VET-PRO VIP 2000 Operator's Manual

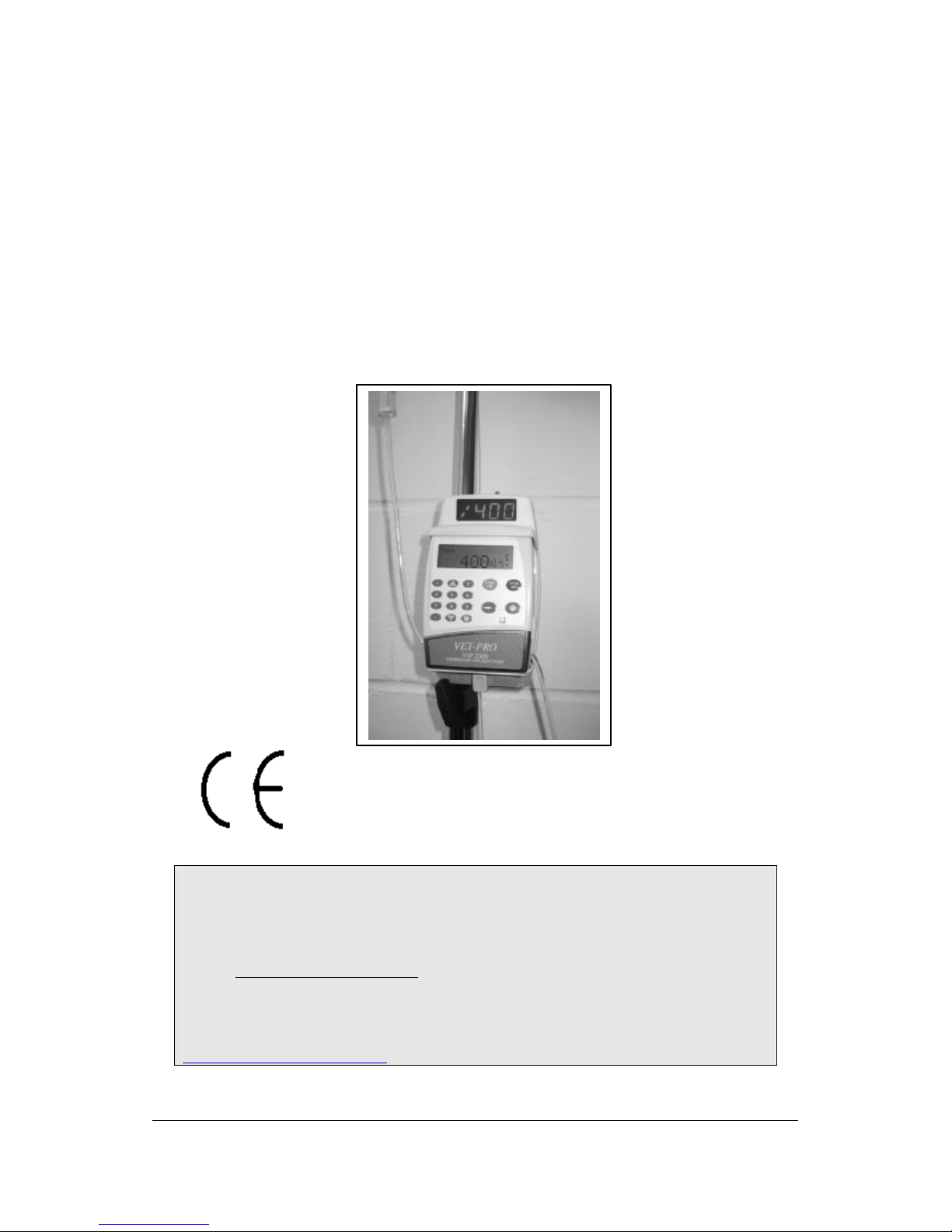

VET-PRO

VIP 2000

VETERINARY INFUSION PUMP

OPERATORS MANUAL

0473

Distributed in the U.K by:

Burtons Medical Equipment Ltd

Units 1 - 4 Guardian Industrial Estate

Pattenden Lane Marden Kent TN12 9QD UK

Email: info@burtons.uk.com

Tel (SALES) : 01622 834300 Fax: 01622 834330

URL:WWW.burtons.uk.com

EDITION MARCH 2002

Ref.: 100-090VX

VET-PRO Operator’s Manual

2

LIMITED WARRANTY

The VET-PRO Infusion Pump has been carefully manufactured from the highest quality

components.

The pump is guaranteed against defects in material and workmanship for twelve (12) months

from date of purchase by the original purchaser.

The obligation under this Limited Warranty, shall be limited, at the manufacturer’s option, or

that of its designated representative, to repairing or replacing pumps, which upon examination,

are found to be defective in material or workmanship. The repair or replacement of any

product under this Limited Warranty shall not extend the above-mentioned Warranty period.

All repairs under this Limited Warranty should be undertaken only by qualified, trained

service personnel. In the event that a pump is found to be defective during the warranty period,

the purchaser shall notify the manufactuer or its designated representative within thirty (30)

days after such defect is discovered.

The defective pump should be sent immediately to the manufacturer or its designated

representative for inspection, repair or replacement. Shipping costs are the purchaser’s

responsibility.

Material returned to the manufactuer or its designated representative should be properly

packaged. Inadequate packaging may result in severe pump damage.

This Limited Warranty shall not apply to defects or damage caused, wholly or in part, by

negligence, spilt fluids, dropping of the pump, misuse, abuse, improper installation or

alteration by anyone other than qualified, trained personnel; or to damage resulting from

inadequate packaging in shipping the pump to the manufacturer or its designated

representative.

If, after inspection, the manufactuer or its designated representative is unable to identify a

problem, the manufactuer or its designated representative reserves the right to invoice

purchaser for such inspection.

This Limited Warranty is the sole and entire warranty pertaining to the manufacturer’s

products and is in lieu of and excludes all other warranties of any nature whatsoever, whether

stated, or implied or arising by operation of law, trade, usage or course of dealing, including

but not limited to, warranties of merchantability and warranties of fitness for a particular

purpose. Purchaser expressly agrees that the remedies granted to it under this limited warranty

are purchaser’s sole and exclusive remedies with respect to any claim of purchaser arising

under this Limited Warranty.

VET-PRO Operator’s Manual

3

Contents

Introduction …………………………………………………………………………

4

Glossary ……………………………………………………………………………..

5

Safety Precautions ……………………………………………………………………

6-7

Specifications ………………………………………………………………………..

8-9

Ordering Information 9

Trumpet and Flow Rate ………………………………………………………………

10-11

VET-PRO Front view ………………………………………………………………

12-13

VET-PRO with Open Door ………………………………………………………….

14

The Charger ………………………………………………………………………….

15

Optional Cage Mounting Bracket 16

Unpacking …………………………………………………………………………..

17

Loading the Administration Set …………………………………………………………….

17

Flush Function. …………………………………………………………………….

18

VET-PRO Operating ………………………………………………………………..

19

Pump Operation Test. ………………………………………………………….……

19

Air in Line Alarm Test. ……………………………………………………………..

20

Door Open Alarm Test. ……………………………………………………………..

21

Down Occlusion Alarm Test. ………………………………………………………

22

Charge Indicator Test. ………………………………………………………………

22

Programs …………………………………………………………………………….

23

Changing Current Program………………………………………………………………... 24-25

Down Occlusion Setting ………………………………………………………..……

26

CONTINUOUS Program……………………………………………………………..

27-30

25

STEPS PROTOCOL……………………………………………………………………..

30-31

TPN Program ………………………………………………………………………..

32-34

INTERMITTENT Program …………………………………………………………..

35-37

PCA Program – with protocols ………………………………..……………………..

37-44

PCA Program – Epidural Mode ………………………………..……………………..

45-46

PCA Program – without protocols ……………………………………………………

46

INFO Mode …………………………………………………………………………

47-48

Program Delay ………………………………………………………………………

48-49

Program Completed …………………………………………………………………

49-50

Locking ……………………………………………………………………………..

50-51

How to Lock …………………………………………………………………………

51-53

Battery Operation. ……………………………………………………………………

53-54

Cleaning and Storage ……………………………………………………………………….

54-55

Alarm Conditions……………………………………………………………………..

55

Troubleshooting

……………………………………………………………………..

55-58

Show Setting

………………………………………………………………………..

58-59

Adjust Setting ……………………………………………………………………….

59-60

VET-PRO Operator’s Manual

4

Introduction

This Manual Provides directions for the setup and operation of the VET-PRO

Pump

VET-PRO Features

S Small, light and compact pump.

S Multi Programs:

CONTINUOUS

Continuous program.

Infusion Rate: 0.1 to 1200 ml/hr.

Volume: 0.1 to 9999 ml.

User can design a specific protocol, for drug

delivery, which contains up to 25 steps.

Infusion Rate: 0.1 to 1200 ml/hr.

Volume: up to 9999ml., For each step.

Accumulated Volume for all steps – up to 10

liters.

Rate Taper program, with programmable up

and down times

INTERMITTENT

A set Dose delivered in set intervals. Between

Intervals the pump will allow a base rate or

KVO.

PCA

Patient Control Analgesia, continuous delivery

plus /or programmed boluses.

Bolus Rate: 0.1-1000 ml/h

S

Highly accurate fluid delivery. The piston mechanism ensures an accurate

volume delivery over more than 24 hours using the same administration set

segment

S Operated with a customized safe administration set

S Rechargeable internal battery

S Can be latched into a Charger, which is mounted on an IV pole

S A.B.S. Anti-Bolus System

S Silent operation

25 STEPS

TPN

VET-PRO Operator’s Manual

5

Glossary

Terms used in manual:

F

Note:

Essential operating procedure or condition.

G

Caution:

A precaution which, if not followed, could result in extensive

damage to the equipment.

I

Warning

A precaution, which, if not followed, can result in personal

injury or loss of life.

VET-PRO Operator’s Manual

6

Safety Precautions

I

Warning

F

To avoid possible personal injury or loss of life, observe the following:

Note: Read the entire Operation Manual before using the pump, since the

text includes important precautions.

•

Disconnect the Charger from the mains, prior to opening the casing.

Voltage present on internal components may cause severe shock or death

on contact. Only trained service personnel should open the pump cover.

•

Before servicing pumps connected to mains via the Charger - remove

rings, watches, and other jewelry, which may present a shock / burn

hazard.

•

To prevent a fire hazard, replace blown fuses on the Charger only with

fuses of the same type and rating (see fuse values on the Charger PCB).

•

The equipment is not suitable for use in the presence of flammable gases

– e.g. air/oxygen/nitrous oxide mixture.

•

Watch your fingers / nails when opening the pump door.

To avoid possible injury to patient, observe the following:

I

Warning

Battery charging is enabled as long as the charger cord is

connected to the mains and the pump is in the charger.

Switching the pump off does not disconnect it from the

mains. In order to disconnect from the mains, take the

charger cable out of the mains. In order to disconnect pump

from the mains, take it out of the charger.

F Note:

To avoid battery damage do not leave the pump battery in a

temperature more than 500C

•

Make sure the pump is attached securely to the Charger, which is

connected snugly to an IV pole.

•

If the pump is dropped, return the pump for inspection by qualified

service personnel.

•

Before operation, verify that administration set tubing is not kinked or

occluded.

VET-PRO Operator’s Manual

7

•

Although the pump will operate using a variety of giving sets, use of

other administration sets may impair the operation of the pump and the

accuracy of the infusion.

F Note:

The maximum volume that may be infused under SINGLE FAULT

CONDITION

is 0.1 ml

G CAUTION

To avoid possible damage to the equipment, observe the

following:

•

Do not immerse the pump in liquids.

•

Clean solution spills on the pump immediately. Use a damp

cloth or sponge. A cleaning disinfectant may be used. Wipe

thoroughly with a dry cloth.

•

Do not clean pump with chemicals such as Xylene, Acetone or

similar solvents. These chemicals cause damage to plastic

components and paint.

IWarning:

Any adjustments, maintenance, or repair of the uncovered

pump while connected to the power should be avoided. If

necessary, these repairs should be carried out by skilled

technicians who are aware of the hazards involved.

IWarning:

The pump should be operated within an ambient temperature

range of 15°C to 35°C. and at up to 85% humidity

IWarning

:

Do not operate the pump near high-energy radio-frequency

emitting equipment, such as electro-surgical cauterizing

equipment, and cellular telephones. False alarm signals may

occur.

VET-PRO Operator’s Manual

8

Specifications

Pumping Mechanism: Piston Mechanism

Flow Rate: PCA: 0 to 100 ml/hr in 0.1ml increments

All other programs: 0.1 to 1200 ml/hr in 0.1ml or

1 ml increments.

Total Infused Volume: PCA: 0.1 to 1,000 ml.

Continuous, TPN, Intermittent: 0.1-9999 ml

25 Steps: 0.1 to 9999 ml. for each step

Accumulated volume for all steps- up to 10 liters.

Total Time Setting 100 hours

Accuracy: ± 3 %.

KVO rate: 0.1 to 5 ml/hr. (to be set)

Air Sensor: Ultrasonic, adjustable air bubble size

Maximum Pressure: 0.7 bar or 10 psi Adjustable (high/normal/low)

Power Supply: 110-240 VAC, 50/60 Hz. 20 W

Battery: Li-Ion 7.2V, 1450mA. (Rechargeable)

Battery Operation at 125 ml/hr 20 hours

Battery Charging:

Automatic when latched into the Charger

connected to an AC power source (4 hours)

Alarms: End Program

Low & End Battery

Air in line

Down Occlusion

Door Open

Pump Unattended

Internal Malfunction

Locking state

Missing Key

Dimensions:

112 x 89 x 32mm. (L x w x h).

Symbol Attention (Consult accompanying documents)

VET-PRO Operator’s Manual

9

Specifications

Classification

Type CF Equipment

(degree of protection against electrical shock)

Housing: ABS (fire retardant)

Weight

280 gr. without battery

390 gr. With battery

Electrical Safety Complies with:

IEC 601-1 (Medical Electrical Equipment Safety),

IEC 601-2-24 (Infusion pumps and controllers),

IEC 601-1-4 (Programmable Electrical Medical

System), UL 2601- 1 and CAN/CSA C22.2 No

601.1.

Standards Manufacture in accordance to ISO 9001 and

EN 46001

CE marked (In accordance with the Medical

Devices Directive 93/42/EEC)

Ordering Information

129-000 VetPro 2000 Infusion pump c/w mains cable, carry case and

operators manual.

129-010 Veterinary Administration Set – Sold in packs of 25.

129-050 Cage mounting bracket – fits Suburban, Shor, Technik, & HC two

cages.

129-051 Cage mounting bracket – fits Geeling cages and others with

50mm x 50mm mesh doors.

VET-PRO Operator’s Manual

10

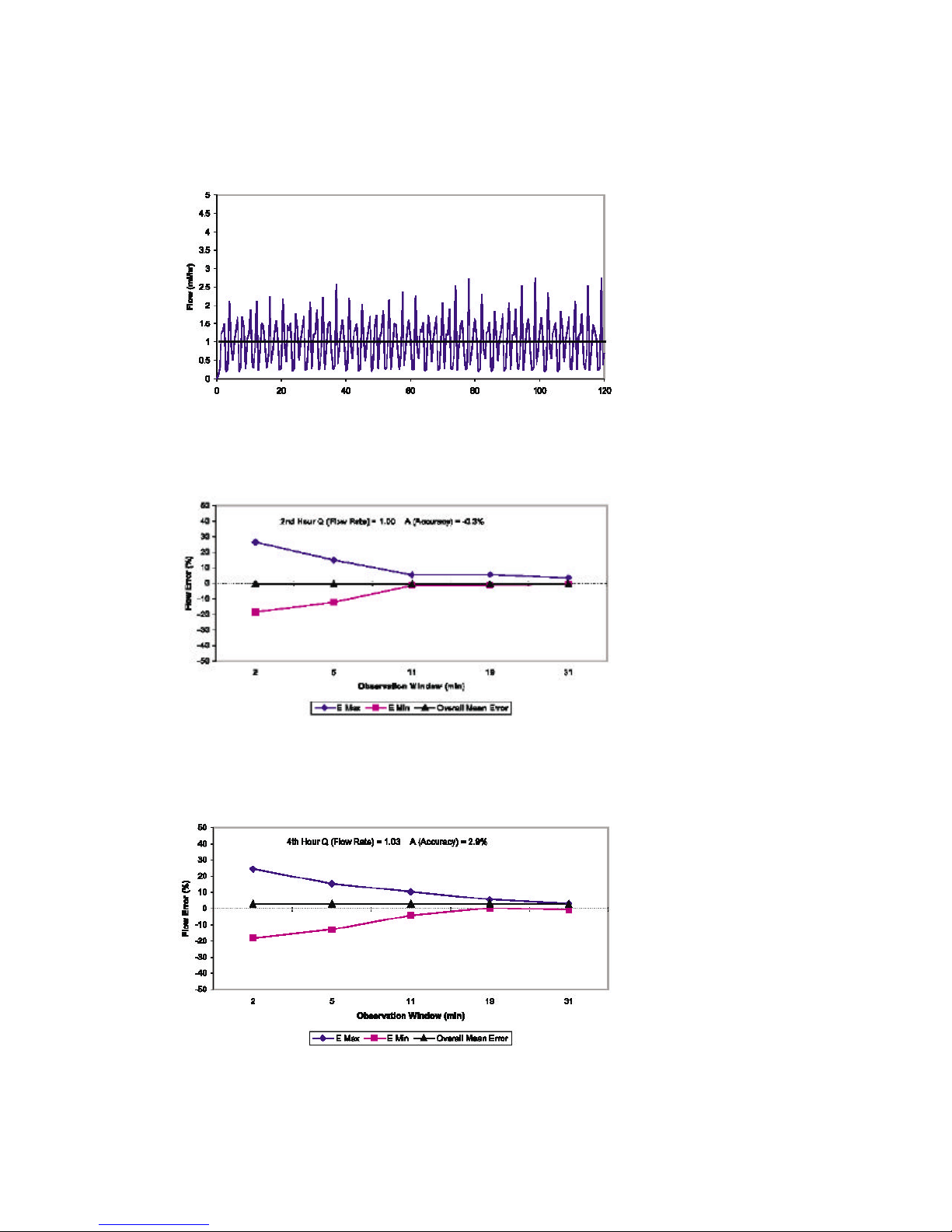

Trumpet and Flow Rate

In VET-PRO, as with all infusion systems, the action of the pumping

mechanism and variations cause short – term fluctuations in rate accuracy.

The following curves show typical performance of the system in two ways:

1. The accuracy of fluid delivery over various time periods is measured

(Trumpet curves).

2. The delay in onset of fluid flow when infusion commences (Start up

curves).

Trumpet curves are named for their characteristic shape. They display discrete

data averaged over particular time periods or “Observation windows”, not

continuous data versus operating time. Over long observation windows, shortterm fluctuation has little effect on accuracy as represented by the flat part of

the curve. As the observation window is reduced, short-term fluctuations have

greater effects as represented by the “mouth” of the trumpet.

Knowledge of system accuracy over various observation windows may be of

interest when certain drugs are being administered. Short term fluctuations in

rate accuracy may have clinical impact depending on the shelf-life of the drug

being infused and the degree of intravascular integration, the clinical effect

cannot be determined from the trumpet curves alone.

The Start-up curves represent continuous flow versus operating time for two

hours from the start of the infusion. They exhibit the delay in onset of delivery

due to mechanical compliance and provide a visual representation of

uniformity. Trumpet curves are derived from the second hour of this data.

Tests performed according to IEC 601-2-24 standard.

VET-PRO Operator’s Manual

11

Start-Up Graph at 1.0 ml/h (Initial Period)

Using Human BodySet

Time (minutes)

Trumpet Graph at 1.0 ml/h (Initial Period)

Using Human BodySet

Overall Mean Error = -0.1% Max Rate Error = 8%

Trumpet Graph at 1.0 ml/h (After 4 Hours)

Using Human BodySet

Overall Mean Error = -1.1% Max Rate Error = 6%

VET-PRO Operator’s Manual

12

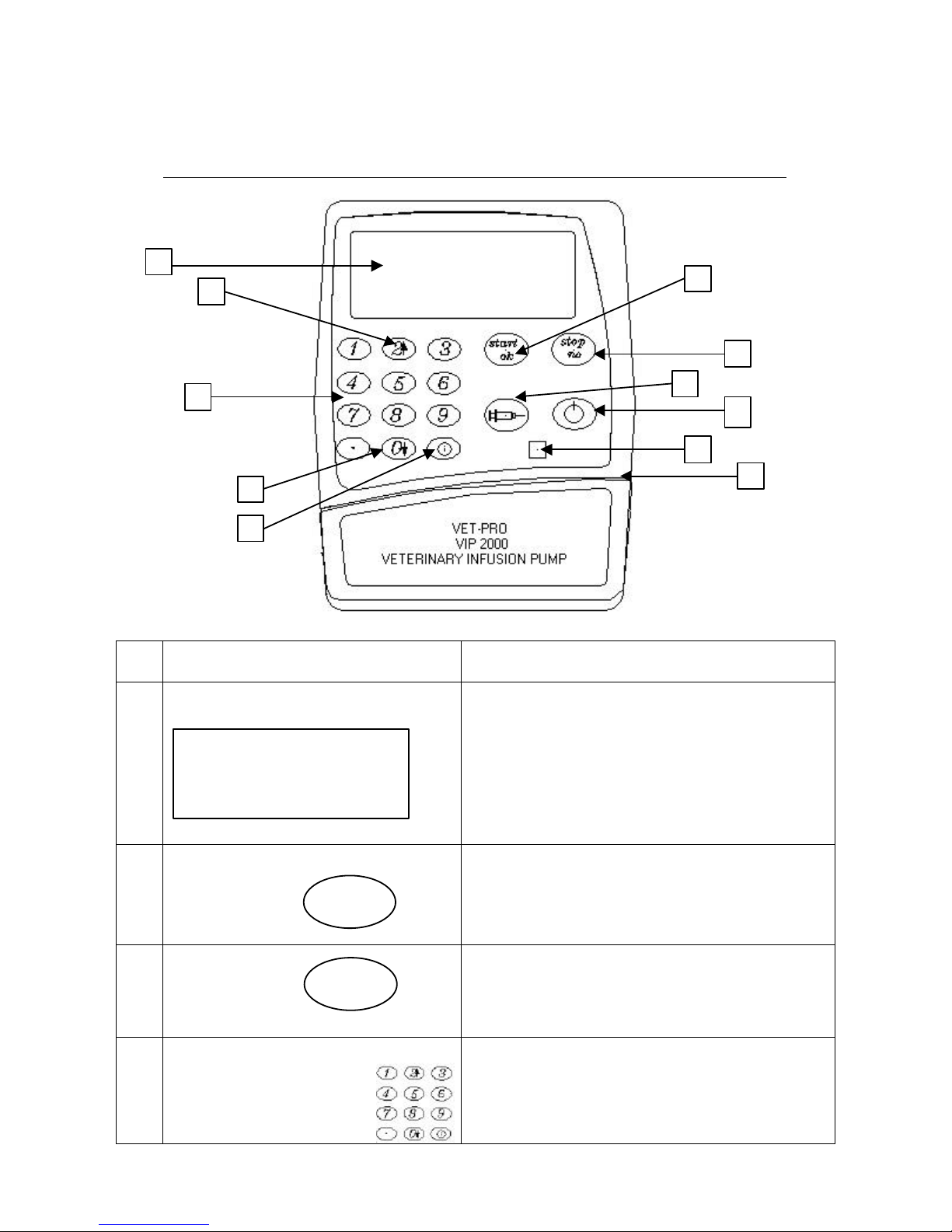

VET-PRO Front View

No.

Description

Function

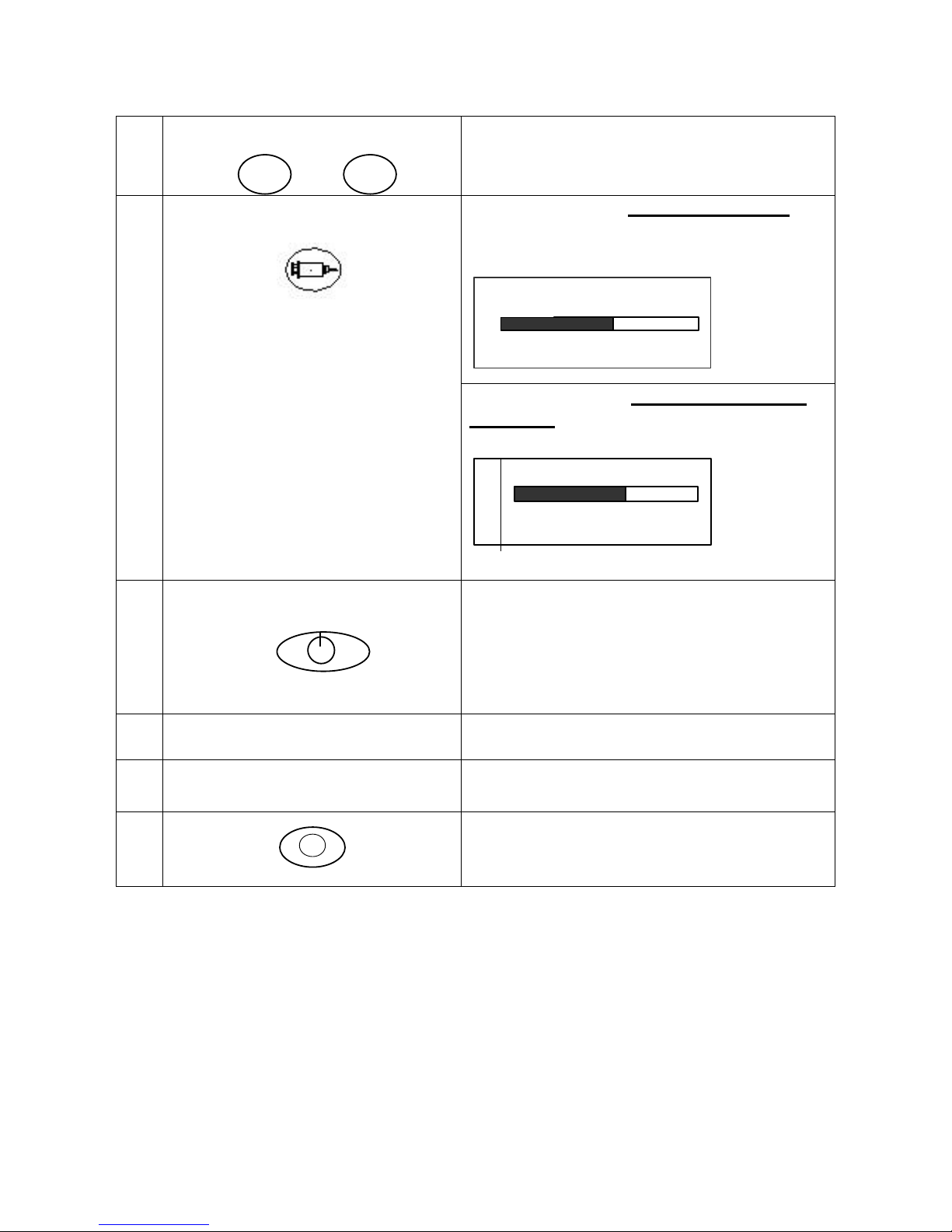

1.

Display

Displays: Selected Infusion Rate, Total Time,

Time Delay, Volume To Be Infused and

Volume Infused.

2.

START/ OK Key

START

OK

Starts pump operation and delivery.

Confirms selection and setting.

3.

STOP/NO key

STOP

NO

• Silences an alarm condition and pauses

operation.

• Zeroes the displayed value during setting

•

Press to return to previous screen

4.

Numeric Keyboard

Used to set the RATE, TIME limit and VTBI.

Dial the required number.

Pressing NO will erase the last digit.

Rate: 125 ml /h

Press OK for Volume

8

7

3

4

9

VET-PRO Operator’s Manual

13

5.

Arrow keys

2£ 0¤

Enable scrolling through options.

Pressing Syringe key during data setting:

Enable Flushing procedure.

Flushing default volume: 4 ml.

6.

Syringe key

Pressing Syringe key during PCA program

operation:

Enable bolus procedure.

7.

On / Off key

Turns the pump on and off.

§ To turn the pump on press until the

self- test screen appears

§ To turn the pump off press until the

OFF Graph is all black and a beep is

sounded.

8.

Operation LED

Flashing of the LED indicates that the set

program is running.

9.

Door Latch

Opens the pump door.

Lift to open the door.

10.

Info key

i

Pressing Info key supplies information about

the pump and its programs (see info mode

chapter).

FLUSH 2 ml

0

4

B Volume, ml.

O

L

U

0 2.8 5

VET-PRO Operator’s Manual

14

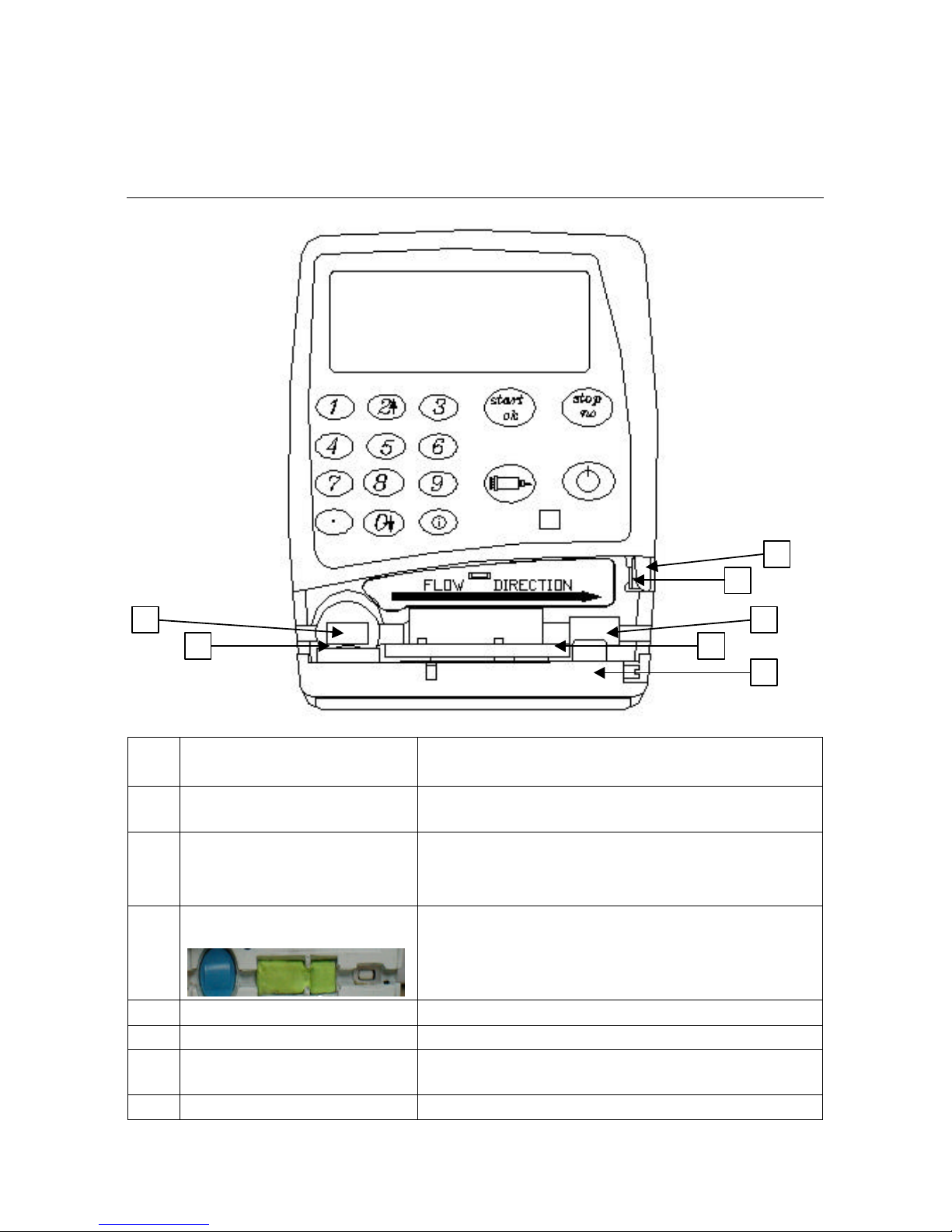

VET-PRO –with door open

No. Description

Function

1.

Latch holder

Holds the door closed when latch is in vertical

position.

2.

Pressure sensor

Detects downstream tubing restriction and

occlusion. Alarm level can be adjusted to suit

patient needs.

3.

Tubing Guide

Guide the administration set

4.

Pressing Plate

Connected to the door by 2 springs.

5.

Pump door

Covers the pressing plate.

6.

Air sensor – front

Ultrasonic air detector, which is mounted on the

front housing.

7.

Air sensor

-

door

Mounted on the door.

2

1

3

4

5

VET-PRO Operator’s Manual

15

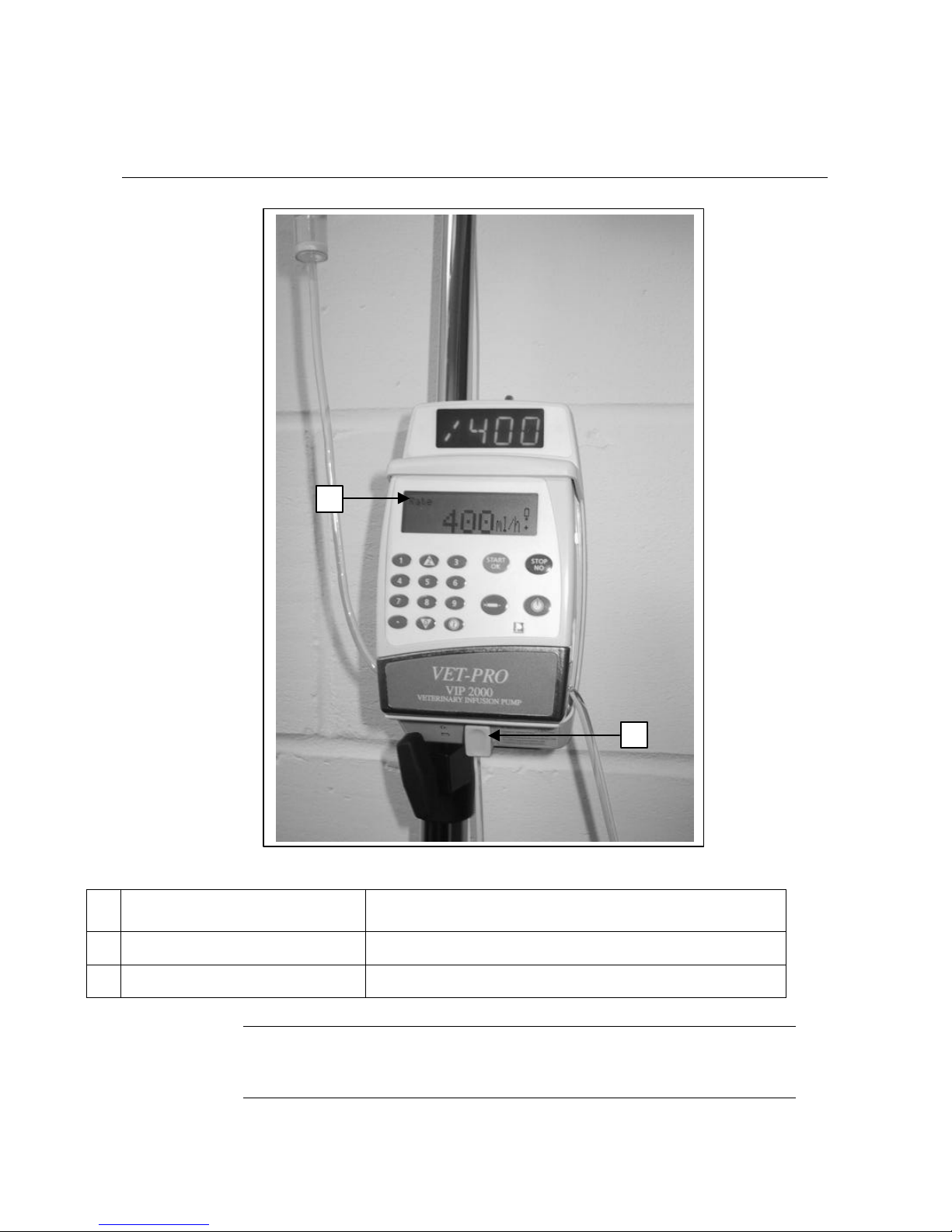

The Charger

IV Set Requirements

The VET-PRO pump should be operated only with the Bodyset.

The Bodyset administration set is supplied with an integrated valve (see

drawings below).

No

. Description Function

1.

Flow counter

Check the Flow

2.

Release Handle

Push to release the pump from the Charger.

F

Note:

The pump is protected against overcharging. In order to keep

your battery fully charged, connect the pump to the mains via the

charger whenever possible.

2

1

VET-PRO Operator’s Manual

16

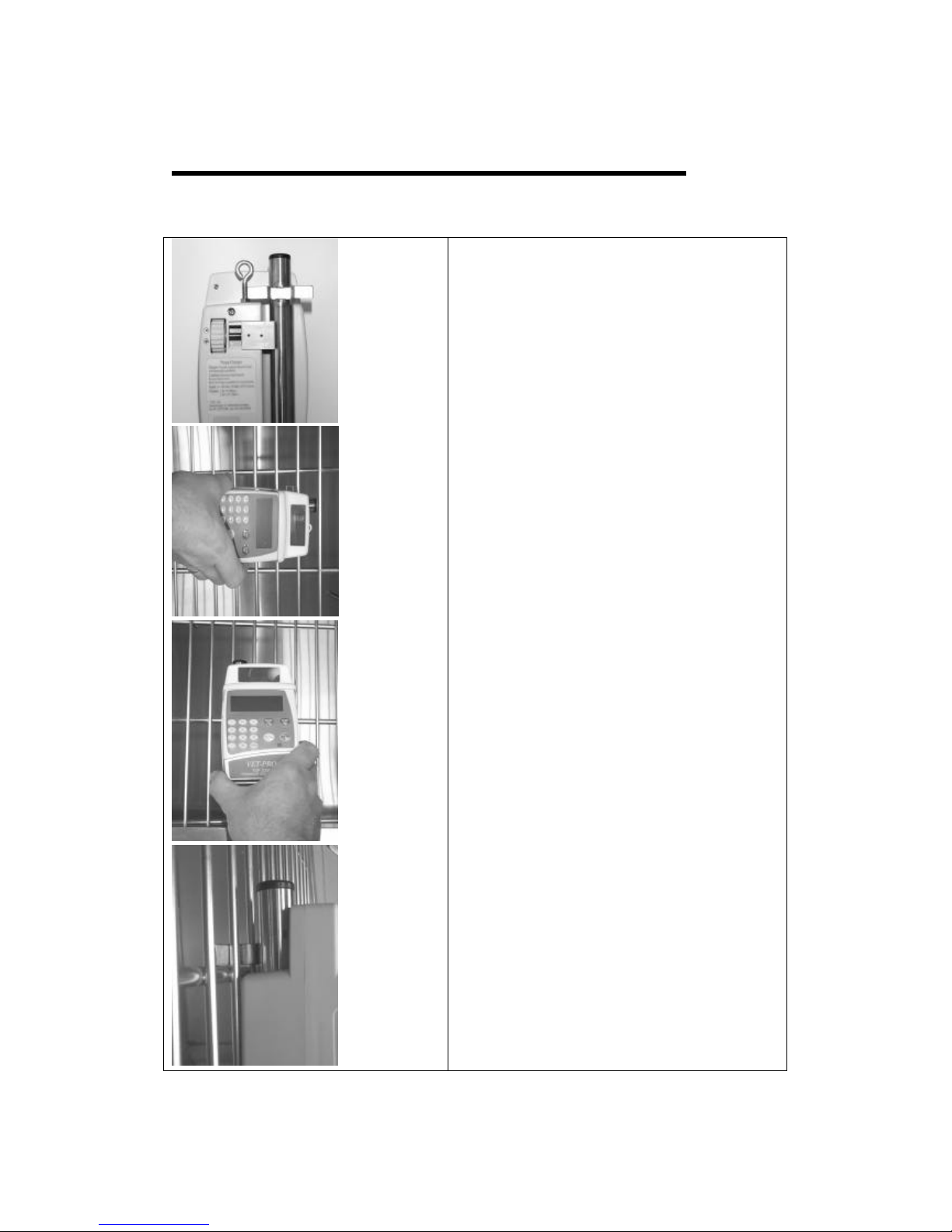

Optional Cage Bracket

Fig.1

Fig.2

Fig.3

Fig.4

Engage the pole of the bracket in the

slot on the rear of the charging base

(Fig.1). Rotate the clamp wheel until

the pole is held firmly. Ensure that the

horizontal arms of the bracket face

outward and are just above the top of

the pole slot.

Locate the arms of the bracket through

the grille of the cage door (Fig.2 & 3).

The arms should be rested on a

horizontal grille brace (Fig.4).

Stock code 129-050 is suitable for use

on most popular cage manufacturers

doors such as Suburban, Shorline,

Technik and HC Two.

Stock code 129-051 is suitable for use

on cage doors with a mesh size of

50mm x 50mm such as Geeling.

Please contact our sales team if you

need guidance on the suitability of

these brackets for your cage doors.

VET-PRO Operator’s Manual

17

Unpacking:

1.

Carefully remove the pump and charger from the box.

2.

Make sure no items were damaged during shipment

3.

Make sure you have the following items:

•

VET-PRO Infusion Pump

•

Charger

•

Battery Pack

•

Operator’s Manual

•

Mains Cable

If any items are missing or damaged, contact your VET-PRO supplier.

Loading the Administration Set

F

Note:

Follow the Instructions supplied with the individual

administration set.

Use of any administration set, other than the original

manufacturers, may impair the operation of the pump and the

accuracy of the infusion.

1.

Lift the door latch to open the pump door.

2.

Insert the IV tubing into the tubing guide, following the direction flow label

located above the tubing slot. Insert the tubing from left to right, and avoid

stretching or pulling the tubing. Check key is located in correct position.

3.

Ensure that the distal flow valve is on the right hand side of the pump.

4.

Close the pump door. Press on the door to close firmly, ensure that the latch

is correctly applied.

F

Note:

Ensure that the tubing is inserted completely into the pumping

channel.

ADMINISTRATION SET RE-ORDER CODE 129-010

SUPPLIED IN PACKS OF 25

VET-PRO Operator’s Manual

18

Flush Function (Priming)

Flush Function is used:

1.

Before starting a program (see instruction below);

2.

After the air in line alarm, as follows:

Press STOP/NO key to mute the alarm. Disconnect IV tubing from

patient; press the SYRINGE key to push air bubbles through.

When flushing is completed press START/OK key to resume program.

Flush operation

1.

Switch on the pump using the ON/OFF key. (Press until the self-test screen

appears). After a short self-test, the pump will display the program setting

and status followed by the last setting rate.

FLUSH

2.

Press the SYRINGE key to flush the

administration set.

ENSURE THE SET IS NOT CONNECTED

TO THE PATIENT !!

Press OK to start

3.

Press the START/OK key to start flushing.

4.

The display will show a graph indicating the

flush operation.

FLUSH 2 ml

0 4

5.

Once the flushing is completed, the display will change back to the previous

screen the pump was in, before flushing.

F

Note:

The flushing rate can be adjust, in adjust setting options, up

to 1200 ml/h. The default is 600 ml/hr. During flushing the

air in line alarm is disabled.

I

Warning

Always disconnect IV tubing from patient before starting

flushing procedure.

Loading...

Loading...