Vestil DGS-A User Manual

12/7/05 09-126-120.doc

O

VESTIL MANUFACTURING CORP.

2999 N. Wayne St., Angola, IN 46703

Ph: 260-665-7586 · Fax: 260- 6 65-1339

E-mail: sales@vestil.com

· www.vestil.com

MODEL DGD-A & DGS-A

Serial number ____________

Assembly / Installation Instructions ………………..… 2

Operation Instructions ……………………….……….. 2

Routine Maintenance & Safety Checks ………………. 3

Exploded Structural Parts Drawing & BOM ………... 4-5

WARNINGS AND SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the following.

o Read and understand the owner’s manual before using or servicing

the DGD-A / DGS-A.

o The load must be removed before any work is performed on the

DGD-A / DGS-A.

o Ensure that all safety and warning labels stay in place and are

legible.

o Do not use the DGD-A / DGS-A if any damage or unusual movement

is observed.

o Always watch the arms and the drum carefully when the DGD-A /

DGS-A is in operation.

o Before transporting a drum, raise the unit so the drum is off the

ground. Transport the drum as close to the ground as possible

without hitting the ground.

o The DGD-A / DGS-A is intended for use with only steel drums

o Do not perform any modifications to the DGD-A / DGS-A without the

manufacturer’s approval. Failure to receive authorization for

changes to the equipment could void the warranty.

o Maintenance and repairs are to be done only by personnel qualified

to perform the required work.

Troubleshooting …………………………....…………. 3

Safety Label Identification .............................................6

Warranty …………………………………….……..…. 7

WNER’S

MANUAL

WHEN ORDERING

REPLACEMENT PARTS:

We take pride in using quality

parts on the equipment we

manufacture. We are not

responsible for equipment

problems resulting from the use

of unapproved replacement

parts.

To order replacement or

spare parts for this equipment,

contact the factory.

In any communication with

the factory please be prepared

to provide the machine’s serial

number, which is indicated on

the machine dataplate.

RECEIVING INSTRUCTIONS

It is possible that the unit could

incur damage during transit.

Inspect the unit closely when

it arrives. If you see evidence

of damage or rough handling to

either the packaging or to the

product when it is being

unloaded, immediately

note of it on the Bill Of Lading!

It is important that you

remove the product’s packaging

upon its arrival to ensure that

there is no concealed damage

or to enable a timely claim with

the carrier for freight damage.

Also verify that the product

and its specifications are as

ordered.

make a

V

ESTIL MFG. CO./T&S EQPT. CO. 1 of 8

12/7/05 09-126-120.doc

O

PERATION INSTRUCTIONS – DGD-A / DGS-A

o

Ensure that all employees involved in the operation of this DGD-A or DGS-A understand and follow these

instructions!

o

Modifications or additions to the DGD-A / DGS-A without prior manufacturer’s authorization may void the

Drum Gripper’s warranty.

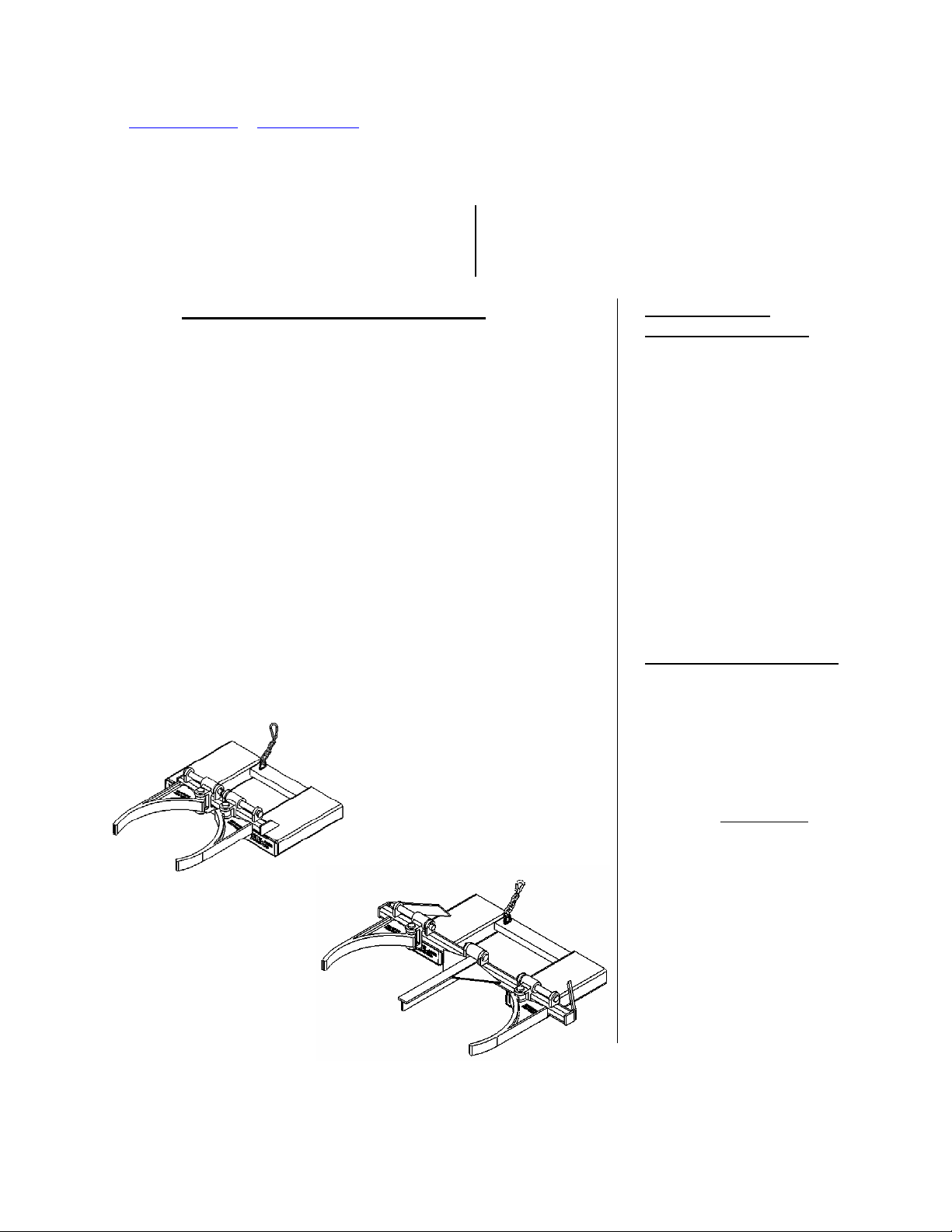

The standard model DGD-A / DGS-A is suitable for lifting and transporting open or closed standard 30 gallon and 55-

gallon steel drums in most (non classified) industrial locations which do not involve hazardous materials.

Loading and Operation:

The load rating, in pounds, is shown on the machine data plate. It indicates the net capacity of the DGD-A / DGS-A

with a static load that is centered and evenly distributed.

1.) Adjust the forks so that the inside width between the forks will fit into the fork pockets. One fork must be

locked to the bed plate.

2.) Drive the truck forward to slip forks into the fork sleeves. Attach safety chain the mast to secure d rum lifter

to forks.

3.) Raise the unit and tilt the forks forward to separate the arms slightly.

4.) Lower the unit over the top of the drum until the arms are at the desired lifting point on the drum.

5.) Raise the forks and tilt them back keeping the drum as close to the floor as possible while transporting.

6.) To release the drum, tilt the forks forward, lower drum to the ground and back away from the drum.

Note: The addition of any ancillary equipment to the DGD-A / DGS-A by third parties must be taken into account when

determining the maximum working load.

Warning: Do not exceed the DGD-A / DGS-A’s load ratings. Injury to personnel or permanent damage to the loading

arms, the drum(s), or drum contents, could result from exceeding the listed capacity.

Inspect the safety chain and lifting arms daily.

Warning: Keep all personnel clear of the machine when it is in operation.

Caution: Always carefully watch the lifting arms and drums when it is in operation.

Caution: Never use the DGD-A / DGS-A if any damage or unusual noise is observed, if it is in need of repairs, or if it

seems to be malfunctioning. Notify your supervisor or maintenance personnel if you notice anything out of the

ordinary.

Ensure that all safety and warning labels stay in place and are legible. Refer to the labels page in this manual.

V

ESTIL MFG. CO./T&S EQPT. CO. 2 of 8

12/7/05 09-126-120.doc

ROUTINE MAINTENANCE & SAFETY CHECKS – _DGD-A / DGS-A

o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures

before beginning work.

o Only qualified individuals trained to understand mechanical devices and their associated hazards should attempt

troubleshooting and repair of this equipment

(A) Before each use inspect for the following:

1.) Damage or structural deformation to the structural members, the fork tubes, lifting arms, retaining chain &

bracket etc.

2.) Unusual noise or binding, or evidence thereof.

3.) Proper functioning of the lock.

4.) Apparent damage or fatigue to the safety, strap / chain (used to secure the drum gripper to the fork truck

mast), or to the safety latch at the end of the strap / chain.

(B) Inspect monthly for:

1.) Pivot point wear.

2.) Integrity of the retaining hardware on all pivot point pins.

3.) The integrity of the hook, chain and chain retaining brackets.

4.) Looseness, wear, or damage to the drum lifting arms.

5.) Unusual noises or movement during operation.

6.) Signs of excessive wear, or damage to any part of the safety strap, including the strap hooks safety latch.

7.) All the information, safety, and warning labels being in place and in good condition.

8.) The need to clean off dirt and debris.

(C) Yearly inspection

1.) Test the drum gripper under full load. Remove the drum(s) and inspect all of the welds for cracks and the

structural parts for signs of fatigue or deformation.

TROUBLESHOOTING GUIDE -- ______

Warning: Before performing any repair or trouble shooting task. (always remove the drum.).

Consult the factory for any problems not addressed below.

Problem: Possible cause(s): Action:

Drum won’t fit between the

gripping arms.

Drums slip out of the gripping arms

when lifted.

Gripping arms are not parallel.

Gripping arms adjusted for smaller

drum.

Drum is not a standard size drum.

Wrong size or type of drum

Arms or center support not in place

properly.

Locking tabs are not secured in

locking slots

Debris/obstruction

Damage or structural deformation

Readjust gripping arms.

Adjust/tilt the mast of the fork

truck forward to separate the arms.

Tilt the mast of the fork truck back

Move gripping arms until locking

slots match locking tabs. Rotate

gripping arm down to insert locking

tab into locking slot.

V

ESTIL MFG. CO./T&S EQPT. CO. 3 of 8

Loading...

Loading...