Vestil WP-3636-84B User Manual

03/10/03 rev. 1/3/2018 WP, MANUAL

FIG. 12 ON P. 14), U

NDAMAGED AND READABL

E.

V

ESTIL MANUFACTURING CORP

.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 Toll Free (800) 348-0868

WP

Fax: (260) 665-1339 www.vestilmfg.com e-mail: sales@vestil.com

AND

SP-

SERIES WORK PLATFORMS

INSTRUCTION MANUAL

KEEP THIS MANUAL FOR FUTURE REFERENCE OF OPERATORS. CHECK VESTIL.COM FOR UPDATES

TO THE MANUAL. DO NOT USE UNLESS EACH LABEL IS AFFIXED TO THE PLATFORM (AS SHOWN IN

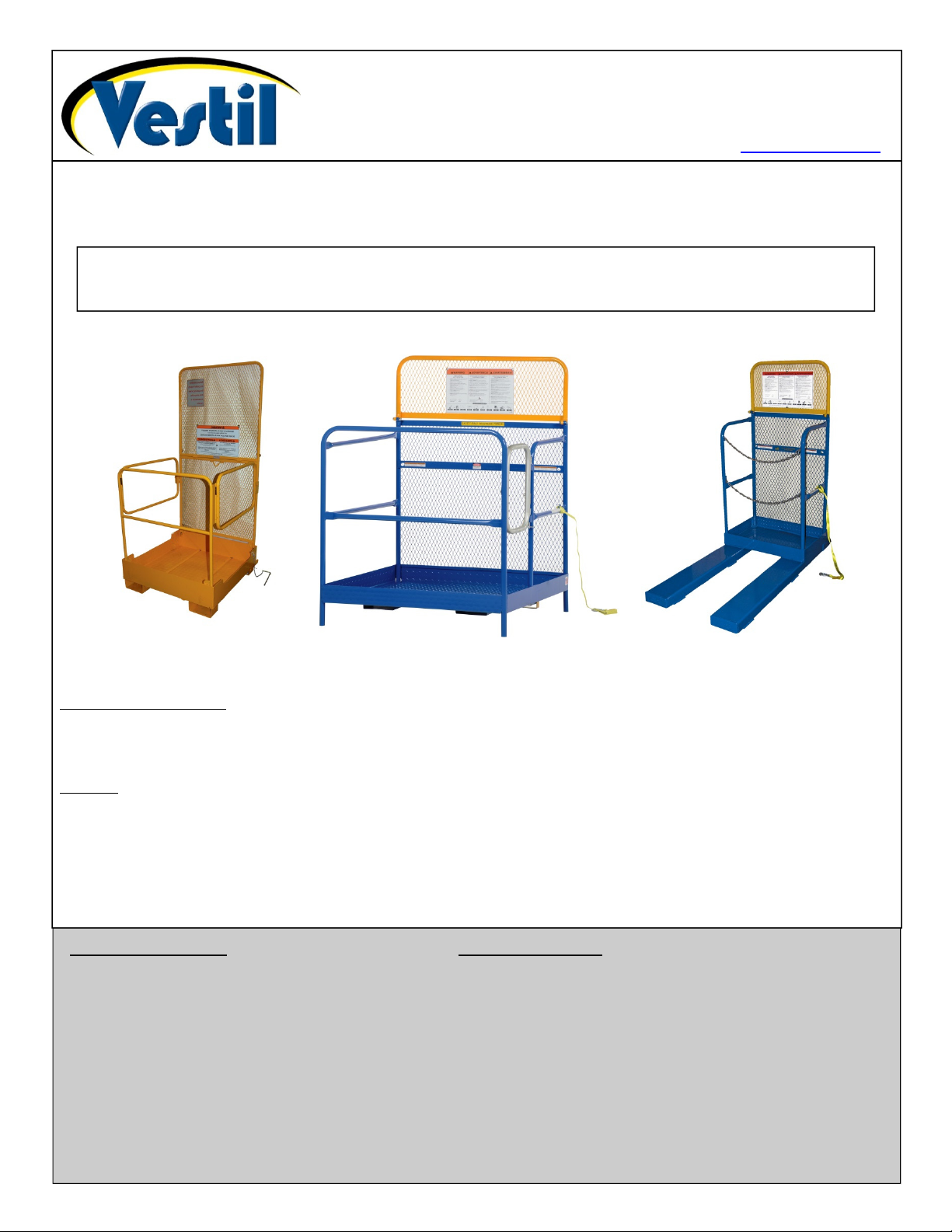

WP-3737-FD WP-SERIES SP-SERIES

CAPACITY: 600LB (273KG) 1,000LB (455KG) 1,000LB (455KG)

Receiving instructions:

After delivery, Inspect the product closely to determine whether it sustained damage during transport. If damage is

discovered, record a complete description of the damage on the bill of lading. If the product is undamaged, discard

the packaging.

NOTES:

Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where the product is

used is exclusively the responsibility of the owner/end-user.

Vestil is not responsible for any consequential damages sustained as a result of failing to exercise sound judgment while

assembling, installing, using or maintaining this product.

Table of Contents Table of Figures

Product Introduction………………………... 2 – 3 Fig. 1 “WP-series Diagram & Parts List”………… ………. 6

Safety Principles……………………............. 4 Fig. 2 “SP-175 series Diagram & Parts List”……………… 6

Safety Guidelines…………………............... 4 – 5 Fig. 3 “Center of Gravity Diagram”………………………… 7

Inspections…………………………………… 5 Fig. 4 “Mast Guard Hinge”……………..…………………… 7

Loading the Platform………………………. 8 Fig. 5A & 5B Tine Lock Operation…….………..…………. 8

Use Instructions……………………………. 9 Fig. 6 “Proper attachment of nylon safety strap

Setup/Fold-Down Instructions Fig. 7 “Caster Insertion”…………………………………….. 12

(WP-3737-FD)……………………………. 10 - 11 Fig. 8 “FTJB & WPJB mounting diagram”………………… 13

Mounting Casters to WP-Series Platforms.. 12 Fig. 9 “Electrical system diagram”…………………………. 13

Emergency Stop Switch Installation………. 13 Fig. 10 “Mounting WPJB”…………………………………… 13

Labeling Diagrams…………………………. 11, 14, 15 Fig. 11 “[WPJB] Fastener order”…………………………… 13

Limited Warranty……………………………. 16

Copyright 2017 Vestil Manufacturing Co. Page 1 of 16

”

……........ 8

03/10/03 rev. 1/3/2018 WP, MANUAL

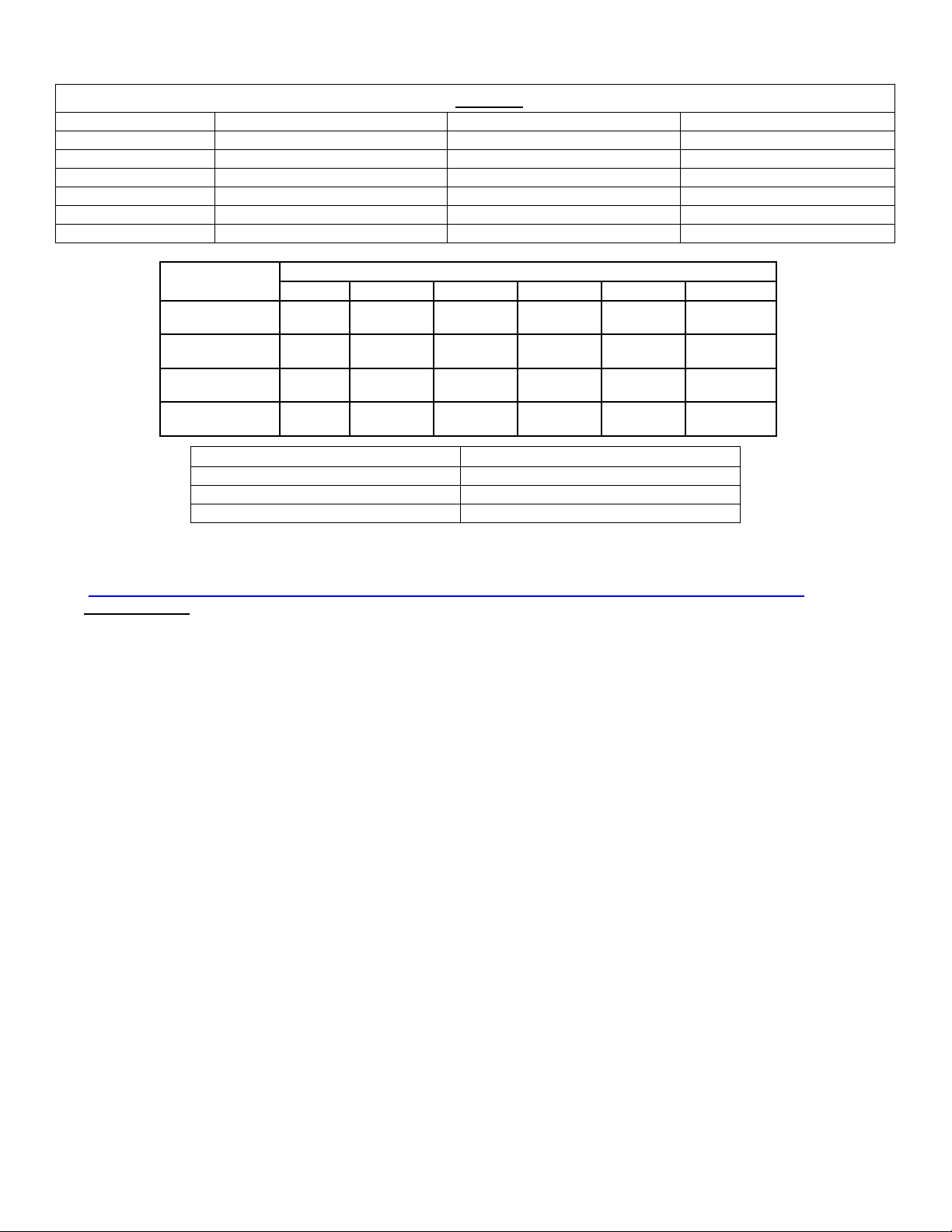

Product specifications:

Thank you for purchasing a fork-mountable work platform made by Vestil Manufacturing Corporation. Our platforms

are durable, high-quality products that combine safety-conscious design features and rigorous engineering. Anyone who

might use or maintain this product should be familiar with the instructions provided in this manual.

Dimensions and other product specifications corresponding to each model appear in the following tables:

Platform dimensions

Model

WP-3636 36” x 36” (91 x 91)cm 16” (41 cm) 60” (152 cm) 200 lb. (91 kg)

WP-3648 36” x 48” (91 x 122)cm 16” (41 cm) 60” (152 cm) 230 lb. (105 kg)

WP-4848 48” x 48” (122 x 122)cm 24” (61 cm) 60” (152 cm) 275 lb. (125 kg)

WP-4848-FF 48” x 48” (122 x 122)cm 24” (61 cm) 60” (152 cm) 295 lb. (134 kg)

WP3636-84B 36” x 36” (91 x 91)cm 16” (41 cm) 84” (213 cm) 246 lb. (112 kg)

WP-3648-84B 36” x 48” (91 x 122)cm 16” (41 cm) 84” (213 cm) 259 lb. (118 kg)

WP-4848-84B 48” x 48” (122 x 122)cm 24” (61 cm) 84” (213 cm) 300 lb. (136 kg)

WP-4848-FF-84B 48” x 48” (122 x 122)cm 24” (61 cm) 84” (213 cm) 316 lb. (144 kg)

WP-3636-DD 36” x 36” (91 x 91)cm 16” (41 cm) 60” (152 cm) 234 lb. (106 kg)

WP-3648-DD 36” x 48” (91 x 122)cm 16” (41 cm) 60” (152 cm) 247 lb. (112 kg)

WP-4848-DD 48” x 48” (122 x 122)cm 24” (61 cm) 60” (152 cm) 288 lb. (131 kg)

WP-4848-DD-FF 48” x 48” (122 x 122)cm 24” (61 cm) 60” (152 cm) 304 lb. (138 kg)

WP3636-84B-DD 36” x 36” (91 x 91)cm 16” (41 cm) 84” (213 cm) 246 lb. (112 kg)

WP-3648-84B-DD 36” x 48” (91 x 122)cm 16” (41 cm) 84” (213 cm) 259 lb. (118 kg)

WP-4848-84B-DD 48” x 48” (122 x 122)cm 24” (61 cm) 84” (213 cm) 300 lb. (136 kg)

WP-4848-FF-84B-DD

*WP-3737-FD

(F

OLD-DOWN MODEL)

Width x Length in

inches (cm)

48” x 48” (122 x 122)cm 24” (61 cm) 84” (213 cm) 316 lb. (144 kg)

37” x 37” (94 x 94)cm 26” (66 cm) 60” (152 cm) 175 lb. (80 kg)

Distance between the

centers of fork pockets

Height of (expanded

metal) mast guard

“Stock-picker” (SP) series work platforms

SP-175 30” x 20” (76 x 51)cm 221/4” (57 cm) 60” (152 cm) 185” (84 kg)

SP-175-84B 30” x 20” (76 x 51)cm 221/4” (57 cm) 84” (213 cm) 190” (86 kg)

NOTE: To calculate the weight of a “fully loaded platform,” select the specific model you own/use, find the net weight

of your model in the table above, and then add: 1) 1,000 pounds (455 kg) for all WP-series models except the folddown WD-3737-FD; 2) 1,000 pounds (455 kg) for SP model platforms; or 3) 600 pounds (273 kg) for WP-3737-FD

platforms.

Work platform safety options

Net weight in

pounds (~kg)

Model Description Weight

WP-CA 4” x 11/4” polyurethane-on-polyurethane casters: 2 swivel & 2 rigid 20 lb. (9.1 kg)

WP-SB Emergency stop button kit 7 lb. (3.2 kg)

WP-SB-FTJB Emergency stop junction box – Fork truck 8 lb. (3.6 kg)

WP-SB-WPJB Emergency stop junction box – Work platform 5 lb. (2.3 kg)

WP-TC Fluorescent tube caddy 15 lb. (6.8 kg)

WP-P-TC Fluorescent tube caddy (plastic)

WP-TT36 36” tool tray 13 lb. (5.9 kg)

WP-TT48 48” tool tray 22 lb. (10 kg)

WP-AFR Automatically deploying ramp 222 lb. (100.9 kg)

WP-WS Caution sign with necessary mounting hardware 3 lb. (1.4 kg)

WP-DL Double chain door lock 2 lb. (0.9 kg)

Copyright 2017 Vestil Manufacturing Co. Page 2 of 16

03/10/03 rev. 1/3/2018 WP, MANUAL

Recommended Lanyard and Safety Harness Options (see sizing chart below)

Item designation Description Lanyard length Weight

WP-LH-S Small harness 6ft. (~1.83m) 10 lb. (4.5 kg)

WP-LH-M Medium harness 6ft. (~1.83m) 10 lb. (4.5 kg)

WP-LH-L Large harness 6ft. (~1.83m) 10 lb. (4.5 kg)

WP-LH-XL Extra large harness 6ft. (~1.83m) 10 lb. (4.5 kg)

WP-LH-XXL Extra-extra large harness 6ft. (~1.83m) 10 lb. (4.5 kg)

WP-LH-XXXL Extra-extra-extra large harness 6ft. (~1.83m) 10 lb. (4.5 kg)

Height of User

5ft 4in – 5ft 7in

(163 – 170)cm

5ft 8in – 5ft 11in

(173 – 180)cm

6ft – 6ft 3in

(183 – 191)cm

6ft 3in and Taller

191cm and taller

WP-series except fold-down 1,000 lb.

SP-series 1,000 lb.

Fold-down WP-3737-FD 600 lb.

34"-36" 38"-40" 42"-44" 46"-48" 50"-54"

Small Small Medium Large X-Large XX-Large

Small Medium Large X-Large XX-Large XXX-Large

Medium Medium Large X-Large XX-Large XXX-Large

Large Large X-Large X-Large XX-Large XXX-Large

Platform Model Maximum Rated Load

Employers are responsible for instructing employees to use the product properly (see OSHA standard 1910.178 and

1993 letter of interpretation accessible at:

http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=21322.

EVERY person who might assemble, use, or perform maintenance on this work platform must read and understand

every instruction BEFOREHAND. Users should have access to the manual at all times and should review the directions

whenever necessary.

Waist Size of User

56"-60"

Copyright 2017 Vestil Manufacturing Co. Page 3 of 16

03/10/03 rev. 1/3/2018 WP, MANUAL

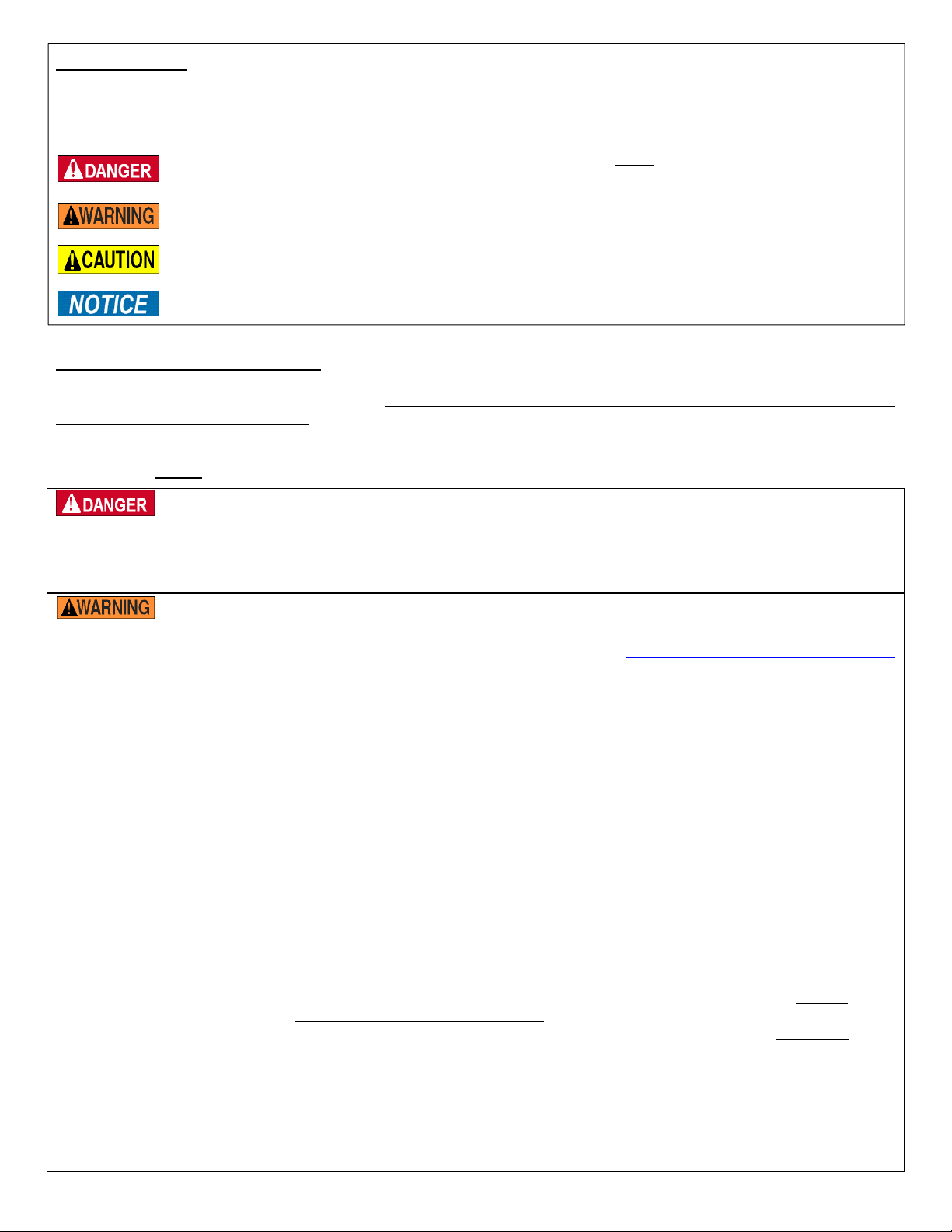

Signal words:

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable seriousness

of those injuries, if the product is misused in the ways described. Other signal words call attention to uses of the product

likely cause property damage.

The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

Identifies practices likely to result in product/property damage, such as operation that might damage the

INJURY.

injury.

platform.

Safe use recommendations:

Failure to read and understand the instructions included in this manual before using or servicing the work

platform constitutes misuse of the product. Study the entire manual before you use the product for the first time

and before each subsequent use. Read the manual to refresh your understanding of the safe use, inspection and

maintenance procedures explained on p. 5. If questions remain about the product after you finish reading the manual,

contact Vestil for answers. DO NOT attempt to resolve any problems with the work platform unless you are authorized to

do so and are certain that it will be safe to use afterwards.

Electrocution might result if the work platform contacts electrified wires. Reduce the likelihood that platform

occupants or bystanders might be electrocuted by applying common sense:

DO NOT contact electrified wires with any part of the platform;

DO NOT use the platform in an area where contact with electrified wires is likely;

DO NOT use the work platform in close proximity to electrified wires or other sources of electricity.

Material handling is dangerous. Improper or careless operation might result in serious personal injuries

sustained by the boom operator(s) and bystanders. Your use of the platform must always conform to OSHA “Powered

industrial trucks” regulations (29 CFR 1910.178 accessible at http://ecfr.gpoaccess.gov/cgi/t/text/text-

idx?c=ecfr&sid=96a878227f273aa6ec3cea186e1c142b&rgn=div8&view=text&node=29:5.1.1.1.8.14.37.3&idno=29 ). In

addition to requirements by law, work platform users should conform to the following:

Contact the manufacturer of your lift truck to verify that the truck is capable of safely handling the fully loaded platform

(see “NOTE” on p. 2). The width of your platform must be equal to or less than the width of your fork truck plus 10 inches

(250mm).

DO NOT exceed the maximum occupancy ratings for each model:

o WP-series = 2;

o SP-175 = 1;

o WP-3737-FD = 2.

ONLY use the work platform as a means for lifting people and necessary tools and equipment.

DO NOT use a structurally compromised work platform. Examples of structural damage includes: broken railings,

broken fork pockets, and holes produced by rust or corrosion in the platform floor or mast guard. Inspect the platform

before each use according to the inspection instructions on p. 5. DO NOT use the platform unless it passes every part

of the inspection.

DO NOT use a damaged platform. Inspect the unit before each use according to the inspection instructions on p. 5.

DO NOT use the platform unless it passes every element of the inspection.

Platform occupants and fork truck operators must wear hard hats whenever this platform is used.

DO NOT use the platform if the safety chain/strap is damaged or missing; DO NOT lift the platform until it is securely

connected to the carriage of the fork truck with the safety strap. NOTE: The safety chain/strap is the primary safety

mechanism, and must be used each time the work platform is used! To use the safety chain/strap properly, attach the

device to the fork truck carriage as instructed in Step 2 on p. 9. Each work platform also includes a secondary safety

feature called a tine lock that secures the platform to a tine of your fork truck. However, the lock might not fit over the

heel of the tine of your fork truck. If this is the case, do not modify the tine lock; simply do not use it.

DO NOT attempt to support a load that weighs more than the platform’s maximum rated load. The net weight, i.e. the

sum of the weight of all occupants and everything else supported by the platform, cannot exceed the maximum rated

load of the platform.

DO NOT stand beneath or travel under the platform while it is elevated.

DO NOT use the gate(s), chains, mast guard, guardrails, etc. as a step.

Copyright 2017 Vestil Manufacturing Co. Page 4 of 16

03/10/03 rev. 1/3/2018 WP, MANUAL

latch

(Continued from p. 4)

Platform occupants must ALWAYS use personal fall protection equipment securely attached to the platform at an

anchorage point (see “Operation and use” diagrams on p. 9) as long as the platform is elevated. Only disconnect from an

anchorage point when the platform rests securely on the ground.

DO NOT use UNLESS each label shown in Fig. 12 on p. 14 is affixed to the platform, undamaged and readable.

Occupant safety depends on maintaining a work platform in level, horizontal position. Only use work platforms on

improved surfaces (asphalt or concrete) that are even and level.

DO NOT mount a work platform on a telehandler, aka boom lift, or rough terrain forklift, even if the handler will be used

on level concrete or asphalt.

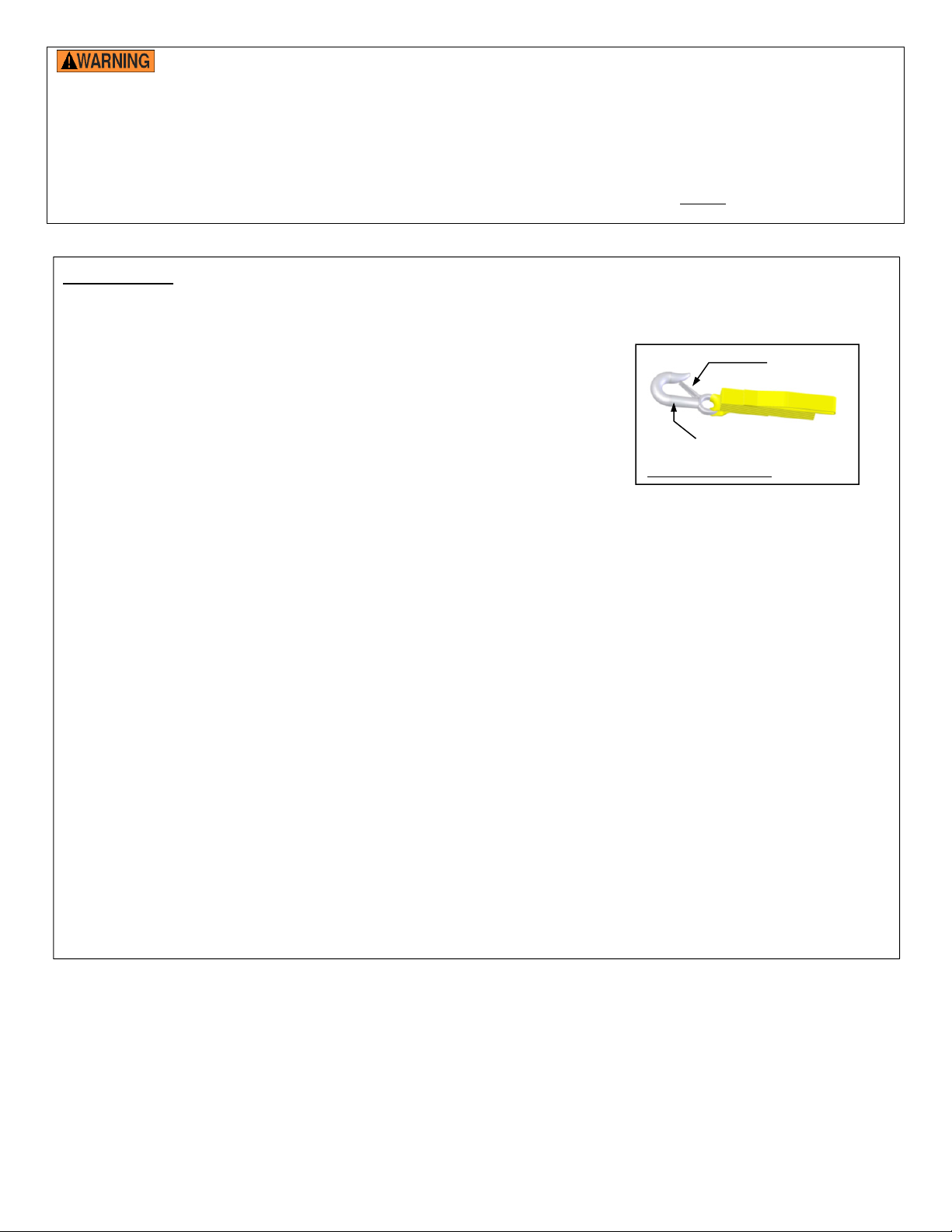

Inspections:

Before each use inspect the listed components:

1. Tine lock(s): confirm normal function. Model specific tine lock information appears on p. 8.

2. Snap hook attached to the free end of the nylon safety strap: confirm

that the spring latch automatically closes securely against the hook as

spring

shown in the diagram to the right. If the hook, nylon strap, or latch is

damaged, do not use the platform until a complete, new safety strap is

obtained and attached to the platform D-link (see p. 9).

3. Gate latch(es):

WP-3737-FD: confirm that each gate latch functions normally (see

“Step 4” on p. 11);

SP-175 series: confirm chains, D-links, snap rings and D-links are

hook

Nylon safety strap

undamaged;

WP-series: gate(s) are spring-actuated and should automatically

close when released. If a gate(s) does not automatically close,

replace the spring before resuming use of the platform.

4. Handrails: check the rails, rail welds, and points of attachment to the platform for bending, warping and

cracking.

5. Lanyard attachment points: check the anchorage weldment (see diagrams on p. 9) and points of attachment to

the mast guard for bending, warping, or cracking.

6. Casters (if equipped with WP-CA kit): check the casters to confirm that each one is properly seated within the

corner handrail posts (see p. 12).

7. Product labels: all labels should be readable and located as shown in the diagram on p. 14. If a label(s) is

unreadable or missing, contact Vestil to order a replacement.

At least 1 time per month, inspect:

1. Fasteners (hardware):

Mast guard hinge - bolts, nuts, washers;

Tine lock - pins, cotter pins, spring pins, and tine brackets (see p. 8);

Gates – chains, latches, hinges, pins, springs.

2. Casters: look for excessive wear, bending or cracking; if present, do not use the casters to move the platform

until the damaged caster(s) is replaced.

3. Fork pockets: confirm that each pocket is structurally sound, not corroded or rusted. Do not use the platform if

the fork pockets are structurally compromised or excessively rusted or corroded.

4. Welds: confirm that all welds are intact.

5. Obvious damage to, or structural deformation of, handrails, gate(s), or the platform itself.

6. Overall condition of platform: the structure should be clean, square and rigid, and free of rust and corrosion.

Remove dirt and debris. Do not use the platform if the base is excessively rusted or corroded.

Copyright 2017 Vestil Manufacturing Co. Page 5 of 16

Loading...

Loading...