Page 1

INSTRUCTION MANUAL

FOR ECONOMY PORTABLE DRUM

LIFTER/ROTATOR/TRANSPROTER

MODELS COVERED: DRUM-LRT-EC, DRUM-LRT-ESJ

DRUM-LRT-EC

DRUM-LRT-ESJ

NOTE: Owner and operator must read and understand this

instruction manual before operation.

Page 2

THANK YOU FOR USING THIS DRUM STACKER. FOR YOUR SAFETY AND C ORRECT OPERATION,

PLEASE CAREFULLY READ THIS INSTRUCTION BEFORE USING IT. ONLY THOSE WHO HAVE

BEEN TRAINED AND AUTHORIZED CAN OPERATE THIS DRUM STACKER.

NOTE: All of the information reported herein is based on data available at the moment of printing. The

factory reserves the right to modify its own products at any moment without notice and incurring in any

sanction. So it is suggested to always verify possible updates.

1 Safety Rules

Warning: Infringe the safety rules and operation instructions in this manual may cause serious injuries or

even death.

1.1 It is forbidden to operate this machine unless:

1) You have learned and obeyed all the safety rules in this manual.

Avoid causing personal accident.

Always make a check before operation.

Make functional test before use.

Check the working place.

Only use it to convey, lift, revolve and tilt the drum.

2) You read, understand and obey

Guides and safety rules of the manufacturer

Safety rules of workers and regulations of working place

Proper government ordinances

1.2 You should obey the following rules to avoid causing person al acci de nt:

It is forbidden to use it as a platform or ladder to lift persons.

Only use it to convey, lift, revolve and tilt the drum.

Only use it on a firm and level ground.

Check for drop-offs, pits, barriers, debris, unstable ground and other dangerous conditions at the

working place before the operation.

It is forbidden to bear the machine or the drum of horizontal force during the operation process.

Collision injury

Check whether there are some barriers or other possible dangers at the top of working place.

It is forbidden for the operator or o ther persons t o s t an d under the machi ne when li f ting or tilti ng

the drum.

It is forbidden to lower the load unless there is no person or barrier under the load.

Personal accident

Always keep your hands, feet and other body parts away from the clamping points, sliding guide or

other pressure points.

Injury caused by misuse

It is forbidden to lift or transport the load unless all clamps have fixed the drum firmly.

Lift or lower the load at a uniform speed and slowly. Sudden start or stop is forbidden.

Faulty methods of operating the machine may cause accidents

Injury caused by machine fault

Never operate a faulty or damaged machine.

Make a thorough check before the operation every time.

Make sure all the markings are intact and correct.

Page 3

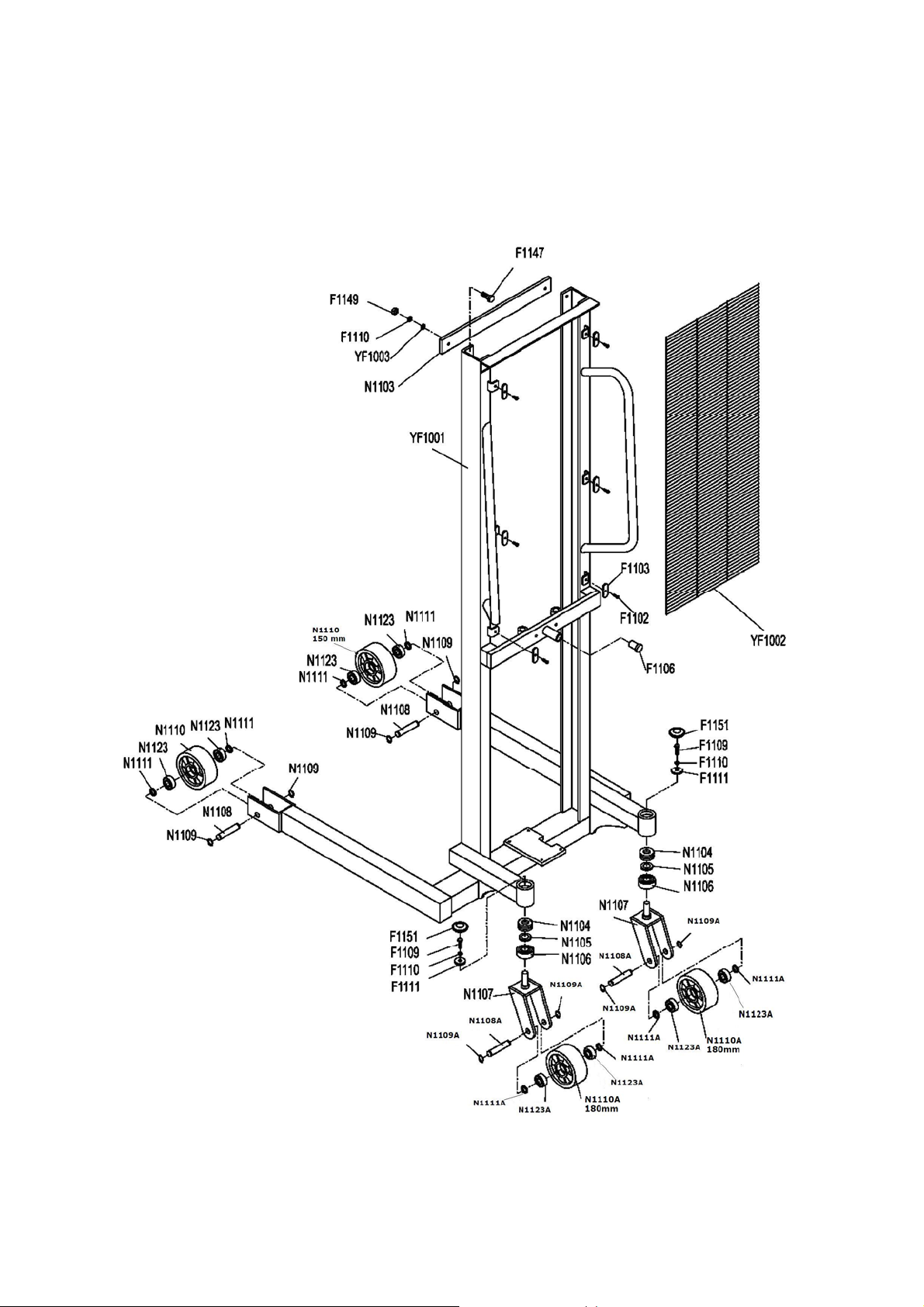

4 Exploded View & Part List

Type: DA40A

Carriage assembly

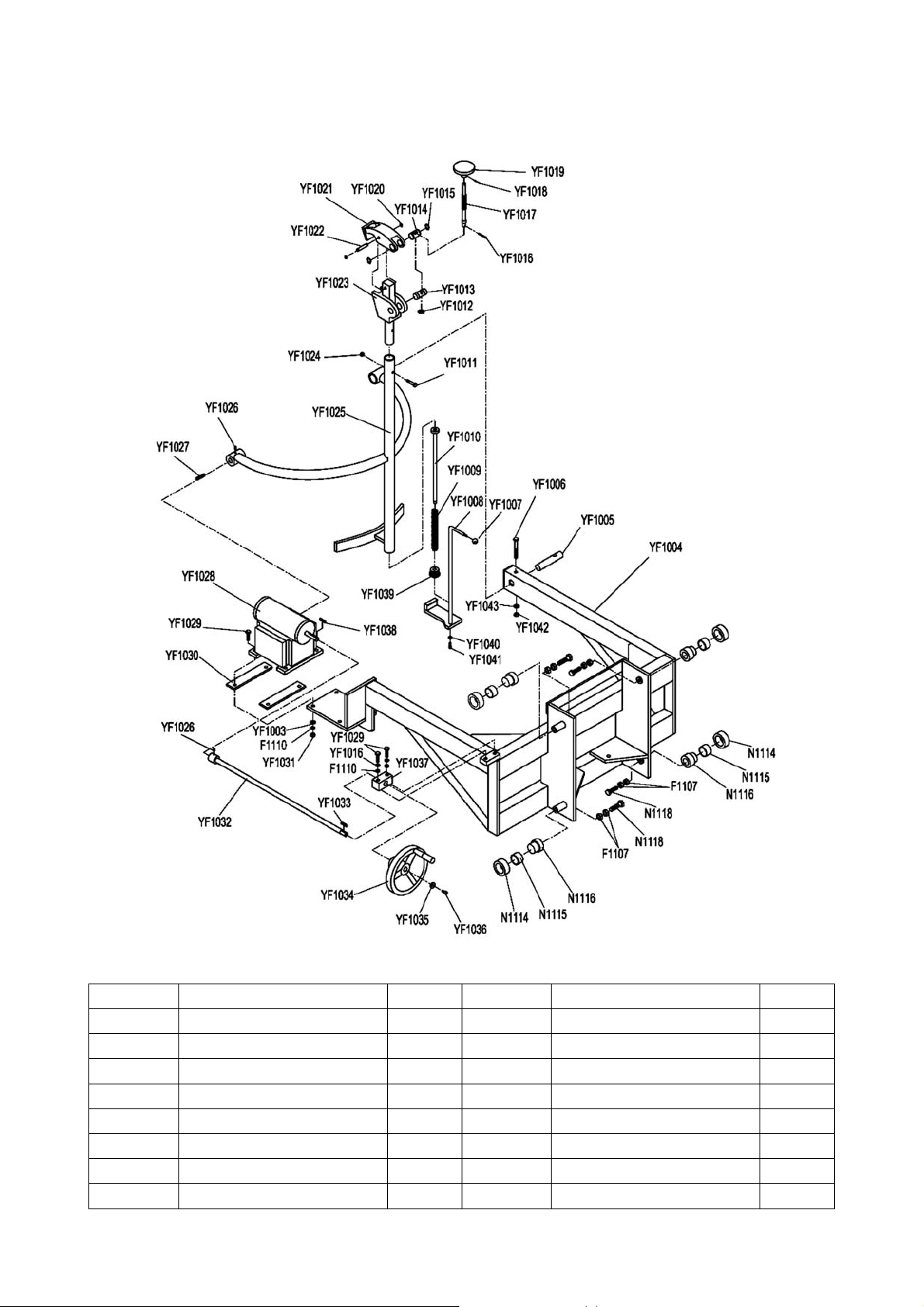

Page 4

Sliding guide assembly

Part No. Description Qty Part No. Description Qty

YF1001 Carriage 1 YF1035 Gasket 1

YF1002 Net 1 YF1036 Screw 1

YF1003 Washer 14 YF1037 Seat 1

YF1004 Sliding guide assembly 1 YF1038 Flat key 1

YF1005 Supporting axle 1 YF1039 Sealing screw 1

YF1006 Bolt 1 YF1040 Gasket 1

YF1007 Ball 1 YF1041 Screw 1

YF1008 Joystick 1 YF1042 Locknut 1

Page 5

YF1009 Spring 1 N1104 Bearing 8304 2

YF1010 Top axle assembly 1 N1105 Spacing ring 2

YF1011 Bolt 1 N1106 Bearing 60203 2

YF1012 Washer 2 N1107 Rear wheel bracket 2

YF1013 Supporting axle 1 N1108A rear wheel axle 4

YF1014 Nut axle 1 N1109A Check ring 8

YF1015 Check ring 2 N1110A Rear wheel (180 mm) 2

YF1016 Split pin 1 N1111A Washer 8

YF1017 Screw rod Tr16×4 1 N1108 Front wheel axle 2

YF1018 Taper bolt 1 N1109 Check ring 8

YF1019 Handwheel 1 N1110 front wheel (150 mm) 4

YF1020 Check ring 2 N1111 Washer 8

YF1021 Upper clamp 1 N1114 Pulley 4

YF1022 Pin axle 1 N1115 Pulley bush 4

YF1023 Lower clamp 1 N1116 Shaft housing 4

YF1024 Locknut 1 N1118 Bolt 4

YF1025 Rotating stand 1 N1123A Rear wheel bearing 8

YF1026 Screw 2 N1123 Front wheel bearing 8

YF1027 Flat key 1 F1102 Screw 6

YF1028 Transmission 1 F1103 Spacing piece 6

YF1029 Bolt 6 F1106 Rubber pad 1

YF1030 Plate 2 F1107 Nut 8

YF1031 Nut 4 F1109 Bolt 2

YF1032 Handwheel axle 1 F1110 Gasket 4

YF1033 Flat key 1 F1111 Washer 2

YF1034 Handwheel 1 F1147 Bolt 2

YF1043 Washer 1 F1149 Nut 2

N1103 Stop plate 1 F1151 Dust cap 2

Page 6

Type: DA40B

Carriage assembly

See carriage assembly of DA40A.

Notes: The structure of DA40B carriage assembly is the same as DA40A. You can refer to contents of

DA40A above.

Sliding guide assembly

Part No. Description Qty Part No. Description Qty

YF1051 Pin axle 2 YF1059 Clamping rod 1

YF1052 Split pin 2.5×22 4 YF1060 Screw M5×40 1

YF1053 Small pad 2 YF1061 Ball M8×25 1

YF1054 Right movable arm 1 YF1062 Locating pin 1

YF1055 Big pad 2 YF1063 Spring 1

YF1056 Screw M5×12 22 YF1064 Locknut 1

YF1057 Fixed arm 1 YF1065 Screw M5×12 1

Page 7

YF1058 Chain 10A- 1×12 1 YF1066 Left movable arm 1

Page 8

Page 9

Parts List of Pump Un it (Standard)

y

g

g

p

g

g

g

g

g

g

g

Parts No.

1201 Dust proof rin

Description Q’t

1 1255A Seal rin

Parts No.

Description Q’t

1202 Cylinder 1 110 Screw 1

1203 O-ring 1 111 Red copper 1

1204 O-ring 1112S

ring 2

1205 Seal ring 1 113 Pressure rod 1

1206 Spacing washer 1 114 S teel ball 1

1207 O-ring 1 115Q Pressure valve 1

1208 Rod 1 116 Split rin

1209 Guide casing 1 166 Retainer 1

1210 Washer 1 117 O-rin

1211 Retaining ring 1 118 Red copper 2

1212 Screw Each 119 Steel needle 1

1213 Welded bond 1 121 Spring pin 1

1

1

1

1214 Pressure bond 1 129 Steel ball 1

1215 Spring pin 1 130Q Discharge valve 1

1217 Spring 1 131 Sprin

1234 O-ring 1132O-rin

1

1

1235 Red copper 1 167 Retainer 1

1236 Bushing 2 133 Discharge valve 1

1237 Bolt 4 134 Valve taper core 1

1239 Spring washer 4 135 Sprin

1

1240 Plain washer 4 136 Pressure 1

1250A Spring cover 1 137 O-rin

1

1251A Pump plug 1 138 Screw 1

1252A Dust proof rin

1 139M Crank link 1

1253A O-ring 1 140M Setting screw 1

1254A Pump body 1 141 Nut 1

Page 10

Parts List of Handle

Parts No.

H1101 Handle 1 H102 Spring pin 1

H1102 Rod and chain 1 H103 Spring leaf 1

H1103 Nut 1 H104 Spring pin 2

H1104 Nut 1 H105 Spring pin 1

H1105 Spring ring 1 H106 Control level 1

H1106

H1107 Axle 1 H111 Nylon roller 1

H1108 Steel roller 1 H112 Spring pin 1

H1109 Retaining ring 2

Description

Pin

Q’ty

1 H108

Parts No.

Description

Rubber cushion

Q’ty

1

Page 11

Keep normal maintenance on the head parts of the clamps.

2 Checks Before Operation

Operator should make visual check on the machine before every shift work.

2.1 Make sure the operation manual is a complete and effecti ve edition.

2.2 Make sure all the markings are intact, correct and properly affixed.

2.3 Check the following p arts whether they are dama ged or improper installed or have some parts loosen

and lost.

Hydraulic system and relative parts

Clamping parts

Front & rear wheels

Carriage

Nuts, bolts and other fastening parts

2.4 check the machine on:

Impression or damage

Clamping parts wearing or damage

Corrosion or oxidation

Welding seams or cracks

3 Functional Test

Operators must make functional tests on drum st ackers of different kinds of functio ns. Only when the tests

are eligible, can they be put into service.

Page 12

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the part is

covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It also

covers defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses, wheels,

seals, brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original components is 30 days. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive environments;

Inadequate or improper maintenance;

Damage sustained during shipping;

Collisions or other incidental contacts causing damage to the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive

and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2016 Vestil Manufacturing Corp.

Loading...

Loading...