Page 1

03/10/03 2/19/2013 FE, manual.doc

FORK EXTENSIONS, SERIES FE

INSTRUCTION MANUAL

STANDARD FE ROUNDED FE TRIANGULAR FE

VESTIL MANUFACTURING CORP.

2999 NORTH WAYNE STREET

P.O. BOX 507, ANGOLA, IN 46703

TELEPHONE: (260) 665-7586 -OR- TOLL FREE (800) 348-0868

FAX: (260) 665-1339

URL: WWW.VESTILMFG.COM EMAIL: SALES@VESTIL.COM

NOTE: Compliance with regulations, codes, and/or statutory (non-voluntary) standards enforced in the

location where the fork extensions are used is exclusively the responsibility of the end-user.

Table of Contents Table of Figures

Product Introduction………………………... 2 Fig. 1 “FE assembly breakdown”…….………… ………… 3

Safety Principles……………………............. 3 Fig. 2 “Standard tine loop”………………..………………... 5

Safety Guidelines…………………............... 4 Fig. 3 “Optional removable pin tine lock”…………………. 5

Inspections…………………………………… 4 Fig. 4 “Product markings and labels”……………………… 6

Properly pair fork extensions and

lift truck tines……………………………. 4

Installation…………………………………… 5

yright 2010 Vestil Manufacturing Corp. 1 of 6

Cop

Page 2

03/10/03 2/19/2013 FE, manual.doc

PRODUCT INTRODUCTION

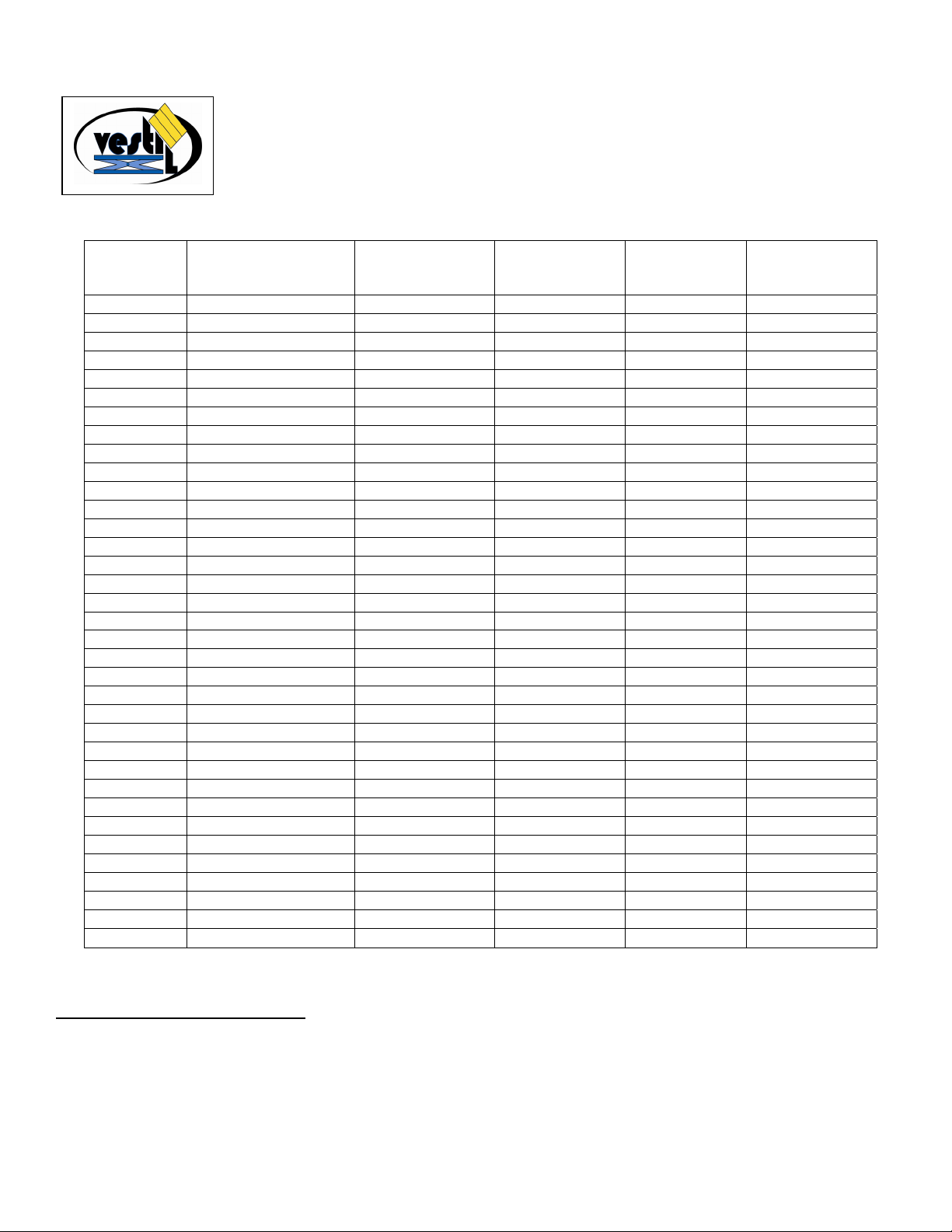

Dimensions and other product specifications appear in the following tables:

Model

FE-4-48 4 (10.2cm) 4½ (11.4cm) 48 (122cm) 2 (5.1cm) 101 (46kg)

FE-4-54 4 (10.2cm) 4½ (11.4cm) 54 (137cm) 2 (5.1cm) 109 (50kg)

FE-4-63 4 (10.2cm) 4½ (11.4cm) 63 (160cm) 2 (5.1cm) 125 (57kg)

FE-4-72 4 (10.2cm) 4½ (11.4cm) 72 (183cm) 2 (5.1cm) 135 (61kg)

FE-4-84 4 (10.2cm) 4½ (11.4cm) 84 (213cm) 2 (5.1cm) 157 (71kg)

FE-4-90 4 (10.2cm) 4½ (11.4cm) 90 (229cm) 2 (5.1cm) 163 (74kg)

FE-4-96 4 (10.2cm) 4½ (11.4cm) 96 (244cm) 2 (5.1cm) 173 (79kg)

FE-4-108 4 (10.2cm) 4½ (11.4cm) 108 (274cm) 2 (5.1cm) 200 (91kg)

FE-4-120-P 4 (10.2cm) 4½ (11.4cm) 120 (305cm) 2 (5.1cm) 224 (102kg)

FE-5-48 5 (12.7cm) 5½ (14cm) 48 (122cm) 2 (5.1cm) 112 (51kg)

FE-5-54 5 (12.7cm) 5½ (14cm) 54 (137cm) 2 (5.1cm) 126 (57kg)

FE-5-63 5 (12.7cm) 5½ (14cm) 63 (160cm) 2 (5.1cm) 155 (70kg)

FE-5-72 5 (12.7cm) 5½ (14cm) 72 (183cm) 2 (5.1cm) 128 (58kg)

FE-5-84 5 (12.7cm) 5½ (14cm) 84 (213cm) 2 (5.1cm) 189 (86kg)

FE-5-90 5 (12.7cm) 5½ (14cm) 90 (229cm) 2 (5.1cm) 195 (89kg)

FE-5-96 5 (12.7cm) 5½ (14cm) 96 (244cm) 2 (5.1cm) 201 (91kg)

FE-5-108 5 (12.7cm) 5½ (14cm) 108 (274cm) 2 (5.1cm) 225 (102kg)

FE-5-120-P 5 (12.7cm) 5½ (14cm) 120 (305cm) 2 (5.1cm) 256 (116kg)

FE-6-48 6 (15.2cm) 6½ (16.5cm) 48 (122cm) 2 (5.1cm) 121 (55kg)

FE-6-54 6 (15.2cm) 6½ (16.5cm) 54 (137cm) 2 (5.1cm) 146 (66kg)

FE-6-63 6 (15.2cm) 6½ (16.5cm) 63 (160cm) 2 (5.1cm) 165 (75kg)

FE-6-72 6 (15.2cm) 6½ (16.5cm) 72 (183cm) 2 (5.1cm) 166 (75kg)

FE-6-84 6 (15.2cm) 6½ (16.5cm) 84 (213cm) 2 (5.1cm) 199 (90kg)

FE-6-90 6 (15.2cm) 6½ (16.5cm) 90 (229cm) 2 (5.1cm) 202 (92kg)

FE-6-96 6 (15.2cm) 6½ (16.5cm) 96 (244cm) 2 (5.1cm) 210 (95kg)

FE-6-108 6 (15.2cm) 6½ (16.5cm) 108 (274cm) 2 (5.1cm) 225 (102kg)

FE-6-120-P 6 (15.2cm) 6½ (16.5cm) 120 (305cm) 2 (5.1cm) 275 (125kg)

FE-4-54-T 4 (10.2cm) 4½ (11.4cm) 54 (137cm) 2 (5.1cm) 140 (64kg)

FE-4-63-T 4 (10.2cm) 4½ (11.4cm) 63 (160cm) 2 (5.1cm) 162 (74kg)

FE-5-54-T 5 (12.7cm) 5½ (14cm) 54 (137cm) 2 (5.1cm) 166 (75kg)

FE-5-63-T 5 (12.7cm) 5½ (14cm) 63 (160cm) 2 (5.1cm) 185 (84kg)

FE-4-54-R 4 (10.2cm) 4½ (11.4cm) 54 (137cm) 2 (5.1cm) 146 (66kg)

FE-4-63-R 4 (10.2cm) 4½ (11.4cm) 63 (160cm) 2 (5.1cm) 162 (74kg)

FE-5-54-R 5 (12.7cm) 5½ (14cm) 54 (137cm) 2 (5.1cm) 166 (75kg)

FE-5-63-R 5 (12.7cm) 5½ (14cm) 63 (160cm) 2 (5.1cm) 185 (84kg)

Vestil Manufacturing Corp. created this manual to acquaint owners and end-users of our fork extensions with safe use

and installation procedures. Employers are responsible for instructing employees to use the product properly.

Employees and any other person

instruction BEFOREHAND. Users should have access to the manual at all times and should review the directions

before each use.

Although Vestil diligently strives to identify foreseeable, hazardous situations, this manual cannot address every

conceivable danger. The end-user is ultimately responsible for exercising sound judgment at all times.

Required width of

supporting truck

tine in inches (~cm)

Thank you for purchasing fork extensions (“FE’s” or “exten

Manufacturing Corporation (“Vestil”). Our extensions are durable, high-quality products

rigorously engineered to provide safety-enhancing features while preserving simplicity.

Although use and maintenance procedures are intuitively obvious, any person who might use

or maintain this product must familiarize him/herself with the instructions provided in this

manual.

Overall width of

fork extension

in inches (~cm)

, who might use or install these attachments, must read and understand every

Overall length

of extension in

inches (~cm)

Height of fork

extension in

inches (~cm)

sions”) made by Vestil

Net weight of

pair in pounds

(~kg)

yright 2010 Vestil Manufacturing Corp. 2 of 6

Cop

Page 3

03/10/03 2/19/2013 FE, manual.doc

FIG. 1: FE assembly breakdown

Weld

Fork pocket section

Cast

tapered

end

Weld

Standard welded

tine loop. Optional

removable pin tine

lock shown on p. 5.

Superstructure

having desired

geometry

S

AFETY PRINCIPLES Vestil manufactures several distinct models of fork extension. Design and performance

features that differentiate between models include: geometry of top surface (flat, triangular or rounded), width required of

supporting fork, and inclusion of a rear spacer. Each fork extension conforms to the generalized specifications disclosed

in this manual and fulfills our demanding standards for quality, safety and durability.

Vestil Manufacturing Corp. recognizes the critical importance of workplace safety. Each person who might participate

in the assembly, installation, use or maintenance of the product must read this manual and fully understand the

directions BEFORE using the product and before performing maintenance on it. Failure to adhere to the

directions in this manual might lead to serious personal injury.

Vestil is not liable for any injury or property damage that occurs as a consequence of failing to heed either: 1) the

instructions that appear in this manual; or 2) the information provided on labels affixed to the product. Furthermore, failure

to exercise good judgment and common sense may result in property damage, serious personal injury or death. Such

failure is solely the fault of the person(s) who acted without good judgment; it is not yet another liability of Vestil.

This manual uses SIGNAL WORDS to classify personal injury risks or situations that might lead to property damage,

as well as to draw attention to safety message(s). The reader must understand that each signal word indicates the

seriousness of the described hazard.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

injury.

Identifies practices likely to result in product/property damage, such as operation that might damage the

fork extension(s).

yright 2010 Vestil Manufacturing Corp. 3 of 6

Cop

Page 4

03/10/03 2/19/2013 FE, manual.doc

SAFETY GUIDELINES

Failure to read and understand the instructions included in this manual before

assembling, installing, using, or maintaining the extensions constitutes misuse

of the product.

Study the entire manual before you use the product for the first time and before each subsequent use

. Read the

manual to refresh your understanding of the safe installation, use, and inspection procedures explained on p. 4-5. DO

NOT attempt to resolve any problems with the product unless you are authorized to do so and are certain

safe to use afterwards.

that it will be

Electrocution might result if a fork extension contacts electrified wires. Reduce the likelihood that a fork

truck operator or bystanders might be electrocuted by applying common sense:

DO NOT contact electrified wires with any part of the fork extensions or with any other part of the fork truck;

DO NOT install the extensions in an area where contact with electrified wires is likely;

DO NOT use the extensions close to electrified wires or other sources of electricity;

Before using the extensions, always inspect the usage area for unusual conditions that require special precautions.

Material handling is inherently dangerous. Improper or careless operation might result in serious personal

injuries sustained by the operator and/or bystanders. Fork extension users should apply the following recommendations:

ONLY use fork extensions as a means for supporting palletized loads or skids.

DO NOT use a structurally compromised fork extension. Examples of structural damage include: a) broken tine lock,

retaining loop, or welds connecting the loop/lock to the main body of the extension (fork pocket); b) cracked, warped,

bent or excessively corroded fork pockets; and c) cracks, warps, bends or excessive corrosion of the cast tapered end

welded to the end of each fork pocket. Inspect the platform before each use according to the inspection instructions on

p. 5. DO NOT use the platform unless it passes every part of the inspection.

DO NOT use a damaged fork extension. Inspect both extensions before each use according to the inspection

instructions below. DO NOT use an FE unless it passes every element of the inspection, or until authorized

maintenance personnel approve the extension for service.

DO NOT stand beneath or travel under the elevated tines of a fork truck while equipped with the fork extensions or

permit others to do so.

DO NOT use a fork extension UNLESS each label shown in Fig. 4 on p. 6 is affixed to the extension and is undamaged

and readable.

DO NOT attempt to lift loads that exceed the 4,000lb. (~1,818kg) maximum rated load.

DO NOT exceed the load rating of the fork truck. (See “4. Contact the manufacturer…” on p. 5).

DO NOT attempt to lift a load using only the tapered (front) end of a fork extension. Permanent damage to the fork

extension, damage to property, or serious personal injury could result.

DO NOT modify either fork extension in any way UNLESS you first obtain express, written approval from Vestil.

Unauthorized modifications might make the extension unsafe to use, and could result in operator and/or bystander

injury. Additionally, any modification not expressly approved by Vestil in writing automatically voids the warranty.

Inspections

Before each use:

Look for damage to either the fork extension or the tine lock/loop. Verify that the locking mechanism functions

normally.

Examine the cast tapered end of the extension. Make sure that it is not cracked or deformed, and that the

weld between the tapered end and the fork pocket portion is intact.

At least once per month:

Inspect each extension for regions where the metal has warped, bent, or cracked.

Closely inspect the tine lock/loop for damage.

Verify that all welds are intact.

Confirm that each label is located as shown in FIG. 4 on p. 6 and is undamaged and readable.

Properly pair fork extensions and lift truck tines

1. Compare the length of the truck tine to the length of the fork extension; the extension must be 150% of the tine length

OR LESS.

2. ONLY use FE-series fork extensions with truck tines that are at least 2in. (~5cm) thick.

3. To prevent side-to-side movement (by the fork extension) during use, select a model that matches the tine width (see

“Required width of supporting truck tine in inches (~cm)” from table on p. 2; also see ANSI/ITSDF B56.1-2005,

paragraph 7.39.5, p. 51, “Fork extensions shall be designed to avoid unintentional disengagement from the forks.

Lateral clearance shall not exceed [ 4.7in. approximately equal to ] 12mm between fork and extension.”)

4. Operate the lift truck in a manner consistent with the training provided by your employer. For instance, per

ANSI/ITSDF B56.1-2009, Safety Standard for Low Lift and High Lift Trucks, Part II, paragraph 5.4.3: “... Fork length

yright 2010 Vestil Manufacturing Corp. 4 of 6

Cop

Page 5

03/10/03 2/19/2013 FE, manual.doc

should be at least two-thirds of load length.” NOTE: B56.1-2009 is not law, so the recommendations are not

compulsory. However, a prior version, B56.1-1969, was incorporated by reference into OSHA regulation, and

therefore, is treated as if it were law.

5. Contact the manufacturer of your fork lift to verify that your fork extensions can safely be used with the fork lift. The

manufacturer must also provide updated labels/tags for the fork lift because, of course, regulations impose these

obligations:

“Modifications and additions which affect [fork lift] capacity and safe operation shall not be performed by the

customer or user without manufacturer’s prior written approval. Capacity, operation, and maintenance

instruction plates, tags, or decals shall be changed accordingly.” See 29 CFR 1910.178(a)(4).

-AND“If [your fork lift] truck is equipped with front-end attachments [like fork extensions] other than factory installed

attachments, the user shall request that the truck be marked to identify the attachments and show the

approximate weight of the truck and attachment combination at maximum elevation with load laterally

centered.” See 29 CFR 1910.178(a)(5).

NOTE: Although the regulations cited above seem to impose a duty on the manufacturer of your fork truck to evaluate

the safety of equipping your forklift with fork extensions, the manufacturer may appropriately refuse to do so. In that

case, you should hire a “Qualified Registered Professional Engineer” to “perform a safety analysis and address any

safety and/or structural issues contained in the manufacturer&39;s [manufacturer’s] negative response prior to granting

approval. Machine data plates must be changed accordingly.” See April 11, 1997 OSHA letter of interpretation to Mr.

Kenneth J. Yotz titled, “Powered industrial truck modifications and approval” accessible at

http://www.osha.gov/pls/oshaweb/owadisp.show_doc

ument?p_table=INTERPRETATIONS&p_id=22384 .

Installation

Standard Welded Loop Tine Lock (Models FE-x-xx)

Raise the forks/tines approximately 4-6in. from the

ground. Lift the nose of the fork extension so that the

extension is angled at 45° to the ground/floor. Guide

the tine lock loop underneath the tapered end of the

tine; slide the fork extension onto the tine until it

reaches the heel of the tine; then lower the extension

onto the fork once the tine lock is behind the heel of the

tine

FIG. 2: Standard

tine loop

Fork extension

Removable Pin Tine Lock (Models FE-x-xx-P)

Remove the lock pin and place the fork extension over

the fork truck’s fork so it is all the way back against the

fork’s heel. Reinstall the locking pin behind the heel of

the tine.

FIG. 3: Optio

nal removable pin tine lock

/ tine

Fork

Fork

extension

Fork / Tine

Cotter pin

Tine lock

loop

Lock pin

yright 2010 Vestil Manufacturing Corp. 5 of 6

Cop

Page 6

03/10/03 2/19/2013 FE, manual.doc

A

FIG. 4: Product markings and labels (per pair)

B: Label #460

B

A: Label #697, 698 or 699

Copyright 2010 Vestil Manufacturing Corp. 6 of 6

Loading...

Loading...