Vestil WT-2424, WT-2221 User Manual [en, es, fr]

VESTIL MANUFACTURING CORPORATION

2999 North Wayne Street

Angola, IN 46703 USA

Phone (260) 665-7586 • Fax (260) 665-1339

sales@vestil.com • www.vestil.com

Ergonomic Solutions

Contents

Warnings and Safety Instructions ................. 1

Receiving Instructions .................................. 1

Operating Instructions .................................. 1

Revised 09-04 16-126-107

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

TILTING WORK TABLE

MODEL WT-2424 & WT-2221

Caster Installation...........................................2

Parts Identification & Drawing (WT-2424) ......3

Parts Identification & Drawing (WT-2221) ......4

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Keep hands and feet away from all moving parts while

table is in use.

• Do not attempt to adjust the height or tilt angle of the

table while a load is sitting on the platform.

• Never stand or sit on the table.

• Remove load before performing any repairs on the table.

• Use only maintenance parts supplied or approved by

the manufacturer.

• Always engage all wheel brakes when table is not being

moved.

• Never exceed the maximum loading capacity of 300 lbs.

• Load must be evenly distributed on table to ensure

maximum stability.

• Always make sure the height adjustment screw is

securely tightened before a load is applied especially

after table has been raised or lowered.

• Failure to follow these guidelines may result in personal

injury and/or property damage.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior

to shipment. However, it is possible that the unit may incur

damage during transit. If you see damage when unloading

make a note of it on the SHIPPER RECEIVER.

Remove all packing and strapping material and

inspect for damage. IF DAMAGE IS EVIDENT, FILE A

CLAIM WITH THE CARRIER IMMEDIATELY!

3) Loosen the height adjustment screw and adjust the

work table to the desired height using the handwheel

located on the base frame.

4) Tighten the height adjustment screw.

5) Adjust the tilt angle of the table to the desired position

using the handwheel directly under the table platform.

6) Place the load on table carefully.

OPERATING INSTRUCTIONS (WT-2221)

1) Position the work table near the desired work area.

2) Lock all four casters.

3) Adjust the height to the correct level by star knob

adjustment located on the center column and sliding it

up or down.

4) Loosen the tilt adjustment knob under platform. Tilt

deck to desired angle and retighten.

5) Place the load on the table.

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

OPERATING INSTRUCTIONS (WT-2424)

1) Position the work table near the desired work area.

2) Lock all four casters.

TILTING WORK TABLE

MODEL WT-2424 & WT-2221

1

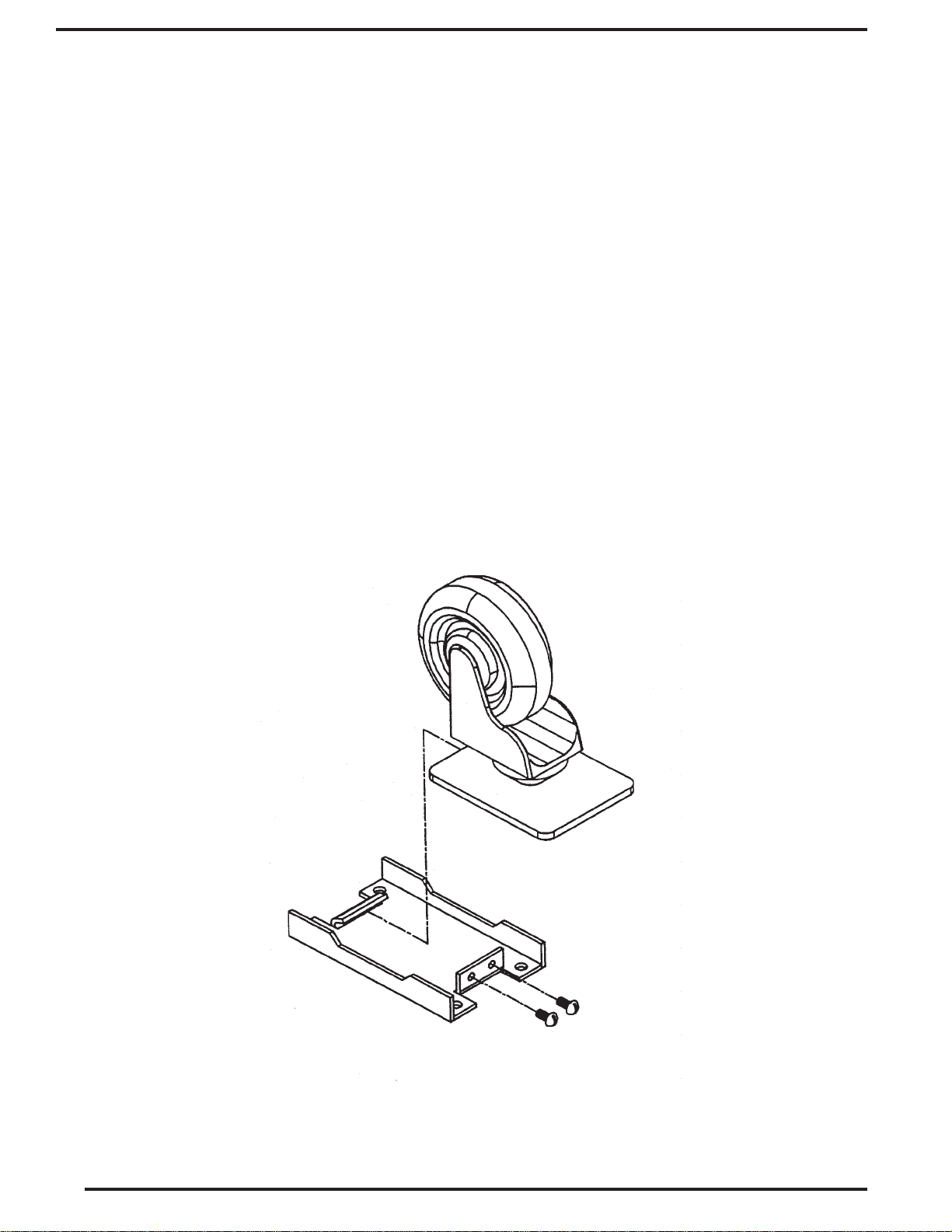

CASTER INSTALLATION INSTRUCTIONS

Securely prop up one end of the carts frame high enough for the casters to fit underneath that end. You will see four

caster mounting brackets welded to the bottom of the carts frame, one at each corner.

If you have both swivel and rigid casters, the casters are to be mounted in adjacent pairs. Typically, the swivel casters

are mounted to the side on which the push handle is located (when applicable). Determine the proper locations for the

casters before you begin.

Turn the included machine screws a couple of threads into the two threaded holes in the ends of each of the caster

mounting brackets.

To install the casters onto the cart:

Insert either of the short sides of the caster’s top plate into the curled end of the caster mounting bracket.

Raise the other end of the caster’s top plate up into the mounting bracket, and secure it there by screwing in the

machine screws completely. The screws should extend underneath the caster’s top plate, thereby retaining it in the

bracket.

2

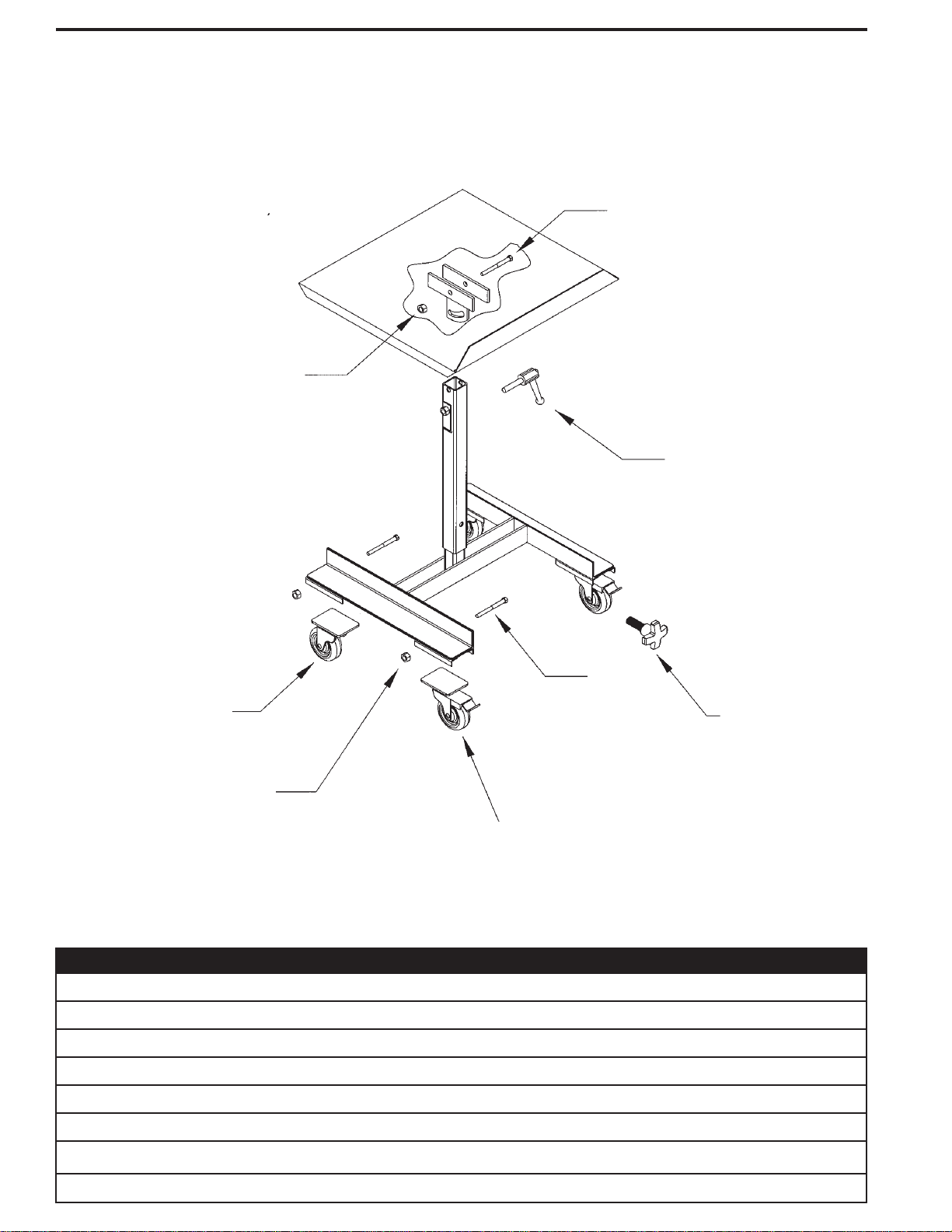

PARTS IDENTIFICATION FOR WT-2424

2

1

4

Lightly oil screws #8 and #12

semiannually or as required.

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

19A

20

21

22

23

DESCRIPTION

Tabletop Weldment

3/8-16" Nylok Nut

3/8-16 X 3" UNC H.H.C.S.

1/4-20 X 1/2" UNC H.H.C.S.

1/4" I.D. X 1-1/4" O.D. Fender Washer

Tilt Boss Sub Assembly

Inner Upright

Tilt Thread

1/2" I.D. Thrust Bearing

Pivot Boss

Handwheel / Crank

Elevating Thread

3/4" I.D. Thust Bearing

3/16" x 1-1/2" Spring Pin

Locking Screw, Height Adjustment

Base Assembly

Plastic End Cap, Base Tube

7/8" I.D. x 1-1/8" O.D. Brass Bushing

3" Swivel Caster w/brake

3" Swivel Caster

Crank Rod

Elevating Thread Sprocket

#40 Standard Roller Chain

Sprocket Weldment

11

17

9

10

16

5

8

15

21

22

ENGINEER NO.

16-513-003

37024

11115

11003

33208

16-526-002

16-514-017

16-526-001

16-110-001

16-020-002

16-145-006

16-026-002

16-110-002

64137

KNOB 2-5

16-514-024

REC -1-1½ x 3-11GA

01-111-037

16-132-002

16-132-003

16-645-005

16-042-002

16-042-001

16-042-002

12

13

3

6

7

14

23

18

19 & 19A

20

PART NO.

WT-TAB

A/L

A/L

A/L

A/L

WT-TBA

WT-IU

WT-TT

WT-.5TB

WT-PB

WT-HC

WT-ET

WT-.75TB

A/L

WT-LS

WT-BA

WT-PC

WT-BB

WT-SC/B

WT-SC

WT-CR

WT-ETS

WT-RC

WT-SP

QUANTITY

1

1

1

4

4

1

1

1

1

1

2

1

1

3

1

1

4

2

2

2

1

1

1

1

E

N

G

L

I

S

H

A/L Available at local hardware store

3

EXPLODED PARTS LIST

MODEL WT-2221

2

3

1

ITEM NO.

1

2

3

4

5

4

5

DESCRIPTION

Handle Tilt Adjusting

Bolt 1/2-13 x 2-3/4

1/2-13 Nylock Nut

Swivel Caster

Bolt 1/4-20 x 3-1/2 - Carriage

6

ENGINEER NO.

16-025-008

11214

37030

16-132-072

21117

7

PART NO.

WTP-HTA

WTP-BLT

WTP-NN-1

WTP-SCSTR

WTP-CRGE

8

QTY.

1

1

1

2

4

6

7

8

4

Swivel Caster/Total Lock

1/4-20 Nylock Nut

Locking screw, height adj.

16-132-002

37018

KNOB 2-5

WPT-SCSTR-TB

WTP-NN-2

WT-LS

2

4

1

Loading...

Loading...