Vestil EHLTT Series Owner's Manual

VESTIL MANUFACTURING

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-9521 Fax (260) 665-1339

E-mail: info@vestil.com

www.vestil.com.com

Contents

Warning and Safety Instructions ....................... 1

Receiving Instructions ...................................... 1

Loading Instructions ......................................... 2

Installation Instructions ..................................... 2

Operating Instructions ...................................... 2

Electric Schematic......................................... 3-4

Power Conversion............................................ 5

Hydraulic Operation & Schematic ................. 6-7

Revised 11-2013

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

LIFT & TILT SCISSOR TABLE

SERIES EHLTT

Periodic Maintenance Instructions ................... 8

Trouble Shooting Guide ..............................9-10

Exploded Parts Drawing ................................ 11

Parts List ........................................................ 12

Warning Label Identification ........................... 13

Material Safety Data Sheets ...................... 14-15

Warranty ......................................................... 16

Service Record............................................... 16

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Not a personnel lift. Keep clear when operating

• Never go under platform if there is weight on unit.

• Remove weight before working on unit.

• Use only maintenance parts supplied or approved by the

manufacturer.

• Do not change pressure relief valve setting.

• Do not clamp cylinder in vise as you may distort barrel.

• Never operate lift unless you are watching it.

• Load lift as uniformly as possible.

• Consult factory for uneven loading.

• Do not continue to hold down the UP control if unit is not

raising.

• Relieve system pressure by holding DOWN button after

unit has come to rest.

• Consult factory if adding conveyor top or performing any

modification to the original equipment.

• Do not use hydraulic oils, brake fluids or jack oils.

Use AW-32 Hydraulic Oil.

• Make sure all operator safety labels are in place.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit may incur

damage during transit. If you see damage when unloading

make a note of it on the SHIPPER RECEIVER.

Remove all packing and strapping material, inspect for

damage. IF DAMAGE IS EVIDENT, FILE A CLAIM WITH THE

CARRIER IMMEDIATELY! Also, check the unit size, type of

power unit, etc., to ensure the unit is correct for the intended

application.

MODEL NUMBER AND CAPACITY

The model number, serial number and capacities are

inscribed on the nameplate. Please remember to include these

numbers in any correspondence with you dealer or the factory.

LIFT & TILT SCISSOR TABLE

SERIES EHLTT

1

LOADING INSTRUCTIONS

SEQUENCE OF OPERATION

The load capacity rating as inscribed on the

nameplate of your unit designates the net capacity,

assuming the load is centered. This capacity must

never be exceeded, as permanent damage or injury

may result.

INSTALLATION TOOLS REQUIRED

A fork truck or some means to lift the table.

An adequately-sized power circuit with the specified

voltage, including a disconnecting means with fuses

or a circuit breaker. See the electrical section and

refer to the NEC and local codes.

INSTALLATION

• Check local codes for requirements pertaining to

your application.

• Blow out any hoses that arrive unconnected in

order to remove any potential contamination.

• Set the machine in place with a fork truck, crane,

etc. (If it is to be pit-mounted, connect power to the

table and raise the platform before setting it into

the pit.)

This machine is furnished with a constantpressure, or dead-main, style push-button control.

Pressing the "LIFT RAISE" button will turn on the

power unit and cause the table to lift straight up. It

will continue to more as long as you hold the button

or until the lift reaches its maximum raised height.

When the button is released, the platform stops and

holds at that particular height.

Pressing the "LIFT LOWER" button

energizes the lowering solenoid's coil and lowers

the platform at a controlled rate of descent. Upon

releasing the button, the platform stops and holds at

that height.

Pressing the "TILT RAISE" button turns on

the power unit and causes the platform to slide in

toward the center of the table and tilt at the same

time. It will continue to tilt until the either the operator

releases the button or the platform reaches its

maximum tilt angle. When the button is released,

the platform stops and holds its position.

Pressing the "TILT LOWER" button also turns

on the power unit and causes the platform to tilt

down toward the horizontal position until either the

button is released or the platform is lowered to the

horizontal position.

• Connect the proper power supply to the table

using personnel qualified to work with electricity.

• Raise the platform to its full raised height using the

push-button control. Install the maintenance props

(one on each side of the frame) and lower the

platform using the push-button control until it rests

on the maintenance props.

• Anchor the frame to the floor using 1/2" concrete

anchors adequate for the floor on which the table

is resting. Shim or grout under the frame sides so

that the entire length of each frame side is

supported.

• Operate the lift through several cycles, verifying

that the "platform raised," "platform tilted," and

"platform level" limit switches all work properly.

Verify the operating of the perimeter pinch point

(toe) safety guard.

• Clean up any spilled oil or debris.

OPERATOR TIPS

• Read and understand all warning labels on the lift

before operating it.

• Stand clear and to the side of the unit when it is

moving.

• Don't use the lift if you suspect it is in need of

repairs or if it is malfunctioning.

• Notify maintenance personnel in the event that

you notice anything out of the ordinary, such as

binding, odd pump noises, etc.

• Don't continue to press either of the "LIFT" buttons

if the platform doesn't move. Doing so could cause

damage to the pump or motor.

2

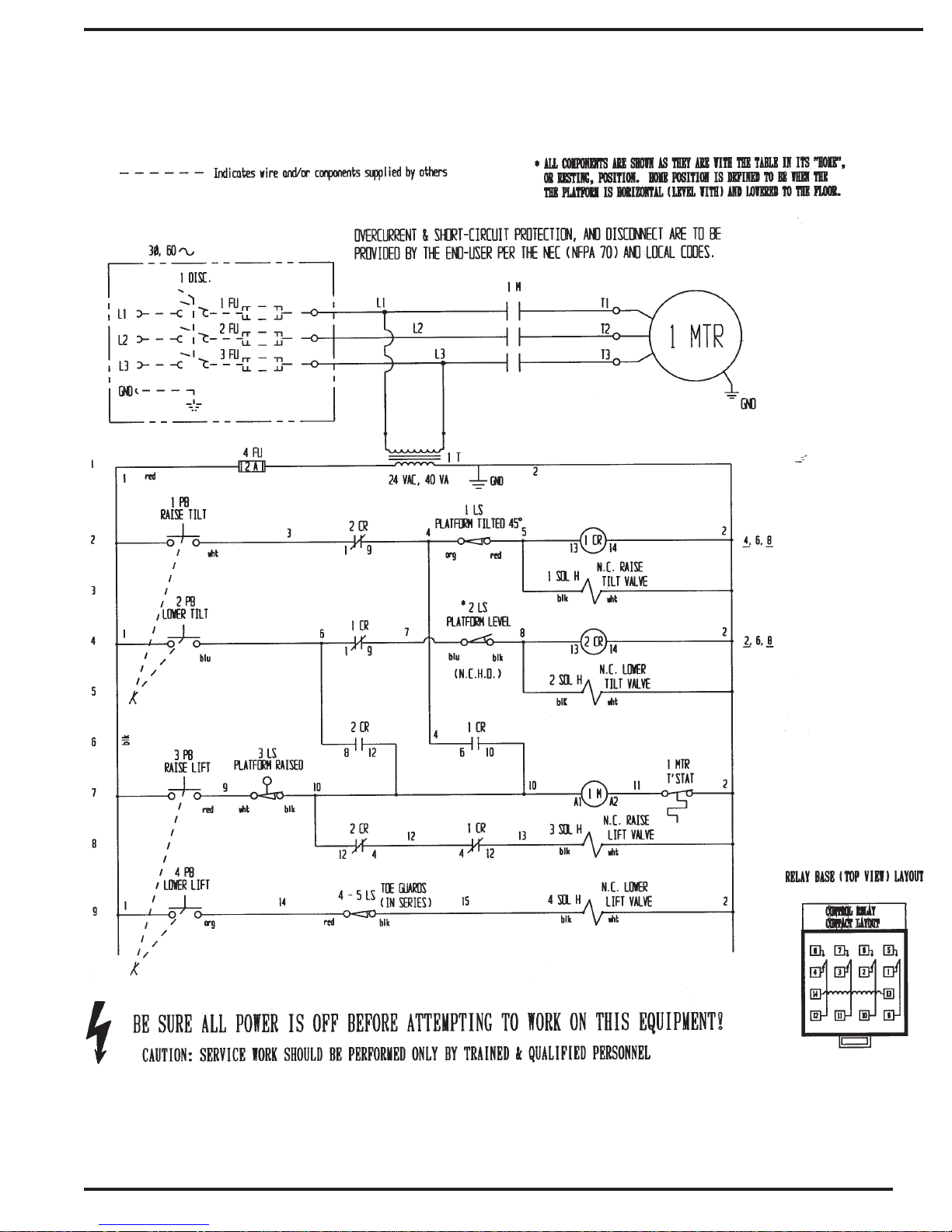

ELECTRICAL SCHEMATIC

3

PRIMARY WIRING FOR CONTROL TRANSFORMER

4

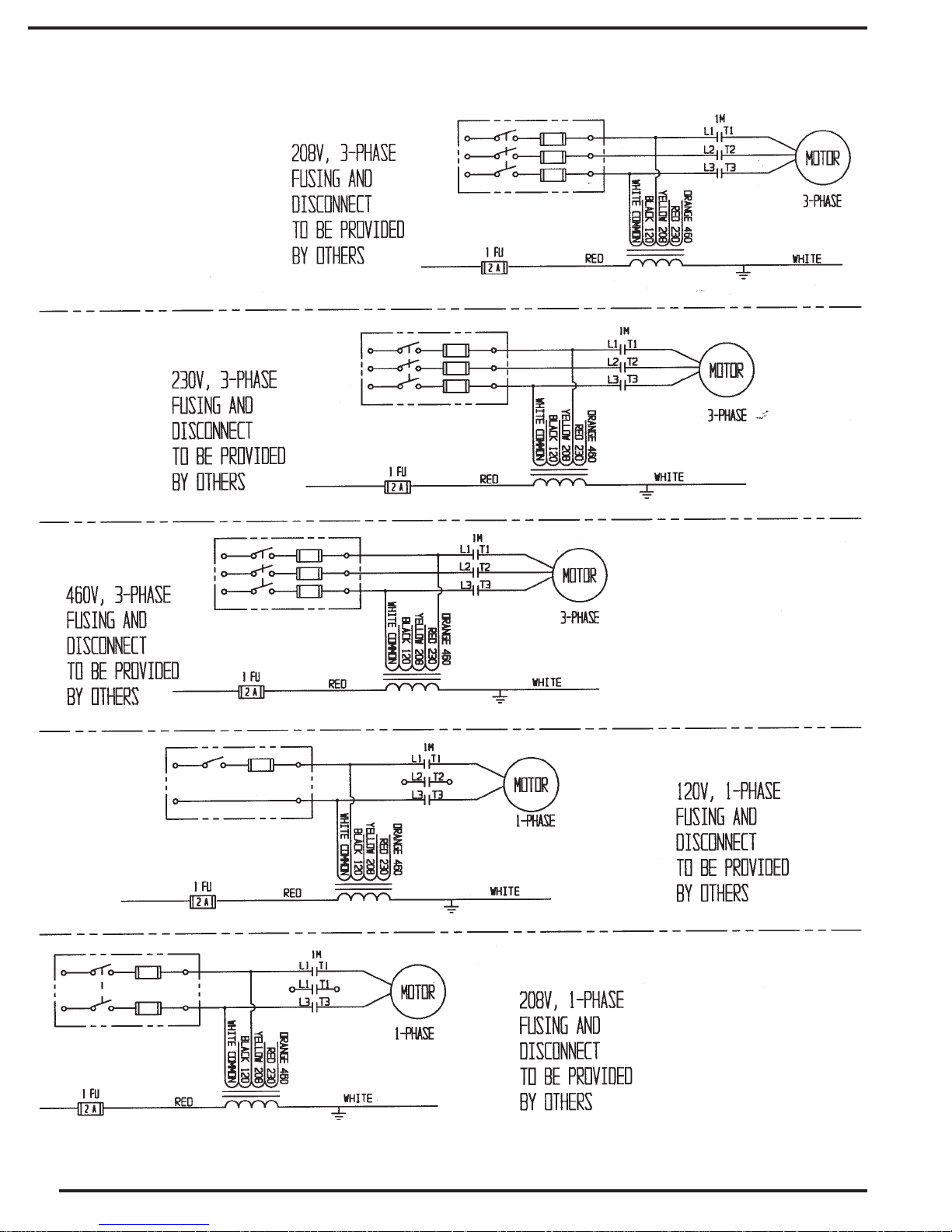

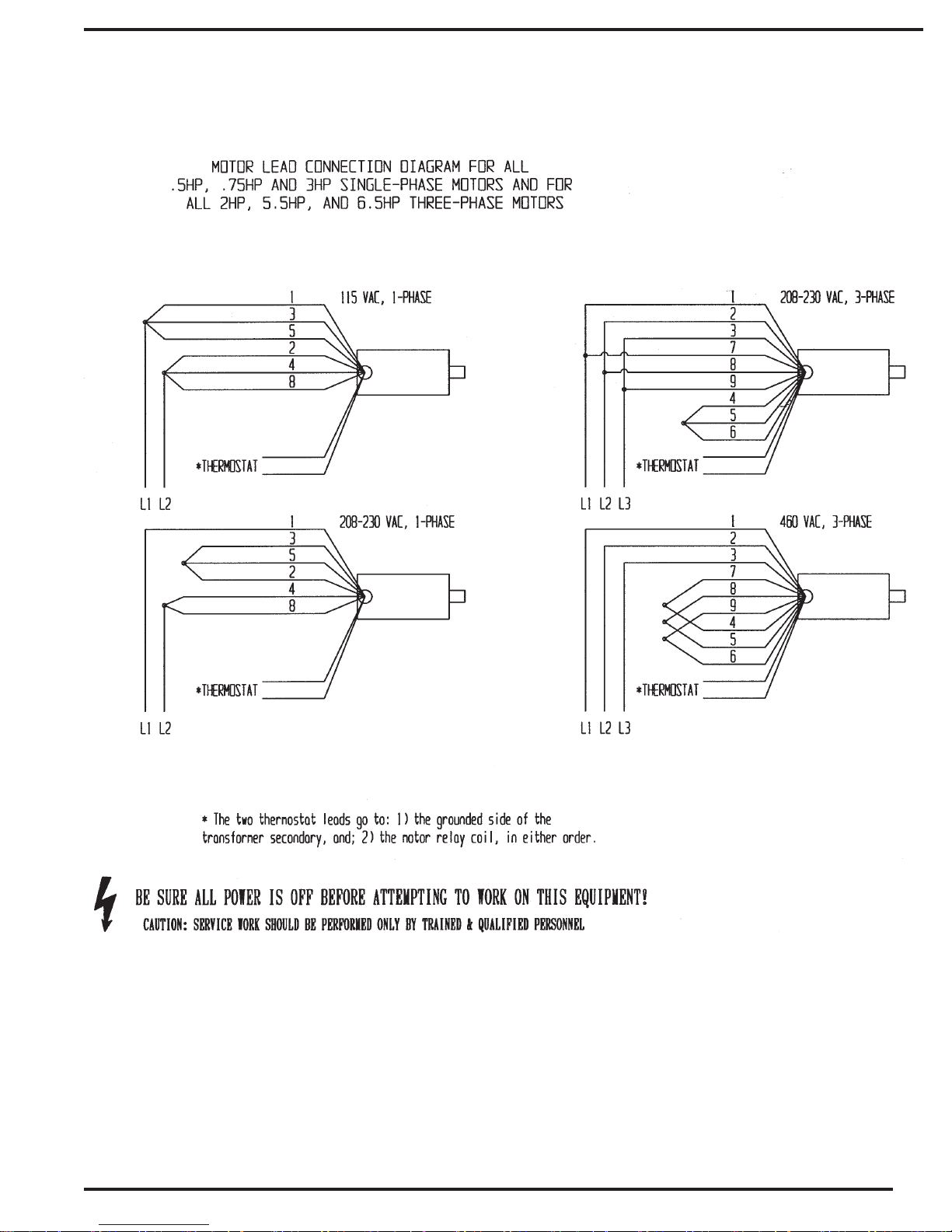

POWER CONVERSION

5

Loading...

Loading...