Vestil WL-100-5-68, WL-100-6-88 User Manual

VESTIL MANUFACTURING CORP.

2999 N. Wayne St., Angola, IN 46703

Ph: 260-665-7586 · Fax: 260- 665-1339

E-mail: sales@vestil.com

· www.vestil.com

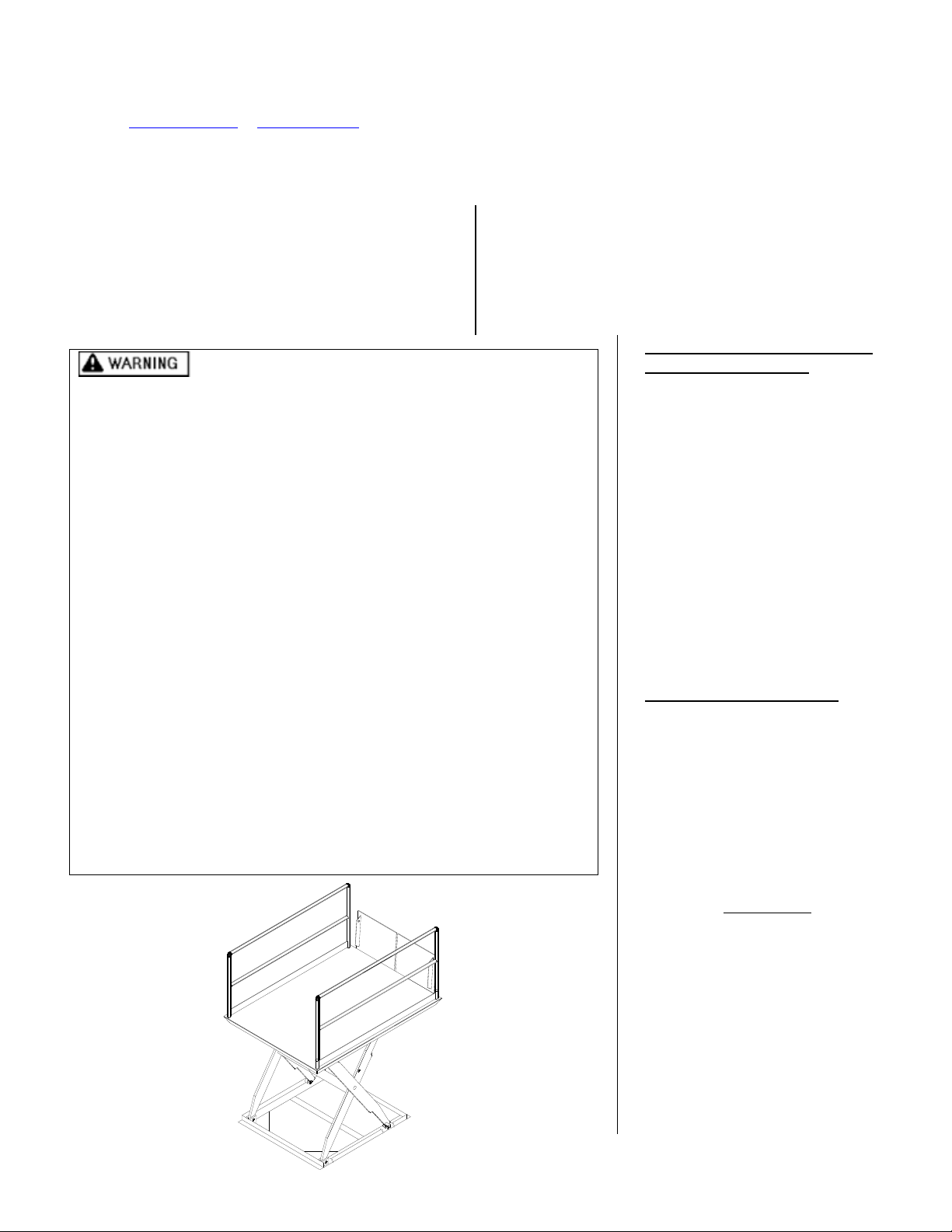

MODEL WL-100

6/25/2015 Manual, WL-100.doc

OPERATION &

M

AINTENANCE

M

ANUAL

Pre-installation Instructions ............................................ 2

Installation Instructions ................................................... 3

Routine Maintenance & Safety Checks .......................... 4

Operation Instructions ..................................................... 5

Structural Expl View & BOM ....................................... 6

Power Unit’s Operation ............................... ................... 7

Motor & Transformer Connections ................................ 8

Material handling is inherently dangerous. To reduce

the likelihood of operator and bystander injury:

o Each person who might operate, use, or maintain this device must

Read and understand this manual in its entirety before operating,

using or performing maintenance on the scissor dock.

o DO NOT work on this device unless it is fully lowered and unloaded

and maintenance props are in place.

o Ensure that all safety and warning labels stay in place and are

legible. See the labels page in this manual.

o The scissor dock’s frame must be securely anchored in concrete.

See the installation instructions.

o Do not use the lift if any damage or unusual noise is observed.

o Always watch the platform and any load on it carefully when the lift

is in operation.

o Do not exceed a travel rate of two feet per second when moving

across the platform.

o The platform’s load ratings must be observed at all times. See the

operation instructions.

o Do no modify the lift without the express, written authorization of

Vestil. Unauthorized modifications might make the scissor lift

unsafe to use.

o DO NOT attempt to repair this scissor lift or perform maintenance on

it unless you are trained and authorized to do so.

o Do not use brake fluid or jack oils in the hydraulic system. If oil is

needed, use an anti-wear hydraulic oil with a viscosity grade of

150 SUS at 100°F, (ISO 32 cSt @ 40°C), or Dexron transmission fluid.

o Use only replacement parts either supplied or approved by the

manufacturer.

Electrical Diagrams ............................... ... ................... 9-10

Power Unit Expl Parts Drawing & BOM .................... 11

Manifold Expl View & BOM, Hydraulic Diagram ..... 12

Power Unit Expl View & BOM .................................. 13

Troubleshooting …………………………....….……. 14

Safety Label Identification .......................................... 15

Warranty ………………………………….….……… 16

WHEN ORDERING

REPLACEMENT PARTS:

We take pride in using quality

parts on the equipment we

manufacture. We are not

responsible for equipment

problems resulting from the use

of unapproved replacement

parts.

To order replacement or

spare parts for this equipment,

contact the factory.

In any communication with

the factory please be prepared

to provide the machine’s serial

number, which is indicated on

the machine dataplate.

RECEIVING INSTRUCTIONS

Every unit is thoroughly

tested and inspected prior to

shipment. However, it is

possible that the unit could

incur damage during transit.

Inspect the unit closely when

it arrives. If you see evidence

of damage or rough handling to

either the packaging or to the

product when it is being

unloaded, immediately

note of it on the Bill Of Lading!

It is important that you

remove the product’s packaging

upon its arrival to ensure that

there is no concealed damage

or to enable a timely claim with

the carrier for freight damage.

Also, verify that the product

and its specifications are as

ordered.

make a

VESTIL MFG. CO./T&S EQPT. CO. 1 of 16

6/25/2015 Manual, WL-100.doc

INSTALLATION NOTES – WL-100

Review these requirements and procedures before installing the lift.

Contact the factory for answers to any questions that remain after reading this manual or for assistance if you

encounter difficulties during installation.

♦ The standard model dock scissor lift is suitable for use outdoors in most industrial and commercial location

------------------------------------------------------------------------------------------------

-------

Installation notes:

• All pit and cement work, curb angles, bumper posts, conduit, and electrical installations, as well as the

mater

ials for the same, are the responsibility of the installer or building owner.

• For a pit installation: a minimum 2” conduit installed in the pit floor or wall is recommended for allowing th

hose and w

• Five minimum 18 AWG wires (or an appropriate hard service cable) are required betw

control enclosure and th

overcurrent and short-circuit prote

• The installation must be made so that it complies with all the regulations applicable to the dock, the lift, and their

locat

the envir

An architectural review of the planned installation is recommended.

• The installation of the dock lift must be performed by suitably trained personnel with access to the

equipment. The electrical aspect

Installation will require the following tools and equipment:

o A lifting boom with rigging, a fork truck with adequate fork length and capacity, or some other appropriate

hoisting means to remove the lift from the freight truck when it arrives and to set the lift into place. The models’

weights can vary from 2,800 – 6,700 pounds.

o Concrete anchors, a masonry drill, a masonry bit, hand tools, grout, and steel shims. Consult the building’s

architect or facility engineer to determine the best size and type of hardware with which to anchor the lift to the

dock approach.

o A power supply circuit and disconnect matching the motor voltage and curr ent r eq uir eme nts . Re fe r to the l abe ls

on the control enclosure and to the electrical section in this manual for more information.

ire access to the lift, and a drain should be installed.

een the power unit’s

e lift’s frame. These wires, the power unit’s disconnect, and the branch circui

ction are the responsibility of the installer or building ow

ion. The installer or building owner must verify that the supplied equipment is installed so it will

onment in which it will be used, and it must be mounted onto, and anchored into, suitable concrete.

s of the installation should be performed by an electric

------------------------------------------------------------------------------------------------

-------

ner.

be suited to

appropriate

ian.

s.

e

t

-------------------------------------------------------------------------------------------------------

♦ Do not work underneath the platform unless the maintenance props are installed in the frame.

♦ The dock lift must be adequately anchored into the concrete at each corner of its frame.

♦ If the supply voltage installed for the lift is different from that originally specified for the order, the

connections of the motor leads and the control transformer’s primary wires must be changed. Consult the

electrical diagrams in this manual.

♦ Modifications or additions to the lift without prior manufacturer’s authorization may void the lift’s warranty

(see ANSI MH29.1, Safety Requirements for Scissor Lifts, section 12.6). The addition of ancillary equipment to the

platform may necessitate that its load capacity be reduced.

VESTIL MFG. CO./T&S EQPT. CO. 2 of 16

INSTALLATION INSTRUCTIONS – WL-100

6/25/2015 Manual, WL-100.doc

1. For pit-mounted units, che

Note: If the unit is to be placed into a pit, the required electrical and hydraulic connections to the dock lift should

be made before it is set

2. Mount the p

im

mediately adjacent to the lift. For mounting in other locations, a longer hose will be required. (Use ½” SAE

100R2 2-wire hydraulic hose with a 3,000 psi working pressure rati

3. Using

or supply voltage is the same as that shown on the machine dataplate (located on the middle of the ri

mot

platfo

rm side). Also verify that the correct control transformer primary leads are connected to the po

at the mot

4. Remo

5. Use riggin

6. Connect the

7. Install a ju

8. Use the pend

9. Remove the jumper wire between terminal #3 an

10. At both the li

11. Close

12. Cut and remove the

13. Raise the platform to

14. Bleed the cylinders following the air bleed procedure at the botto

15. While lowere

16. Rais

17.

18. Shim and/or grout under t

19. Remove the maintenance props and operate the lift through several full up/down cycles. Verify that the upper

20. Check the hy

21. Clean up any debri

ve all steel strapping and shipping materials from the lift. Do not remove the lifting ta

place. Note: If the lift is being pit-mounted, guide the hose and the wires or cable into the pit (such as when a pit

conduit is present) when lowering it. Use care to avoid damage to the lift’s internal electrical and hydraulic

components from the underside. Remove the lifting ta

Note: First, either flush or blow out the hose and fittings if any contaminants are observed inside them.

overload relay setting matches the motor’s full-load amperage at the selected supply

placed into the frame. Use the manual valve to lower the platform so the leg set rests on the props. (Push down,

turn the knob CCW, and release it to open the lowering valve. Push down and turn CW to cl

ground

and secure the control enclosure door an

strip

s drop down and move freely, and that the switch in the middle of each strip is not actu

(mounted on the non bridge-end of the frame) so that the motor turns off at th

Afterward, remove the maintenance props and lower the platform using the pendant control. Hold the “DOWN”

pushbutton for several seconds after t

migrate to th

e the lift, install the maintenance props,

Anchor the frame to the floor through each of the two 13/16” holes located near each frame co

travel limit switch (mounted in the frame) and th

function properly.

anti-wear hydraulic oil with a viscosity grade of 150 SUS at 100°F (ISO 32 at 40°C) or a non-synthetic automatic

tra

nsmission flui

ower unit in the desired location. The standard 8’ hose will allow th

an appropriate wiring method, connect the power supply to the power unit’s mot

or relay’s termin

g to pick up the unit at the two lifting tabs (one on each end of the platform) and move th

½” hydraulic hose between

mper wire from terminal #3 to terminal #4 in the power unit’s control enclosure. Verify that the

ant control to raise the platform just high enough to allow the table’s safety maintenance props to be

ft’s frame junction box and the power unit’s control enclosure, connect the five wires (inc

ing wire) to the limit switch and toe guard circuit wires. See the electrical diagram in this manual

e reservoir.

d, check the platform for proper lowered height, or that it is flus

draulic oil level. It should be filled to within 3” of the top of the reservoir. If oil is need

d.

into place.

als.

plastic ties that hold the aluminum toe guard strips up during shipping. Verify th

a height of 60”, measured from the bottom of the frame. Adjust the upper limit switch arm

he full

s or spilled oil, and verify that all of the warning and safety labels are inta

ck that the pit conforms to the pit diagram.

e power unit to be mounted

ng.)

or relay. Verify that the

bs.

bs.

the power unit and the lift’s frame.

voltage.

ose it.)

d termin

d put the plastic cover over the power unit.

he platform is lowered so that any air in the hose will be able to more easily

and lower the leg set onto them once again.

length of the frame sides.

al #4.

ated.

at height.

m of the “Power Unit Operation” page.

h with the ground if pit mounted.

rner.

e toe guard switches (around the perimeter of the platform)

ct.

ght

wer supply

e lift into

luding the

.

at all the

ed, use an

VESTIL MFG. CO./T&S EQPT. CO. 3 of 16

6/25/2015 Manual, WL-100.doc

ROUTINE MAINTENANCE & SAFETY CHECKS – WL-100

o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures

before b

o Warning: Rai

unit.

o Only qualified individuals trained t

circuit

s should attempt troubleshooting and repair of this equipm

ing work.

eginn

se the platform and install the maintenance props before beginning any inspections or work on the

o understand mechanical devices and their associated electrical an

ent

d hydraulic

(A) Before each

1.) Frayed wires

2.) Oil leaks

3.) Pinched or chafed hoses

4.) Damage or structural deformation to the structural members, the cylinder brackets, etc.

5.) Unusual noise or binding, or evidence thereof.

6.) Proper functioning of all limit switches, including those on the perimeter pinch point guard.

(B) Inspect monthly for:

1.) The oil level. Oil should be 1½” to 2” below the reservoir’s fill hole with the lift fully lowered.

See below for the hydraulic oil specification.

2.) Worn or damaged hydraulic hoses and electrical wires.

3.) Pivot point wear.

4.) Rollers’ looseness and wear.

5.) Integrity of the retaining rings on all rollers and on all pivot point pins.

6.) The integrity of the frame anchor bolts, and for cracks in the concrete around them.

7.) Proper functioning of any hand- or foot-operated mechanisms.

8.) Damage or deformity of the bridge plates (including the hinge) and the handrails.

9.) Unusual noises or movement during operation.

10.) All the information, safety, and warning labels being in place and in good condition.

11.) The need to clean off dirt and debris.

12.) Grease all pivot points.

(C) Yearly inspection

The oil should be changed if the oil darkens, becomes gritty, or turns a milky color (indicating the presence of

water). Replace with an anti-wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 at 40°C). Ex: AW

32 or HO 150 hydraulic oil, or a non-synthetic transmission fluid. You may use a synthetic transmission fluid if you flush

the system with the synthetic fluid before filling the reservoir.

use inspect for the following:

VESTIL MFG. CO./T&S EQPT. CO. 4 of 16

6/25/2015 Manual, WL-100.doc

OPERATION INSTRUCTIONS – WL-100

The Occupational Safety and Health Administration (OSHA) incorporated Commercial Standard CS202-56 into its

mass of regulation [29 CFR 1910.6(j)(1)], which instituted design and performance requirements on Dock Leveling

Devices. However, the Dept. of Commerce (DoC) withdrew CS202-56 in 1980 and replaced it with ANSI MH30.1-2000.

The DoC also recommends ANSI MH29.1 as a source of instructions about industrial scissor lift operation. MH29.1 is the

appropriate choice in this case, because our WL-100 series of products are industrial scissor tables.

Safe operation is the responsibility of the operator according to ANSI MH29.1, Section 5. In addition to

the instructions that appear in this manual, ALL end-users of this product should refer to ANSI MH29.1 for information

regarding owner/operator responsibilities for safe operation, care, and maintenance. To reduce the likelihood that

personal injuries might occur as a result of using this product, each person who might install, use, or maintain this

product must understand and follow these recommendations:

Do not exceed the maximum rated load (capacity). Permanent damage to the lift or injury to personnel could

result from exceeding the listed capacity.

Keep all personnel clear of the scissor dock when it is in operation.

Never use the scissor dock if any damage or unusual noise is observed, if it is in need of repairs, or if it seems to

be malfunctioning. Notify your supervisor or maintenance personnel if you notice anything out of the ordinary.

Check the operation of the perimeter pinch point guards daily. Do not use the lift if the aluminum frame bars of

the guard are bent or if the circuit does not function.

DO NOT use the lift unless all labels are readable. Contact Vestil for replacement labels as necessary.

The standard model scissor dock is suitable for use indoors or outdoors in most industrial and commercial

locations. It is intended to be used to raise and lower material handlers such as fork trucks and pallet jacks to allow

freight to be loaded and unloaded from semi trailers.

Keep all personnel clear of the lift when it is in operation. Be certain no part of any person or object is under

any part of the lift before lowering the platform.

Loading:

The load rating, in pounds, is shown on the machine dataplate located on the bevel of the bridge plate end of the

platform. It indicates the net capacity of the scissor dock with a static load that is centered and evenly distributed on

the platform.

o Cons ul t ANSI MH29.1, Section 3 for loading definition

When not ful

75% for end loading. The actual axle capacities (The hydraulic hose and bridge plates are at the lift’s “ends.”)

In the fully lowered position, cross-traffic loads must not exceed two times the platform’s load rating.

Do not exceed a rate of two feet per second when moving loads across the platform.

: Ancillary equipment reduces the maximum rated load of the dock scissor lift. If you or a third party adds after-

Note

market features to the scissor lift, you must recalculate the maximum rated load. To do so, subtract the total weight

of all equipment added to the scissor dock from the maximum rated load (capacity).

ly lowered, the lift’s maximum single axle load is roughly 65% of the rated capacity for side loading, and

s.

Operation:

Inspect the perimeter pinch point guards’ operation daily.

Caution: Always carefully watch the platform and any load on it when the lift is in operation.

The scissor dock is furnished with a constant-pressure (dead-man

o Pressing the

while the con

o Pressing the “DOWN” pushbutton will energize the lowering valve to allow the platform to descend by gravity

(the motor does not run). Releasing the control button, or the operation of the pinch point guard, will stop the

platform movement and the unit will hold its position.

To lower the platform in the event of a malfunction or power outage, remove the power unit cover an

the colored,

the lift! Push the knob in, twist the knob counterclockwise 180°, and release it. When the platform has been

lowered, push the knob in again, twist the knob clockwise 180°, and release it.

“UP” pushbutton will turn on the power unit to raise the platform. The platform will rais

trol is pressed. Upon releasing the control, the platform will stop and hold its position.

knurled knob on the end of the lowering valve. Be certain there are no obstructions or personnel under

style) pushbutton control on a coil cord.

e only

d locate

VESTIL MFG. CO./T&S EQPT. CO. 5 of 16

Loading...

Loading...