Vestil DFDL-3 User Manual

VESTIL MANUFACTURING CORPORATION

P.O. Box 507., Angola, IN 46703 USA

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Drum Handling Solutions

Revised 08-04 40-126-101

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

FORK MOUNTED DRUM LIFTERS

Contents

Warnings and Safety Instructions .............. 1 & 2

Receiving Instructions & Warranty .................. 1

Operating Instructions ..................................... 2

Periodic Maintenance Instructions .................. 2

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Never operate drum lifter unless you are watching it.

• Never use the drum lifter if the unit is in need of repairs or in

the case of a malfunction.

• Do not stand below any part of a raised drum lifter or drum.

• Never exceed maximum loading capacity of the drum lifter

• Always load drum at the center of the drum lifter.

• Consult factory for uneven loading.

• When elevation is not required, always transport the

drum in the lowered position.

• Do not allow drum to impact on floor, ground, or dumping

station etc., or there may be damage to the unit.

• Remove drum before working on unit.

• Consult factory if adding or performing any modification

to the original equipment.

• Use only maintenance parts supplied or approved by the

manufacturer.

• Make sure all operator safety labels are in place (p.16).

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit may incur

damage during transit. If damage is noticed when unloading,

make a note of it on the BILL OF LADING. Remove all packing

and strapping material, then inspect the unit again for damage.

IF DAMAGE IS EVIDENT, FILE A CLAIM WITH THE CARRIER

IMMEDIATELY!

WARRANTY

This product is warranted for 90 DAYS from date of purchase

to be free of manufacturing defects in material and workmanship.

This warranty does not cover normal wear of parts or

damage resulting from any of the following: negligent use or

misuse of the product, use or application contrary to

installation instructions, or disassembly, repair or alteration by

any person prior to authorization from a factory representative.

Eagle Beak Drum Lifter .................................3-6

Fork Mounted Bottom Poly Drum Lifter ..........7-9

Fork Mounted Top Poly Drum Lifter...........10-12

Deluxe Combination Drum Lifter ...............13-15

Warning Label Identification ........................... 16

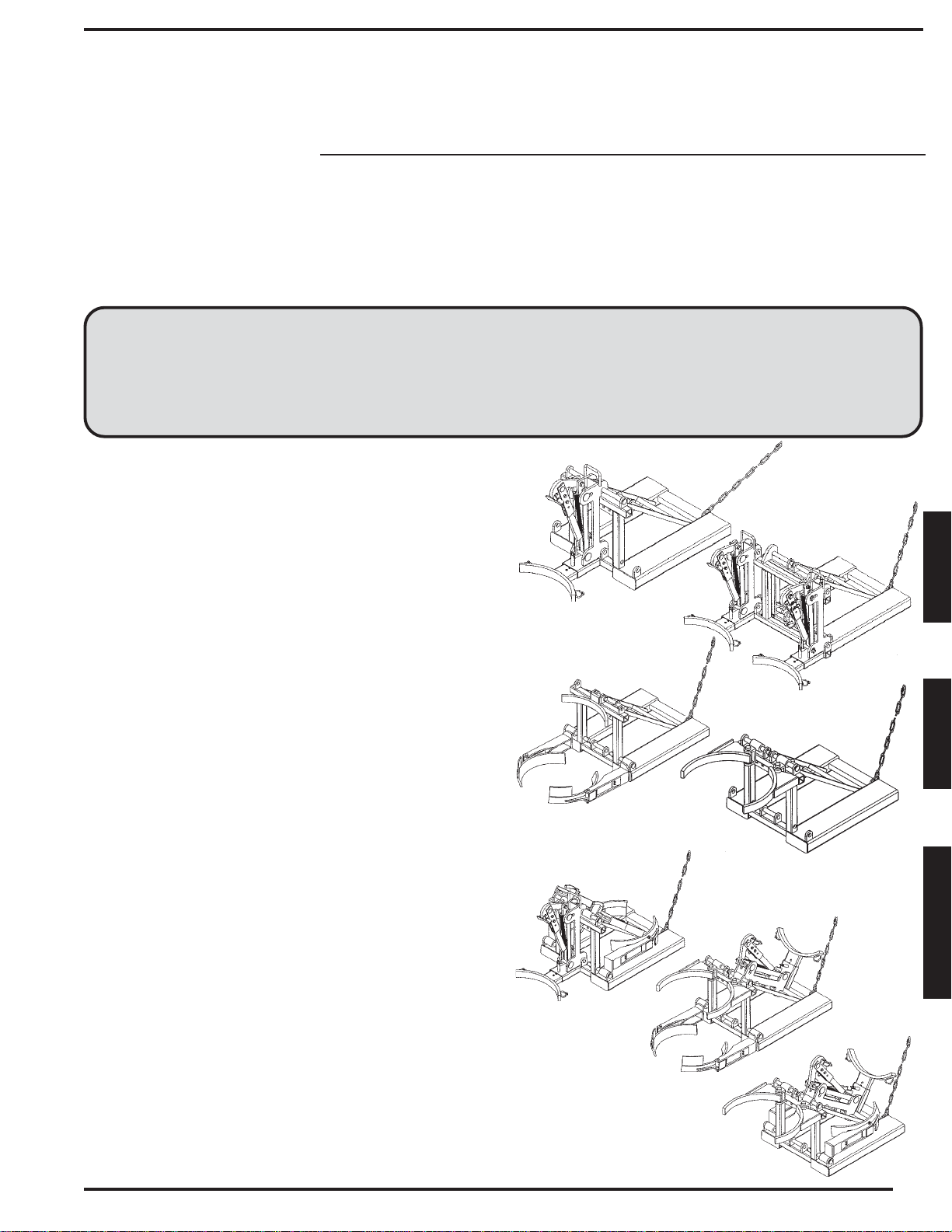

Single & Double

Eagle-Beak Drum Lifter,

model FMDL-1 & FMDL-2

Fork Mounted Bottom

Poly Drum Lifter,

model FPDL-8-L

Deluxe Combination

Fork Mounted Drum Lifter,

model DFDL-3

(shown in Eagle-Beak,

Bottom Poly Drum Lifter

and Top Poly Drum Lifter)

Fork Mounted Top

Poly Drum Lifter,

model FPDL-11-H

1

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

Safety Instructions for the Operator

1.) Please read all instructions THOROUGHLY before attempting to operate your new Drum Lifter.

2.) a) The Model FMDL-1 intended to lift and move a 30 or 55 gallon, open and closed head plastic, steel and fiber drums with

a top lip strong enough to support the weight of the drum, and has a MAXIMUM CAPACITY RATING of 1,000 pounds.

b) The model FMDL-2 is intended to lift two 30 or 55 gallon, open and closed head, plastic, steel and fiber drums with top

lip strong enough to support the weight of the drum, and has a MAXIMUM CAPACITY RATING of 2,000 pounds for two

drums (1,000 pounds per drum).

c) The model FPDL-8-L is intended to lift and move a 55 gallon, round bottom plastic drums and has a MAXIMUM CAPACITY

RATING OF 800 pounds.

d) The model FPDL-11-H is intended to lift and move a 30 or 55 gallon, closed head, plastic drums with a top lip at least

3/16" high; and has a MAXIMUM CAPACITY RATING of 1,000 lbs.

e) The model DFDL-3 is intended to lift and move 30 or 55 gallon, open or closed head, steel, plastic, and fiber drums with

MAXIMUM CAPACITY RATINGS as follows:

Single Eagle-Beak: 1,000 lbs.

Bottom Lip Poly Drum Lifter: 800 lbs.

Top Lip Poly Drum Lifter: 1,100 lbs.

** DO NOT exceed these ratings as the unsafe condition that may result could cause damage or excessive wear, or make

the unit awkward to handle.

3.) When operating, loading, unloading or maintaining your drum lifter, always use care and good judgement, have good footing

and a firm hold. Keep hands and loose clothing, etc. away from all moving parts. Never allow anyone to be below any parts

of a raised drum lifter or drum. Read operating instructions before operation.

Operating Instructions for FMDL-1 and FMDL-2

1.) Adjust the forks so that the inside width between the forks will fit into the fork pockets. One fork must be locked to the bed

plate.

2.) Drive the truck forward to slip forks into the fork sleeves. Attach safety chain to mast to secure drum lifter to forks.

3.) Tilt the fork truck mast forward and drive the truck with the forks near floor level to center the lifter in front of the drum until

the lifter, contacts the drum at the bottom drum grip.

4.) With the mast still in the tilted forward position, raise the forks up.

5.) When the upper jaw on the drum lifter engages the top of the drum lip, straighten the mast and raise the forks to transport

the drum. Attach the ratcheting strap to the bottom drum grip and tighten it around the drum.

6.) To release the drum, remove ratcheting strap and lower the forks so that the drum sets flat on the floor and continue to lower

forks until the upper jaw disengages itself.

Operating Instructions for FPDL-8-L

1.) (same as FMDL-1 & FMDL-2 Step #1)

2.) (same as FMDL-1 & FMDL-2 Step #2)

3.) Tip the forks down so the bottom grip arms are approximately parallel to the floor and as close to the floor as possible.

4.) Center the drum lifter on the drum and drive forward until the drum comes into contact with the upper support bracket.

5.) Raise the forks to transport the drum.

6.) To release the drum, tilt the forks forward, set the drum down and back the fork truck away from the drum.

Operating Instructions for FPDL-11-H

1.) (same as FMDL-1 & FMDL-2 Step #1)

2.) (same as FMDL-1 & FMDL-2 Step #2)

3.) Raise the unit and tilt the forks forward to separate the arms slightly.

4.) Lower the unit over the top of the drum until the arms are at the desired lifting point on the drum.

5.) Raise the forks and tilt them back keeping the drum as close to the floor as possible while transporting.

6.) To release the drum, tilt the forks forward, lower drum to the ground and back away from the drum.

Periodic Maintenance Instructions

Lubricate all pivot with light oil as needed.

2

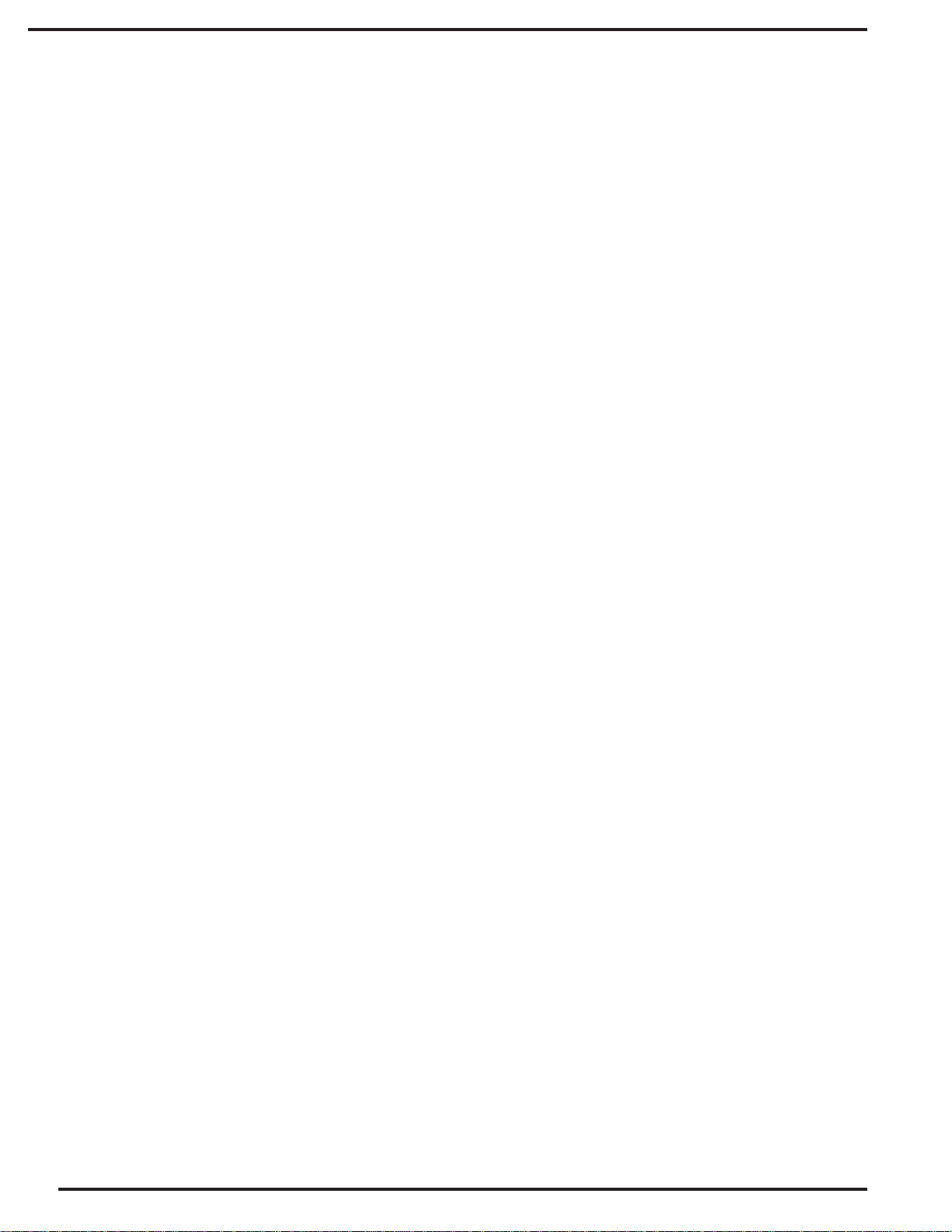

Single & Double Eagle-Beak Drum Lifter,

model FMDL-1 & FMDL-2

E

N

G

L

I

S

H

3

SINGLE EAGLE-BEAK DRUM LIFTER

MODEL FMDL-1

ITEM NO.

1

2

3

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DESCRIPTION

Frame, Weldment, Eagle Beak Base

Pin, Hitch, 1/2 x 2-2/3 Lg.

Pin, Main Clevis, 1 ID x 8-5/8 Lg.

Pin, Cotter, 3/16 x 1-1/2 Lg.

Specialty Hardware, Chain, 5/16 x 48 Lg.

Ratcheting Strap (not shown)

Frame, Weldment, Eagle Beak Handle

Frame, Weldment, Eagle Beak Channel

Frame, Weldment, Eagle Beak Tube

Bracket, Weldment, Eagle Beak, Small Grip

Bracket, Weldment, Eagle Beak, Large Grip

Pin, Weldment, 1-3/8 OD x 7/8 x 1-3/4 Lg. Shaft

Nut, Hex, 5/8-18 Unc

Pin, 3/4 x 4-1/2 Lg.

Pin, cotter, 3/16 x 1-1/4 Lg.

Bolt, Hex Head, 5/8-18 Unc x 3 Lg.

Pin, 1/2 x 1-1/2 Under Head to Side of Hole

Clip, Hitch Pin, Trade Size 11

Spring, Tension

Washer, Flat 5/8

Frame, Spring Steel, 5/64 x 1-1/2 x 10 Lg.

Bolt, Hex Head, 1/4 - 20 Unc x 5/8 Lg.

Nut, Hex, Nylok, 1/4 - 20 Unc

Machinery Bushing, 1-1/2 OD x 3/4 ID x 14 Ga.

ENGINEER NO.

40-514-008

DIR-99

40-112-001

65125

37-145-004

I-RS

40-514-006

40-514-018

40-514-011

40-516-001

40-516-002

40-612-004

63163

CP-3/4X4-1/2-Z

65125

16315

CP-1/2X1-3/4-Z

45286

FMDL-SPG

33015

40-014-029

11003

37018

33474

4

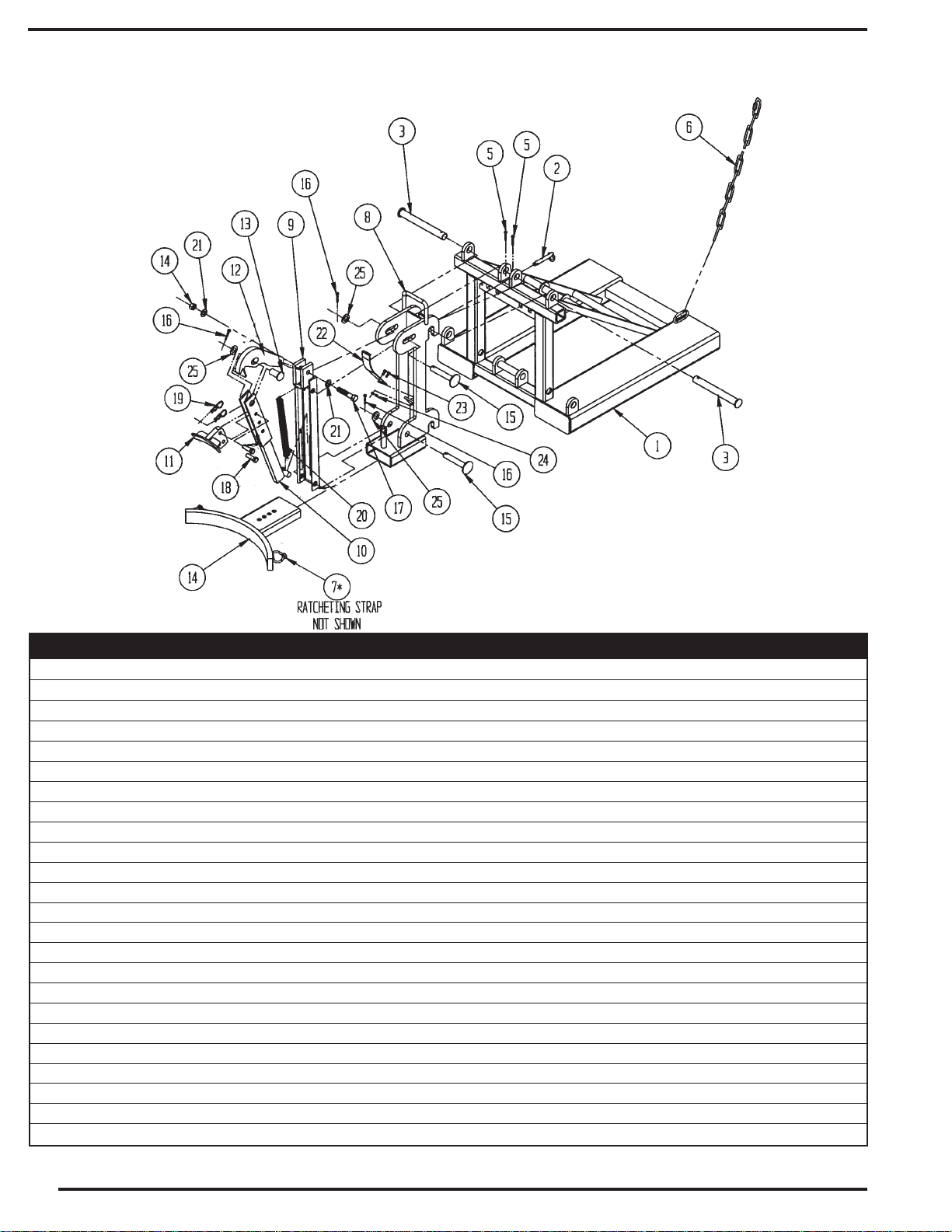

ITEM NO.

1

2

3

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

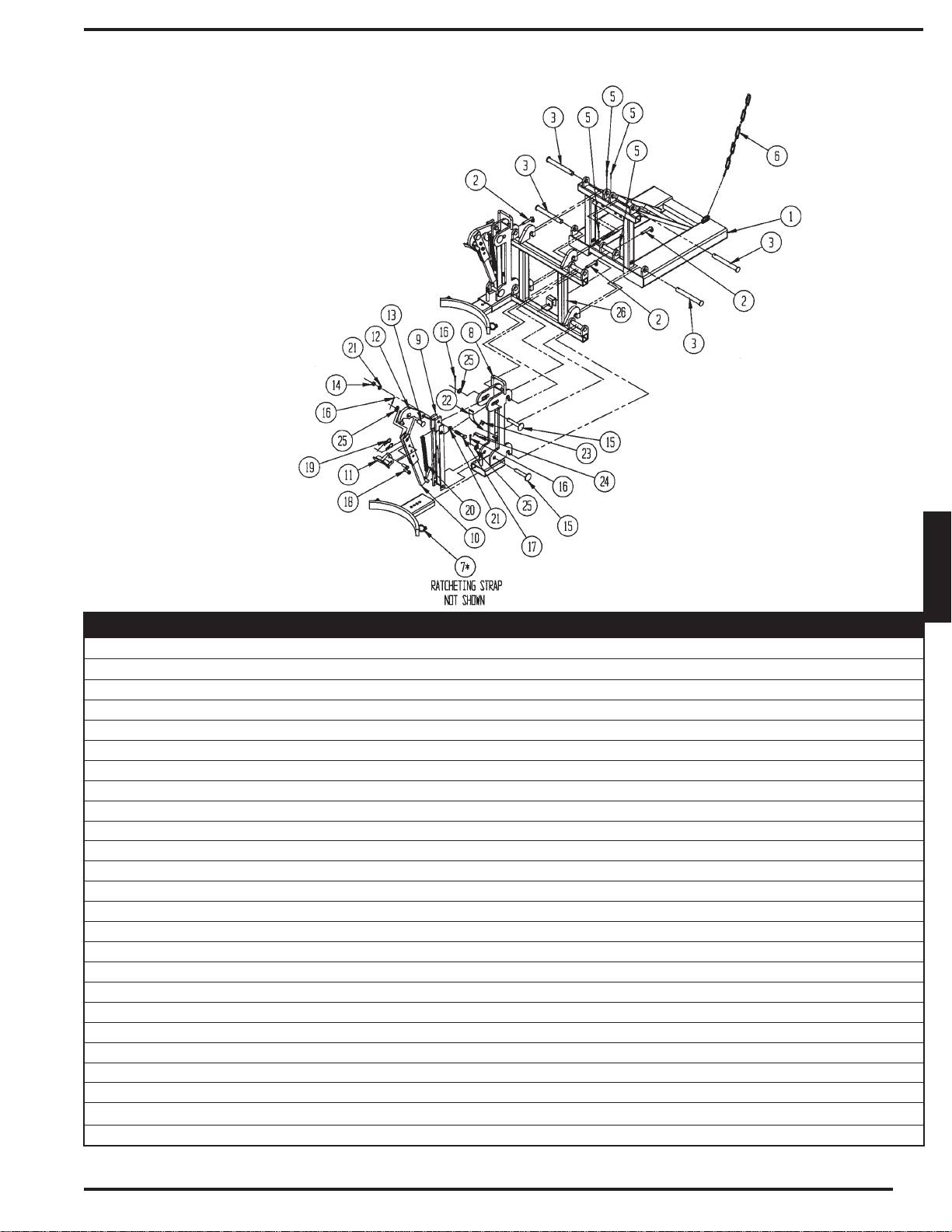

DOUBLE EAGLE-BEAK DRUM LIFTER

MODEL FMDL-2

DESCRIPTION

Frame, Weldment, Eagle Beak Base

Pin, Hitch, 1/2 x 3-3/4 Lg.

Pin, Main Clevis, 1 ID x 8-5/8 Lg.

Pin, Cotter, 3/16 x 1-1/2 Lg.

Specialty Hardware, Chain, 5/16 x 48 Lg.

Ratcheting Strap (not shown)

Frame, Weldment, Eagle Beak Handle

Frame, Weldment, Eagle Beak Channel

Frame, Weldment, Eagle Beak Tube

Bracket, Weldment, Eagle Beak, Small Grip

Bracket, Weldment, Eagle Beak, Large Grip

Pin, Weldment, 1-3/8 OD x 7/8 x 1-3/4 Lg. Shaft

Nut, Hex, 5/8-18 Unc

Pin, 3/4 x 4-1/2 Lg.

Pin, cotter, 3/16 x 1-1/4 Lg.

Bolt, Hex Head, 5/8-18 Unc x 3 Lg.

Pin, 1/2 x 1-1/2 Under Head to Side of Hole

Clip, Hitch Pin, Trade Size 11

Spring, Tension

Washer, Flat 5/8

Frame, Spring Steel, 5/64 x 1-1/2 x 10 Lg.

Bolt, Hex Head, 1/4 - 20 Unc x 5/8 Lg.

Nut, Hex, Nylok, 1/4 - 20 Unc

Machinery Bushing, 1-1/2 OD x 3/4 ID x 14 Ga.

Frame, Weldment, FMDL-2 Attachment

E

N

G

L

I

S

H

ENGINEER NO.

40-514-008

DIR-99

40-112-001

65125

37-145-004

I-RS

40-514-006

40-514-018

40-514-011

40-516-001

40-516-002

40-612-004

63163

CP-3/4X4-1/2-Z

65125

16315

CP-1/2X1-3/4-Z

45286

FMDL-SPG

33015

40-014-029

11003

37018

33474

40-514-007

5

Loading...

Loading...