Operation manual

M2

M2.02

M2.06

ii

1

Operation manual

Please enter the serial numbers here.

These numbers should be quoted when inquiring about Customer Service, Repairs or Spare Parts (see page 6).

We reserve the right to make any changes without previous notice.

Copyright © 2012 Vetus N.V. Schiedam Holland

Serial numbers

Engine serial number Vetus:

Engine serial number Mitsubishi:

Gearbox serial number:

M2.02

M2.06

340802.01

2

Please read and observe the information given in this operation manual. This will enable

you to avoid accidents, preserve the manufacturer’s warranty and maintain the engine

in peak operating condition.

Make sure that the manual will remain intact

and damage is prevented. Keep the manual

away from humidity and heat.

Do not alter the content of the manual.

The manual is an integral part of the engine.

Hand over the manual tot the new owner if

boat or engine is being sold.

For the Guarantee Conditions, see the Vetus Diesel ‘Service and Warranty Manual’

(320199.06).

This engine has been built exclusively for the

application specied in the scope of supply and is to be used only for the intended

purpose. Any use exceeding that scope is

considered to be contrary to the intended

purpose. The manufacturer will not not assume responsibility for any damage resulting

therefrom. The risks involved are to be borne

by the user.

Use in accordance with the intended purpose also implies compliance with the conditions laid down by the manufacturer for

operation, maintenance and servicing. The

engine should only be operated, maintained

and serviced by persons which are familiar

with the former and the hazards involved.

The relevant accident prevention guidelines

and other generally accepted safety and

industrial hygiene regulations must be observed.

Unauthorized engine modications will invalidate any liability claims against the manufacturer for resultant damage.

Manipulations of the injection and regulating

system may also inuence the performance

of the engine, and its emissions. Adherence

to legislation on pollution cannot be guaranteed under such conditions.

3

Contents

1 Safety measures 4

Warning indications 4

Preventing re and explosion 5

Prevention of injury 6

When problems occur 8

2 Introduction 9

Data tag 10

Serial number 10

Cylinder numbering and direction

of rotation 11

Fuel pump seal 11

Identication of engine parts 12

Control panels 14

Control lever 15

3 First commissioning 16

4 Running-in 25

5 Use 26

General guidelines 26

Starting 28

Cruising 32

Stopping 34

6 Maintenance 36

Introduction 36

Maintenance schedule 38

Checking engine oil level 40

Checking and cleaning the raw

water strainer 41

Checking coolant level 42

Draining of water from the water

separator/fuel lter 44

Engine oil change 47

Battery, cables and connections 50

Gearbox oil level check 54

Fuel lter replacement 55

Bleeding, after fuel lter replacement 57

Changing the gearbox oil (Technodrive) 58

Changing the gearbox oil (ZFHurth) 59

Checking valve clearance 60

Checking the V-belt 62

Flexible engine mounts, hose connections and fasteners 63

Raw water pump inspection 64

Coolant replacement 66

Checking the starter motor and

alternator 70

Checking engine speed 71

Cleaning the heat exchanger 72

7 Winter storage procedure 76

8 Recommissioning after win-

ter storage 84

9 Troubleshooting 90

9 Troubleshooting 97

10 Technical data 100

Engine specications 100

Gearbox specications 103

Torque wrench settings 104

11 Operating media 105

Fuel 105

Lubricating oil 106

Coolant 109

12 Wiring diagram 110

13 Overall dimensions 112

14 Index 113

4

1 Safety measures

Danger

Indicates that great potential danger exists

that can lead to serious injury or death.

Warning

Indicates that a potential danger that can lead

to injury exists.

Caution

Indicates that the usage procedures, actions

etc. concerned can result in serious damage

to or destruction of the engine. Some CAUTION indications also advise that a potential

danger exists that can lead to serious injury or

death.

note

Emphasises important procedures, circumstances etc.

Symbols

Indicates that the relevant procedure

must be carried out.

Indicates that a particular action is for-

bidden.

Pass the safety precautions on to other people who will use the engine.

General rules and laws concerning safety

and accident prevention must always be observed.

Warning indications

The following warning indications are used in

this manual in the context of safety:

Warning indications

5

1 Safety measures

• Do not smoke if refuelling.

• Avoid spilling fuel on hot surfaces. Spilled

fuel must be cleaned up immediately.

• Do not use petrol or diesel to clean components but make use of good quality, noninammable, non-poisonous solvents that

are available from dealers.

• Always be alert to possible fuel or oil leakage!

If you discover a leak, take counter-measures immediately. If fuel or oil is spilled on

a hot engine, re can break out. This can

cause physical injury or damage to the

equipment.

• Do not ll the fuel tank while the engine is

running!

Only refuel with the engine stopped.

• Never put ammable materials in the vicinity of the engine!

• Keep the engine and engine compartment

clean!

Remove all inammable materials such as

fuel, oil and other litter before it builds up

in the vicinity of the engine.

• Connecting (emergency) extra starting battery

Proceed as follows when an extra starting

battery is used to jump start the engine:

- First connect the positive lead

- Lastly connect the earth cable (negative

pole) to the engine block

If this cable is connected in error to the

negative pole of the engine battery, a

spark can occur. The result of this could

be that explosive gas produced by the

battery explodes.

- Once the engine is started, rst remove the

earth cable.

Preventing re and explosion

Fire risk!

6

1 Safety measures

Prevention of injury

• The moving parts of the engine are dangerous. Never touch moving parts of the engine while it is running, to prevent cuts and

other injuries.

• Stop the engine before carrying out maintenance!

• Always stop the engine before topping up

or replacing fuel, oil or coolant.

• Before carrying out inspection or maintenance, the ignition key must be removed

and the main battery switch turned o.

• Satisfy yourself that everything is in order

before the engine is started again!

Make sure that no-one is working on or

close to the engine before you start it. Remove all foreign objects from around the

engine, such as litter, oil, tools and other

components that are not part of the engine.

• Install all protective covers!

To prevent injury, make sure that all protective covers and cover plates are replaced

over moving parts.

• Remove any tool used to turn the engine

over. If you leave this in position, serious

injury or damage to the equipment can result.

• NEVER open the cap of the expansion tank

when the engine is at working temperature.

• Only check the coolant level after the engine has been stopped and the ller cap

on the heat exchanger is cool enough to be

removed with bare hands.

• Never attempt to adjust the fan belt on a

running engine.

7

1 Safety measures

Prevention of injury

• Be careful with battery acid!

If battery acid comes in contact with the

eyes or skin, rinse the aected part immediately with copious amounts of water. If

battery acid comes in contact with the eyes,

rinse them out immediately with plenty of

water and consult a doctor.

• Be careful with antifreeze!

If you accidentally swallow antifreeze, make

yourself vomit and consult a doctor immediately. If antifreeze comes in contact with

your eyes, wash them out immediately with

plenty of water and consult a doctor.

• Make sure that you are wearing suitable

clothing before starting work!

For your own safety you will most likely

need special equipment – safety helmet,

eye protection, safety boots, safety goggles, heavy gloves, ear protectors etc. Use

them when necessary.

• Carry out maintenance procedures safely

by only using suitable tools.

• Exhaust gases

Do not start the engine if the exhaust system is not connected.

8

When the engine stops suddenly:

If the engine stops suddenly, do not start it

again immediately. Track down the cause and

carry out the necessary repairs before you

start the engine again. If you do not do this,

serious engine problems can develop.

If the oil pressure is too low:

Stop the engine immediately and check the

lubrication system. Running an engine with

low oil pressure can cause bearing and other

parts to seize.

lf the engine overheats:

If the engine should overheat, do not switch

it o immediately. If an overheated engine is

stopped suddenly, this can cause the coolant

temperature to rise rapidly and moving parts

to seize. First let the engine run in neutral to allow the hot parts of the engine to cool down,

stop the engine and allow it to cool, and then

gradually top up the coolant. Remember:

adding coolant to an overheated engine can

cause damage to the cylinder head.

If the fan belt is broken:

Immediately stop the engine. If an engine is

used with a broken fan belt, this can lead to

the engine overheating, which in turn can

cause coolant to spray out of the expansion

tank.

If the engine behaves strangely:

Stop the engine or reduce the speed as far as

possible.

Do not use the engine again until the cause of

the defect has been solved.

1 Safety measures

When problems occur

9

Vetus diesel engines are designed for pleasure craft. Consequently, a wide range of variants are oered to meet the requirements of

specic cases.

Your engine is appropriately equipped for

your vessel, which means that not necessarily

all components described in this manual are

mounted to your engine.

We have endeavoured to highlight any dierences so that you will able to locate the operating and maintenance instructions relevant

to your engine quickly and easily.

Please read this manual before starting your

engine and always observe the operating and

maintenance instructions.

We are available to help with any additional

inquiries.

Sincerely,

Vetus n.v.

2 Introduction

Dear customer,

10

2 Introduction

Data tag

Serial number

1 Engine data tag

The Vetus engine serial number and performance data are printed on the engine data

tag.

Model and engine serial number must be given when ordering spare parts.

2 Engine data tag location

The type plate is positioned as shown.

3 Engine serial number

The Mitsubishi engine serial number is

stamped on the fuel injection pump. (arrow)

VD01036

VD01044

VD01035

Lead seal

Maximum speed

adjustment screw

11

2 Introduction

Cylinder numbering and direction of rotation

Fuel pump seal

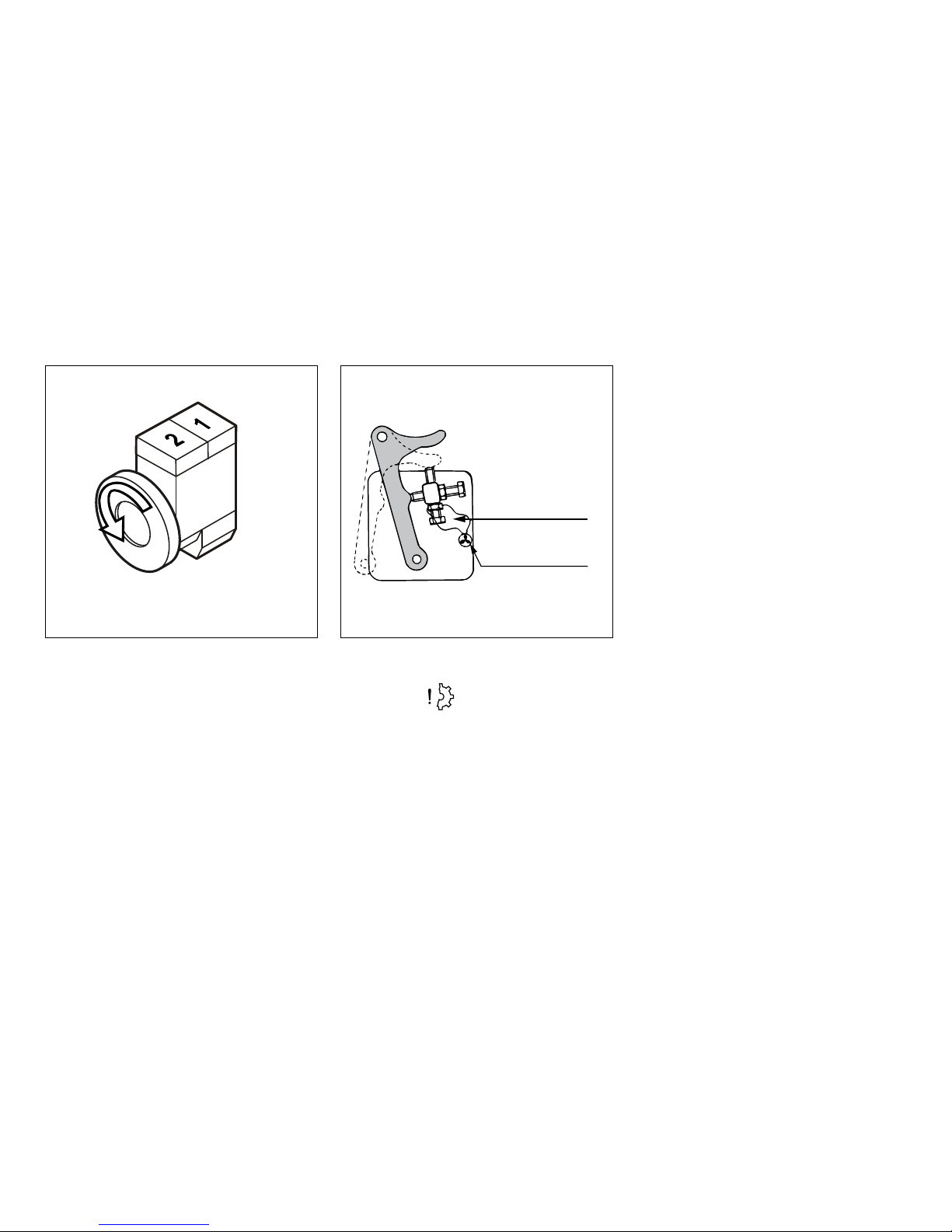

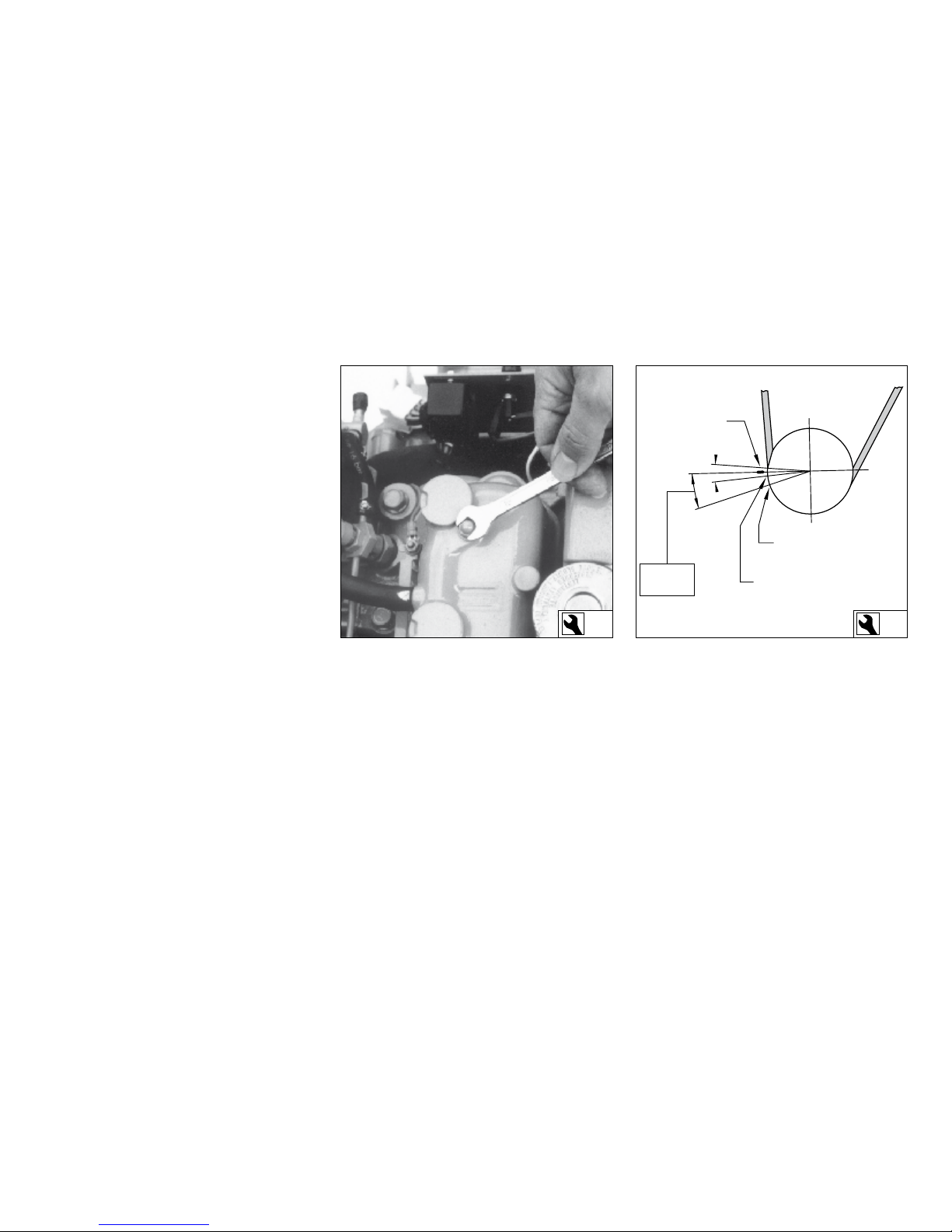

4 Cylinder numbering and direction of

rotation

Cylinder numbering

Cylinders are numbered consecutively, beginning at the front end.

Direction of rotation

The direction of rotation is viewed towards

the ywheel counter clockwise.

5 Fuel pump seal

Caution

Breaking the seals on the regulator to alter

the settings of maximum rpm and maximum

injector volume may only be carried out by

authorised Vetus Service personnel.

Breaking the seals and altering the settings

can lead to:

- Accelerated wear of engine components.

- Increased fuel and oil consumption.

- Incorrectly adjusted injector volume and

poor engine performance.

- Breaking emission regulations.

VD00930

VD00922

1235 46789

1 171614 1513121110 18

12

2 Introduction

Identication of engine parts

Service side

1 Oil ller cap

2 Raw water inlet ø 20 mm

3 Raw water pump

4 Oil dipstick

5 Manual operation of fuel supply pump

6 Oil lter

7 Water separator/fuel lter drain plug

8 Water separator/Fuel lter

9 Connection for gearbox push-pull cable

10 Fuse

11 Electrical system connector box

12 Fuel return pipe connection ø 8 mm

13 Air inlet silencer

14 Water separator/fuel lter air bleed

nipple

15 Manual operation of electric stop

16 Fuel supply pipe connection ø 8 mm

17 Fuel lift pump

18 Connection for throttle push-pull cable

VD01253

19

20

212223

30 31, 2628 2925, 26, 2724

32

33

13

2 Introduction

Identication of engine parts

Starter side

19 Gearbox

20 Gearbox drain plug

21 Gearbox oil dipstick/ller cap

22 Starter motor

23 Alternator

24 V-belt

25 Connection for extra expansion tank

(Keel cooling model only)

26 Calorier connection

27 Cooling system air bleed nipple

28 Filler cap for cooling system

29 Expansion tank

30 Heat exchanger

31 Cooling system drain plug

32 Airvent connection

33 Exhaust injection bend ø 40 mm

VD01254

5

3

7

8

6

4

9

1 2

5

3

7

8

6

4

14

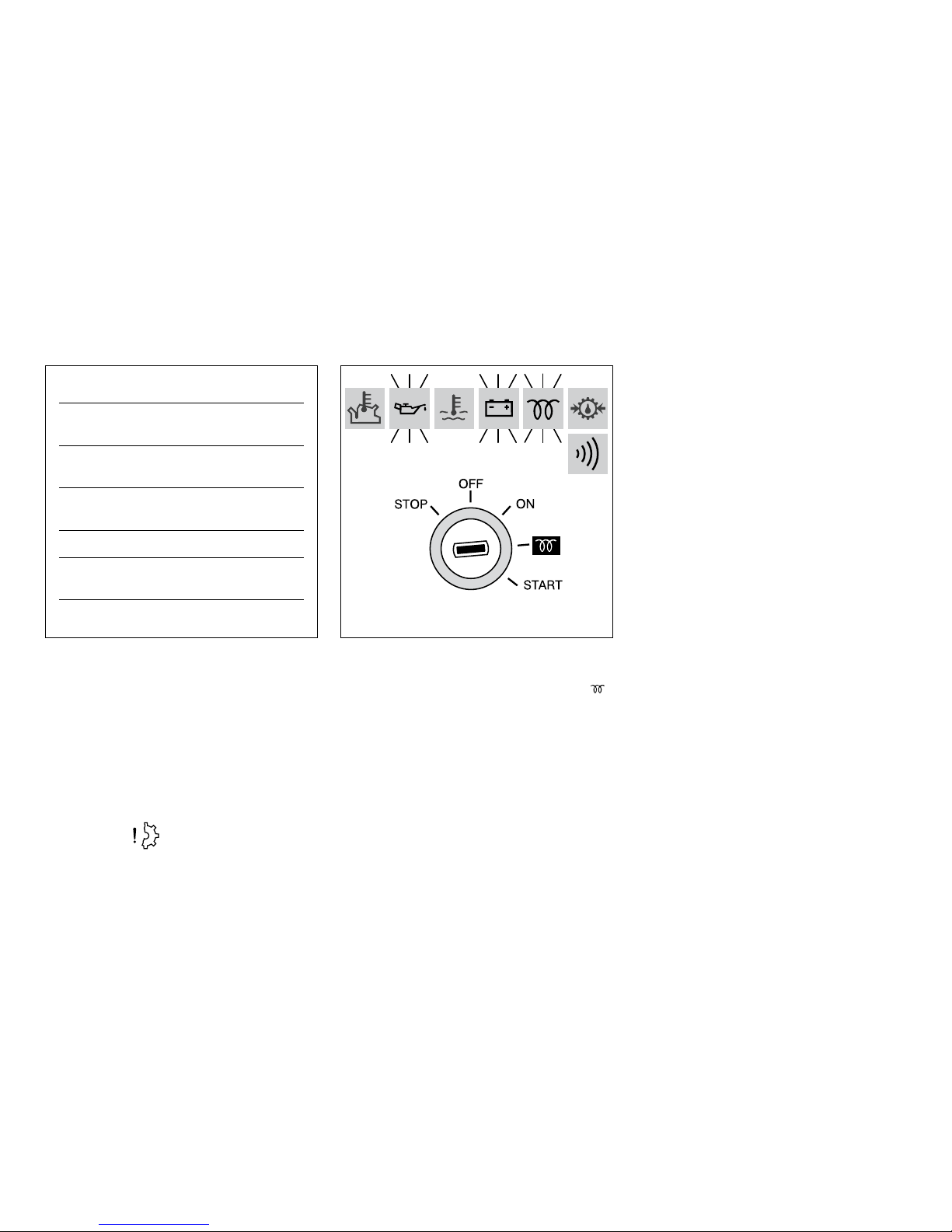

8 Indicator light pre-heating

9 Warning light gearbox low oil pressure

[1]

1 Tachometer/Operating hours counter

2 Voltmeter

3 Starter pre-heat switch/lock

4 Warning light high raw water temperature

5 Warning light low oil pressure

6 Warning light high coolant temperature

7 Warning light battery charging

2 Introduction

Control panels

Basic panel, model 22

Fly-bridge panel, excl. voltmeter, model 21

Sailingboat panel, model 10

VD00576

VD00575

[1]

This is an option, not tted as standard.

Single lever control

handle for two engines

Single lever control

handle for 1 engine

neutral

gearbox reverse gearbox forward

forward throttlereverse throttle

15

2 Introduction

Control lever

6 Operating lever

Operating lever for 1 or 2 engines. The control lever works as shown in the dia-

gram.

Starting from neutral put the engine in ahead

or astern by moving the lever 35° forwards or

backwards.

The throttle lever operates at an angle of 60°

forwards and 60° reverse.

VD00788

OIL OIL

16

3 First commissioning

1 Commissioning the engine

Before starting the engine for the rst time,

the following procedures must be carried out:

2 Filling with engine oil

As a rule engines are delivered empty of oil.

• Fill the engine with oil through the ller

neck on top of the valve cover.

For quantity and oil specication see page

102 and 106.

• Check the oil level with the dipstick, see

page 40.

A second oil lling cap is located at the distribution cover.

Engine Oil

2.4 litres 15 W40

(4.2 Imp. pt, 5.1 US pt)

API: CF4, CG4, CH4, CI4

ACEA: A3/B3, A3/B4, E7

For example:

- Vetus Marine Diesel Engine Oil 15W40

- Shell Rimula R4 L 15W40

VD01013

VD01002

27

17

OIL OIL

17

3 First commissioning

3 Filling gearbox with oil

• Fill the gearbox with oil.

• Check the oil level with the dipstick, see

page 42.

Technodrive:

type TMC40P : 0.2 litres, ATF

[1]

(0.35 Imp. pt, 0.42 US pt)

type TMC60A : 0.6 litres, ATF

[1]

(1.05 Imp. pt, 1.25 US pt)

ZF Hurth:

type ZF10M : 0,42 litres ATF

[1]

(0.73 Imp. pt, 0.89 US pt)

Vetus engines are normally equipped

with Technodrive or ZF-Hurth gearboxes.

In case your engine is equipped with

another brand of gearbox follow the instructions given in the supplied owners

manual.

[1]

ATF :Automatic Transmission Fluid;

Transmissie olie type A, Sux A.

[1]

ATF :Automatic Transmission Fluid;

Transmissie olie type A, Sux A.

VD01033

VD01034

1 cm

(

3

/8”)

COOLANT

17

COOLANT

18

3 First commissioning

4 Filling the cooling system,

interCooling

,

• Remove the cap of the ller neck on the top

of the heat exchanger housing.

• Remove the bolt from the upper side of the

thermostat cover, so that air can escape

from the cooling system.

• Fill the cooling system.

Use a mixture of 40% antifreeze (ethyleneglycol based) and 60% tap water or use a special coolant.

For specications see page 109.

The level of the coolant must be approx. 1 cm

(3/8”) below the lower edge of the ller neck.

Bleeding will take place automatically during

lling!

• Replace the ller cap.

• Reinstall the bolt in the thermostat cover..

Coolant quantity

: 2.2 litres

(3.9 Imp. pt, 4.6 US pt)

VD01005

VD01004

VD00158

note

If a water heater is connected to the engine,

see page 20 and 21.

Caution

Never ll the cooling system with sea water or

brackish water.

2

1

DO NOT OPEN

1.5 bar

2

1

DO NOT OPEN

1.5 bar

19

3 First commissioning

5 Filling the cooling system,

keel Cooling

• Remove the cap ‘

do not open

’ (1) of the

ller neck on the top of the heat exchanger

housing.

• Fill the cooling system.

• Reinstall the ller cap ‘

do not open’

.

• Remove the pressure cap (2) of the extra

expansion tank.

• Top up the extra expansion tank to the minimum level.

• Reinstall the pressure cap (2).

Use a mixture of 40% antifreeze (ethyleneglycol based) and 60% tap water or use a special coolant.

For specications see page 109.

note

If a water heater is connected to the engine,

see page 20 and 21.

VD00929

VD00925

Caution

Never ll the cooling system with sea water or

brackish water.

VD00932

2

1

DO NOT OPEN

1.5 bar

20

3 First commissioning

6 Filling coolant system, if a water heater

is connected (1)

The

highest

point of the water heater is situ-

ated at a

loWer

level than the expansion tank

for the ship’s engine.

The water heater will be filled and bled auto-

matically during lling of the cooling system.

• Remove the ‘

do not open

’ cap (1) and ll the

cooling system via the ller neck.

• Add coolant into the expansion tank (2) until minimal level has been reached.

Use a mixture of 40% antifreeze (ethyleneglycol based) and 60% tap water or use a special coolant.

For specications see page 109.

VD00895

VD00925

Caution

Never ll the cooling system with sea water or

brackish water.

2

3

1

DO NOT OPEN

1.5 bar

21

3 First commissioning

7 Filling coolant system, if a water heater

is connected (2)

The

highest

point of the water heater is situ-

ated at a

higher

level than the expansion tank

for the ship’s engine.

The water heater will

not

be filled and bled

automatically during lling of the cooling

system.

• Fill the cooling system via the expansion

tank (2).

• Open valve (3) during lling and bleeding

the system.

Use a mixture of 40% antifreeze (ethyleneglycol based) and 60% tap water or use a special coolant.

For specications see page 109.

VD00896

VD00925

note

• Remember to close valve (3) after lling the

system.

Caution

Never ll the cooling system with sea water or

brackish water.

Neutral

(No throttle, gearbox

not engaged)

FUEL

22

3 First commissioning

8 Fuel

• Ensure that the fuel tank is lled with diesel

fuel.

Use only clean, water-free, commercial approved diesel fuel.

For fuel grade see page 105.

• Bleed the fuel system, see page 45.

9 Other preparations

• Check that the battery is charged and check

the battery cable connections.

• Set the main switch to position ‘

on

’.

• Open the sea cock.

• Check that the gearbox control lever is set

to ‘

neutral

’.

VD

Warning

Never ll the fuel tank while the engine is

running. Do not spill fuel. Prevent unnecessary pollution.

VD00002

VD00789

OIL

23

3 First commissioning

10 Test run

• Start the engine.

How to start the engine and what to check

before, during and immediately after starting is described on page 28 and further.

• Allow the engine to test run for about 2

minutes at idling speed .

• Stop the engine

• Check the oil level. If necessary top up to

the indicated level.

• Start the engine.

• Allow the engine to test run for about 10

minutes at idling speed.

• Stop the engine.

• Check that the engine and all connections

(fuel, coolant and exhaust) for leaks.

VD01001

VD01046

Caution

Stop the engine immediately if it makes

any strange noises, vibrates excessively or

if black smoke comes out of the exhaust!

24

3 First commissioning

11 Bleeding

The cooling system must be bled as soon as

the engine has reached normal working temperature.

• Open the cap on the ller neck.

• Vary the revolutions between idling and

2000 rev/min.

• Add coolant if necessary.

• Replace the cap on the ller neck.

• Check the coolant temperature.

12 Sea trial

• Check the operation of the remote control.

• Carry out a sea trial

VD00663

VD01003

VD00791

25

4 Running-in

In order to ensure a long life for your engine, please observe the following for the

first 50 operating hours:

• Allow the engine to reach operating temperature before applying a load.

• Avoid fast acceleration.

• Do not allow the engine to run faster

than 3/4 of maximum RPM.

After the rst 50 operation hours carry out the

following maintenance:

• Drain water from fuel lter, see page 44.

• Engine oil change, see page 47.

• Replace oil lter, see page 48.

• Replace fuel lter, see page 55.

• Change gearbox oil (Technodrive), see

page 58.

• Change gearbox oil (ZF Hurth), see page 59.

• Check V-belt, see page 62.

• Check exible engine mounts, see page 63.

• Check engine for leaks, see page 63.

• Check tightness of all fasteners, bolts and

nuts, see page 63.

26

5 Use

General guidelines

General guidelines for use

Implementing the following recommendations will result in longer life and better performance and more economical operation of

your engine.

• Carry out the maintenance described regularly, including the ‘Daily procedures before

starting’.

• Use anti-freeze in the engine coolant all

year long, this helps prevent corrosion as

well as protecting against frost damage. For

specications see page 109.

• Never run the engine without a thermostat.

• Use a good quality lubricating oil. For speci-

cations see page 106.

• Use a good quality diesel fuel that is free of

water and other pollutants.

• Always stop the engine immediately if one

of the warning lamps for oil pressure, high

coolant temperature, high raw water temperature

[1]

or battery charging lights up.

• Always follow the safety advice, see page 4.

[1]

Only engines with intercooling.

27

5 Use

General guidelines

note

First commissioning

Follow the instructions given for ‘First commissioning’ on page 16 and further if the engine is being commissioned for the rst time.

After repair work:

Check that all guards have been replaced and

that all tools have been removed from the engine.

When starting with pre-heating, do not use

any other substance (e.g. injection with ‘Easy

Start’). Doing so could result in an accident.

half throttle,

gearbox not engaged

28

5 Use

Starting

Before starting, always check the following

points:

• Engine oil level.

• Coolant level.

• Sea cock open.

• Main switch ‘on’.

• Gearbox in ‘

neutral

’ position.

1 Control lever

Set the control lever to ‘half throttle’ without

engaging the gearbox.

2 Switching on

• Turn the start key on the instrument panel

clock-wise; the warning lights for oil pressure and alternator will now light up and

the alarm buzzer will sound.

Warning

Never start the engine with the fuel injection pump removed. Disconnect battery.

VD00923

VD00107

29

5 Use

Starting

3 Pre-heating

The ideal pre-heating time depends on ambient temperature; the lower the ambient

temperature, the longer the pre-heating time

required. See table.

• Turn the key further clockwise to the ‘

’

position.

While pre-heating takes place the preheating

indicator light will be on and the alarm buzzer

o.

• Hold the key in this position for about 6 seconds.

Ambient Tem-

perature

Pre-heating time

Above + 5°C

(41°F)

about 6 seconds

+5°C to -5°C

(+41°F to +23°F)

about 12 seconds

Below -5°C (23°F) about 18 seconds

Maximum pre-

heating time

1 minute

VD00108

Caution

To prevent the glow plugs from burning out,

never exceed the stated maximum pre-heating time.

30

5 Use

Starting

4 Starting

Now turn the key further to the ‘

start

’ posi-

tion.

Release the key as soon as the engine res

(the key will return to the ‘on’ position) and

throttle back.

Leave the key in this position while the engine

is running.

Caution

Release the key if the engine does not re

within 10 seconds.

Let the starter motor cool for 30 seconds before turning the key to the ‘

start

’ position

again.

VD00110

VD00109

31

5 Use

Starting

Check that the indicator lights for oil pressure

and alternator are o.

Cooling water should now ow out of the exhaust; if this is not the case, stop the engine

immediately

[1].

Let the engine run for 5 to 10 minutes in neutral. A good warm up is essential to ensure

maximum lifetime and good performance.

never turn the main switch o while the engine is running.

Caution

Never turn the key to the ‘

start

’ position

while the engine is running.

Doing so will damage the starter motor.

VD00629

[1]

Only engines with intercooling.

32

5 Use

Cruising

The instrument panel is provided with the following instruments (Depending of the type of

panel, see page 17).

5 Tachometer

Indicating the number of revolutions per

minute of the engine.

Also the number of running hours is indicated.

Idling speed : 850 rpm

Warning

Avoid idling for more than 10 minutes.

This can lead to carbon deposits in the combustion chambers and incomplete combustion of fuel.

VD00577

33

5 Use

Cruising

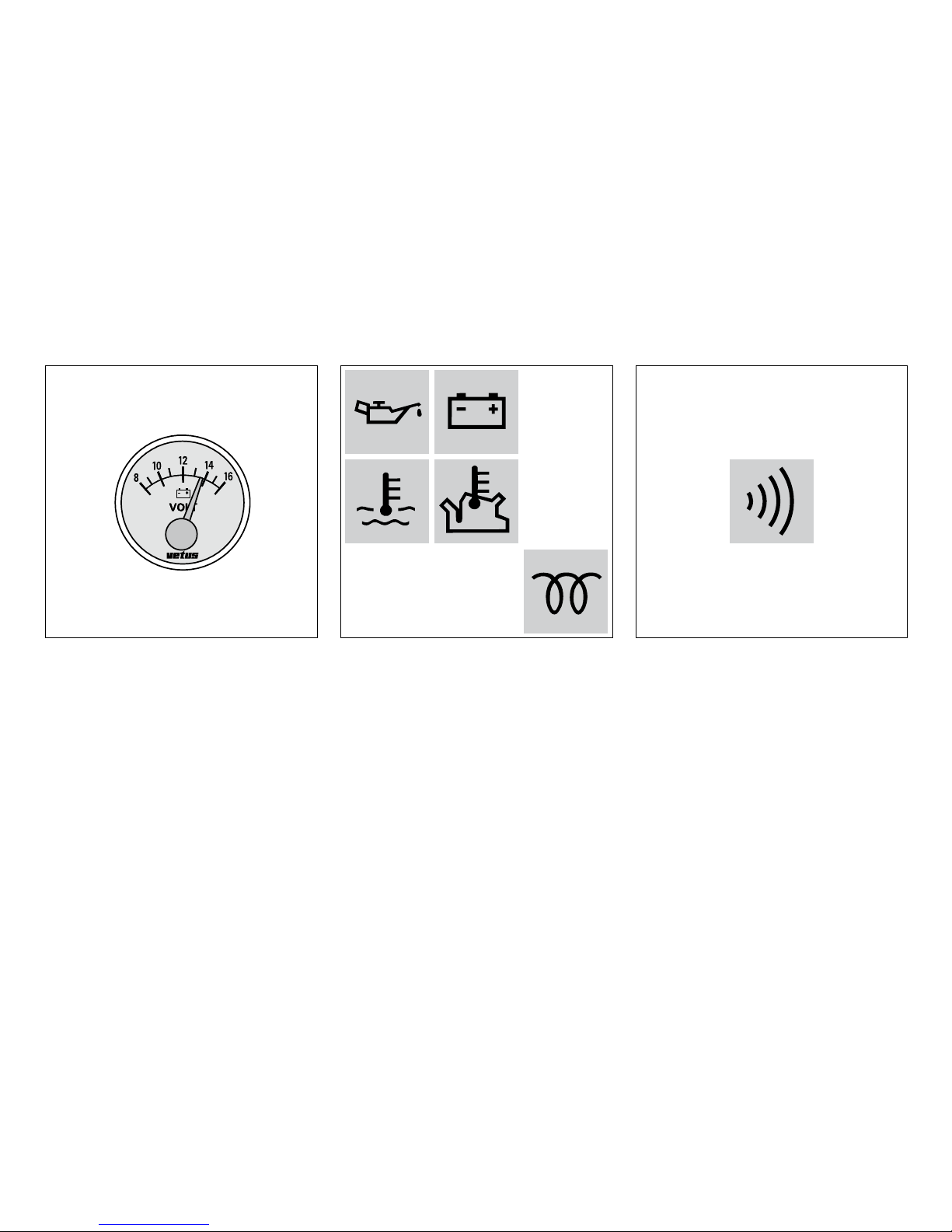

6 Voltmeter

Indicating the battery voltage.

When the engine is running, the battery voltage should be between 12 and 14 Volts.

With the engine stopped and the start key in

the rst position, the voltmeter should indicate 12 Volts.

7 Warning lights

None of the ve warning lights should light

up while the engine is running.

8 Alarm buzzer

Oil pressure, battery charging and temperature indicator lights are all connected to an

alarm buzzer. If this alarm buzzer sounds

while running, Stop the engine immediately!

VD00578

Neutral

34

5 Use

Stopping

9 Stopping

• Reduce engine speed to idle and shift the

gearbox to ‘Neutral’.

• Turn the key entirely to the left, through

the ‘

oFF

’ position.

• When the engine has stopped, turn the key

to the ‘

oFF

’ position.

VD00105

VD00790

VD00106

note

Never stop the engine immediately after it

has been in operation for a long time. Allow

the engine to idle for a few minutes before

stopping.

note

If the engine is not to be used for some time,

it is recommended that the sea cock is closed

and the battery main switch turned o.

35

5 Use

Stopping

10 Stopping on the engine itself

On the engine itself stopping is possible by

pressing the black button on the fuel injection pump.

If the fuel supply is not shut o by the electrically operated fuel solenoid stopping of the

engine can be done this way.

VD01037

36

6 Maintenance

Introduction

Introduction

The following guidelines should be observed

for daily and periodic maintenance. Perform

each function at the indicated time interval.

The intervals stated are for normal operational conditions. Service the unit more frequently under severe conditions.

Failure to carry out maintenance can result in

faults and permanent damage to the engine.

No claim can be made on the Guarantee if

maintenance has been neglected.

37

6 Maintenance

Introduction

Keep record of the following information

in the logbook and/or the ‘Service and Warranty Manual’:

- Total engine hours (reading engine hour

counter).

- Amounts of oil, fuel and coolant needed for

topping up.

- The dates and intervals at which the oil and

coolant are changed.

- Oil pressure and coolant temperature.

- Parts on which maintenance is conducted

and type of maintenance (adjustment,

repair or replacement), and the results of

each procedure.

- Changes in operating conditions, such as

‘Exhaust gas became black’, etc.

38

6 Maintenance

Maintenance schedule

Danger

Stop the engine before carrying out any maintenance work

Every 10 hours or daily, before starting page

Check engine oil level 40

Check water strainer 41

Check coolant level 42

After the rst 50 hours page.

Drain water from fuel lter 44

Engine oil change 47

Replace oil lter 48

Check gearbox oil level 54

Replace fuel lter 55

Check V-belt 62

Check exible engine mounts 63

Check engine for leaks 63

Check tightness of all fasteners, bolts and nuts 63

Every 100 hours, at least once every year page

Drain water from fuel lter 44

Engine oil change 47

Replace oil filter 48

Battery, cables and cable connections 50

Check gearbox oil level 54

Every 500 hours, at least once every year page

Replace fuel filter 55

Change gearbox oil (Technodrive) 58

Change gearbox oil and replace filter (ZF Hurth) 59

Check valve clearance 60

Check V-belt 62

Check flexible engine mounts 63

Check engine for leaks 63

Check tightness of all fasteners, bolts and nuts 63

39

[1]

Consult the service manual, work to be carried out by a Vetus Mit-

subishi dealer.

6 Maintenance

Maintenance schedule

Danger

Stop the engine before carrying out any maintenance work

Every 500 hours

page

Check glow plugs

[1]

Every 1000 hours, at least once every 2 years page.

Raw water pump inspection 64

Replace coolant 66

Every 1000 hours page.

Check starter motor 70

Check alternator 70

When required page

Bleeding fuel system 45

Check idle rpm 71

Cleaning heat exchanger 72

OIL OIL

40

6 Maintenance

Checking engine oil level

Daily, before starting.

1 Check oil level

• Turn the engine o.

The dipstick is located on the starboard side

of the engine.

2 Oil level

The oil level must be at or near the upper

mark on the dipstick

[1]

.

• If necessary top up with the same brand

and type of oil.

3 Topping up oil

The oil lling cap is on top of the the valve

cover,.

A second oil lling cap is located at the distrubution cover, see page 16.

VD00155

VD01001

VD01013

[1]

The dierence between the two oil level

marks is: 1.0 litres (1.8 Imp. pt, 2.1 US pt)

41

6 Maintenance

Checking and cleaning the raw water strainer

Daily, before starting.

4 Checking the raw water strainer

• Check daily whether there is any dirt in the

raw water strainer.

5 Cleaning the strainer

• Close the seacock before removing the lid

of the water strainer.

• Clean the raw water strainer as often as is

necessary, depending on the pollution of

the waterways, but at least once every 6

months. A clogged raw water strainer will

result in excessive temperatures or overheating of the engine coolant.

• Check the sealing between the lid and

housing after cleaning and re-assembling

the strainer. An improperly sealed lid will result in air sucked in by the sea water pump

which again will result in overheating of the

engine.

VD00802

VD00801

note

Only engines with intercooling!

1 cm

(3/8”)

COOLANT

COOLANT

42

6 Maintenance

Checking coolant level

Daily, before starting.

6 Checking coolant level

• Check the coolant level in the header tank.

This has to be checked when the engine is

cold.

• Remove the cap of the ller neck on the

heat exchanger.

7 Coolant level

The level of the coolant must be approx. 1 cm

(3/8”) below the lower edge of the ller neck.

8 Topping up coolant

• If necessary, top up.

The internal cooling system can be lled with

a mixture of anti-freeze (40 %) and tap water

(60 %) or with a special coolant. For specication, see page 109.

VD00158

VD01003

VD01004

Warning

Never open the cap on the header tank when

the engine is at operating temperature.

note

For a keel-cooled version, see page 19.

If a water heater is connected, see page 20

and 21

Caution

Never ll the cooling system with sea water or

brackish water.

43

6 Maintenance

Checking coolant level

Daily, before starting.

• When topping up coolant, remove the

bolt from the upper side of the thermostat cover, so that air can escape from

the cooling system.

VD01005

44

6 Maintenance

Draining of water from the water separator/fuel lter

Every 100 operating hours.

Danger

Do not smoke when draining o water and

sediment. Keep ame and sources of ignition

out of the area. Remove spilled fuel and litter

before you start the engine.

9 Empty fuel lter

• Open the drain plug at the lower side of the

lter.

• Drain the water and close the drain plug.

10 Empty water separator

Empty the separately installed water separator/fuel lter:

• Open the drain plug at the lower side of the

lter.

• Drain the water and close the drain plug.

Note : The water separator is not within the

scope of supply but installation is required!

VD00803

VD01006

45

6 Maintenance

Draining of water from the water separator/fuel lter

Every 100 operating hours.

11 Bleeding

After the water separator/fuel lter has been

drained, the air has to be bled from the fuel

system

The fuel system is self-bleeding; but manual

bleeding the system is recommended.

• Open the two bleeding nipples.

- One (1) bleeding nipple is located at the

lter.

- A second bleeding nipple is located at the

fuel injection pump.

• Prime the fuel system by pumping the fuel

pump.

• Close the bleeding nipples when all air has

escaped.

N.B. It is necessary to operate the lever over

the full stroke for proper operation.

141013

VD001008

VD01007

VD01009

46

6 Maintenance

Draining of water from the water separator/fuel lter

Every 100 operating hours.

12 Start the engine

• Operate the starter switch until the engine

res; release the starter switch if the engine

does not re within 20 seconds.

• Wait until the starter motor has stopped

before making a new attempt to start the

engine.

• Repeat the above if the engine cuts out after a short time.

VD00109

47

6 Maintenance

Engine oil change

Every 100 operating hours.

13 Engine oil change

Change the engine oil every 100 hours of

operation (together with engine oil lter replacement).

If the engine runs less than 100 hours during

the year the oil should be changed at least

once a year.

Run the engine for a few minutes before

changing the oil; warm oil can be pumped

out more easily.

Change the oil with a switched o engine at

operation temperature. (Lube oil temperature

approx. 80°C (176°F).)

Danger

Be aware of the risk of skin burning during

draining the hot oil! Used oil must be collected in a container for proper disposal according to laws and regulations.

Warning

Never use additives.

This could cause damage to the engine which

is not covered by the guarantee.

48

Warning

The engine oil must be disposed in

accordance with the applicable en-

vironmental regulations.

6 Maintenance

Engine oil change

Every 100 operating hours.

14 Draining the oil

• Remove the dipstick; insert the suction

hose of the supplied sump pump in the

dipstick tube.

• Push down the pump handle quickly and

pull it up slowly.

• Pump the sump empty.

• After draining remove the suction hose of

the sump pump out of the dipstick tube.

15 Removing the oil lter

• Unscrew the oil lter, with a commercially

available tool.

Catch any dripping oil.

VD01026

VD01010

Danger

Beware of burns from hot oil.

49

6 Maintenance

Engine oil change

Every 100 operating hours.

16 Oiling the oil seal

• Clean the contact surface of the gasket.

• Lubricate the oil seal of the new lter ele-

ment with clean engine oil.

17 Oil lter installation

• Install the lter in accordance with the instructions printed on the lter element

housing.

18 Relling with oil

• Rell the engine with new oil (for specication see page 106) through the ller opening in the valve cover.

• Operate the engine at idling speed for a

short period of time. Check for oil leaks

whilst the engine is running. Stop the engine. Allow 5 minutes for the oil to return

to the sump. Check the oil level with the

dipstick.

VD01011

VD00124

VD01013

amount of oil (oil filter inCl.)

: 2.9 litres

(5.1 Imp. pt, 6.1 US pt)

oil filter, art.Code

: STM0051

50

6 Maintenance

Battery, cables and connections

Every 100 operating hours.

Warning notes and safety regulations for

working with batteries

Wear eye protection.

Keep children away from acid and batteries.

Explosion hazard:

A highly-explosive oxyhydrogen gas

mixture occurs when charging batteries, therefore:

Fires, sparks, naked ames and smoking are prohibited:

• Avoid causing sparks when dealing

with cables and electrical equipment, and beware of electrostatic

discharges.

• Avoid short-circuits.

Pb

Corrosive hazard:

Battery acid is highly corrosive, therefore:

• Wear protective gloves and eye protection.

• Do not tilt battery, acid can escape

from the degassing openings or

vents.

First aid:

• Rinse o acid splashed in the eyes

immediately for several minutes

with fresh water. Then consult a

doctor immediately.

• Neutralize acid splash on skin or

clothes immediately with acid neutralizer (soda) or soap suds and

rinse with plenty of water.

• If acid is consumed, consult a doctor immediately.

Warning note:

• Do not place batteries in direct daylight without protection.

• Discharged batteries can freeze up,

therefore store in an area free from

frost.

Disposal:

Hand in old batteries at a collection

point.

Keep the batteries upright and do not

tip during transport and storage to

prevent acid leaking out.

Never dispose of old batteries as domestic waste.

Careful! Metal parts of the battery will

are always live so never lay objects or

tools on the battery.

51

6 Maintenance

Battery, cables and connections

Every 100 operating hours.

19 Battery, battery connections

Keep battery clean and dry.

• Remove battery cables (negative rst).

• Clean battery posts (+ and −) and clamps

and grease with acid-free and acid-resistant

grease.

Ensure that clamps make good contact after

reassembling.

• Hand tighten the bolts only.

VD00117

1

Vetus maintenance-free batteries

GREEN DOT

ALL DARK

CLEAR

52

6 Maintenance

Battery, cables and connections

Every 100 operating hours.

20 Checking specic gravity

Every Vetus Maintenance-free battery has a

hydrometer (1) built into the cover.

Visual inspection of the hydrometer will show

one of three conditions:

21 Hydrometer operation

Green dot visible:

State of charge 65 % or more.

Dark:

State of charge less than 65 %. Recharge immediately.

Clear or light yellow:

Electrolyte level low.

In case of low level, caused by overcharging

the battery for a long period of time with a

voltage too high, replace battery. Check alternator and/or voltage regulator.

VD00121, VD00122, VD00123

VD00118

Conventional batteries

Conventional batteries

53

6 Maintenance

Battery, cables and connections

Every 100 operating hours.

22 Checking electrolyte level

For conventional batteries it is required to

check the electrolyte level regularly. Remove

vent caps (taking care no spark or open ame

is nearby) and inspect the level. Fluid should

be 10 to 15 mm (

3

/8” to 5/8”) above top of all

plates. If necessary top up with distilled water.

Replace vent caps and charge the battery for

15 minutes at 15 - 25 Amps to mix electrolyte.

23 Checking specic gravity

Measure the electrolyte specic gravity of the

individual cells with a commercial hydrometer. The hydrometer reading (see table) indicates the state of charge. Hydrometer reading

of all cells should be at least 1.200 and show

less than 0.050 between high and low. If not,

recharge or replace battery.

Specic

gravity

State of

charge

1,.8 kg/l 100%

1.20 kg/l 50% recharge

1.12 kg/l 10%

recharge

immediately

During checking the temperature of the electrolyte should preferably be 20°C (68°F).

Measuring the specic gravity shortly after

water has been added results in an incorrect

measurement. First charge the battery to mix

the added water thoroughly.

VD00120

VD00119

54

25 Oil level check (ZF-Hurth)

6 Maintenance

Gearbox oil level check

Every 100 operating hours.

Vetus engines are normally equipped with

Technodrive or ZF-Hurth gearboxes. Consult

the supplied Owners Manual for more details

about care and maintenance. In case your

engine is equipped with another brand of

gearbox follow the instructions given in the

supplied owners manual for changing oil and

other care and maintenance.

24 Oil level check (Technodrive)

• Take the dipstick out of the gearbox housing by pulling or unscrewing.

• Check the oil level by lowering the dipstick

(cleaned) into the hole.

The oil level must between the two marks on

the dipstick

• If necessary top up by pouring oil into the

ller hole or the dipstick hole.

For oil type and specication see page 108.

17

VD01038

VD01032

55

6 Maintenance

Fuel lter replacement

Every 500 operating hours.

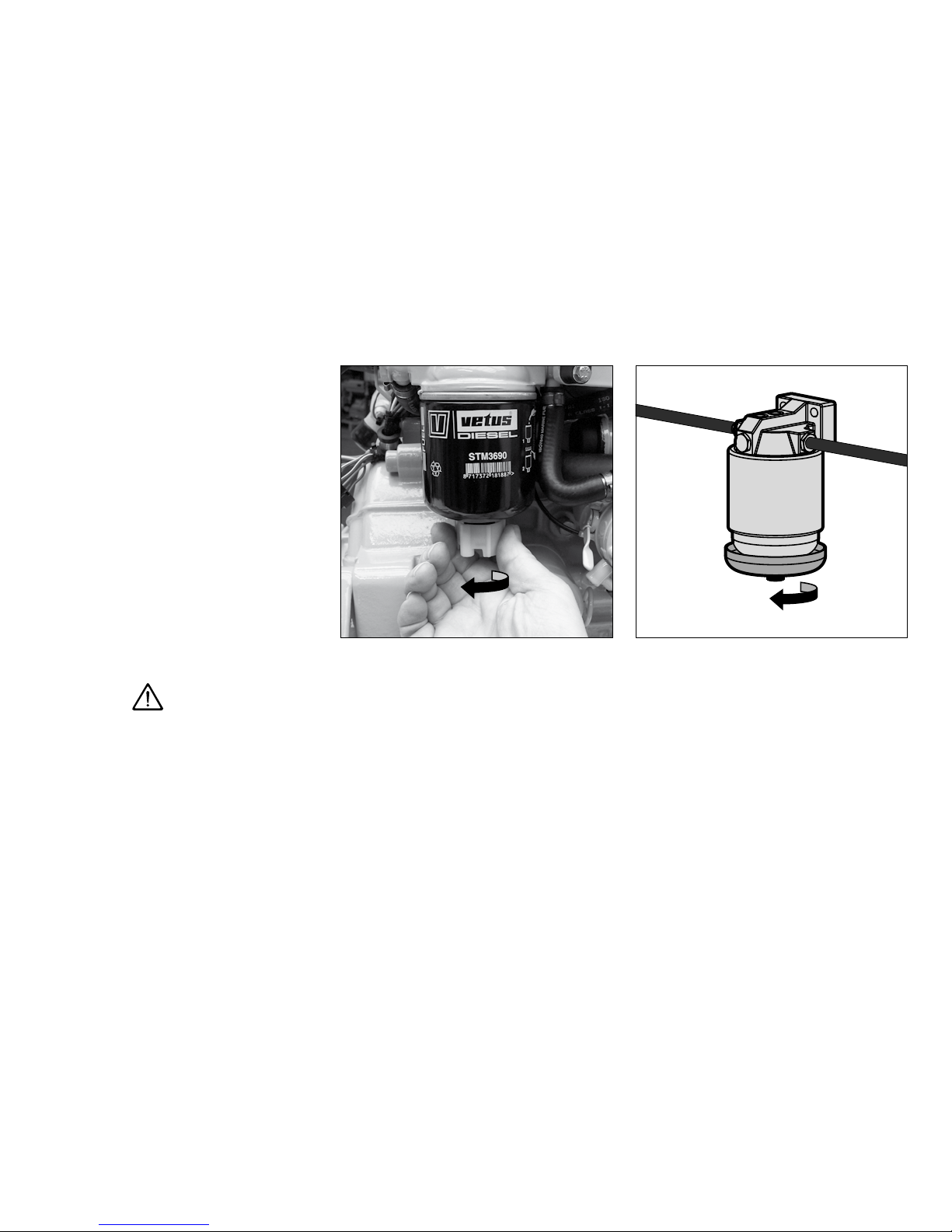

26 Fuel lter removal

The fuel lter is to be replaced as a unit.

• Close the fuel stopcock.

• Remove the fuel lter, use a lter wrench.

Catch any fuel.

Danger

Keep naked ames away when working on

the fuel system. Do not smoke!

VD01017

56

6 Maintenance

Fuel lter replacement

Every 500 operating hours.

27 Fuel lter installation

• Clean any debris from the lter carrier rim.

• Lubricate the rubber gasket sparingly with

clean engine oil.

• Fill the new lter with clean diesel fuel.

• Install the lter. When the rubber gasket

touches the housing, apply another tightening of a half to three quarters of a turn

by hand.

• Open fuel stopcock.

• Check for leaks.

VD00133

VD00154

fuel filter, art.Code

: STM3690

57

6 Maintenance

Bleeding, after fuel lter replacement

Every 500 operating hours.

28 Bleeding

• After replacing the fuel lter the air has to

be bled from the fuel system.

• For bleeding see page 45.

29 Start the engine

• Operate the starter switch until the engine

res; release the starter switch if the engine

does not re within 20 seconds.

Wait until the starter motor has stopped

before making a new attempt to start the

engine.

• Repeat the above if the engine cuts out after a short time.

• Check for leaks once more.

VD00109

OIL

58

6 Maintenance

Changing the gearbox oil (Technodrive)

Every 500 operating hours.

30 Draining the oil

• Remove the drain plug to drain the oil.

• Remove the llercap to vent the gearbox

and check if all oil has been drained

• Collect the oil in a dripping pan.

31 Filling with new oil

• Rell the gearbox to the correct level via the

lling hole.

• For quantity and oil specication see page

108.

In case your engine is equipped with another

brand of gearbox follow the instructions given in the supplied owners manual for changing oil and other care and maintenance.

14

VD01033

VD01255

59

6 Maintenance

Changing the gearbox oil (ZF-Hurth)

Every 500 operating hours.

32 Draining the oil

Drain the oil with the aid of a separate sump

pump.

• Remove the dipstick.

• Insert the suction hose of the sump pump

in the dipstick hole. Push down the pump

handle quickly and pull it up slowly.

• Remove the sump pump when all the old

oil has been pumped out.

Or, if sucient space below the gearbox is

available, oil can be drained by removing the

drain plug.

• Collect the oil in a dripping pan.

33 Filling with new oil

• Rell the gearbox to the correct level via the

dipstick opening.

For oil specication see page 108.

In case your engine is equipped with another

brand of gearbox follow the instructions given in the supplied owners manual for changing oil and other care and maintenance.

17

VD01042

VD01043

VD01034

17°

Markering op

motorblok

Markering BDP

Markering

injectietijdstip

2°

2°

60

6 Maintenance

Checking valve clearance

Every 500 operating hours.

34 Checking / adjusting valve clearance

Checking the valve clearance must be done

with a cold engine, that is an engine which

did not run for at least 6 hours.

35 Remove rocker cover

• Remove the 2 nuts of the rocker cover.

• Complete the following steps:

36 Locating TDC

• Locate the Top Dead Center (TDC), at the

end of the compression stroke, for cylinder

1 by barring the engine slowly until the TDC

marks of the engine block and the crank

pulley match.

Note: There are two TDC’s e.g. compression

and suction. At the TDC at the end of the compression stroke the rocker arm does not move

when the crank pulley is rotated a little.

10 27

VD01040

VD01049

61

6 Maintenance

Checking valve clearance

Every 500 operating hours.

37 Adjusting valve clearance

Cylinders are numbered consecutively, beginning at the front end.

• Check valve clearance at cylinder 1 and adjust if necessary.

• Rotate the crankshaft 180° clockwise and

check valve clearance at cylinder 2.

10

VD01016

VD00922

ValVe ClearanCe: inlet

0.25 mm (0.010”)

exhaust

0.25 mm (0.010”)

62

6 Maintenance

Checking the V-belt

Every 500 operating hours.

38 Inspection V-belt

• Inspect the belt for wear and tear (fraying

and cracking). Belts which are in poor condition should be replaced.

39 Checking tension

• Check tension of the V-belt by applying

moderate nger and thumb pressure. If the

deection of the belt is more than 12 mm

(1/2”), using about 10 kg (20 lbs) thumb

pressure, it should be tensioned.

40 Tensioning V-belt

• Loosen the bolt of the adjustment bracket

and both the alternator mounting bolts.

Now push the alternator outwards until the

belt tension is correct.

• Now rst re-tighten the upper mounting

bolt of the alternator.

• Then re-tighten the bolt of the adjustment

bracket and the lower mounting bolt.

1412

VD00128

VD00034

VD00129

Danger

Check, tension and change belts only with the

engine o. Ret belt guard, if provided.

V-belt, art.Code:

STM7369

63

6 Maintenance

Flexible engine mounts, hose connections and fasteners

Every 500 operating hours.

41 Check exible engine mounts

• Check the bolts which secure the damper

element, the mounting bolts to engine bed

and the nuts at the adjustment spindle for

tightness.

• Inspect the rubber element of the engine

support for cracks. Also check the deection of the damper element, the deection

inuences the alignment of engine and

propshaft! Re-align engine in case of doubt.

• Inspect all hose connections of the coolingsystem. (Cracked hoses, loose hose clamps)

43 Check fasteners

• Check tightness of all fasteners, bolts and

nuts.

42 Inspection hose connections

VD01046

VD00928

64

6 Maintenance

Raw water pump inspection

Every 1000 operating hours.

44 Raw water pump inspection

The rubber impeller of the outboard water

pump is not proof against running dry. If the

water supply has been blocked, it may be necessary to replace the impeller. Always carry a

spare impeller on board.

45 Pump cover removal

Inspection where appropriate changing is as

follows:

• Close the sea cock.

• Remove the cover of the pump by unscrew-

ing the screws out of the housing.

46 Impeller removal

• Slide the impeller o of the shaft using a

waterpump plier.

• Mark the impeller to ensure correct re-installation if it is to be re-used. The impeller

must be installed in the same position as

removed.

10

VD01125

VD01126 / VD01031

note

Only engines with intercooling!

65

6 Maintenance

Raw water pump inspection

Every 1000 operating hours.

47 Impeller inspection

• Inspect the impeller for damage.

• Replace the impeller if necessary.

48 Re-install the impeller

• The impeller should be lubricated with

glycerin or a non-petroleum based lubricant such as a silicone spray before tting it

into the impeller housing.

• Fit the impeller to the pump shaft. (if an

existing impeller is re-used, install it in the

same position as removed).

49 Reinstall the pump cover

• Reinstall the cover with a new O-ring.

• Check the water lter and open the sea

cock.

VD00004

VD00127

VD00927

impeller + o-ring, art.Code

: STM7691

o-ring, art.Code

: STM7696

66

6 Maintenance

Coolant replacement

Every 1000 operating hours.

50 Coolant replacement

The coolant has to be replaced every 1000 operating hours or at least once every two years.

N.B. Replacing the coolant may also be necessary as part of the winter storage procedure;

in case that the coolant present in the cooling

system oers insucient protection for the

winter.

Danger

Be aware of the risk of skin burning during

draining the hot coolant! Used coolant must

be collected in a container for proper disposal

according to laws and regulations.

Warning

Cooling system protective

liquids must be disposed

of in accordance with environmental regulations.

67

6 Maintenance

Coolant replacement

Every 1000 operating hours.

51 Draining of coolant

• Remove the drain plugs from the engine

block (1) and heat exchanger (2).

• Remove the ller cap to vent the cooling

system and check that all the coolant has

been drained.

• After draining replace the drain plugs.

note

Keel cooler

How the cooling system in engines with

keel cooling should be drained depends

on the installation of the keel cooler.

Refer to the keel cooler manufacturer’s instructions for this.

Check using a coolant hydrometer whether the coolant is providing sucient protection against freezing if total draining o

is not possible.

14 13

1

2

VD01018

VD01025

68

6 Maintenance

Coolant replacement

Every 1000 operating hours.

52 Filling the cooling system

• Remove the cap of the ller neck on the top

of the heat exchanger housing.

• Remove the bolt from the upper side of the

thermostat cover, so that air can escape

from the cooling system.

• Fill the cooling system.

Use a mixture of 40% antifreeze (ethyleneglycol based) and 60% tap water or use a special coolant.

For specications see page 109.

Caution

Never ll the cooling system with sea water or

brackish water.

Water heater

If a water heater is connected to the engine and this heater is positioned above

the upper side of the engine than bleeding

of the heater will not take place automatically! Fill the heater separately to bleed the

cooling system completely.

Coolant quantitiy:

2.2 litres

(3.8 Imp. pt, 4.6 US pt)

17

VD01005

VD01004

note

For a keel-cooled version, see page 19.

If a water heater is connected, see page 20

and 21

1 cm

(3/8”)

COOLANT

69

6 Maintenance

Coolant replacement

Every 1000 operating hours.

The level of the coolant must be approx. 1 cm

(

3

/8”) below the lower edge of the ller neck.

Bleeding will take place automatically during

lling!

• After lling replace the ller cap and reinstall the plug.

• After the engine has run for the rst time

and has reached operating temperature

and has cooled down again to ambient

temperature, check the coolant level in the

heat exchanger housing.

• If necessary, add coolant.

Caution

Never ll the cooling system with sea water or

brackish water.

VD00158

70

6 Maintenance

Checking the starter motor and alternator

Every 1000 operating hours.

53 Checking the starter motor

• Check for visible defects.

• Check whether the Bendix engages with

the starter ring when the starter motor is

activated. If the Bendix does not engage

properly, contact your Vetus dealer.

54 Checking the alternator

• Check for visible defects.

• Remove the alternator belt. Turn the pulley

by hand to check whether the alternator

can be turned easily. If this is not the case,

contact your Vetus dealer.

VD01252

VD01251

Lead seal

Maximum speed

adjustment screw

Minimum speed

adjustment screw

71

6 Maintenance

Checking engine speed

At full load (with the boat cruising) the maximum engine speed should be about 3,000

resp. 3600 RPM (see technical data page 101).

If the engine does not reach this speed, it is

being overloaded!

If this is the case, check the ship’s propeller for

defects or irregularities, and also to see that it

is the correct pitch and diameter.

56 Adjusting engine idling speed

If the engine speed diers from that stated

above, it must be adjusted.

The engine idling speed can be reset using

the adjustment screw on the fuel pump.

55 Checking engine speed

The engine idling speed should be 850 rpm.

• Allow the engine to warm up normally (until the coolant temperature reaches at least

60°C (140°F).) before checking and/or adjusting the idling speed.

• Check the engine RPM using a rev. counter,

or use the rev. counter tted to the control

panel.

Warning

The maximum engine speed adjustment screw has been correctly set at

the factory and sealed. DO NOT attempt to remove this seal.

10

VD00134

VD00931

72

6 Maintenance

Cleaning the heat exchanger

note

Cleaning of the heat exchanger is not a

routine maintenance job.

Only clean the heat exchanger if this is

(badly) fouled.

Under normal conditions of use cleaning the

heat exchanger is not necessary!

The engine temperature will be higher than

normal if the heat exchanger is fouled.

Possible causes of fouling are:

- Small rubber particles from a damaged sea

water pump impeller.

- Growth of algae or seaweed.

note

Only engines with intercooling!

73

6 Maintenance

Cleaning the heat exchanger

57 Remove the drain plug

• Close the seacock and detach the water inlet hose from the sea water pump.

• Drain the coolant: To do this, remove the

drain plug from the heat exchanger housing.

• Remove the ller cap from the top of the

heat exchanger housing to allow air into

the system and check that all coolant has

drained o.

58 Removal of bolts out of the end covers

• Take out both central bolts from the end

covers and take the end covers with the Orings out of the housing.

note

Only engines with intercooling!

13

5

VD01003

VD01018

VD01019

74

6 Maintenance

Cleaning the heat exchanger

59 Remove heat exchanger

• Slide the heat exchanger out of the housing.

60 Cleaning the heat exchanger

• Clean the heat exchanger: Use a pipe cleaner to remove fouling in the pipes.

• Then rinse the heat exchanger pipes with

clean water.

• Ensure that both heat exchanger end

chambers are free from dirt.

note

Only engines with intercooling!

6

VD01021

VD01020

STM7217

75

6 Maintenance

Cleaning the heat exchanger

61 Replacing heat exchanger

• Replace the heat exchanger in the original

position in the heat exchanger housing.

• Use new O-rings (61 x 2.5 mm) which have

been greased.

• Ret the drain plug.

• Reconnect all hoses previously removed.

• Rell the cooling system, see page 68.

note

Only engines with intercooling!

o-ring, art.Code:

STM6113 (2 x)

62 Replacing the end covers

• Fit the end covers in the housing.

• Tighten up the bolts when both covers are

in the correct position.

STM6202

VD00157

76

7 Winter storage procedure

Make sure that the engine compartment is

well ventilated during the winter period.

Good ventilation prevents damp in the engine compartment, thus preventing corrosion

of the engine from occurring.

The engine should be inspected at the end of

the sailing season and any necessary repairs

carried out.

Consult a Vetus Dealer if help is required with

this.

Inspections and maintenance work to be carried out are:

77

7 Winter storage procedure

Inspections and maintenance work to be carried out: page

1 Clean the engine, remove any salt. Paint any rust spots and spray the whole engine with a protective

medium, for example CRC protective 6-66.

78

2 Drain o the water from the fuel system and ll the fuel tank. 78

3 Make sure that the engine fuel system is lled with a fuel mixture with protective properties. 79

4 Flush out the raw water circuit with fresh water and if necessary ll with antifreeze. Clean the heat

exchanger if necessary.

80

5 Make sure that the cooling system is lled with a suitable anti-freeze. 81

6 Change the oil lter and the engine oil. 82

7 Change the oil in the gearbox. 82

8 Disconnect the battery cables, charge the batteries if necessary and grease the battery terminals. 83

78

7 Winter storage procedure

1 Corrosion protection

The various parts of the engine (except the

engine block) have been treated with an

anti-corrosion protective medium. In order

to prevent corrosion, the engine should be

rinsed o to remove any salt residues. If there

is any corrosion, the paint should be touched

up. Engine parts that become hot must be

touched up with heat-resistant paint.

2 Fuel system

• Drain the water from the water separator/

fuel lter and the fuel tank.

Ensure that the tank is completely lled with

fuel.

• Install a new fuel lter. (page 55).

VD00803

VD00133

79

7 Winter storage procedure

3 Protective fuel mixture

• Connect the fuel supply pipe to a can lled

with protective diesel fuel, for example ‘Calibration Fluid’ (ISO 4113) or with a mixture

of 1 part of engine oil

[1]

to 9 parts of clean

fuel

[2]

.

• Use this mixture to run the engine at no

load for approx. 5 minutes.

• Stop the engine.

[2]

Only use CEN EN 590 Diesel fuel.

Preferably water-free fuel.

Collect some fuel from the return pipe,

while engine is running.

VD00136

tip!

Combine running the engine with the

protective fuel mixture with ushing

the raw water circuit with fresh water,

see ‘Winter storage procedure - Raw

water cooling system’.

Caution

Never run the engine under load with

this mixture of fuel and oil.

VD

[1]

Engine oil with protective properties.

E.g.:

- Vetus Marine Diesel Engine Oil 15W40

- Shell Rimula R4 L 15W40

80

7 Winter storage procedure

4 Raw water cooling system

• Close the sea cock.

• Remove the lid of the water strainer.

• If necessary, clean the raw water strainer.

• Connect the raw water intake to a fresh wa-

ter (tap water) supply or a tank containing

fresh water. Open the tap and allow the engine to idle for at least 5 minutes to remove

any salt and contamination from the raw

water cooling system.

Make sure that there is a sucient supply

of water to prevent the engine from overheating.

• Stop the engine and close the sea cock.

• The raw water system must be protected in

areas where the temperature drops to below zero during the winter.

Pour 1 litre (1/4 gallon) of anti-freeze (preferably a non-toxic biodegradable anti-freeze)

into the water strainer and run the engine

until the anti-freeze has disappeared into

the cooling system.

tip!

Combine ushing the raw water circuit

with fresh water with running the engine with the protective fuel mixture,

see ‘Winter storage procedure - Protective fuel mixture’

Heat exchanger

Only clean the heat exchanger if this is

absolutely necessary, see page 72.

Raw water pump

Check the impeller of the raw water

pump at least once every two years, see

page 64.

VD00125

VD00801

note

Only engines with intercooling!

81

7 Winter storage procedure

Anti-freeze can be toxic. Take care that no

anti-freeze is spilled into the waterway

• Check the seal between the lid and housing after cleaning and re-assembling the

strainer.

An improperly sealed lid will result in air

sucked in by the raw water pump which again

will result in overheating of the engine

5 Fresh water cooling system

To avoid corrosion during winter storage the

cooling system must be lled with an antifreeze/water mixture (or a coolant).

For specications see page 109.

N.B. Replacing the coolant is only necessary if

the coolant present in the cooling system offers insucient protection for the winter.

For coolant replacement see page 66.

VD01003

tip!

Protect the sea cock as follows:

With the motor stopped.

• Place the sea cock in a position that it

is just opening.

• Pour a small amount of non-toxic biodegradable anti-freeze into the raw

water strainer.

• Close the sea cock as soon as it is

lled with anti-freeze.

82

7 Winter storage procedure

6 Lubrication system

With the engine still at operating temperature: (If not, run the engine until warm, then

turn o.)

• Replace the oil lter and change the engine

oil; use oil with protective properties. See

page 47.

For quantity and oil specication see page

102 and 106.

7 Changing the gearbox oil

• Stop the engine and change the oil of the

gearbox. (page 58 and 59)

VD01026

VD01010

VD01034

83

7 Winter storage procedure

8 Electrical system

• Disconnect the battery cables. • Charge batteries during winter lay-up regularly if required!

• Follow the recommendations given on

pages 50 to 53 or consult the recommendations given by the battery supplier for inspection and maintenance of the batteries.

CT40063

VD00139

84

8 Recommissioning after winter storage

The engine must be inspected and any maintenance work carried out at the beginning of

the sailing season.

Consult a Vetus Dealer if help is required with

this.

Inspections and maintenance work to be carried out are:

Inspections and maintenance work to be carried out are: page

1 Drain the water from the fuel system. 85

2 Check the raw water system. 86

3 Check the coolant level in the internal cooling system. 87

4 Check the oil level. 87

5 Check the batteries and reconnect these. 88

6 Check the operation of the engine. 88

7 Check all hose connections for leaks. 89

8 Check the operation of the instruments and the engine controls. 89

85

8 Recommissioning after winter storage

1 Fuel system

• Drain the water from the water separator/

fuel lter. (page 44)

• Drain the water from the fuel tank. • Open the fuel valve.

VD00141

VD00803

VD00137

86

8 Recommissioning after winter storage

2 Raw water cooling system

• Check that the lid of the raw water strainer

is reinstalled.

• Check whether the lid of the raw water

pump and drain plugs are reinstalled. (pages 64, 67)

• Re-tighten possible loose hose clamps.

10

VD01125

VD00801

VD01045

note

Only engines with intercooling!

OIL

COOLANT

87

8 Recommissioning after winter storage

• Open the sea cock.

3 Fresh water cooling system

• Check the coolant level. (page 42)

4 Lubrication system

• Check the engine oil level. (page 40)

VD01003

VD00138

VD01001

88

8 Recommissioning after winter storage

5 Electrical system

• Make sure that the batteries are fully

charged. (page 50, 83)

• Connect the batteries.

6 Switching on

• Turn the start key on the instrument panel

clock-wise; the warning lights for oil pressure and alternator will now light up and

the alarm buzzer will sound.

VD00140

CT40063

VD00107

89

8 Recommissioning after winter storage

7 Check engine for leaks

• Start the engine.

• Check the fuel system, the cooling system

and the exhaust for leakage.

8 Checking instruments and remote con-

trols

• Check the operation of the instruments, the

remote control and the gearbox.

VD00581

VD01046

90

9 Troubleshooting

General

Engine faults are in most cases caused by improper operation or insucient maintenance.

In case of a fault, always check rst that the

operation and maintenance instructions have

been followed.

In the following tables information is given

about the possible causes of faults and suggested remedies. Please note that these tables can never be complete.

If you are unable to identify the cause of the

fault or to rectify it yourself, then contact the

nearest service representative.

Danger

Before starting, make sure that nobody is in

the immediate vincinity of the engine.

When carrying out repair, never start the engine with the fuel injection pump removed

removed.

Disconnect battery!

91

9 Troubleshooting

Fault nding table

Fault page

1 Engine will not crank 92

2 Engine cranks but will not start, no smoke from exhaust 92

3 Engine cranks but will not start, smoke from exhaust 93

4 Engine starts but runs unevenly (rough idling) or stalls 93

5 Engine does not reach maximum rpm under load 94

6 Engine overheats 95

7 Engine not ring on all cylinders 95

8 Engine has little or no oil pressure 96

9 Engine oil consumption excessive 96

10 Fuel consumption excessive 97

11 Black exhaust smoke (idling) 97

12 Blue exhaust smoke (idling) 97

13 Black exhaust smoke (at load) 98

14 White exhaust smoke (at full load) 98

15 Burnt oil trace in exhaust line . 99

92

1 Engine will not crank

Possible fault Remedy

Faulty or discharged battery (too

low voltage ) .

Check / recharge battery and

check engine alternator and/or

battery charger.

Fuse blown. Replace.

Loose or corroded connections

in starting circuit.

Clean and tighten connections.

Wrong engine electric mass connection.

Repair.

Starter relay is not engaged due

to a voltage too low; caused by

a very long intermediate cable

from engine to control panel.

Install an auxiliary starter relay

Faulty starter-switch or faulty

starter-relay.

Check / replace.

Faulty starter-motor or pinion

does not engage.

Check / replace starter-motor.

Seized components. Repair.

Control lever not in neutral. Put operating lever in neutral.

Water in the cylinder . Check / Repair.

2 Engine cranks but will not start, no smoke from exhaust

Possible fault Remedy

(Nearly) Empty fuel tank. Rell.

Fuel stop valve closed. Open.

Fuel pre-lter clogged . Clean /replace

Fuel lter clogged with water

and/or contamination.

Check or replace.

Vent line of fuel supply tank

clogged.

Check / clean.

Faulty injector/injection pump.. Check, replace if required.

Leaking fuel supply line or fuel

injection line.

Check / replace.

Air in fuel system. Check and bleed.

Exhaust restricted. Check.

9 Troubleshooting

Fault nding table

93

9 Troubleshooting

Fault nding table

3 Engine cranks but will not start, smoke from exhaust

Possible fault Remedy

Faulty injector/injection pump. Check, replace if required.

Air in fuel system. Check and bleed.

Wrong fuel quality or contaminated fuel.

Check fuel. Drain and ush fuel

tank. Replace with new fuel.

Incorrect injection timing. Check / adjust.

Setting of stop valve incorrect. Check / adjust.

Incorrect lube oil SAE class or

quality for ambient temperature.

Replace.

Faulty glow plugs. Check / replace.

Insucient intake air. Check.

Incorrect valve clearance. Adjust.

4 Engine starts but runs unevenly (rough idling) or stalls

Possible fault Remedy

(Nearly) Empty fuel tank. Rell.

Fuel supply line restricted. Check / clean.

Fuel lter clogged with water

and/or contamination.

Check or replace.

Vent line of fuel supply tank

clogged.

Check / clean.

Faulty injector/injection pump. Check, replace if required.

Leaking fuel supply line or fuel

injection line.

Check / replace.

Air in fuel system. Check and bleed.

Wrong fuel quality or contaminated fuel.

Check fuel. Drain and ush fuel

tank. Replace with new fuel.

Exhaust restricted. Check.

Incorrect valve clearance. Adjust.

Idle setting too low. Check/ adjust.

94

9 Troubleshooting

Fault nding table

5 Engine does not reach maximum rpm under load

Possible fault Remedy

Fuel pre lter clogged . Clean/replace.

Fuel lter clogged with water

and/or contamination.

Check or replace.

Faulty injector/injection pump. Check, replace if required.

Leaking fuel supply line or fuel

injection line.

Check / replace.

Air in fuel system. Check and bleed.

Wrong fuel quality or contaminated fuel.

Check fuel. Drain and ush fuel

tank. Replace with new fuel.

Incorrect injection timing. Check / adjust.

Setting of stop valve incorrect. Check / adjust.

Oil level too high. Lower level.

Lubricating oil incorrect SAE

spec or quality for ambient

temperature.

Replace.

Insucient intake air. Check.

Exhaust restricted. Check / clean.

Incorrect valve clearance. Adjust.

Transmission defect. Check

Engine overloaded. Check size of propeller. Clean the

propeller.

Boat load inadequate . -

5 Engine does not reach maximum rpm under load

Possible fault Remedy

Hull/propeller dirty . Clean

95

9 Troubleshooting

Fault nding table

6 Engine overheats

Possible fault Remedy

Faulty injector/injection pump. Check, replace if required.

Sea cock closed. Open.