Page 1

T & S Equipment Company

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

2999 North Wayne St., Angola, IN 46703

Ph: (260)665-9521 Fax: (260)665-1339

Website: www.tseq.com

Ergonomic Solutions

Contents

Warnings And Safety Instructions ....................1

Receiving Instructions ......................................1

Operating Instructions ......................................1

Loading Chart...................................................2

Revised 02-02 21-126-101

A company dedicated to solving ergonomic and material

handling problems since 1955.

OWNER'S

MANUAL

SELF ELEVATING TABLE

MODEL ETS-460

Parts List ..........................................................3

Warning Label Identification ............................. 4

Limited Warranty/Service Record.....................5

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Never load the unit unless you are watching it.

• Do not operate unless all guards are in place and secure.

• Keep hands and feet clear of all moving parts.

• Never exceed the maximum loading capacity of 460 lbs.

• Load must be evenly distributed on table to insure

stability.

• Consult factory for uneven loading.

• Always operate unit on a level surface to insure stability.

• Always apply wheel brakes when unit is not been moved.

• Use caution in moving a loaded cart; avoid obstructions

and floor defects.

• Always be sure that all of the springs in use are securely

attached to their hanger bars.

• Always leave at least four (4) springs in use at all times.

• Remove weight before working on unit.

• Never go under platform if there is weight on unit.

• Use only maintenance parts supplied or approved by the

manufacturer.

• Consult factory if adding or performing any modification

to the original equipment.

• Make sure all operator safety labels are in place (p.4).

• Failure to follow these guidelines may result in personal

injury or death.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit may incur

damage during transit. If damage is noticed when unloading,

make a note of it on the BILL OF LADING. Remove all

packing and strapping material, then inspect the unit again for

damage. IF DAMAGE IS EVIDENT, FILE A CLAIM WITH

THE CARRIER IMMEDIATELY!

MODEL NUMBER AND CAPACITY

The model number, serial number and capacity

is inscribed on the nameplate. Please remember to

include these numbers in any correspondence with your

dealer or the factory.

OPERATING INSTRUCTIONS

1) Position the work table near desired work area.

2) Lock back casters.

3) Determine initial total weight of the items that are to be

placed on table.

4) Refer to the provided load chart for the proper number

of springs to use.

5) Remove the front cover and unhook the number of

springs that are not going to be used from the bottom

spring hanger bars. Properly unhooked springs can be

left hanging from the top spring hanger bars.

6) Replace the front cover.

7) Place the previously specified load on table.

8) At the end of each run of parts, remove the front cover

and rehook all 14 springs to the bottom spring hanger bars.

9) Replace the front cover.

SELF ELEVATING TABLE

MODEL ETS-460

1

Page 2

2

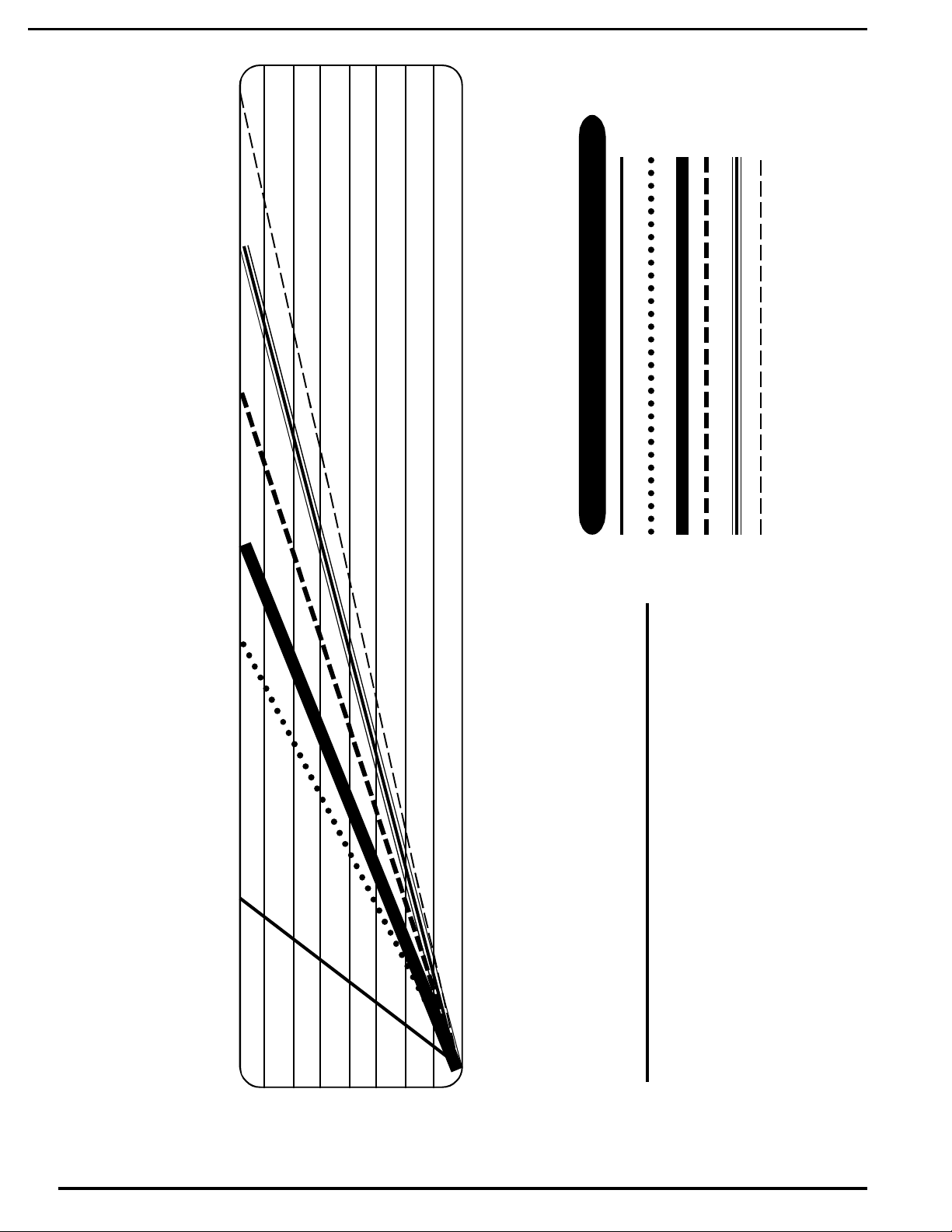

WEIGHT (POUNDS) ON PLATFORM

NUMBER OF SPRINGS

PLATFORM HEIGHT LOADED (INCHES)

4 7 8 10 12 14

15

20

25

30

MODEL ETS-460 LOAD CHART & SPRING GUIDE

This chart is helpful in determining the number of springs necessary to

counterbalance your load requirement.

1.) Determine the Maximum Weight of your application.

2.) Using the line graph, locate the closest line intersecting the weight.

3.) Reference this line to the Number of Springs required to

counterbalance loaded table.

Number of Springs

4

7

8

10

12

14

Page 3

SPRING ELEVATING TABLE • ETS-460 SERIES

E

N

G

L

I

S

H

4

10

11

10

12

4

3

2

1

5

6

7

8

9

6

8

9

6

13

15

6

13

14

KIT NO.

A

A,B

B

B

B

B

A,B

A,B

A,C

C

C

A/L Available at local hardware store

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

A

B

C

DESCRIPTION

Front cover panel

Lifting hole grommet

Top plate / top spring bar assembly

Screw, 1/4"-20 x 3/4"(thread cutting HWH-type F)

Extension spring

Nylock nut, 3/8"-16

Spacer bushing, 3/8" ID x 7/8" OD x 0.688"

"E" clip, 5/8" shaft dia.

Bolt-on bearing post

Roller bearing (MFG. EQUIP & SUPPLY)

Bolt, 3/8"-16 x 2 1/4" (BHSCS)

Bolt, 3/8"-16 x 1 3/4" (BHSCS)

Bolt, 3/8"-16 x 5"

Wheel, caster (rigid)

Wheel, caster (swivel w/ brake)

Bolt Kit (includes 4,6,11-13)

Bearing Kit (includes 6-12)

Caster Kit (includes 13-15)

PARTS IDENTIFICATION

SELF ELEVATING TABLE • ETS-460 SERIES

ENGINEER NO.

21-014-002

01-034-021

21-514-020

32408

21-146-003

a/k

21-113-020

5133-62

21-113-021

6203-2RS

a/k

a/k

a/k

16-132-003

16-132-002

21-154-001

21-154-002

21-154-003

PART NO.

ETS-FCP

ETS-LHG

ETS-TPABA

ETS-SCRW

ETS-EXTSP

a/k

ETS-NYLN

ETS-ECLP

ETS-BOBP

ETS-RLRB

a/k

a/k

a/k

ETS-CSTRR

ETS-CSTRSWB

ETS-KITA

ETS-KITB

ETS-KITC

QTY.

1

1

1

2

14

8

4

8

8

8

4

4

4

2

2

1

1

1

3

Page 4

4

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

3

2

CAPACITY TAG

2

LOCATED UNDER

HANDLE

1

2

! !

WARNING

KEEP CLEAR

WHEN IN USE

* Product safety signs or labels should be

periodically inspected and cleaned by the

product users as necessary to maintain

good legibility for safe viewing distance.

ANSI 535.4 (10.21)

Contact manufacturer for replacement

labels.

1

POUR INSTRUCTIONS OU QUESTIONS SUPPLÉMENTAIRES CONTACTER

T & S EQUIPMENT CO. • P.O. BOX 496 ANGOLA, IN 46703 • 260-665-9521

FOR USER INSTRUCTIONS OR QUESTIONS CONTACT

PARA INSTRUCCIONES DE USO Ó CONSULTAS CONTACTAR

AVISO

MANTENGASE

ALEJADO CUANDO SE

ESTA OPERANDO

3

DO NOT OBSTRUCT PLATFORM

!

NO OBSTRUYA LA PLATAFORMA

AVERTISSEMENT

!

SE TENIR À DISTANCE LORS

DU FONCTIONNEMENT

!

CAUTION

PRECAUCION

!

PRUDENCE

205

220

NE PAS ENCOMBRER LA PLATE-FORME

T & S Equipment Co.

Ph. (260)665-9521 Fax (260)665-1339

304

Page 5

LIMITED WARRANTY

covered unless done at manufacturer’s facilities. Any modifications performed without written approval

E

N

G

L

I

S

H

ONE YEAR LIMITED WARRANTY. The manufacturer warrants for the original purchaser against

defects in materials and workmanship under normal use one year after date of purchase. (Not to exceed

15 months after date of manufacture.) Any part which is determined by the manufacturer to be defective

in material or workmanship and returned to the factory, shipping costs prepaid, will be, as the exclusive

remedy, repaired or replaced at our option. Labor costs for warranty repairs and/or modifications are not

of the manufacturer may void warranty. This limited warranty gives purchaser specific legal rights which

vary from state to state.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, the manufacturer’s

liability for consequential and incidental damages is expressly disclaimed.

The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price paid.

Misuse or modification may void warranty.

WARRANTY DISCLAIMER. Our company has made a diligent effort to illustrate and describe the

products shown accurately; however, such illustrations and descriptions are for the sole purpose of

identification, and do not express or imply a warranty that the products are merchantable, or fit for a

particular purpose, or that the products will necessarily conform to the illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the

UNIFORM COMMERCIAL CODE and laws as enacted in the State of Indiana.

DISPOSITION. Our company will make a good faith effort for prompt correction or other

adjustment with respect to any product which proves to be defective within the Limited Warranty.

Warranty claims must be made in writing within said year.

SERVICE RECORD

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

5

Loading...

Loading...