Page 1

10/27/2010 rev. 10/27/2010 APS manual.doc

ASP-SERIES ADJUSTABLE STEP MATE STANDS

INSTRUCTION MANUAL

VESTIL MANUFACTURING CORP.

2999 NORTH WAYNE STREET, P.O. BOX 507, ANGOLA, IN 46703

TELEPHONE: (260) 665-7586 -OR- TOLL FREE (800) 348-0868

FAX: (260) 665-1339

URL: WWW.VESTILMFG.COM EMAIL: SALES@VESTIL.COM

NOTE: Compliance with regulations, codes, and/or statutory (non-voluntary) standards enforced in the

Table of Contents Table of Figures

Product Introduction……………………….......... 2 Fig. 1A “ASP-PORT”…………………………………………….. 3

Safety Principles……………………................... 2 Fig. 1B “[ASP-PORT] Hardware kit”………………..………….. 3

Safety Guidelines…………………..................... 3 Fig. 1C “ASP-PORT fastened to step stand”…………...…….. 3

ASP-PORT installation & use…………………… 3 Fig. 2A “ASP-PORT-HT”………………..…………..…...……… 4

ASP-PORT-HT features & use instructions…… 4 Fig. 2B “Engaging side frame of step stand”………………………… 4

Inspections & Maintenance……………………... 4 Fig. 3 “Stand leveling”……………………………5

Fig. 4 “Product markings and labels”…………………………... 5

location where the product is used is exclusively the responsibility of the end-user.

Cop

yright 2010 Vestil Manufacturing Corp.

p. 1 of 5

Page 2

10/27/2010 rev. 10/27/2010 APS manual.doc

PRODUCT INTRODUCTION

Thank you for purchasing an ASP-series “Adjustable Step-Mate Stand” (“step stand,” or

“steps”) made by Vestil Manufacturing Corporation (“Vestil”). Our step stands are durable, highquality products that combine safety-enhancing features and reliable mechanisms. Although

use and maintenance procedures are intuitively obvious, all persons who might use or maintain

this product must familiarize themselves with the instructions provided in this manual.

The standard design incorporates serrated, no-slip tread and independently adjustable legs. Option packages include:

stainless steel or aluminum construction rather than standard painted steel; “ASP-PORT” bolt-on wheel and handle kit;

“ASP-PORT-HT” specially-adapted dolly with pneumatic wheels. Dimensions and other product specifications appear in

the following table:

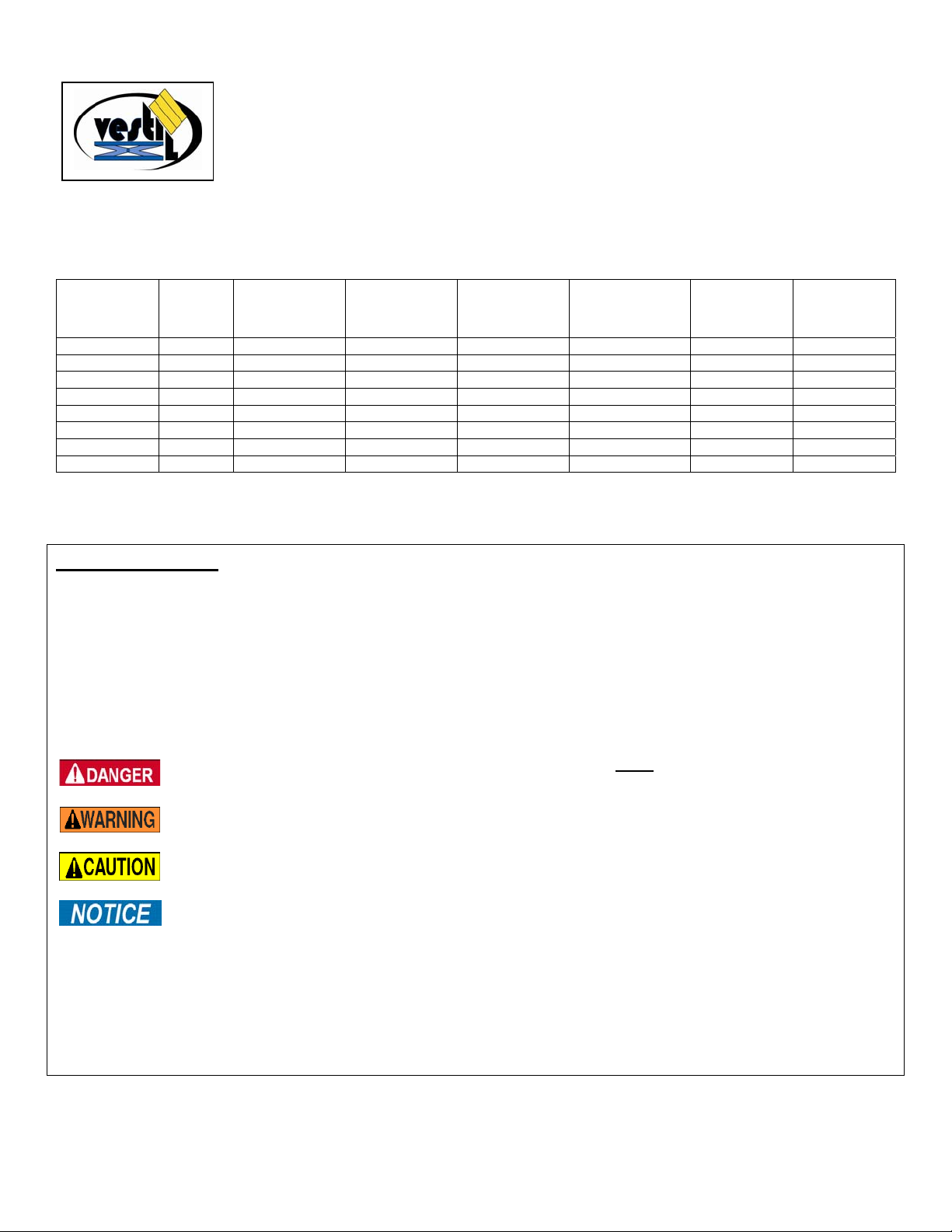

Overall size

(WxL) in inches

(~cm)

Number of

steps

Standard

painted steel

model

designation

Net weight in

pounds (~kg)

Stainless steel

model

designation

Net weight in

pounds (~kg)

24 x 24 2 ASP-24 25 (11.4kg) ASP-24-SS 28 (12.7kg) ASP-24-A 19 (8.6kg)

36 x 24 2 ASP-36 33 (15kg) ASP-36-SS 36 (16.4kg) ASP-36-A 23 (10.5kg)

48 x 24 2 ASP-48 38 (17.3kg) ASP-48-SS 42 (19.1kg) ASP-48-A 25 (11.4kg)

60 x 24 2 ASP-60 44 (20kg) ASP-60-SS 48 (21.8kg) ASP-60-A 28 (12.7kg)

72 x 24 2 ASP-72 47 (21.4kg) ASP-72-SS 52 (23.6kg) ASP-72-A 30 (13.6kg)

24 x 36 3 ASP-24-3 40 (18.2kg) ASP-24-3-SS 44 (20kg) ASP-24-3-A 26 (11.8kg)

36 x 36 3 ASP-36-3 51 (23.2kg) ASP-36-3-SS 56 (25.5kg) ASP-36-3-A 32 (14.5kg)

48 x 36 3 ASP-48-3 62 (28.2kg) ASP-48-3-SS 68 (31kg) ASP-48-3-A 37 (16.8kg)

Aluminum

model

designation

Net weight in

pounds (~kg)

Safety Principles

Vestil Manufacturing Corp. recognizes the critical importance of workplace safety. However, although Vestil diligently

strives to identify foreseeable hazardous situations, this manual cannot address every conceivable danger. The end-user

is ultimately responsible for exercising sound judgment at all times.

This manual will acquaint persons authorized to use and/or maintain this step stand with safe use and maintenance

procedures. Therefore, each person, who might use or perform maintenance on the step stand, must read and

understand every instruction BEFORE using the device or performing maintenance. Users should have access to

the manual at all times and should routinely review the directions.

This manual uses SIGNAL WORDS to classify personal injury risks and situations that might lead to property damage,

as well as to draw attention to safety message(s). The reader must understand that each signal word indicates the

seriousness of the identified hazard.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

Identifies practices likely to result in product/property damage, such as operation that might damage the

Employers are responsible for training employees to use the product properly. If you do not understand an instruction,

ask your supervisor or employer for assistance, because failure to follow the directions in this manual might result in

serious personal injury or even death.

Vestil is not liable for any injury or property damage that occurs as a consequence of failing to apply either: 1) the

instructions that appear in this manual; or 2) the information provided on labels affixed to the product. Furthermore, failure

to exercise good judgment and common sense might result in property damage, serious personal injury or death. Such

failure is solely the fault of the person(s) using the step stand.

INJURY. Use of this signal word is limited to the most extreme situations.

INJURY.

injury.

step stand.

Cop

yright 2010 Vestil Manufacturing Corp.

p. 2 of 5

Page 3

10/27/2010 rev. 10/27/2010 APS manual.doc

SAFETY GUIDELINES

Study the entire manual before you use the product for the first time and before each subsequent use

Failure to read and understand the instructions included in this manual before

using or servicing the step stand constitutes misuse of the product.

. Read the

manual to refresh your understanding of the safe use, inspection and maintenance procedures explained on p. 3-5. If

questions remain about the product after you finish reading the manual, ask your employer or supervisor for help. DO

NOT attempt to resolve any problems with the step stand unless you are authorized to do so and are certain

safe to use afterwards.

that it will be

Electrocution might result if the step stand contacts electrified wires. Reduce the likelihood of electrocution

by applying common sense:

DO NOT contact electrified wires with any part of the step stand;

DO NOT use the steps in an area where contact with electrified wires is likely;

DO NOT use the steps close to electrified wires or other sources of electricity;

Before using the steps, always inspect the usage area for unusual conditions that require special precautions.

Read the entire manual before installing option kits or adjusting or using the step stand. If

questions remain after you finish reading the manual, ask your supervisor or employer for clarification. Improper assembly

or installation might result in serious personal injuries:

ALWAYS level the step stand before using it. (See “Leveling the step stand” on p. 5).

DO NOT store items, materials, etc. on the step stand.

DO NOT place weight that exceeds the maximum rated load (capacity) on one or more steps.

DO NOT use a structurally compromised step stand. Examples of structural damage include: broken or severely

damaged posts (legs), steps, or frame, and damage caused by rust or corrosion. Inspect the step stand according to

the inspection instructions on p. 4. DO NOT use the steps unless the unit and all installed options pass every part of

the inspection.

ASP-PORT Option Package:

FIG. 1A:

ASP-PORT

(includes

hardware kit: 3

bolts, 3 flat

washers, 3 hex

nuts, and drill

bit

Bolt holes

Frame

supporting

uppermost

step

Bolt tab

(circled)

FIG. 1B: Hardware kit

Right side

FIG. 1C: ASPPORT fastened to

step stand

INSTALLATION AND USE INSTRUCTIONS

to the handle except as necessary to transport to step stand (see Step 5 below).

Step 1: Hold the PORT handle assembly up to the side of your ASP-series step stand;

then mark the stand with the locations of the 3 bolt holes. [NOTE: The right side of the

handle should roughly align with the rear legs. See diagram below.]

Step 2: Drill each of the holes using the 9/32in. drill bit included in the hardware kit.

.

Part

Number

Description Quantity

Item

No

1 14-525-001 Handle weldment 1

2

3

16-132-009

65078

Hard rubber wheel

1¼in. x 4in.

1/8in. x 1½in. zincplated cotter pin

2

2

4 ND87060 9/32 in. drill bit 1

¼ in. – 20 x 1½ in.

5 11009

zinc-plated HHCS #2

3

bolt

6 33004

7 37018

¼ in. type A narrow

flat washer

¼ in. – 20 zinc-plated

UNC nylock nut

3

3

ASP-PORT is NOT a handrail! Do not lean against or apply weight

Step 3: Fasten the handle to the step stand. Feed a bolt through each of the holes,

and secure it with a flat washer and ¼ in. hex nut.

Rear

legs

Wheel

shaft

Step 4: Adjust the height of the legs so that the step stand rests firmly on all 4 (rubber)

feet.

Step 5: To transport the step stand, grasp the top of the handle, brace the wheel shaft

with your foot, and tilt the stand toward you until the wheels contact the ground.

Cop

yright 2010 Vestil Manufacturing Corp.

p. 3 of 5

Page 4

10/27/2010 rev. 10/27/2010 APS manual.doc

ASP-PORT-HT features and use instructions:

FIG. 2A: ASP-PORT-HT

Load platform

Inspections & Mainten

At least 1 time per week, inspect:

1. Wearing parts:

Rubber feet –examine the feet for excessive wear, and replace them as necessary to provide a reliable, no-slip

contact with the ground.

Threaded legs

Fasteners - bolts, nuts, washers. Replace all damaged fasteners BEFORE using the steps again.

[ASP-PORT] Wheels – inspect the surface of each wheel for damage that could prevent smooth operation, and

examine the cotter pins and wheel rims. Replace wheel(s) if necessary.

Handle weldment – inspect welds for cracks

[ASP-PORT-HT] – examine wheels and check the inflation pressure. Add/remove air as required to match the

inflation recommendations of the wheel manufacturer. Inspect the cotter pins and washers that prevent the

wheels from sliding off of the wheel shaft. Replace any component(s) that is damaged too significantly to

function/operate properly.

2. Steps and frame: confirm that each step and the frame are structurally sound, not corroded or rusted. DO NOT use

the step stand if a step(s) are structurally compromised or dangerously rusted or corroded.

3. Welds: confirm that all welds are intact. DO NOT use the step stand if authorized maintenance personnel determine

that a damaged weld compromises the soundness of the steps.

4. Overall condition of Step stand, [ASP-PORT] handle, [ASP-PORT-HT] dolly: the structure should be clean, square

and rigid, and free of rust and corrosion. Remove dirt and debris. DO NOT use the step stand if rusted or corroded to

a degree that compromises structural integrity.

ance

FIG. 2B: Engaging side frame of step stand

FIG. 2C: Step stand frame-engaging brackets

Cop

yright 2010 Vestil Manufacturing Corp.

p. 4 of 5

USE INSTRUCTIONS

Step 1

either the left or right side of the

step stand.

Step 2

(see Fig. 2A) underneath the

step stand.

Step 3

push it forward until the side

frame of the step stand aligns

with the frame-engaging

brackets (see Fig.’s 2B and 2C);

-ORManually lift the stand and set it

down so that the side frame fits

inside the frame-engaging

brackets.

Step 4

with your foot, and then tilt the

dolly back. Transport the step

stand to the desired location.

Step 5

the frame and brackets separate;

-ORManually lift the step stand out of

the brackets.

: Position the dolly on

: Slide the load platform

: Tilt the dolly forward and

: Brace the wheel shaft

: Tilt the dolly forward until

Page 5

10/27/2010 rev. 10/27/2010 APS manual.doc

Leveling the step stand:

Before walking/standing on the step stand, make sure that the steps are level. Adjust the height of each of the legs to level the

stand. Grasp the rubber boot and turn the threaded leg counterclockwise to decrease height, or clockwise to in crease the height of

the particular corner of the stand.

Leg post

: Stand leveling

FIG. 3

Threaded leg

Turn counterclockwise to decrease height Turn clockwise to increase height

FIG. 4: Product Markings and Labels

(Label #213)

A

C

B

B (Label #726)

A

C (Large Vestil logo)

Copyright 2010 Vestil Manufacturing Corp.

p. 5 of 5

Loading...

Loading...