Page 1

Manual Weighingblock VB2 series and Uniscale

Normal Calibration

Calibration

switch

ON

PRINT

NET

GROSS

OFF

ZERO

TARE

Communica-tions

port

External power

9 VDC

Alkaline

batteries

The Weighingblock is a robust Scale. It is designed for portable use. When

transported by car between different working places we recommend using of a

protected space or a case. This will extend the interval for service.

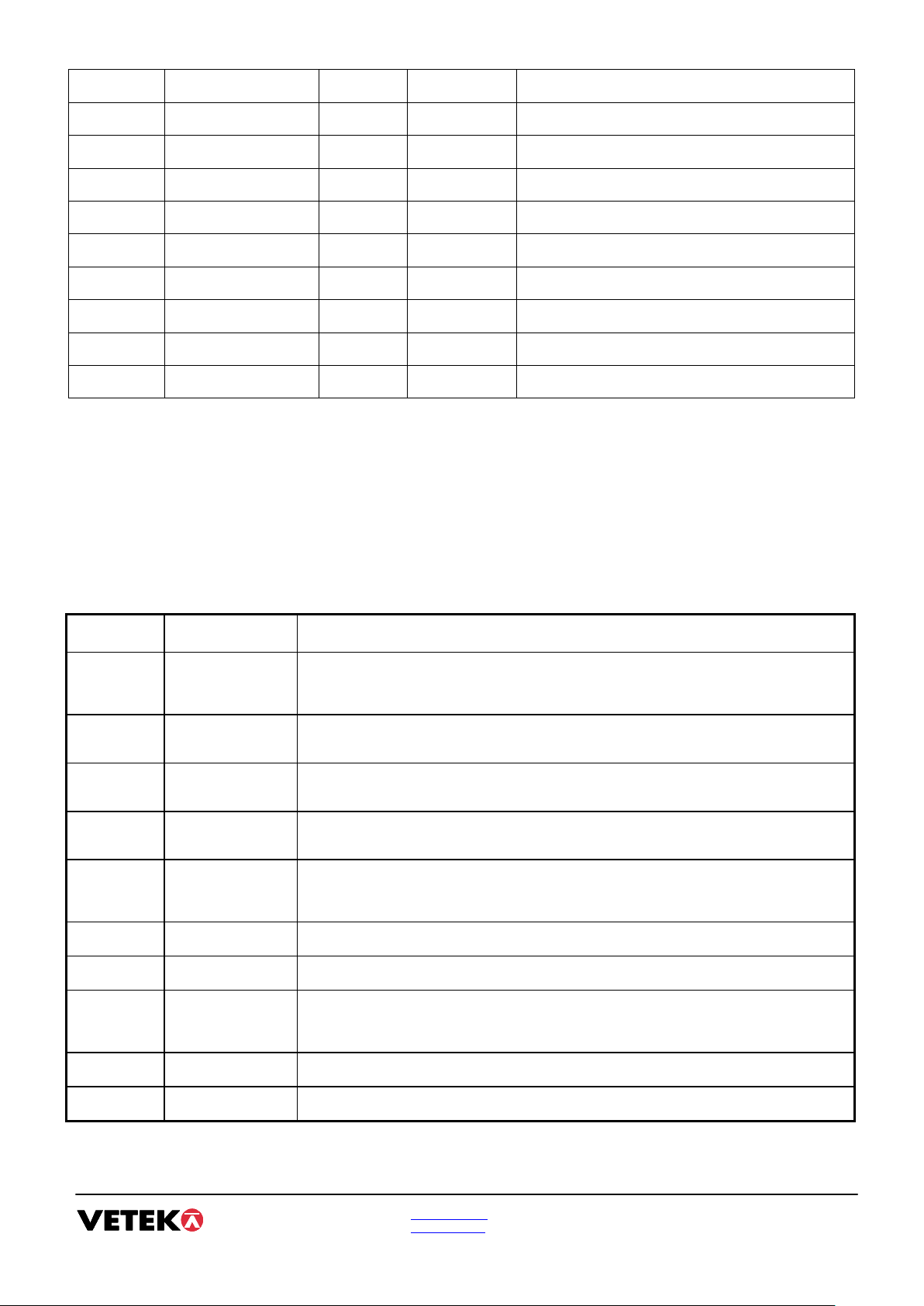

Overview different ranges.

Model

Model

Capacity / Graduation

VB2-30-EC

Max 30 kg / 10 g

VB2-100-EC

Max 100 kg / 10 (50) g

VB2-200-EC

Max 200 kg / 20 (100) g

VB2-200-EC-TM

Max 200 kg / 100 g

VB2-200-50-TM

Max 200 kg / 50 g

VB2-30-05

Max 30 kg / 5 g

VB2-100-02

UNISCALE 100kg/2g

Max 100 kg / 2 g

VB2-100-10

Max 100 kg / 10 g

WS-130

Max 130 kg / 10 g (special)

VB2-130-10

UNISCALE 130kg/10g

Max 130 kg / 10 g

VB2-200-10

Max 200 kg / 20 g

UNISCALE 200kg/5g

Max 200 kg / 5 g

UNISCALE 200kg/50g

Max 200 kg / 50 g

Note: At page 8 in this manual you will find a short form instruction. Normally the only

instruction shipped together with the Scale.

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

Tel +46 176 208 920

page 1

Manual_VB_V2

Page 2

Table of contents Page

Indicator ON

In not EC-type approved version: Sends "Print" data to printer if scale is stable and not in

overload. Not active when "Continuous" option is selected in User Menu.

“Dot”. Extended graduation to 10 g for VB2-100-EC and 20 g for VB2-200-EC when pushed

and 5 sec after release.

Toggles between Gross and Net weight display only if a Tare has been established.

Sets scale to display "0" when in Gross mode, and within zero band range. When pushed

in for 3 seconds, the Scale switches off.

Used to establish a Tare (zero the Scale) while in either Gross mode or

Net mode. This operation cannot be performed at or below Gross zero.

ON

PRINT

NET

GROS

OFF

ZERO

TARE

Introduction, Keyboard Functions 2

Configuration and Setup Menu. Display 3

Parameters 4

Calibration 5

Specifications and Displayed Error Codes 6

Fault localization and repair 7

Instruction for handling 8

Solenoid module VBB-10 9

Introduction

Veteks new VB2 series of Weighingblocks are rugged digital scale casted in strong aluminum. It comes standard with a large (.75") LCD

screen for easy readout. All setup parameters may be entered via the membrane panel keys. The Scale has an ”intelligent” auto

power off function and is equipped with 6 pcs alkaline 1,5 V batteries LR6/AA. If the battery is not good enough to ensure a

correct value the scale will turn off.

The scale is developed especially for weighing of refrigerant cylinders, and to control when transferring refrigerants to other cylinders or

equipments. The scales setup parameters are altered through the Setup menu while a few other parameters are altered

through the User menu The configuration section of the manual explains how to use the five front panel keys to

maneuver and save settings in both menus.

There are categories of Scales: Non - Automatic weighing instruments and Automatic weighing instruments.

Weighingblocks and other Scales used only for weighing e.g. cylinders are Non - Automatic weighing instruments. When

using a Non - Automatic scale in commercial purpose in any of the EC countries it is prescribed by law that the scale

must be EC-type approved. If the purpose not is commercial or the Scale is used as an automatic batching Scale there is

no legal demands.

If the Scale is used as a Batching Scale it is an Automatic weighing instruments and there is no legal demands. But this

has to be checked with the authorities in each country.

VB2 series of EC-type approved Weighingblocks:

The parameters shall not ever be changed because of the approval. Authority must do the verification. The user needs a good acknowledge

about all rules and the laws. To get complete information we recommend taking a look at http://www.sp.se or other authorities web sites.

VB2 series of not approved Weighingblocks:

Cannot be verified

The Weighingblocks are suitable for use in weighing applications as: refrigeration cylinders, fire protection

cylinders, CO2, cylinders, parcels, persons, etc.

Keyboard functions

The calibration switch is only for calibration.

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

Tel +46 176 208 920

page 2

Page 3

Configuration

LCD Enunciator

MEANING

0

Better known as the “Center of Zero” enunciator, this light is active whenever the displayed

weight is within ± 0.25 divisions of true zero.

N

Indicates that the indicator is displaying net weight.

G

Indicates that the indicator is displaying gross weight.

T

Indicates that a tare weight has been established in the system.

lb, kg

Indicates the unit of the displayed weight (normally disabled).

bAtt

Indicates a low battery condition. Re-charge the battery or replace if alkaline batteries.

Indicates stable weighing.

ON

PRINT

NET

GROSS

OFF

ZERO

TARE

Setup menu.

To do this configuration you need to have a good acknowledge how a digital electronic Scale works. Note: If the

Scale fails, it is not always sure the Scale needs a configuration.

Except the Normal Meny the Weighingblock has two menus.

The Setup menu, containing most of the indicator's functional Setup parameters, consists of 15 separate menu selections,

each with its own sub-menu of choices.

The User menu, except A5 and A10 containing most of the indicator's serial communication parameters, which not are

shown in this manual.

SETUP MENY

1. Turn the power OFF.

2. Put Calibration Switch to the Calibration position.

3. Turn the indicator ON.

4. The display shows "F1" to indicate that the unit is in Setup menu mode.

5. To move to a new “F” heading, use TARE or ON to move up or down.

6. To move to the selection value, press ZERO once.

7. Increase and decrease the value with PRINT and TARE.

8. To save the value, press NET.

9. Press Dot to go back to parameter number.

10. To go back to normal menu put Calibration Switch to the Normal position.

NOTES ON THE SETUP MENU

There is an F21 sub-menu present that is for FACTORY USE ONLY!

DISPLAY

VB2 Enunciator Definitions

PARAMETER DESCRIPTION CODE/VALUE

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

Tel +46 176 208 920

page 3

Page 4

F1

Graduations

Specifies number of the Weighingblocks graduations. Value should be

consistent with legal requirements and environmental limits on the useful

system resolution.

500 1000 1500

2000 VB2-100-EC / 200-EC 2500

3000 VB2-30-EC 4000 5000

6000: VB2-30-05 8000

10000: VB2-100-10 / 200-20

13000: WS-130

F2

Sampling rate

Sampling rate. 10 or 80Hz. Only choose 80hz for very fast weighing

applications. Normally always 10hz is chosen.

80

10: all versions

F3

Zero Track Band

Selects the range within which the scale will automatically zero. Note that the

scale must be in standstill to automatically zero. Selections are in Display

Divisions. “d” = graduation

0d, 0.5d: , 1d: all EC-versions

3d: all other versions 5d

F4

Zero Range

Selects the range within which the scale may be zeroed. Note that the

indicator must be in standstill to zero the scale.

100% (US) 1.9% (CE)

2%: all EC versions

20%: all other versions

F5

Motion Band

Sets the level at which motion is detected by comparing the present display

update with the previous one. If motion is not detected for two seconds or

more, scale is in standstill and can process a Print or Zero command.

Maximum value varies depending on local regulations.

0,25 1d 3d all

versions

5d 10d

F6

Digital Filter

Averages weight readings to produce higher accuracy. The higher the filter

number, the greater the accuracy but the slower the response time. Choose 4

or 8 unless a very fast response is needed.

1 2

4 8 all versions

F7

Overload Limit

Selects the desired formula which determines the point at which the indicator

shows overload (""). All selections are based on the primary unit

selected in F8. "FS" = Full scale in primary units.

FS FS + 2% all none EC ver.

FS + 1d FS + 9d all EC ver.

F8

Calib. Unit

Selects the primary base unit to be used in the calibration process. Also the

default unit for normal operation. "1" = primary unit is lb. "2" = primary

unit is in kg.

1

2 all versions

F9

Display Div.

Determines the desired weight increments. Value should be consistent with

legal requirements.

1: VB2-100-10/30-EC, WS-130

2: VB2-200-20

5: VB2-100-EC/30-05/100-50

F10

Decimal Pt.

Determines location of the decimal point.

0 0,0

0,00 all versions except VB2-3005

0,000 VB2-30-05 0,0000

F11

Batching funct.

Activating Batching function (not be used with “EC”-Scales)

0: Approved Scales

1: Not Approved Scales

2: for scales with set points (F13,14)

F13

Set point 1

For special versions only

Any value.

F14

Set point 2

For special versions only

Any value.

F16

Zero Calibration

Places indicator into the zero calibration routine. Scrolling down with the

ZERO key one level begins the procedure.

Press ZERO key to begin

sequence

F17

Span Calibration

Places indicator into the span calibration routine. Scrolling down with the

ZERO key one level begins the procedure.

Press ZERO key to begin

sequence

F21

Factory Reset

This sub-menu will reset all parameters in the “F” and “A” menu to the default

settings. USE WITH CAUTION!

Press the ZERO key twice to

execute.

A5

Disable the lb/kg

Key

Allows the lb/kg key to be disabled so that an operator cannot accidentally

press the key and change the displayed units.

"0" = Disable the lb/kg key "1" = Enable the lb/kg key

”2” Activate the extended graduation for VB2-100-EC

0 all versions

1

2 (only for VB2-100-EC and for

batching Scales)

A10

Auto Power Off

Period

Selects the auto power off time period in minutes: “Off” = Disabled (Always

ON)

1, 2, 4, 10, 20, 60, off All

versions factory default is 10

Calibration

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

page 4

Tel +46 176 208 920

Page 5

We recommend the scale to be calibrated at yearly intervals.

ON

PRINT

NET

GROSS

OFF

ZERO

TARE

The minimum test weight that can be used is 70% of full-scale capacity.

To adjust the zero point using the F16 zero adjust procedure:

1. Turn the power OFF

2. Put Calibration Switch to the Calibration position.

3. Turn the indicator ON.

4. Scroll to "F 16". Use TARE or ON to move up or down.

5. Press ZERO. The display will momentarily show "C 0" followed by a value. (If you want,

press Dot to go back to parameter number.)

6. After making sure that there are no weights on the platform, press ZERO to zero out the

displayed value.

7. Press NET to save the zero point value. The display will show "EndC0"momentarily, and

then revert back up to F16. At this time, proceed to the F17 span calibration to complete

indicator calibration.

To adjust the max point using the F17 span adjusts procedure:

1. Scroll to "F 17", then press ZERO to enter span calibration menu.

2. The display will momentarily show "C 1" for the span calibration, followed by a value with one flashing digit.

This value will be zero. Place the test weight on the Scale.

3. Pressing TARE or ON will change the position of the flashing digit.

4. Increase the flashing digit by pressing Dot. Decrease the flashing digit by pressing ZERO.

5. After setting the exact value, press NET to save the value.

6. If the adjustment was successful, the display will show "EndC1" momentarily, and then revert back up to F17.

"Err0" – The calibration test weight or the adjusted keyed-in weight is larger than the full capacity

of the scale. Change the calibration test weight or check the input data.

"Err1" – Change the calibration test weight or check the input data.

"Err2" – The internal resolution of the scale is not high enough to accept the calibration value.

Select a larger parameter for the Span Gain (F2).

7. Put the Calibration Switch to the normal mode.

8. Check the Scale.

Specifications and displayed error codes.

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

page 5

Tel +46 176 208 920

Page 6

General

Model

Capacity /

Graduation

Weight kg

Dimension

mm

Battery

VB2-30-EC

Max 30 kg / 50 g

3,6

210 x 260x 65

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-100-EC

WS-100-EC

Max 100 kg / 50 g

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-200-EC

Max 200 kg / 100 g

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-30-05

Max 30 kg / 5 g

Not approved version

3,6

210 x 260x 65

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-100-02

Max 100 kg / 2 g

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-100-10

Max 100 kg / 10 g

Not approved version

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-130-10

WS-130

Max 130 kg / 10 g

Not approved version

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-100-50

Max 100 kg / 50 g

Not approved version

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

VB2-200-10

Max 200 kg / 20 g

Not approved version

4,5

260 x 345 x 55

6 of alk. 1,5 V batteries LR6/AA for 15 hours

operation.

Display

0.75" (19 mm) 7-segment, Liquid Crystal, 6-Digit

Additional Symbols

Net, Gross, Stable, Tare, lb, kg, Zero

Keyboard

5-key flat membrane panel

Operating Temperature

0 to +30 grad C (-10 to +40 grad C not approved version)

Storage Temperature

-25 to +70 grad C

CODE

MODE

MEANING / POSSIBLE SOLUTION

Normal Operating

Mode

Gross Overload. A weight greater than the rated capacity has been applied to the scale. Remove

the weight from the platter or try re-calibrating the scale. Otherwise, check for a bad load cell

connection or possible load cell damage due to overloading.

bAtt

Normal Operating

Mode

Indicates a low battery condition. Re-charge the battery or replace if alkaline batteries.

Err 0

Span Calibration

Mode (F17)

Keyed-in weight value is larger than full-scale capacity. Use a smaller test weight or check keyedin value.

Err 1

Span Calibration

Mode (F17)

Keyed-in weight value is less than 1% of full-scale capacity. Use a larger test weight or check

keyed-in value.

Err 2

Span Calibration

Mode (F17)

There is not enough load cell signal to produce the internal counts necessary to properly calibrate

the scale. First check all load connections. Use F16 mode to view internal counts. See Appendix C

for more information.

Err 3

All Modes

Non-volatile memory read error. One or more setup parameters have been lost.

Err 4

All Modes

Non-volatile memory writes error. Indicator needs service.

Err 5

Key-in Span

Calibration Mode

(F20)

You have attempted to enter a zero value for C1. Enter a known calibration value greater than

zero.

Err 7

Initialization

No reading from the ADC. Make sure there is a load cell(s) connected to the indicator at start-up.

Err 9

Normal Operating

Span calibration value has been lost. Re-calibrate the Scale.

Alternative power is a 9 VDC adaptor (centre minus).

OPERATOR INTERFACE

ENVIRONMENTAL

Displayed error codes.

Fault localization and repair.

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

page 6

Tel +46 176 208 920

Page 7

Please note: If a verified Scale is repaired it probably needs a new verification, check with authorities

Terminal

J1

Description

Colours

Loadcell

AG

Colours

Loadcell 1042

Colours

Loadcell LOC o

FAS

Colours

Loadcell

SP4

E+ (1)

Out +5 VDC*

Brown

Green

Red

White

S+ (2)

In +

Yellow

Red

Green

Green

E-(3)

Out 0 VDC

Green

Black

Black

Black

S-(4)

In -

White

White

White

Red

in your country.

Fault localization

If the Weighingblock is “dead”.

1. Change to new alkaline batteries.

2. Change the membrane key buttons if you have reason to believe it’s broken.

If the Scale starts but the display shows wrong.

1. Adjust and Calibrate the Scale.

2. If it not works, the Scale must be demounted.

Demounting.

1. Demount the bottom plate of the Weighingblock trough the two screws covered by a piece of tape. Be

careful with the keyboard connection.

2. Check the inside of the Scale visually. Look for bad cables and connections.

3. If needed, clean the PC-board.

If the Scale shows F1

1. Probably the Calibration Switch has been changed to calibration mode?

2. Reset to normal mode.

Check the Loadcell

Check the Loadcell with a universal volt instrument, see table. The left pin is number 1.

If it is problem to get a reading on the display or it is important to calibrate.

1. Check the excitation voltage (E+ and E-) from the Indicator. Should be 5,0* (+-0,4) VDC.

2. Check the input to the Indicator (S+ and S-). The output from the Loadcell S+ and S- (pin 2

and 4) will increase from aprox. 0 to 10 mV analogue to the capacity range (100 or 30 kg).

Note S+ is plus and S- is minus. The polarity is important.

3. If the input is wrong, <0 mV or > +10 mV with unloaded Scale check the Loadcell. Do have

only E+ and E- connected (or probably an external Power 5 VDC) and checks the output

from the Loadcells direct on the wires. Should be 0 mV to +10 mV depending on the load.

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

page 7

Tel +46 176 208 920

Page 8

Instruction for handling Weighingblock VB2-series and UNISCALE

LCD

Enunciator

MEANING

0

Better known as the “Center of Zero” enunciator, this light is active

whenever the displayed weight is within ± 0.25 divisions of true zero.

N

Indicates that the indicator is displaying net weight.

G

Indicates that the indicator is displaying gross weight.

T

Indicates that a tare weight has been established in the system.

lb, kg

Indicates the unit of the displayed weight (normally disabled).

bAtt

Indicates a low battery condition. Re-charge the battery or replace if

alkaline batteries.

Indicates stable weighing.

ON

PRINT

NET

GROSS

OFF

ZERO

TARE

This instruction is valid for the new design with waist and rounded corners. Shipped after 2002-09-18 with serial

number higher than 74201

This instruction is for the user of the Scale. It is the last site in the complete manual. Hopefully is this the only

needed information. For complete information, contact you wholesaler, Vetek AB or download it from our web

site http://www.vetek.com

We hardly recommend that the user of this Scale to get a good acknowledge about all rules and the law. To get

complete information we recommend taking a look at the Authorities web sites.

Enunciator Definitions Shown above is the LCD display. Before reading the value the stable indicator must be ”on”.

If not wait a few seconds until it appears.

Handling

1. Press ON to start the scale.

2. If necessary, press ZERO to obtain a weight reading of zero.

3. Press OFF to switch off the scale. Hold 3 seconds.

4. The scale switches off automatically after 10 minutes when not in use

Weighing (e.g. a cylinder with liquid)

1. Unload scale and press ZERO.

2. Place the object (cylinder, container, etc) on the scale’s platter and allow the weight indication to stabilize. If

the item weight exceeds the scale’s weight capacity, it displays “”. Press TARE to zero the

Scale. The display shows zero weight and turns the NET enunciator on.

3. NET/GROSS toggles between Gross and Net weight display only if a Tare has been established.

4. “Dot”. Extended graduation to 10 g for VB2-100-EC when pushed and 5 sec after release.

General advice

When the Scale is not in use and is transported between different working places we recommend to use a

case or any other protection against vibrations and other hard environmental conditions.

Protect the scale with a transparent plastic bag if there is any risk of leakage or when working in a wet

environment.

Use onle 6 pcs alkaline 1,5 V batteries LR6/AA. Alternative power is a 9 VDC adaptor (centre minus).

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

page 8

Tel +46 176 208 920

Page 9

Communication Port (not valid for UNISCALE)

VBB-10 consist of:

VBB-10-10 Box with Solenoid

VBB-10-11 “Zero modem cable” 9-pin female/female

VBB-10-12 Mains cable.

This instruction is valid for the new design with waist and rounded corners

(for units shipped after 2003-03-01).

This new generation of Weighingblock have a Communication Port as standard. It is possible to connect

different accessories as Printer, PC/Notebook or Solenoid module VBB-10.

Printer for the weight value.

Many printers in the market can be connected e.g. Martels MCP9800. For more information, contact Vetek AB.

PC/Notebook

The Scale can be connected to a PC/Notebook. For more information, contact Vetek AB.

Solenoid module VBB-10 (Note: this function in VB2 is standard for Scales delivered after march 2003)

One time set up: F11 must be “1” and A5 must be “2” (normally done when delivered)

Handling

1. Mount the Solenoid module to the cylinder.

2. Connect the ”zero modem cable” and the Mains cable. (For

the points 3 – 10 below it is no need for the Scale to be on the floor, you can keep it in your hands)

3. Start the Scale with ON and wait a few seconds.

4. To set the Batching Weight:

5. Press, ”Dot”, display shows 0,0 (flashing).

6. Press ON until the first relevant digit flash.

7. Change to the wished value with ”Dot”.

8. Press ON until the next relevant digit flash.

9. Change to the wished value with ”Dot”.

10. When the Scale shows wished value, save with NET

11. Press ZERO it the Scale not shows zero and put the object on the Scale. The Scale shows the gross weight.

12. Batching: Press TARE. The Scale shows zero and the valve is opened.

13. When the weight difference on the Scale is same as Batching Weight the valve will close.

14. The Scale shows the Batching Weight. Press NET/GROSS for gross weight.

General advice

Too fast batching gives less accuracy.

Do not touch the tube to the cylinder during batching.

Hantverksvägen 15,

76493 Väddö, Sweden.

info@vetek.com

www.vetek.com

page 9

Tel +46 176 208 920

Loading...

Loading...