Page 1

GLOBAL OBD II WITH TOOLPAK

Printed in USA 3/99

Manual P/N 02002745

Page 2

GLOBAL OBD II WITH TOOLPAK

GLOBAL OBD II

WITH TOOLPAK

APPLICATION

Operator's Manual

Diagnostics for Vehicle Electronics

Page 3

GLOBAL OBD II WITH TOOLPAK

Page 4

GLOBAL OBD II WITH TOOLPAK

GLOBAL OBD II

WITH TOOLPAK

APPLICATION

Operator's Manual

Page 5

GLOBAL OBD II WITH TOOLPAK

SOME THINGS YOU SHOULD KNOW

!

CAUTION: EXHAUST GAS

When performing any checks with the engine running

in an enclosed space such as a garage, be sure there is proper

ventilation. Never inhale exhaust gases; they contain carbon

monoxide, a colorless, odorless extremely dangerous gas which

can cause unconsciousness or death.

CAUTION:

!

To help avoid personal injury always set the parking brake

securely and block the drive wheels before performing any

checks or repairs on the vehicle.

DISCLAIMER

The Mastertech, Tech 1A and Tech 1 are designed for use by trained service

personnel only. They have been developed for the sole purpose of diagnosing and repairing automotive electronic systems. Every attempt has been

made to provide complete and accurate technical information based on

factory service information available at the time of publication. However, the

right is reserved to make changes at any time without notice.

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Copyright © 1999 Vetronix Corporation Printed in USA 3/99

TECH 1®, TECH 1A®, and Mastertech

are registered trademarks of Vetronix Corporation

®

Manual P/N 02002745

Page 6

GLOBAL OBD II WITH TOOLPAK

INTRODUCTION

This document provides a basic description of the Global OBD II Software.

This software is contained on the Application Cartridge and performs the

basic functions required by the California Air Resource Board (CARB) as

part of the On-Board Diagnostics Phase II (OBD II).

OBD II IMPLEMENTATION

The OBD II system was implemented on some production vehicles in early

1994, even though automobile manufacturers were required to meet the

OBD II regulation for all vehicles sold in California by 1996. Because of their

early adaptation, 1994-95 vehicles equipped with the OBD II system (pre-

1996) were given exemptions by the California Air Resources Board. These

exemptions gave automobile manufacturers the opportunity to implement

certain OBD II modes for 1994-95.

When performing diagnostics on 1994-95 vehicles and communication

problems occur when using the Global OBD II Software, the communication

problem may be a vehicle software problem. If communication problems

occur, refer to the service manual or Technical Service Bulletin information

published by the manufacturer for the vehicle being tested. Communication

problems between the tester and vehicle will not cause incorrect electronic

powertrain operation.

i

Page 7

GLOBAL OBD II WITH TOOLPAK

GLOBAL OBD II WITH TOOLPAK SOFTWARE FUNCTIONS

The Global OBD II with Toolpak Software performs the following functions:

• Automatic determination of the communication protocol.

• Display of the Readiness Tests status.

• Display of the vehicle’s Current Data parameters.

• Display of Freeze Frame Data saved by the controller.

• Display of Diagnostic Trouble Codes saved by the controller.

• Clearing Emission-Related Diagnostic Information (DTCs, Freeze Data,

and Readiness Test Status).

• Display of O2 Sensor Test Results.

• Display of Pending Diagnostic Trouble Codes (DTCs) saved by the

controller.

• Display of test results for non-continuously monitored systems.

• Display of Vehicle Identification Number (VIN) stored by the vehicle

controller.

• Display of software calibration identification number contained within the

vehicle ECU.

• Display of software verification number within the vehicle ECU software.

• Enable conditions required to conduct an evaporation system leak test.

• Provides useful information to help diagnose and troubleshoot OBD II

compliant vehicles.

ii

Page 8

GLOBAL OBD II WITH TOOLPAK

OBD II SYSTEM AND VEHICLE INFORMATION

MONITOR OPERATION

The OBD II system is capable of identifying the likely area of a malfunction

within the electronic powertrain control system. Observe the following

before beginning diagnostic service:

• MIL OPERATION. When excessive tailpipe emissions or powertrain

component failure are detected by the OBD II

Indicator Lamp (MIL) will illuminate.

• LOW FUEL TANK LEVEL. Automobile manufacturers may disable OBD

II monitors which can be affected by running the vehicle out of fuel

(example: a monitor may become disabled when fuel tank volume is

below 15% of maximum fuel tank capacity).

• ALTITUDE. Automobile manufacturers may disable OBD II monitors

which can be affected by altitude (example: a monitor may become

disabled when vehicle is operated above 8,000 feet elevation).

• AMBIENT TEMPERATURE. Automobile manufacturers may disable

OBD II monitors which can be affected by ambient temperature (example: a monitor may become disabled when a vehicle is started below

20°F ambient).

system, the Malfunction

• POWER TAKE-OFF UNIT. Automobile manufacturers may disable

OBD II monitors which can be affected by power take-off unit operation

(example: a monitor may become disabled when a vehicle power takeoff is engaged or active).

All of the above are part of the California Air Resources Board

OBD II regulation and are options available to the automobile manufacturer

for vehicle Powertrain Control Module (PCM) development. In the case of

some monitors, per the above, a manufacturer may have determined that

a monitor is unreliable or not complete when certain conditions exist,

therefore not enabling proper operation.

iii

Page 9

GLOBAL OBD II WITH TOOLPAK

THIS PAGE INTENTIONALLY LEFT BLANK

Page 10

GLOBAL OBD II WITH TOOLPAK

TABLE OF CONTENTS

SECTION PAGE

1. TEST MODES AVAILABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. HARDWARE REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4. TEST MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

MODE F0: DATA LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

SUBMODE F0: DISPLAY DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

DATA LIST MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

SUBMODE F1: DATA SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

F0: ALL PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

F1: USER LIST PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

MULTIPLE ECUS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

MODE F1: READINESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

MODE F2: DTCS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

S

SUBMODE F0: READ DTC

SUBMODE F1: FREEZE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

SUBMODE F2: CLEAR INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

SUBMODE F3: PENDING DTC

MODE F3: SNAPSHOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

SUBMODE F4: TRIGGER POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

TRIGGER POINT SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

SUBMODE F3: SNAPSHOT REPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

SNAPSHOT DATA CAPTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

SNAPSHOT REPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

MODE F4: OBD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

SUBMODE F0: EVAP LEAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

MODE F5: SYSTEM TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

SUBMODE F0: OXYGEN SENSOR RESULTS . . . . . . . . . . . . . . . . . . . . . 4-24

SUBMODE F1: OTHER RESULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

MODE F8: INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

SUBMODE F0: VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

SUBMODE F1: S/W CALIB. ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

SUBMODE F2: S/W VERIF. ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Table of Contents continues on the following page.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

S

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Page 11

GLOBAL OBD II WITH TOOLPAK

TABLE OF CONTENTS

continued

SECTION PAGE

MODE F9: OBD II TOOLPAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

SUBMODE F0: DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

SUBMODE F0: PREP VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

SUBMODE F1: PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

SUBMODE F9: REPAIR VERIFICATION . . . . . . . . . . . . . . . . . . . . . 4-40

SUBMODE F1: PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

SUBMODE F0: DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

SUBMODE F1: RANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

SUBMODE F2: DTC LIBRARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

SUBMODE F3: READINESS INFORMATION . . . . . . . . . . . . . . . . . . . . . . 4-47

SUBMODE F4: OXYGEN SENSOR INFORMATION . . . . . . . . . . . . . . . . 4-48

SUBMODE F0: LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

SUBMODE F1: TYPE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

SUBMODE F2: MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

SUBMODE F0: INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

SUBMODE F1: TORQUE SPECIFICATION . . . . . . . . . . . . . . 4-54

SUBMODE F2: REMOVE AND REPLACE . . . . . . . . . . . . . . . 4-55

S

5.0 DISPLAYING DATA FOR MULTIPLE ECU

6.0 DIAGNOSTIC DATA PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

7.0 APPENDICES

APPENDIX A: UNDERSTANDING OBD II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

APPENDIX B: OBD II OXYGEN SENSOR LOCATION INFORMATION . . . . . . . . . . . B-1

APPENDIX C: DEFINITION OF CODE TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

APPENDIX D: IF YOU'RE HAVING A PROBLEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

APPENDIX E: GLOSSARY OF TERMS, ACRONYMS . . . . . . . . . . . . . . . . . . . . . . . . . E-1

AND ABBREVIATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Copyright © 1999 Vetronix Corporation Printed in USA 3/99

TECH 1®, TECH 1A®, and Mastertech

are registered trademarks of Vetronix Corporation

®

Manual P/N 02002745

Page 12

GLOBAL OBD II WITH TOOLPAK

The following section defines available test modes, hardware requirements,

and operating instructions for all OBD II compliant vehicles. All OBD II

functions except OBD II Toolpak require communication with the vehicle

ECU(s). Once the necessary hardware has been installed, communication

between the tester and vehicle ECU(s) can be initialized.

1.0 TEST MODES AVAILABLE

The following test modes are available when testing vehicles that are OBD

II compliant.

F0: Datalist

F0: Display Data

F1: Data Setup

F1: Readiness

F2: DTCs

F0: Read DTCs

F1: Freeze Data

F2: Clear Info

F3: Pending DTCs

F3: Snapshot

F4: OBD Controls

F0: Evap Leak

F5: System Tests

F0: O2S Results

F1: Other Results

F8: Information

F0: VIN

F1: S/W Calibration ID

F2: S/W Verification ID

F9: OBD II Toolpak

✳

✳

✳

NOTE: Not all models support OBD Controls or Information

test modes. The tester will automatically determine whether

the vehicle under test supports the test mode when the mode

is selected by the user.

1-1

Page 13

GLOBAL OBD II WITH TOOLPAK

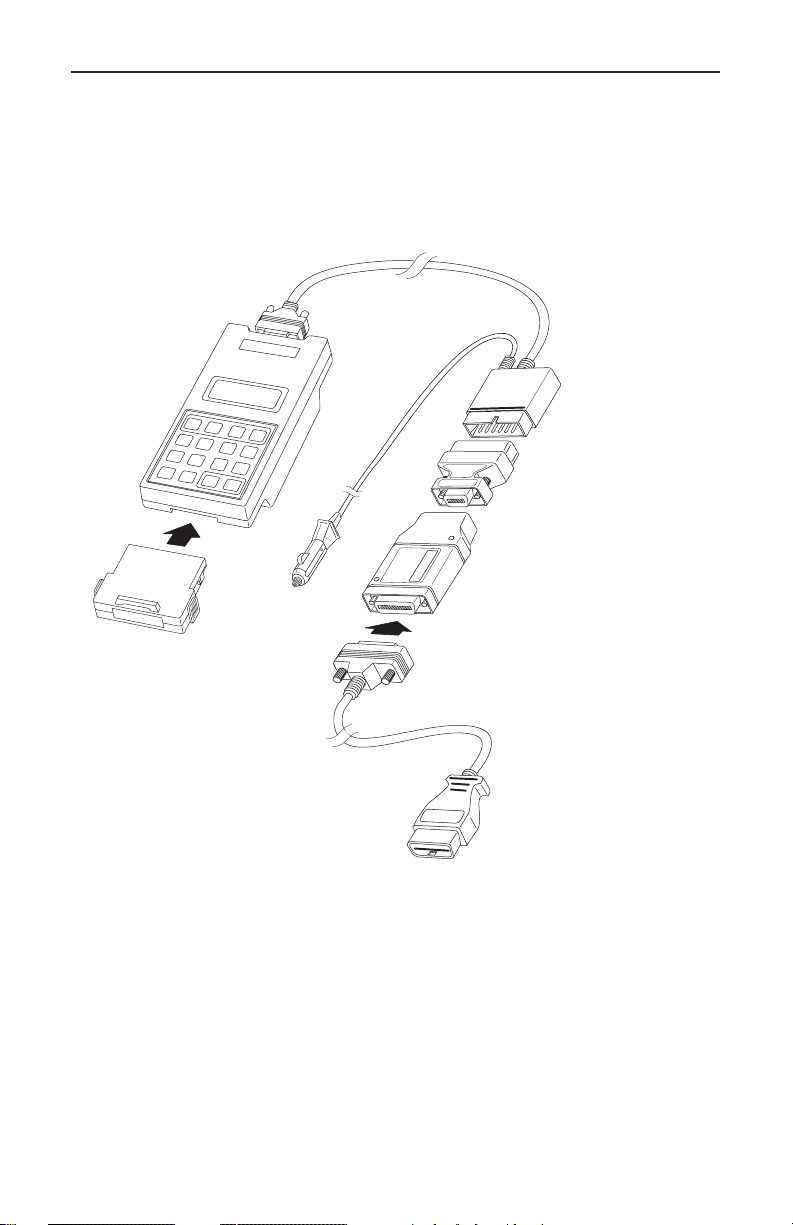

MASTERTECH

SETUP

mastertech

MASTERTECH

TESTER

Y

E

S

N

O

E

N

T

E

R

F

1

F

2

H

E

L

RS232

V

etro

DATA LINK

P

R

C

V

F

7

S

E

N

D

7

E

X

IT

O

F

F

n

ix

I/P

123

F

4

F

5

4

56

F

8

89

F

0

O

N

0#

F

3

F

6

F

9

APPLICATION

CARTRIDGE

DLC

CABLE

1-2

16/14 PIN

OBD II ADAPTER (TYPE 3) CABLE

Page 14

GLOBAL OBD II WITH TOOLPAK

2.0 HARDWARE REQUIRED

In order to be fully functional, the Global OBD II with Toolpak Application

cartridge requires that special OBD II Interface Circuitry be used with the

Mastertech and Tech 1/1A testers. This circuitry can be installed in the

following configurations:

Mastertech

The following procedure describes how to setup the Mastertech tester to test

OBD II compliant vehicles.

SETUP PROCEDURE

1. Make sure the tester is OFF. Insert the Global OBD II with Toolpak

application cartridge into the cartridge slot at the top of the OBD II

compliant Mastertech.

2. Be sure the vehicle ignition switch is off.

3. Remove any adapters installed on the Data Link Connector (DLC)

cable.

4. Connect the DLC cable to the tester and tighten the screws.

5. Connect the 16/14 Pin OBD II Adapter Cable to the DLC cable.

6. Connect the OBD II Adapter Cable to the vehicle DLC.

7. Turn the tester ON. Power and ground are provided through the DLC

connector, so connecting the 12V power cable to the vehicle is not

required.

8. Turn the vehicle ignition switch ON to begin diagnostics.

9. Refer to this manual and the application cartridge operator's manual for

software operating instructions.

2-1

Page 15

GLOBAL OBD II WITH TOOLPAK

TECH 1A

SETUP

OBD II Interface Cartridge

(P/N 02002178)

TECH 1A

Application

Cartridge

tech 1A

↓

YES

N

O

↓

↓

0

F

0

4

F

4

8

9

F

8

F

9

↓

1

F

2

1

3

F

2

5

F

3

F

5

6

F

7

6

F

7

E

X

IT

ENTER

DLC Cable

16/14 Pin OBD II

Adapter Cable

(P/N 02001969)

2-2

Page 16

GLOBAL OBD II WITH TOOLPAK

TECH 1A

The following procedure describes how to setup the TECH 1A tester to test

OBD II compliant vehicles.

SETUP PROCEDURE

1. Insert the OBD II Interface Cartridge into the Auxiliary cartridge slot at

the top, rear of the tester.

2. Insert the Global OBD II with Toolpak application cartridge into the

Master cartridge slot at the bottom, rear of the tester.

3. Be sure the vehicle ignition switch is off.

4. Remove any adapters installed on the Data Link Connector (DLC)

cable.

5. Connect the DLC cable to the tester and tighten the screws.

6. Connect the 16/14 Pin OBD II Adapter Cable to the DLC cable.

7. Connect the OBD II Adapter Cable to the vehicle DLC.

8. Power and ground are provided through the DLC connector, so connecting the 12V power cable to the vehicle is not required.

9. Turn the vehicle ignition switch ON to begin diagnostics.

10. Refer to this manual and the application cartridge operator's manual for

software operating instructions.

2-3

Page 17

GLOBAL OBD II WITH TOOLPAK

TECH 1

SETUP

tech 1

TECH 1

YES

NO

↓

↓

1

2

F

1

3

F

2

F

3

6

F

5

7

F

6

F

7

EXIT

ENTER

DC

Power

Cable

8

Application

Cartridge

0

F

0

4

5

F

4

9

F

8

F

9

DLC Cable

T

EC

H

1

A

U

S

E

W

ITH

D

O

N

O

T

V

I

M

A

D

A

P

T

E

R

C

H

1

1

4

/1

2

P

I

N

TECH 1 14/12 Pin

T

E

VIM Adapter

(P/N 02001198)

V

E

H

I

C

M

L

E

O

D

I

N

U

T

L

E

E

R

F

A

C

E

TECH 1 OBD II

Vehicle Interface

Module (VIM)

(P/N 02001808)

VIM 16/24 Pin

Adapter Cable

(P/N 02001744)

2-4

Page 18

GLOBAL OBD II WITH TOOLPAK

TECH 1

The following procedure describes how to setup the TECH 1 tester to test

OBD II compliant vehicles.

SETUP PROCEDURE

1. Insert the Global OBD II with OBD II Toolpak application cartridge into

the Master cartridge slot at the bottom, rear of the tester.

2. Be sure the vehicle ignition switch is off.

3. Remove any adapters installed on the Data Link Connector (DLC)

cable.

4. Connect the DLC cable to the tester and tighten the screws.

5. Connect the TECH 1 14/12 Pin VIM Adapter to the DLC cable.

6. Connect the TECH 1 OBD II Vehicle Interface Module (VIM) to the

TECH 1 14/12 Pin VIM Adapter.

7. Connect the 16/24 Pin OBD II Adapter Cable to the VIM.

8. Connect the OBD II Adapter Cable to the vehicle DLC.

9. Connect the 12V power cable to the vehicle cigarette lighter.

10. Turn the vehicle ignition switch ON to begin diagnostics.

11. Refer to this manual and the application cartridge operator's manual for

software operating instructions.

2-5

Page 19

GLOBAL OBD II WITH TOOLPAK

PRINTING CAPABILITIES

The Global OBD II with Toolpak software supports printing data via a TECH

1 printer, VP411 printer, or other compatible serial printer, connected to the

tester. If you are using a TECH 1 tester, refer to the RS232 Operator's

Manual for setup and printing instructions. If you are using a TECH 1A or

MASTERTECH tester, refer to the tester Operator's Manual for setup and

printing instructions.

Two types of printing are supported by the OBD II software:

• Pressing the • key in a DATA DISPLAY mode (e.g., DATA

READINESS TEST) causes the tester to print a list of data appropriate

LIST or

to

the mode ( a list of diagnostic data parameters or Readiness Test Status ).

• The tester can be setup to print an image of the tester’s screen (referred

to as SCREEN PRINT).

For information on the VP411 serial printer, contact your sales representative.

2-6

Page 20

GLOBAL OBD II WITH TOOLPAK

3.0 GETTING STARTED

POWERING THE MASTERTECH, TECH 1A OR TECH 1

The tester must be provided with an external power source (e.g. vehicle

power or an AC/DC power supply). OBD II compliant vehicles provide power

at the Data Link Connector (DLC), so when using a MASTERTECH or

TECH 1A, the tester only needs to be connected to the vehicle DLC. With

the TECH 1, you must connect the DC Power Cable to the vehicle cigarette

lighter or to an AC/DC power supply.

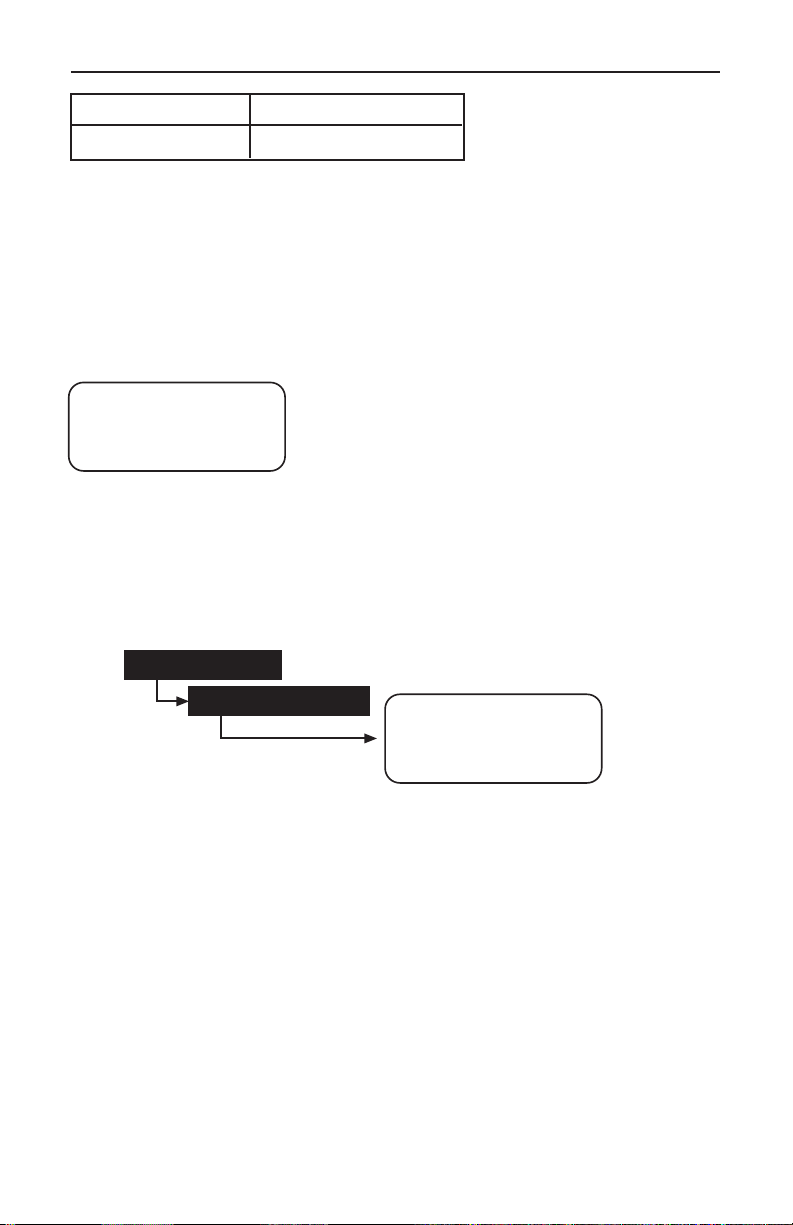

ESTABLISHING COMMUNICATION

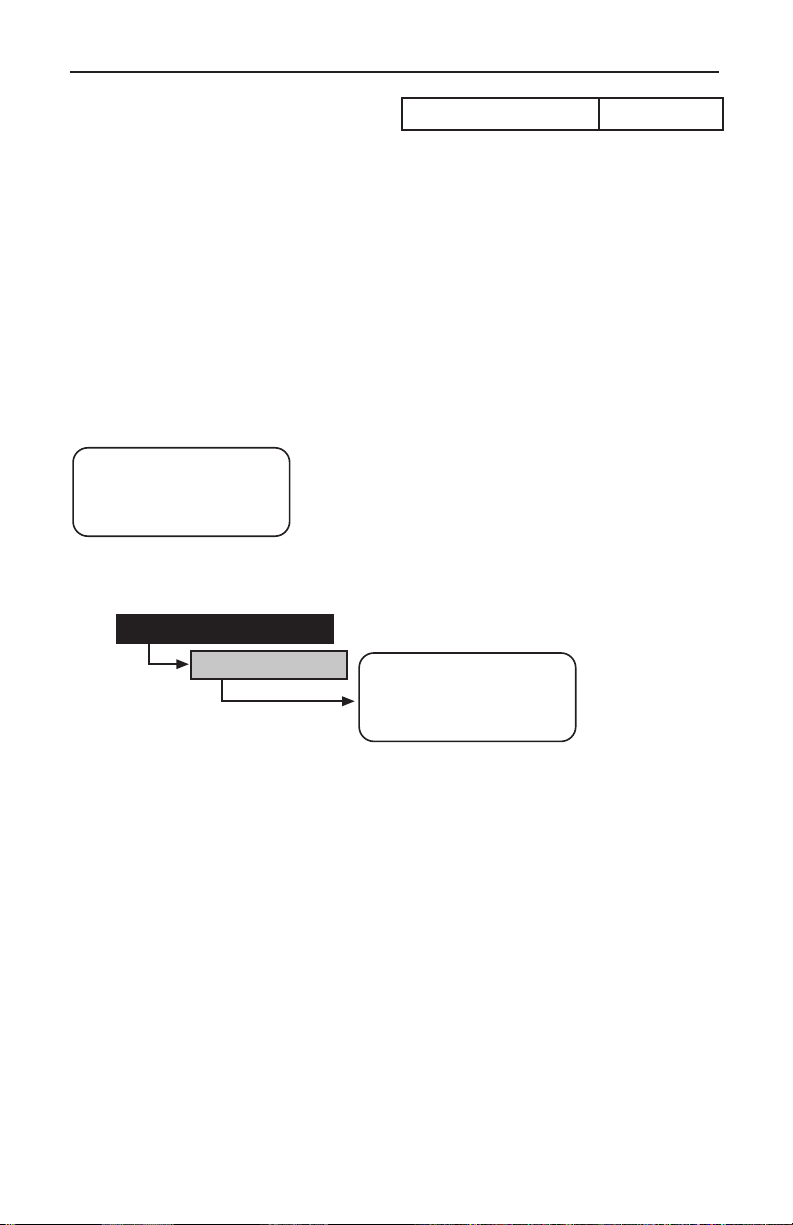

Main Menu

F0: Powertrain

F1: Replay Data

F9: OBD II Toolpak

By selecting Global OBD II with Toolpak, you are

now at the Main Menu from which you can

initialize communications by selecting F0:

Powertrain, replay snapshot without vehicle communication by selecting F1: Replay Data, or

view useful diagnostic information by selecting

F9: OBD II Toolpak.

SELECT MODE

F0: Datalist

F1: Readiness

F2: DTCs

After selecting F0: Powertrain and initializing

communication with the vehicle, the SELECT

MODE menu will be displayed. All selections

from the SELECT MODE menu require vehicle

communications except F9: OBD II Toolpak.

2 ECUs RESPONDED

$10 ENGINE

$18 TRANS

If the vehicle you are testing contains more than

one OBD II ECU, the tester will display a list of all

ECUs which have responded during the initialization process. Refer to the DISPLAYING DATA

FOR MULTIPLE ECUs section.

COMMUNICATION FAILURE

If the tester fails to get a response from the vehicle, it will display a retry count

and one of two error messages. At that point, it will continue to retry

communication approximately every 3 seconds. If the communication

problem is resolved (e.g. the ignition is switched to ON) and communication

begins, the tester will automatically proceed to the next phase. If communication cannot be established, see APPENDIX D , IF YOU’RE HAVING A

PROBLEM.

3-1

Page 21

GLOBAL OBD II WITH TOOLPAK

THIS PAGE LEFT INTENTIONALLY BLANK

Page 22

GLOBAL OBD II WITH TOOLPAK

4.0 TEST MODES

Once communication with the vehicle has been established, a select mode

menu is displayed. (In some cases, a readiness tests warning message is

displayed prior to the menu. See READINESS TESTS section.)

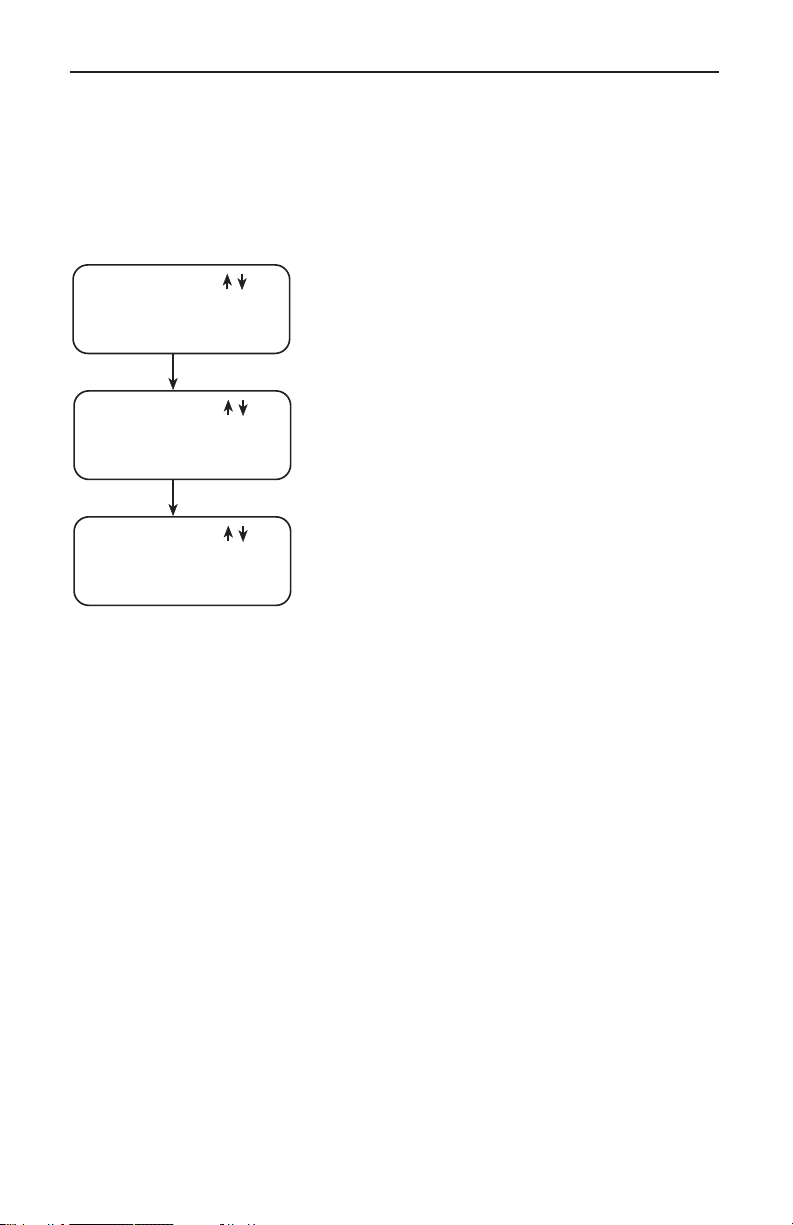

SELECT MODE MENU

SELECT MODE

F0: Datalist

F1: Readiness

F2: DTCs

This menu allows you to perform basic testing

on the vehicle. You can select the desired function by pressing the key indicated to the left of the

function. The menu automatically scrolls every 3

seconds until you press U or D, at which time

SELECT MODE

F3: Snapshot

F4: OBD Controls

F5: System Tests

SELECT MODE

F8: Information

F9: OBD II Toolpak

scrolling stops.

Pressing U or D will then cause the menu to

manually scroll.

If the vehicle you are testing contains more than one ECU, the tester will

display a list of all ECUs which have responded during the initialization

process. Refer to DISPLAY DATA FOR MULTIPLE ECUs section.

4-1

Page 23

GLOBAL OBD II WITH TOOLPAK

MODE F0 DATA LIST

SUBMODE F0 DISPLAY DATA

F0: DATALIST

The DATA LIST mode allows you to view the current state of diagnostic data

parameters as reported by the vehicle’s ECUs.

DATA LIST MENU

When you select DATA LIST from the OBD II

DATA LIST MENU

F0: Display Data

F1: Data Setup

F0: DISPLAY DATA

OPERATING PROCEDURE:

FUNCTIONS menu, the tester will display the

DATALIST MENU. This menu allows you to

either go directly to displaying data or to the

DATA LIST SETUP mode to select the data you

want to display.

F0: DATA LIST

SELECT ECU

F0: DISPLAY DATA

Engine Speed

756 RPM

ECT (˚)

185˚F

1. Select F0: DATA LIST from the SELECT MODE menu.

2. Select F0: DISPLAY DATA from the DATA LIST menu. The tester will

display either ALL PARAMETERS or USER DATA LIST PARAMETERS,

depending on which selection was last made since the tester was

powered up.

4-2

Page 24

GLOBAL OBD II WITH TOOLPAK

DATA LIST MODE F0

DATA SETUP SUBMODE F1

F1: DATA SETUP

The DATA SETUP mode allows you to select the data you want to display.

You can select either ALL PARAMETERS or USER LIST PARAMETERS

which allows you to monitor any combination of parameters (from 1

parameter to all parameters). The update rate for the parameters depends

on the number of parameters selected. A single parameter can be sampled

as fast as 8 times per second. The more parameters that are selected, the

slower the update rate will be.

OPERATING PROCEDURE:

F0: DATA LIST

SELECT ECU

F1: DATA SETUP

F0: ALL PARMS

F1: USER LIST PARAMETERS

Engine Speed

756 RPM

ECT (˚)

185˚F

1. Select F0: DATA LIST from the SELECT MODE menu.

2. Select F1: DATA SETUP from the DATA LIST menu.

3.

Select F0: ALL PARMS. or F1: USER LIST PARAMETERS

from the DATA

LIST SETUP menu. The message “WAITING FOR DATA” will be

displayed. The tester will display either ALL PARAMETERS or CUSTOM

LIST PARAMETERS depending on which selection was made.

4-3

Page 25

GLOBAL OBD II WITH TOOLPAK

MODE F0 DATA LIST

SUBMODE F1 DATA SETUP

F0: ALL PARAMETERS

The selection of F0: ALL PARMS will monitor all of the information available

from the ECU. Depending on the number of diagnostic data parameters in

the data list, the update rate can be 3 seconds or longer.

F1: USER LIST PARAMETERS

Engine Speed

***Selected***

YES: Select 3

NO: De-Select

SELECT ECU

F0: ALL ECUs

F1: $10 ENGINE

F2: $18 TRANS

DATA LIST SETUP

F0: Select ECU

F1: Select D.L.

Parameters

The selection of F1: USER LIST PARAMETERS

will display a list of parameters from which to

select. F1:USER LIST PARAMETERS allows

you to select any combination to monitor (from 1

parameter to all parameters). Parameters are

selected by scrolling through the list using the

u and d keys and then pressing Y and

n to select and deselect the listed parameter.

When the parameters have been selected, press

e to go to the display mode. The tester

will remember the selected parameters ( until

the tester is turned OFF) so you won’t have to reselect them every time.

If there are multiple OBD II ECUs, and the DATA

SETUP mode is selected, an additional DATA

LIST SETUP menu is available. The F0: SELECT ECU menu allows you to select which

ECU(s) will contribute to the DATA LIST. Once

the ECU(s) that will contribute data

are selected, press F1: DATA SETUP to choose

all parameters available or a custom list of

parameters from the chosen ECU(s).

4-4

Page 26

GLOBAL OBD II WITH TOOLPAK

DATA LIST MODE F0

MULTIPLE ECUs

MULTIPLE ECUs

Diagnostic parameter data can be selected from all ECUs or individual

ECUs that the tester has identified. This mode should be set up before

display data is selected to ensure your desired ECU data is being displayed.

For further information on multiple ECU data list display, refer to DISPLAYING DATA FOR MULTIPLE ECUs section.

F0: DATA LIST

F1: DATA SETUP

SELECT ECU

F0: SELECT ECU

F0: ALL ECUs

Fn: $XX

n = User selected

XX = ECU description

OPERATING PROCEDURE (vehicles with multiple ECUs only):

1. Select F0: DATA LIST from the SELECT MODE menu.

2. Select F1: DATA SETUP from the DATA LIST menu.

3. Select F0: SELECT ECU from the DATA LIST SETUP menu.

4. Select F0: ALL ECUs or Fn:XX where n=user selected and

XX= a description of the ECU from which you desire information.

5. After selecting the desired ECU, the user is returned to the DATA LIST

SETUP menu, where the displayed diagnostic data parameters can be

selected, or the user can exit the menu to the DATA LIST MENU, where

the selected data list will be displayed.

4-5

Page 27

GLOBAL OBD II WITH TOOLPAK

THIS PAGE LEFT INTENTIONALLY BLANK

4-6

Page 28

GLOBAL OBD II WITH TOOLPAK

READINESS MODE F1

F1: READINESS

The READINESS test mode allows you to display the status of the vehicle’s

on-board monitors, which monitor the operation of the emissions-related

components. These READINESS tests must run in order for the DTC and

test result displays to accurately reflect the conditions of the vehicle’s

emissions-related components.

If the vehicle you are testing contains more than one OBD II ECU, you will

be asked to select which ECU information you would like displayed.

If the tester determines that the ECU has not

Not All Vehicle

System Readiness

Tests Have Been

Completed

F1: READINESS

SELECT ECU

SELECT ECU ✶

completed all of the readiness tests, it will display

a warning message. You can then select the

READINESS tests menu item from the SELECT

MODE menu to examine the status of these

tests. For information on how to complete any of

the readiness tests, refer to service information

from the vehicle manufacturer.

READINESS TEST

Misfire

Monitoring

SUPPORTED

✶ For vehicles with multiple ECUs only.

OPERATING PROCEDURE:

1. Select F1: READINESS from the SELECT MODE menu.

2. Select the ECU from which you choose to monitor data (for vehicles with

multiple ECUs only). The message “WAITING FOR DATA” is displayed,

followed by the READINESS TEST information.

3. The first three items on the display indicate the vehicle's monitoring

capability for continuously monitored systems:

• Misfire monitoring.

• Fuel system monitoring.

• Comprehensive component monitoring.

4-7

Page 29

GLOBAL OBD II WITH TOOLPAK

MODE F1 READINESS

These are indicated as either being SUPPORTED or NOT SUPPORTED

(N/A), depending on the vehicle's ECU.

The other 8 display items indicate the status of the tests which

are performed at least “once per trip.”

• Catalyst monitoring.

• Heated catalyst monitoring.

• Evaporative system monitoring.

• Secondary air system monitoring.

• A/C system refrigerant monitoring.

• Oxygen sensor monitoring.

• Oxygen sensor heater monitoring.

• EGR system monitoring.

These tests can be COMPLETED, NOT COMPLETED, or NOT SUPPORTED.

4-8

Page 30

GLOBAL OBD II WITH TOOLPAK

READINESS MODE F1

READINESS TEST OPERATION

OBD II SYSTEM AND VEHICLE INFORMATION

The OBD II system is capable of identifying the likely area of a malfunction

within the electronic engine control system. Observe the following before

beginning diagnostic service:

• LOW FUEL TANK LEVEL. Automobile manufacturers may disable

READINESS tests which can be affected by running the vehicle out of

fuel (example: a monitor may become disabled when fuel tank volume is

below 15% of maximum fuel tank capacity).

• ALTITUDE. Automobile manufacturers may disable READINESS tests

which can be affected by altitude (example: a READINESS test may

become disabled when vehicle is operated above 8,000 feet elevation).

• AMBIENT TEMPERATURE. Automobile manufacturers may disable

READINESS tests which can be affected by ambient temperature

(example: a READINESS test may become disabled when a vehicle is

started below 20°F ambient).

• POWER TAKE-OFF UNIT. Automobile manufacturers may disable

READINESS tests which can be affected by power take-off unit operation

(example: a READINESS test may become disabled when a vehicle

power take-off is engaged or active).

All of the above are part of the California Air Resources Board

OBD II regulation and are options available to the automobile manufacturer

for vehicle Powertrain Control Module (PCM) development. In the case of

some READINESS tests, per the above, a manufacturer may have determined that a READINESS test is unreliable or not complete when certain

conditions exist, therefore not enabling proper operation.

ACTIVE KEYS

u Move marker.

d Freeze menu scroll.

• Print readiness test results.

x Return to SELECT MODE menu.

4-9

Page 31

GLOBAL OBD II WITH TOOLPAK

MODE F2 DTCs

SUBMODE F0 READ DTCs

F2: DIAGNOSTIC TROUBLE CODES (DTCs)

F0: READ DTCs

When you select the F0: READ DTCs mode, the tester reads all DTCs which

have been stored by the vehicle’s controllers and then displays:

• a two-column list of all DTCs.

• the ID of the ECU reporting the DTCs.

• how many codes have been reported by that ECU.

SELECT ECU

F1: $10 ENGINE

F2: $22 CHASS.

If the vehicle you are testing contains more than

one OBD II ECU, you will be asked to select

which ECU information you would like displayed.

F2: DTCs

F0: READ DTCs

SELECT ECU

SELECT ECU ✶

ECU $10 DTCs:3

✽

P0443f

P0110

P0111

✶ For vehicles with multiple ECUs only.

OPERATING PROCEDURE:

1. Select F2: DTCs from the SELECT MODE menu.

2. Select F0: READ DTCs for the DTC menu.

3. Select desired ECU from the SELECT ECU menu (for vehicles with

multiple ECUs only). The DTC information will then be displayed.

4-10

Page 32

GLOBAL OBD II WITH TOOLPAK

DTCs MODE F2

READ DTCs SUBMODE F0

Generally, 6 DTCs can be displayed at one time. If more than 6 DTCs are

reported by the ECU, the tester will display a "↓" prompt in the lower righthand corner indicating that more DTCs are present but are not displayed.

Use the u, d, l, and r keys to move through the list of DTCs.

A DTC description can be displayed by moving the "✽"next to the desired

DTC and pressing e. The u and d keys will scroll through the DTC

descriptions.

A DTC will display an " f " after the DTC number to signify that there is freeze

data available for that DTC. You can go directly to the FREEZE DATA

display by pressing ™. This performs exactly the same function as

selecting FREEZE DATA from the SELECT MODE menu, but saves you a

few key presses.

ACTIVE KEYS

e Display the description for the selected DTC.

™ Go directly to FREEZE DATA.

• Print freeze data list (if equipped with serial printer).

u / d Move through list of DTCs.

l / r

x Return to previous menu.

4-11

Page 33

GLOBAL OBD II WITH TOOLPAK

MODE F2 DTCs

SUBMODE F1 FREEZE DATA

F1: FREEZE DATA

The vehicle’s ECU stores diagnostic data information about the state of the

vehicle when a Diagnostic Trouble Code (DTC) occurs. This data is referred

to as Freeze Frame Data and can be read by the tester using the FREEZE

DATA mode. You can select this mode from the SELECT MODE menu.

SELECT ECU

F1: $10 ENGINE

F2: $18 TRANS

If multiple ECUs are available, the SELECT

ECU menu is displayed once FREEZE DATA is

selected from the SELECT MODE menu. Only

one ECU’s data can be displayed in FREEZE

DATA mode.

F2: DTCs

SELECT ECU

F1: FREEZE DATA

SELECT ECU ✶

Trouble Code

P0130

Engine Speed

1000 RPM

✶ For vehicles with multiple ECUs only.

OPERATING PROCEDURE:

1. Select F2: DTCs from the SELECT MODE menu

2. Select F1: FREEZE DATA from the menu.

3. Select the ECU from which you choose to monitor data (for vehicles with

multiple ECUs only). The message “WAITING FOR DATA” will appear.

The FREEZE DATA information will then be displayed.

FREEZE DATA is only available for the first DTC which was detected by the

vehicle. The first parameter in the list is the DTC which caused the FREEZE

DATA to be saved. The FREEZE DATA is displayed in the same format as

the data list in the DATA LIST mode.

4-12

Page 34

GLOBAL OBD II WITH TOOLPAK

DTCs MODE F2

FREEZE DATA SUBMODE F1

ACTIVE KEYS

y / n Scroll through displayed data parameters.

º Mark top displayed parameter as “fixed” for creating

your own data pairs; unlocks bottom parameters if

fixed.

¡ Mark bottom displayed parameter as “fixed” for creat-

ing your own data pairs; unlocks top parameters if

fixed.

£ Toggle the data descriptor line with the Parameter

Identification (PID) number and the ECU number.

¶ Toggle unit conversions for applicable parameters

between English and metric.

• Print freeze data list (if equipped with a serial printer).

x Return to SELECT MODE menu.

4-13

Page 35

GLOBAL OBD II WITH TOOLPAK

MODE F2 DTCs

SUBMODE F2 CLEAR INFO

F2: CLEAR INFORMATION

The CLEAR INFORMATION mode is used to clear DTCs from all vehicle

ECUs along with any other diagnostic

information which the controller has

saved, such as FREEZE DATA.

IMPORTANT: Clearing diagnostic information also clears the status of

readiness tests (making them incomplete). It can take 30 to 60 minutes of

vehicle drive and engine run time (and in some cases longer) to complete

all of these tests if they are cleared. Some inspection and maintenance

programs require that the readiness tests be complete before the inspection

can proceed.

When you select F2: CLEAR INFO, you are first prompted with a warning

message. This is to prevent inadvertent clearing of codes. If you press n

or

x in response to the prompt, the

tester will return to the DTC menu.

If you press y in response to the prompt, the tester will cause all OBD II

controllers to clear all emissions-related

DTCs, FREEZE DATA, and READINESS TEST results. When the function is complete, the tester will display

the screen “ALL DIAGNOSTIC INFORMATION CLEARED.”

F2: DTCs

F2: CLEAR INFO

Clear All

Diagnostic Info?

YES = Continue

NO = Quit

OPERATING PROCEDURE:

1. Select F2: DTCs from the SELECT MODE menu.

2. Select F2: CLEAR INFO from the DTCs menu.

3. Press y to clear DTCs. A warning message will appear to prevent

accidental clearing of codes. A screen will then appear to confirm deletion

of diagnostic information stored in the vehicle controllers.

4-14

Page 36

GLOBAL OBD II WITH TOOLPAK

DTCs MODE F2

CLEAR INFO SUBMODE F2

Module(s)

$10

Did Not Respond

Some vehicles will not allow DTCs to be cleared

while the engine is running. In this case, the

tester will display a prompt screen to turn off the

engine, leaving the key in the ON position. For

some vehicles, communication may be lost when

the key is turned off and then back on. If a

COMMUNICATION ERROR screen is displayed,

Try Again With

Ignition ON And

Eng. NOT Running

[EXIT]

exit back to the MAIN MENU and re-select

Powertrain. You should now be able to clear the

diagnostic information.

ACTIVE KEYS

y Clears all emissions-related information.

n / x Return to SELECT MODE menu.

4-15

Page 37

GLOBAL OBD II WITH TOOLPAK

ECU $10 DTCs:4

✽

P0100 P0122

P0101

P0118

MODE F2 DTCs

SUBMODE F3 PENDING DTCs

F3: PENDING DTCs

For PENDING DTCs mode, the vehicle’s controller performs analysis

similar to that used to determine if the equivalent DTC is present, but with

less stringent requirements. For example, a DTC may require a condition to

be present for several drive cycles, while the equivalent pending DTCs may

be set with the first occurrence of the condition.

Results of the PENDING DTCs request are displayed in a manner similar to

the DTC display mode. They are displayed with the same Pxxxx DTC

designations and the same descriptors as the DTCs.

If the vehicle you are testing contains more than one OBD II ECU, you are

asked to select which ECU information you would like displayed.

F2: DTCs

F3: PENDING DTCs

SELECT ECU

SELECT ECU ✶

✶ For vehicles with multiple ECUs only.

OPERATING PROCEDURE:

1. Select F2: DTCs from the SELECT MODE menu.

2. Select F3: PENDING DTCs from the DTCs menu.

3. Select the ECU from which you choose to monitor data (for vehicles with

multiple ECUs only). The message “WAITING FOR DATA” is displayed,

followed by the PENDING DTCs information.

4-16

Page 38

GLOBAL OBD II WITH TOOLPAK

DTCs MODE F2

PENDING DTCs SUBMODE F3

ECU $10 P0100

Mass or Volume

Air Flow Circuit

Malfunction

A detailed description can be displayed for any

pending DTC by moving the ✽ next to the desired

code and pressing e. The ✽ is moved by

pressing the arrow keys.

ACTIVE KEYS

e Displays description of the pending DTC.

u / d Move marker.

x Exits to SELECT MODE menu.

4-17

Page 39

GLOBAL OBD II WITH TOOLPAK

MODE F3 SNAPSHOT

F3: SNAPSHOT

SETUP

The SNAPSHOT mode helps the user to isolate an intermittent or transient

problem by storing data parameters before or after the problem occurs. The

information can be saved and used for a later replay or hard copy print

option.

F3: SNAPSHOT

F0: ANY DTC TRIGGER

F1: SINGLE DTC TRIG.

OR

OR

F2: MANUAL TRIGGER

SELECT ECU

SELECT ECU ✶

Engine Speed

1052 RPM

Ign. Timing

18.5° W

F3: REPLAY SNAPSHOT

F4: TRIGGER POINT

F9: DATA SETUP

F0: ALL PARMS

F1: CUSTOM LIST

✶ For vehicles with multiple ECUs only.

OPERATING PROCEDURE:

1. Select F3: SNAPSHOT from the SELECT MODE menu.

2. Select any of the available trigger types from SNAPSHOT MENU.

3. Data from only one ECU can be saved in tester memory. Therefore, if

multiple ECUs are detected, you will be asked to select one of the ECUs.

4. To choose which snapshot parameters are displayed, press ª to select

DATA SETUP from the SNAPSHOT MENU. After selecting F9: DATA

SETUP, refer to F0: ALL PARMS and F1: CUSTOM LIST PARAMETERS

in the DATA LIST section for displaying all parameters or selecting a

custom list of parameters.

4-18

Page 40

GLOBAL OBD II WITH TOOLPAK

SNAPSHOT MODE F3

TRIGGER POINT SUBMODE F4

TRIGGER TYPES

In the SNAPSHOT mode, data is saved in the tester while it is waiting for a

trigger condition. Once the trigger occurs, data continues to be saved in the

tester’s memory until the memory is full. SNAPSHOT MENU allows the user

to start the snapshot process by selecting a trigger mode. Three types of

triggers can be selected:

TRIGGER TYPES

KEYPRESS DESCRIPTION

F0: ANY DTC Snapshot trigger on the occurrence of any

DTC.

F1: SINGLE DTC Snapshot trigger on the occurrence of a

single DTC that you specify.

F2: MANUAL TRIG.

TRIGGER POINT SETUP

SELECT TRIGGER

F0: Beginning

F1: Center

F2: End

Snapshot trigger by an e, x, or

ª

key press.

The snapshot menu allows you to select how

much data is saved after trigger occurs by selecting F4: TRIG. POINT from the SNAPSHOT

MENU screen. To change the trigger point, select the key next to the desired point. This trigger

point is saved as long as the tester has power.

4-19

Page 41

GLOBAL OBD II WITH TOOLPAK

MODE F3 SNAPSHOT

SUBMODE F3 SNAPSHOT REPLAY

SNAPSHOT DATA CAPTURE

When the trigger type is selected, the tester displays a status message in the

form of a flashing “W” indicating that the tester is storing data and waiting for

the trigger.

While waiting for a trigger to occur, you can press the e, x, or

ª key at any time to trigger the snapshot manually regardless of the trigger

type selected.

When a trigger has occurred, the flashing “W” will change to a constantly

displayed “T.”

When the tester memory is full, the tester displays an “0” to indicate that the

snapshot is complete. Pressing x after a trigger has occurred will end

the data capture phase.

F3: SNAPSHOT REPLAY

Once you have captured snapshot data, you can examine it by pressing £

from the SNAPSHOT menu. Use the u and d keys to scroll through the

samples. The last snapshot is retained in the tester unless:

• It is overwritten by a new snapshot.

• A new application is selected from the application menu.

• A new master cartridge is installed in the tester.

• The tester is unplugged from power for more than 24 hours.

You can review the captured snapshot in one of two ways:

1. A snapshot can also be replayed after communication is established by

selecting F3: SNAPSHOT REPLAY from SNAPSHOT MENU.

2. Without vehicle communications by selecting F1: REPLAY SNAPSHOT

DATA from the MAIN MENU (this menu option is only displayed if a

snapshot has been taken).

4-20

Page 42

GLOBAL OBD II WITH TOOLPAK

SNAPSHOT MODE F3

SNAPSHOT REPLAY SUBMODE F3

SNAPSHOT TRIGGER

Point: Center

Type: Manual

Engine Speed

1024 RPM

Ign. Timing

29.5° -2

Engine Speed

1024 RPM

Ign. Timing

29.5° -7.1

When the SNAPSHOT REPLAY mode is first

entered, the tester displays information about

the saved snapshot. The snapshot’s trigger point

(Beginning,

(Manual,

Center, or End) and trigger type

Any DTC or Single DTC) are displayed

for a couple seconds before the snapshot data is

displayed. When replaying a saved snapshot,

the sample at the time of the trigger is initially

displayed. Samples before and/or after the trigger can be viewed by pressing the u and d

keys to scroll through the samples.

The sample number of a snapshot is displayed in

the lower right of the display screen. This index

number will initially be a “0”; samples after the

trigger will be displayed as positive numbers and

samples before the trigger will be displayed as

negative numbers. While replaying a snapshot,

pressing e will cause the software to toggle

between the sample index and the sample time.

The sample time display gives the time in seconds

(relative to the trigger sample) at which the TECH

1

received the currently displayed sample.

For

example, a sample time of +3.4 means the sample

was received 3.4 seconds after the trigger sample.

A sample time of -2.6 seconds means the

was received 2.6 seconds before

the trigger.

sample

4-21

Page 43

GLOBAL OBD II WITH TOOLPAK

MODE F3 SNAPSHOT

ACTIVE KEYS

y / n Scroll through displayed data parameters.

U / D Scroll through samples.

º Mark top displayed parameter as “fixed” for creating

your own data pairs.

¡ Mark bottom displayed parameter as “fixed” for creat-

ing your own data pairs.

™ Display trouble codes for current sample.

£ Toggle the data descriptor line with the Parameter

Identification (PID) number and the ECU number.

¢ Display first (earliest) sample.

fi Display trigger sample (“0”).

§ Display last (most recent) sample.

¶ Toggle unit conversions for applicable parameters.

• Print data list (if equipped with serial printer).

X Return to SNAPSHOT MENU.

4-22

Page 44

GLOBAL OBD II WITH TOOLPAK

OBD CONTROLS MODE F4

EVAP LEAK SUBMODE F0

F4: OBD CONTROLS

The OBD CONTROLS mode allows the user to perform individual output

controls to check for proper vehicle component or system operation. The

OBD CONTROLS that the user can control depend on the vehicle under

test.

F0: EVAP LEAK

The EVAP LEAK test is used to enable the conditions required to conduct

an evaporation system leak test. Selecting F0: EVAP LEAK does not

actually run the test, but instead closes the system, preventing leakage. Offboard test equipment can then be used to test the vehicle's evaporative

emission system. The vehicle manufacturer is responsible for automatically

aborting the leak test when necessary.

F4: OBD CONTROLS

F0: EVAP LEAK

EVAP LEAK TEST

ENABLED

[EXIT]

OPERATING PROCEDURE:

1. Select F4: OBD CONTROLS from the SELECT MODE menu.

2. Select F0: EVAP LEAK from the OBD CONTROL menu.

3. Press x to return to the OBD CONTROL menu.

If the conditions necessary to run the evaporative emissions system leak

test are not correct, the vehicle ECU may respond with a manufacturer

defined reason the test cannot be run or may not respond at all. If the vehicle

PCM does not support OBD CONTROLS, the tester will display "No Control

Tests Supported" when the OBD CONTROLS test mode is selected.

NOTE: The tester will automatically determine whether the

vehicle under test supports the test mode.

4-23

Page 45

GLOBAL OBD II WITH TOOLPAK

MODE F5 SYSTEM TEST

SUBMODE F0 O2S RESULTS

F5: SYSTEM TEST

F0: O2S RESULTS

The OXYGEN SENSOR (O2S) RESULTS mode allows the tester to display

the results of the oxygen sensor testing performed by the vehicle’s engine

controller. These tests are “once per trip” tests and are performed after

the ignition is turned on under conditions defined by the vehicle manufacturer. The O2S RESULTS mode is

vehicles use the other results test

n = User selected

X = Vehicle dependent

F5: SYSTEM TESTS

F0: O2S RESULTS

Fn: O2S BANK X

not available for all vehicles. Some

mode to report results of O2S testing.

Fn: SENSOR X

R L Sw Tim

O.16 Secs

L R Sw Tim

0.088 Secs

OPERATING PROCEDURE:

1. Select F5: SYSTEM TEST from the SELECT MODE menu.

2. Select F0: O2S RESULTS from the SELECT TEST menu.

3. Select the desired bank from SELECT BANK menu.

4. Select the desired oxygen sensor from the BANK and SENSOR menu.

The message "WAITING FOR DATA" is displayed, followed by the

Oxygen Sensor data display.

If the tester displays the warning message indicating that the

O2S MONITORING TEST RESULTS may not be valid, the vehicle ECU is

reporting that the O2S tests have not been completed or that the selected

ECU does not monitor the O2S tests. The status of the oxygen sensor tests

can be monitored in F1: READINESS TEST MODE under the value of

OXYGEN SENSOR MONITORING. For some vehicles, O2S test results

may not be available until all readiness tests have been completed.

4-24

Page 46

O2 SENSOR TEST MENU

GLOBAL OBD II WITH TOOLPAK

SYSTEM TEST MODE F5

O2S RESULTS SUBMODE F0

SELECT BANK

F0: O2S BANK 1

F1: O2S BANK 2

º

BANK 1 SENSOR

F0: SENSOR 1

F1: SENSOR 2

O2S DATA DISPLAYS

R L Sw Tim

O.16 Secs

L R Sw Tim

0.088 Secs

The vehicle can provide O2S test results for up

to 8 oxygen sensors. When O2S RESULTS is

selected, the tester queries the ECU to determine which oxygen sensors are present. It then

displays a list of these sensors so that you can

select which sensor’s test results to examine. To

select a bank or sensor, press the number listed

on the left. Refer to APPENDIX B: OBD II OXYGEN SENSOR LOCATION IN

a discussion of oxygen

sensor locations. If there

FORMATION for

is no response to the query, the tester displays

a warning message indicating that the O2S Test

results may not be supported.

Once the sensor has been selected,

the tester determines which O2 sensor data

parameters are available

displays data for each

for display. It then

of the parameters. The

parameters vary depending on the vehicle manufacturer. Only parameters which are supported

by the vehicle ECU are displayed.

4-25

Page 47

GLOBAL OBD II WITH TOOLPAK

MODE F5 SYSTEM TEST

SUBMODE F0 O2S RESULTS

The OXYGEN SENSOR MONITORING TEST RESULTS are reported as

constants programmed in the vehicle ECU or calculated values by the

vehicle ECU. Refer to the table below for programmed and calculated data

parameters.

PARAMETER TID TYPE

R>>L O2S V $01 Constant

L>>R O2S V $02 Constant

LOW SW V $03 Constant

HIGH SW V $04 Constant

R>>L SW TIM $05 Calculated

L>>R SW TIM $06 Calculated

MIN O2S V $07 Calculated

MAX O2S V $08 Calculated

O2S TRANS T $09 Calculated

NOTE: Parameter IDs greater than 9 are manufacturer-specific

and are therefore defined only by an ID preceded by a “$” (e.g.,

$70 and $71 for Chrysler O2S test results). You should refer to

the vehicle’s service manual to determine how to interpret

these parameters.

4-26

Page 48

SYSTEM TEST MODE F5

O2S RESULTS SUBMODE F0

ADDITIONAL O2S INFORMATION

GLOBAL OBD II WITH TOOLPAK

TID $05 Val $29

Min $0A Max $32

TID $06 Val $16

Min $0A Max $32

Pressing fi while the O2S RESULTS data is

being displayed will cause the tester to display

additional information about the displayed parameters. The

(TID)

along with hexadecimal displays of the

tester displays the Test ID number

current data value (“Val”), the ECU programmed

minimum value (“Min”) and the maximum ECU

programmed value (“Max”) for this parameter.

“Min” and “Max” are values reported by the ECU.

“Val” should be within those limits.

ACTIVE KEYS

y / n Scroll through displayed data parameters.

º Mark top displayed parameter as “fixed” for creating

your own data pairs; unlocks bottom parameter if

fixed.

¡ Mark bottom displayed parameter as “fixed” for cre-

ating your own data pairs; unlocks top parameter if

fixed.

£ Toggle the data descriptor line with the Parameter

Identification (PID) number and the ECU number.

¢ Toggle the data descriptor line with the Test Identifi-

cation (TID) number and the oxygen bank and sensor.

fi Toggle the data descriptor line with the Test Identifi-

cation (TID) number and the hexadecimal equivalent

of the received data. The calculated value line is

toggled with the “Min” and “Max” values received

from the ECU for that TID.

• Print data list (if equipped with serial printer).

X Return to SELECT MODE menu.

4-27

Page 49

GLOBAL OBD II WITH TOOLPAK

MODE F5 SYSTEM TEST

SUBMODE F1 OTHER RESULTS

F1: OTHER TEST RESULTS

The OTHER RESULTS test mode is similar to the O2 sensor test results.

Some manufacturers use this mode as an alternate means of reporting O2

sensor test results. In this mode, the vehicle’s ECU reports data for various

Test IDs (TIDs) and Component IDs (CIDs) that are specified by the vehicle

manufacturer. Descriptions for the TIDs and CIDs are available in the

vehicle service manual or from the manufacturer.

If the vehicle you are testing contains more than one OBD II ECU, you will

be asked to select which ECU information you would like displayed.

F5: SYSTEM TESTS

F1: OTHER RESULTS

SELECT ECU

SELECT ECU ✶

TID/CID RESULT

✽

01/01……Pass

01/02……Fail

02/01……Pass

✶ For vehicles with multiple ECUs only.

OPERATING PROCEDURE:

1. Select F5: SYSTEM TESTS from the SELECT MODE menu.

2. Select F1: OTHER RESULTS from the SELECT TEST menu.

3. Select the ECU from which you choose to monitor data (for vehicles with

multiple ECUs only). The message “WAITING FOR DATA” is displayed,

followed by the OTHER RESULTS test information.

4-28

Page 50

GLOBAL OBD II WITH TOOLPAK

SYSTEM TEST MODE F5

OTHER RESULTS SUBMODE F1

01/01 ECU $10

Test Value $0200

Min Limit N/A

Max Limit $0300

In addition to reporting data for these TIDs and

CIDs, the vehicle reports test limits (minimum,

maximum, or both) for acceptable operation.

The tester compares the data with the test limits

and displays a PASS or FAIL indication for each

TID and CID. The actual received data can be

viewed by moving the star cursor (✶) with the

arrow keys to the desired item and pressing

e. If “N/A” (not available) is displayed for

a limit, then the ECU did not send a value for that

limit.

ACTIVE KEYS

e Displays actual received data.

u / d Move marker.

x Return to SYSTEM TESTS menu.

4-29

Page 51

GLOBAL OBD II WITH TOOLPAK

MODE F8 INFORMATION

SUBMODE F0 VIN

F8: INFORMATION

The INFORMATION mode is used to enable the user to request vehicle

specific information from the vehicle ECU, such as VIN, Software Calibration

ID, or Software Verification Number.

If the vehicle PCM does not support vehicle PCM information, the tester will

display "No Vehicle Info Supported" when the INFORMATION mode is

selected.

F0: VIN

The VIN selection allows the user to electronically read the Vehicle Identification Number that is stored in the vehicle's ECU. The VIN is used to

uniquely identify the vehicle. This mode is only selectable when it is

supported by the vehicle ECU.

F8: INFORMATION

F0: VIN

VIN

XXXXXXXXXX

XXXXXXX

[ENTER]

OPERATING PROCEDURE:

1. Select F8: INFORMATION from the SELECT MODE menu.

2. Select F0: VIN from the SELECT TYPE menu.

3. Press x or e to return to the INFORMATION menu.

4-30

Page 52

GLOBAL OBD II WITH TOOLPAK

INFORMATION MODE F8

S/W CALIB. ID SUBMODE F1

F1: S/W CALIB. ID

The S/W CALIBRATION ID selection is used for identification of the software

calibration contained within the vehicle ECU. Each software calibration ID

uniquely identifies the software installed in the ECU. Multiple calibration IDs

may be reported for a ECU, depending on software architecture. A

calibration ID number will have at least one unique software verification

number. This mode is only selectable when it is supported by the vehicle

ECU.

F8: INFORMATION

F1: S/W CALIB. ID

CAL ID 1

XXXXXXXXXXXXXXX

CAL ID 2

XXXXXXXXXXXXXXX

OPERATING PROCEDURE:

1. Select F8: INFORMATION from the SELECT MODE menu.

2. Select F1: S/W CALIB. from the SELECT TYPE menu.

3. Press x to return to the INFORMATION menu.

4-31

Page 53

GLOBAL OBD II WITH TOOLPAK

MODE F8 INFORMATION

SUBMODE F2 S/W VERIF ID.

F2: S/W VERIF ID.

The SOFTWARE VERIFICATION NUMBER selection is used for determining whether emission-related calibrations within the ECU software have

been altered. Software Verification Numbers are calculated based on

memory content at the time of the request. Any changes to calibration will

be detected in the Software Verification Number. This mode is only

selectable when it is supported by the vehicle.

F8: INFORMATION

F2: S/W VERIF. ID

VERIF. NUM. 1

XXXXXXXX

VERIF. NUM. 2

XXXXXXXX

OPERATING PROCEDURE:

1. Select F8: INFORMATION from the SELECT MODE menu.

2. Select F2: S/W VERIF. ID from the SELECT TYPE menu.

3. Press x to return to the INFORMATION menu.

NOTE: Multiple Software Verification Numbers may be reported by an ECU. Each Software Verification Number will

correspond to a unique Software Calibration ID number.

NOTE: Turn the engine off when requesting the Software

Verification Number from the vehicle ECU. Failure to turn the

engine off may cause the ECU to require more time to calculate

the calibration number and may therefore not respond to the

request.

4-32

Page 54

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

F9:OBD II TOOLPAK

The OBD II Toolpak is used to help diagnose and troubleshoot OBD II compliant

powertrain control systems. Using the OBD II Toolpak mode provides you with

pertinent text and data so you can learn about and more efficiently diagnose the

vehicle under test.

Examples of data features contained within the program are:

• Vehicle preparation

• Diagnostic procedures

• Repair verification

• Diagnostic data parameter descriptions

• Diagnostic data parameter common values

• Diagnostic Trouble Code (DTC) Library

• Readiness Test description

• Oxygen sensor location information

• Oxygen sensor type information

• Oxygen sensor maintenance information

When using this application cartridge on 1994 to current OBD II compliant PCM

vehicles, the cartridge will display diagnostic data parameters based on Society

of Automotive Engineers (SAE) recommended practice J1979. Additionally, the

basic functions contained within this cartridge are required by California Air

Resources Board (California ARB) as part of the On-Board Diagnostics level II

(OBD II).

4-33

Page 55

GLOBAL OBD II WITH TOOLPAK

THIS PAGE INTENTIONALLY LEFT BLANK

4-34

Page 56

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

SELECTING OBD II TOOLPAK MODE

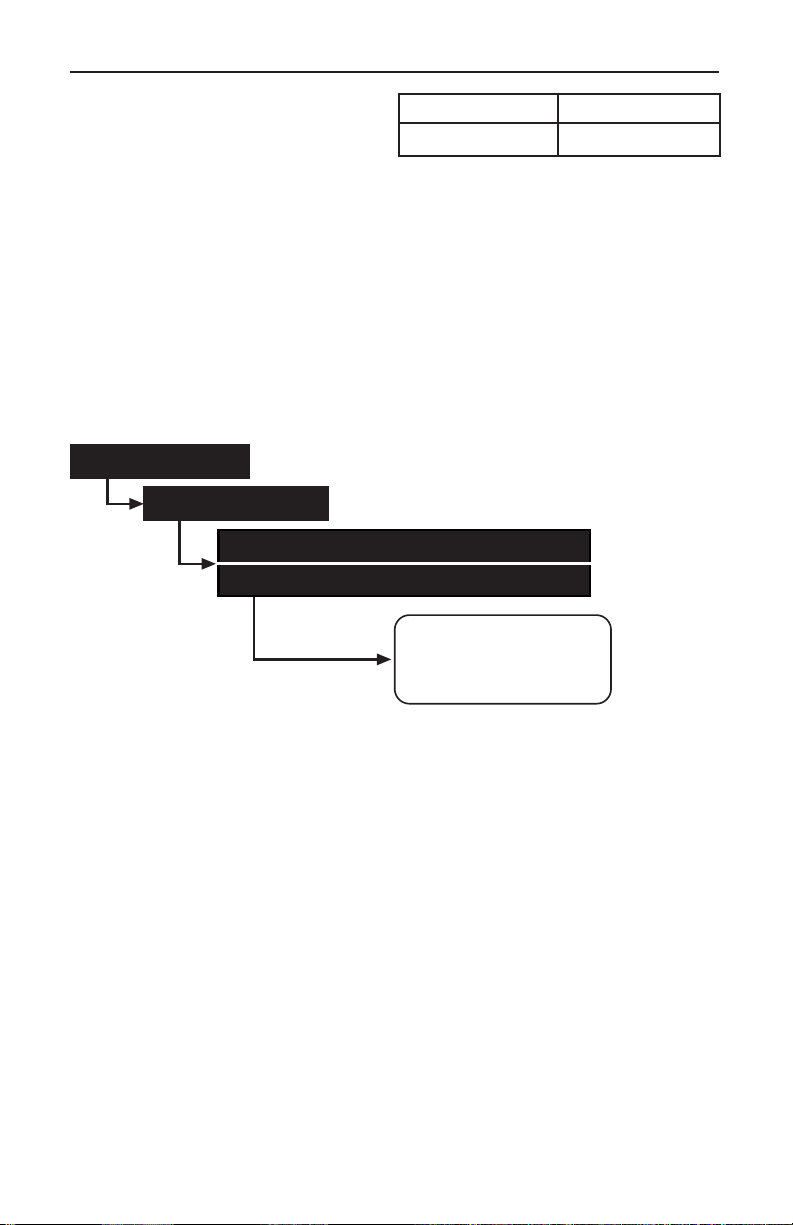

The OBD II Toolpak functions can be entered in two ways: from the main

menu or from the Select Mode menu.

FROM THE OBD II MENU

Entering F9: OBD II Toolpak from the main menu is available any time power

is applied to the tester.

FROM THE SELECT MODE MENU

Entering F9: OBD II Toolpak from the Select Mode menu is only available

after communication with the OBD II compliant vehicle has been initialized.

OBD II

communications

initialized with

vehicle

SELECT MODE

F8: Information

F9: OBD II Toolpak

ª

º

MAINI MENU

F0: Powertrain

F1: Replay Data

F9: OBD II Toolpak

ª

No OBD II

communications with

vehicle

OBD II TOOLPAK

F0: Diagnostics

F1: Parameters

F2: DTC Library

u

d

OBD II TOOLPAK

F3: Monitor Info

F4: O2S Info

4-35

Page 57

GLOBAL OBD II WITH TOOLPAK

THIS PAGE INTENTIONALLY LEFT BLANK

4-36

Page 58

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

DIAGNOSTICS SUBMODE F0

PREP VEHICLE SUBMODE F0

F0: DIAGNOSTICS

The F0: Diagnostics mode provides the following information:

• How to prepare a vehicle powertrain system for testing

• How to perform a diagnostic approach using each of the software

modes on OBD II compliant vehicles.

• How to verify a repair using the modes is contained in the F0:

Diagnostics mode.

F0: PREP VEHICLE

The Prep Vehicle mode is used to properly prepare the vehicle powertrain

for diagnostic procedures. Following the instructions in this mode will

ensure that the vehicle system is preconditioned and ready for diagnostic

testing.

OPERATING PROCEDURE:

1. Press ª to select OBD II TOOLPAK from the Select Mode menu.

2. Press º to select Diagnostics from the OBD II Toolpak menu.

3. Press º to select Prep Vehicle from the Diagnostics menu.

4. Review and answer the prompts that are displayed on the screen using

the y and n keys. Use u or d to advance through the text

description screens.

5. Press x to return to the previous menu.

ACTIVE KEYS

u / d Scroll up and down.

y / n Answer question or query.

e Advance to the next menu.

x Exit to the previous question or test menu.

4-37

Page 59

GLOBAL OBD II WITH TOOLPAK

MODE F9 OBD II TOOLPAK

SUBMODE F0 DIAGNOSTICS

SUBMODE F1 PROCEDURE

F1: PROCEDURE

The OBD II system represents the latest in on-board failure detection

strategies. Strategies such as misfire detection, component, and fuel

system status are some examples of diagnostic data that can be obtained

from the OBD II system.

Along with the new, more stringent methods of failure detection came

standardized diagnostic test modes. These standardized test modes are

supported in the Global OBD II application as modes F0 through F8.

F1: Diagnostic Procedure is designed to assist you in learning how to

diagnose an OBD II system fault or assess current system condition. While

there are many approaches that can be used, there is no one right way to

perform this task.

This submode helps formalize a strategy and teaches you how, using a

sensible approach, to use the Global OBD II application modes F0-F8 and

determine a solution to a problem within the OBD II system.

OPERATING PROCEDURE

1. Press ª to select OBD II TOOLPAK from the Select Mode menu.

2. Press º to select Diagnostics from the OBD II Toolpak menu.

3. Press ¡ to select Procedure from the Diagnostics menu.

First time users

: to ensure proper operation, this mode is best reviewed

before actual testing on the vehicle is performed. Prior to the testing it will

be to your advantage to know the answers to the following:

- Is the MIL on?

- Are DTCs present? If so, record the DTC numbers.

- Is the fuel tank cap installed and is it tight (3 clicks)?

- Is the fuel tank level greater than 15% of total volume?

4. Press u, d, y, n, or e to review and answer the prompts

displayed on the screen, and to read any key help screens that may be

displayed for navigation help.

4-38

Page 60

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

DIAGNOSTICS SUBMODE F0

PROCEDURE SUBMODE F1

5. Press x to return to the previous question or test menu.

ACTIVE KEYS

u / d Scroll up and down.

y / n Answer question or query.

e Advance to the next menu.

x Exit to the previous question or test menu.

4-39

Page 61

GLOBAL OBD II WITH TOOLPAK

MODE F9 OBD II TOOLPAK

SUBMODE F0 DIAGNOSTICS

SUBMODE F9 REPAIR VERIFICATION

F9: REPAIR VERIFICATION

After repairs are made to a vehicle powertrain system the status of system

DTC’s and monitor tests should be checked. Using this submode will help

determine the effectiveness of repairs just completed to the system using

the test modes within the Global OBD II application, including the importance of manufacturer OBD II drive cycle and monitor completion after

repairs.

OPERATING PROCEDURE

1. Press ª to select OBD II TOOLPAK from the Select Mode menu.

2. Press º to select Diagnostics from the OBD II Toolpak menu. The key

help screen will be displayed.

3. Press ª to select Repair Verification from the Diagnostics menu.

First time users: to ensure proper operation, this mode is best reviewed

before actual testing on vehicle is performed.

4. Use the u and d keys to review the prompts that are displayed on the

screen. Read any key help screens that may be displayed for navigation

help.

NOTE: For automobile manufacturer drive cycle information,

refer to the service manual for the vehicle that is currently

being tested.

5. Press x to return to the previous question or test menu.

ACTIVE KEYS

u / d Scroll up and down.

x Exit to the previous question or test menu.

4-40

Page 62

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

PARAMETERS SUBMODE F1

F1: PARAMETERS

The Parameters submode displays text descriptions for each diagnostic

data parameter displayed in the Global OBD II application. Common high

and low values for each diagnostic data parameter are also available for

reference.

NOTE: When the tester is connected to the vehicle and Data

List is selected, the total number of displayed diagnostic data

parameters will depend on the vehicle ECU calibration. This

is not a function of the tester.

4-41

Page 63

GLOBAL OBD II WITH TOOLPAK

MODE F9 OBD II TOOLPAK

SUBMODE F1 PARAMETERS

SUBMODE F0 DEFINITIONS

F0: DEFINITIONS

The text descriptions of each diagnostic data parameter are available when

the tester is connected to a vehicle and a live data list is displayed, or during

a shop or training review session and the tester is not connected to a vehicle.

OPERATING PROCEDURE - Viewing on-vehicle live data list

1. Set up and display a data list using F0: Data List.

2. Scroll through the Data List until the parameter for which you want

information is displayed. Press º to select the top parameter, or press

¡ to select the bottom parameter. An asterisk (✶) will appear next to the

selected parameter.

3. Press e to display the first text screen for the selected parameter.

Press d to advance through the text description screens. Press u to

view the previous text description screen.

4. To select a different parameter, press x to return to the Data List

parameter pair screen. Press the opposite function key used to select the

previous parameter ( º or ¡ ) to deselect the parameter. The asterisk

(✶) will disappear.

Scroll through the Data List until a parameter for which you want

information is displayed. Repeat Steps 2 and 3.

5. Press x to return to the Data List parameter pair screen or Select

Mode menu.

4-42

Page 64

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

PARAMETERS SUBMODE F1

DEFINITIONS SUBMODE F0

OPERATING PROCEDURE - Not viewing on-vehicle live data list

1. Press ª to select OBD II Toolpak.

2. Press ¡ to select Parameters from the OBD II Toolpak menu.

3. Press º to select Definitions from the Parameters menu. The key help

screen will be displayed.

4. Press u or d to move the cursor to the desired diagnostic data

parameter.

5. Press e to display the first text screen for the selected parameter.

Press d to advance through the text description screens. Press u to

view the previous text description screen.

6. Press x to return to the Parameter Definition list or the Parameters

menu.

ACTIVE KEYS

ª Select OBD II Toolpak.

u / d Scroll up and down.

º / ¡ Select or deselect a parameter.

e View parameter description.

x Exit to the previous test menu.

4-43

Page 65

GLOBAL OBD II WITH TOOLPAK

MODE F9 OBD II TOOLPAK

SUBMODE F1 PARAMETERS

SUBMODE F1 RANGES

F1: RANGES

Common high and low values for each diagnostic data parameter are

available when connected to a vehicle and viewing a live data list, or during

a shop or training review session. Current diagnostic data parameter values

are available during connection to the vehicle powertrain system. The

common high and low values were obtained by collecting data from actual

OBD II certified I4, V6, and V8 powertrain systems operating with no faults

detected.

OPERATING PROCEDURE

1. Press ª to select OBD II TOOLPAK from the Select Mode menu.

2. Press ¡ to select Parameters from the OBD II Toolpak menu.

3. Press ¡ to select Ranges from the Parameters menu. The key help

screen will be displayed.

4. Press d , u , or E to advance through the text description

screens. These text screens indicate that the displayed common high

and low values are from actual OBD II certified systems.

5. Press u or d to move the cursor to the desired data parameter.

6. Press e to display the first data condition screen for the selected

parameter. The data condition screen displays the condition for which the

hi/lo data is valid. The data condition and parameter name will toggle on

the first display line. The y or n keys can be used to toggle

between the data condition and the parameter name.

7. Press u or d to advance through the data conditions. As before, The

data condition and parameter name will toggle on the first display line.

The y or n keys can be used to toggle between the data condition

and the parameter name.

The data conditions are listed in the following chart:

4-44

Page 66

GLOBAL OBD II WITH TOOLPAK

OBD II TOOLPAK MODE F9

PARAMETERS MODE F1

RANGES SUBMODE F1

Data Condition Display, Line 1

key on, engine off Key On, Eng Off:

key on, engine running at idle KOER, IDLE RPM:

key on, engine running at 2500 RPM KOER, 2500 RPM:

key on, engine running, in drive, 0 MPH KOER-DRV, 0MPH:

key on, engine running, in drive, 15 MPH KOER-DRV, 15MPH:

key on, engine running, in drive, 25 MPH KOER-DRV, 25MPH:

key on, engine running, in drive, 35 MPH KOER-DRV, 35MPH:

key on, engine running, in drive, 45 MPH KOER-DRV, 45MPH:

key on, engine running, in drive, 55 MPH KOER-DRV, 55MPH:

key on, engine running, in drive, KOER-DRV, WOT:

wide open throttle acceleration

key on, engine running, in drive, KOER-DRV, CTD:

closed throttle deceleration

8. The actual value for the current parameter is displayed on line 2 (ONLY

if the tester is connected to an OBD II system and F9: OBD II Toolpak is

selected from the select mode menu). If the tester is not connected to an

OBD II system and F9: OBD II Toolpak has not been selected from the

select mode menu only the common high and low values are displayed.

9. Common high (hi) and low (lo) parameter values for the data condition

are displayed on lines 3 and 4 (common hi and lo values were obtained

from actual vehicle powertrain systems with OBD II certified systems).

10. Press x to return to the parameter list or Parameters menu.

ACTIVE KEYS

u / d Scroll up and down.

e Select parameter to view.

y & n Toggle display.

x Exit to the previous test menu.

4-45

Page 67

GLOBAL OBD II WITH TOOLPAK

MODE F9 OBD II TOOLPAK

SUBMODE F2 DTC LIBRARY

F2: DTC LIBRARY

An OBD II ECU is capable of setting a DTC which indicates the failed circuit

or component. In some cases, reading DTCs from the ECU may reveal

multiple stored DTCs. However, the ECU is programmed to potentially store

several hundred DTC’s.

F2: DTC Library enables you to obtain text description information for each

powertrain DTC available for display. The DTC Library consists of a

combination of DTCs defined by the manufacturer specifically for the vehicle

under test and DTCs defined by the Society of Automotive Engineers (SAE).

For any DTC number that is not defined by the manufacturer of the vehicle

under test, a description defined by Society of Automotive Engineers (SAE)

recommended practice J2012 will be displayed. A specific DTC may be

entered individually or you can scroll through the entire DTC list.