Page 1

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

FMDL-S

PLASTIC BARREL HANDLER

BARREL HANDLER) ENGAGING BARREL HANDLER

ERIES SINGLE & DOUBLE EAGLE BEAK FORK-MOUNTED DRUM LIFTERS

U

SE AND MAINTENANCE MANUAL

FMDL-1 (E

FPDL-11-H (T

AGLE BEAK™)

OP ENGAGING PLASTIC

FMDL-2 (E

AGLE BEAK™)

DFDL-3 (E

FPDL-8-L (B

AGLE BEAK™, TOP, & BASE

ASE ENGAGING

)

)

V

2999 N

T

ORTH WAYNE STREET,

ELEPHONE:

ESTIL MANUFACTURING CORP

P.O. B

(260) 665-7586 -OR- T

OX

507, A

OLL FREE

NGOLA, IN

.

46703

(800) 348-0868

FAX: (260) 665-1339

URL:

NOTE: C

IN THE LOCATION WHERE THE DEVICE IS USED IS EXCLUSIVELY THE RESPONSIBILITY OF THE END-USER

ENFORCED WHERE THE DRUM LIFTER IS USED, CONTRADICTS AN INSTRUCTION(S) OR PART OF AN INSTRUCTION(S)

AND THEREFORE REQUIRES YOU TO DEPART FROM THESE DIRECTIONS, VESTIL IS NOT RESPONSIBLE FOR ANY

CONSEQUENTIAL DAMAGES SUSTAINED AS A RESULT OF THE INSTALLATION

Table of Contents Table of Figures

Product Introduction…………………... 2 Fig. 1 “FMDL-1 Exploded parts diagram and parts list”……… 4

Safety Principles…………………….....3 Fig. 2 “FMDL-2 Exploded parts diagram and parts list”…....... 5

Safety Guidelines…………………....... 3 Fig. 3 “FPDL-11-H Exploded parts diagram and parts list”….. 6

Use Instructions……………………….. 11 Fig. 4 “FPDL-8-L Exploded parts diagram and parts list”….… 7

Maintenance Recommendations……. 11 - 12 Fig. 5 “DFDL-3 Exploded parts diagram and parts list”…........ 8

Fig. 6 “Center of gravity diagrams”…………………………….. 9 - 10

Fig. 7 “Product label placement diagram”……………………... 12

WWW.VESTILMFG.COM EMAIL: SALES@VESTIL.COM

OMPLIANCE WITH REGULATIONS, CODES, AND/OR STATUTORY (NON-VOLUNTARY) STANDARDS ENFORCED

.

. I

F LAW,

Copyright 2010 Vestil Manufacturing Corp.

Page 1 of 12

Page 2

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

P

RODUCT INTRODUCTION

Thank you for purchasing an FMDL-series fork-mounted drum lifter (“drum lifter” or “lifter”)

made by Vestil Manufacturing Corporation. Our drum lifters are durable, high-quality products

rigorously engineered for dependability and simplicity. Although use and maintenance procedures

are relatively intuitive, any person who might use or maintain this product must be familiar with the

instructions provided in this manual. Dimensions and other product specifications appear in the

following table:

Model Description Compatible Drums

Eagle Beak™

FMDL-1

single drum

carrier

FMDL-2

Eagle Beak™

two drum carrier

Deluxe 3-mode

DFDL-3

drum lifter: Eagle

beak, Bottom

grip & Top grip

FPDL-8-L

(“L” = low

attachment

FPDL-11-H

(

“H” = high

attachment

Bottom gripping

drum handler for

oddly shaped

)

plastic drums

Top gripping

drum handler for

oddly shaped

)

plastic drums

• 30 & 55 gallon

• Open & closed head

T:

• Steel, plastic, & fiber

• 30 & 55 gallon

• Open & closed head

• Steel, plastic, & fiber

• 30 & 55 gallon

• Open & closed head

• Steel, plastic, & fiber

• 55 gallon

• Open & closed head

• Plastic

• 30 & 55 gallon

• Closed head

• Steel, plastic, & fiber

Maximum Rated

Load in Pounds

(~kg)

1,000

(~455kg)

2,000

(~909kg)

Eagle Beak™ =

1,000 (~455kg)

Bottom grip =

800 (~364kg)

Top grip =

1,100 (~455kg)

800

(~364kg)

1100

(~500kg)

Overall

Dimensions in

Inches (~cm)

26½ x 46½ x 29

(67 x 118 x 74)cm

42 x 49½ x 29

(107 x 126 x 74)cm

26½ x 52 x 30

(67 x 132 x 76)cm

26½ x 56½ x 23

(67 x 144 x 58)cm

26½ x 48½ x 23

(67 x 123 x 58)cm

Net Weight in

Pounds (~kg)

240

(~109kg)

340

(~155kg)

313

(~142kg)

160

(~73kg)

185

(~84kg)

Vestil Manufacturing Corp. created this manual to acquaint persons authorized to use and/or maintain this drum

handling device with safe use and maintenance procedures. Employers are responsible for instructing employees to

use the product properly. An employee and any other person, who might use or perform maintenance on the drum

lifter, must read and understand every instruction BEFORE using or performing maintenance activities. Users

should have access to the manual at all times and should routinely review the directions.

Although Vestil diligently strives to identify foreseeable, hazardous situations, this manual cannot address every

conceivable danger. The end-user is ultimately responsible for exercising sound judgment at all times.

Copyright 2010 Vestil Manufacturing Corp.

Page 2 of 12

Page 3

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

S

S

AFETY PRINCIPLES

Vestil manufactures several kinds of fork-mountable drum handling equipment. This manual

addresses the specifications, features, and capabilities of 3 product lines: 1) FMDL-series; 2) FPDL-series; and 3) DFDL-3.

Each lifter conforms to the generalized specifications disclosed in this manual and fulfills our demanding standards for

quality, safety and durability.

Vestil Manufacturing Corp. recognizes the critical importance of workplace safety. Each person who might participate

in the use or maintenance of the product must read this manual and fully understand the directions BEFORE using or

performing maintenance on the drum lifter. If you do not understand an instruction, ask your supervisor or

employer for assistance. Failure to adhere to the directions in this manual might result in serious personal injury or

even death.

Vestil is not liable for any injury or property damage that occurs as a consequence of failing to apply either: 1) the

instructions that appear in this manual; or 2) the information provided on labels affixed to the product. Furthermore, failure

to exercise good judgment and common sense might result in property damage, serious personal injury or death. Such

failure is solely the fault of the person(s) who acted without good judgment; it is not another responsibility delegated to

manufacturers.

This manual uses SIGNAL WORDS to classify personal injury risks and situations that might lead to property damage,

as well as to draw attention to safety message(s). The reader must understand that each signal word indicates the

seriousness of the described hazard.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

Identifies practices likely to result in product/property damage, such as operation that might damage the

INJURY. Use of this signal word is limited to the most extreme situations.

INJURY.

injury.

drum lifter.

AFETY GUIDELINES

Failure to read and understand the instructions included in this manual before using

or servicing the drum lifter constitutes misuse of the product. Study the entire manual before you install the

product. Read the manual to refresh your understanding of the safe use and inspection procedures explained on p. 9. DO

NOT attempt to resolve any problem(s) with the lifter unless you are both authorized to do so and certain that it will be safe

to use afterwards.

Electrocution might result if any part of the lifter or fork truck contacts electrified wires. Reduce the likelihood

of electrocution by applying common sense:

DO NOT contact electrified wires with any part of the drum lifter, drum or fork truck;

DO NOT use or store the drum lifter in an area where contact with electrified wires is likely or possible;

Before engaging or using the lifter, inspect the usage area for unusual conditions and implement precautions that account

for those conditions.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious personal

injuries or even be killed. To reduce the likelihood of injury:

• DO NOT exceed the maximum rated load of your lifter (see Label on product; also see table on p. 2).

• DO NOT use a structurally compromised drum lifter. Examples of structural damage include: 1) missing, broken or

significantly bent drum-engaging arms; 2) broken, missing, or deformed safety chain/strap; 3) damaged or broken fork

pockets. Inspect the drum lifter according to the inspection instructions on p. 9-10. Replace each part that fails to pass an

inspection. DO NOT use the drum lifter until authorized maintenance personnel approve the lifter for service.

• DO NOT stand, or allow other persons to stand, beneath any part of the lifter or drum.

• DO NOT use the lifter to transport anything but drums matched to the specific lifter according to the table on p. 2.

• ONLY transport drums in accordance with the fork truck training you received.

• DO NOT use the lifter to transport a drum(s) over rough, uneven, or damaged terrain UNLESS the drum is secured to the

lifter with a ratchet strap.

• DO NOT modify the drum lifter or any component of the lifter in any way UNLESS you first obtain written approval from

Vestil. Unauthorized modifications might make the lift unsafe to use.

• DO NOT use the lifter UNLESS all product labels (see FIG. 6 on p. 10) are readable and undamaged.

• In order for the Eagle Beak™ mechanism to work properly, each drum (including its contents) must weigh AT LEAST

50lbs (~22.7kg).

Copyright 2010 Vestil Manufacturing Corp.

Page 3 of 12

Page 4

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

&24

NOTE:

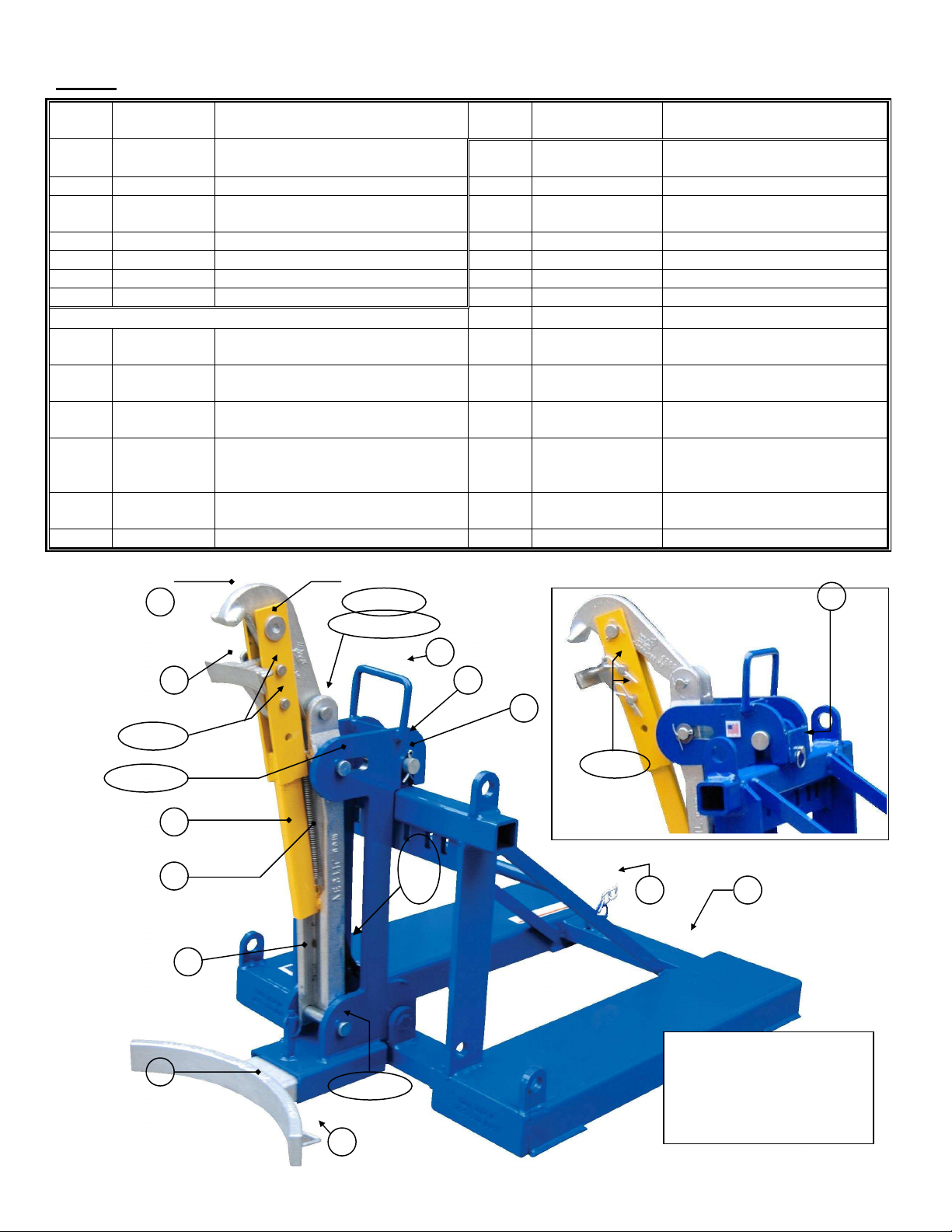

FIG. 1: FMDL-1 Exploded parts diagram and parts list

Item

No.

1 40-514-008

2 DIR-99 ½ in. x 2¾ in. hitch pin 15 CP-3/4x4-1/2-Z ¾ in. x 4½ in. pin

3 15-112-014

4 I-RS Ratchet strap [not shown] 17 65078

5 65125 3/16 in. x 1½ in. cotter pin 18 CP-1/2x1-3/4-Z ½ in. x 1½ in. pin

6 37-145-004 5/16 in. x 48 in. chain 19 45286 Trade size 11 hitch pin clip

7 N/A Cast loop for ratchet strap 20

Part No. Description

Eagle Beak™ base frame

weldment

1 in. diameter x 4½ in. main clevis

pin

Eagle Beak drum lip gripping mechanism (8-26)

8 40-514-006

9 40-514-018

10 40-514-011

11 40-516-001 Eagle Beak™ lower jaw casting 25 33474

12 40-016-052 Eagle Beak™ upper jaw casting 26 40-514-010

13 40-612-004 7/8 in. x 1-3/4 in. pin weldment

Eagle Beak™ handle frame

weldment

Eagle Beak™ channel frame

casting

Eagle Beak™ tube frame

13, 16, 25

14, 17, 17, 21

Item

No.

14 CP-5/8 x 2½-Z

16 65125 3/16 in. x 1-1/4 in. cotter pin

21

22 40-014-029

23 11003

24 37018 ¼ in. – 20 UNC nylock hex nut

Part No. Description

5

/8 in. x 2½ in. clevis pin

1

/8 in. x 1½ in. cotter pin

FMDL-SPG Tension spring

33016 5/8 in. flat washer

5/64 in. x 1½ in. x 10 spring

steel frame

¼ in. - 20 UNC x 5/8 in. hex

head bolt

1½ in. (outer diameter) x ¾ in.

(inner diameter) x 14 GA

machinery bushing

Drum side wall support

casting

18, 19

22,

23

15, 16, 25

Beak™ mechanism to work

properly, the drum and its

contents must weigh AT

LEAST 50 lbs. (~22.7kg).

In order for the Eagle

Copyright 2010 Vestil Manufacturing Corp.

Page 4 of 12

Page 5

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

&24

NOTE:

to work properly, each drum

FIG. 2: FMDL-2 Exploded parts diagram and parts list

Fork pocket

13, 16, 25

18, 19

22,

23

15, 16, 25

Item No. Part No. Description

1 40-514-008 Eagle Beak™ base frame weldment

2 DRI-99 ½ x 2¾ in. hitch pin

3 40-112-001 1in. diameter x 8-5/8 in. pin

4 I-RS Ratchet strap

5 65125 3/16 x 1½ in. cotter pin

6 37-145-004 5/16 x 48 in. chain

7 N/A Ratchet strap attachment loop (part of item no. 26)

Eagle Beak drum lip-gripping mechanism

8 40-514-006 Eagle Beak™ handle frame weldment

9 40-514-018 Eagle Beak™ channel frame weldment

10 40-514-011 Eagle Beak™ tube frame casting

11 40-516-001 Eagle Beak™ lower jaw casting

12 40-516-002 Eagle Beak™ upper jaw casting

13 40-612-004 7/8 in. x 1-3/4 in. pin weldment

14 CP-5/8 x 2½-Z 5/8 in. x 2½ in. clevis pin

15 CP-3/4x4-1/2-Z ¾ in. x 4½ in. pin

16 65125 3/16 in. x 1-1/4 in. cotter pin

17 65078

18 CP-1/2x1-3/4-Z ½ in. x 1½ in. pin

19 45286 Trade size 11 hitch pin clip

20 FMDL-SPG Tension spring

21 33016 5/8 in. flat washer

22 40-014-029 5/64 in. x 1½ in. x 10 spring steel frame

23 11003 ¼ in. - 20 UNC x 5/8 in. hex head bolt

24 37018 ¼ in. – 20 UNC nylock hex nut

25 33474 1½ in. (outer diameter) x ¾ in. (inner diameter) x 14

26 40-014-066 Drum side wall support casting

14, 17, 17, 21

1

/8 in. x 1½ in. cotter pin

GA machinery bushing

In order for the

Eagle Beak™ mechanism

and its contents must weigh

AT LEAST 50 lbs.

(~22.7kg).

Copyright 2010 Vestil Manufacturing Corp.

Page 5 of 12

Page 6

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

FIG. 3: FPDL-11-H Exploded parts diagram and parts list

Item No. Part No. Description

1 40-514-008 Eagle Beak™ base frame casting

2 40-514-016 Left side upper drum gripper casting

3 40-512-002 Left side hinge casting

4 40-112-001 1 in. diameter 8-5/8 in. main clevis pin

5 15-112-014 1 in. diameter x 4½ in. pin

6 N/A Fork pockets

7 65125 3/16 in. x 1½ in. cotter pin

8 37-145-004 5/16 in. x 48 in. chain

9 65125 3/16 in. x 1½ in. cotter pin

10 40-514-017 Right side upper drum gripper casting

11 40-512-001 Right side hinge casting

Copyright 2010 Vestil Manufacturing Corp.

Page 6 of 12

Page 7

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

FIG. 4: FPDL-8-L Exploded parts diagram and parts list

7, 8, 9

7, 8, 9

Item No. Part No. Description

1 40-514-008 Eagle Beak base frame weldment

2 40-514-020 Left side lower drum gripper weldment

3 40-514-019 Left side lower drum gripper arm weldment

4 40-014-029 Spring steel bar frame

5 11003 ¼ in. – 20 UNC x ¾ in. hex head bolt

6 37018 ¼ in. -20 UNC nylock hex nut

7 11219 ½ in. – 13 UNC x 4 in. hex head bolt

8 37030 ½ in. - 13 UNC nylock hex nut

9 SPMSIRJ ¾ in. (outer diameter) x ½ in. (inner diameter) 8-

5/8 in. axle sleeve tube

10 40-112-001 1 in. diameter x 8-5/8 in. main clevis pin

11 65125 3/16 in. x 1½ in. cotter pin

12 40-514-021 Upper side wall support weldment

13 15-115-014 1 in. diameter x 4½ in. retaining pin

14 N/A Fork pockets

15 37-145-001 5/16 in. x 48 in. chain

16 40-514-005 Right side lower drum gripper weldment

17 40-514-009 Right side lower drum gripper arm weldment

Copyright 2010 Vestil Manufacturing Corp.

Page 7 of 12

Page 8

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

NOTE:

FIG 5: DFDL-3 exploded parts diagram and parts list (2 views)

Item No. Part No. Description

1 40-514-008 Eagle Beak™ base frame weldment

2 40-514-022 Eagle Beak drum lip gripping assembly [corresponds to

item no’s 8-26 on p. 4]

3 40-514-012 Right side lower drum gripper assembly [corresponds to

item no’s 4 - 9, 16, 17on p. 7]

4 40-514-013 Left side lower drum gripper assembly [corresponds to item

no’s 2 – 9 on p. 7]

5 40-514-014 Right side upper drum gripper assembly [corresponds to

item no’s 5, 9-11 on p. 6]

6 40-514-015 Left side upper drum gripper assembly [corresponds to item

no’s 2, 3, 5 & 9 on p. 6]

7 n/a Fork pocket

8 37-145-004 5/16 in. x 48 in. chain (not shown)

9 40-112-001 1 in. diameter x 8-5/8 in. main clevis pin

10 n/a 3/16 in. x 1½ in. cotter pin

In order for the

Eagle Beak™ mechanism

to work properly, the drum

and its contents must weigh

AT LEAST 50 lbs.

(~22.7kg).

Copyright 2010 Vestil Manufacturing Corp.

Page 8 of 12

Page 9

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

cm) from the outer edge of each fork pocket (halfway between the fork

In order for the Eagle Beak™ mechanism to work properly, the drum and its contents must weigh AT LEAST

from the outer edge of each fork pocket (halfway between the fork

drum and its contents must weigh AT

FIG. 6A: FMDL-1 center of gravity diagrams

13 ¼ ”

281/8”

Horizontal center of gravity (HCG):

• 281/8 inches (~71.4 cm) from the open ends of the fork pockets; and

• 141/4 inches (~36.2

pockets).

Vertical center of gravity:

• 13¼ inches (~33.7cm) from the bottom of the fork pockets.

NOTE:

50 lbs. (~22.7kg).

FIG. 6B: FMDL-2 center of gravity diagrams

141/4”

13 ¼”

111/8”

281/8”

141/4”

Horizontal center of gravity (HCG):

• 281/8 inches (~71.4 cm) from the open ends of the fork pockets; and

• 141/4 inches (~36.2cm)

pockets).

Vertical center of gravity:

• 111/8 inches (~28.3cm) from the bottom of the fork pockets.

NOTE: In order for the Eagle Beak™ mechanism to work properly, each

LEAST 50 lbs. (~22.7kg).

Copyright 2010 Vestil Manufacturing Corp.

Page 9 of 12

111/8”

Page 10

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

from the outer edge of each fork pocket (halfway between the fork

edge of each fork pocket (halfway between the fork

14 ¼“

FIG. 6C: FPDL-8-L center of gravity diagrams

14 ¼”

Horizontal center of gravity (HCG):

• 27 inches (~68.6cm) from the open ends of the fork pockets; and

• 14¼ inches (~36.2cm)

pockets).

Vertical center of gravity:

• 9 inches (~22.9cm) from the bottom of the fork pockets.

FIG. 6D: FPDL-11-H center of gravity diagrams

Horizontal center of gravity (HCG):

• 24 inches (~61cm) from the open ends of the fork pockets; and

• 14¼ inches (~36.2cm) from the outer

pockets).

Vertical center of gravity:

• 15 inches (~38.1cm) from the bottom of the fork pockets.

Copyright 2010 Vestil Manufacturing Corp.

Page 10 of 12

Page 11

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

Use Instructions

Step 1: Adjust the positions of the forks/tines of your lift truck to match the locations of the fork pockets. Apply the

operation procedures learned during your lift truck training program to properly adjust fork position.

Step 2: Mount the drum lifter on the forks of your lift truck. Slowly drive the truck forward until the forks contact the ends

of the fork pockets.

Step 3: Connect the drum lifter to the fork truck by attaching the safety chain to the fork carriage. Wrap the chain around

the fork carriage and then fasten the snap hook to the chain or cold shut (the loop welded to the supporting frame that

attaches to the fixed end of the chain) without slack. The chain must not be able to disconnect from the carriage without

deliberate effort. For instance, the chain must not be able to slide free of the carriage. If different procedures are applied

at your worksite, follow those procedures instead of these directions.

The chain is an essential safety-enhancing feature. Use the chain to connect the drum lifter to the

carriage of your fork truck. Wrap the chain around the carriage and fasten the free end to the chain with no slack. The

chain will not prevent the drum lifter from sliding off of the forks if it is improperly connected to the fork carriage.

Slowly lower the forks to avoid damaging impacts between the floor/ground and the drum or lifter.

Eagle Beak™ and DFDL-3 models:

NOTE: In order for the Eagle Beak™ mechanism to work properly, the drum and its contents must weigh AT LEAST 50

lbs. (~22.7kg).

Step 4 Engage the selected drum with the lifter: Raise the forks just a few inches off of the ground/floor, and tilt the mast

of you fork truck forward. Drive slowly towards the selected drum until the lower jaw of the Eagle Beak™ ((item no. 11 in

Fig. 1, p. 4) contacts the side of the drum directly beneath the lip of the drum.

Step 5 Grasp the lip of the drum: Slowly raise the forks until the upper jaw engages the top of the drum lip. Continue to

raise the forks until the drum is elevated a few inches above the floor/ground. Attach one end of the ratchet strap to one

cast loop on the drum side wall casting (Fig. 1, item 26, p. 4). Attach the other end of the ratchet strap to the other cast

loop on the side wall casting; then work the ratchet mechanism until the strap is tight.

Step 6 Transport the drum: Straighten the mast and transport the drum to the desired unloading location. Raise the forks

when/as required by conditions along the travel path.

Step 7 Release the drum: Lower the forks until the drum is just a few inches above the floor, and then remove the ratchet

strap. Tilt the fork truck mast forward. Slowly lower the forks until the Eagle Beak™ disengages the lip of the drum and the

drum is fully supported by the floor/ground.

FPDL-11-H and DFDL-3 models:

Step 4 Position the fork lift and drum lifter: Raise the forks and adjust the location of the fork lift to position the drum

grippers above the top of the drum. Tilt the mast forward, i.e. point the forks toward the floor.

Step 5 Position drum grippers: Lower the forks; the drum grippers will slide over the lip of the drum. Position the grippers

below the lip or the middle rim as desired.

Step 6 Transport the drum: Straighten the mast and raise the forks until the gripper engages the lip or rim, and then slowly

raise the forks until the drum is elevated a few inches above the floor. Tilt the mast back; then transport the drum to the

desired location.

Step 7 Release the drum: First tilt the mast forward and then slowly lower the forks until the drum is fully supported by the

floor. To finish disengaging the drum, back the fork truck away from it.

FPDL-8-L and DFDL-3 models:

Step 4 Position fork lift and drum lifter: Adjust the mast position so that the drum grippers are parallel to the ground.

Slightly elevate the forks above the floor.

Step 5 Prepare the engage the drum: Adjust the position of the fork truck to center the drum lifter on the drum; then drive

forward until the side of the drum contacts the upper side wall support weldment (FIG. 4, item no. 4, on p. 7).

Step 6 Transport drum: Raise the forks until the lower drum gripper weldments (FIG. 4, item no’s 2 & 16, on p. 7) engage

the base of the drum. Raise the drum a few inches above the ground; secure it to the lifter by attaching the ratchet strap to

the cast loops of the side wall support (FIG. 4, item no. 12, p. 7); then transport it to the desired unloading point.

Step 7 Release the drum: First tilt the mast forward; then slowly lower the forks until the drum is fully supported by the

ground/floor. Slowly back the fork lift away from the drum until the drum and lifter disengage.

Maintenance Recommendations

Before each use, inspect the listed components:

1. Safety chain and snap hook (attached to the free end of the safety chain): confirm that the spring latch

automatically closes securely against the hook. DO NOT use the lifter if the hook, chain, cold shut (the loop

welded to the lifter frame, which connects to one end of the chain), or ratchet strap loop castings are damaged.

Copyright 2010 Vestil Manufacturing Corp.

Page 11 of 12

Page 12

08/2010 rev. 11/16/2012 FMDL manual, operation instructions.doc

Label #

218

2. Product labels: all labels should be readable and located as shown in FIG. 6. If a label(s) is unreadable or

missing, contact Vestil to order a replacement.

At least 1 time per month, inspect:

1. Fasteners (hardware):

Bolts, nuts, washers, pins, cotter pins;

Chain and snap hook.

2. Fork pockets: confirm that each pocket is structurally sound, uncorroded and free of rust. Do not use the lifter if

the fork pockets are structurally compromised, rusted or corroded.

3. Welds: confirm that all welds are intact.

4. Drum grippers, Eagle Beak® upper and/or lower jaw, fork pockets, and supporting frame: must be undamaged.

For example, no structural deformation, warps, or cracks.

5. Overall condition of drum lifter: the structure should be clean, square and rigid, and free of rust and corrosion.

Remove dirt and debris. Do not use the lifter if the supporting frame and/or one or both grippers are excessively

rusted or corroded.

FIG. 7: Product label placement diagram

Label #218:

Copyright 2010 Vestil Manufacturing Corp.

Page 12 of 12

Loading...

Loading...