Page 1

Vestil Manufacturing Corporation

2999 North Wayne St., P.O. Box 507

Angola, IN 46703 USA

Ph 260-665-7586 • Fax: 260-665-1339

www.vestil.com • sales@vestil.com

03-04

A company dedicated to solving ergonomic and material

handling problems since 1955.

OWNER'S

MANUAL

DRUM DEHEADER

Model D-HEAD-1

OPERATING INSTRUCTIONS

MODEL D-HEAD-1 DRUM DEHEADER

Insure that all employees understand and follow the

following instructions.

The drum deheader works much like a kitchen can opener

on a larger scale. The Vestil Drum Deheader Model

D-HEAD-1 utilizes pressure created by a vise-grip style

clamp to force rolling cutting wheels into the drum lid. The

finished opening has a very smooth rolled edge making it

safer to handle due to no sharp edges to cut the handler.

The opener uses replaceable cutting blades that can be

easily replaced when cutting capabilities are decreased.

The opener can be used on a variety of styles of drums

with permanently sealed lids. There may be some

instances however where bung nuts may come into contact

with the cutting head. Many times the deheader can be

manipulated around these obstacles with a little care.

However, in few instances, there may be special made

drums that this opener may not be able to work with.

The first step in opening any drum is to make sure that the

contents are completely emptied from the drum before

beginning. If working with hazardous materials, be sure the

proper gear is worn and all necessary precautions are

taken to avoid accidents. The drum deheader is not spark

resistant and can possibly created sparks if struck against

another object so use on highly flammable materials or

explosives is not recommended.

Place a 1/2" drive ratchet into the 1/2" "socket like"

receptacle in the top of the wrench. Rotate the ratchet

clockwise and hold the drum wrench 90° to the drum side

to maintain force on the cutting wheel. After completing

one rotation around the drum, readjust the clamping force

again to 20 - 30 lbs. This may be required several times

dependent on the thickness of the drum. When making

consecutive rotations around the drum, be sure to stay in

the same cutting path as the previous cut. After cutting

through the drum lid, take a hammer to tap the lid down

into the drum for easier removal.

As with many hand tools, using the drum wrench several

times will help the operator perfect their style and will

become easier for them to operate. Pneumatic impact

wrenches or air ratchets can also be used with this

wrench to speed the process, but caution should be

used. Air tools are extremely powerful and can injure an

operator when an obstruction is encountered.

To replace blades, simply remove the screw in the center

of the cutting wheel and slide the wheel out from the

side. Place the new cutting wheel with the offset to the

top and reinstall the screw. Tighten the screw down until

the cutting wheel does not rotate and back the screw out

slightly to allow rotation again.

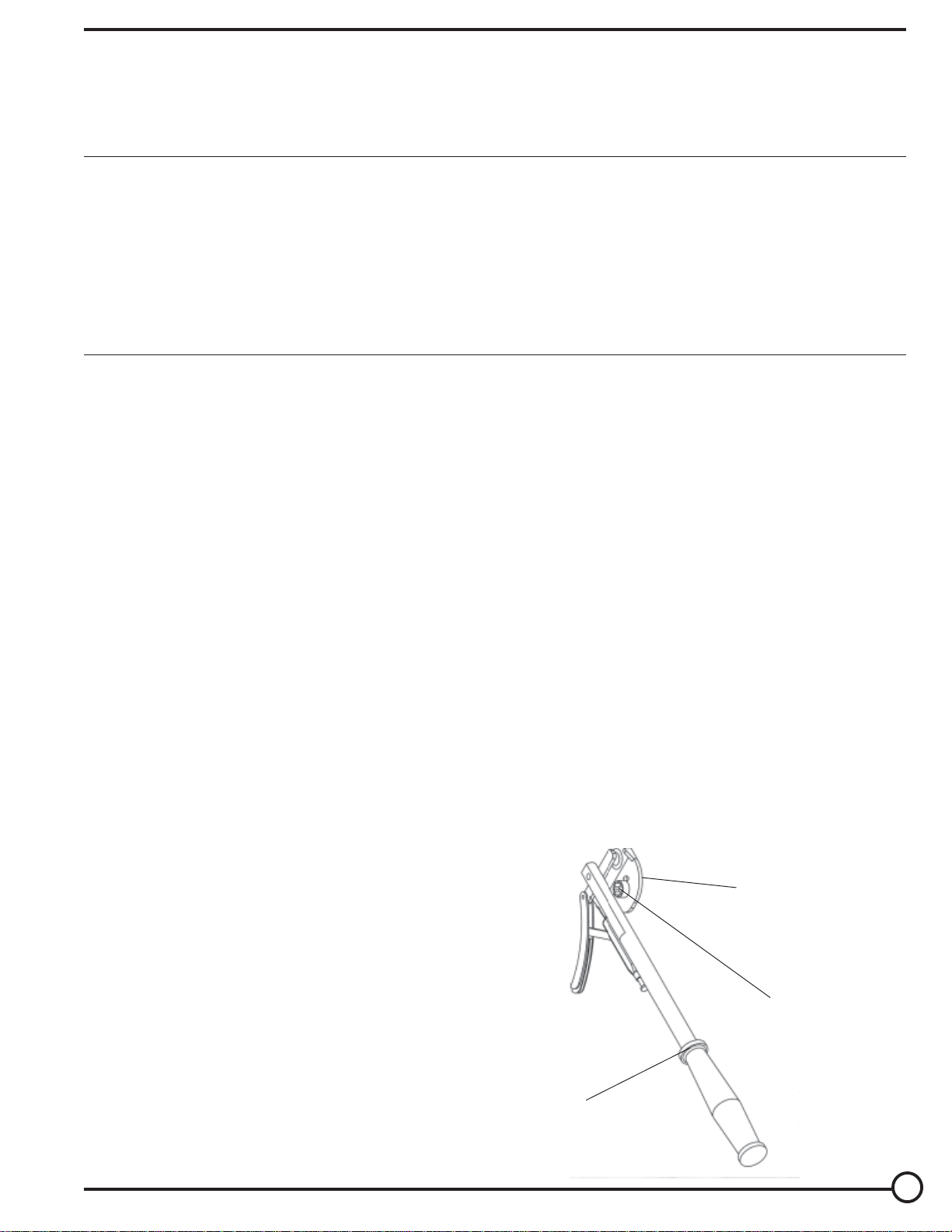

CUTTING WHEEL

Secure the drum opener to the top lip of the drum with the

1/2" drive socket up and the cutting wheel against the

inside of the lip. The cutting wheel should be as low as

possible on the drum lid to allow for easier cutting. The

two drive gears should rest against the outer ledge of the

drum ring. Clamp the drum deheader down onto the drum

ring when location of the cutting wheel and gear is

achieved. Adjust the clamping force much like a "vise

grip" style wrench. Be careful not to clamp too much

pressure as the cutting wheel is hardened and can break

when excessive force is applied. Try to adjust the wrench

so it takes 20 - 30 lbs. to close the wrench.

1/2" DRIVE SOCKET

PRESSURE

ADJUSTMENT KNOB

1

Loading...

Loading...