Page 1

0317

DCR-205-DC, MANUAL

VESTIL MANUFACTURING CORP.

2999 N. Wayne St., Angola, IN 46703

Ph: 260-665-7586 · Fax: 260-665-1339

E-mail: sales@vestil.com · Website: www.vestil.com

OWNER ’S

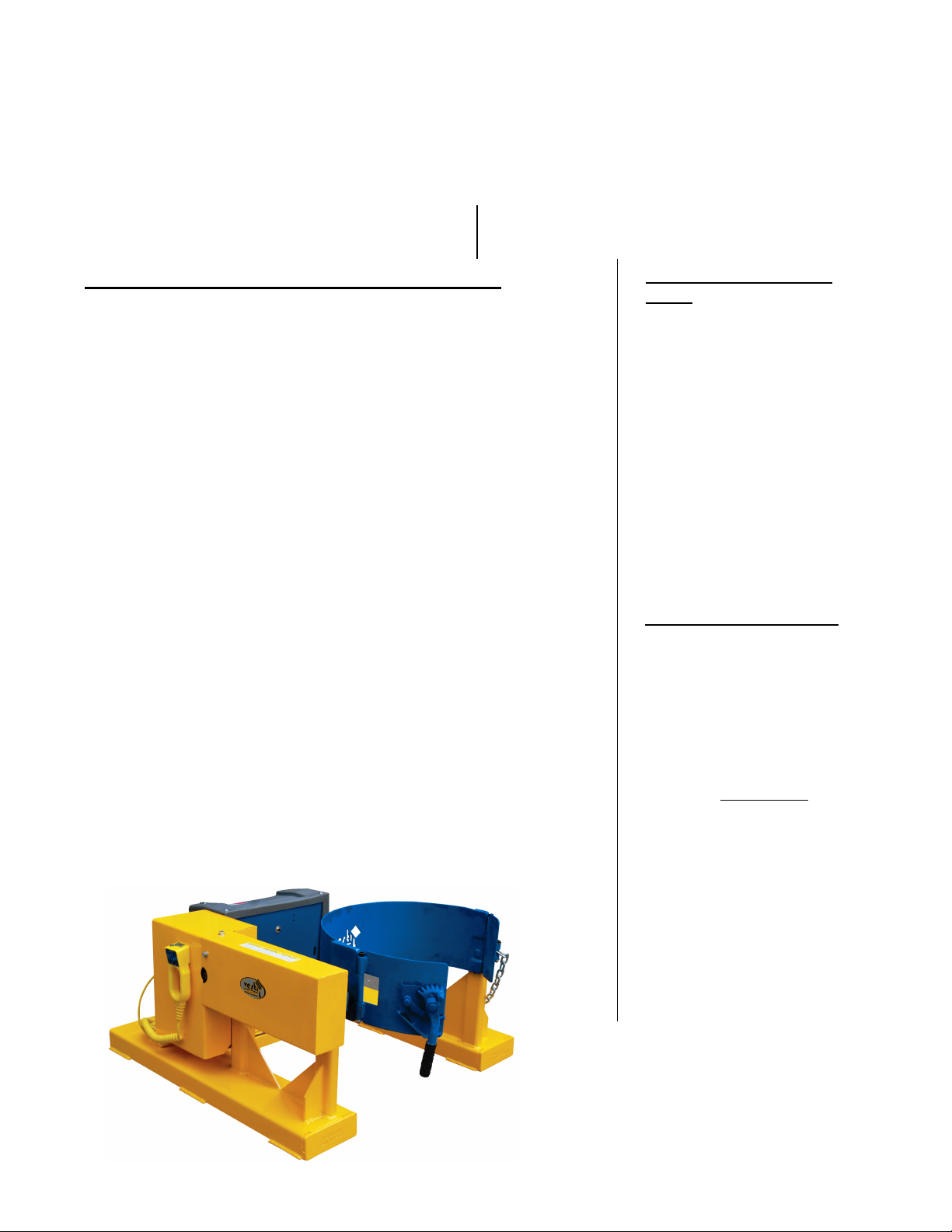

DCR-205-XX-DC Powered Drum Rotators

Maintenance, Inspection, & Safety Checks .......... 2

Operation Instructions .................................. 3

Exploded Parts DiagramBill of Materials ............. 4

IMPORTANT NOTES, WARNINGS AND SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the following.

* Failure to read and understand this owner’s manual before using or

servicing the drum carrier/rotator constitutes a misuse of the product.

All persons who will install, use, or care for this product must be familiar

with this material.

o The load must be removed from the drum saddle before any work is

performed on the drum carrier/rotator.

o Ensure that all information / safety / warning labels stay in place and are

legible.

o Do not use the drum carrier/rotator if any damage, unusual noise, or

unusual motion is observed; if it is in need of repairs, or; if it seems to be

malfunctioning. Notify your supervisor or maintenance personnel if you

notice anything out of the ordinary.

o Always watch the drum it’s contents carefully when the drum

carrier/rotator is in operation.

o Before transporting the drum carrier/rotator, raise the fork trucks forks

high enough that the product and its load are raised off the ground

slightly. Transport the drums as close to the ground as is possible without

letting them drag.

o The drum carrier/rotator is intended for use only with adequately-rated fork

trucks or counterbalanced pallet trucks being operated on improved,

compacted, and level surfaces.

o Do not use brake fluid or jack oils in the hydraulic system. If oil is

needed, use an anti-wear hydraulic oil with a viscosity grade of

150 SUS at 100°F, (ISO 32 cSt @ 40°C), or Dexron transmission fluid.

o Contact the manufacturer for any needed MSDS information.

♦ Do not perform any modifications to the drum carrier/rotator without the

manufacturer’s approval. Failure to receive authorization for changes to

the equipment could void the warranty.

♦ Maintenance and repairs are to be done only by personnel qualified to

perform the required work. Consideration will not be given for warranty

repair charges without prior written authorization by the manufacturer.

Labeling diagram ..................................... 5

Electrical circuit diagram ........................... 6

Limited warranty ..................................... 7

MANUAL

ORDERINGING REPLACEMENT

PARTS:

We take pride in using quality

parts on the equipment we

manufacture. We are not

responsible for equipment

problems resulting from the use

of unapproved replacement

parts.

To order replacement or

spare parts for this equipment,

contact the factory.

In any communication with

the factory please be prepared

to provide the machine’s serial

number, which is indicated on

the machine dataplate.

RECEIVING INSTRUCTIONS

It is possible that this product

could incur damage during

transit.

Inspect the unit closely when

it arrives. If you see evidence

of damage or rough handling to

either the packaging or to the

product when it is being

unloaded, immediately

note of it on the Bill Of Lading!

It is important that you

remove the product’s packaging

upon its arrival to ensure that

there is no concealed damage

or to enable a timely claim with

the carrier for freight damage.

Also verify that the product

and its specifications are as

ordered.

make a

VESTIL MFG. CO.

1

Page 2

0317

DCR-205-DC, MANUAL

MAINTENANCE, INSPECTION, & SAFETY CHECKS – DCR-205-XX-DC

o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures

before beginning work.

o Only individuals qualified to understand the mechanical design aspects and the associated hazards of this type of

equipment should attempt to troubleshooting and/or repair it.

The model DCR-205-xx-DC drum carrier/rotator is equipped with two (2) 12 volt, 35 ampere-hour, sealed,

maintenance-free AGM-type batteries to provide a 24 VDC power supply to the rotation system’s drive motor and motor

control components.

The unit is supplied with an on-board 24V, 3 ampere battery charger which will typically fully recharge the batteries in

about eight (8) hours. The charger is powered by attaching the connector end of most any three-prong extension cord

to the flanged inlet located in the top of the gray plastic battery department cover. The charger can be left on

indefinitely without causing harm to the batteries.

Do not use an extension cord smaller than 18 gauge, or longer than fifty (50) feet, to power the battery charger.

The touchpad located on the front of the gray battery compartment cover indicates the approximate state of ch arge of

the batteries, and is shown as a percentage of full charge based on the batteries’ combined voltage.

When the batteries are fully charged, approximately 200 full raise/lower cycles can be expected before the batteries

will need to be recharged. Charge the batteries overnight at least every two (2) weeks even if it is not in use.

If it will not be used for several weeks or longer, it is advisable to remove the batteries from the machine.

Inspect daily for:

1.) Damage to the product’s securing chain or web strap.

2.) Damage or structural deformation to the structural members.

3.) Unusual noise or binding, or evidence thereof.

Inspect monthly for:

1.) Pivot point wear.

2.) Looseness and wear of the gears, sprockets, chains, hinge points, component mounts, etc.

3.) Integrity of the retaining hardware on all rollers and on all pivot point pins.

4.) Proper functioning of drum saddle’s locking mechanism.

5.) Unusual noises or movement during operation.

6.) All the information/safety/warning labels being in place and in good conditio n .

7.) The need to clean off dirt and debris.

Test the battery voltage. In order to get an accurate indication of the batteries’ state of charge, the reading must

be taken at least two hours after the charger has been turned off after having completed a full (8 hour) charge

cycle. The batteries will read 12.65 volts when fully charged.

With the exception of the gearmotor, lubricate all of the gear-train grease fittings once a month with a good g rade

of industrial grease. Otherwise, periodically lubricate the cradle hinges, the drum saddle’s ratchet and pawl

mechanism, and the chains.

Yearly inspection:

If possible, test the product with a full load. Afterward, inspect for:

1.) Cracks at weld joints.

2.) Deformation or bending of any parts, or wrinkled or cracked paint which could indicate the same.

VESTIL MFG. CO. 2

Page 3

0317

DCR-205-DC, MANUAL

OPERATION INSTRUCTIONS – DCR-205-XX-DC

o Consult ANSI B56.1 for the owner’s / user’s re sponsibilities regarding the operation, care, and maintenance of this

machine.

o Ensure that all employees involved in the operation of this drum carrier/rotator understand and follow these

instructions!

The standard model DCR-205-xx-DC is suitable for transporting standard closed 55-gallon steel drums in most non-

Classified indoor and outdoor locations. It is intended to be used to transport and dump non-Classified liquids.

Attaching the drum carrier/rotator to the forks of a lift truck:

The load rating, in pounds, is shown on the machine dataplate located on the frame of the drum carrier/rotator. It

indicates the net capacity of the drum carrier/rotator when dumping a full liquid-filled drum. For drums that are only

half-full, the net capacity that the unit will rotate drops to 500 lbs.

The truck’s forks must be adjusted to have at least 24½” between them, and one fork must be locked in place to the

truck mast’s fork carriage.

Insert the fork truck’s forks into the fork pockets until the ends of the forks contact the drum carrier/rotator’s fork

tube end caps.

Open the drum carrier/rotator’s saddle and secure it open by attaching the hook cradle chain to ?????

With its forks near the floor, drive the lift truck forward until the back side of the drum saddle is against the side of

the drum. The saddle should be positioned at or just above the center of the drum, but not against one of the drum’s

rings.

Close the drum saddle’s gate and secure the chain to the chain slot. Lock the drum in place by rotating the drum

saddle’s gate handle 90° clockwise. Grasp and shake the top of the drum to ensure that it is securely held.

Do not exceed a rate of three feet per second (2 mph) when transporting drums with the drum carrier/rotator.

Warning: Do not exceed the drum carrier/rotator’s load ratings. Injury to personnel, or permanent damage to the

drum carrier/rotator, the drum, or the drum’s contents could result from exceeding the listed capacity.

Operation of the drum carrier/rotator:

On a daily basis, inspect the safety chain or web strap that is used to secure the product to the fork truck’s mast.

Warning: Keep all personnel clear of the drum carrier/rotator when it is in operation. Be certain no part of any person

or object is under any part of the drum before lowering it or dumping its contents.

Caution: Always watch the drum it’s contents carefully when the drum carrier/rotator is in operation.

Caution: Do not use the drum carrier/rotator if any damage, unusual noise, or unusual motion is observed; if it is in

need of repairs, or; if it seems to be malfunctioning. Notify your supervisor or maintenance personnel if you notice

anything out of the ordinary.

The model DCR-205-xx-DC drum carrier/rotator is operated by means of a pushbutton control connected to a coiled

retractile cord. The speed is controlled by a touchpad located on the front of the gray plastic battery department

cover.

Manual operation: The drum carrier/rotator can also be operated manually using the crank handle that came with the

unit. To use the hand crank, the chain connecting the gearmotor to the drive shaft will need to be removed, and the

hollow shaft of the crank handle is to be inserted onto the square end of the drive shaft.

Ensure that all information/safety/warning labels stay in place and are legible. Refer to the labels page in this

manual.

VESTIL MFG. CO. 3

Page 4

0317 DCR-205-DC, MANUAL

Exploded part diagram and bill of materials

VESTIL MFG. CO. 4

Page 5

Labeling diagram:

The product should always be labeled as diagrammed below. Replace any label that is missing,

damaged, or not easily readable (e.g. faded).

A

B

C

A: Label 232

B: Label 221

D: Label 218

D

C: Label 295

5

Page 6

Page 7

Rev. 11/2014

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and

workmanship during the warranty period. Our warranty obligation is to provide a replacement for a defective

original part if the part is covered by the warranty, after we receive a proper request from the warrantee (you) for

warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part u

sed to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and inclu

de the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized repr

esentative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such as bearings,

hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warra

nty period for original dynamic components is 90 days. For wearing parts, the warranty period is 90 days.

The warranty periods begin on the date when Vestil ships the product to the warrantee. If the product was purchased

from an authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its sole

discretion, extend the warranty periods for products shipped from authorized distributors by up to 30 days to account

for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

Occurrence of any of the following, which automatically voids the warranty:

3.

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modification(s) might make the product unsafe to use or might

cause excessive and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp

. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

7

Loading...

Loading...