Page 1

VESTIL MANUFACTURING CORPORATION

Revised 01-13

P.O. Box 507., Angola, IN 46703 USA

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Ergonomic Solutions

Revised 05-05 15-126-121

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

TILT MASTER & TILT MASTER STRADDLE

MODELS TM / TMS

Contents

Warnings & Safety Instructions ....................... 1

Replacement Parts.......................................... 1

Receiving Instructions ..................................... 1

Operation Instructions .................................. 2-3

Routine Maintenance & Safety Checks ........... 4

TM Exploded Structural Parts ......................... 5

TM, TMS Bill of Materials ................................ 6

TMS Exploded Structural Parts ........................... 7

WARNINGS & SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the

following.

• Read and understand the owner’s manual before using or

servicing the Tilt Master.

• For battery powered units, review the additional warnings

included in the “Operation Instructions” section of the

manual.

• Watch the container carefully when the tilter is in operation.

• Have the caster lock engaged solidly when the tilter is in

operation.

• Verify the container (not just the pallet) is fully back

against the fork carriage before tilting.

• Be alert of the possibility of parts falling from the container

when it is being tilted.

• Before transporting the container, raise the forks slightly.

• The load must be removed and the forks fully lowered

before any work is performed on the hydraulic system.

• Do not use the Tilt Master if damage or unusual noise is

observed.

• Do not perform any modifications to the Tilt Master without

the manufacturer’s approval. Failure to receive authorization for changes to the equipment could void the warranty.

• Maintenance and repairs are to be done only by personnel

qualified to perform the required work.

• Do not use brake fluid or jack oils in the hydraulic system.

If oil is needed, use an anti-wear hydraulic oil with a

viscosity grade of 150 SUS at 100° F, (ISO 32 cSt @ 40° ),

or Dexron transmission fluid.

• Ensure that safety and warning labels stay in place and

are legible.

• Use only replacement parts either supplied or

approved by the manufacturer.

Electrical Diagrams .......................................... 8

Motor & Transformer Diagrams ........................ 9

Hydraulic Diagrams ........................................ 10

Power Unit’s Operation .................................. 11

Modular Power Unit Breakdown - DC .......12-13

Modular Power Unit Breakdown - AC........ 14-15

Troubleshooting ............................................. 16

Safety Label Identification ......................... 17-18

Warranty......................................................... 19

WHEN ORDERING REPLACEMENT PARTS

We take pride in using quality parts on the equipment we

manufacture. We are not responsible for equipment problems

resulting from the use of unapproved replacement parts.

To order replacement or spare parts for this equipment,

contact the factory.

In any communication with the factory please be prepared to

provide the machine’s serial number, which is indicated on the

machine dataplate.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit could incur

damage during transit.

Inspect the unit closely when it arrives.

of damage or rough handling to either the packaging or to the

product when it is being unloaded,

it on the Bill Of Lading!

It is important that you remove the product’s packaging upon

its arrival to ensure that there is no concealed damage or to

enable a timely claim with the carrier for freight damage.

Also verify that the product and its specifications are as

ordered.

TM-SERIES Tilt Master

TMS-SERIES Tilt Master

STRADDLE

If you see evidence

immediately make a note of

1

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

Page 2

OPERATION INSTRUCTIONS – TM, TMS

•

Ensure that all employees involved in the operation of the Tilt Master model box/basket rotator understand and follow

these instructions!

The standard model Tilt Master is suitable for use indoors in most industrial locations. It is intended to be used to

transport, lift and rotate rigid, sturdy tote boxes or baskets containing nonhazardous materials so that they can be

gradually, manually unloaded. The model TM is intended for use only with open-bottom pallets or skids. The model TMS

can be used with either open- or closed-bottom pallets.

Loading:

The load rating, in pounds, is shown on the machine dataplate located on the top of the fork carriage. It indicates the

net capacity of the tilter, based on loads having a center of gravity not exceeding 20” horizontally and 20” vertically. The

load must be evenly distributed across both of the lifting forks.

Warning:

result from exceeding the listed capacity.

Warning:

the Tilt Master to become unstable and tip over.

Caution:

damage to the structure and its parts.

Note:

mining the maximum centers of gravity and working load that can be placed on the fork carriage.

To load the Tilt Master, fully lower the fork carriage. Push the tilter’s forks under the skid or container, or place the skid

or container on the forks with a fork truck, until the skid or container is back against the carriage. The forks can be raised

slightly to lift them off of the load rollers, and the load can be moved to the work location.

Do not exceed the load ratings stated above. Injury to personnel or permanent damage to the machine could

Tilting any load exceeding the 20” center of gravity rating (either horizontally or vertically) can potentially cause

Do not drop loads onto the Tilt Master’s forks. Shock loads to the carriage can cause premature wear and

The addition of any ancillary equipment to the Tilt Master by third parties must be taken into account when deter-

Operation:

When the Tilt Master is in the desired location, depress the pedal on the side of each swivel caster to prevent the tilter

from rolling during its operation.

Warning:

unit from rolling.

Warning:

Warning:

able to avoid being trapped or injured in the event there is an unexpected movement of the material or the machine.

Caution:

Warning:

The Tilt Master is furnished with a constant-pressure (dead-man style) push-button control.

Press the “UP” push-button to turn on the power unit to rotate the forks upward. The forks will rotate only while the

control is pressed. Upon releasing the control, the forks will stop and hold position.

Pressing the “DOWN” push-button energizes the lowering valve to allow the forks to rotate downward by gravity (the

motor does not run). Again, releasing the control will stop the forks’ movement, and the unit will hold its position.

Caution:

malfunctioning. Notify your supervisor or maintenance personnel if you notice anything out of the ordinary.

On DC-powered units, attempting to raise the carriage when the battery is low will cause the motor relay protection to

prevent the motor’s operation. Adequate battery voltage is indicated by a green LED on the motor relay. See the next

page for more notes regarding operation of battery-powered units.

Ensure that all safety and warning labels stay in place and are legible. Refer to the labels page in this manual.

Do not tilt loads more than two inches off the floor without the caster brakes properly engaged, to prevent the

Keep personnel clear of the machine when it is in operation.

Loads in containers can shift quickly when tilted. Always have an effective escape route for personnel to be

Always carefully watch the Tilt Master and any load on it when it is in operation.

Be certain no part of any person or object is under the forks or fork carriage before lowering the unit.

Never use the tilter if any damage or unusual noise is observed, if it is in need of repairs, or if it seems to be

2

Page 3

ADDITIONAL INSTRUCTIONS FOR BATTERY-POWERED UNITS

Note: If this product has the 24V powered traction-drive option, consult that option’s information for more

specific details regarding the batteries and battery charger.

Warning!

! Working with or near lead acid batteries is dangerous. Batteries contain sulfuric acid and produce explosive gases.

A battery explosion could result in loss of eyesight or serious burns.

! Do not smoke or allow a spark or flame near batteries. Charge batteries in locations that are clean, dry, and well

ventilated. Do not lay tools or anything metallic on top of any battery. All repairs to a battery must be made by

experienced and qualified personnel.

! When working with batteries, remove personal items such as rings, bracelets, necklaces, and watches. Batteries can

produce enough energy to weld jewelry to metal, causing a severe burn.

! Always have fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

! Operating the battery with a low battery voltage can cause premature motor contact failure.

! Do not expose the tilter or charger to rain or adverse conditions.

! Replace defective cords or wires immediately.

! Check the battery’s water level frequently.

Battery Charger Operating Instructions

Never operate the charger with either of the cables coiled. Operating a battery charger with the cord either coiled or

wrapped around itself could cause the cord to overheat, melt, and cause a short-circuit or a fire.

Connection: the ribbed wire of the charger’s output cord must be connected to the battery’s negative (-) terminal. The

non-ribbed wire (with words printed on it) must be connected to the battery’s positive (+) terminal.

When properly connected, the charger will indicate the status of its output:

Flashing green LED – the charger is not seeing a good connection to the battery.

Solid yellow LED – the charger is providing charging current to the battery.

Solid green LED – the charger is maintaining a fully charged battery.

Plug the charger into a standard 115V receptacle. If an extension cord must be used, keep it as short as possible.

Caution:

cords, receptacles, and other equipment.

The battery charger can be left connected to the battery indefinitely without risk of harming the battery.

Remember to unplug the charger before moving the equipment. Failure to do so could cause damage to

E

N

G

L

I

S

H

Troubleshooting

If the unit does not operate, check all of the wiring connections to make sure they’re both mechanically and electrically sound – specifically at the battery, the motor, and at any location a wire is connected to the chassis. Also, make

sure the quick-connect plug on the end of the pendant control cord is plugged in correctly (if applicable).

A fully charged lead acid battery in good condition at room temperature should read 12.65 volts. At 11.9 volts it is

considered to be fully discharged and in need of charging. When checking battery voltage, wait at least 1/2 hour

after the charger has been turned off before checking the battery’s voltage.

If the batteries don’t seem to be taking a charge, check the charger’s 115V supply circuit and the charger’s output with a

voltmeter. If all check okay, confirm the battery’s state of charge using a hydrometer or a voltmeter.

3

Page 4

ROUTINE MAINTENANCE & SAFETY CHECKS – TM, TMS

•

Care should be taken to identify all potential hazards and comply with applicable safety procedures before beginning

work.

•

The load must be removed and the forks fully lowered before any work is performed on the hydraulic system.

•

Only qualified individuals trained to understand mechanical devices and their associated electrical and hydraulic

circuits should attempt troubleshooting and repair of this equipment

(A) Before each use inspect for the following:

1.) Frayed wires

2.) Oil leaks

3.) Pinched or chafed hoses

4.) Damage or structural deformation to the structural members, the cylinder brackets, etc.

5.) Unusual noise or binding, or evidence thereof.

6.) Proper functioning of the locking caster (to prevent wheel rotation).

7.) Proper functioning of all limits.

(B) In addition to the above, inspect monthly for:

1.) The oil level. Oil should be 1” to 1½” below the reservoir’s fill hole with the forks fully lowered.

2.) Worn or damaged hydraulic hoses and electrical wires.

3.) Pivot point wear at the hinge pins and cylinder ends.

4.) Intact pin and clevis retaining rings and / or fasteners.

5.) Looseness, wear, or damage to the casters’ bearings, mounting hardware, locking mechanism, or surface

material.

6.) Proper water level in the battery. (DC units.)

7.) Unusual noises.

8.) Information and warning labels being in place and in good condition.

9.) The need to clean off dirt and debris.

(C) Yearly inspection

The oil should be changed if the oil darkens, becomes gritty, or turns a milky color (indicating the presence of water).

Replace with an anti-wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 @ 40°C). Ex: AW 32 or HO

150 hydraulic fluid, or Dexron transmission fluid.

Ordering replacement parts:

We take pride in using quality parts on the equipment we manufacture. We are not responsible for equipment problems

resulting from the use of unapproved replacement parts.

Note: Motors, cylinders, and pumps can vary by model. Consult the manufacturer to determine the exact part numbers

for these items.

To order replacement or spare parts for this equipment, contact the manufacturer.

In any communication with the manufacturer, please be prepared to provide the machine’s serial number, which is

indicated on the machine dataplate.

4

Page 5

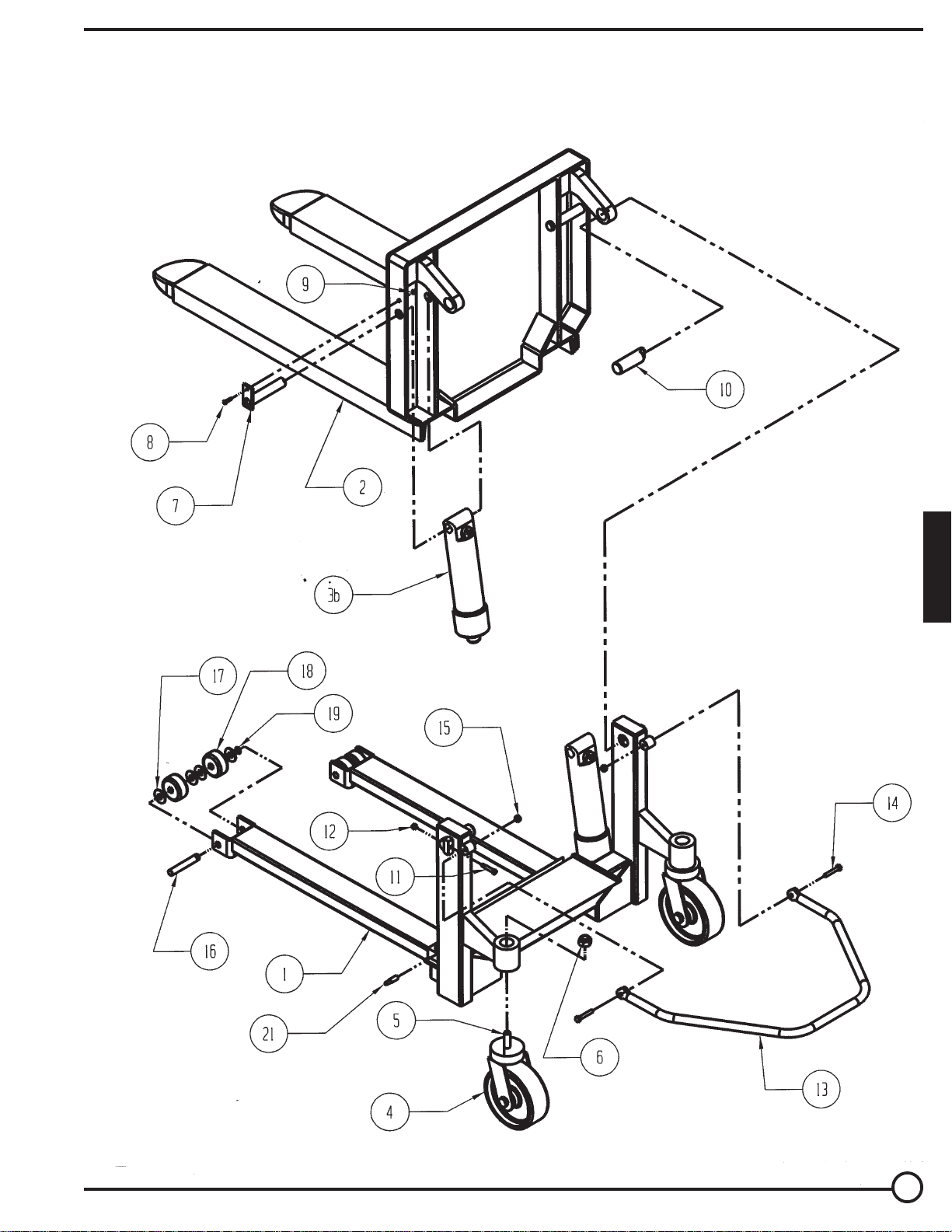

EXPLODED STRUCTURAL PARTS VIEW — TM

E

N

G

L

I

S

H

5

Page 6

BILL OF MATERIALS - TM

Item No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Description

Frame weldment

Deck weldment

Cylinder, 3” x 10”, TM-60

Cylinder, 2-1/2” x 10”, TM-40

Cylinder, 2” x 10”, TM-20

Caster, Ø8” x 3” phenolic, swivel

olt, 3/4” -10 x 3 long

B

3/4” -10 jam top lock nut

Cylinder pin weldment

Bolt, 1/4” -20 x 1” long

Nut, 1/4” -20

Hinge pin weldment, Ø1 1/8” x 4”

Screw, self-tapping, 5/16” x 3/4” long

Cap, plastic, black

Push handle

Bolt, 3/8”-16 x 2-1/4” long

Nylock nut, 3/8” - 16

Roller pin, Ø3/4” x 4-3/4” long

Flat washer, 3/4” ID

Wheel, Ø3” x 1-1/2” wide phenolic

Snap ring, external, 3/4”

Limit switch, roller arm

Bolt, cylinder retaining, 1/2” -13 x 2” long

Part No.

38-514-033

38-513-006

99-021-901

99-021-906

99-021-914

PH-8/3-S-SWB-NTP

13365

37275

38-612-003

A/L

A/L

38-612-004

A/L

99-024-003

38-525-001

A/L

A/L

38-112-014

A/L

PH-3/1.5

A/L

01-022-001

01-118-001

Qty.

1

1

2

2

2

2

2

2

2

2

2

2

2

2

1

2

2

2

8

4

2

1

2

Item No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

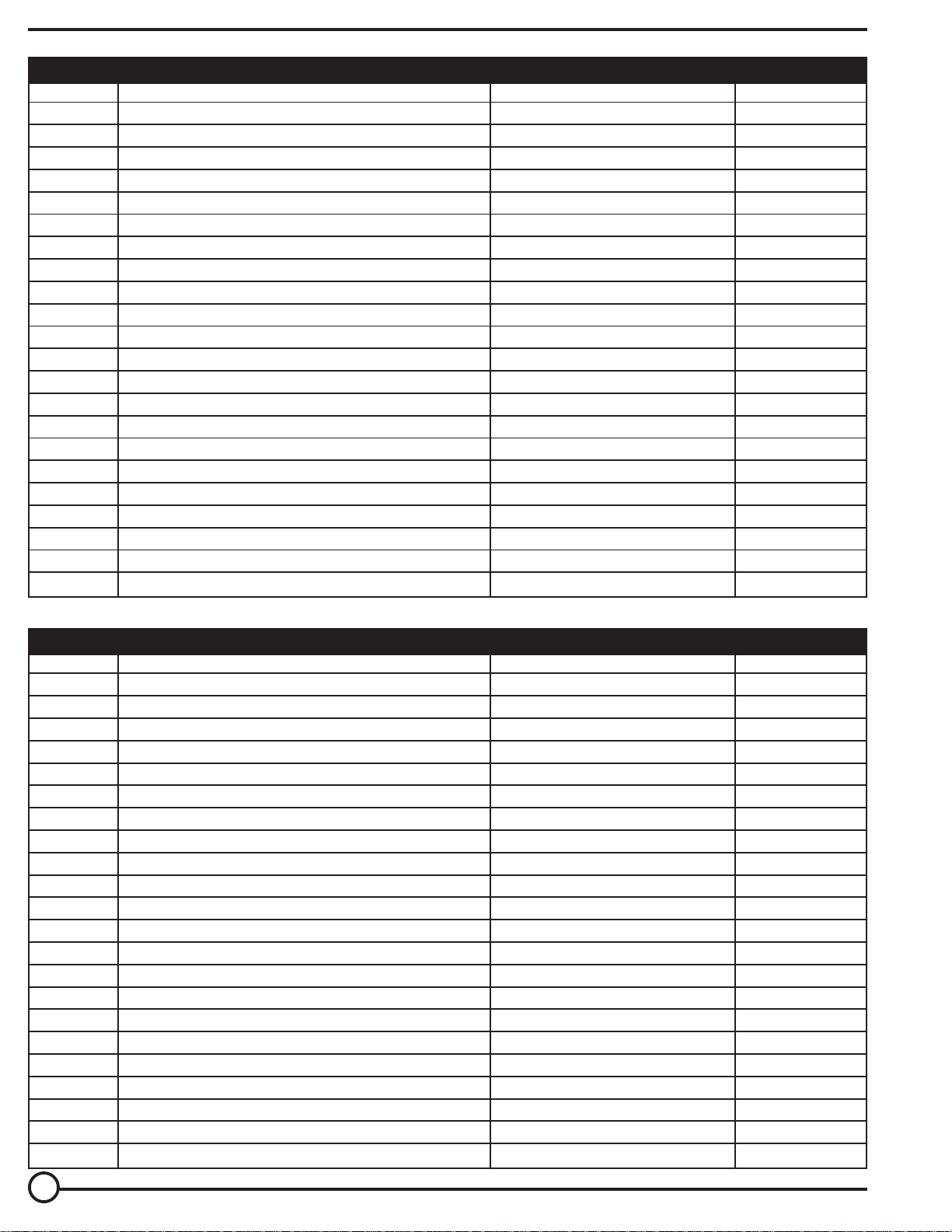

BILL OF MATERIALS - TMS

Description

Frame weldment

Deck weldment

Handle assembly weldment

Bolt, 1/2” -13 x 2-1/4” long

Nylock nut, 1/2” -13

Hinge pin weldment, Ø1/8” x 4” long

Cap, plastic, black

Stem caster, Ø8” x 3” wide phenolic swivel

Bolt, 3/4” -10 x 3-1/4” long

Lock nut, 3/4” -10

Cylinder, 2” x 10”, TMS-20

Cylinder, 2-1/2” x 10”, TMS-40

Cylinder, 3” x 10”, TMS-60

Cylinder pin weldment

Bolt, 1/4” -20 x 1” long

Nut, 1/4” -20

Bolt, cylinder retaining, 1/2” -13 x 2” long

Wheel, Ø8” x 2” wide phenolic

Bolt, w/ grease zirk, 1/2” -13 x 3-1/2” long

Class II lifting fork, 36” long

Bolt, 3/8” -16 x 1” long, w/ 3/8” -16 lock nut

Screw, self-tapping, 5/16” x 3/4” long

Limit switch, roller arm (not shown)

Part No.

38-514-034

38-513-008

38-525-001

A/L

A/L

05-112-003

99-024-003

PH-8/3-S-SWB-NTP

A/L

A/L

99-021-914

99-021-906

99-021-901

38-612-003

A/L

A/L

01-118-001

PH-8/2-W

ZA2

15-028-007

A/L

A/L

01-022-001

Qty.

1

1

1

2

4

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1

6

Page 7

EXPLODED STRUCTURAL PARTS VIEW — TMS

E

N

G

L

I

S

H

7

Page 8

Mobile Power Unit electrical system diagram, DC configuration (battery powered)

Mobile Power Unit electrical system diagram, AC configuration

Electrocution hazard: Disconnect the power cord from the energy source BEFORE opening/removing

the plastic housing. DO NOT modify the power unit.

Page 9

MOTOR & TRANSFORMER CONNECTION DIAGRAMS

Caution!

If the motor voltage is changed, the wire on the control transformer’s primary wire has to be changed to

match the new motor voltage also

E

N

G

L

I

S

H

9

Page 10

HYDRAULIC DIAGRAM – LIFT-HOLD-LOWER CIRCUITS

•

Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures before

beginning work. Fully lower or secure the forks, and ensure that all system pressure and power have been removed,

before attempting to work on the electrical or hydraulic systems.

•

Fully lower the unit before beginning any inspections or work.

•

Only qualified individuals trained to understand mechanical devices and their associated electrical and hydraulic

circuits should attempt troubleshooting and repair of this equipment

•

Caution: Do not use brake fluid or jack oils in the hydraulic system. If oil is needed, use an anti-wear hydraulic oil

with a viscosity of 150 SUS at 100°F (ISO 32 @ 40°C), or non-synthetic transmission fluid.

10

Page 11

THE POWER UNIT’S OPERATION – TM, TMS

The electric / hydraulic pallet tilter utilizes an electric motor directly coupled to a gear-type hydraulic pump to produce the

needed fluid pressure and flow to allow the cylinder(s) to perform the work of tilting a container.

A hydraulic manifold houses the hydraulic control components, and is bolted directly onto the gear pump.

The power unit’s hydraulic components are all rated for 3,000 psi working pressure.

• Important parts of the power unit include:

- The electric motor operates on 12 VDC deep-cycle battery supply.

- The gear pump. Its shaft is coupled directly to the shaft of the electric motor.

- The check valve. Its purpose is to prevent the backflow of fluid through the pump. In this way it allows the fork

carriage to be held at a given elevation indefinitely.

- The pressure relief valve. Its job is to open a path for fluid to flow back to the reservoir in the event that the fluid

pressure built up by the pump exceeds 3,000 psi. Thus the system cannot see more than 3,000 psi.

- The lowering solenoid valve. This is an electrically operated cartridge valve. It contains a screen to keep contaminants from entering the valve.

- The pressure-compensated flow control spool. This rests under the lowering valve, and regulates the fluid flow back

to the reservoir when the valve opens. It allows the forks to always lower at the same rate regardless of whether

there is a load on the fork carriage or not.

- The hydraulic tilt cylinder(s). These are displacement-style cylinders. They have a bleeder valve located at their top

end to allow air to be bled from the hydraulic system.

- The safety velocity fuse. This is a device that is installed in the cylinder’s hose port. It closes quickly in the event of a

catastrophic hose failure to prevent the fork carriage from collapsing down. The forks remain stationary until pressure is reapplied to the system.

- The hydraulic fluid. The system uses HO150 hydraulic fluid. Any anti-wear hydraulic fluid with a viscosity grade of

150 SUS at 100°F (ISO 32 @ 40°C) such as AW-32 or Dexron transmission fluid are acceptable.

When the forks are to be tilted, press the “UP” push-button. The motor turns, and in turning it spins the hydraulic

gear pump. Oil is drawn from the reservoir through the suction filter and into the pump. The pump pushes the thenpressurized oil through the check valve and out to the tilt cylinder(s).

When the fork carriage is to be lowered, press the “DOWN” push-button. The lowering valve opens, bypassing the

check valve and allowing the oil in the cylinder(s) to return back to the reservoir through the return hose. The rate at

which the fork carriage lowers is regulated by the internal pressure-compensated flow spool.

E

N

G

L

I

S

H

• In the event that the fork carriage creeps down slowly after releasing the “DOWN” control, it will be necessary to

remove the lowering cartridge valve for inspection and cleaning, as follows:

- Lower the forks until they are fully lowered.

- Remove any load from the forks.

- Remove the nut holding the solenoid coil on the valve stem, then remove the coil, and then unscrew the valve from

the manifold.

- Inspect the valve for contaminants, and the valve’s o-rings and backup washers for cuts, tears, or other damage.

- With the valve immersed in mineral spirits or kerosene, use a thin tool such as a small screwdriver or a small hex

wrench to push the poppet in and out several times from the bottom end of the valve. The valve should move freely,

about 1/16” from closed to open position. If it sticks in, the valve stem could be bent and will need to be replaced if it

doesn’t free up after cleaning. Blow the valve off with a compressed-air gun while again pushing the poppet in and

out.

- Inspect the bottom of the manifold’s valve cavity for contaminants.

- Again with the thin tool, press on the middle of the flow control spool located in the bottom of the cavity. It should

move down and back up freely.

- Reinstall the valve into the manifold, tightening the valve with approximately 20 lb-ft of torque.

• If the fork carriage lowers extremely slowly, or not at all, the cylinder’s velocity fuse could be closing. This can be

caused by air in the hydraulic cylinder(s). To bleed the air from the system:

- Lower the fork carriage until it is fully lowered.

- Remove any load from the forks.

- Hold a rag over the cylinder’s bleeder valve (it looks like a grease zirk) and open the valve about 1/2 turn with a 1/4”

or 5/16” wrench. Oil and air will sputter from the valve – once no air is observed, close the valve.

11

Page 12

Page 13

Page 14

MODULAR POWER UNIT PARTS BREAKDOWN — AC-1

Note: Motors, cylinders, and pumps can vary by model. Consult the manufacturer to determine the exact part numbers

for these items.

14

Page 15

MODULAR POWER UNIT PARTS BREAKDOWN — AC-2

•

Note: Motors, cylinders, and pumps can vary by model. Consult the manufacturer to determine the exact part

numbers for these items.

E

N

G

L

I

S

H

15

Page 16

TROUBLESHOOTING GUIDE — TM, TMS

Before performing any task, always lower the carriage fully to the floor and disconnect the power supply.

Consult the manufacturer for problems not addressed below.

* Check the DC notes page for troubleshooting other problems specific to battery-powered units.

Problem:

Power unit doesn’t run when “UP”

button is pressed.

Motor runs properly, carriage doesn’t

raise. Motor and pump not noisy.

Motor or control enclosure hums,

chatters, or buzzes, or some type of

squeal can be heard; the carriage

does not move, or the carriage

moves only slowly.

Carriage raises, then drifts down.

Carriage lowers too quickly.

Carriage lowers too slowly.

Carriage won’t lower.

Spongy or jerky carriage motion.

Possible cause(s):

No supply voltage (AC).

Upper-travel limit switch is engaged or

bad.

Bad connection in control circuit.

No control voltage (AC).

Bad motor relay coil.

Battery voltage low (DC).

Motor rotation is wrong (AC).

Pump has failed.

Fluid level is low.

See second item above, for when

carriage doesn’t raise.

Excess voltage drop to motor, due to

power wire size too small, wire run

too long, or incoming voltage too

low (AC).

Motor is “single-phasing” (AC).

Contamination holding open the

lowering valve or the check valve.

See last paragraph, above.

See above.

Flow control spool is stuck.

Flow control spool is stuck.

Pinched hose.

Velocity fuse locking (carriage only

slowly creeps down.)

Velocity fuse locking.

Control transformer (AC).

No supply voltage (AC).

Valve solenoid is bad.

Bad connection in control circuit.

Physical blockage of the structure.

Solenoid valve or suction hose screen

plugged.

Excessive air in the hydraulic

cylinders.

Action:

Test with meter. Check fuses,

breakers, and overloads to

determine the cause.

Inspect and test switch. Replace if

bad.

Test all circuits with meter.

Check for 24 VAC at control

transformer’s secondary; replace

fuse if blown.

Test with meter; replace if bad.

Test with meter. Charge battery if low

(is motor relay LED on?).

Verify motor shaft rotates CCW.

Consult factory for replacement.

Ensure reservoir is filled.

Same as above.

Check power installation for adequacy.

Check incoming voltage

is running

Determine cause of loss of voltage on

one phase; correct.

Remove and inspect. Clean per

instructions in this manual.

Same as above.

Same as above.

See below.

Remove plug from FC port; push on

flow spool to ensure it is fully

pressed into the cavity.

Check pressure, supply, and return

hoses for kinks.

Same as for jerky carriage motion.

Same as for jerky carriage motion.

Test with meter; replace if bad.

Check for 24 VAC at secondary;

replace fuse if blown.

Check with multimeter on diodecheck

function. (Reading for ohms will not

provide an accurate test of the coil.)

Test all of circuit with meter.

Inspect for foreign material or objects

blocking the carriage.

Remove and inspect. Clean per

instructions in this manual.

Bleed air per procedure described in

this manual.

. Correct problem found.

while motor

16

Page 17

SAFETY LABEL IDENTIFICATION

* Product safety signs or labels should be periodically inspected and cleaned by the product users as necessary to

maintain good legibility for safe viewing distance — ANSI 535.4 (10.21). Contact the manufacturer for replacement

labels.

1

RAISE

EL AUMENTO

AUGMENTATION

376

LOWER

MAS BAJO

PLUS BAS

377

MODEL TM

2

3

2

4

1

E

N

G

L

I

3

S

H

5

Inside on Reservoir

ISO 32 / 150 SUS

HYDRAULIC OIL OR HIGH-SYNTHETIC TRANSMISSION FLUID

ACEITE HIDRAULICO O LIQUIDOS DE TRANSMISION NO

SINTETICOS

HUILE OU LIQUIDE HYDRAULIQUE NON-SYNTHÉTIQUE

VESTIL MANUFACTURING CORPORATION • Phone (260) 665-7586 • www.vestil.com

Rev. 1003

6

7

Both Sides

VESTIL

MANUFACTURING

CORPORATION

Phone: (260) 665-7586

Fax: (260) 665-1339

E-mail: sales@vestil.com

www.vestil.com

580

206

8

8

Both Sides

4

5

6

7

17

Page 18

SAFETY LABEL IDENTIFICATION

* Product safety signs or labels should be periodically inspected and cleaned by the product users as necessary to

maintain good legibility for safe viewing distance — ANSI 535.4 (10.21). Contact the manufacturer for replacement

labels.

1

RAISE

EL AUMENTO

AUGMENTATION

376

LOWER

MAS BAJO

PLUS BAS

377

MODEL TMS

2

3

2

1

4

3

4

5

5

Inside on Reservoir

6

ISO 32 / 150 SUS

HYDRAULIC OIL OR HIGH-SYNTHETIC TRANSMISSION FLUID

ACEITE HIDRAULICO O LIQUIDOS DE TRANSMISION NO

SINTETICOS

HUILE OU LIQUIDE HYDRAULIQUE NON-SYNTHÉTIQUE

VESTIL MANUFACTURING CORPORATION • Phone (260) 665-7586 • www.vestil.com

6

7

Both Sides

VESTIL

MANUFACTURING

CORPORATION

Phone: (260) 665-7586

Fax: (260) 665-1339

E-mail: sales@vestil.com

www.vestil.com

18

580

Rev. 1003

206

8

7

8

Both Sides

Page 19

Rev. 01/2011

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a

is covered by the warranty

, after we receive a proper request from the warrantee (you) for wa rranty service.

replacement for a defective original part, if the part

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped

to the warrantee.

What is a “proper request”?

A request for warranty service is pr oper if Vestil receives: 1) a photocopy of the Customer Invoice

shipping date; AND 2) a written request

by any of the following methods:

for warranty service including your name and phone number. Send requests

that displays the

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses,

wheels, seals, brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original dynamic components is 1 year

. For wearing parts, the warranty period is 90 days.

Both warranty periods begin on the date when Vestil ships the product to the warrantee. If the product was purchased

from an authorized distributor, the periods began when the distributor shipped the product. Vestil may extend the

warranty period for products shipped from authorized distributors by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty

:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications

: DO NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modification(s) might make the product unsafe to use or might

cause excessive and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Loading...

Loading...