Page 1

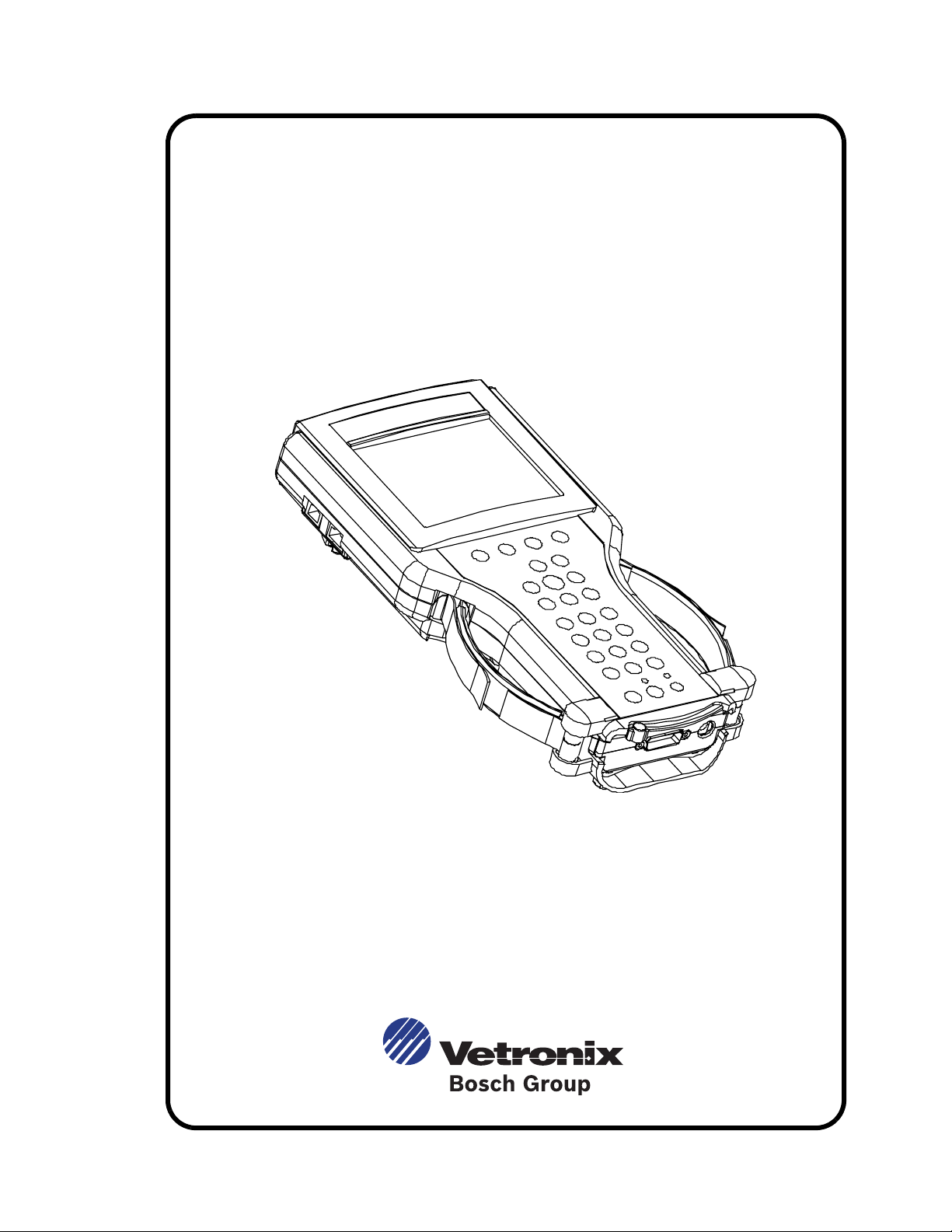

Tech 2

Page 2

Tec h 2

Vetronix Corporation

Copyright © 2006

Manual P/N 08002927

®

is a registered trademark of Vetronix Corp.

Printed in USA 9/06

This entire document and all information contained herein are proprietary, confidential, and exclusive trade

secret property of Vetronix Corporation, and shall not be reproduced, duplicated, or copied in whole or in

part, or made available to any person, firm, or corporation without the prior written permission of Vetronix

Corporation.

Page 3

CUSTOMER SUPPORT OVERVIEW

To obtain assistance with a question or problem concerning the operation of your Vetronix product and its

attached products, or to arrange for warranty and non-warranty repairs, telephone the Vetronix Customer

Support Center. To order replacement parts, contact Vetronix Customer Service.

BEFORE CALLING

Before making a call to Customer Support:

• Name and address

• Serial number of equipment or tool

• Name, part number and quantity of the item to be requested

• Telephone number where the technician may be reached

Prepare a brief description of the problem, which:

• Tells when the problem occurred

• Lists any error codes displayed

• Tells what accessories were being used when the problem occurred, and vehicle information

MAKING THE CALL

The Vetronix Customer Support Center operates from 7:30 a.m. to 4:30 p.m. (Pacific standard time)

Monday to Friday.

In the United States and Canada to contact Customer Support, dial:

• English 1-800-321-4889

A Vetronix Customer Support representative will come on the line or respond by fax to answer questions,

make suggestions, and take repair and parts orders. To make sure every problem is resolved to the

satisfaction of the caller, the Vetronix Customer Support representative will record each problem, question,

or suggestion into a special problem tracking system. Any problems that cannot be resolved over the phone

will be directed to the appropriate group for resolution.

Page 4

TECH 2 USER’S GUIDE

This user’s guide is designed to provide a comprehensive overview of the Tech 2.

Everything contained in this manual is based on the latest product information available at the time of

publication. The right is reserved to make changes at any time without notice.

No part of this publication may be reproduced, stored in any retrieval system, or transmitted in any form by

any means, including but not limited to electronic, mechanical, photocopying, recording, or otherwise,

without the prior written permission of the Vetronix Corp. This includes all text, illustrations, tables, and

charts.

Requests for permission should be sent to:

Vetronix Corp.

2030 Alameda Padre Serra

Santa Barbara, CA 93103-1716

U.S.A.

Page 5

DECLARATION OF CONFORMITY

according to ISO/IEC Guide and EN 45014

Manufacturer’s Name: Vetronix Corporation

Manufacturer’s Address: Vetronix Corporation

2030 Alameda Padre Serra

Santa Barbara, CA 93105

declares, that the product

Product Name: Tech 2

Model Number(s): 03006541-003

Product Options: ALL

conforms to the following Product Specifications:

Safety: IEC 1010-1: 1990 + A1 / EN 61010-1: 1993

EMC: CISPR 11: 1990 / EN 55011 1991 - Class A

EN 50082-1: 1992

IEC 801-2: 1991 / prEN 55024-2 1992 - 3kV

CD, 8kV AD

IEC 801-3: 1984 / prEN 55024-3 1991 - 3V/m

IEC 801-4: 1988 / prEN 55024-4 1992 - 0.5 kV

Signal Lines. 1kV Power Lines

Supplementary Information:

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the

EMC Directive 89/336/EEC.

Page 6

SOFTWARE LICENSE AGREEMENT

Please read this license agreement carefully before proceeding to operate the equipment. Rights to the

software are offered only on the condition that the customer agrees to all terms and conditions of the license

agreement. Proceeding to operate the equipment indicates your acceptance of these terms and conditions.

1. USE: Customer may use the software only on the computer system on which it was originally installed.

Customer may not reverse assemble or decompile software unless authorized by law.

2. OWNERSHIP: Customer agrees that it does not have any title or ownership of the software, other than

ownership of the physical media. Customer acknowledges and agrees that the software is copyrighted

and protected under the copyright laws. Customer acknowledges and agrees that the software may have

been developed by a third party software supplier named in the copyright notices included with the

software, who shall be authorized to hold the Customer responsible for any copyright infringement or

violation of this agreement.

3. TERMINATION: Vetronix Corp. may terminate this software license for failure to comply with any of

these terms provided Vetronix Corp. has requested Customer to cure the failure and Customer has failed

to do so within thirty (30) days of such notice.

LIMITED WARRANTY

SOFTWARE: VTX warrants for a period of ninety (90) days from the date of purchase that the VTX

software product will execute its programming instructions when properly installed. VTX does not warrant

that the operation of the VTX software will be uninterrupted or error free. In the event that this VTX

software product fails to execute its programming instructions during the warranty period, the remedy shall

be a replacement of such software product.

LIMITATION OF WARRANTY: VTX makes no other express warranty, whether written or oral with

respect to this product. Any implied warranty of merchantability or fitness for or a particular purpose is

limited to the 90-day duration of this written warranty. Some states or provinces do not allow limitations on

how long an implied warranty lasts, so the above limitation or exclusion may not apply to you.

EXCLUSIVE REMEDIES: The remedies provided above are Customer’s sole and exclusive remedies. In

no event shall VTX be liable for any direct, indirect, special, incidental or consequential damages (including

lost profit) whether based on warranty, contract, tort or any other legal theory.

Page 7

Table of Contents

1. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

USING THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

VEHICLE SYSTEM FAMILIARITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

THINGS YOU SHOULD KNOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

TECH 2 DISCLAIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

FCC COMPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

VDE CERTIFICATION (FOR EUROPEAN USE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

TAKING THE PRODUCT BACK AND RECYCLING . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

TEC H 2 OVE RV IEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Technician Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2. CARE AND CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CLEANING THE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CLEANING THE KEYPAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

MAINTAINING THE CABLE ASSEMBLIES AND CONNECTORS . . . . . . . . . . . . 2-2

STORING THE TECH 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

3. GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

INITIAL HARDWARE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

PCMCIA CARD REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

PCMCIA CARD INSERTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

VEHICLE COMMUNICATIONS INTERFACE MODULE REMOVAL . . . . . . . . . . 3-7

HAND STRAP ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

TECH 2 KEYPAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

CONTROL KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

TECH 2 SOFT KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Te ch 2 TOC-1

Page 8

SELECTION KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

ACTION KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

FUNCTION KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

HELP KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

TECH 2 CONNECTIONS TO VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

TECH 2 CONNECTION TO PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4. POWER SUPPLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

CIGARETTE LIGHTER POWER CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

BATTERY POWER CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

NAO POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

5. ADAPTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

DLC CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

RS-232 CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

RS-232/DB9 ADAPTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

RS-232 LOOPBACK ADAPTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

POWER ON SELF TEST (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

SELF TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Tech 2 Self Test Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

NO POWER TO TECH 2 TROUBLESHOOTING TABLES . . . . . . . . . . . . . . . . . . . . . 6-16

CIGARETTE LIGHTER POWER CABLE 3-AMP FUSE REPLACEMENT . . . . . . . 6-19

BATTERY POWER CABLE 3-AMP FUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . 6-20

7. ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8. SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

TECH 2 FLOWCHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Service Programming and View Captured Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Tool Options and Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Tool Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

TECHLINE INFORMATION SYSTEM 2000 (TIS 2000) . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

SERVICE PROGRAMMING SYSTEM (SPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

TOC-2 Tech 2

Page 9

Remote SPS Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Performing Remote SPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Verifying Reprogramming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

SOFTWARE DOWNLOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Tech 2 Update Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

SNAPSHOT UPLOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Uploading the Snapshot to the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

Viewing the Snapshot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Replaying the Snapshot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Single-Column versus Two-Column Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Displaying Diagnostic Trouble Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

Displaying Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Lock/Unlock Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

Viewing Capture Info Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Saving a Snapshot to Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Printing a Snapshot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

TECH 2 PATHING TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

Powertrain Pathing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

Body Pathing Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

Chassis Pathing Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-66

Te ch 2 TOC-3

Page 10

TOC-4 Tech 2

Page 11

1. INTRODUCTION

USING THIS MANUAL

To increase their effectiveness with the Tech 2, familiarize yourself with the format and information

contained in this guide.

VEHICLE SYSTEM FAMILIARITY

While the Tech 2 is a powerful tool, it cannot replace knowledge and skill. To get the most out of the Tech 2,

you must have a complete understanding of vehicle systems.

When using the Tech 2 to diagnose a vehicle, we recommend that you also refer to the service manual and

the latest service bulletins.

Te ch 2 Page 1-1

Page 12

Introduction

THINGS YOU SHOULD KNOW

CAUTION!

CAUTION

CAUTION!

CAUTION

When performing any checks with the engine running in an enclosed space

such as a garage, make sure there is proper ventilation. Never inhale

exhaust gases; they contain carbon monoxide, a colorless, odorless,

extremely dangerous gas that can cause unconsciousness or death.

To help avoid personal injury, always set the parking brake securely and

block the drive wheels before performing any checks or repairs on the

vehicle.

TECH 2 DISCLAIMER

The Tech 2 is designed for use by trained service personnel only. It has been developed for the sole purpose

of diagnosing and repairing automotive systems with electronic controls and interfaces. Every attempt has

been made to provide complete and accurate technical information based on factory service information

available at the time of publication. However, the right is reserved to make changes at any time without

notice.

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy. If not installed and used in accordance with the instruction manual,

it may cause harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference, in which case the user will be required to correct the interference at

his or her own expense.

Page 1-2 Tech 2

Page 13

Introduction

VDE CERTIFICATION (FOR EUROPEAN USE)

This equipment complies with the requirements of VDE 0871/6.78. Improper use or maintenance neglect

may cause unacceptable radio or TV interference.

CAUTION!

CAUTION

NOTE

The Tech 2 uses parts that can produce arcs or sparks. When used in a

garage environment, the Tech 2 must be located not less than 18 inches

(460 mm) above the floor.

• Do NOT clasp battery clips together when connected simultaneously

to the vehicle's 12-volt cigarette lighter or power supply. Reverse

polarity in the vehicle's cigarette lighter may be present. Damage may

occur to the Tech 2 or to the vehicle.

• If power is applied to the Tech 2 and the display remains blank,

reverse polarity in the cigarette lighter may be present. Damage to the

Tech 2 could occur. Do NOT connect the DLC cable to the vehicle.

Verify that the center contact of the vehicle's cigarette lighter has +12

volts and that the outer contact is grounded.

• Turn off the power before inserting or removing the PCMCIA card.

Continual removal and reinsertion of this card is not recommended.

• Align all cards and components carefully before inserting them into

the Tech 2.

• Make sure all cables and adapters are firmly connected before starting

to use the Tech 2.

• Always read the instructions completely before attempting a new

procedure.

• Do not connect the RS-232 and RS-485 ports to a direct phone line.

The Tech 2 was not designed for this method of communication.

• Do not place the Tech 2 so that the tilt stand can make contact with the

vehicle battery terminal as this could short out the battery.

TAKING THE PRODUCT BACK AND RECYCLING

Applicable to product that is sold into the European Union, the European Union has passed a directive

called Waste Electrical and Electronic Equipment, or WEEE for short, to ensure that systems are setup

throughout the EU for the collection, treating and recycling of electronic waste.

Te ch 2 Page 1-3

Page 14

Introduction

This ensures that the devices are recycled in a resource-saving way representing no danger to health or the

environment.

FIGURE 1-1. WEEE Logo

The WEEE symbol (see Figure 1-1) on the product or its packaging shows that the product must not be

disposed of as residual garbage. The user is obliged to collect the old devices separately and return them to

the WEEE take-back system for recycling.

The WEEE directive concerns all Bosch devices but not external cables or batteries. For more information

on the Bosch GmbH Recycling Program, contact one of the Vetronix/Bosch Group sales and service

locations listed below.

Bulgaria

I.C Iletisim Teknolojileri Elek. San. Ve Tic. Ltd. Sti.

Bayar Cad. Bayar Is Merkezi NO: 109A D:8

81090 Kozyatagi, Istanbul

Turkey

Ireland

Advanced Diagnostics

Unit 5

Alliance Close

Attleborough Fields Industrial Estate

Nuneaton

Warwickshire, CV11 6SD

Romania

I.C Iletisim Teknolojileri Elek. San. Ve Tic. Ltd. Sti.

Bayar Cad. Bayar Is Merkezi NO: 109A D:8

81090 Kozyatagi, Istanbul

Turkey

Slovenia

Phone: +90 (216) 445 90 12

Fax: +90 (216) 445 90 13

Email: info@icteknoloji.com

WWW: www.icteknoloji.com

Phone: 44 24 76757951

Fax: 44 24 76757952

Email: shaun@advanceddiagnostics.co.uk

WWW: www.advanceddiagnostics.co.uk

Phone: +90 (216) 445 90 12

Fax: +90 (216) 445 90 13

Email: info@icteknoloji.com

WWW: www.icteknoloji.com

GIIR d.o.o

Gabrovacki out II deo 32a

18000 Nis

Serbia & Montenegro

(Yugoslavia)

Page 1-4 Tech 2

Cell: #381 65 4000068

Office: #381 18 534-272

Fax: #381 338 832

Email: giir@bankerinter.net

Page 15

United Kingdom

Advanced Diagnostics

Introduction

Unit 5

Alliance Close

Attleborough Fields Industrial Estate

Nuneaton

Warwickshire, CV11 6SD

Phone: 44 24 76757951

Fax: 44 24 76757952

Email: shaun@advanceddiagnostics.co.uk

WWW: www.advanceddiagnostics.co.uk

Te ch 2 Page 1-5

Page 16

Introduction

TECH 2 OVERVIEW

The Tech 2 is a hand-held computer designed to aid in the diagnosis and repair of automotive systems with

electronic controls and interfaces.

POWER SUPPLY

The Tech 2 can be powered from:

• The automobile battery power cable

• The cigarette lighter power cable

• The Tech 2 power supply

• The DLC (Data Link Connector) connection in some vehicles

COMMANDS

The Tech 2 prompts you to enter commands via the membrane keypad for:

• Retrieving and viewing diagnostic information.

• Selecting self tests.

• Performing vehicle diagnostics.

DATA STORAGE

The Tech 2 contains electronic components called PCMCIA (Personal Computer Memory Card Industry

Association) cards, which store diagnostic programs. The Tech 2 can be updated as vehicle models change

by reprogramming the PCMCIA card via the RS-232 connector.

HARDWARE

The Tech 2 has been designed as a rugged, shop-ready tool by having:

• A sturdy case

• A sealed keypad

• Heavy-duty cables and connectors

You can expect years of trouble-free service if you take reasonable care of the Tech 2 and follow the

maintenance procedures outlined in this chapter.

Page 1-6 Tech 2

Page 17

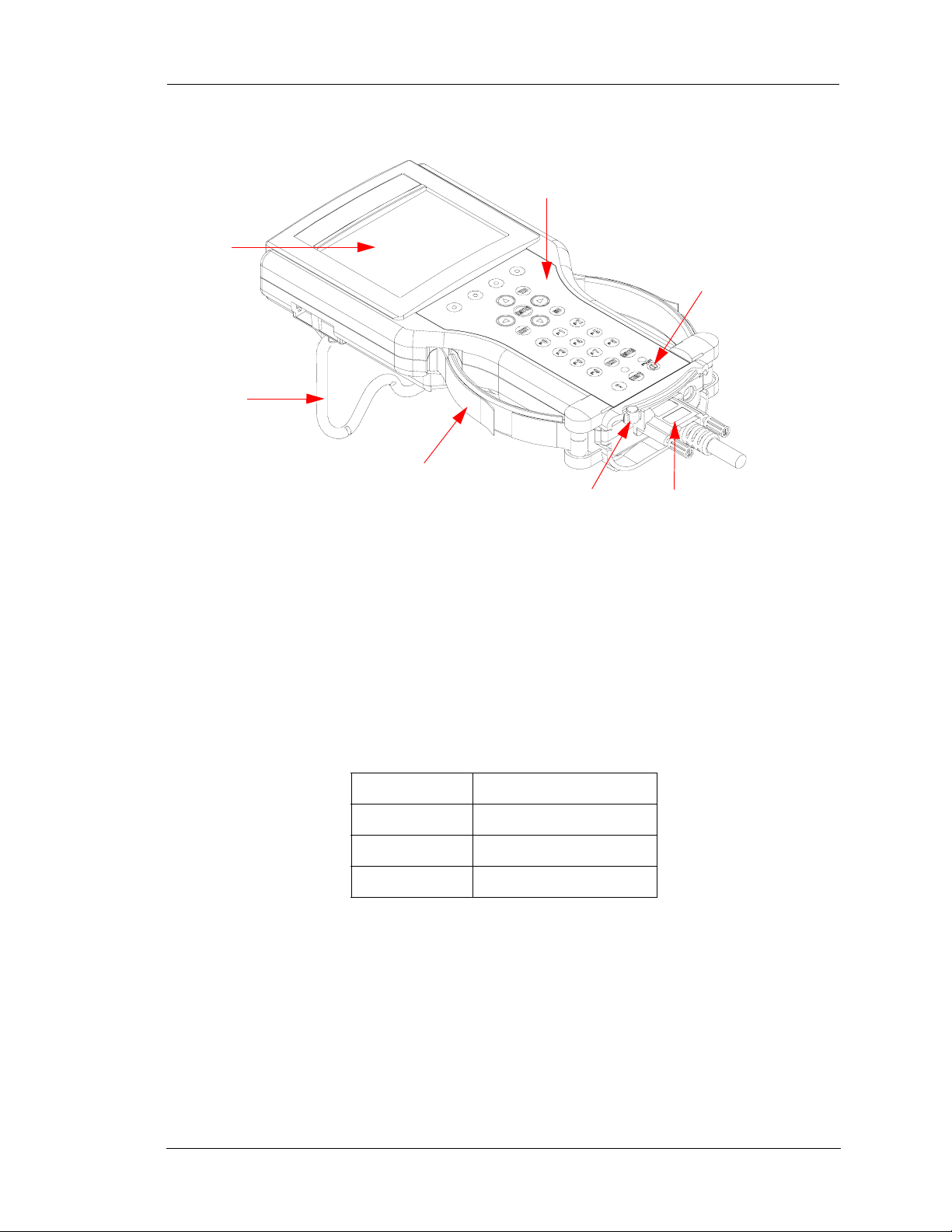

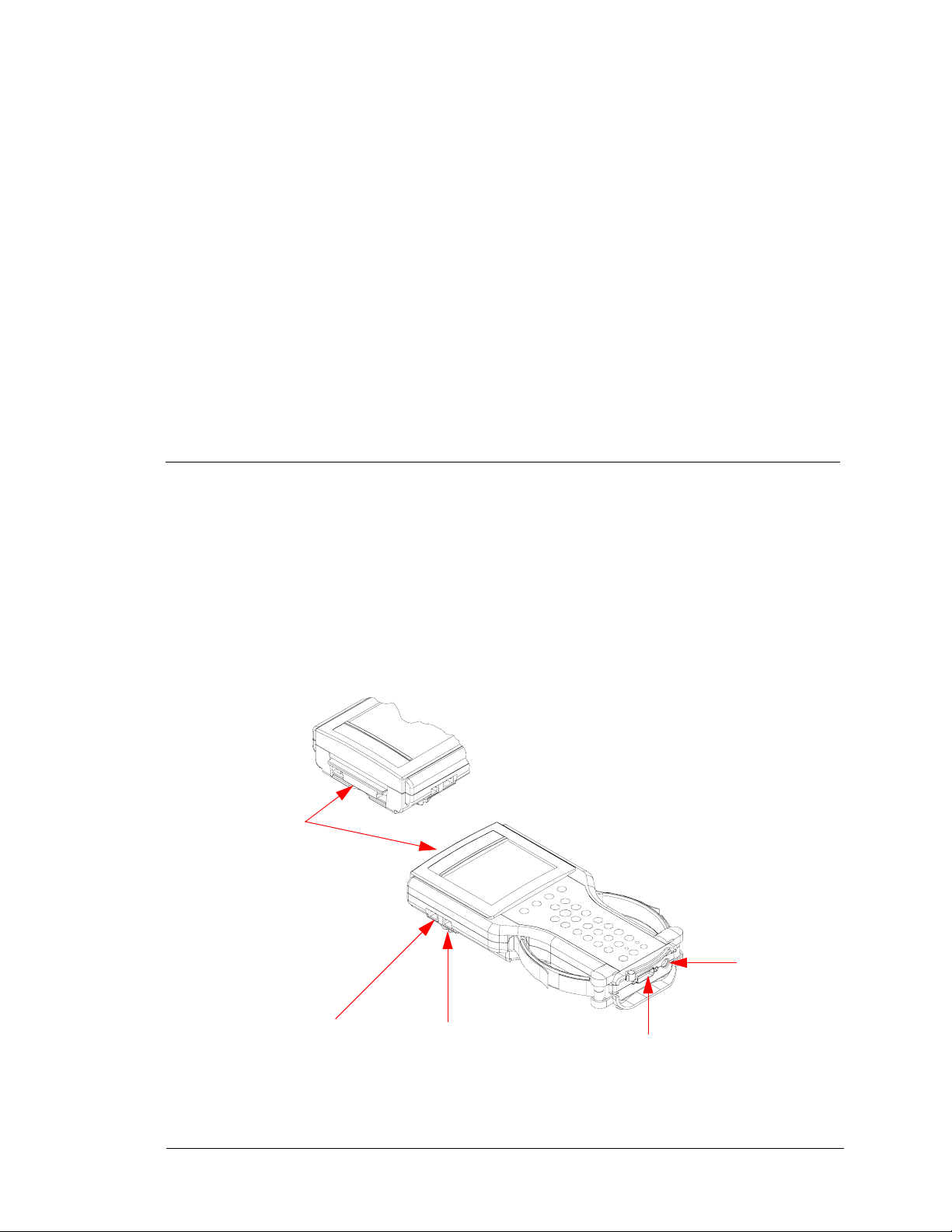

Display

Tilt stand

Adjustable strap

Keypad

VCI latching lever

Introduction

Power On/Off button

DLC Cable Connector

FIGURE 1-2. External Features of the Tech 2 (Front View)

MECHANICAL DIMENSIONS

The dimensions of the Tech 2 are as follows:

Width

Height

Depth

Wei ght

TABLE 1-1. Mechanical Dimensions

6.1 inches (155 mm)

11.8 inches (300 mm)

2.0 inches (55 mm)

2.2 pounds (1.0 kg)

Te ch 2 Page 1-7

Page 18

Introduction

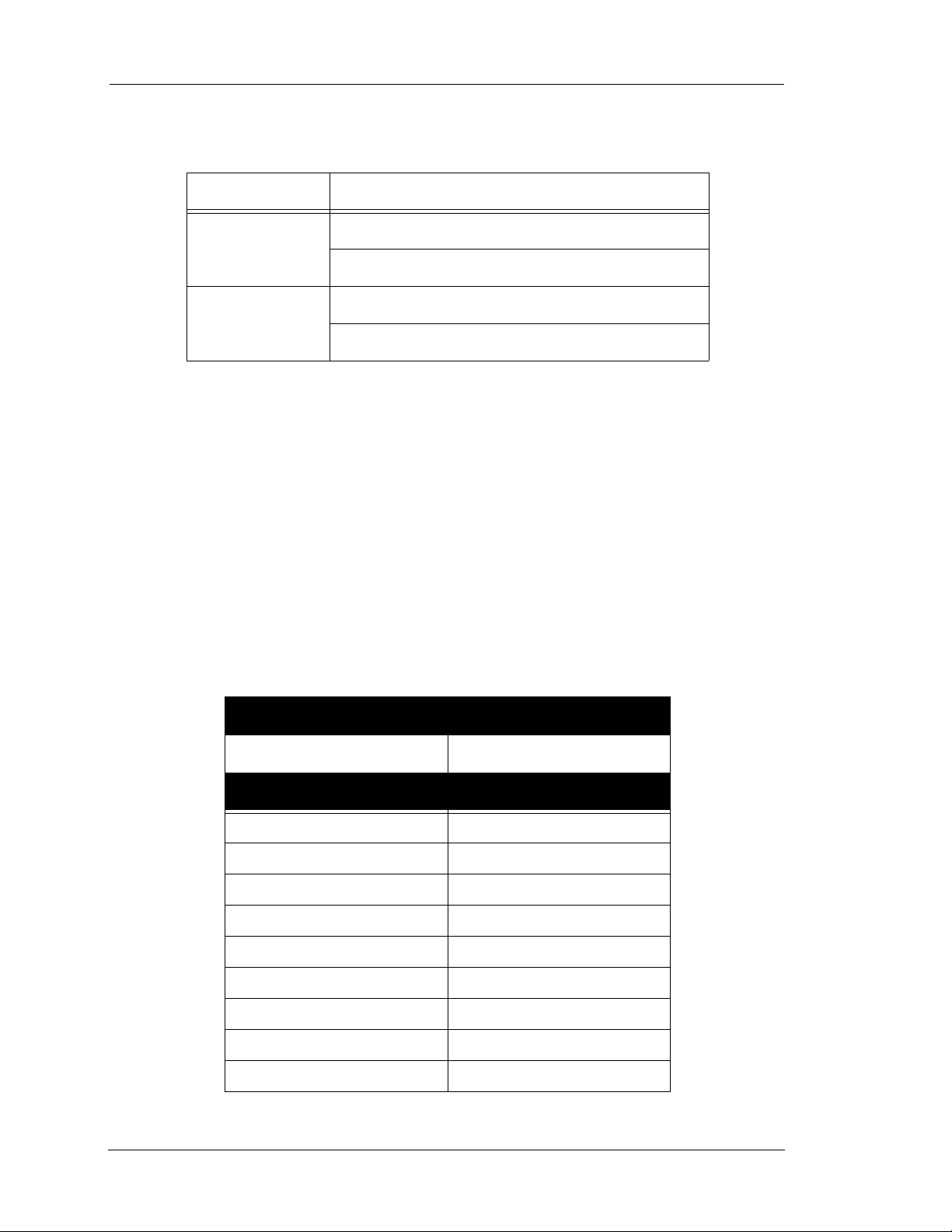

ENVIRONMENTAL SPECIFICATIONS

Conditions Specifications

Operating:

Temperature

Non-Operating: -40º to 70ºC (-40º to 158ºF)

Operating:

Relative Humidity

Non-Operating: 90% at 65ºC (non-condensing)

0º to 40ºC (32º to 104ºF)

15% to 95% at 40ºC (non-condensing)

TABLE 1-2.

WARRANTY

The Tech 2 is warranted against defects in materials and workmanship for 1 year. If your Tech 2 must be sent

in for repair, contact Customer Support (see inside front cover).

Important: This warranty does not cover any part that has been abused, altered, used for a purpose other

than which it was intended, or used in a manner inconsistent with instructions regarding use. This includes,

but is not limited to, removal of any Tech 2 screws.

Your Tech 2 is composed of a base kit and a variety of the following subcomponents:

Product Number Product Name

01002668 Vetronix Tech 2 Unit

Part Number Base Kit

02002952 DLC cable

02002954 Cigarette lighter power

02002956 Battery power cable

02002955 SAE 16/19 pin adapter

02002953 DLC loopback adapter

01001089 PC Interface Kit

02001606 RS232 loopback adapter

02002971 Storage case

02002961 NAO 12/19 adapter

TABLE 1-3. Base Kit Parts List

Page 1-8 Tech 2

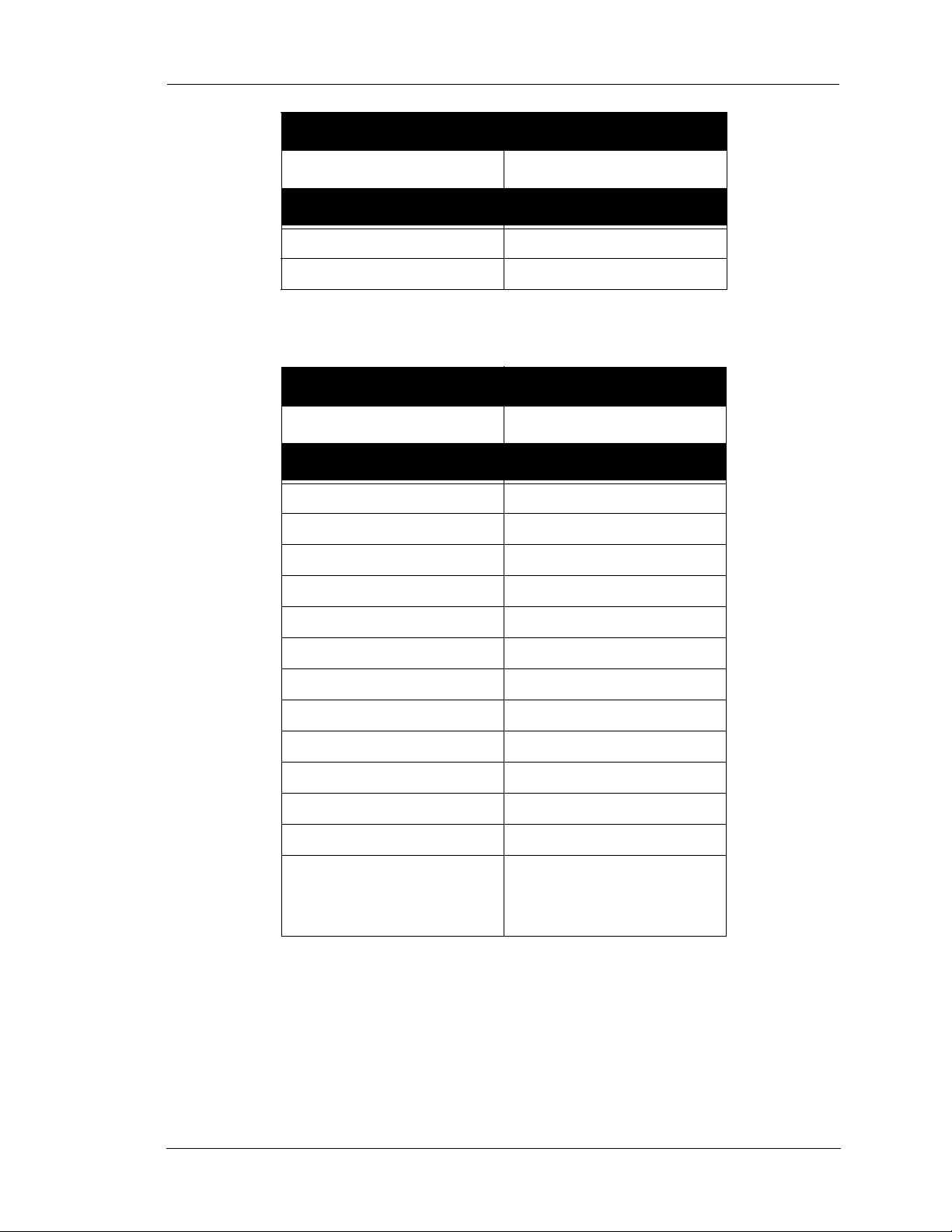

Page 19

Product Number Product Name

01002668 Vetronix Tech 2 Unit

Part Number Base Kit

02002972 NAO power supply

02002974-003 10 MB PCMCIA card

TABLE 1-3. Base Kit Parts List (Continued)

Product Number Product Name

01002398 Vetronix Tech 2 Pro

Part Number Base Kit

02002952 DLC cable

Introduction

02002954 Cigarette lighter power

02002956 Battery power cable

02002955 SAE 16/19 pin adapter

02002953 DLC loopback adapter

01001089 PC Interface Kit

02001606 RS232 loopback adapter

02002971 Storage case

02002961 NAO 12/19 adapter

02002972 NAO power supply

02002994-003 32 MB PCMCIA card

02002441

01002623-21

PC Security device

GM Expertec TIS 2000

(GM Expertec SPS, Vetronix Tech 2

updated snapshot uploading

program)

TABLE 1-4. Pro Kit Parts List

Te ch 2 Page 1-9

Page 20

Introduction

TECHNICIAN NOTES

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

Page 1-10 Tech 2

Page 21

2. CARE AND CLEANING

After using the Tech 2, a few simple steps will insure that you get the most life out of this diagnostic tool.

NOTE

Although the Tech 2 is water resistant, it is not waterproof, so be sure to dry the Tech 2 thoroughly prior to

usage and/or storage.

Do not spray or pour cleaner anywhere on the Tech 2. If the Tech 2

becomes dirty, clean it with mild detergent or hand soap. Avoid using

harsh solvents, such as petroleum-based cleaning agents, acetone, benzene,

trichlorethylene, etc. Harsh solvents can etch Tech 2 plastic surfaces.

Maintenance of the Tech 2 requires periodic inspection and cleaning of the following:

• The display window

• The keypad

• The cable assemblies and connectors

Make sure the Tech 2 is not connected to a vehicle or other power source and follow the cleaning procedures

detailed below.

CLEANING THE DISPLAY

The display collects dust and grime during normal use. Occasionally wipe the screen with a clean, soft,

static-free cloth. Remove stubborn stains by applying a non-abrasive glass cleaner to a soft cloth and wipe

the cloth across the display area.

Te ch 2 Page 2-1

Page 22

Care and Cleaning

CLEANING THE KEYPAD

Clean the keypad with a non-abrasive cleaner. Apply a small amount of cleaner on a soft cloth and wipe the

cloth across the keypad area.

MAINTAINING THE CABLE ASSEMBLIES AND CONNECTORS

Inspect cable assemblies during connection and disconnection to components. Watch for any cuts or

abrasions along the cables. Check the connectors and connector pins for grease, dirt, and corrosion. If

contaminants are present, remove them with a mild soap solution.

STORING THE TECH 2

• Store the Tech 2 away from solvents and other liquids. It is NOT moisture proof.

• Store the Tech 2 away from direct sunlight. Ultraviolet and infrared light will darken the display.

• Store the Tech 2 in its plastic case. Otherwise, the high-impact plastic cover could become scratched.

Page 2-2 Tech 2

Page 23

3. GETTING STARTED

This section covers all Tech 2 vehicle applications and therefore some of the information provided may not

be required for individual applications.

The Tech 2 contains two serial communication ports: the RS-232 and the RS-485. Use the RS-232 port for

downloading data from another computer to the Tech 2. The RS-485 port is currently not used.

The Tech 2 also contains two PCMCIA ports, a power jack connector, and a Vehicle Communications

Interface (VCI) connector. One of the PCMCIA slots contains a memory card with diagnostic information.

The power jack accepts power from the AC/DC power supply, battery, or cigarette lighter power cable. The

VCI connector accepts the DLC cable or DLC loopback adapter.

PCMCIA port

Power jack

connector

RS-485 port

FIGURE 3-1. Identification of the Tech 2’s External Ports

Te ch 2 Page 3-1

RS-232 port

VCI connector

Page 24

Getting Started

INITIAL HARDWARE INSTALLATION

The Tech 2 hardware initial installation requires the following steps:

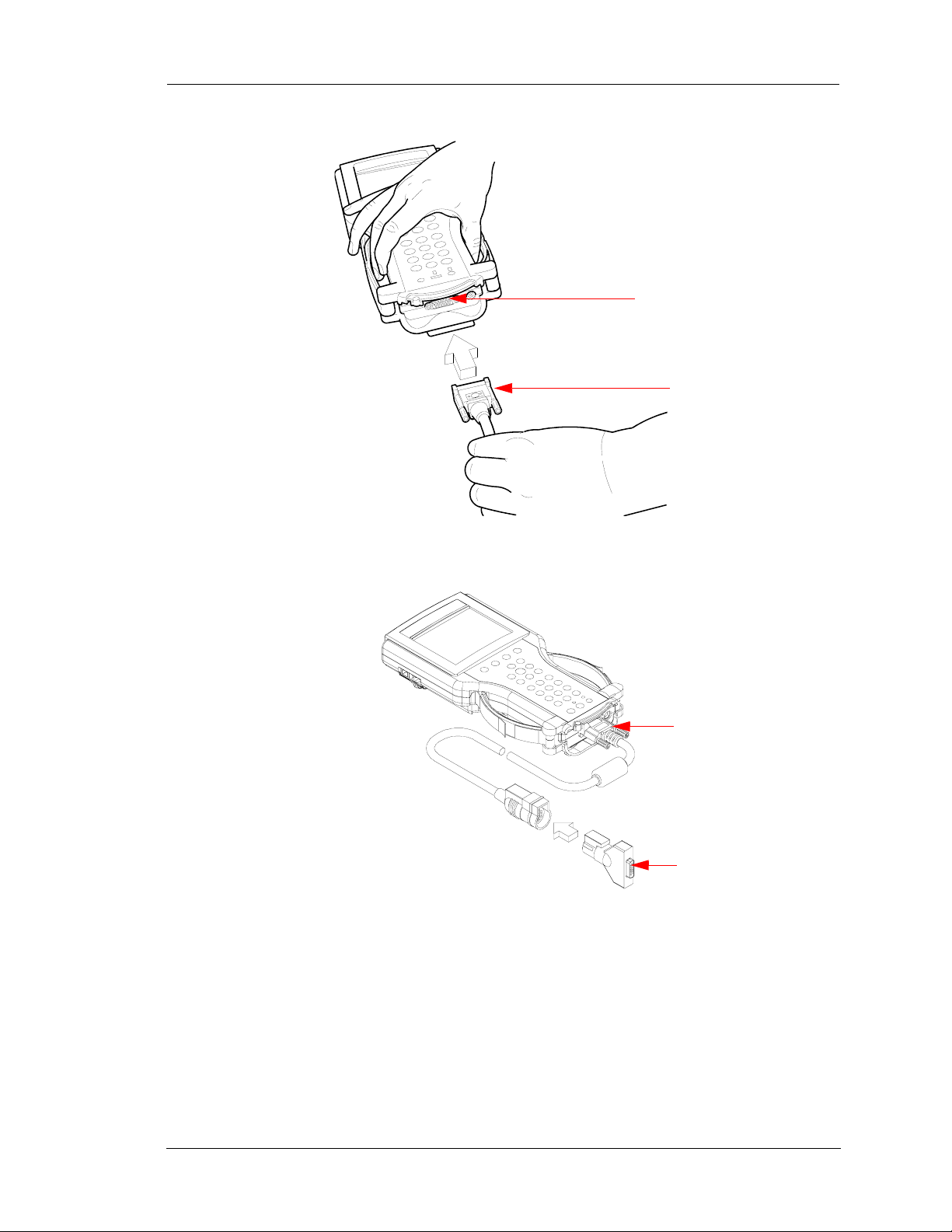

1. Remove the RS-232 loopback adapter (P/N 02001606) from the storage case (P/N 02002971). Plug it

into the RS-232 port (Figure 3-2).

2. Attach the Tech 2 DLC cable (P/N 02002952) to the VCI connector (Figure 3-3).

3. Locate the DLC loopback adapter (P/N 02002953) in the storage case. Attach it to the DLC cable

(Figure 3-4).

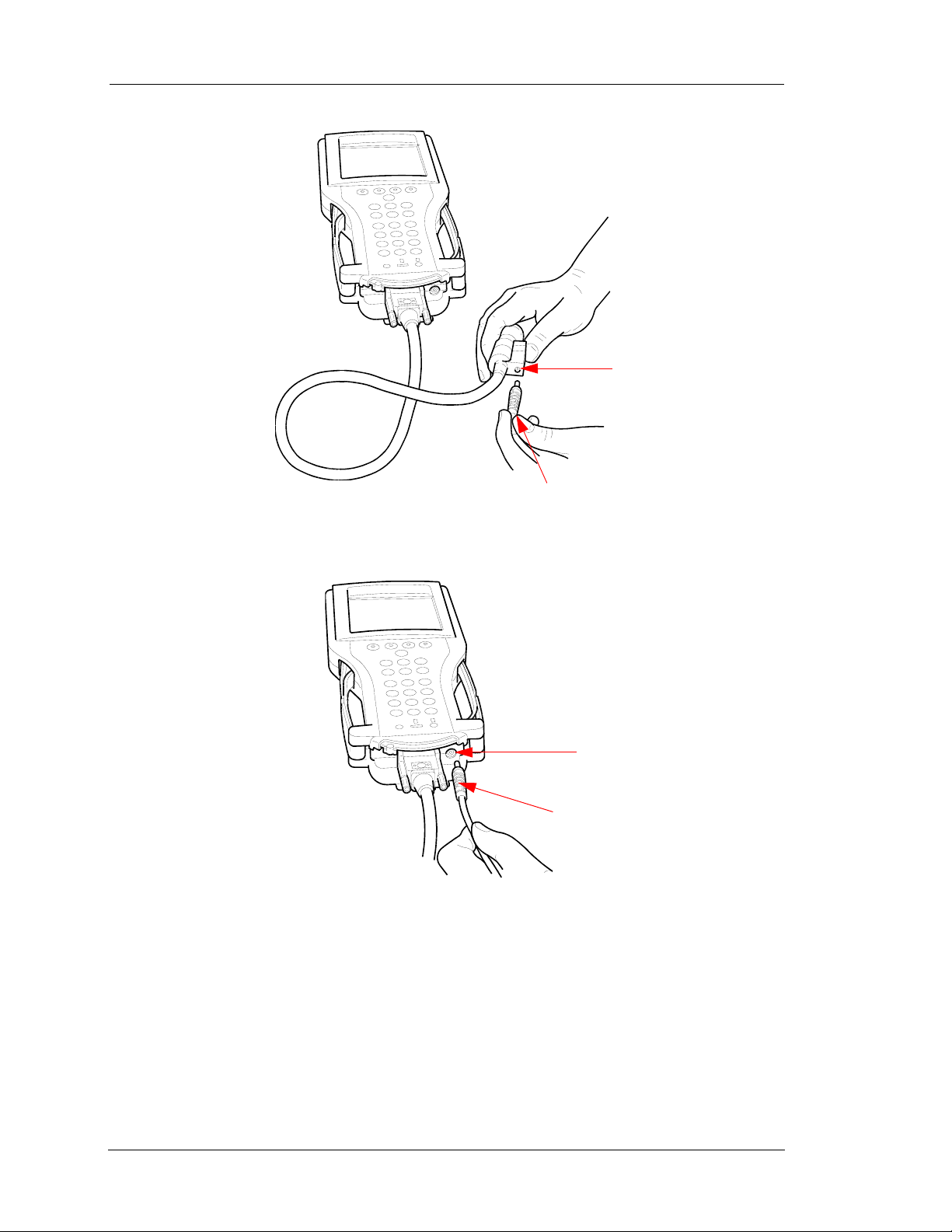

4. Locate the NAO (P/N 02002972) power supply and appropriate power cord in the storage case. Insert

the power jack into the Tech 2 DLC cable (Figure 3-5) or into the bottom of the Tech 2 next to DLC

cable connector (Figure 3-6).

5. Turn on power by pressing the PWR button located on the Tech 2 key pad.

6. Tech 2 hardware is verified automatically by the POST Test (for information on this program, see

Chapter 6).

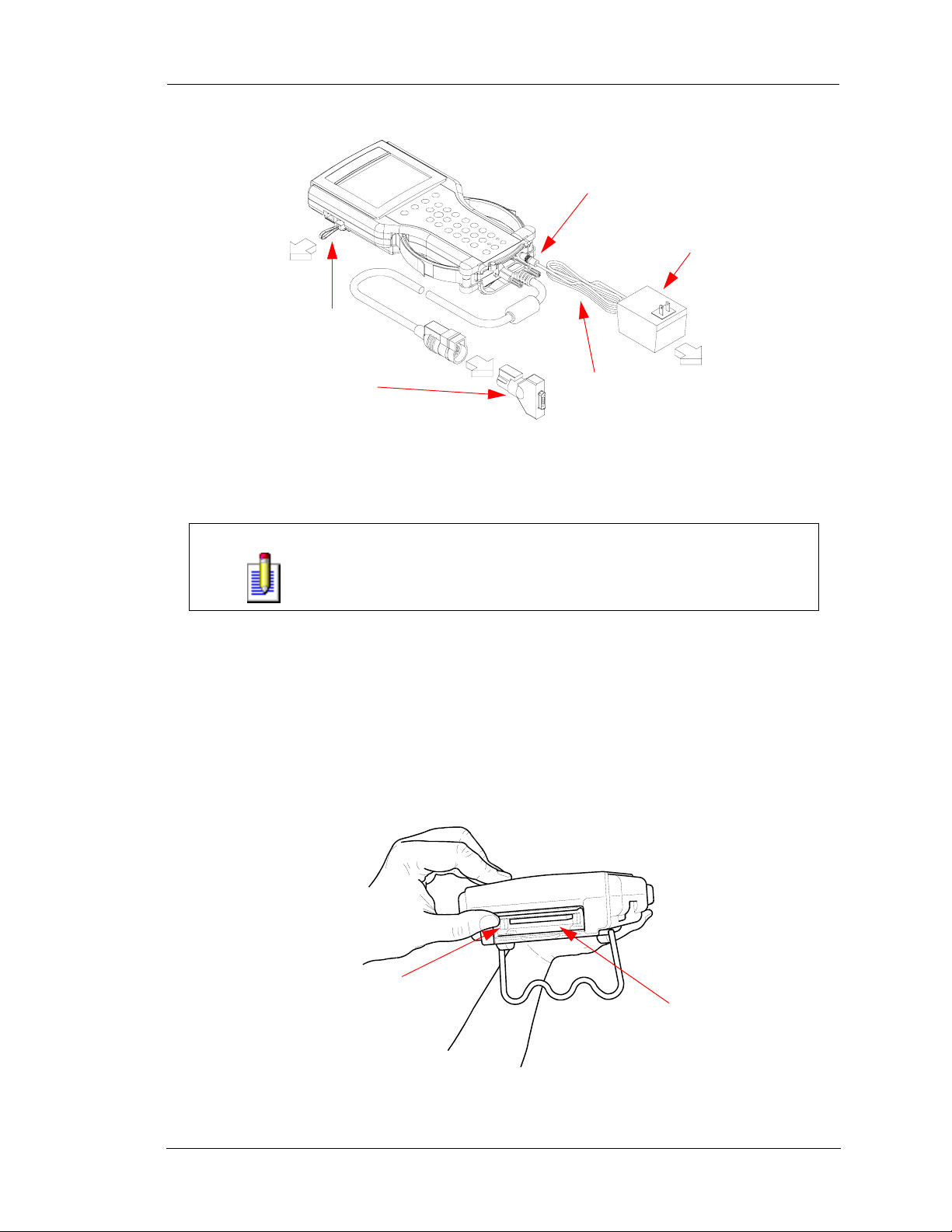

7. Disconnect the RS-232 loopback adapter, the power supply, and the DLC loopback adapter and return

to the Tech 2 storage case (Figure 3-7).

RS-232 port

RS-232 loopback

adapter

(P/N 02001606)

FIGURE 3-2. Connection of RS-232 Loopback Adapter to Tech 2 RS-232 Port

Page 3-2 Tech 2

Page 25

VCI Connector

Tech 2 DLC cable

(P/N 02002952)

Getting Started

FIGURE 3-3. Connection of Tech 2 DLC Cable to the VCI Connector

Tech 2 DLC cable

(P/N 02002952)

DLC loopback adapter

(P/N 02002953)

FIGURE 3-4. Connection of DLC Loopback Adapter to DLC Cable

Te ch 2 Page 3-3

Page 26

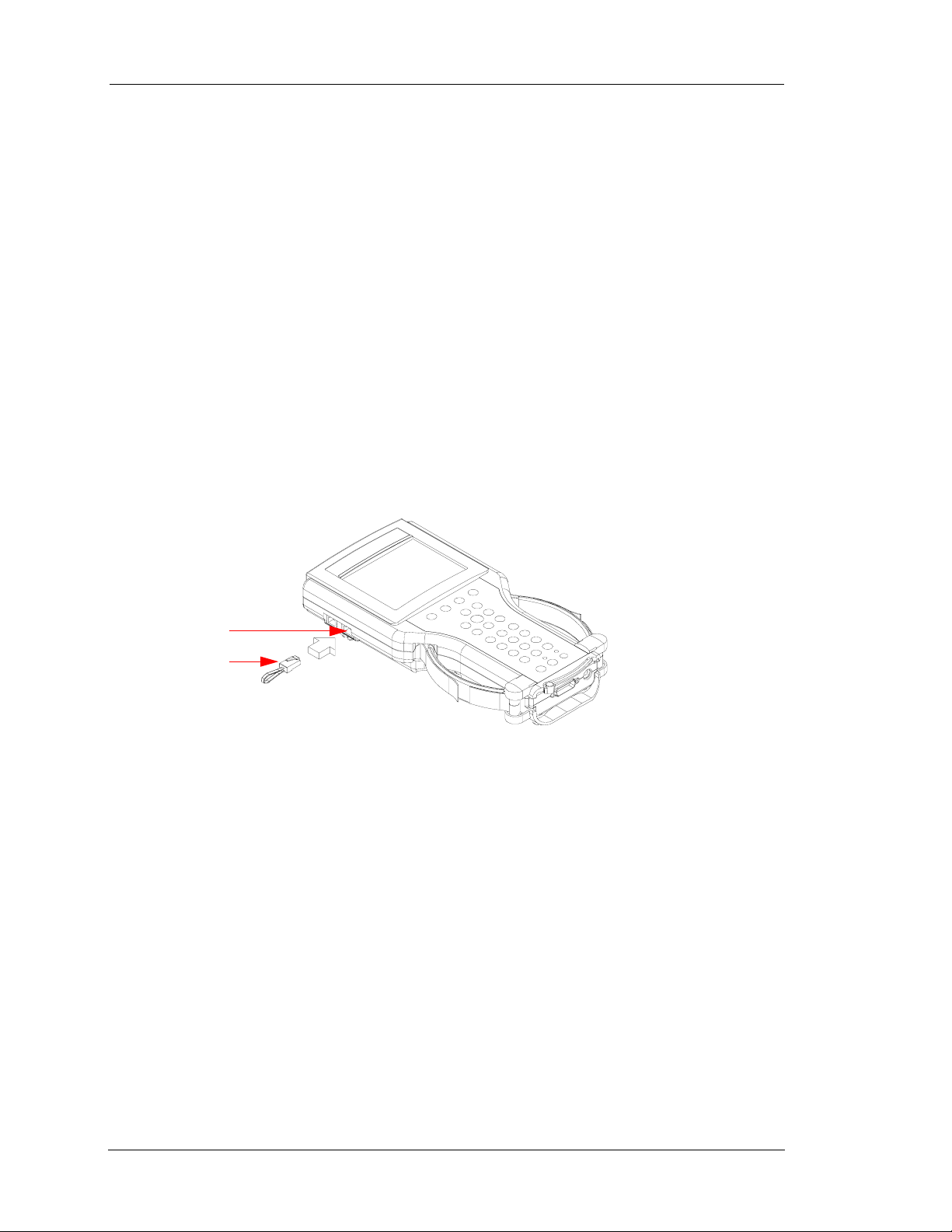

Getting Started

Tech 2 DLC cable

power jack connector

Power jack (NAO power supply)

FIGURE 3-5. Connection of Power Jack to Tech 2 DLC Cable

Tech 2 power jack connector

Power jack (NAO power supply)

FIGURE 3-6. Connection of Power Jack to the Bottom of Tech 2

Page 3-4 Tech 2

Page 27

DLC loopback adapter

(P/N 02002953)

Getting Started

Power jack

NAO power supply

(P/N 02002972)

RS-232 loopback adapter

(P/N 02001606)

FIGURE 3-7. Disconnection of RS-232 Loopback Adapter, DLC Loopback Adapter, and

Power Supply

NOTE

When using the Tech 2 for vehicle communications, the Tech 2 must be

powered with the cigarette lighter power cable (P/N 02002954) to ensure a

proper ground.

Tech 2 DLC cable

(P/N 02002952)

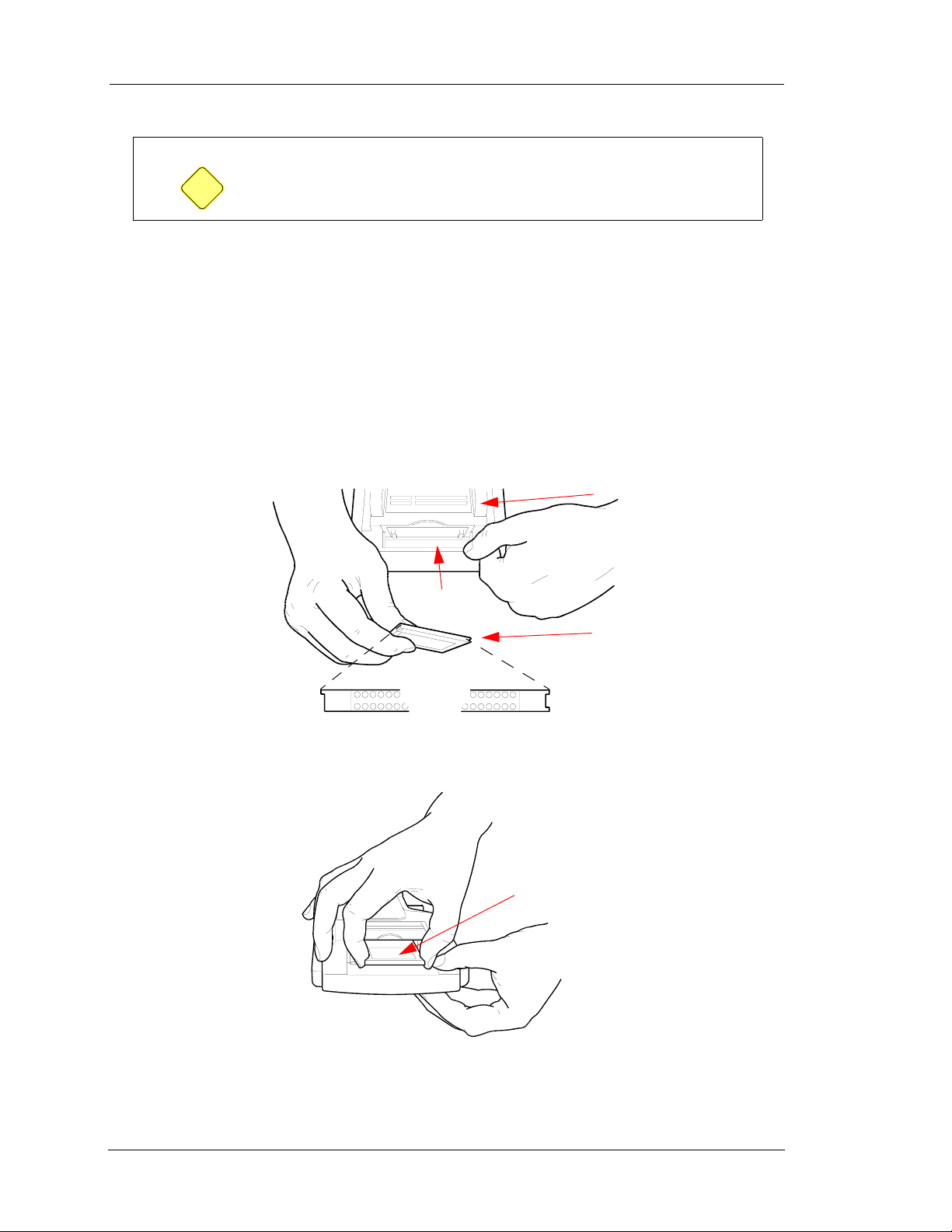

PCMCIA CARD REMOVAL

The PCMCIA Card is accessed by opening the hinged door located at the top of the Tech 2. The card is

found in the upper slot. The lower slot will be used for future enhancements. Press the "up arrow button"

(located on the left hand side of the Tech 2) to eject the card (Figure 3-8).

Up arrow eject button

Empty lower PCMCIA slot

FIGURE 3-8. Ejection of PCMCIA Card

Te ch 2 Page 3-5

Page 28

Getting Started

CAUTION!

CAUTION

Use only Vetronix supplied PCMCIA cards. The PCMCIA slots are

designed to interface with 5-volt cards. Permanent damage to Tech 2 could

occur if a 3.3-volt card is inserted into the Tech 2 PCMCIA connector.

PCMCIA CARD INSERTION

The PCMCIA Card is keyed with two notches on one side and one notch on the other side (Figure 3-9).

Make sure that the notches are in the correct position before inserting the card. Slowly insert the card

(Figure 3-10) until it clicks into place.

Make sure the PCMCIA card is inserted into the upper slot. The card fits into both slots; however, if the card

is placed in the lower slot, the Tech 2 will not function properly.

Bottom side of Tech 2

Tech 2 door

FIGURE 3-9. PCMCIA Card Keying

Tech 2 PCMCIA card

FIGURE 3-10. PCMCIA Card Insertion

Tech 2 PCMCIA card

Page 3-6 Tech 2

Page 29

Getting Started

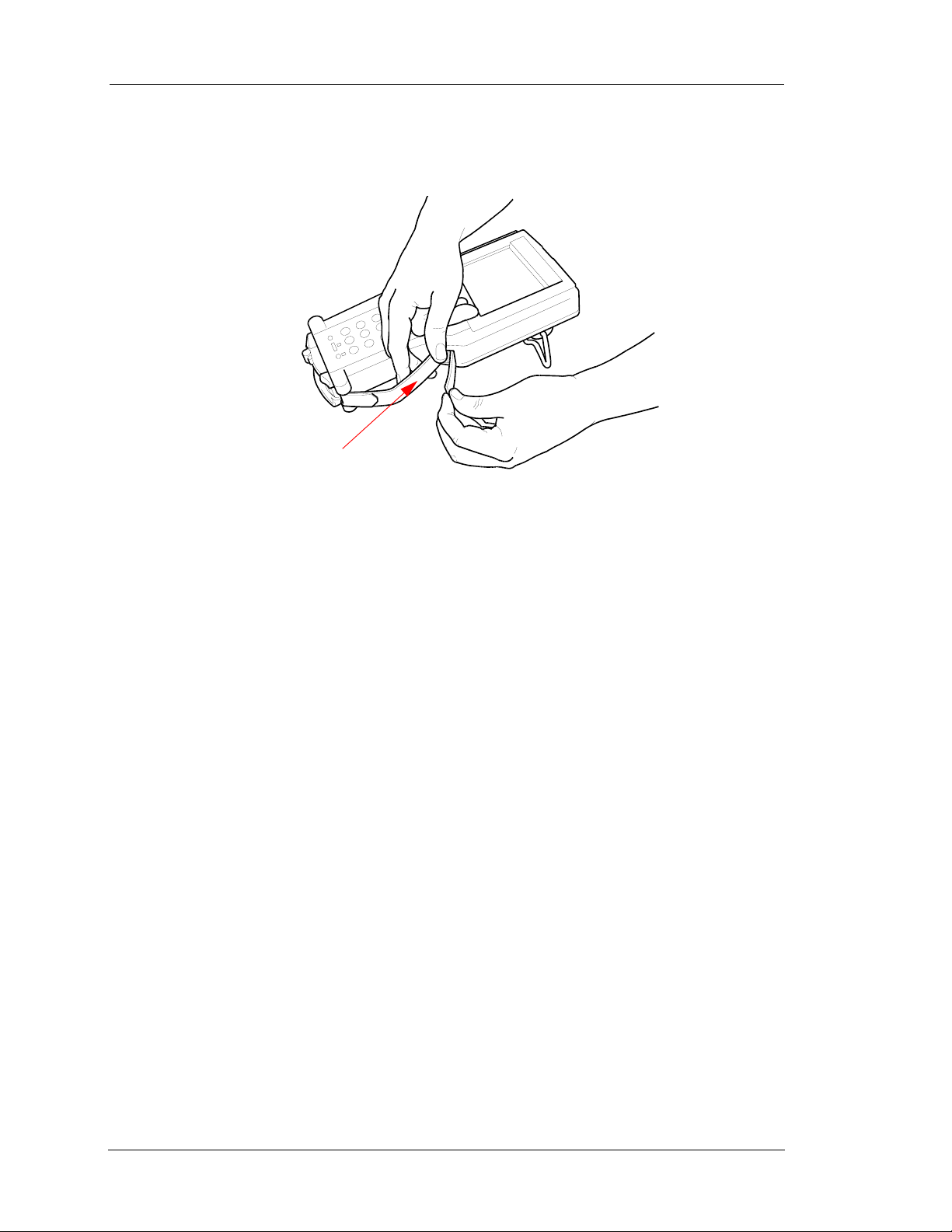

VEHICLE COMMUNICATIONS INTERFACE MODULE REMOVAL

The Vehicle Communications Interface (VCI) module is located at the lower end of the Tech 2. Removal of

this module is required only if the VCI needs to be updated. To remove the module disconnect Tech 2 DLC

cable if attached, move the lever (Figure 3-11) all the way toward the right side of the Tech 2 (Figure 3-12).

The VCI module can now be removed.

VCI module lever

VCI module

FIGURE 3-11. VCI Module Removal

VCI module lever

(moved all the way to the right)

FIGURE 3-12. VCI Model Removed

Te ch 2 Page 3-7

Page 30

Getting Started

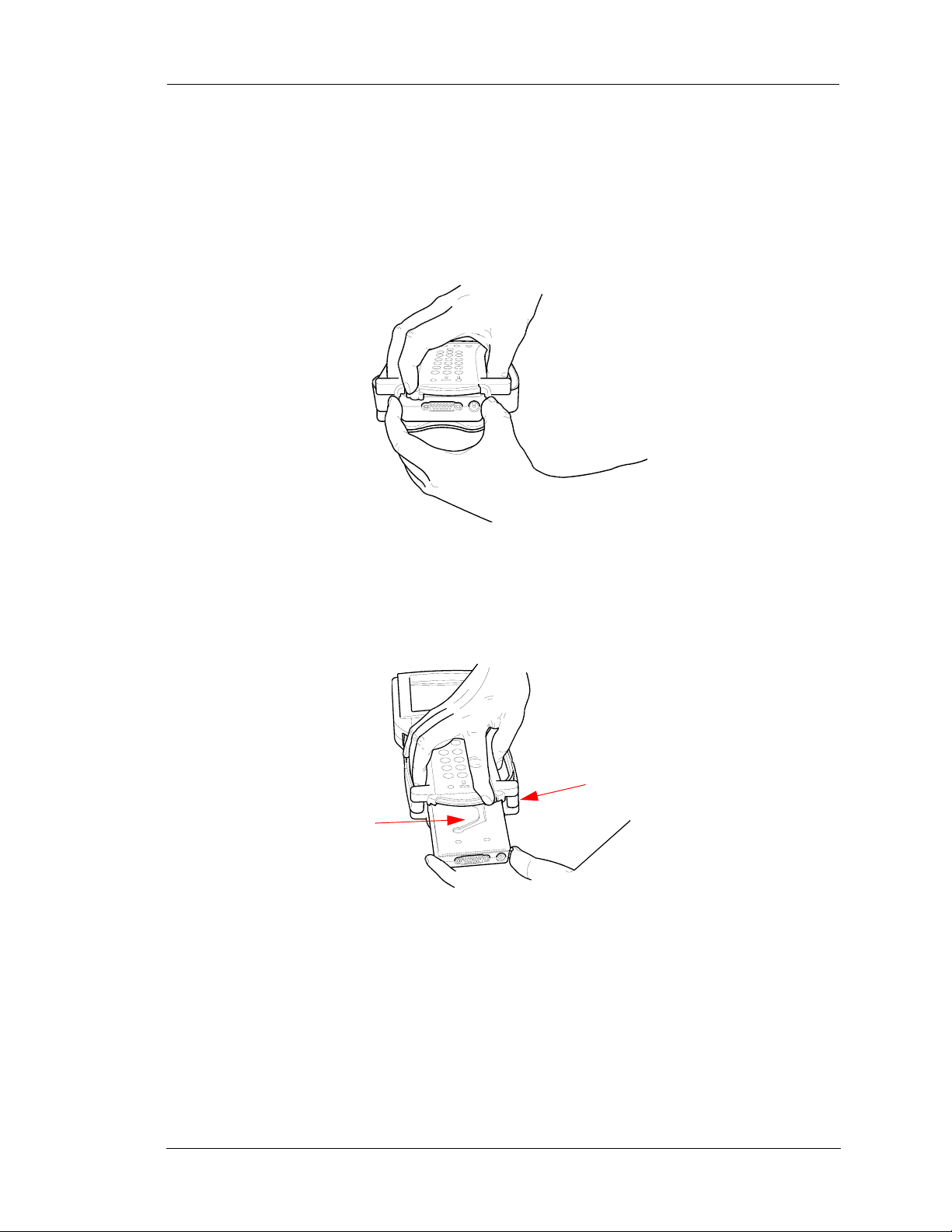

HAND STRAP ADJUSTMENT

The Tech 2 velcro hand straps may be adjusted for individual needs as shown in Figure 3-13.

Velcro strap

FIGURE 3-13. Tech 2 Hand Strap Adjustment

Page 3-8 Tech 2

Page 31

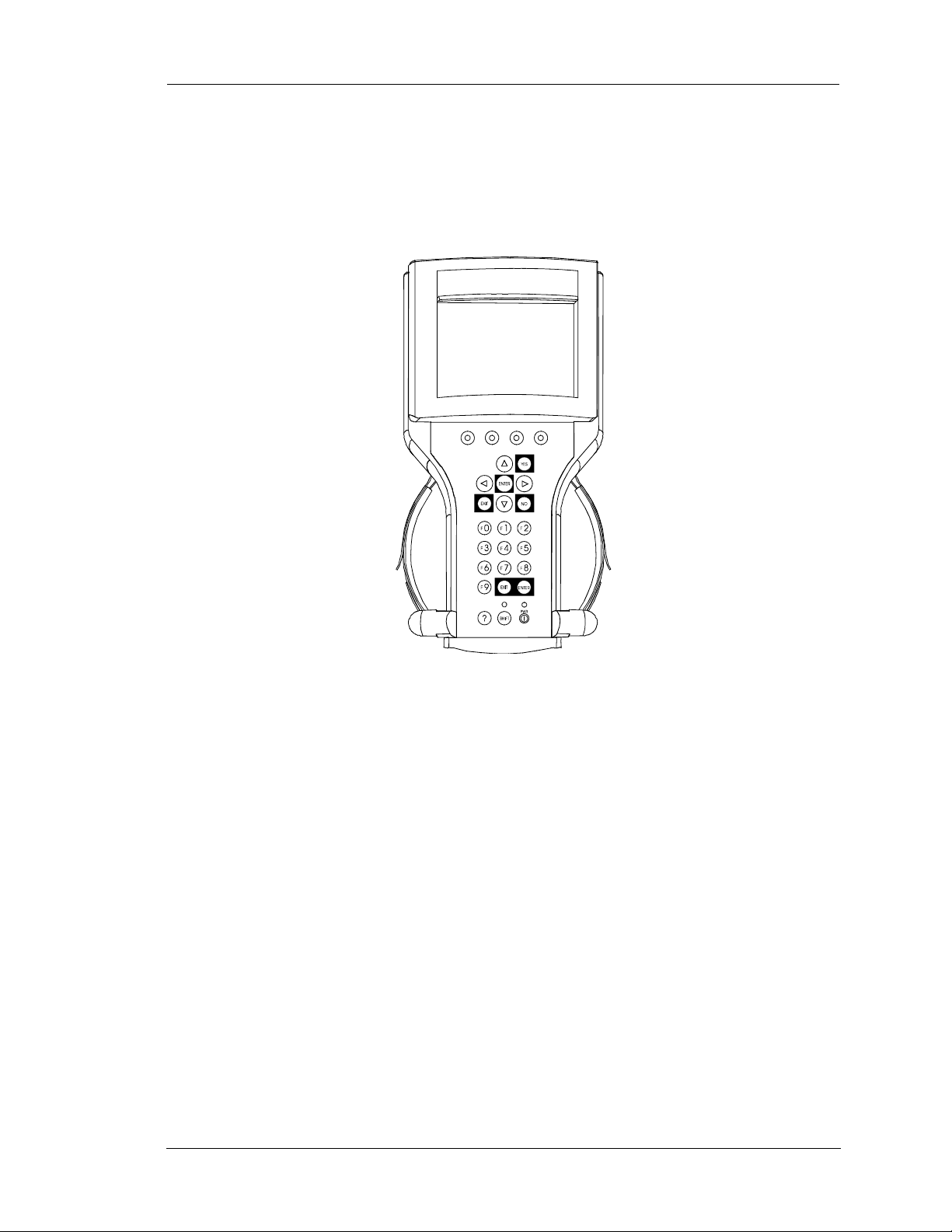

TECH 2 KEYPAD

The Tech 2 keypad consists of six major keypad operation areas:

Soft keys

Getting Started

Selection (arrow) keys

Function keys (F0 - F9)

Help key

Action keys

(YES, NO,

ENTER, EXIT)

Control keys

(SHIFT, PWR)

FIGURE 3-14. Tech 2 Keypad

Te ch 2 Page 3-9

Page 32

Getting Started

CONTROL KEYS

The [PWR] key is used to turn the Tech 2 on or off (Figure 3-15). The status indicator light above this key is

illuminated green when the Tech 2 is operational.

The [SHIFT] key is used with the up and down arrow keys to change screen brightness and contrast

(Figure 3-15).

To adjust screen brightness and contrast, perform the following:

1. Press the [SHIFT] key once (amber status indicator light above [SHIFT] lights up).

2. Use up and down arrows to adjust screen brightness and contrast.

3. Press [SHIFT] key again when desired brightness is reached (status indicator light above [SHIFT] is

off).

The Tech 2 should return to normal operation after following the above steps.

Shift status indicator light

Shift key

FIGURE 3-15. Location of Control Keys

Page 3-10 Tech 2

Power status indicator light

Power key

Page 33

Getting Started

TECH 2 SOFT KEYS

Four soft keys are located directly below the Tech 2 screen (Figure 3-16). The soft keys correspond directly

to the four possible selection boxes found at the bottom region of the Tech 2 screen. These selections may

change from screen to screen and are under the control of the application software. To make a screen

selection, press the corresponding soft key. In the example shown in Figure 3-17, the first soft key was

pressed to select [Display Time].

FIGURE 3-16. Location of Soft Keys

FIGURE 3-17. Soft Key Selection for [Display Time]

Te ch 2 Page 3-11

Page 34

Getting Started

SELECTION KEYS

The Tech 2 selection keys are four directional arrow keys (Figure 3-18). The arrow keys are pressed to move

the highlighted area to a selection on the screen (Figure 3-19) or to scroll the screen if there is more than one

screen. Once the desired selection is highlighted, press [ENTER] to activate the selection.

FIGURE 3-18. Location of Selection Keys

Top [ENTER] key

Down arrow (used to move

highlighted area from

Engine 1 to Engine 2)

Highlighted area

Bottom [ENTER] key

FIGURE 3-19. Positioning Highlighted Area to Make a Selection

Page 3-12 Tech 2

Page 35

Getting Started

ACTION KEYS

Action keys are used to respond to a specific question, initiate an action, or to exit from the Tech 2 program

(Figure 3-20). Specific "yes or no" questions often appear on the Tech 2 screen. The [YES] and [NO] keys

are used to respond to these questions. Either of the two [ENTER] keys may be pressed to activate a menu

selection. Either of the two [EXIT] keys may be pressed to leave the current Tech 2 screen and return to a

previous screen.

FIGURE 3-20. Location of Action Keys

Te ch 2 Page 3-13

Page 36

Getting Started

FUNCTION KEYS

Ten function keys (F0 to F9) are located on the Tech 2 keypad (Figure 3-21). A function key may be pressed

to initiate a specific Tech 2 function. In some cases the function keys are used for numeric data entry. The

arrow keys and [ENTER] may also be used to initiate a function selection, however, this may require

additional keystrokes.

FIGURE 3-21. Location of Function Keys

Page 3-14 Tech 2

Page 37

Getting Started

HELP KEY

The [?] key (Figure 3-22) may be pressed at any time to obtain a help screen. The help screen provides

specific information relating to the operation of the Tech 2.

FIGURE 3-22. Location of Help Key

Te ch 2 Page 3-15

Page 38

Getting Started

TECH 2 CONNECTIONS TO VEHICLE

The Tech 2 receives power through the DLC cable connection to vehicles equipped with On-Board

Diagnostics (OBD II) (Figure 3-23). In the case of vehicles not equipped with OBD II, an external power

source such as a vehicle cigarette lighter must be used (Figure 3-24).

SAE 16/19 pin adapter

(P/N 02002955)

DLC cable connector

FIGURE 3-23. Attaching the Tech 2 to OBD II-Equipped Vehicles

Pin adapter 12/19, or 16/19

DLC power jack location.

FIGURE 3-24. Attaching the Tech 2 to Non-OBD II-Equipped Vehicles

Cigarette lighter power cable

(P/N 02002954)

To ensure proper ground, power tester

through the DLC power jack, NOT

the power jack on the Tech 2.

Page 3-16 Tech 2

Page 39

Getting Started

TECH 2 CONNECTION TO PC

It may be necessary to connect the Tech 2 with a PC for the following reasons:

• Transfer of vehicle data (calibration information, "snapshot," etc.) from the Tech 2 to the PC

• Transfer of vehicle calibration data from the PC to the Tech 2

• Transfer of data (software update, etc.) from the PC to the Tech 2

• Before connecting Tech 2 to the PC, the following steps should be taken:

• Make sure that the RS-232 cable (P/N 02001358) is attached to the Tech 2 RS-232 port located on the

left side of the Tech 2 (Figure 5-3).

• Make sure the appropriate power supply is connected to the DLC cable power jack connector (Figure 4-

1), or to the power jack connector at the bottom of the Tech 2 (Figure 3-25).

• Make sure the PCMCIA card is fully inserted into the upper slot at the top of the Tech 2 (Figure 3-8,

Figure 3-9, and Figure 3-10).

Tech 2 power jack connector

Power jack

NAO power supply (P/N 02002972)

FIGURE 3-25. Tech 2 Connection to PC

Plug serial port adapter (P/N 01001089) into the unused serial port (com port) on the back of the computer

terminal. Then plug the Tech 2's RS-232 cable into the serial port adapter and connect the appropriate power

supply.

Te ch 2 Page 3-17

Page 40

Getting Started

RS-232 communications cable

(P/N 02001358)

Serial port adapter

(P/N 02001030)

Appropriate power supply

Power jack (plugged into Tech 2

power jack connector)

FIGURE 3-26. Tech 2 Connection to PC1

Page 3-18 Tech 2

Page 41

Getting Started

FIGURE 3-27. Tech 2 Start-Up Screen

Te ch 2 Page 3-19

Page 42

Getting Started

Page 3-20 Tech 2

Page 43

4. POWER SUPPLIES

Power up the Tech 2 using either:

• The power jack connector at the bottom of the Tech 2 unit (Figure 4-1), or

• The DLC cable power jack connector behind the area where various DLC adapters are connected

(Figure 4-1).

For non-vehicle communications, connect the power source to either location.

For vehicle communications, connect the power source to the DLC cable power jack connector only. Proper

grounding may not be present if the power source is connected directly to the Tech 2.

When the Tech 2 is connected to the DLC of an appropriate vehicle, the vehicle

battery supplies power. When the Tech 2 is not connected to the vehicle's DLC, the

DLC cable power jack connector accepts power from the following:

• Cigarette lighter power cable (Figure 4-1, see text below)

• Battery power cable (Figure 4-1, see text below)

• NAO power supply (Figure 4-1 and Figure 4-2, see NAO Power Supply on page 3)

If the DLC and external power source are both connected, the power jack connection supplies current to the

Tech 2. In this instance, power from the vehicle's DLC connector is automatically disconnected from the

Tech 2 internal power supply.

CIGARETTE LIGHTER POWER CABLE

This cable contains one fuse and two connectors. It has a cigarette lighter plug at one end and a power jack at

the other (Figure 4-1). The power jack connects to the Tech 2 DLC cable and carries power to the Tech 2

when the selected vehicle adapter does not provide power.

Te ch 2 Page 4-1

Page 44

Power Supplies

BATTERY POWER CABLE

This cable has red and black battery clamps attached to one end and a power jack to the other (Figure 4-1).

The power jack connects to the Tech 2 DLC cable and carries current to the Tech 2 when the selected vehicle

adapter does not provide power and there is no cigarette lighter adapter available.

NOTE

This cable contains two 3-amp fuses. If you need to replace them, use

identical 3-amp fuses. See Chapter 6 for information on fuse replacement.

Tech 2 power jack connector

(for non-vehicle communications)

Tech 2 DLC cable

(P/N 02002952)

DLC cable power jack connector

(for vehicle communications)

NAO power supply

(P/N 02002972)

Battery power cable

(P/N 02002956)

Fuse box - 3 amps

FIGURE 4-1. Tech 2 Power Connections (Without Direct Power Connection from the DLC)

Cigarette lighter power cable

(P/N 02002954)

Battery clamps

Page 4-2 Tech 2

Page 45

Power Supplies

NAO POWER SUPPLY

North American electrical supply is normally 110 volts. The Tech 2 base kit includes an external AC to DC

power supply with 110 V AC/60 Hz input (Figure 4-2). Output is 12 volts at 1.5 amps.

FIGURE 4-2. NAO Power Supply (110 Volts)

CAUTION!

CAUTION

To avoid personal injury due to electric shock, use a grounded outlet only.

The NAO power supply is for North American use only. These devices are

intended for indoor use only.

Te ch 2 Page 4-3

Page 46

Power Supplies

Page 4-4 Tech 2

Page 47

5. ADAPTERS

A number of adapters are available for the Tech 2 which allow connection to many different vehicles

(Table 5 -1, Tech 2 Adapters). Specific adapters are included in the Tech 2 base kit depending upon Tech 2

configuration

—NAO. Adapters not included in the base kit may be purchased separately from Vetronix.

DLC CABLE

The DLC cable (P/N 02002952) has a 26-pin connector with thumb screws at one end that connects to the

Tech 2's VCI cable connector. At the other end is a 19-pin connector that connects to a variety of adapters

(Figure 5-1 and Figure 5-2).

VCI cable connector

(26-pin connector)

DLC cable

(19-pin connector end)

Various vehicle adpaters

(not all supplied)

FIGURE 5-1. DLC Cable Adapter Connections

Te ch 2 Page 5-1

Page 48

Adapters

Description Function

SAE 16/19 Pin Adapter This adapter allows DLC connection to some 1994-

1995 NAO vehicles and all NAO vehicles from 1996

onward.

NAO 12/19 Pin Adapter This adapter allows ALDL connection to some 1994-

1995 NAO vehicles and all previous 1993 and below

vehicles equipped with 12-pin ALDL connectors.

TABLE 5-1. Tech 2 Adapters

RS-232 CABLE

GM Part

Numbers

02002955

02002961

The RS-232 cable (P/N 02001358) has an 8-pin RJ45 plug connector at each end (Figure 5-2). This cable

attaches to the Tech 2 RS-232 port and is used to communicate with a PC.

RS-232 cable

Detail of 8-pin RJ45 connector

Tech 2 RS-232 port

FIGURE 5-2. RS-232 Cable Connections

Page 5-2 Tech 2

Page 49

Adapters

RS-232/DB9 ADAPTER

The RJ45/BB9 adapter (P/N 02001030) has an RJ45 connector at one end and a DB9 connector at the other

(Figure 5-3). This adapter allows the connection of the Tech 2 to a PC.

RS-232 LOOPBACK ADAPTER

The loopback adapter (P/N 02001606) has an 8-pin RJ45 connector that attaches to the Tech 2 RS-232 port

(Figure 5-3). It is used to perform the Tech 2 self test.

RS-232 cable connected to Tech 2

8-Pin RJ45 connector

RS-232/DB9 adapter

FIGURE 5-3. RS-232/DB9 Adapter Connections

Te ch 2 Page 5-3

Page 50

Adapters

Page 5-4 Tech 2

Page 51

6. TROUBLESHOOTING

This section is a general troubleshooting guide for all vehicle applications of the Tech 2 scan tool. Some of

the information may differ for your particular vehicle application.

When the Tech 2 appears to be operating abnormally, refer to this section for probable causes and solutions.

The following two types of self tests are available on the Tech 2:

• Power On Self Test (POST) : checks the major functions of the Tech 2 at power-up.

• Self Tests : check the major and minor functions of the Tech 2.

If errors are detected, a Tech 2 malfunction is present which may result in vehicle misdiagnosis. For

Customer Support information, refer to the inside cover of this user's guide.

POWER ON SELF TEST (POST)

Power On Self Tests run automatically each time the power [PWR] button on the Tech 2 keypad is pressed

on.

The screen displays pass or fail results for each area tested. POST automatically

checks the following:

• MC68332 processor

• External RAM (Random Access Memory)

• Flash memory

• Display controller and display

• Sound transducer

• MC68332 RAM

Te ch 2 Page 6-1

Page 52

Troubleshooting

• Real-time clock

• Keypad controller and keypad

• Main UART (Universal Asynchronous Receiver/Transmitter)

Results of POST may include fatal errors that do not allow you to continue, or non-fatal errors that allow

you to continue without full Tech 2 operation. If normal Tech 2 functions are stopped or limited, contact

Customer Support to determine if service is required.

At completion of POST, the following audible signals indicate a pass or fail

condition:

• One beep - No problem. Your Tech 2 is operating normally.

• No beep - Sound transducer has failed. Contact Customer Support.

• Three short beeps - Tech 2 has failed POST. Contact Customer Support.

SELF TESTS

Tech 2 self tests verify that the Tech 2 is functioning normally. The self tests evaluate all critical areas of the

Tech 2 and display pass or fail messages for each subsystem tested. Self tests isolate user error from system

hardware failures. The self tests should be performed periodically to insure that the Tech 2 is operating

properly.

The Tech 2 must meet the following requirements in order to do a self test:

• Screen display must be fully readable

• Keypad must be operational

Begin the Tech 2 self-testing program by following these steps:

1. Press ENTER while viewing the Tech 2 start-up screen (Figure 6-1).

2. Select F3: Tool Options from the Tech 2 main menu (Figure 6-2).

3. Select F3: Self Test from the tool options menu (Figure 6-3).

Page 6-2 Tech 2

Page 53

FIGURE 6-1. Tech 2 Start-Up Screen

Troubleshooting

FIGURE 6-2. Tools Options Selected on Main Menu

Te ch 2 Page 6-3

Page 54

Troubleshooting

FIGURE 6-3. Self Test Selected on Tool Options Menu

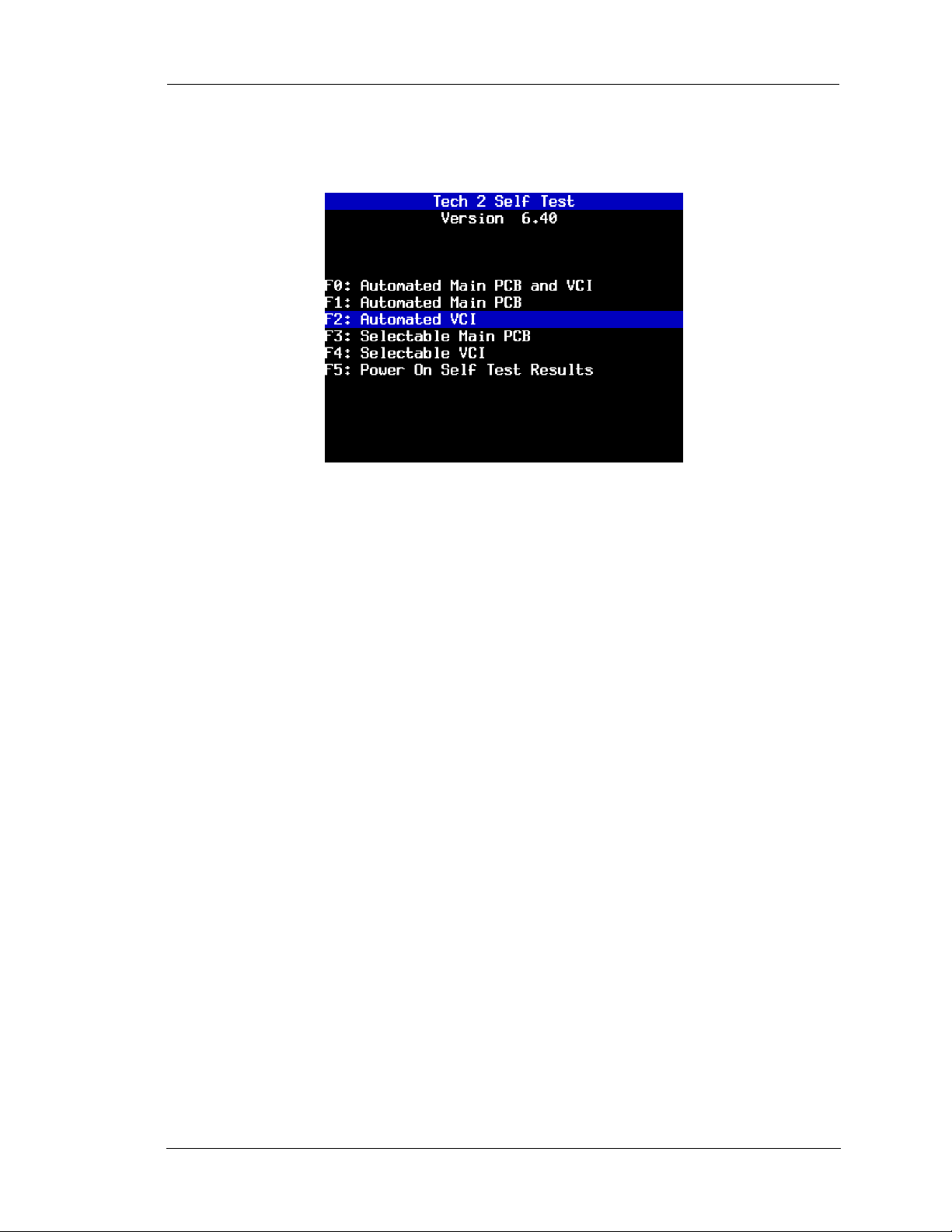

TECH 2 SELF TEST MAIN MENU

Each Tech 2 Self Test main menu selection is explained in detail on the following pages. All users have

access to all the options listed (see Figure 6-5). Read all screen instructions and connect or disconnect the

appropriate cables and loopback adapters. Screen messages display when external loopback connectors are

connected. For specific loopback connection information, refer to Figure 3-2, Figure 3-4, and Figure 6-4.

F0: Automated Main PCB and VCI Test

Selecting Automated Main PCB and VCI (Figure 6-5) is a quick way to test the performance of the main

Printed Circuit Board (main PCB—the Tech 2 main circuit board) and the Vehicle Communications

Interface (VCI). The Tech 2 displays a test-in-progress screen (Figure 6-6) while performing all the PCB and

VCI tests in sequential order.

Page 6-4 Tech 2

Page 55

Troubleshooting

Tech 2 VCI connector

DLC loopback adapter

(P/N 02002953)

FIGURE 6-4. Connection of DLC Loopback Adapter to the Tech 2 VCI Connector

FIGURE 6-5. Tech Automated Main PCB and VCI Test Selected on Tech 2

Self Test Main Menu

The Automated Main PCB portion tests the following components:

•RAM / ROM

• RS-485 loopback

• RS-232 loopback

• Keypad

• PCMCIA slot 1

*. Each of these tests requires the conenction of a loopback adapter to the Tech 2.

Te ch 2 Page 6-5

*

*

Page 56

Troubleshooting

• PCMCIA slot 2

• Display controller

• Sound transducer

• Real-time clock

Refer to Table 6 -1 and Table 6-2 for help in diagnosing problems that involve the Tech 2's PCB and VCI.

FIGURE 6-6. Automated Main PCB and VCI Test Results Screen

If the Tech 2 passes all Automated Main PCB and VCI tests, you do not need to run any more tests to verify

that the Tech 2 is working properly.

The following test results are displayed:

Total Pass 1 - indicates that Tech 2 passed test

0 - indicates a test failure

Total Failures 0 - indicates that Tech 2 passed test

1 - indicates a test failure

PCMCIA Cards Present 1 or 2 indicates how many cards present in Tech 2

Once tests are complete, select the soft keys Main Details or VCI Details (Figure 6-6) to review the results

of the main PCB or VCI tests (see Figure 6-7 and Figure 6-8).

If any failures occur, select F3: Selectable Main PCB (Figure 6-11) or F4: Selectable VCI (Figure 6-13)

from the Tech 2 Self Test main menu to further isolate the failure. Report failure information to Customer

Support.

Page 6-6 Tech 2

Page 57

FIGURE 6-7. Main Details Selection

Troubleshooting

FIGURE 6-8. VCI Details Selection

Te ch 2 Page 6-7

Page 58

Troubleshooting

Test Results Solution

RAM/ROM 0-Pass

1-ROM read fail

2-RAM read fail

3-RAM write and read do not compare

RS-485 loopback Pass

Fail-Loopback may not be connected

RS-232 loopback Pass

Fail-Loopback may not be connected

Keypad Test successful

Keypad failed

Exiting test before all keys are pressed

results in a failed keypad test

PCMCIA (tests

both card slots)

Display controller

(contrast and

characters)

Sound transducer User determines if sound transducer is

Real-time clock Time is displayed correctly.

Card detected

Card not present

Fail

User determines if display is correct. If the display shows a noticeable failure during

working.

Invalid values are displayed for date,

year, hour, minute, or second.

Record type of failure.

Cycle Tech 2 power (press [PWR]) and retest.

If problem persists, contact Customer Support.

Check loopback connection.

If problem persists, contact Customer Support.

Check loopback connection.

If problem persists, contact Customer Support.

Cycle Tech 2 power and retest.

If problem persists, contact Customer Support.

Check that card is inserted properly.

Cycle Tech 2 power and retest.

If problem persists, contact Customer Support.

tests, contact Customer Support.

If no sound is emitted by repeatedly selecting

Automated Test or Sound On, contact Customer

Support.

Reset clock.

Cycle Tech 2 power and retest.

If time is not retained, contact Customer Support.

TABLE 6-1. PCB Diagnostic Chart

Test Results Solution

MUX

(Multiplexer)

VCI adapter ID

(performed only

during selectable

VCI test)

VCI ADC

(Analog to digital

converter)

Cross point Pull up - pass/fail

MUX A: S5 & S14

pass/fail

MUX B: S1 & S3

pass/fail

Recognized adapter

Cannot identify adapter

Channel A - pass/fail

Channel B - pass/fail

TPU5, TPU1, and TPU0 - pass/fail

(results from selectable VCI test)

TABLE 6-2. VCI Module Diagnostic Chart

If MUX A or B fails, cycle Tech 2 power and

retest.

If problem persists, contact Customer Support.

If adapter fails, use a different adapter to make

sure that the VCI correctly identifies the adapters.

Cycle Tech 2 power and retest failed adapter. If

adapter fails second test, contact Customer

Support.

If channel A or B fails, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

If a failure occurs, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

Page 6-8 Tech 2

Page 59

Te st Results Solution

Troubleshooting

SIPO (Serial In

Parallel Out)

DLC

(Data Link

Connector)

CCD

(Chrysler Collision

Detection)

GND FET

(Ground Field

Effect Transistor)

VCI HBCC

(Hosted Bus

Control Chip)

VCI DUART

(Dual Universal

Asynchronous

Receiver

Transmitter)

Pass/fail for each area tested If a failure occurs, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

DLC1 - DLC2

pass/fail count

DLC2 - DLC1

pass/fail count

CCD - pass/fail

CCD - loopback not connected

GND FET - pass/fail Check loopback adapter to make sure it is

HBCC - pass/fail If HBCC chip fails, cycle Tech 2 and retest.

Channel A - pass/fail

Channel B - pass/fail

If a failure occurs, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

Connect loopback and retest if loopback not

connected.

If test fails, disregard results. Test is not for GM

vehicles (other than Saab) at this time.

connected, cycle Tech 2 retest.

If problem persists, contact Customer Support.

If problem persists, contact Customer Support.

If channel A or B fails, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

VCI I/O 1 - I/O 16

Tes t

VCI loopback Pass/fail message for each I/O loopback

VCI short L & M Open I/O 7 - pass/fail

VCI J1708 Internal transceiver -

Pass/fail messages displayed for each of

the I/O lines (results from selectable

VCI test).

test.

Open I/O 9 - pass/fail

Hi I/O 7 - pass/fail

Hi I/O 9 - pass/fail

Lo I/O 7 - pass/fail

Lo I/O 9 - pass/fail

pass/fail

Differential - pass/fail

Differential - pass/fail (results from

selectable VCI test)

TABLE 6-2. VCI Module Diagnostic Chart (Continued)

If test fails, was loopback installed?

Once an error has been detected on one of the I/O

lines, you can test the specific line by selecting F3

or F4 tests.

If the test fails continuously or intermittently,

contact Customer Support.

For any failure, make sure the loopback is

connected. Use F:1 Check ID to verify that the

loopback is found.

Cycle Tech 2 and retest. If problem persists,

contact Customer Support.

For any failure, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

For any failure, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

Te ch 2 Page 6-9

Page 60

Troubleshooting

Test Results Solution

VCI TPU (Time

Processor Unit)

VCI level shifters MUX A 2.5 V Hi - pass/fail

TPU0 - pass/fail

TPU1 - pass/fail

TPU5 - pass/fail

TPU12 & TPU15 - pass/fail (or not

tested if no loopback)

TPU13 & TPU14 - pass/fail (or not

tested if no loopback)

MUX A 2.5 V Lo - pass/fail

MUX A 5.0 V Hi - pass/fail

MUX A 5.0 V Lo - pass/fail (results

from selectable VCI test)

For any failure, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

For any failure, cycle Tech 2 and retest.

If problem persists, contact Customer Support.

TABLE 6-2. VCI Module Diagnostic Chart (Continued)

F1: Automated Main PCB Test

This test works the same as the Automated Main PCB and VCI test, except the VCI portion of the test is not

included (Figure 6-9).

FIGURE 6-9. Automated Main PCB Test Selected on Tech 2 Self Test Main Menu

Page 6-10 Tech 2

Page 61

Troubleshooting

F2: Automated VCI Test

This test works the same as the Automated Main PCB and VCI test, except the PCB portion of the test is not

included (Figure 6-10).

FIGURE 6-10. Automated VCI Test Selected on Tech 2 Self Test Main Menu

Te ch 2 Page 6-11

Page 62

Troubleshooting

F3: Selectable Main PCB Test

Select F3: Selectable Main PCB (Figure 6-11) after a fail message has been displayed during the

Automated Main PCB and VCI or Automated Main PCB tests. When you select F3: Selectable Main PCB,

a screen like the one shown in Figure 6-12 is displayed. You may then select individual tests for failed

components. For specific information on failed components, refer to the Main Printed Circuit Board (PCB)

Diagnostic Chart (Table 6-1, PCB Diagnostic Chart, on page 6-8).

FIGURE 6-11. Selectable Main PCB Test Selected on Tech 2 Self Test Main Menu

FIGURE 6-12. Selectable Main PCB Self Test Screen

Page 6-12 Tech 2

Page 63

Troubleshooting

F4: Selectable VCI Test

Select F4: Selectable VCI (Figure 6-13) after a fail message displays during the Automated Main PCB and

VCI or Automated VCI tests. When you select F4: Selectable VCI, a screen like the one shown in Figure 6-

14 is displayed. You may select individual tests for failed components from this screen. If you select More

Tests, a screen like the one shown in Figure 6-15 is displayed. If you then select Previous Menu, the screen

shown in Figure 6-14 returns. For specific information on failed components, refer to the Vehicle

Communications Interface (VCI) Module Diagnostic Chart (Table 6 -2, VCI Module Diagnostic Chart, on

page 6-8).

FIGURE 6-13. Selectable VCI Test Selected on Tech 2 Self Test Main Menu

FIGURE 6-14. First Selectable VCI Self Test Screen

Te ch 2 Page 6-13

Page 64

Troubleshooting

FIGURE 6-15. Second Selectable VCI Self Test Screen

Page 6-14 Tech 2

Page 65

Troubleshooting

F5: Power On Self Test Results

Select F5: Power On Self Test Results (Figure 6-16) after a fail message displays during the Power On

Self Test (POST). Specific information on the failure displays on the screen. Select F0, F1, F2, F3, or F4 to

further isolate the specific fault.

FIGURE 6-16. Power On Self Test Results Selected on Tech 2 Self Test Main Menu

Te ch 2 Page 6-15

Page 66

Troubleshooting

NO POWER TO TECH 2 TROUBLESHOOTING TABLES

Use the following tables to diagnose, isolate, and correct power source problems that may cause a No Power

condition to your Tech 2 scan tool.

To help determine the power supply source, see Chapter 4.

Power Source: DLC Cable

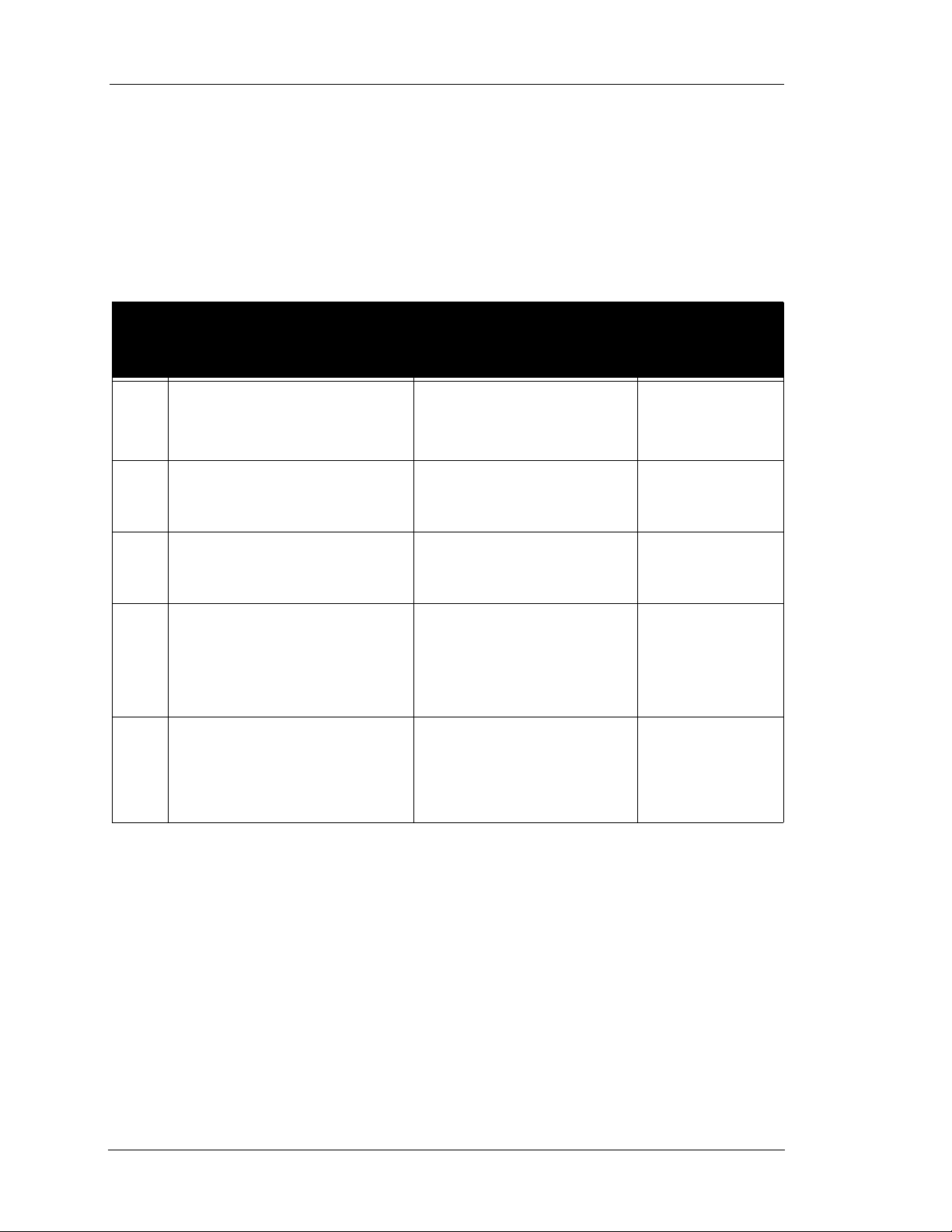

Step Action Ye s No

1 Does vehicle support power through

DLC cable connection exclusively? (If

you are not sure, consult your service

manual.)

2 • Using a digital multi-meter (DMM),

verify vehicle battery voltage.

Is battery fully charged?

3 • Verify connection at vehicle DLC

connector for loose or damaged pin(s).

Did you find a problem?

4 • Disconnect DLC cable from vehicle.

• Power on Tech 2 using alternate power

source at DLC cable power jack

connection.

Did your Tech 2 power on?

5 • Remove DLC cable from Tech 2 and

attach alternate power supply at VCI

power jack connection located at the

bottom of Tech 2.

Does Tech 2 power on?

TABLE 6-3. DLC Cable No Power Troubleshooting Table

Go to Step 2. Use alternate power.

Go to Step 3. Charge battery.

Repair connector.

(Consult vehicle service manual.)

Problem with vehicle.

(Consult vehicle service manual.)

Replace DLC cable. Problem with Tech 2.

Go to Step 4.

Go to Step 5.

Contact Customer

Support.

Page 6-16 Tech 2

Page 67

Troubleshooting

Power Source: Cigarette Lighter Power Cable

Step Action Ye s No

1 • Unplug cigarette lighter power cable

from DLC cable.

• Using a digital multi-meter (DMM),

verify voltage output at cigarette

lighter power cable power jack.

Do you have battery voltage output?

2 • Check fuse in cigarette lighter power

cable (refer to Figure 6-17).

Does fuse need replacing?

3 • Remove DLC cable from Tech 2.

• Plug in cigarette lighter power jack to

the VCI power jack connector located

at bottom of Tech 2.

Does the Tech 2 power on?

4 • Using a DMM, verify voltage output

at battery.

Do you have battery voltage output?

5 • Disconnect cigarette lighter power

cable from vehicle and verify voltage

output at vehicle cigarette lighter

socket.

Do you have battery voltage output?

Go to Step 3. Go to Step 2.

Replace fuse. Go to step 3.

Replace DLC cable. Problem with Tech 2.

Contact Customer

Support.

Go to Step 5. Charge battery.

Replace cigarette lighter power

cable.

Problem with vehicle.

Consult vehicle

service manual.

TABLE 6-4. Cigarette Lighter Power Cable No Power Troubleshooting Table

Te ch 2 Page 6-17

Page 68

Troubleshooting

Power Source: Battery Power Cable

Step Action Ye s No

1 • Unplug battery power cable power

jack from DLC cable.

• Using a digital multi-meter (DMM),

verify voltage output at battery power

cable power jack.

Do you have battery voltage output?

2 • Check fuse(s) in battery power cable

(refer to Figure 6-18).

Does fuse(s) need replacing?

3 • Remove DLC cable from Tech 2.

• Plug in battery power cable power

jack to the VCI power jack connector

located at bottom of Tech 2.

Does the Tech 2 power on?

4 • Using a DMM, verify voltage output

at battery.

Do you have battery voltage output?

TABLE 6-5. Battery Power Cable No Power Troubleshooting Table

Go to Step 3. Go to Step 2.

Replace fuse(s). Go to Step 3.

Replace DLC cable. Problem with Tech 2.

Contact Customer

Support.

Replace battery power cable. Charge battery.

Power Source: Battery Power Cable

Step Action Ye s No

1 • Unplug NAO (or Universal) power

supply power jack from DLC cable.

• Using a digital multi-meter (DMM),

verify voltage output at power jack.

Do you have battery voltage output?

2 • Remove DLC cable from Tech 2.

• Plug in NAO (or Universal) power

supply power jack to the VCI power

jack connector located at bottom of

Tech 2.

Does the Tech 2 power on?

TABLE 6-6. NAO or Universal No Power Troubleshooting Table

Go to Step 2. Replace NAO or

Universal power

supply.

Replace DLC cable. Problem with Tech 2.

Contact Customer

Support.

Page 6-18 Tech 2

Page 69

Troubleshooting

CIGARETTE LIGHTER POWER CABLE 3-AMP FUSE REPLACEMENT

A three-amp removable fuse is located in the cigarette lighter power cable (P/N 02002954) connector.

When required, check or replace the fuse by performing the following steps:

1. Ensure the cigarette lighter power cable is not connected to the vehicle or Tech 2.

2. Unscrew the fuse retainer cap and remove the 3-amp fuse.

3. Inspect the fuse for damage and replace it with an identical 3-amp fuse if required.

4. Verify by connecting the cigarette lighter power cable to the Tech 2 and vehicle.

Cigarette lighter power cable

3-amp fuse

Fuse retainer cap

FIGURE 6-17. Cigarette Lighter Power Cable 3-Amp Fuse Replacement

Te ch 2 Page 6-19

Page 70

Troubleshooting

BATTERY POWER CABLE 3-AMP FUSE REPLACEMENT

Two three-amp fuses are located in the battery power cable (P/N 02002956) three-amp fuse box.

When required, check or replace the fuse(s) by following the steps below.

CAUTION!

CAUTION

1. Ensure the battery power cable is not connected to the vehicle battery or Tech 2.

2. Use a standard fuse puller to remove the fuse(s) from the fuse box.

3. Inspect the fuse(s) for damage and replace with identical 3-amp fuse(s) if required.

4. Verify by connecting the battery power cable to the Tech 2 and vehicle battery.

3-amp fuse

To help avoid personal injury by electric shock, make sure the battery

power cable is not connected to the vehicle’s battery before removing the

fuse(s).

Battery power cable

3-amp fuse box

Battery clamps

FIGURE 6-18. Battery Power Cable 3-Amp Fuse Replacement

Page 6-20 Tech 2

Page 71

TECHNICIAN NOTES

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

Troubleshooting

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

--------------------------------------------------------------------------------

Te ch 2 Page 6-21

Page 72

Troubleshooting

Page 6-22 Tech 2

Page 73

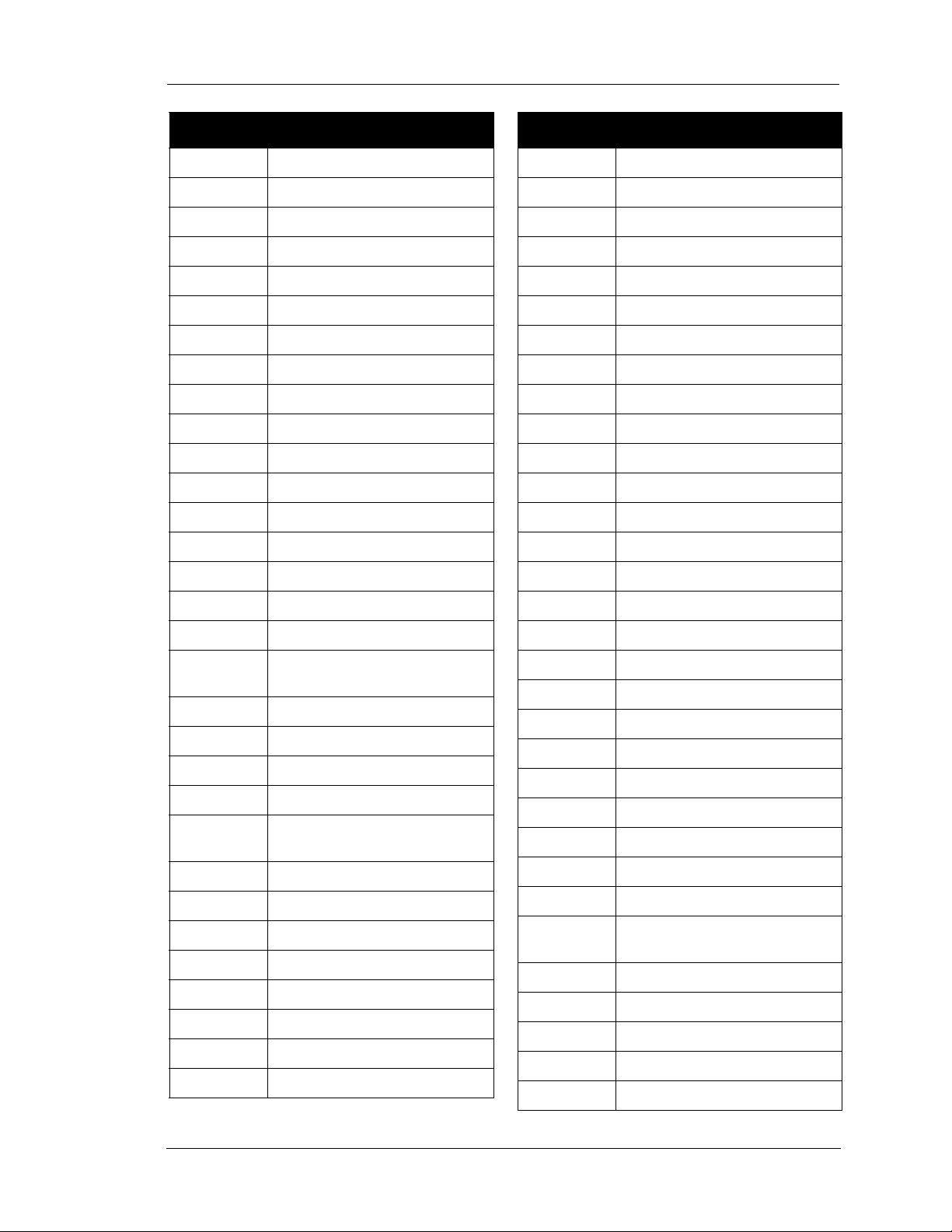

7. ABBREVIATIONS

TER M DEFINITION

3GR third gear

4GR fourth gear

4WAL four-wheel antilock

4WD four-wheel drive

AAT ambient air temperature

ABS antilock brake system

A/C air conditioning

accel acceleration

accum accumulator

accy accessory

ACL air cleaner

ACM air conditioning module

act actual

actv activate

A/D analog to digital

AD accommodated device

adapt adaptive

adapts adapters

ADG accommodated device gateway

adj adjust

TERM DEFINITION

ADL automatic door lock

ADS auxiliary discriminating sensor

A/F air/fuel ratio

aft after

ahrs amp hours

AIR secondary air injection

ALC automatic lamp control

automatic level control

ALDL assembly line diagnostic link

ALM automatic level module

AM amplitude modulation

amp amplifier

amps amperages

APP accelerator pedal position

Apr April

ARS adaptive receptive system

asm assembly

ASR acceleration slip regulation

A/T automatic transmission

ATC active transfer case

automatic transfer case

Te ch 2 7-1

Page 74

Abbreviations

TER M DEFINITION

ATF automatic transmission fluid

Aug August

auto automatic

aux auxiliary

avg average

AWD all-wheel drive

B+ battery positive voltage

BARO barometric pressure

batt battery

BBV brake booster vacuum

BCM body control module

BFC body function controller

blts belts

BLW brake lining wear

bn bank

TER M DEFINITION

cm centimeter

cmd command

cmmd commanded

CMP camshaft position

CNG compressed natural gas

CO carbon monoxide

CO2 carbon dioxide

combo combination

comm communication

compl complete(d)

cond condition

config configuration

const constant

COP computer operating properly

CPP clutch pedal position

BPCM battery pack control module

BPMV brake pressure modulator valve

BTCM brake torque control module

BTSI brake transmission shift interlock

cal calibration

calc calculated

CAN controller area network

CASE crankshaft angle sense error

cass cassette

CC climate control

CCM central control module

CCW counter clockwise

CD compact disc

CDX compact disc changer

CKP crankshaft position

CKT circuit

CL closed loop

CPS childseat positioning sensor

CTP closed throttle position

ctrl control

ctsy courtesy

CVRSS continuously variable road sensing

suspension

CVRTD continuously variable real time

damping

cyl cylinder

DAB delayed accessory bus

dB decibels

dBm decibel meter

DC duty cycle

DCM door control module

DDM driver door module

DDS driver door switch

Dec December

dec decrement

7-2 Tech 2

Page 75

Abbreviations

TERM DEFINITION

decel decelerate

def defrost

defog defogger

deg degrees

deg C degrees Celsius

del delivered

DERM diagnostic energy reserve module

des desired

desc description

DI distributor ignition

diag diagnostic

DIC driver information center

diff differential

dig digit

DIM dash integration module

dis disable

discon disconnect

discrim discriminate

disp display

DLC data link connector

DMCM drive motor control module

DMM digital multimeter

DNR Dolby noise reduction

DOHC dual overhead cam

dol Dolby

dr door

DRL daytime running lights

DRP dynamic rear proportion

drvr driver

DSM driver seat module

DSP digital signal process

DTC diagnostic trouble code

TERM DEFINITION

dwn down

E&C entertainment and comfort

EBCM electronic brake control module

EBM electronic brake module

EBTCM electronic brake and traction control

module

EC engine control

ECC electronic climate control

ECL engine coolant level

ECM electronic control module

engine control module

econ economy

ECT engine coolant temperature

ECU electronic control unit

EEPROM electrically erasable programmable

read-only memory

EGR exhaust gas recirculation

EHCU electric hydraulic control unit

EI electronic ignition

elec electric

EMB electromagnetic brake

enab enabled

eng engine