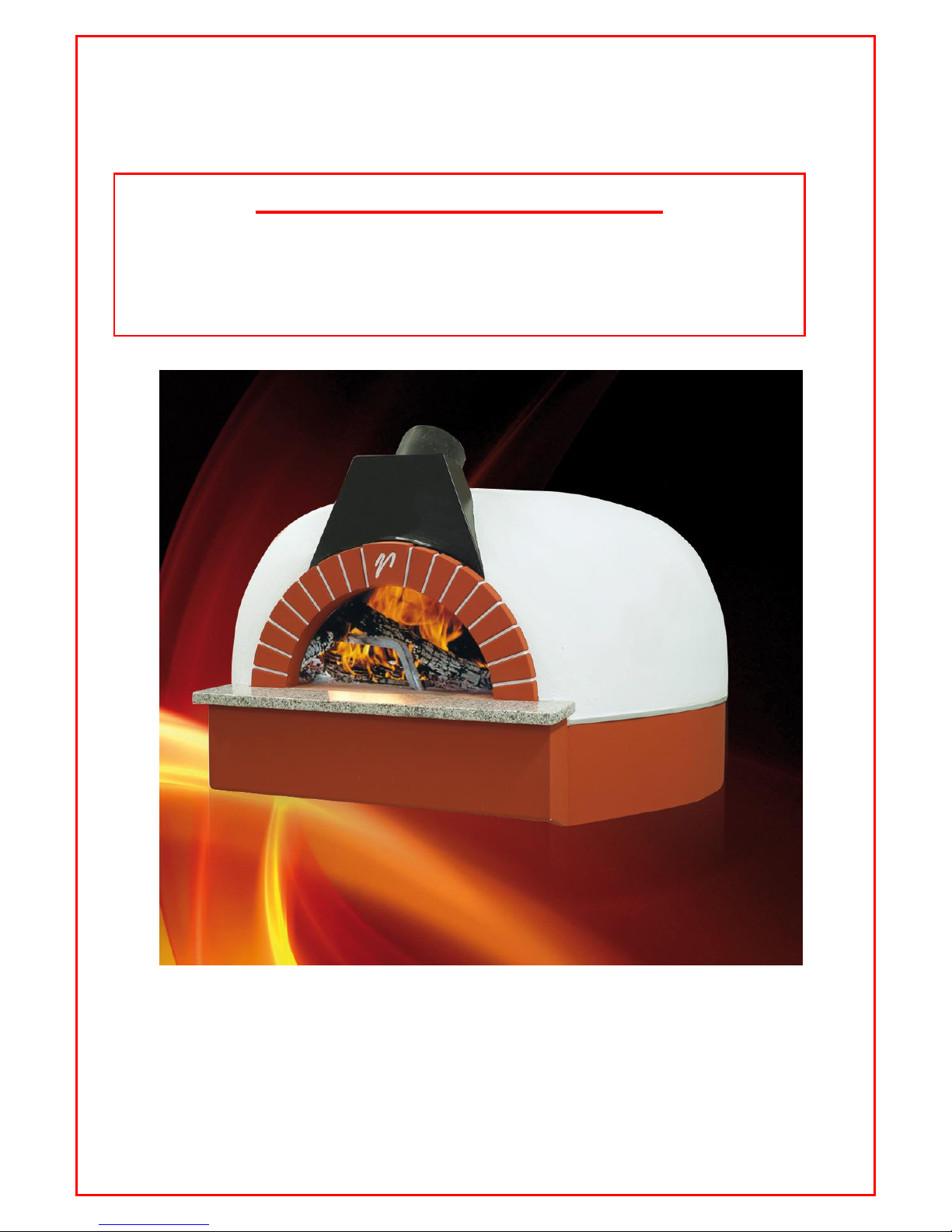

OPERATOR’S HANDBOOK

WOODBURNING PROFESSIONAL OVEN

“VESUVIO” MOD. IGL

2

CONTENTS

PART A FIRST OVEN’S FIRING

PART B OUTLET FLUE MANIFOLD

PART C FIRE’SPOSITION AND WOOD’S USE – DIRECTIONS FOR THE USE

PART D BACKING TIMES

PART E CLEANING AND MAINTENANCE

PART F HANDLING AND UNLOADING OF THE OVEN

3

IMPORTANT

IMPORTANT

IN CASE OF AN EXTENDED INACTIVITY OF THE OVEN, PROCEED WITH A SLOW RELIGHTING FOR

ABOUT 24/36 HOURS

IMPORTANT

Even if the oven is delivered in white colour we suggest not to carry out any outside

covering, DURING THE FIRST MONTH OF WORKING OF THE OVEN ( paints,

tiles and so on…) since, because of its features of transpiration which make it

unique in its way, any coveruing on the crown’s surface would not allow the normal

discharge of the moisture , with consequent formation of bubbles. Therefore during

the first 30 days of working the venations who will appear on the upper insulation

are perfectly normal and do not damage at all the good working of the oven.

PART A OVEN'S FIRING

1) Light the fire in the central part of the oven.

2) Keep an even inside temperature to about 150 C for the first two days

3) Raise of 50 C from the third day, for each day (and keep it constant for all the day until

the total dehumidification of the handwork )

The oven when it's new, has a big water's content, which during the drying must not turn into

steam inside the handwork.

Therefore it's NECESSARY to start very carefully with the first firing in order to avoid the

above mentioned effect, which could create cracks to the handwork.

For THE FIRST FIRING, which has to be carried out gradually and constantly for 7 days, we

suggest you to follow these instructions:

IMPORTANT

THE OVEN’S CROWN MUST NOT BE FIXED BUT THERE MUST BE BETWEEN THEM A THERMAL EXPANSION

JOINT, IN ORDER TO LEAVE A RIGHT DEGREE OF MOBILITY, TO COMPENSATE THE TEHRMAL

EXPANSIONS. THIS JOINT MAY INCREASE OR DECREASE DURING THE OVEN’S LIFE, BECAUSE OF THE

THERMAL EXPANSION , THESE MOVEMENTS ARE PERFECTLY NORMAL AND NOT NOT COMPROMISE AT

ALL THE PERFORMANCES OR STABILITY OF THE OVEN.

WE RECOMMEND TO FOLLOW CAREFULLY WHAT ABOVE INDICATED, SINCE THE ALMOST

TOTALITY OF THE CRACKS ON THE CROWN’S ELEMENTS OCCUR DUE TO A TOO FAST

DRYING.

LITTLE AND EVENTUAL CRACKS INSIDE THE CROWN’S ELEMENTS ARE PERFECTLY NORMAL AND ARE DUE

TO THE THERMAL EXPANSION OF THESE ONES TO THE HIGH TEMPERATURES. SUCH CRACKS DO NOT

COMPROMISE IN ANY WAY THE WORKING OF THE OVEN, ON THE CONTARY, THEY ARE SYMPTOMS OF A

VERY GOOD DEHUMIDIFICATION OF THE HANDWORK.

4

PART B – OUTLET FLUE MANIFOLD

PART C –

FIRE'S POSITION AND WOOD'S USE-DIRECTIONS FOR USE

With a normal oven's utilisation the fire should be positioned sideways; as the part most

exposed to the fire will suffer consequently the most thermal expansions and the most wear

during the years.

We recommend to alternate the fire from the right side to the left side and vice-versa; in this

way you will obtain a constant balance for the structure and surely a better yield in time.

We suggest to use thin, light and dry wood, to make easier the fire's lighting and a better

initial heating.

Successively, in order to have an optimum yield with a low wood consumption, we suggest to

use heavier and thicker wood (Oak - Beech – Oliva in trunks long cm 30-40), by observing

the quantities shown in our brochure.

We don't suggest the use of resinous wood (Pine - Spruce) because it transmits a particular

and not suitable odour; we don't suggest also the use of Poplar - Birch because of its high

residual of carbonic particles.

Do not use any other kind of fuel, such as coal, charcoal slak, petrols, an so on.

The wood oput into the oven must NEVER be beaten against the crown because at high

temperatures some damages to the structure may occur.

WE REMIND YOU THAT THE CHIMNEY

FLUE MUST NOT REST ITS WEIGHT ON

THE FLUE MANIFOLD EQUIPPED WITH

THE OVEN.

CONCERNING THE CHIMNEY FLUE, THIS

ONE MUST BE INSTALLED BY SKILLED

PERSONNEL AND MUST BE CONFORM TO

THE NORMS UNI 9615..

OUTLET DIAMETER OF

THE FLUE MANIFOLD =

20 CM.

OUTLET FLUE

MANIFOLD

5

PART D COOKING TIMES

The cooking times are very variable; normally from 1,5 to 3,5 minutes for the traditional pizza,

and are due to the kind of dough and to the inside temperature employed from each single

pizzaman. One of the most important performance of our Vesuvio ovens is just the uniform

backing capacity even in stressing working conditions.The perfect balance between the crown

and the floor and the special refractory "cotto clay" contained in the floor enable an optimal

backing, both slow at low temperature (250/300 C ) and fast and high temperature (over 400

C without that the pizza dough sticks or burns.

PART E - INSIDE CLEANING AND MAINTENANCE

DON'T USE wet rags or other materials containing dampness. NEVER THROW water inside;

IT'S IMPORTANT TO AVOID strong thermal rushes which could damage the oven.

DON’T USE SALT INSIDE THE OVEN.

We suggest to use the suitable brass brushes for the inside cleaning of the oven, which you

can easily find in commerce and DO NOT NEVER beat the shovel on the oven’s cooking floor

in order to avid any damages.

6

PART E HANDLING AND UNLOADING OF THE OVEN

HANDLING WITH LIFT FORK

OVEN OT SERIE

USE LIFT TRUCK FORKS SUFFICIENTLY LONG,

SO THAT ALL THE OVEN’S BASE

RESTS ON THE FORKS, AS SHOWN IN PICTURE

2 AND 3 .

DO NOT USE SHORT FORKS WHICH DURING THE

LIFTING COULD DAMAGE THE OVEN

Picture 2

Picture 3

7

POSITION AT THE LOW PART OF THE STEEL STRUCTURAL WORK, N. 2 STIFF BARS, ON WICH

TO HOOK THE LIFTING BANDS. THESE LIFTING BANDS MUST STAY FROM THE OUTSIDE OF

THE OVEN , IN ORDER NOT TO ENDANGER IT.

HANDLING WITH JIB CRANE

WE SUGGEST TO HANDLE THE OVENS AS SHOWN IN THE PICTURES :

LIFT THE OVEN BY SLINGING SO THAT THE SLING ROPES NEVER PRESS AGAINST

THE OVEN’S STRUCTURE

ALWAYS MAINTAIN THE ROPES SPACED, SO THAT THEY DO NOT PRESS AGAINST

THE OVEN’S STRUCTURE.

LIFTING OVEN SERIE IGL:

8

WEIGHT OF THE OVENS IN KG.

ALWAYS USE HOISTING EQUIPMENTS FITTING THE SIZE AND WEIGHT

OF THE OVEN.

KG

140

1500

120X160

1500

140X160

1650

140X180

1800

180X180

2100

IGL OVENS

100 1000

120 1250

Loading...

Loading...