Page 1

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

FTLP-SERIES EQUIPMENT PLATFORMS

INSTRUCTION MANUAL

MODEL: FTLP-5454 FTLP-5454-HR

MAXIMUM RATED LOAD: 2,000LBS (~909KG) 2,000LBS (~909KG)

VESTIL MANUFACTURING CORP.

2999 NORTH WAYNE STREET, P.O. BOX 507, ANGOLA, IN 46703

TELEPHONE: (260) 665-7586 -OR- TOLL FREE (800) 348-0868

FAX: (260) 665-1339

URL: WWW.VESTILMFG.COM EMAIL: SALES@VESTIL.COM

NOTE: Compliance with regulations, codes, and/or statutory (non-voluntary) standards enforced in the

location where the platform is used is exclusively the responsibility of the end-user.

Table of Contents Table of Figures

Product Introduction………………………... 2 Fig. 1 “FTLP-series Exploded Parts Diagram & Parts List”….. 4

Safety Principles……………………............. 2 Fig. 2A “FTLP-5454 Center of Gravity Diagram”…………….. 5

Safety Guidelines…………………............... 3 Fig. 2B “FTLP-5454-HR Center of Gr avity Diagram”…..…….. 5

Inspections & Maintenance………………… 3 - 4 Fig. 3 “Mast Guard Hinge”……………..………………...……… 6

Loading and Using the Platform…………… 6 - 7 Fig. 4 “Proper Attachment of Safety Strap to Carriage”……… 6

Fig. 5 “Safety Strap Attachment to Platform”…………...…....... 6

Fig. 6 “Anchorage Points”……………………………………….. 7

Fig. 7 “Ramp Closure Mechanism”……………………………. 7

Fig. 8 “Product Markings and Labels”…………………………. 8

Cop

yright 2010 Vestil Manufacturing Corp.

p. 1 of 8

Page 2

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

PRODUCT INTRODUCTION

Standard design features include: fork pockets that receive the tines (forks) of a fork lift; loading ramp; toeboards;

textured floor plate for improved tractions; and a safety chain to secure the work platform to the fork carriage to prevent

the platform from sliding off of the forks if the lift operator accidentally tilts the mast forward during use. Optional features

include: mast guard; guard rails; and entryway-spanning chains. Dimensions and other product specifications appear in

the following table:

Model

FTLP-5454 54 x 54 (137 x 137)cm 7½ x 2½ (19 x 6.4)cm 2,000 (909kg) 300 (136kg)

FTLP-5454-HR* 54 x 54 (137 x 137)cm 7½ x 2 ½ (19 x 6.4)cm 2,000 (909kg) 410 (186kg)

*Includes removable handrails (2), entryway chains (2), and expanded metal mast guard.

: To calculate the weight of a “fully loaded platform,” select the specific model you own/use, find the net weight of

NOTE

your model in the table above, and then add 2,000 pounds (909kg).

Platform dimensions

width x length in

Thank you for purchasing a fork-mountable equipment loading platform (“platform” or

“loadi

ng platform”) made by Vestil Manufacturing Corporation (“Vestil”). Our platforms are

durable, high-quality products that combine safety-features and reliable mechanics. Although

use and maintenance procedures are relatively intuitive, all persons who might use or

maintain this product must familiarize themselves with the instructions provided in this manual.

inches (~cm)

Fork pocket dimensions

width x height in inches

(~cm)

Uniform maximum

rated load in pounds

(kg)

Net weight in

pounds (~kg)

Safety Principles

Vestil Manufacturing Corp. recognizes the critical importance of workplace safety. However, although Vestil diligently

strives to identify foreseeable hazardous situations, this manual cannot address every conceivable danger. The end-user

is ultimately responsible for exercising sound judgment at all times.

This manual will acquaint persons authorized to use and/or maintain this equipment platform with safe use and

maintenance procedures. Each person, who might use or perform maintenance on the equipment platform, must

read and understand every instruction BEFORE using the device or performing maintenance. Users should have

access to the manual at all times and should routinely review the directions.

Employers are responsible for training employees to use the product properly. If you do not understand an instruction,

ask your supervisor or employer for assistance, because failure to follow the directions in this manual might result in

serious personal injury or even death.

Vestil is not liable for any injury or property damage that occurs as a consequence of failing to apply either: 1) the

instructions that appear in this manual; or 2) the information provided on labels affixed to the product. Furthermore, failure

to exercise good judgment and common sense might result in property damage, serious personal injury or death. Such

failure is solely the fault of the person(s) using the equipment platform.

This manual uses SIGNAL WORDS to classify personal injury risks and situations that might lead to property damage,

as well as to draw attention to safety message(s). The reader must understand that each signal word indicates the

seriousness of the described hazard.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

Identifies practices likely to result in product/property damage, such as operation that might damage the

INJURY. Use of this signal word is limited to the most extreme situations.

INJURY.

injury.

equipment platform.

Cop

yright 2010 Vestil Manufacturing Corp.

p. 2 of 8

Page 3

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

SAFETY GUIDELINES

Study the entire manual before you use the product for the first time and before each subsequent use

Failure to read and understand the instructions included in this manual before

using or servicing the work platform constitutes misuse of the product.

. Read the

manual to refresh your understanding of the safe use, inspection and maintenance procedures explained on p. 5. If

questions remain about the product after you finish reading the manual, contact Vestil for answers. DO NOT attempt to

resolve any problems with the work platform unless you are authorized to do so and are certain

afterwards.

that it will be safe to use

Electrocution might result if the platform contacts electrified wires. Reduce the likelihood of electrocution by

applying common sense:

DO NOT contact electrified wires with any part of the platform;

DO NOT use the platform in an area where contact with electrified wires is likely;

DO NOT use the platform close to electrified wires or other sources of electricity;

Before using the platform, always inspect the usage area for unusual conditions that require special precautions.

Material handling is dangerous. Improper or careless operation might result in serious personal injuries

sustained by the fork truck operator, platform occupant, and/or bystanders. Apply to the following suggestions to reduce

the likelihood of injury (unless law compels different action(s)):

Contact the manufacturer of your lift truck to verify that the truck is capable of safely handling the fully loaded platform.

To calculate the weight of a “fully loaded platform,” select the specific model you own/use, find the net weight of your

model in the table above, and then add 2,000 pounds (909kg). The width of your platform must be equal to or less

than the width of your fork truck plus 10 inches (250mm).

ONLY use the platform as a means for lifting and transporting equipment NOT people.

DO NOT use a structurally compromised platform. Examples of structural damage includes: broken/severely damaged

railings, mast guard, or fork pockets, and holes produced by rust or corrosion in the platform floor. Inspect the platform

before each use according to the inspection instructions on p. 3-4. DO NOT use the platform unless it passes every

part of the inspection.

DO NOT use the platform if the safety strap is damaged or missing; DO NOT lift the platform until it is securely

connected to the carriage of the fork truck with the safety strap (see Step 1 & 2 on p. 6).

DO NOT attempt to lift a load that weighs more than the maximum load rating of the platform. The net weight, i.e. the

combined weight of everything supported by the platform including any person supported by the platform while loading

or unloading equipment, cannot exceed the maximum rated load of the platform.

DO NOT stand beneath or travel under the platform while it is elevated.

DO NOT use the chains, mast guard, or guardrails as a step.

DO NOT use the platform to transport people! A person should only stand or walk on the platform to load and unload

equipment.

DO NOT use the platform UNLESS each label shown in Fig. 8 on p. 8 is affixed to the platform, undamaged and

readable.

Inspections & Maintenance

Before each use inspect the listed components:

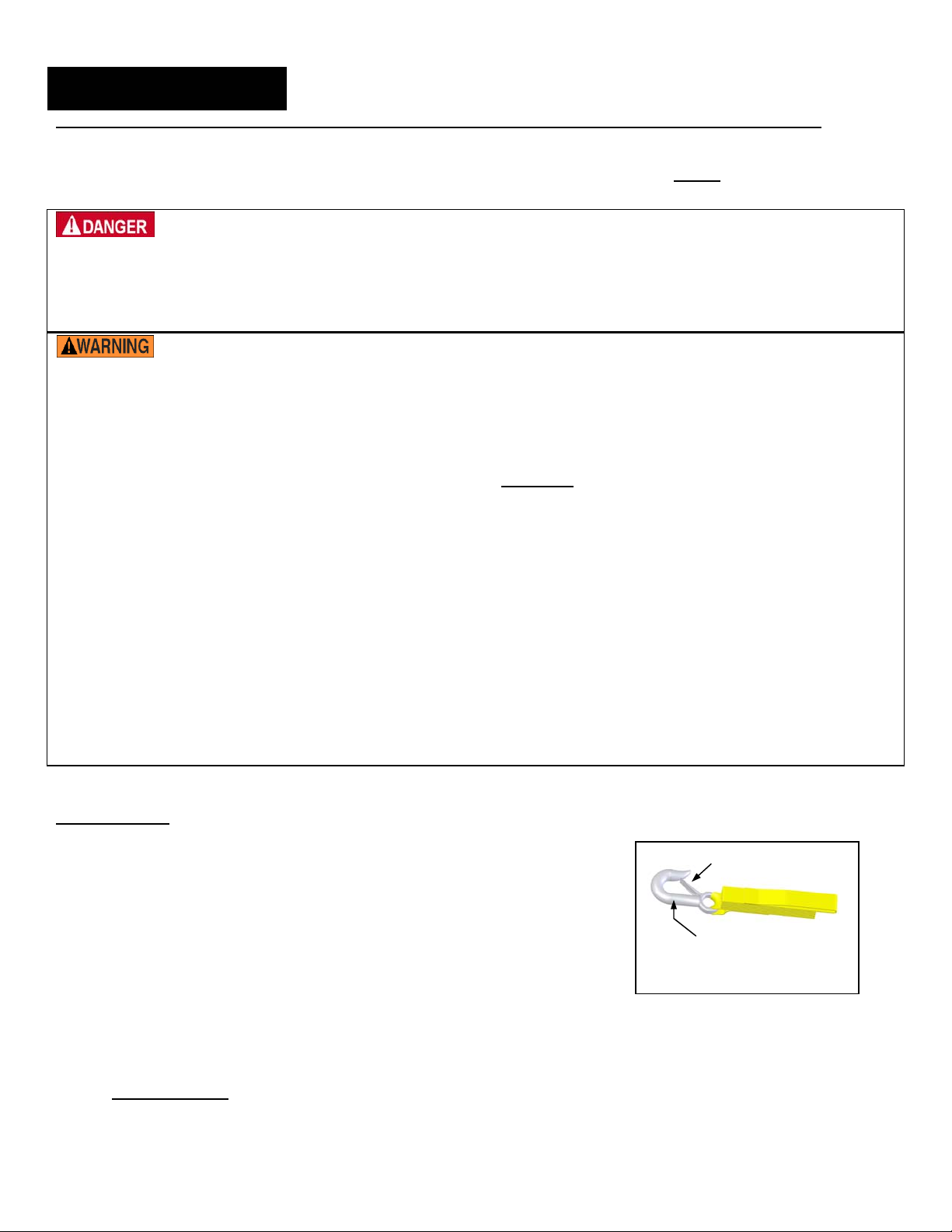

1. Snap hook (attached to the free end of the nylon safety strap): confirm that

the spring latch automatically closes securely against the tip of the hook as

shown in the diagram to the right. If the hook, nylon strap, or latch is

spring

latch

damaged, then do not use the platform until a complete, new safety strap is

obtained and attached to the platform. Refer to steps 1 & 2 on p. 6 for

attachment procedures.

2. [FTLP-54

54-HR] Handrails: check the rails, rail welds, and points of contact

between the rails and the sleeves welded to the platform for bending,

warping and cracking.

hook

Nylon safety strap (item no. 1

on p. 4)

3. [FTLP-5454-HR] Lanyard attachment points: check the anchorage weldment

(see FIG. 6 on p. 7) and points of attachment to the mast guard for bending,

warping, or cracking.

4. Product labels: all labels should be readable and located as shown in the diagram on p. 8. If a label(s) is unreadable

or missing, contact Vestil to order a replacement.

At least 1 time per month, inspect:

1. Fasteners (hardware):

Mast guard hinge - bolts, nuts, washers. Replace all damaged fasteners.

Gate – chains, snap hooks, welded D-rings (attachment points for each chain) . DO NOT use the platform

until all damaged hooks and chains are replaced and damaged D-rings are restored to original condition.

Cop

yright 2010 Vestil Manufacturing Corp.

p. 3 of 8

Page 4

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

2. Fork pockets: confirm that each pocket is structurally sound, not corroded or rusted. DO NOT use the platform if the

fork pockets are structurally compromised or dangerously rusted or corroded.

3. Welds: confirm that all welds are intact. DO NOT use the platform if authorized maintenance personnel determine

that a damaged weld compromises the soundness of the platform.

4. Barriers: inspect handrails, mast guard, and entryway chains for ob vious damage or deformation.

5. (Overall condition of) Platform: the structure should be clean, square and rigid, and free of rust and corrosion.

Remove dirt and debris. DO NOT use the platform if the base is rusted or corroded.

FIG. 1: FTLP-SERIES EXPLODED PARTS DIAGRAM AND PARTS LIST

7

Item no. 2

Item

* = Optional features usable with FTLP-5454-HR platform &

Description Part No. Quantity

No.

Nylon safety strap and hook

1

2 5/16in. quick link 45214 1

3 3/16in. x 9in. chain 08-145-007 1

*4 Mast guard 14-514-134 1

*5 ¼ in. spring hook 0500499 4

*6 ¼ in. x 60in. chain 99-145-036 2

Platform & ramp weldment:

7

*8 Handrail 14-524-001 2

ramp weldment.

FTLP-5454

FTLP-5454-HR

08-145-027

14-513-011

14-513-012

1

1

1

Cop

yright 2010 Vestil Manufacturing Corp.

p. 4 of 8

Page 5

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

A

A

FIG. 2A: FTLP-5454 Center of Gravity Diagram

Model

FTLP-5454 32in. (~81¼ cm) 0.8in. (~2cm)

A: Horizontal

Center of Gravity

B: Vertical Center

of Gravity

Horizontal center of gravity (B)

measured from back of toe

guard

B

Lanyard attachment points

Mast

guard

Vertical center of

gravity (A) calculated

from bottom of platform

floor

center of gravity

(C.O.G.)

WP-series

FIG. 2B: FTLP-5454-HR Center of Gravity Diagram

Model

A: Horizontal Center

of Gravity

FTLP-5454-HR 25.3in. (~64.3cm ) 11.3in. (~28.7cm)

B: Vertical Center

of Gravity

Vertical center of

gravity (A) calculated

from bottom of platform

floor

Cop

yright 2010 Vestil Manufacturing Corp.

p. 5 of 8

B

Horizontal center of gravity (B)

measured from back of mast

guard

Page 6

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

t

Fig. 3: Mast Guard Hinge

Upper mast guard

wer mast guard

Lo

lower portions of the mast guard are

improperly fastened, the guard cannot

adequately protect platform occupants.

Therefore, make sure that hinge

fasteners (circled in the drawings) are

tightened to 35ft·lb of torque.

Retighten the connection to 35 ft·lb

whenever:

1. The work platform is taken out of

storage:

Raise the upper portion of the

mast guard, and then

Hex

nut

Bo

l

Tighten the bolts and nuts.

2. If the mast guard is bumped (or

deflected from vertical):

Immediately lower the platform to

the ground; then

Straighten the mast guard (return

Clo

se-up of connection

between top and bottom

it to the vertical orientation) and

retighten the bolts and nuts.

portions of mast guard.

If the upper and

Loading and using the platform:

Step 1: Mount the platform on the forks of your lift truck.

Drive the fork truck forward until the toe guard (or mast guard

for FTLP-5454-HR) contacts the back (vertical part) of the tines.

Step 2: Fasten the nylon safety strap to the fork carriage.

The nylon strap is an essential safetyenhancing feature. If the forks are accidentally tilted forward,

the strap will not prevent the platform from sliding off of the fork

lift if it is improperly connected to either the platform or the fork

lift. Use the strap to connect the platform to the carriage of your

fork truck. Wrap the strap around the carriage with no slack at

the point indicated by dotted arrows in Fig. 4.

When the platform is delivered to you, you will also receive a nylon safety strap and a quick link. Attached to one end of

the strap is a latching safety hook; at the other end is a small loop. Slide the small loop onto the quick link; then attach the

quick link to the D-ring welded to the back of the platform (see Fig. 5 below) and close the link. Wrap the strap around the

carriage (see FIG. 4 above) and connect the hook to the D-ring with no slack. Increase the number of wraps around the

carriage, if necessary, to eliminate slack.

FIG. 5: Safety Strap Attachment to Platform

Tie-down rings

Cop

yright 2010 Vestil Manufacturing Corp.

p. 6 of 8

FIG. 4: Proper Attachment of Safety Strap to Carriage

Mast

Carriage

Fork

(tine)

D-ring welded to

platform

Latching

hook

Quick link

Nylon safety strap

Page 7

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

Step 3: Load the platform

The fork truck operator and bystander(s) might sustain serious personal injuries or could be killed if the

platform is misused. Disregarding obvious hazards constitutes product misuse. To reduce the likelihood of harmful

consequences:

FTLP-series products are medium-duty rated platforms. Therefore,

ONLY use the platform with sit-down rider high lift fork trucks having

a maximum rated load of at least 3,000 pounds at a 24in. load

FIG. 6: Anchorage

Points (arrows)

Anchorage

weldm

ent

center.

ALWAYS review the “Safety Guidelines” on p. 3 before each use.

Apply ANSI/ITSDF B56.1-2005, “Safety Standard for Low Lift and

High Lift Trucks,” suggestions regarding the use of fork-mounted

platforms. The publication is freely downloadable:

http://www.itsdf.org/pB56.asp

When raised 4 feet (~1.2m) or higher, guard rails are required if

any person must occupy the platform to load/unload equipment. Do

not lean against the handrails or safety chains. NO person should

occupy the platform during load transport. Maximum occupancy is 2

persons.

If work site practice requires that any person who occupies an

elevated platform must wear a safety harness and lanyard, only 1

person should connect to a given anchorage point. Anchorage

points are present at each end of the anchorage weldment (see

arrows in FIG. 6). NO person should occupy the platform during load

transport. Maximum occupancy is 2 persons.

FIG. 7: Ramp Closure Mechanism

Only use the platform on smooth, level, finished surfaces capable of

supporting the combined weight of the person(s) occupying the

platform and all equipment and/or material present on the platform,

the platform itself, the lift truck and operator.

Avoid sudden stops or quick turns while transporting the platform.

DO NOT drive the fork truck while the platform is occupied. If it

is necessary to reposition the fork truck or to relocate the platform,

fully lower the forks, require all persons to disconnect safety lanyards

and dismount the platform.

Set the parking brake before lifting the platform.

Before transporting the platform, secure it to the (fork truck) mast.

Inspect the platform for signs of damage, and verify that the ramp

closure mechanism functions properly as shown in FIG. 7.

Closure

chain

Closure plate

Load equipment onto the platform:

1. Pull upwards on the free end of the closure chain (see Fig. 7 above) pull the chain through the opening in the closure

plate;

2. Lower the ramp;

3. Center the load/equipment on the platform;

4. Secure the load to the platform with tie-down straps or equivalent means. Attach the ends of the straps to the tie-

down D-rings (see FIG. 5 on p. 6). Make sure that the load is immobilized and secured to the platform.

5. Raise the ramp and secure it with the closure chain. Lift the platform only as high as necessary to avoid contact with

obstacles present along the path of travel. Transport the load to the desired location.

6. Adjust the elevation of the platform so that it rests on the surface that will receive the load/equipment (the bed of a

truck, for example). Make sure that the platform is level; adjust the tilt of the mast if necessary to level the platform.

Lower the ramp and release the tie-down straps. Transfer the equipment/load to the truck or other surface.

7. Raise the ramp and secure it with the closure chain; then return the platform to its storage location.

Cop

yright 2010 Vestil Manufacturing Corp.

p. 7 of 8

Page 8

10/21/2010 rev. 10/22/2010 FTLP manual, operation instructions.doc

FIG. 8: Product Markings and Labels

D

C

A

(Label #729)

B

A

B (Label #726)

C (Large Vestil logo) D (Label #287)

Copyright 2010 Vestil Manufacturing Corp.

p. 8 of 8

Loading...

Loading...