Vestil ZLTT User Manual

Rev 02/08 08/04

O

VESTIL MANUFACTURING CORP.

2999 N. Wayne St., Angola, IN 46703

Ph: 260-665-7586 · Fax: 260-665 -1339

E-mail: sales@vestil.com

· www.vestil.com

WNER’S

MANUAL

MODEL ZLTT GROUND-CLEARANCE LIFT-AND-TILT TABLE

Serial number: _______________

Installation Instructions ……………….....................… 2

Warnings & Safety Instructions .…………….……….. 3

Operation Instructions ................................................... 4

Routine Maintenance & Safety Checks …………....… 5

Exploded Structural Parts Drawing & BOM ……….. 6 - 7

Motor & Transformer Connections ............................... 8

Electric / Hydraulic BOM ............................................. 9

WARNINGS AND SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the following.

o Read and understand the owner’s manual before using or servicing

the lift.

o The load must be removed and the platform fully lowered before

any work is performed on the lift.

o Ensure that all safety and warning labels stay in place and are

legible.

o Do not use the lift if any damage or unusual noise is observed.

o Always watch the platform and the container carefully when the lift

is in operation.

o Do not perform any modifications to the lift without the

manufacturer’s approval. Failure to receive authorization for

changes to the equipment could void the warranty.

o Maintenance and repairs are to be done only by personnel qualified

to perform the required work.

o Do not use brake fluid or jack oils in the hydraulic system. If oil is

needed, use an anti-wear hydraulic oil with a viscosity grade of

150 SUS at 100°F, (ISO 32 cSt @ 40°C), or Dexron transmission fluid.

Electrical Diagram .............................. ... ...................... 10

Hydraulic Diagram ....................................…….......... 11

Power Unit’s Operation …………………….…….…. 12

Safety Labels ................................................................ 13

Troubleshooting ………………………………….….. 14

Notes ............................................................................ 15

Warranty ……………………...…………………..…. 16

WHEN ORDERING

REPLACEMENT PARTS:

We take pride in using quality

parts on the equipment we

manufacture. We are not

responsible for equipment

problems resulting from the use

of unapproved replacement

parts.

To order replacement or

spare parts for this equipment,

contact the factory.

In any communication with

the factory please be prepared

to provide the machine’s serial

number, which is indicated on

the machine dataplate.

RECEIVING INSTRUCTIONS

Every unit is thoroughly

tested and inspected prior to

shipment. However, it is

possible that the unit could

incur damage during transit.

Inspect the unit closely when

it arrives. If you see evidence

of damage or rough handling to

either the packaging or to the

product when it is being

unloaded, immediately

note of it on the Bill Of Lading!

It is important that you

remove the product’s packaging

upon its arrival to ensure that

there is no concealed damage

or to enable a timely claim with

the carrier for freight damage.

Also, verify that the product

and its specifications are as

ordered.

make a

VESTIL MFG. CO./T&S EQPT. CO. 1 of 16

08/04

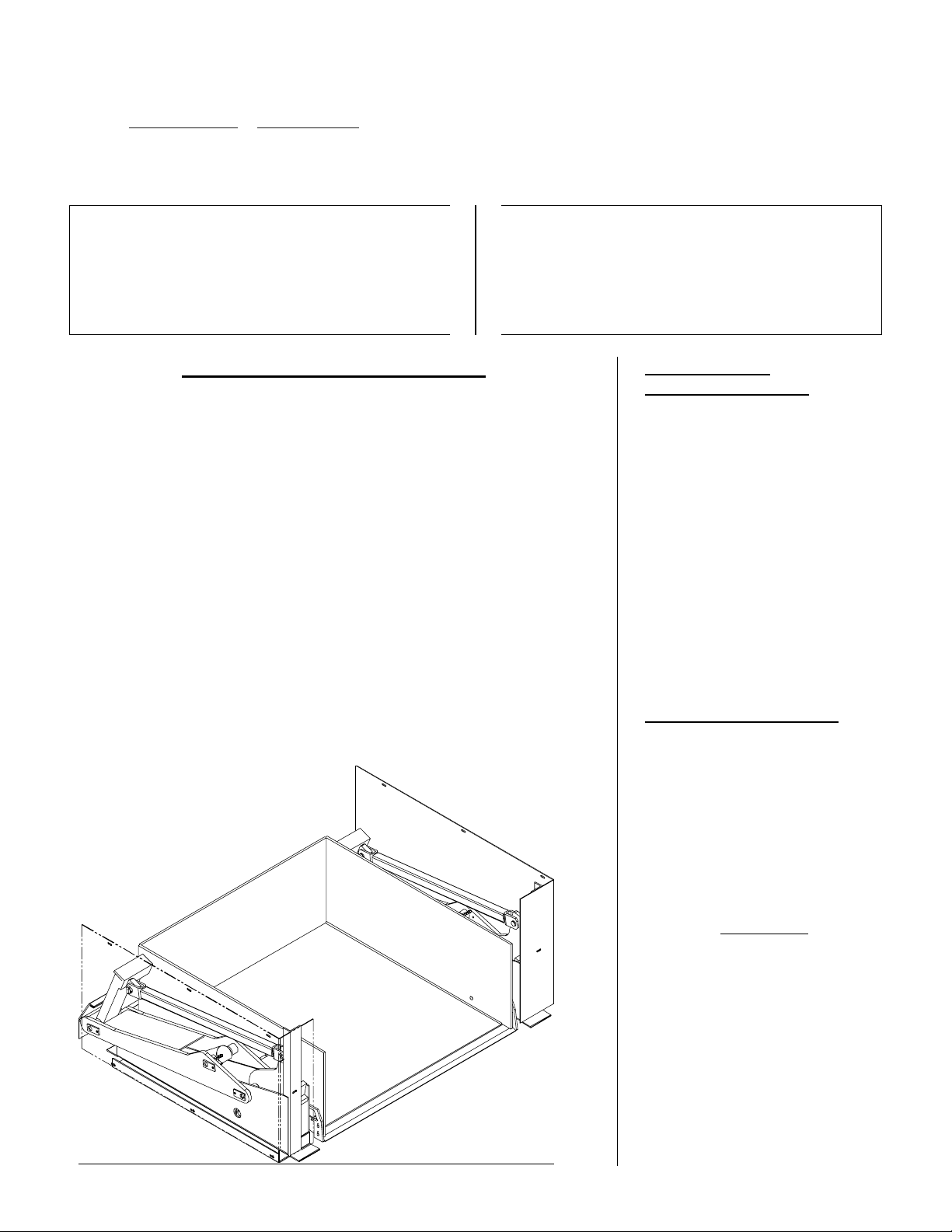

INSTALLATION INSTRUCTIONS – MODEL ZLTT

Review this entire page before installing the lift. Consult the factory

in the event there are any questions or problems at the time of installation.

The lift-and-tilt table must be removed from the shipping wood and securely anchored to the floor before use!

• The standard model ground-clearance lift-and-tilt table is suitable for use indoors in most industrial locations

and many commercial locations, and is typically provided as a turnkey system. Anchoring the unit to the

floor and an electrical supply to the remote power unit is typically all that is required for installation.

• Modifications or additions to the lift without prior manufacturer’s authorization may void the lift’s warranty

(see ANSI MH29.1, Safety Requirements for Scissor Lifts, section 12.6.) The addition of ancillary equipment

to the platform may necessitate that its load capacity be reduced.

• The installation must be made so that it complies with all the regulations applicable to the machine and its

location. The end-user must verify that the supplied equipment is installed so it will be suited to the

environment in which it will be used.

• Installation must be performed by suitably trained personnel with access to the appropriate equipment. The

electrical aspects of the installation should be performed by an electrician.

----------------------------------------------------------------------------------------

For a standard installation you will need the following:

1. A smooth, level concrete surface on which to mount the lift.

2. A fork truck with fork extensions, or a hoisting means to unload the lift and its power unit from the freight

truck and set it into place.

Caution: To prevent damage to the unit, careful consideration must be used when choosing a lifting

method.

Note: The unit must only be lifted when in the level and fully lowered position and fully supported

underneath, across its width.

3. Concrete anchors, a masonry drill, a masonry bit, hand tools, grout, steel shims, and tools to square up the

frame before anchoring. Consult the building’s architect or facility engineer to determine the best size and

type of hardware with which to anchor the machine to the floor.

4. A power supply circuit and disconnect matching the motor voltage and current requirements. Refer to the

labels on the control enclosure and to the electrical section in this manual for more information. The enduser is responsible for supplying the branch circuit’s required overcurrent and short-circuit protection.

---------------------------------------

1. Move the lift into place with forks placed under the unit’s frame from the side. Use fork extensions if

necessary. Use care to avoid damage to the electrical and hydraulic components mounted to the lift.

Note: The lift must only be lifted when in the lowered position and fully supported underneath, across its

width.

2. Temporarily connect the power supply to the pigtail cord supplied with the table, and raise the platform so

the table’s safety maintenance props can be utilized. Lower the platform so the unit is supported by the

props.

3. Square the frame to ensure the frame sides are parallel and square with each other.

4. Use appropriate concrete fasteners to anchor the lift’s frame to the floor, at each corner.

5. Shim and/or grout under the full length of the frame sides.

6. Make permanent connection to the power supply, using an appropriate wiring method.

7. Raise and tilt the unit through several full up/down cycles. Verify that the upper travel limit switches

(lifting and tilting) and the toe guard switch function properly.

8. Check the hydraulic oil level. It should be filled to within 1” to 1½” of the reservoir’s fill hole. If oil is

needed, use an anti-wear hydraulic oil with a viscosity grade of 150 SUS at 100°F (ISO 32 at 40°C) or a nonsynthetic automatic transmission fluid.

9. Clean up any debris or spilled oil, and verify that all of the warning and safety labels are intact.

VESTIL MFG. CO./T&S EQPT. CO. 2 of 16

08/04

WARNINGS AND SAFETY INSTRUCTIONS, MODEL ZLTT

Ensure that all employees understand and follow the following instructions.

o Read and understand the owner’s manual before using or servicing the lift.

o The unit must be lowered to the floor and the load removed from the platform before any

work is performed on the lift.

o Ensure that all safety and warning labels stay in place and are legible. See the labels page

in this manual.

o The lift’s frame must be securely anchored to the floor. See the installation instructions.

o Do not use the lift if any damage or unusual noise is observed.

o Always watch the lift and any load on it carefully when it is in operation.

o The platform’s load must be centered and evenly distributed on the platform.

o Do not perform any modifications to the lift without the manufacturer’s approval. Failure

to receive authorization for changes to the equipment could void the warranty.

o Maintenance and repairs are to be done only by personnel qualified to perform the

required work.

o Do not use brake fluid or jack oils in the hydraulic system. If oil is needed, use an anti-

wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 @ 40°C), or a

non-synthetic automatic transmission fluid.

o Use only replacement parts either supplied or approved by the manufacturer.

VESTIL MFG. CO./T&S EQPT. CO. 3 of 16

08/04

OPERATION INSTRUCTIONS – MODEL ZLTT

o Ensure that all employees involved in the operation of this lift-and-tilt understand and

follow these instructions!

Loading:

The load rating, in pounds, is shown on the machine dataplate located on the torsion rod at

the operator’s right side corner. It indicates the net capacity of the ZLTT with the load

centered and evenly distributed.

Warning: The vertical center-of-gravity of the load on the platform should be at least 12”

inside the main box pivot point when the platform is tilted.

Note: The addition of any ancillary equipment to the platform by third parties must be

taken into account when determining the maximum working load.

Warning: Do not exceed the platform’s load ratings. Permanent damage to the equipment

or injury to personnel could result from exceeding the listed capacity.

Operation:

Inspect the perimeter pinch point guards’ operation daily.

Warning: Keep all personnel clear of the machine when it is in operation. Be certain no part

of any person or object is under any part of the platform before lowering the unit.

Caution: Always carefully watch the platform and any load on it when it is in operation.

The ground-clearance lift-and-tilt table is furnished with either a constant-pressure (dead-

man style) pushbutton (standard) or dual twin foot switch (optional) control.

Pressing either the “LIFT RAISE” or “TILT RAISE” pushbutton or foot switch will turn on the

power unit to raise or tilt the platform, respectively. The platform will move only while

the control is pressed. Upon releasing the control, the platform will stop and hold its

position.

Pressing the “LIFT LOWER” or “TILT LOWER” pushbutton or foot switch will energize the

corresponding lowering valve to allow the platform to descend by gravity (the motor

does not run). Again, releasing the control will stop the platform movement, and the

unit will hold its position.

Caution: Never use the lift if any damage or unusual noise is observed, if it is in need of

repairs, or if it seems to be malfunctioning. Notify your supervisor or maintenance

personnel if you notice anything out of the ordinary.

Ensure that all safety and warning labels stay in place and are legible. Refer to the labels

page in this manual.

VESTIL MFG. CO./T&S EQPT. CO. 4 of 16

08/04

ROUTINE MAINTENANCE & SAFETY CHECKS – ZLTT

o Warning: Care should be taken to identify all potential hazards and comply with

applicable safety procedures before beginning work.

o Warning: Raise the platform and install the maintenance props before beginning any

inspections or work on the unit.

o Only qualified individuals trained to understand mechanical devices and their associated

electrical and hydraulic circuits should attempt troubleshooting and repair of this

equipment.

(A) Before each use inspect for the following:

1.) Frayed wires.

2.) Oil leaks.

3.) Pinched or chafed hoses.

4.) Damage or structural deformation to the structural members, cylinder brackets, etc.

5.) Unusual noise or binding, or evidence thereof.

6.) Proper functioning of all limit switches, including those on the loading-side pinch point

guard or photoswitch.

(B) Inspect monthly for:

1.) The oil level. Oil should be 1½” to 2” below the reservoir’s fill hole with the lift in the

fully raised position. See below for oil specification.

2.) Worn or damaged hydraulic hoses and electrical wires.

3.) Pivot point wear.

4.) Rollers’ looseness and wear.

5.) Integrity of the retaining rings on all rollers and on all pivot point pins.

6.) The integrity of the frame anchor bolts, and for cracks in the concrete around them.

7.) Proper functioning of any hand- or foot-operated mechanisms.

8.) Unusual noises or movement during operation.

9.) All the information, safety, and warning labels being in place and in good condition.

10.) The need to clean off dirt and debris.

(C) Yearly inspection

The oil should be changed if the oil darkens, becomes gritty, or turns a milky color

(indicating the presence of water). Replace with an anti-wear hydraulic oil with a

viscosity grade of 150 SUS at 100°F, (ISO 32 at 40°C). Ex: AW 32 or HO 150 hydraulic oil,

or a non-synthetic transmission fluid. You may use a synthetic transmission fluid if you

flush the system with the synthetic fluid before filling the reservoir.

VESTIL MFG. CO./T&S EQPT. CO. 5 of 16

Loading...

Loading...