Page 1

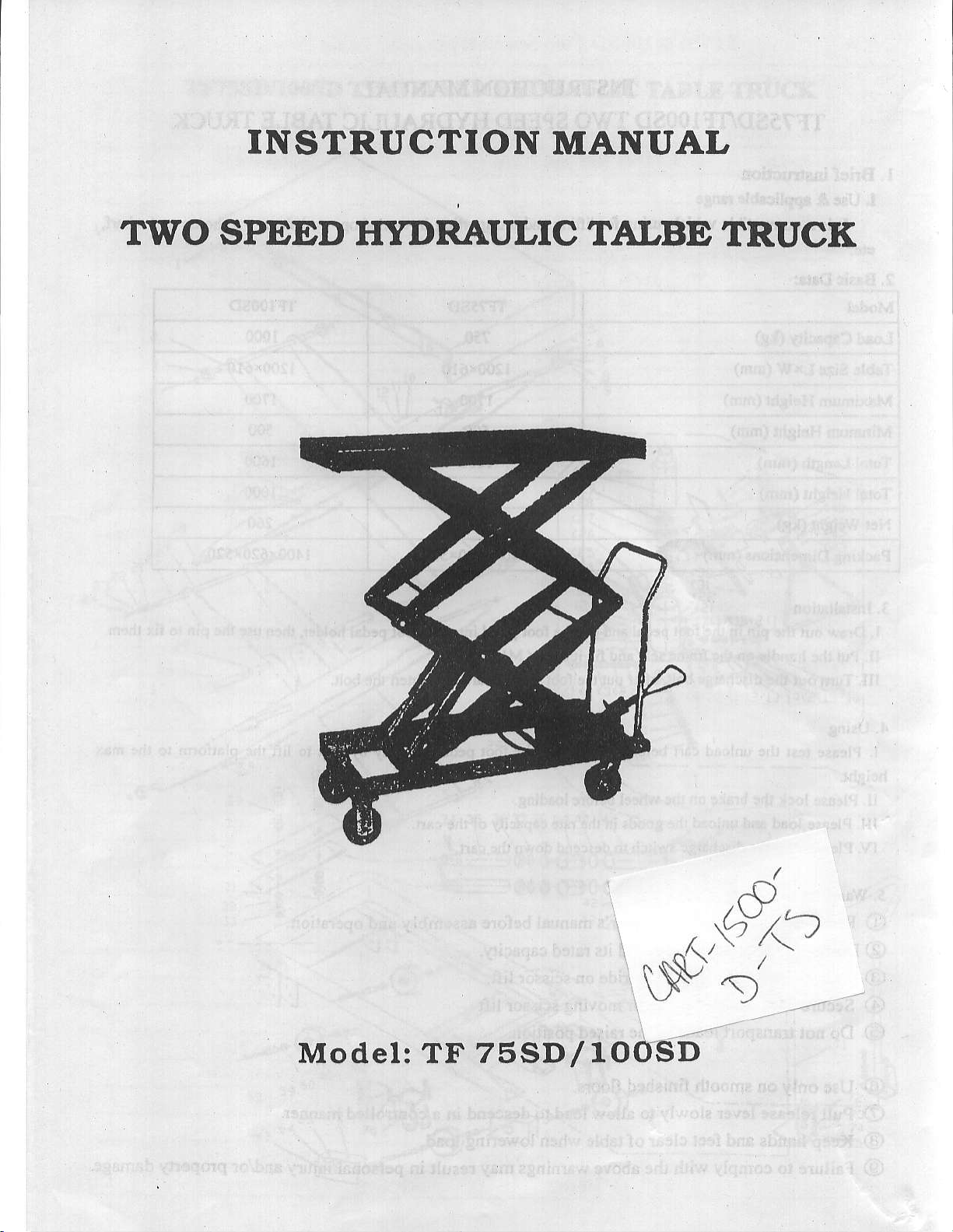

INSTRUCTION

MANUAL

TWO SPEED

ITYDRAULIC TALBE

TRUCK

Model: TF 7sSD/TOOSD

Page 2

INSTRUCTIONMANUAL

TF?sSDIFIOOSD

L Brief

I. Usc

atc.

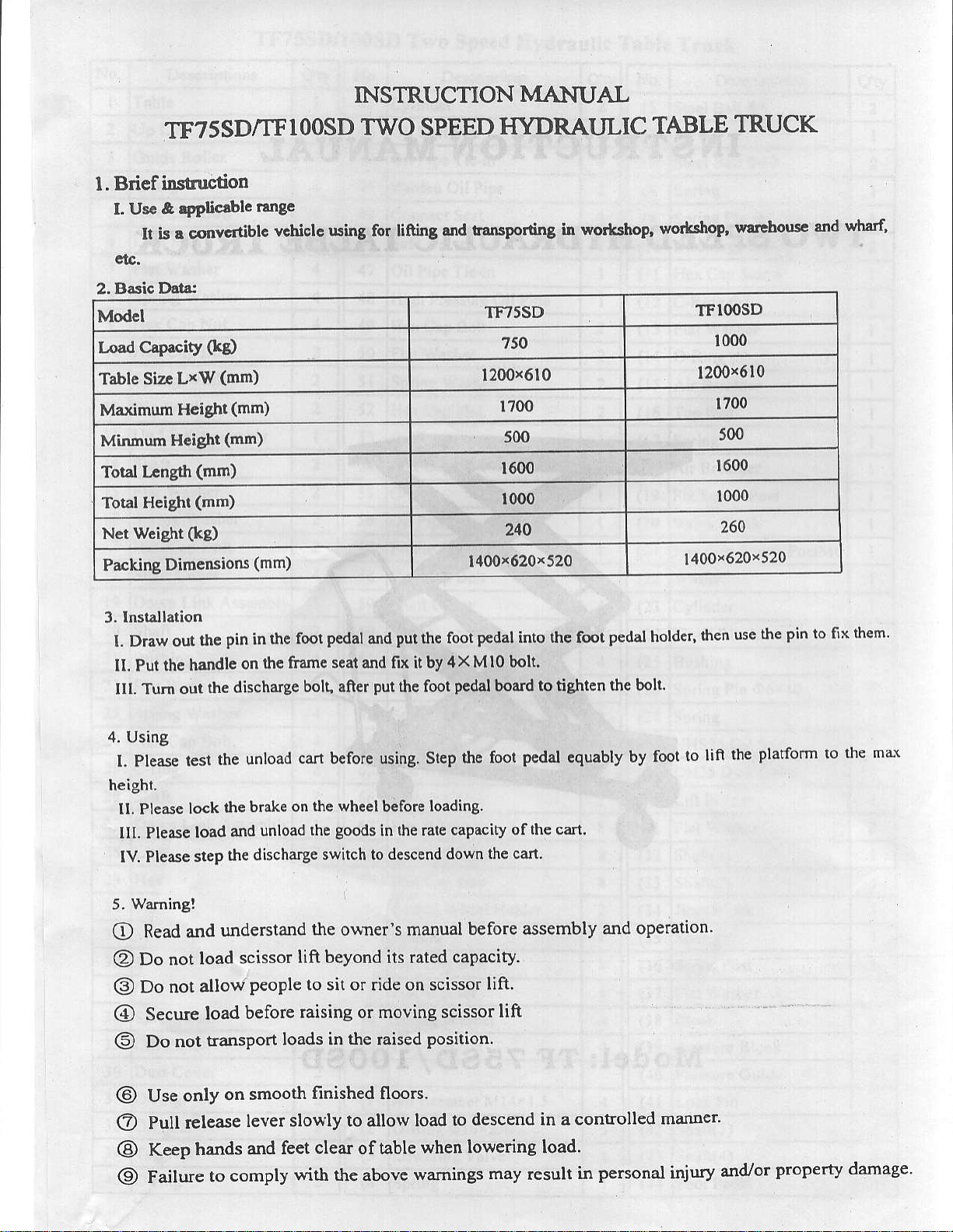

2. Basic Dda:

Modcl

Losd Clpacity

Table Siz.

Maximum

Minmum

Tot3l

Total Height

Net Weight

Packing Dimensions

instruction

& lpplicdblc

It is s cqrvc

(kg

(!tln)

LxW

Hcight

Height

lrngth

(mm)

(mm)

(k8)

(mm) 1700

(mm)

FTYDRAI.JLIC

TF75SD

r.ng.

v.hicla uting fot linilg

ibl.

TWO SPEED

.trd tansPorting

750

1200x610

500

1600

1000

240

(mm) 1400r 620

in wo*shoP,

x

520

TABLE

wortslpP,

TRUCK

watlhous'

TFIOOSD

1000

1200x610

1700

500

1600

1000

260

1400x620x520

snd

wharf,

3. lnslallation

I. Draw out

Il. Put the handlc

IIl. Tum

4. Using

l. Please

height.

tl. Pledre

lll. Please

lv. Please

Warning!

5.

Read and

O

Do not

@

Do not

@

Secure

@

Do

@

the

the

out

tesl

lock

load

slep

load

allow

load

not transport

pin

the foot

in

framc scal and fix it by 4

the

on

discharge

unload

the

brake on

the

and

discharge

lhe

bolt, aner

can before using. Step

unload

understand

scissor

lift beyond its rated

people to sit

before

raising or moving scissor

loads

pedal

the wheel

goods

the

swilch

the

o\rner's manual

put

and

put

thc foot

before

the rate capacity ofthe

in

to descend

or ride on

in the

raised

foot

the

x

Pcdal

lhe foot

loading.

down the

befo.e assembly

capacity.

scissor

position

p€dal

into the foot

Mlo bolt.

board to tighten

pcdal

cafi.

can

lift.

lift

pedal

thc bolt.

equably

by fool

and operation

holder,

to

then

lifi

pin

the

use

platform to the

the

to fix lhem'

ma\

@

@

@

@

only

Use

release

Pull

Keep

hands

Failure

smooth

on

lever sloely

and

comply

to

finished floors.

to

allolv

feet clear oftable

with the above

load to

descend in a conEolled

when lowering load.

wamings

may

result

personal

in

manner

injury

and/or

property damage

Page 3

TT'7sSD/IOOSD

TWO

SPEED EYDRAT'LIC

6

7

TABI.E TRUCI(

3!

.4.

(::

t<2

36

'-.\

F#A

(11t9(e

h{tK

(l

r!5

ll

r

r6l

7.

'/.';

i!

Jo

js

ir

rii"

gn

a:s--r

-73

*75

ii

il

li

li

Page 4

TF75SD/I00SD

Two Speed

Hydrautic

Table

Truck

No.

2 Up

Descriplions

laDte

Link

Assembly

3 Cuide Roller

4

C-ring

5

llex Cap Bolt 4

6 Link

7 Flat

l0 Hex

ll

t2 Big

ll

l4 Shaft 2

l6 Spring Washer 2

l7 Hex

IE

I9

Seat

Washer 4

Spring Washer

Hex

Nut 4

Cap

Bolt

Cap

Spring Washer 2

Washer 2

Up Link Assembly

Flat

Washer 2

Bolr 2

Cap

Shaft Cover

Dorvn Link Assembly I

20 Shaft

:l Bushing 4

Flat Washer

Spring Washer +

?l Hex

C-ring

26

Shaft

7i Do\}n

23

Link Seat

:9

Hex Cap Bolt

t0 Fi\ing

il Flat Washer

Bolt J

Cap

Link Assembly I

Seat

3: Spring Washer

He\ Cap Nut

j.{

Spring Pin

i5 Lift Piston z

Dust

Cover

3i

O-ring

i3

OilSeal :

i9

Top

Nu!

r0

O-ring

Q'ry

4

t

4

2

4

No.

4l

Cylinder

42

Oil

43

Oil Pipc Tie.in

44

Harden

45

Connect

46

Safe Valve

47

Oil Pipe

48

High Pressure

49

Hex

50 Flat

5l

Spring

Hex Cap

Descriptions

Seal Sets

Oil Pipe

Seat

Tie-in

Oil Pipe

Cap Bolt

Washer

Washer

Nut

OilBox

5.1 Hex

55

58

Cap Bolt

O-ring

OilPipe

Frame

Hex Cap

Shaft Cover

Seat

Bolt

60

6l

Wheel

Her Cap Nut

Semicircle Screrv

Spring

FIat \\'asher

Protect

67 Flat Washer

68

Spring

69 Hex

70

S\\ivel \\'heel

7l

Handle

12

Hex Cap Bolt l

FIat \\'asher 4

Spring Washer

1i Hex

Air Breather

(2

O-Ring

(3

Lowering Valve

(.1

Spring

\\'asher

Co\er

Washer

Cap Bolt

Holder

Cap N"ut {

IvI l4!

Ol6x2.4 )

L5

Q'ty

2

t

2

2

2

2

2

+

4

E

'+

2

2

8

8

8

I

-l

4

No.

(6

(r

(e

(10

(l

I Hex Cap Screw

(t2

(13

(14

(15

(16

(t7

(16

(19

(20

(21

(ll

(23

Descriptions

Ball OE

Steel

Spring I

Ball Ol0

Steel

Spring I

(D5x

Spring

Dischalge

C-Ring O7

Flat

O-Ring I

Air Breather I

Pin

Washer

l6

Block

Top Rod I

Spring I

Breather

Air

Fix

Screw Post I

Valve Block

He\ Cap Screw Postll6 I

Washer I

Cylinde. I

(24

Bushing

(?6

Spring

(27

Spring I

(18

UHS25

trftl) ljusl Lo\ea

(30

Lift Piston

(il

Flat Washer

Shaft(l)

(33

Shaft(?)

(ll

Jiont Block

(i5

Spring

(i6

Screw

(37

Flar \! asher

(18

Block

(39

Pressure

(10

Pressure Guide

(tI

(42

Shaft(3)

(Jl

Shaft(4)

(ll

Fool

Pin 06x.10 I

Oil Seal

Post

Block

Pedal I

Q'ty

z

.,

I

2

I

I

I

I

I

I

I

Page 5

Vestil

Quality

Assurance and

Cart 400, 6501T, 800D,

Cart Model

Manufacture

Inspectors Narne

Inspection Date

Empty Tests

Numbe r

Down Timc

Maximunr Fleight

Mirinun l-teight

Weight Tiists

Number stlokes I{S

Nunber

shifr weight

Test Weight

Down Tinre

Date

strokes

of str0kes I..S

up

Deviation Inspection Sheet

1000, 1500

Lrro

),rlJ,'l

W^/

f\t

Seconds

I7

iDches

67,0

7')

J

kl.J

l.!

Inches

Pounds

Pounds

Seconds

14,[

l[5r

Leak Test

(hold full load for 15min w/out

dlift down)

Acceptable

(Reasons if Not)

Deviations from Norur

#sno

\lzs/No

Page 6

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the part is

covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It also

covers defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses, wheels,

seals, brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original components is 90 days. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive environments;

Inadequate or improper maintenance;

Damage sustained during shipping;

Collisions or other incidental contacts causing damage to the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive

and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2016 Vestil Manufacturing Corp.

Loading...

Loading...