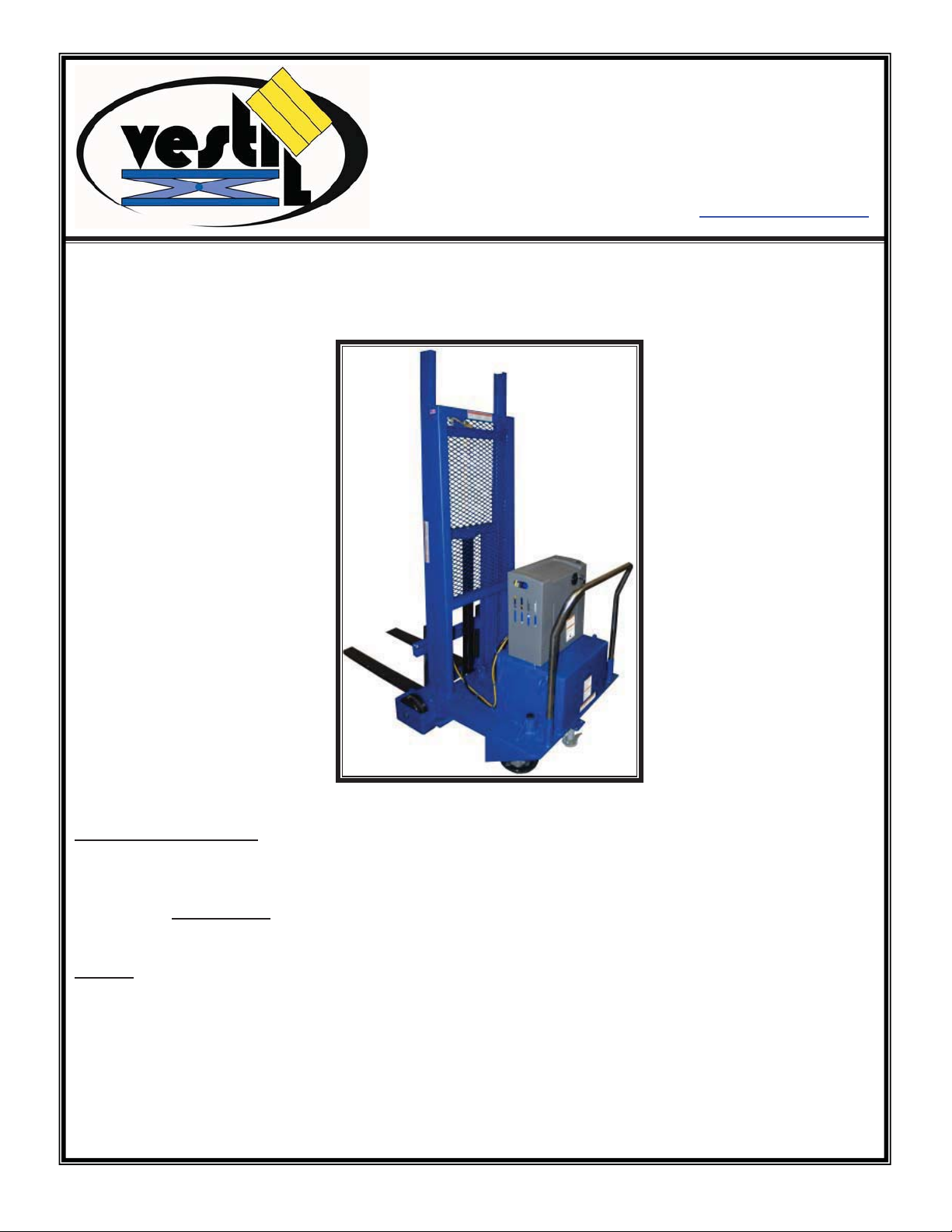

Page 1

rev. 1/23/2013 Product manual, operation instructions.doc

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail: sales@vestil.com

INSTRUCTION MANUAL

Receiving instructions:

After delivery, IMMEDIATELY remove the packaging from the product in a manner that preserves the

packaging and maintains the orientation of the product in the packaging; then inspect the product closely

to determine whether it sustained damage during transport. If damage is discovered during the

inspection, immediately record a complete description of the damage on the bill of lading. If the

product is undamaged, discard the packaging.

NOTES:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where

the product is used is exclusively the responsibility of the owner/end-user.

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply either: a)

the instructions in this manual; or b) information provided on labels affixed to the product.

responsible for any consequential damages sustained as a result of failing to exercise sound judgment

while assembling, installing, using or maintaining this product.

Neither is Vestil

Page 2

rev. 1/23/2013 Product manual, operation instructions.doc

SIGNAL WORDS

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable

seriousness of those injuries, if the product is misused in the ways described. Other signal words call attention to

uses of the product likely cause property damage.

The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

SERIOUS INJURY. Use of this signal word is limited to the most extreme

situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

SERIOUS INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

MODERATE injury.

Identifies practices likely to result in product/property damage, such as operation that

might damage the product.

Each person who assembles, installs, uses, or maintains this product should read the entire manual and fully

understand the directions in advance. If after reading the manual you do not understand an instruction, ask

your supervisor or employer for clarification, because failure to adhere to the directions in this manual

might result in serious personal injury.

SAFETY GUIDELINES

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, material

handling is inherently dangerous and no manual can address every conceivable risk. The end-user ultimately is

responsible for exercising sound judgment at all times.

Electrocution might result if any part of the product contacts electrified wires. Reduce the likelihood of

electrocution by applying common sense:

¾ DO NOT contact electrified wires with any part of this device, your body, or clothing.

¾ DO NOT use or store the product where contact with electrified wires is likely.

¾ Always inspect the usage area before using the product & implement precautions that account for conditions.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious

personal injuries or even be killed. To reduce the likelihood of injury:

x Failure to read and understand the entire manual before assembling, installing, using or servicing the

product is a misuse of the product.

x Read the manual to refresh your understanding of proper use and maintenance procedures.

x DO NOT attempt to resolve any problem(s) with the product unless you are both authorized to do so and certain that

it will be safe to use afterwards.

x DO NOT modify the product in any way UNLESS you first obtain written approval from Vestil. Unauthorized

modifications might make the lift unsafe to use.

x DO NOT exceed the maximum rated load (see Label 287 on product).

x Inspect the product before each use.

A. DO NOT use this product if the inspection reveals structural damage. Examples of structural damage include,

but are not limited to, the following: 1) Cracked, broken or significantly deformed load-bearing members; 2)

cracked welds; 3) missing, or deformed safety chain/strap; 3) corrosion, severe wear, or other condition that

affects the ability of the product to support weight or itself. Replace each part that fails to pass an inspection,

and DO NOT use the product until it is fully restored to normal condition.

B. DO NOT use the product if any unusual noise or movement is observed. If a malfunction occurs, remove the

unit from service and notify your supervisor & maintenance personnel about the issue.

x DO NOT use this device UNLESS all product labels (see “Label Placement Diagram”) are readable and undamaged.

Proper use, maintenance, and storage are essential for this product to function properly.

o Always use this product in accordance with the instructions in this manual and consistent with any training relevant

to machines, devices, etc. used in conjunction with this product.

o Keep the product clean & dry. Lubricate moving parts.

o FOR HYDRAULIC UNITS: Do not use brake fluid or jack oils in the hydraulic system. If oil is needed, use an anti-

wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 cSt @ 40°C), or Dexron transmission fluid.

o Contact the manufacturer for MSDS information

Page 3

Page 4

Page 5

Page 6

Page 7

DRAWING NUMBER

E

E

DWG #:

REV.

073003JY-1A

REV.

ECR #

DATE

REVISIONS

INITIAL

073003JY-1A

25

REV.

*

16 17 19 20

26

14

10

12

3 13

27

23

11

24

22

8

16 17 18

25

21

9

6

ITEM REQ PART NO. DESCRIPTION

ITEM REQ PART NO. DESCRIPTION

1 1 4JY1119 BASE

1 1 4JY1119 BASE

2 1 1212SR BATTERY CHARGER

2 1 1212SR BATTERY CHARGER

3 1 01-033-024 18/3 W/4 PIN PLUG

3 1 01-033-024 18/3 W/4 PIN PLUG

4 4 37927 TINNERMAN CLIP

4 4 37927 TINNERMAN CLIP

5 1 99- 023-001 RESERVOIR

5 1 99- 023-001 RESERVOIR

6 1 99-034-013 BATTERY STRAP

6 1 99-034-013 BATTERY STRAP

7 1 24DC36 BATTERY

7 1 24DC36 BATTERY

8 1 BV-48 BREATHER

8 1 BV-48 BREATHER

9 1 15-533-013 CABLE, BATTERY 23" BLACK

9 1 15-533-013 CABLE, BATTERY 23" BLACK

10 1 15-533-014 CABLE, BATTERY 23" RED

10 1 15-533-014 CABLE, BATTERY 23" RED

11 2 23305 SHCS UTILITY GRADE

11 2 23305 SHCS UTILITY GRADE

HIGH COLLAR LOCK WAS HER

2 33688

2 33688

2 33008 USS FLAT WASHER Z PLATED

2 33008 USS FLAT WASHER Z PLATED

12 1 99-135-011 MOTOR,12VDC

12 1 99-135-011 MOTOR,12VDC

13 1 15-022-004 RELAY, START SOLENOID

13 1 15-022-004 RELAY, START SOLENOID

14 1 HS64 CLAMP, WORM GEAR

14 1 HS64 CLAMP, WORM GEAR

15 1 BG-12V GAUGE, BATTERY INDICATOR

15 1 BG-12V GAUGE, BATTERY INDICATOR

16 3 ZB2BZ009 BASE,CONTACT BLOCK

16 3 ZB2BZ009 BASE,CONTACT BLOCK

17 3 ZB2BE101 CONTACT BLOCK N.O.

17 3 ZB2BE101 CONTACT BLOCK N.O.

18 2 ZB2BA2C

18 2 ZB2BA2C

19 1 KEY SWITCH, 2 POSITION

19 1 KEY SWITCH, 2 POSITION

20 1 01-134-007 LEGEND, ON - OFF

20 1 01-134-007 LEGEND, ON - OFF

21 1 091802JY FIBERGLASS COVER

21 1 091802JY FIBERGLASS COVER

22 1 HS52 CLAMP, WORM GEAR

22 1 HS52 CLAMP, WORM GEAR

23 1 01-143-906 PUMP

23 1 01-143-906 PUMP

24 1 01-627- 010 MANIFOLD ASSM ( SEE PAGE 2)

24 1 01-627- 010 MANIFOLD ASSM ( SEE PAGE 2)

25 2 29201 TPHMS, Z PLATED

25 2 29201 TPHMS, Z PLATED

26 2 29185 TPHMS, Z PLATED

26 2 29185 TPHMS, Z PLATED

27 4 23255 SHCS UTILITY GRADE

27 4 23255 SHCS UTILITY GRADE

4 33687 HIGH COLLAR LOCK WASHER

4 33687 HIGH COLLAR LOCK WASHER

28 1 152400-03 MOLDED CORD

28 1 152400-03 MOLDED CORD

29 1 150CCTM.OEM CONNECTOR, CHARGE

29 1 150CCTM.OEM CONNECTOR, CHARGE

30 10" 3MT ST3540 1"HOOK&LOOPPRESS SENSITIV

30 10" 3MT ST3540 1"HOOK&LOOPPRESS SENSITIV

HIGH COLLAR LOCK WAS HER

OPERTOR, BLACK, NON-ILLUM.

OPERTOR, BLACK, NON-ILLUM.

1

4

THIS PRINT IS CONFIDENTIAL AND IS

THE PROPERTY OF

THIS PRINT SHALL NOT BE USED, COPIED OR REPRODUCED

BE REVEALED ANY MANNER TO ANYONE UNLESS WRITTEN

T & S EQUIPMENT CO.

IN WHOLE OR IN PART NOR SHALL THE CONTENTS

PERMISSION IS OBTAINED FROM

T & S EQUIPMEN T CO.

REMOVE ALL BURRS AND SHARP EDGES

CONCENTRICCONCENTR

ANGLES

DECIMALS

FRACTIONSFRACTIONS

.006 TIR

+/- 0° 30'

x.xxx +/- .005

x.xx +/- .010

x.x +/- .025

+/- 1/32 +/- 1/16

.060 TIR

+/- 1° 0'

+/- .015

TOLERANCE MACHINE WELDMENT

4

7

5

28 29

30

2

T & S EQUIPMENT COMPANY

SCALE:

DATE:

MATERIAL:

NTS

07/30/03

APPROVED BY:

DC MODULAR POWER UNIT

DRAWN BY:

J.YOUNG

SIZE: A

DRAWING NUMBER:

073003JY-1A

REV:

Page 8

DRAWING NUMBER

073003-JY-1B

REV.

*

DWG #:

REV.

REV.

073003JY-1B

ITEM REQ PART NO. DESCRIPTION

ITEM REQ PART NO. DESCRIPTION

31 1

31 1

32 1 568-011-BN70

32 1 568-011-BN70

33 1 99-153-015 VALVE,CARTRIDGE,NC

33 1 99-153-015 VALVE,CARTRIDGE,NC

34 1 99-034-010 COIL, WEATHER TITE PLUG

34 1 99-034-010 COIL, WEATHER TITE PLUG

35 1 99-153-006 VALVE, PRESSURE RELIEF

35 1 99-153-006 VALVE, PRESSURE RELIEF

36 1 568-334-BN70

36 1 568-334-BN70

37 1 99-531-005 FILTER

37 1 99-531-005 FILTER

38 1

38 1

39 1 01-127-010 MANIFOLD

39 1 01-127-010 MANIFOLD

40 1 6801--06-06-NOW MJ-MAORB 90 DEG.

40 1 6801--06-06-NOW MJ-MAORB 90 DEG.

41

41

ECR #

568-015-BN70 O-RING

568-015-BN70 O-RING

99-153-038 FLOW CONTROL, 1.0 GPM

99-153-038 FLOW CONTROL, 1.0 GPM

1 99-153-011 VALVE, CHECK

1 99-153-011 VALVE, CHECK

DATE

O-RING

O-RING

O-RING

O-RING

REVISIONS

INITIAL

35

34

38

32

33

31

40

41

39

36

37

THIS PRINT IS CONFIDENTIAL AND IS

THE PROPERTY OF

THIS PRINT SHALL NOT BE USED, COPIED OR REPRODUCED

BE REVEALED ANY MANNER TO ANYONE UNLESS WRITTEN

T & S EQUIPMENT CO.

IN WHOLE OR IN PART NOR SHALL THE CONTENTS

PERMISSION IS OBTAINED FROM

T & S EQUIPMEN T CO.

REMOVE ALL BURRS AND SHARP EDGES

CONCENTRICCONCENTR

ANGLES

DECIMALS

FRACTIONSFRACTIONS

.006 TIR

+/- 0° 30'

x.xxx +/- .005

x.xx +/- .010

x.x +/- .025

+/- 1/32 +/- 1/16

.060 TIR

+/- 1° 0'

+/- .015

TOLERANCE MACHINE WELDMENT

T & S EQUIPMENT COMPANY

SCALE:

NTS

DATE:

07/30/03

MATERIAL:

APPROVED BY:

DC MODULAR POWER UNIT

DRAWING NUMBER:

073003JY-1B

DRAWN BY:

J.YOUNG

SIZE: A

REV:

Page 9

DRAWING NUMBER

REV.

DWG #:

073003JY-2A

REV.

ECR #

DATE

REVISIONS

INITIAL

073003JY-2A

REV.

9

7

21

12

10

11

14

16 17 18

16 17 19 20

ITEM REQ PART NO. DESCRIPTION

10

15

13

3

22

8

2

ITEM REQ PART NO. DESCRIPTION

1 1 4JY1119 BASE

1 1 4JY1119 BASE

2 1 ELECTRIC BOX (SEE PAGE 2)

2 1 ELECTRIC BOX (SEE PAGE 2)

3 1 21-034-005 AC ADAPTER PLUG

3 1 21-034-005 AC ADAPTER PLUG

4 4 37927 TINNERMAN CLIP

4 4 37927 TINNERMAN CLIP

5 1 99-023-001 RESERVOIR

5 1 99-023-001 RESERVOIR

6 1 MOTOR BRACE

6 1 MOTOR BRACE

4 23255 SHCS UTILITY GRADE

4 23255 SHCS UTILITY GRADE

7

7

4 33687 HIGH COLLAR LOCK WASHER

4 33687 HIGH COLLAR LOCK WASHER

8 1 BV-48 BREATHER

8 1 BV-48 BREATHER

2 29185 TPHMS, Z PLATED

2 29185 TPHMS, Z PLATED

9

9

2 29201 TPHMS, Z PLATED

2 29201 TPHMS, Z PLATED

10

10

11 2 23305 SHCS UTILITY GRADE

11 2 23305 SHCS UTILITY GRADE

2 33688

2 33688

2 33008 USS FLAT WASHER Z PLATED

2 33008 USS FLAT WASHER Z PLATED

12 1 01-627-010 MANIFOLD ASSM (SEE PAGE 2)

12 1 01-627-010 MANIFOLD ASSM (SEE PAGE 2)

13 1 01-143-906 PUMP

13 1 01-143-906 PUMP

14 1 HS52 CLAMP, WORM GEAR

14 1 HS52 CLAMP, WORM GEAR

15 1 091802JY FIBERGLASS COVER

15 1 091802JY FIBERGLASS COVER

16 3 ZB2BZ009 BASE,CONTACT BLOCK

16 3 ZB2BZ009 BASE,CONTACT BLOCK

17 3 ZB2BE101 CONTACT BLOCK N.O.

17 3 ZB2BE101 CONTACT BLOCK N.O.

18 2 ZB2BA2C

18 2 ZB2BA2C

19 1 ZB2BG4C SWITCH, KEY, 2 POSITION

19 1 ZB2BG4C SWITCH, KEY, 2 POSITION

20 1 01-134-007 LEGEND, ON - OFF

20 1 01-134-007 LEGEND, ON - OFF

21 1 99-135-003 MOTOR, ELECTRIC, 1PH

21 1 99-135-003 MOTOR, ELECTRIC, 1PH

22 6 11005 HHCS, Z PLATED

22 6 11005 HHCS, Z PLATED

6 33004 USS FLAT WASHER, Z PLATED

6 33004 USS FLAT WASHER, Z PLATED

6 33618 LOCK WASHER, Z PLATED

6 33618 LOCK WASHER, Z PLATED

6 36102 HEX NUT, Z PLATED

6 36102 HEX NUT, Z PLATED

HIGH COLLAR LOCK WASHER

HIGH COLLAR LOCK WASHER

OPERATOR, BLACK, NON-ILLUM.

OPERATOR, BLACK, NON-ILLUM.

22

22

1

6

22

4

THIS PRINT IS CONFIDENTIAL AND IS

THE PROPERTY OF

THIS PRINT SHALL NOT BE USED, COPIED OR REPRODUCED

T & S EQUIPMENT CO.

IN WHOLE OR IN PART NOR SHALL THE CONTENTS

BE REVEALED ANY MANNER TO ANYONE UNLESS WRITTEN

PERMISSION IS OBTAINED FROM

T & S EQUIPMENT CO.

REMOVE ALL BURRS AND SHARP EDGES

CONCENTRICCONCENTR

ANGLES

DECIMALS

FRACTIONSFRACTIONS

x.xxx +/- .005

x.xx +/- .010

x.x +/- .025

.006 TIR

+/- 0° 30'

+/- 1/32 +/- 1/16

.060 TIR

+/- 1° 0'

+/- .015

TOLERANCE MACHINE WELDMENT

5

4

T & S EQUIPMENT COMPANY

SCALE:

NTS

DATE:

07/30/03

MATERIAL:

APPROVED BY: DRAWN BY:

J.YOUNG

SIZE: A

AC MODULAR POWER UNIT

DRAWING NUMBER:

073003JY-2A

REV:

Page 10

DRAWING NUMBER

REV.

DWG #:

073003JY-2B

REV.

ECR #

DATE

REVISIONS

INITIAL

073003JY-2B

REV.

17

14

12

13

10

18

19

16

20

15

ITEM REQ PART NO. DESCRIPTION

ITEM REQ PART NO. DESCRIPTION

1 4 71616 TSHMS, SS

1 4 71616 TSHMS, SS

2 1 01-129-001 TRANSFORMER

2 1 01-129-001 TRANSFORMER

3 1 132560 CONTACTOR, MOTOR

3 1 132560 CONTACTOR, MOTOR

4 4 27531 PHSMS, Z PLATED

4 4 27531 PHSMS, Z PLATED

5 4 32028 HWH TEK DRILL & TAP

5 4 32028 HWH TEK DRILL & TAP

6 3" TB-TRACK RAIL, DIN

6 3" TB-TRACK RAIL, DIN

7 1 01-029-006 JUCTION BOX

7 1 01-029-006 JUCTION BOX

8 1 AB66JP PANEL, JUNCTION BOX

8 1 AB66JP PANEL, JUNCTION BOX

9 4 C500 CONNECTOR, ROMEX, 2 SCREW

9 4 C500 CONNECTOR, ROMEX, 2 SCREW

10 1 01-127-010 MANIFOLD

10 1 01-127-010 MANIFOLD

11 1 6801-06-06-NOW MJ-MAORB 90 DEG.

11 1 6801-06-06-NOW MJ-MAORB 90 DEG.

12 1 99-153-011 VALVE, CHECK

12 1 99-153-011 VALVE, CHECK

568-015-BN70 O-RING

13 1

13 1

14 1 568-011-BN70

14 1 568-011-BN70

15 1 99-153-015 VALVE,CARTRIDGE,NC

15 1 99-153-015 VALVE,CARTRIDGE,NC

16 1 99-034-008 COIL, 24V AC

16 1 99-034-008 COIL, 24V AC

17 1 99-153-006 VALVE, PRESSURE RELIEF

17 1 99-153-006 VALVE, PRESSURE RELIEF

18 1 568-334-BN70

18 1 568-334-BN70

19 1 99-531-005 FILTER

19 1 99-531-005 FILTER

20

20

568-015-BN70 O-RING

O-RING

O-RING

O-RING

O-RING

1

1

99-153-038 FLOW CONTROL, 1.0 GPM

99-153-038 FLOW CONTROL, 1.0 GPM

9

4

5

2

7

1

5

3

REMOVE ALL BURRS AND SHARP EDGES

CONCENTRICCONCENTR

THIS PRINT IS CONFIDENTIAL AND IS

THE PROPERTY OF

THIS PRINT SHALL NOT BE USED, COPIED OR REPRODUCED

T & S EQUIPMENT CO.

IN WHOLE OR IN PART NOR SHALL THE CONTENTS

BE REVEALED ANY MANNER TO ANYONE UNLESS WRITTEN

PERMISSION IS OBTAINED FROM

T & S EQUIPMENT CO.

ANGLES

DECIMALS

FRACTIONSFRACTIONS

TOLERANCE MACHINE WELDMENT

.006 TIR

+/- 0° 30'

x.xxx +/- .005

x.xx +/- .010

x.x +/- .025

+/- 1/32 +/- 1/16

.060 TIR

+/- 1° 0'

+/- .015

9

7

8

6

9

T & S EQUIPMENT COMPANY

SCALE:

NTS

07/03/03

DATE:

MATERIAL:

APPROVED BY: DRAWN BY:

J.YOUNG

SIZE: A

AC MODULAR POWER UNIT

DRAWING NUMBER:

073003JY-2B

REV:

Page 11

Page 12

rev. 1/23/2013 Product manual, operation instructions.doc

Label Placement Diagram

LIMITED WARRANTY

Page 13

rev. 1/23/2013 Product manual, operation instructions.doc

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the part is

covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the following

original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It also covers

defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses, wheels, seals,

brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original components is 1 year. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

x Product misuse;

x Negligent operation or repair;

x Corrosion or use in corrosive environments;

x Inadequate or improper maintenance;

x Damage sustained during shipping;

x Collisions or other incidental contacts causing damage to the product;

x Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive and/or

abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Loading...

Loading...