sea cock

is closed and the battery main switch

turned off.

Never stop the engine immediately after

it has been in operation for a long time.

Allow the engine to idle for a few minutes

before stopping.

N.B. The ‘stop’ position, left of the ‘off’

position on the control panel, has normally

no function for this engine.

When 2 control panels are connected to

one engine, the engine can always be

stopped by turning the key to the ‘stop’

position, no matter what the position is of

the key on the other panel.

Stopping

Use

22

VD00106 VD00105

Loading...

Loading...