Page 1

11/4/2013 D & H series hoppers, manual

D & H-SERIES HOPPERS

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail: sales@vestil.com

Instruction Manual

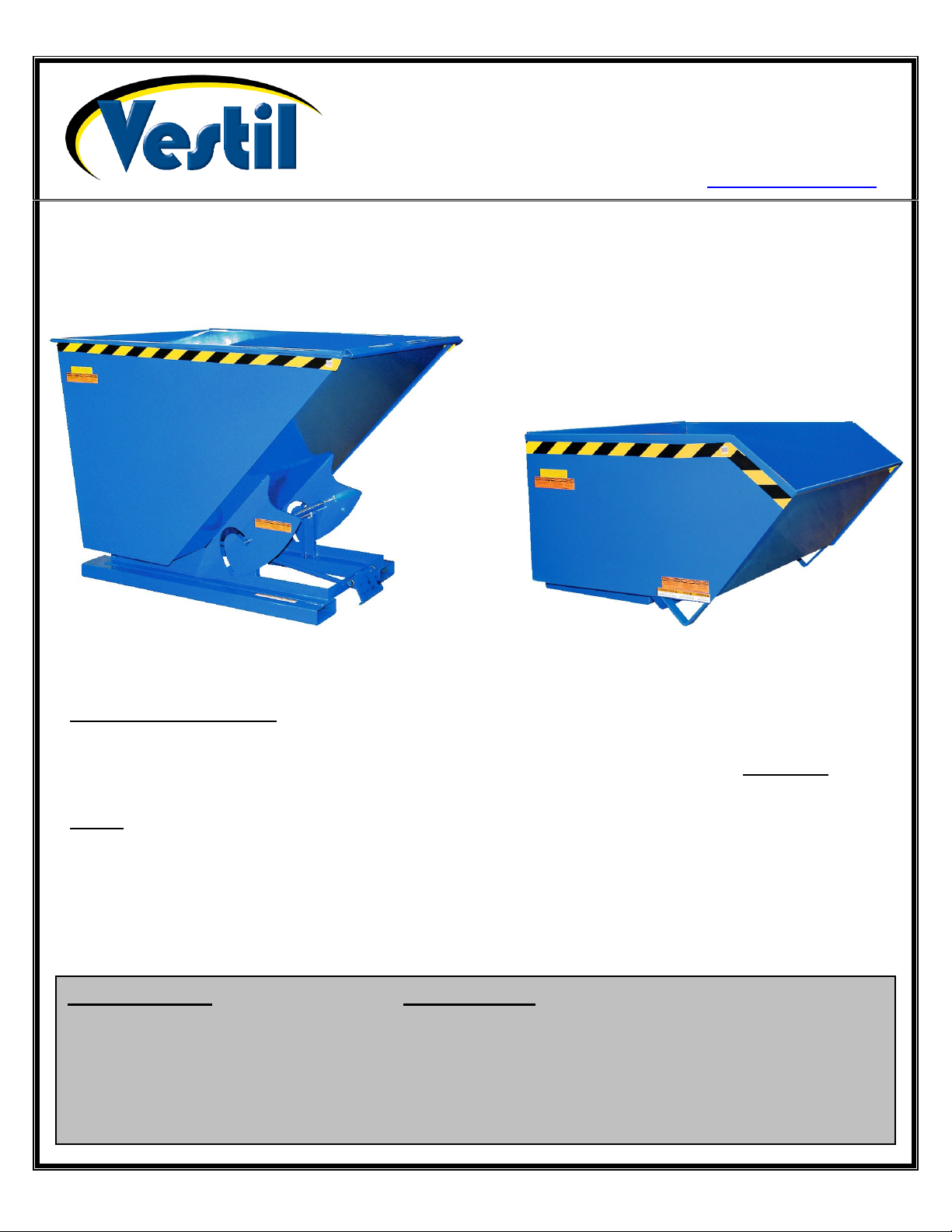

D-SERIES HOPPERS H-SERIES HOPPERS

RECEIVING INSTRUCTIONS:

After delivery, IMMEDIATELY remove the packaging from the Hook-Base in a manner that preserves the

packaging and maintains the orientation of the product in the packaging; then inspect the product closely to determine

whether it sustained damage during transport. If damage is discovered during the inspection, immediately record

a complete description of the damage on the bill of lading. If the product is undamaged, discard the packaging.

NOTES:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where the product

is used is exclusively the responsibility of the owner/end-user.

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply either:

a) Instructions in this manual; or

b) Information provided on labels affixed to the product. Neither is Vestil responsible for any consequential

damages sustained as a result of failing to exercise sound judgment while assembling, installing, using or maintaining

this product.

Table of Contents Table of Figures

Product Introduction…………………… 2 – 4 Fig. 1 H-series hoppers diagram and parts list ………….................. 5

Safety Principles……………………….. 8 Fig. 2 D-series hoppers diagram and parts list.................................. 6

Safety Recommendations…………….. 8 Fig. 3 Leak proof H-hopper & parts diagram…………………………. 7

Loading instructions…………………… 9 Fig. 3 H-series markings & label placement diagram……………….. 11

Use & Operation Instructions…………. 9 Fig. 4 D-series markings & label placement diagram……………….. 12

Inspections & Maintenance…………… 10

Limited Warranty………………………. 13

Copyright 2013 Vestil Manufacturing Corp. Page 1 of 13

Page 2

11/4/2013 D & H series hoppers, manual

V

PRODUCT INTRODUCTION

Thank you for purchasing a fork-mountable, self-dumping hopper (“hopper” or “product”) made by Vestil

Manufacturing Corporation (“Vestil”). Our hoppers are durable, high-quality products that incorporate safetyconscious features. Each hopper conforms to the generalized specifications disclosed in this manual.

Standard design features include: 2 fork pockets that receive the tines (forks) of a fork truck; dump-actuating

cable that allows the hopper to be dumped by the forklift driver; and either a safety chain or safety strap to wrap

around the fork carriage and prevent the hopper from sliding off of the forks during use. Dimensions of offered

models, as well as other product specifications appear in the following table:

Model

H-series hoppers (low profile 90° self-dumping steel)

Light duty (12 gauge steel)

H-25-LD

H-50-LD

H-100-LD

H-150-LD

Medium duty (10 gauge steel)

H-25-MD

H-50-MD

H-100-MD

H-150-MD

Heavy duty (8 gauge steel)

H-25-HD

H-50-HD

H-100-HD

H-150-HD

D-series Hoppers (self-dumping steel hoppers with bumper release)

Light duty 2,000lb (909kg) maximum rated load models; fabricated from 12 gauge steel

Model

D-25-LD

D-33-LD

D-50-LD

D-75-LD

D-100-LD

D-150-LD

D-200-LD

D-250-LD

D-300-LD

olume in Cubic

Yards (m

(~0.19 m

(~0.38 m

(~0.76 m

(~1.15 m

(~0.19 m

(~0.38 m

(~0.76 m

(~1.15 m

(~0.19 m

(~0.38 m

(~0.76 m

(~1.15 m

¼

½

1

1½

¼

½

1

1½

¼

½

1

1½

3

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

Volume in

Cubic Yards

3

(~m

¼

(~0.19 m

1

/3

(~0.25 m

½

(~0.38 m

¾

(~0.57 m

1

(~0.76 m

1½

(~1.15 m

2

(~1.53 m

2½

(~1.91 m

3

(~2.29 m

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

Uniform Maximum

)

Rated Load in

Pounds (kg)

2,000

(~909kg)

2,000

(~909kg)

2,000

(~909kg)

2,000

(~909kg)

4,000

(~1,818kg)

4,000

(~1,818kg)

4,000

(~1,818kg)

4,000

(~1,818kg)

6,000

(~2,727kg)

6,000

(~2,727kg)

6,000

(~2,727kg)

6,000

(~2,727kg)

Hopper Inside Dimensions

in Inches (~cm)

20 x 41¼ x 27

~(50.8 x 104.8

20 x 41¼ x 27

~(50.8 x 104.8

30 x 41¼ x 27

~(76.2 x 104.8

7

/8

x 70.8)cm

7

/8

x 70.8)cm

7

/8

x 70.8)cm

28¼ x 54½ x 32½

~(71.8 x 138.4 x 82.6)cm

38 x 54¼ x 32½

~(96.5 x 138.4 x 82.6)cm

40 x 63¾ x 41½

~(71.8 x 138.4 x 82.6)cm

53 x 63¾ x 41½

~(134.6 x 162 x 105.4)cm

66¼ x 63¾ x 41½

~(168.3 x 162 x 105.4)cm

3

/16 x 63¾ x 41½

78

~(198.6

x 162 x 105.4)cm

Overall Dimensions (W x

D x H) in Inches (cm)

25 x 46 x 18

~(63.5 x 116.8 x 45.7)

25 x 51¼ x 28

~(63.5 x 130.2 x 71.1)cm

49 x 51¼ x 28

~(124.5 x 130.2 x 71.1)cm

49 x 52 x 40

~(124.5 x 132.1 x 101.6)cm

25 x 46 x 18

(63.5 x 116.8 x 45.7)

25 x 51¼ x 28

(63.5 x 130.2 x 71.1)cm

49 x 51¼ x 28

(124.5 x 130.2 x 71.1)cm

49 x 52 x 40

(124.5 x 132.1 x 101.6)cm

25 x 46 x 18

(63.5 x 116.8 x 45.7)

25 x 51¼ x 28

(63.5 x 130.2 x 71.1)cm

49 x 51¼ x 28

(124.5 x 130.2 x 71.1)cm

49 x 52 x 40

(124.5 x 132.1 x 101.6)cm

Overall Dimensions (W x

D x H) in Inches (~cm)

26 x 52 x 38

~(66 x 132.1 x 96.5)cm

26 x 52 x 38

~(66 x 132.1 x 96.5)cm

33¼ x 52 x 38

~(84.5 x 132.1 x 96.5)cm

31½ x 60½ x 43

~(80 x 153.7 x 109.2)cm

41¼ x 61 x 42

5

/

8

~(104.8 x 154.9 x108.3)cm

43¼ x 61 x 52

~(109.9 x 154.9 x 132.1)cm

56¼ x 61 x 523/8

~(142.9 x 154.9 x 133)cm)

69½ x 69 x 52

~(176.5 x 175.3 x 132.1)cm

7

/16 x 61 x 50¾

81

~(206.9 x 154.9 x 128.9)cm

Distance between

Fork Pocket Centers

in Inches (cm)

11-5/8

(~29.5cm)

11-5/8

(~29.5cm)

21-5/8

(~55cm)

21-5/8

(~55cm)

11-5/8

(~29.5cm)

11-5/8

(~29.5cm)

21-5/8

(~55cm)

21-5/8

(~55cm)

11-5/8

(~29.5cm)

11-5/8

(~29.5cm)

21-5/8

(~55cm)

21-5/8

(~55cm)

Distance between

Fork Pocket Centers

in Inches (~cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

Net Weight

in Pounds

(~99.5kg)

(~116.4kg)

(~157.7kg)

(~171.4kg)

(~104.1kg)

(~125.5kg)

(~179.5kg)

(~210.5kg)

(~98.2kg)

(~126.8kg)

(~210kg)

(~245.5kg)

Net Weight

in Pounds

(~163.6kg)

(~170.5kg)

(~186.4kg)

(~218.2kg)

(~238.2kg)

(~286.4kg)

(~329.5kg)

(~345.5kg)

(~443.2kg)

(kg)

219

256

347

377

229

276

395

463

216

279

462

540

(~kg)

360

375

410

480

524

630

725

760

975

Copyright 2013 Vestil Manufacturing Corp. Page 2 of 13

Page 3

11/4/2013 D & H series hoppers, manual

Medium duty 4,000lb (1,818kg) maximum rated load models; fabricated from 10 gauge steel

D-25-MD

D-33-MD

D-50-MD

D-75-MD

D-100-MD

D-150-MD

D-200-MD

D-250-MD

D-300-MD

¼

(~0.19 m

1

/3

(~0.25 m

½

(~0.38 m

¾

(~0.57 m

1

(~0.76 m

1½

(~1.15 m

2

(~1.53 m

2½

(~1.91 m

3

(~2.29 m

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

20 x 41¼ x 27

~(50.8 x 104.8

20 x 41¼ x 27

~(50.8 x 104.8

30 x 41¼ x 27

~(76.2 x 104.8

28¼ x 54½ x 32½

~(71.8 x 138.4 x 82.6)cm

38 x 54¼ x 32½

~(96.5 x 138.4 x 82.6)cm

40 x 63¾ x 41½

~(71.8 x 138.4 x 82.6)cm

53 x 63¾ x 41½

~(134.6 x 162 x 105.4)cm

66¼ x 63¾ x 41½

~(168.3 x 162 x 105.4)cm

3

78

/16 x 63¾ x 41½

~(198.6

x 162 x 105.4)cm

Heavy duty 6,000lb (2,727kg) maximum rated load models; fabricated from 8 gauge steel

D-25-HD

D-33-HD

D-50-HD

D-75-HD

D-100-HD

D-150-HD

D-200-HD

D-250-HD

D-300-HD

D-350-HD

¼

(~0.19 m

1

/3

(~0.25 m

½

(~0.38 m

¾

(~0.57 m

1

(~0.76 m

1½

(~1.15 m

2

(~1.53 m

2½

(~1.91 m

3

(~2.29 m

3½

(~2.68 m

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

3

)

20 x 41¼ x 27

~(50.8 x 104.8

20 x 41¼ x 27

~(50.8 x 104.8

30 x 41¼ x 27

~(76.2 x 104.8

28¼ x 54½ x 32½

~(71.8 x 138.4 x 82.6)cm

38 x 54¼ x 32½

~(96.5 x 138.4 x 82.6)cm

40 x 63¾ x 41½

~(71.8 x 138.4 x 82.6)cm

53 x 63¾ x 41½

~(134.6 x 162 x 105.4)cm

66¼ x 63¾ x 41½

~(168.3 x 162 x 105.4)cm

3

78

/16 x 63¾ x 41½

~(198.6

x 162 x 105.4)cm

88¼ x 63¾ x 41½

~(224.2 x 162 x 105.4)cm

7

/8

x 70.8)cm

7

/8

x 70.8)cm

7

/8

x 70.8)cm

7

/8

x 70.8)cm

7

/8

x 70.8)cm

7

/8

x 70.8)cm

26 x 52 x 38

~(66 x 132.1 x 96.5)cm

26 x 52 x 38

~(66 x 132.1 x 96.5)cm

33¼ x 52 x 38

~(84.5 x 132.1 x 96.5)cm

31½ x 60½ x 43

~(80 x 153.7 x 109.2)cm

41¼ x 61 x 42

5

/

8

~(104.8 x 154.9 x108.3)cm

43¼ x 61 x 52

~(109.9 x 154.9 x 132.1)cm

56¼ x 61 x 523/8

~(142.9 x 154.9 x 133)cm)

69½ x 69 x 52

~(176.5 x 175.3 x 132.1)cm

7

81

/16 x 61 x 50¾

~(206.9 x 154.9 x 128.9)cm

26 x 52 x 38

~(66 x 132.1 x 96.5)cm

26 x 52 x 38

~(66 x 132.1 x 96.5)cm

33¼ x 52 x 38

~(84.5 x 132.1 x 96.5)cm

31½ x 60½ x 43

~(80 x 153.7 x 109.2)cm

41¼ x 61 x 42

5

/

8

~(104.8 x 154.9 x108.3)cm

43¼ x 61 x 52

~(109.9 x 154.9 x 132.1)cm

56¼ x 61 x 523/8

~(142.9 x 154.9 x 133)cm)

69½ x 69 x 52

~(176.5 x 175.3 x 132.1)cm

7

81

/16 x 61 x 50¾

~(206.9 x 154.9 x 128.9)cm

92 x 69 x 52

~(233.7 x 175.3 x 132.1)cm

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

18

(~45.7cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

28

(~71.1cm)

(~177.3kg)

(~190.9kg)

(~238.6kg)

(~284.1kg)

(~304.5kg)

(~331.8kg)

(~361.4kg)

(~450.5kg)

(~186.4kg)

(~190.9kg)

(~206.8kg)

(~254.5kg)

(~281.8kg)

(~338.6kg)

(~353.6kg)

(~404.5kg)

(~450.5kg)

(~504.5kg)

Options

Model Description Net Weight

H-DAMP-4

H-DAMP-6

LEKP

D-DPLG-1

D-DPLG-2

H-DPLG-1

H-DPLG-2

LUG

Hopper dumping speed regulator for 4,000lb (medium duty) models 30 lb. (13.6kg)

Hopper dumping speed regulator for 6,000lb (heavy duty) models 40 lb. (18.2kg)

“Leak proof” welded hopper 5 lb. (2.3kg)

1in. drain plug option 2 lb. (0.9kg)

2in. drain plug option 2 lb. (0.9kg)

1in. drain plug option 2 lb. (0.9kg)

2in. drain plug option 2 lb. (0.9kg)

4 welded lifting lugs (around perimeter of hopper mouth) 150 lb. (68.2kg)

385

(~175kg)

390

420

525

625

670

730

795

991

410

420

455

560

620

745

778

890

991

1,110

Copyright 2013 Vestil Manufacturing Corp. Page 3 of 13

Page 4

11/4/2013 D & H series hoppers, manual

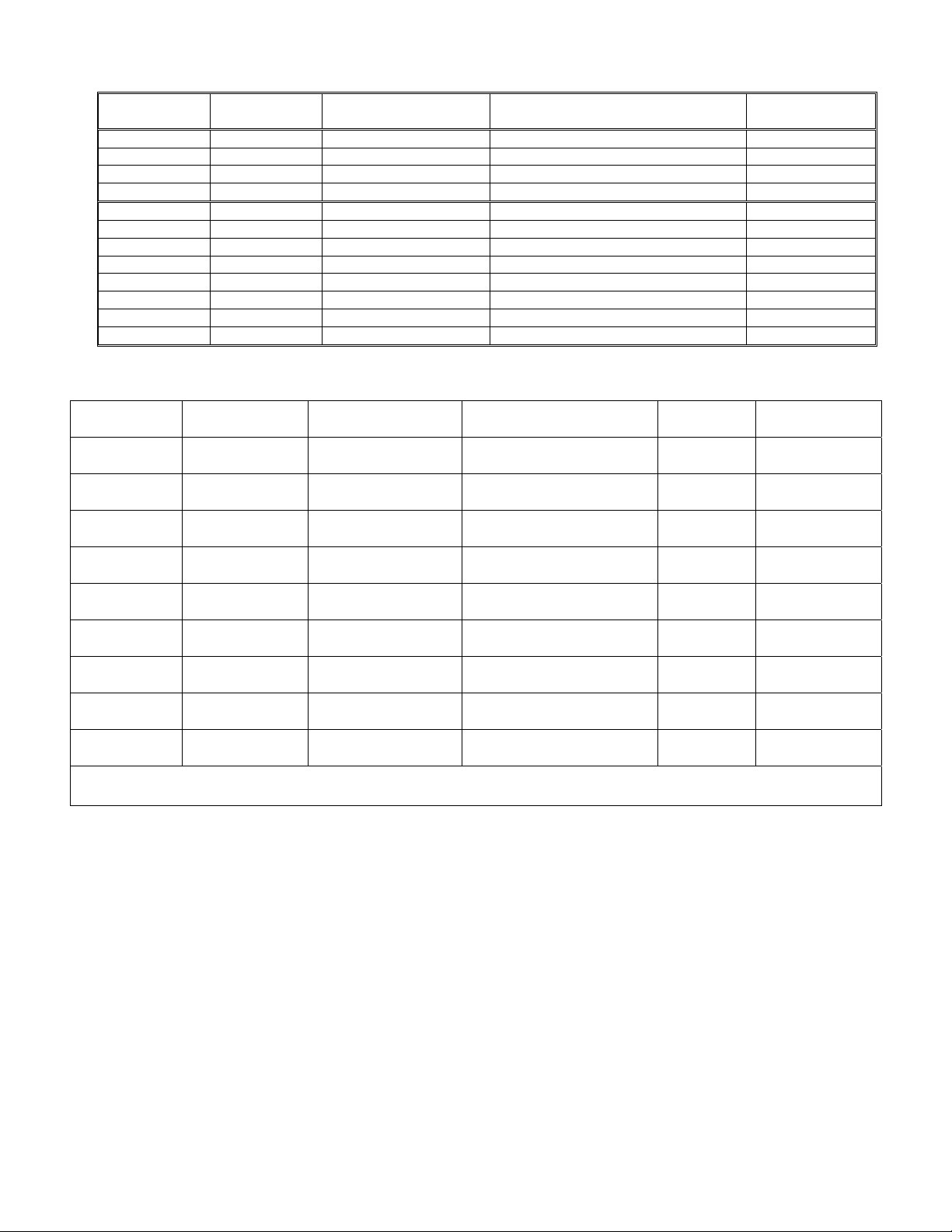

Heavy-duty polyethylene lids

Model

PLID-H-25 1 37-024-038-004 H-25-LD, H-25-MD, H-25-HD 7 (3.2kg)

PLID-H-50 1 37-024-038-003 H-50-LD, H-50-MD, H-50-HD 8 (3.6kg)

PLID-H-100 2 37-024-038-002 H-100-LD, H-100-MD, H-100-HD 14 (6.4kg)

PLID-H-150 2 37-024-038-001 H-150-LD, H-150-MD, H-150-HD 16 (7.3kg)

PLID-D-33 1 37-024-087-002 D-33-LD, D-33-MD, D-33-HD 7 (3.2kg)

PLID-D-50 1 37-024-087-001 D-50-LD, D-50-MD, D-50-HD 8 (3.6kg)

PLID-D-75 1 37-024-086-002 D-75-LD, D-75-MD, D-75-HD 9 (4.1kg)

PLID-D-100 1 37-024-086-001 D-100-LD, D-100-MD, D-100-HD 10 (4.5kg)

PLID-D-150 1 37-024-085-004 D-150-LD, D-150-MD, D-150-HD 14 (6.4kg)

PLID-D-200 2 37-024-085-003 D-200-LD, D-200-MD, D-200-HD 16 (7.3kg)

PLID-D-250 2 37-024-085-002 D-250-LD, D-250-MD, D-250-HD 18 (8.2kg)

PLID-D-300 2 37-024-085-001 D-300-LD, D-300-MD, D-300-HD 20 (9.1kg)

Number of

Pieces

Part Number Fits Hopper Models

Net Weight in

Pounds (kg)

Caster kits

Model

HOP-SC6-2

HOP-SC8-2

HOP-RC6-2

HOP-RC8-2

HOP-PC6-2

HOP-PC8-2

HOP-PHC6-2

HOP-PHC8-2

HOP-SC6-2.5

NOTE: “Uniform capacity” is the maximum weight that each caster set can support, and equals the combined weight of the

hopper and it contents. ONLY select a caster kit that equals or exceeds the maximum rated load of your hopper!

Dimensions in

Inches (cm)

6 x 2

(15¼ x 5.1)cm

8 x 2

(20.3 x 5.1)cm

6 x 2

(15¼ x 5.1)cm

8 x 2

(20.3 x 5.1)cm

6 x 2

(15¼ x 5.1)cm

8 x 2

(20.3 x 5.1)cm

6 x 2

(15¼ x 5.1)cm

8 x 2

(20.3 x 5.1)cm

6 x 2½

(15¼ x 6.4)cm

Uniform Capacity

in Pounds (kg)

4,800

(2,182kg)

4,800

(2,182kg)

2,400

(1,091kg)

2,400

(1,091kg)

4,800

(2,182kg)

4,800

(2,182kg)

4,800

(2,182kg)

4,800

(2,182kg)

6,000

(2,727kg)

Caster Material

Quantity

per Order

Semi-steel 4

Semi-steel 4

Mold-on rubber 4

Mold-on rubber 4

Polyurethane on steel 4

Polyurethane on steel 4

Glass-filled nylon 4

Glass-filled nylon 4

Steel 4

Net Weight in

Pounds (kg)

33

(15kg)

42

(19.1kg)

28

(12.7kg)

37

(16.8kg)

33

(15kg)

42

(19.1kg)

37

(16.8kg)

54

(24.5kg)

65

(29.5kg)

Copyright 2013 Vestil Manufacturing Corp. Page 4 of 13

Page 5

11/4/2013 D & H series hoppers, manual

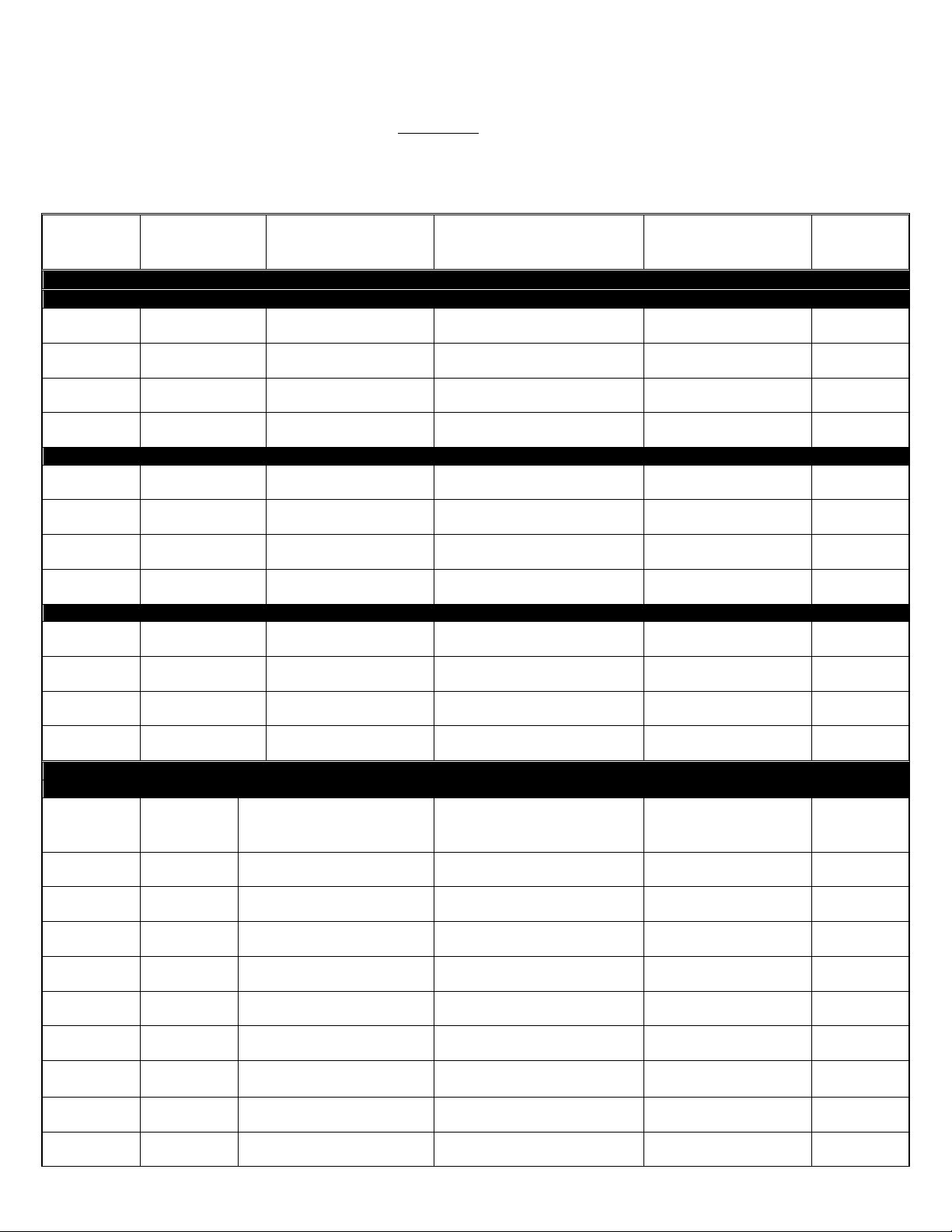

Fig. 1: H-series hoppers diagram and parts list

Release latch bar

Pivot pin channel

Release latch

lever

Item

Part no. Description Quantity

no.

1 37-514-005 Base frame weldment 1

2 37-545-008 Hopper chute weldment 1

3 37-537-010 Chute release lever weldment 1

4 37-146-005 Release torsion spring 1

5 37-145-002 5/16in. x 57½in. safety chain 1

6 45214

7 29-048-061 Rubber pumper 1

8 11061

9 37-112-045 Pivot pin 2

10 65127

11 33006

12 37021

5

/16in. quick link 2

5

/16in. – 18 x 2in. HHCS zinc-plated bolt 2

3

/16in. x 2in. zinc-plated cotter pin 3

5

/16in. USS zinc-plated flat washer 2

5

/16in. – 18 nylock nut 2

3

4

6

5

Copyright 2013 Vestil Manufacturing Corp. Page 5 of 13

3

2

10

7 8 11 12

1

Page 6

11/4/2013 D & H series hoppers, manual

5

3

3

5

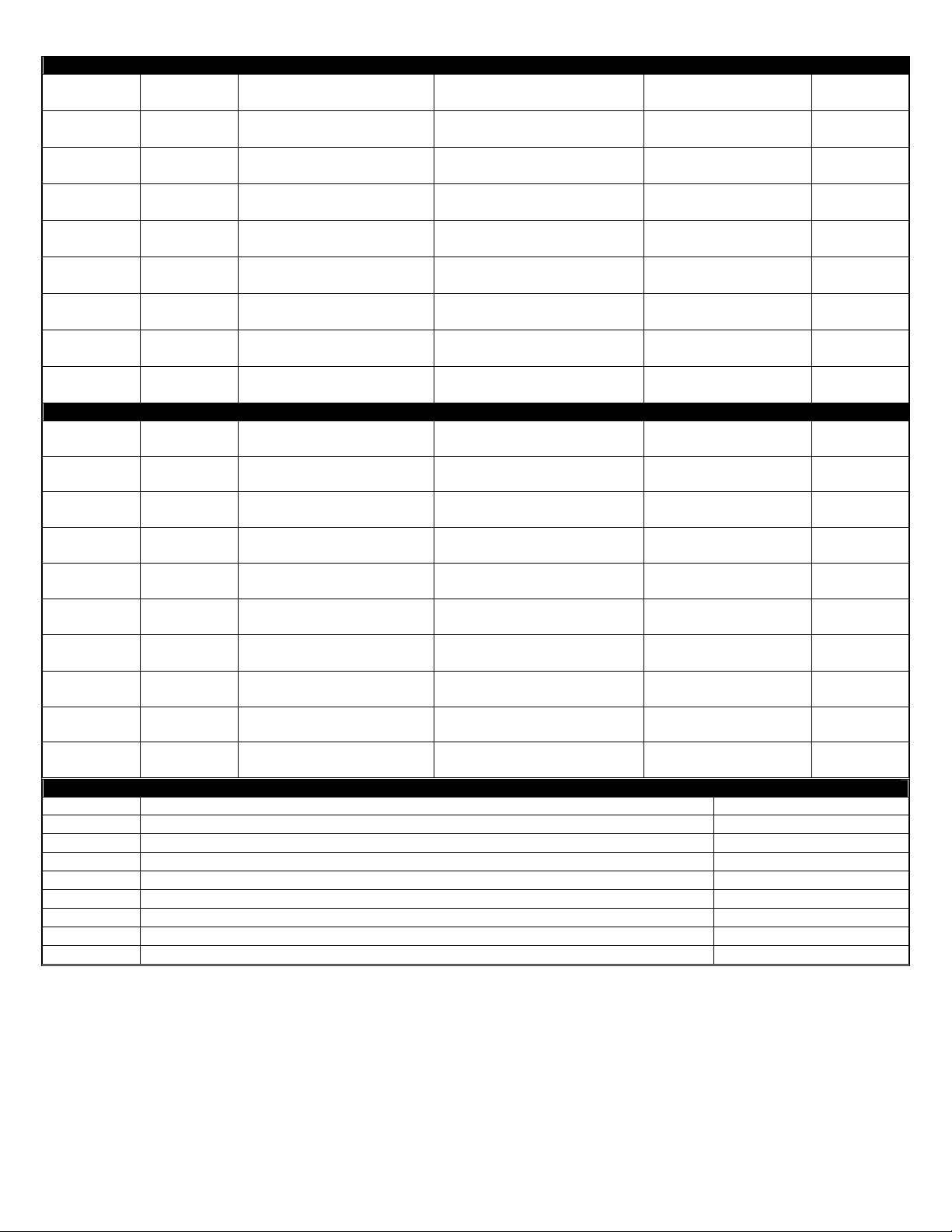

Fig. 2: D-series hoppers diagram and parts list

Item

No.

Part No. Description Quantity

1 37-514-004 Base frame weldment 1

2 37-545-046 Chute weldment 1

3 37-112-007 Pivot pin 1

4 37-537-006 Release lever rod weldment 1

5 37-112-006 Bumper plate pin 1

6 37-146-005 Chute release torsion spring 2

7 45214

8 65125

/16in. quick link 1

/

in. x 1½ in. zinc-plated cotter pin 1

16

9 01-112-009 Hinge pin 2

10 68015 ¾ in. external retaining ring 3

11 64141

/

in. x 2 in. spring pin 1

16

12 37-537-010 Chute release assembly 1

13 37-037-040 Chute release bumper plate 1

14 37-145-004

/16in. x 48in. safety chain 1

12

5

1

7 8 9

3

5

10

13

2

13

1 3

Copyright 2013 Vestil Manufacturing Corp. Page 6 of 13

Page 7

11/4/2013 D & H series hoppers, manual

FIG. 3: Leak Proof H-Hopper (Option LEKP) Diagram and Parts List

3

2

8

1 6 7 4 5

Item no. Part no. Description Quantity

1 S929134-F1 Leak proof base frame weldment 1

2 S929134-C1A Leak proof chute weldment 1

3 37-537-012 Release lock lever assembly 1

4 S929134-CYL1-B 1 in. x 14 in. hydraulic cylinder body 1

5 S929134-CYL1-R 1 in. x 14 in. hydraulic cylinder rod 1

6 S929134-P4B Cylinder pin (body end) 1

7 S929134-P4A Cylinder pin (rod end) 1

chute and cause it to no longer be watertight. Similarly, do not allow water to accumulate in the chute, which will

allow rust to develop. Rinse the hopper chute after emptying contents, and dry the chute before filling it again.

8 37-112-003 Hinge axle pin hoppers (H style) 1

DO NOT put or store corrosive substances in the chute of a hopper. Corrosion will damage the

To dump a leak-proof H-hopper, simply pull the release lever. Once released, the cylinder will extend until the

chute dumps. Manually return the chute to the latched position.

Copyright 2013 Vestil Manufacturing Corp. Page 7 of 13

Page 8

11/4/2013 D & H series hoppers, manual

SAFETY PRINCIPLES

Vestil Manufacturing Corp. created this manual to acquaint owners and users of our fork-mounted hoppers with safe use and

maintenance procedures. Although Vestil diligently strives to identify foreseeable, hazardous situations, this manual cannot

address every conceivable danger. The end-user is ultimately responsible for exercising sound judgment at all times.

The mechanisms of each hopper are relatively intuitive to operate. Nonetheless, all persons who might use or operate this

product should familiarize themselves with the instructions provided in this manual. Each person who might use or maintain the

product must read this entire manual and fully understand the directions BEFORE using or performing maintenance on the

hopper.

Failure to apply the directions in this manual might lead to serious personal injury or even death. Vestil is not liable

for any injury or property damage that occurs as a consequence of failing to apply either: 1) the instructions that appear in this

manual; or 2) the information disclosed on labels affixed to the product. Furthermore, failure to exercise good judgment and

common sense could result in property damage, serious personal injury or death, and also are not the responsibility of Vestil.

To draw attention to hazards that users might encounter, this manual classifies personal injury risks and situations that could

lead to property damage with SIGNAL WORDS. These signal words announce an associated safety message. The reader must

understand that the signal word chosen indicates the seriousness of the described hazard.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

Identifies practices likely to result in product/property damage, such as operation that might damage

Safety Recommendations:

Study the entire manual before using the product for the first time. Read the manual when necessary to refresh your

understanding of the safe operation, inspection and maintenance procedures explained on p.9. If questions remain after you

finish reading this manual, ask your supervisor or employer for assistance. DO NOT attempt to resolve any problems with the

boom unless you are authorized to do so and are certain that it will be safe to use afterwards.

INJURY. Use of this signal word is limited to the most extreme situations.

INJURY.

injury.

the hopper.

Electrocution might result if the hopper contacts electrified wires. Reduce the likelihood that an operator or

bystander might be electrocuted by applying common sense:

DO NOT contact electrified wires with the hopper or any part of the forklift truck.

DO NOT use the hopper in an area where it will contact electrified wires.

Before using the hopper, always inspect the usage area for unusual conditions that require special precautions.

Material handling is dangerous. Improper or careless operation might result in serious personal injuries

sustained by the hopper/forklift operator(s) and bystanders. Reduce the likelihood of injury boom operators by applying the

following:

Failure to read and understand the instructions included in this manual before using or servicing the hopper constitutes

misuse.

DO NOT use a malfunctioning or structurally damaged hopper. Examples structural damage include: 1) damage to the

hopper release mechanism (that allows the hopper to dump); 2) broken fork pocket(s); 3) main connection pin; or 4)

broken welds. Inspect the hopper before each use according to the inspection instructions on p. 9. DO NOT use the

hopper unless it passes every part of the inspection.

DO NOT use the hopper if the safety chain is damaged or absent; DO NOT lift the hopper until it is securely connected

to the carriage of the fork truck with the safety chain.

DO NOT fill the hopper with a load weighing more than the maximum rated load (see Table, p. 2-3).

DO NOT stand beneath or travel under the hopper at any time. DO NOT permit any person to stand beneath or travel

under the hopper.

DO NOT allow people to ride on or in the hopper.

DO NOT use the hopper if any product label (see p. 10 or 11) is unreadable, damaged, or missing. Contact Vestil to

order replacement labels.

ALWAYS apply proper (fork) lift truck operation practices learned during your training program. Before raising the

hopper from the floor AND tilt the (forklift) mast toward the cab of the truck to ensure that the hopper will not slide

towards the tips of the forks.

DO NOT modify the hopper in any way! Modification(s) might make the hopper unsafe to use.

DO NOT dump the hopper UNLESS every person in the vicinity is safely behind the forklift truck.

DO NOT dump the hopper if the forklift is facing down a slope. Only dump the hopper while parked on a level surface.

Copyright 2013 Vestil Manufacturing Corp. Page 8 of 13

Page 9

11/4/2013 D & H series hoppers, manual

Loading instructions:

Verify that the hopper chute is latched to the base frame, i.e. NOT released and cannot rotate, before filling the chute

with refuse. Warning: Do not exceed the dumper’s (and if portable, its casters’) load ratings or fill the hopper above the top

of the hopper’s sides. Injury to personnel or permanent damage to the equipment could result from overloading.

Standard D-series and H-series self-dumping hoppers are suitable for use indoors and outdoors and in most industrial

and commercial settings. They are intended for use in conjunction with a rider forklift truck as a means to dump nonhazardous refuse into larger trash receptacles.

D-series hoppers: the chute rotates through a 70° dump angle. To dump the hopper, the forklift operator can either

1. Press the bumper release plate (Item no. 13 on p. 6) on the front of the hopper by driving the forklift forward until

the side of the dumpster presses against the bumper plate and releases the chute; or

2. Manually release the chute from the forklift cab by pulling the release cable.

H-series hoppers: the low-profile hopper rotates through a 90° dump angle. To dump the hopper, the forklift operator

must simply pull the release cable.

Use and Operation instructions:

Step 1: Drive the forklift forward to insert the forks into the fork pockets. Continue driving forward until the forks are

completely inserted.

D-series: drive as far forward as possible;

H-series: drive forward until the forks contact the caps at the ends of the fork pockets.

Step 2: Securely attach the hopper to the fork carriage with the safety chain (item no. 5 on p. 5; item no. 14 on p. 6). Wrap

the chain around part of the fork carriage; then connect the quick link at the end of the chain to a link in the chain with as

little slack as possible.

DO NOT wrap the release cable around any part of your body, especially your hand(s), or attach the

handle at the end of the cable to your clothing. If you do and the chute is released, you might be seriously injured.

Step 3: Store the handle of the release cable within reach of the forklift operator, for instance, by hooking it to the frame of

the cab. Make sure that there is plenty of slack in the cable to avoid accidentally releasing/dumping the chute.

Step 4: Drive the forklift to the trash receptacle; then tilt the mast of the forklift forward and raise the forks. Elevate the

hopper to a height as shown in the diagrams below:

H-series D-series

Back end of chute

Top of side wall of

dumpster/receptacle

Interior cavity

of dumpster

Step 5: Dump the contents of the hopper by releasing the chute. To release the chute, pull the release cable. For D-series

hoppers, an alternative method of releasing the chute is to drive the forklift toward the dumpster and contact the chute

release bumper plate (item no. 13 on p. 6) with the top of the side wall of the dumpster.

Step 6: Return the chute to the latched position. Tilt the forklift mast toward the cab; then back away from the dumpster.

D-series hoppers automatically return to the latched position. For H-series hoppers, lower the forks until the hopper

contacts the ground; then slowly lower the forks the rest of the way to the ground until the chute latches to the base frame.

Confirm that the chute is properly latched by raising the forks. The chute should not rotate. If necessary, lower the forks

completely and manually latch the chute to the frame by pressing down on the back of the chute (see “H-series” diagram

in Step 4).

Back end of chute

Top of

dumpster

side wall

Chute release bumper plate

Interior cavity

of dumpster

Copyright 2013 Vestil Manufacturing Corp. Page 9 of 13

Page 10

11/4/2013 D & H series hoppers, manual

Inspections & Maintenance:

Inspection and maintenance personnel should immobilize the boom before either conducting inspections or

performing maintenance. The boom is properly immobilized if it cannot tip over.

If one or more problem is discovered during an inspection, restore the hopper to normal operating condition

BEFORE using it again. DO NOT use a structurally damaged hopper. Structural damage includes, but is not limited to,

cracked welds, warping or deformation of one or both of the fork pockets, chute, pivot points, or frame members.

Inspections:

(A) Before each use inspect the following components:

1.) Release cable – fraying, birdcaging, thinning;

2.) Hopper chute or base frame – damage, deformation, corroded or excessively rusted regions;

3.) Pivot points – unusual noise or binding (when chute rotates), distortion of pivot pin or pivot pin

channels (see Figures 1 and 2 on p. 5 & 6);

4.) Release/Latch mechanisms – torsion spring should cause the chute release lever weldment (item

number 3 on p. 5; item no. 3 on p. 6) to automatically recoil; the release latch should firmly engage

the release lock bar proper function;

5.) Hopper retaining mechanisms – look for evidence of fatigue or damage to the safety chain, the point

of attachment to the base frame, or the quick links.

(B) Inspect the following components at least once per month and replace any component that is excessively worn or

no longer operates normally:

1.) Pivot points – look for excessive wear, warping, or other significant damage to pivot pins, cotter pins

that retain pivot pins in place, or pin channels (see Figures 1 and 2 on p. 5 & 6).

2.) Fasteners (bolts, nuts, pins, cotter pins, retaining rings) – inspect for looseness and wear.

3.) Casters – check for looseness, excessive wear, or damage to the casters, caster bearings, mounting

brackets, or hardware.

4.) Release mechanism – verify that the mechanisms function properly. The torsion spring should cause

the chute release lever weldment (item number 3 on p. 5 & 6) to automatically recoil; the release latch

should firmly engage the release lock bar proper function;

5.) All moving parts – listen for unusual noises and watch for irregular movement. Remove dirt and

debris from areas that could affect the hopper’s dumping motion;

6.) Labels – all labels must be firmly affixed in the locations shown in Fig. 3 or 4 on p. 10 or 11.

Maintenance:

The end-user, i.e. operators and employers, should implement a maintenance program to ensure that the product

functions properly and is adequately maintained. The following steps should be applied to complement established

maintenance programs.

The end-user is responsible for selecting and training employees to work on the hopper. ONLY

trained, authorized maintenance personnel or contractors should inspect, maintain, or repair the hopper.

Step 1: Tag the hopper, “Out of Service.”

Step 2: Remove any dirt or other matter from all surfaces.

Step 3: Conduct a “Before each use” inspection. If deformity, corrosion, rusting, or excessive wear of structural

members is found, DO NOT use the product.

Step 4: Perform all other necessary adjustments, replacements and/or repairs, but DO NOT modify the hopper.

The reader should understand the significant difference between necessary adjustments and

repairs, and modifications.

An “adjustment” is a simple correction that restores the hopper to normal operating condition, such as

tightening loose fasteners, or removing dirt or other debris from the surface. “Repair” means removing worn parts

and installing new replacement parts.

DO NOT use the hopper if adjustments and/or repairs are incomplete! Return it to service ONLY after

finishing all necessary repairs and adjustments.

A “modification” is a change that alters the hopper from normal operating condition, like bending the structural

members or removing a part or several parts. NEVER modify the hopper unless you are certain that the hopper

will be safe to use afterwards, or without first obtaining express, written approval from Vestil. Modifications might

make the hopper unsafe to use.

Step 5: Make a dated record of any repairs, adjustments and/or replacements.

Copyright 2013 Vestil Manufacturing Corp. Page 10 of 13

Page 11

11/4/2013 D & H series hoppers, manual

Fig. 3: H-series markings & label placement diagram

Copyright 2013 Vestil Manufacturing Corp. Page 11 of 13

Page 12

11/4/2013 D & H series hoppers, manual

Fig. 4: D-series markings & label placement diagram

Copyright 2013 Vestil Manufacturing Corp. Page 12 of 13

Page 13

11/4/2013 D & H series hoppers, manual

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the part

is covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses,

wheels, seals, brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original dynamic components is 1 year. For wearing parts, the warranty period is 90 days.

Both warranty periods begin on the date when Vestil ships the product to the warrantee. If the product was purchased

from an authorized distributor, the periods began when the distributor shipped the product. Vestil may extend the

warranty period for products shipped from authorized distributors by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modification(s) might make the product unsafe to use or might

cause excessive and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2013 Vestil Manufacturing Corp. Page 13 of 13

Loading...

Loading...