Page 1

Table of Contents Rev. 2/28/2020 ALL-T-2/4-GPT MANUAL

Vestil Manufacturing Corp.

Table of Contents

ALL-T-(2 or 4)-GPT

ALL-T-(2 or 4)-GPT-PT

ALL-T-(2 or 4)-GPT-L

ALL-T-(2 or 4)-GPT-10HP

ALL-T-(2 or 4)-GPT-L-10HP

Receiving instructions:

After delivery, remove the packaging from the product. Inspect the product closely to determine whether it

sustained damage during transport. If damage is discovered, record a complete description of it on the bill of lading. If

the product is undamaged, discard the packaging.

NOTE:

The end-user is solely responsible for confirming that product design, use, and maintenance comply with laws,

regulations, codes, and mandatory standards applied where the product is used.

Replacement Parts and Technical Assistance:

If you have questions that are not addressed in these instructions and to order replacement parts, labels, and

accessories, call (260) 665-7586 and ask for the Service and Parts Department. The department can also be

contacted online at http://www.vestilmfg.com/parts_info.htm.

Specifications…………………...…………................................................................................................................... 2, 3

Applicable National Standards…………………………………………………………………………………………………4

Signal Words……….……………….............................................................................................................................. 4

Safety Instructions.................................................................................................................................................... 4

Operating the Truck…………………….………............................................................................................................ 5

Fork Carriage Controls……...……………………………………………………………………………………................... 5 - 6

Lifting and Transporting Loads………….……………………………………………………………………………………. 6

Parking Brake………………………………................................................................................................................... 7

Disengaging the Transmission (Neutral Mode)...…………………………………………………………………………… 7

Record of Satisfactory Condition……………………………………………………………………………………………… 7

Inspections and Maintenance…………………………………………………………………………………………………. 7 - 8

Complete Exploded Views & Bill of Materials………………………………………………………………………………..9 - 16

ALL-T-2-GPT; ALL-T-4-GPT; ALL-T-2-GPT-L; & ALL-T-4-GPT-L…………………………………………………….. 9 - 10

ALL-T-2-GPT-10HP; ALL-T-4-GPT-10HP; ALL-T-2-GPT-L-10HP; & ALL-T-4-GPT-L-10HP…………................... 11-12

ALL-T-2-GPT-PT; ALL-T-4-GPT-PT; ALL-T-2-GPT-L-PT; & ALL-T-4-GPT-L-PT…………………………………… 13-14

ALL-T-2-GPT-PT-10HP; ALL-T-4-GPT-PT-10HP; ALL-T-2-GPT-L-PT-10HP; & ALL-T-4-GPT-L-PT-10HP…….. 15-16

Rear Wheel Axle Assemblies (1) and (2) Exploded Views and Bills of Materials………………………..……………... 17

Steering Handle Subassembly Exploded View and Bill of Materials……………………………………………………... 18

Power Unit Subassembly Exploded Views and Bills of Materials…………………………………………………………. 19-22

ALL-T-2-GPT & ALL-T-4-GPT…………………………………………………………………………………………….. 19

ALL-T-2-GPT-10HP; ALL-T-4-GPT-10HP; ALL-T-2-GPT-L-10HP; & ALL-T-4-GPT-L-10HP………………………. 20

ALL-T-2-GPT-PT; ALL-T-4-GPT-PT; ALL-T-2-GPT-L-PT; & ALL-T-4-GPT-L-PT…………………………………… 21

ALL-T-2-GPT-PT-10HP; ALL-T-4-GPT-PT-10HP; ALL-T-2-GPT-L-PT-10HP; & ALL-T-4-GPT-L-PT-10HP…….. 22

Sprocket Drive Subassemblies, Right Side, Exploded Views and Bills of Materials……………………………………. 23

Sprocket Drive, Subassemblies, Left Side, Exploded Views and Bills of Materials..…………………………………… 24

Labeling Diagram…….……………………………………………………………………………………………………..….. 25

Limited Warranty……………………………………………………………………………………………………………….. 26

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

http://www.vestilmfg.com/ e-mail: info@vestil.com

All Terrain Pallet Truck

Instruction Manual

Fax: (260) 665-1339

ALL-T-(2 or 4)-GPT-L-PT

ALL-T-(2 or 4)-GPT-PT-10HP

ALL-T-(2 or 4)-GPT-L-PT-10HP

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 1 of 26

Page 2

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

13” to 24”

(33.0cm to 61.0cm)

12,000 lb.

(5,454.5 kg)

1,000 lb.

(454.5kg)

549 lb.

(249.5 kg)

Engine

ment

653/4”

167cm

36”

91.4cm

12”

30.5cm

745/16”

188.8cm

13”

33.0cm

451/8”

114.6cm

391/16”

99.2cm

953 lb.

433.2kg

2000 lb.

909.1kg

7011/16”

179.5cm

36”

91.4cm

12”

30.5cm

7713/16”

197.6cm

16”

40.6cm

483/8”

122.9cm

395/16”

99.9cm

1051 lb.

477.7kg

2000 lb.

909.1kg

773/4”

197.5cm

48”

121.9cm

12”

30.5cm

865/16”

219.2cm

13”

33.0cm

453/8”

115.3cm

395/16”

99.9cm

997 lb.

453.2kg

2000 lb.

909.1kg

8211/16”

210.0cm

48”

121.9cm

12”

30.5cm

8913/16”

228.1cm

16”

40.6cm

489/16”

123.3cm

397/16”

100.2cm

1094 lb.

497.3kg

2000 lb.

909.1kg

661/2”

168.9cm

36”

91.4cm

12”

30.5cm

751/16”

190.7cm

13”

33.0cm

453/8”

115.3cm

395/16”

99.9cm

1012 lb.

460kg

4000 lb.

1818.2kg

717/16”

181.5cm

36”

91.4cm

12”

30.5cm

789/16”

199.5cm

16”

40.6cm

481/2”

123.2cm

395/16”

99.9cm

1056 lb.

480kg

4000 lb.

1818.2kg

781/2”

199.4cm

48”

121.9cm

12”

30.5cm

871/16”

221.1cm

13”

33.0cm

453/8”

115.3cm

395/16”

99.9cm

1065 lb.

484.1kg

4000 lb.

1818.2kg

837/16”

211.9cm

48”

121.9cm

12”

30.5cm

909/16”

230.0cm

16”

40.6cm

481/2”

123.2cm

395/16”

99.9cm

1162 lb.

528.2kg

4000 lb.

1818.2kg

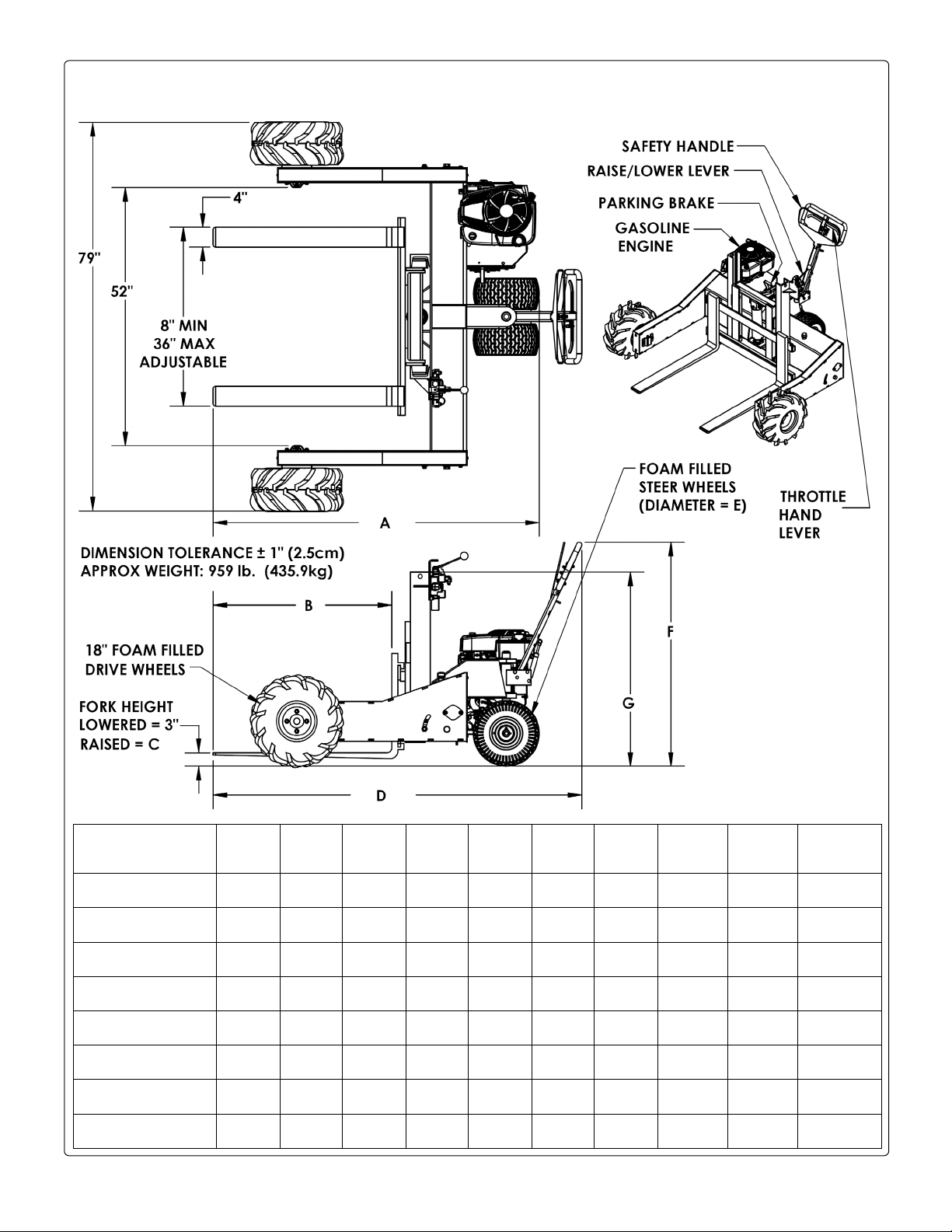

SPECIFICATIONS: UNITS WITHOUT POWERED TILT

Dimensions, capacity, net weight, and other attributes appear in the diagrams and table below.

Model

PMT-GPT

Service Range of

Ball Hitch

Uniform Pulling

Capacity

Hitch Lifting Capacity

(Max. Tongue Weight)

Net Weight

Model A B C D E F G

ALL-T-2-GPT

ALL-T-2-GPT-10HP

ALL-T-2-GPT-L

ALL-T-2-GPT-L-10HP

ALL-T-4-GPT

ALL-T-4-GPT-10HP

ALL-T-4-GPT-L

ALL-T-4-GPT-L-10HP

Net

weight

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 2 of 26

Capacity

displace-

190cc

344cc

190cc

344cc

190cc

344cc

190cc

344cc

Page 3

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

189.2cm

91.4cm

50.8cm

207.2cm

121.1cm

117.5cm

575kg

909.1kg

219.7cm

121.9cm

50.8cm

237.6cm

121.1cm

117.5cm

585.9kg

909.1kg

219.7cm

121.9cm

50.8cm

237.6cm

121.1cm

117.2cm

601.8kg

909.1kg

221.5cm

121.9cm

50.8cm

239.6cm

119.9cm

117.5cm

620.9kg

1818.2kg

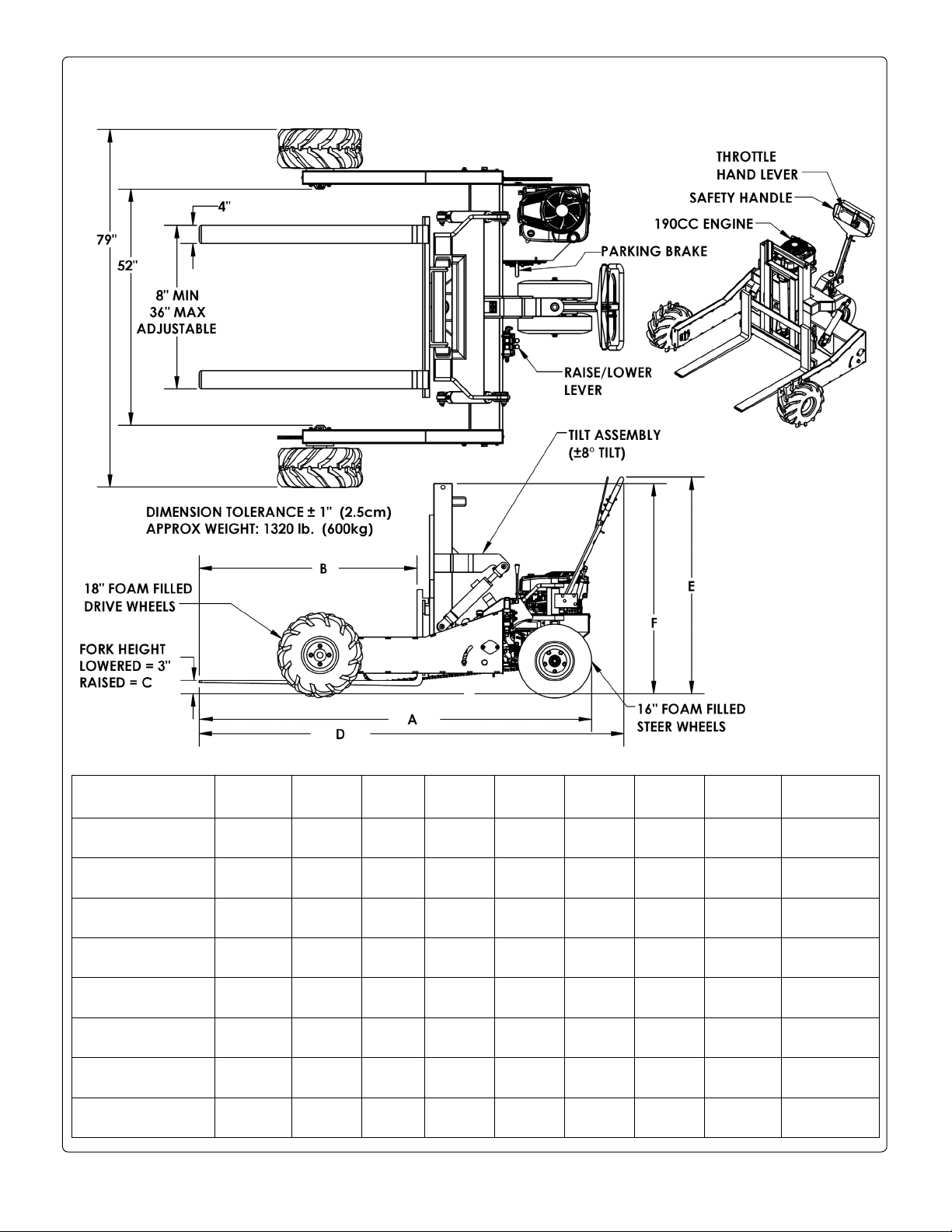

SPECIFICATIONS: UNITS WITH POWERED TILT (“-PT” IN MODEL NAME)

Dimensions, capacity, net weight, and other attributes appear in the diagrams and table below.

Model A B C D E F

ALL-T-2-GPT-PT

ALL-T-2-GPT-PT-

10HP

ALL-T-2-GPT-L-PT

ALL-T-2-GPT-L-PT-

10HP

ALL-T-4-GPT-PT

ALL-T-4-GPT-PT-

10HP

ALL-T-4-GPT-L-PT

ALL-T-4-GPT-L-PT-

10HP

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 3 of 26

741/2”

741/2”

189.2cm

861/2”

861/2”

753/16”

191.0cm

753/16”

185.9cm

873/16”

873/16”

221.5cm

36”

36”

91.4cm

48”

48”

36”

91.4cm

36”

91.4cm

48”

48”

121.9cm

20”

20”

50.8cm

20”

20”

20”

50.8cm

20”

50.8cm

20”

20”

50.8cm

819/16”

819/16”

207.2cm

939/16”

939/16”

825/16”

209.1cm

825/16”

209.1cm

945/16”

945/16”

239.6cm

4711/16”

4711/16”

121.1cm

4711/16”

4711/16”

473/16”

119.9cm

471/8”

199.7cm

473/16”

471/8”

119.7cm

461/4”

461/8”

117.2cm

461/4”

461/8”

461/4”

117.5cm

461/8”

117.2cm

461/4”

461/8”

117.2cm

Net

weight

1265 lb.

1300 lb.

590.9kg

1289 lb.

1324 lb.

1332 lb.

605.5kg

1367 lb.

621.4kg

1366 lb.

1401 lb.

636.8kg

Capacity

2000 lb.

2000 lb.

909.1kg

2000 lb.

2000 lb.

4000 lb.

1818.2kg

4000 lb.

1818.2kg

4000 lb.

4000 lb.

1818.2kg

Engine

displacement

190cc

344cc

190cc

344cc

190cc

344cc

190cc

344cc

Page 4

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

APPLICABLE NATIONAL STANDARDS

This product is a rough terrain lift truck. The Industrial Truck Standards Development Foundation (ITSDF)

publishes national standard ANSI/ITSDF B56.6 (the “Standard”) on its website (www.itsdf.org

). The standard is freely

downloadable at http://www.itsdf.org/cue/b56-standards.html. Before putting your pallet truck into service, acquire a

copy of the Standard and apply all recommendations in Part II: For the User. If instructions provided in this manual

conflicts with instructions in the Standard, then you should apply the instructions in the Standard.

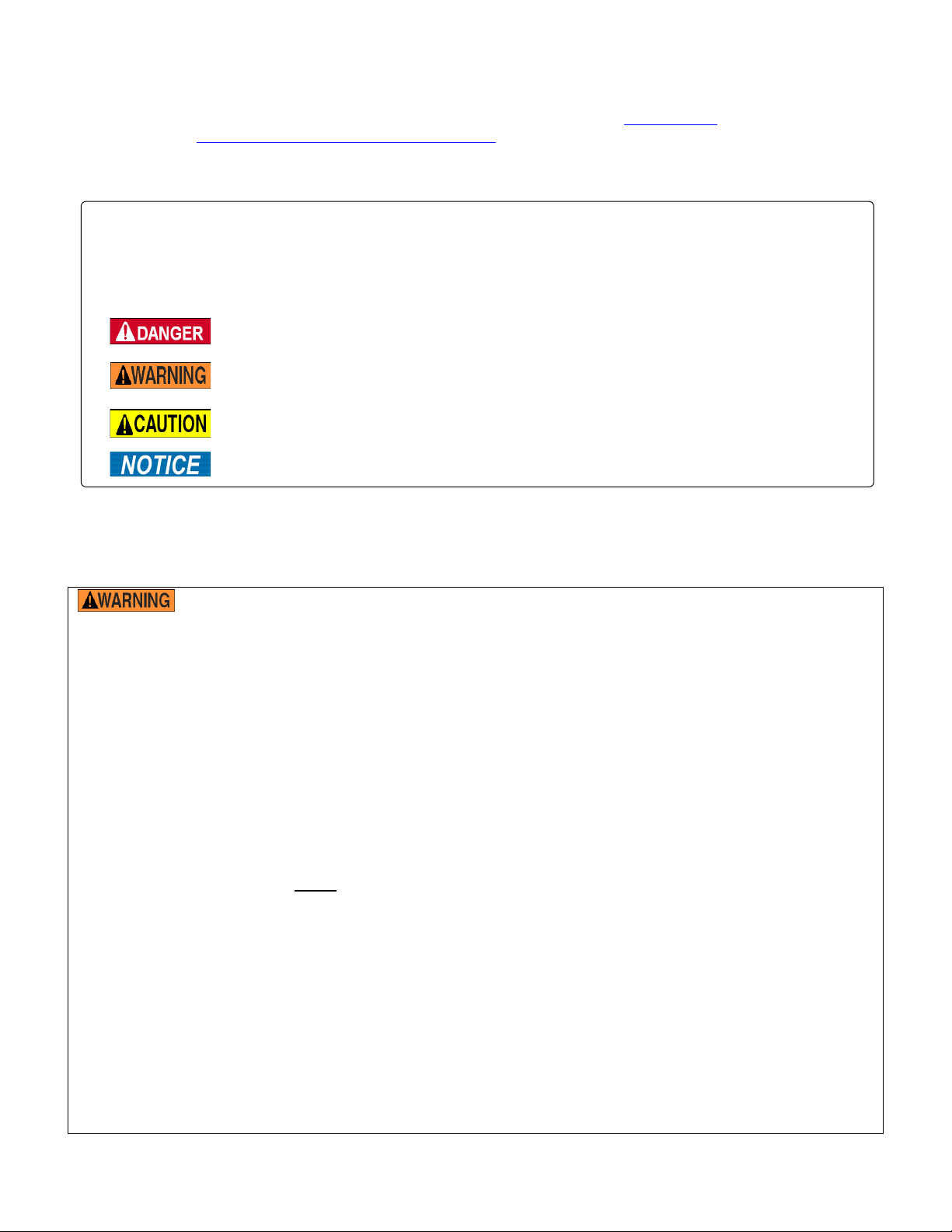

SIGNAL WORDS

This manual uses SIGNAL WORDS to direct the reader’s attention to important safety-related messages.

These messages describe uses of the product that could result in personal injury or property damage. Each

signal word corresponds to a specific hazard level. The following are definitions of signal words that might

appear in this manual.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

SERIOUS INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

SERIOUS INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

MODERATE injury

Identifies practices likely to result in product/property damage, such as operation that

might damage the product.

.

SAFETY INSTRUCTIONS

Vestil strives to identify all foreseeable hazards associated with the use of its products. However, material

handling is dangerous and no manual can address every risk. Ultimately the most effective way to prevent

injury is for the operator to apply sound judgment whenever using this device.

Improper or careless operation of this device might result in serious personal injuries.

• Read and understand this entire manual before using or servicing this pallet truck. Read the manual

whenever necessary to refresh your understanding of proper operation and maintenance procedures. An instruction

manual for the gasoline motor is provided with this unit. Read the entire manual before operating the truck for the

first time.

• DO NOT exceed the capacity of your unit. Capacity information is provided in the Specifications tables on pages 2

& 3. The truck is also labeled with its capacity. See label 287 in Labeling Diagram on p. 25.

• Inspect the truck as directed in Inspections and Maintenance on pages 5-6. DO NOT use the device unless it is in

satisfactory condition. See Record of Satisfactory Condition on p. 7.

• NEVER park the truck on sloped terrain. Only park on level ground. Always apply the parking brake whenever the

truck is stopped.

• Only use this product to lift and move palletized loads.

• Completely engage loads with forks. Fork length should be at least two-thirds of length of the parallel dimension

of the pallet.

• DO NOT allow people to ride on the truck or the load.

• Ascend and descend grades slowly. Do not traverse grades of more than 7%. The forks should only be raised as

far as necessary to clear the road surface. Travel straight up and down the grade, i.e. avoid turning on grades. If

your pallet truck is equipped with the powered tilt feature (-PT in model name), make sure that the carriage is not

tilted forward whenever crossing grades. Traverse grades with the forks downgrade from you.

• If the load obstructs forward view, travel with the load trailing.

• Any load applied to the forks must be centered and evenly distributed on a pallet.

• Only use the truck if you are familiar with the controls. Start, stop, turn, and reverse directions smoothly to shifting

the load. Sudden shifting could cause the load and truck to overturn.

• Reduce speed during turns. Turn slowly and carefully.

• Avoid running over loose objects on the roadway surface.

• DO NOT modify the truck in any way without express, written approval from Vestil. Unapproved modifications

automatically void the Limited Warranty on p. 26 and might make the product unsafe to use.

• DO NOT use this product UNLESS every label shown in the Labeling diagram on p. 25 is in place, undamaged,

and easily readable.

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 4 of 26

Page 5

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

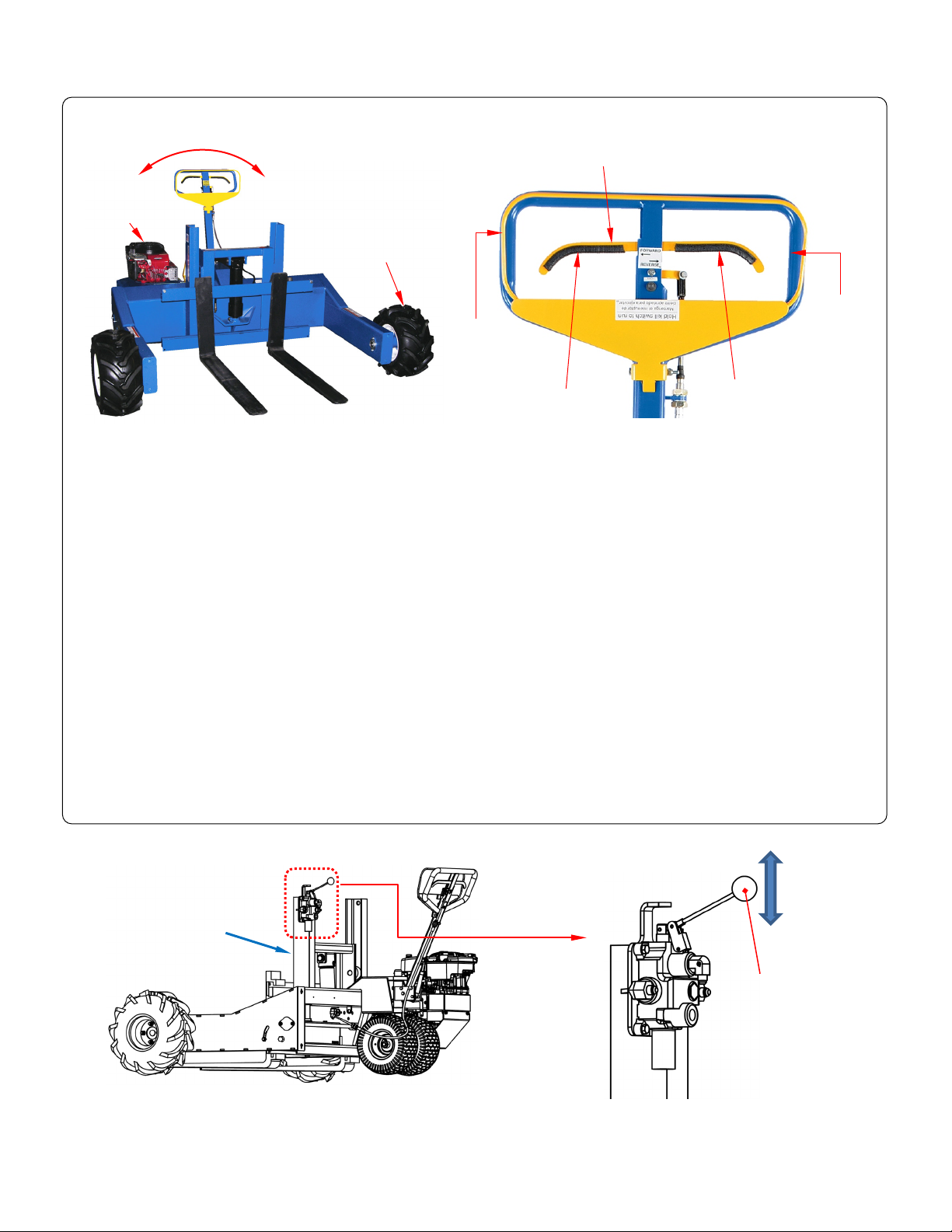

Forward

Reverse

Kill switch

Handle

(blue)

Direction control lever

Drive wheel

Fork

Fork carriage

Handle

Motor

Lower

carriage

Raise

carriage

OPERATING THE TRUCK

assembly

(yellow)

Startup procedure

1. Find the choke and throttle controls for the motor. Apply the engine startup procedure in the motor manufacturer’s

instruction manual.

2. Squeeze the kill switch against the handle with one hand. Pull the engine starter cord with the other hand.

3. After the engine starts, set the choke switch to the open position and allow the engine to warm up for a few

minutes.

4. Set the engine throttle to the desired speed: increasing the throttle increases the speed and vice versa.

Propulsion (Driving the Truck)

a. To move forward, squeeze the right side of the direction control lever towards the top of the handle. The further the

lever is moved the faster the unit moves. Release the lever to stop.

b. To move in reverse, squeeze the left side of the lever towards the top of the handle.

c. Practice shifting between forward and reverse.

NOTE: Do not quickly shift from forward to reverse or vice versa. Sudden shifts can damage the transaxle.

d. When moving heavy loads, i.e. loads close to the unit’s capacity, drive slowly. Driving slowly decreases the load on

the engine.

Steering

Steer the unit by swinging the handle to one side or the other. While turning, the rpm’s of the outer drive wheel

increase and the rpm’s of the inner drive wheel decrease. When turning sharply in one direction or the other, the

difference between rpm’s of the wheels is greater (i.e. the outer wheel turns much faster than the inner wheel).

FORK CARRIAGE CONTROLS

A. Raising and lowering the carriage

1. Raise the forks: (continues on following page)

a. Grasp the knob of the fork carriage control lever and push it forward i.e. away from you/towards the truck.

The hydraulic cylinder extends and causes the carriage to rise.

carriage

control

lever

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 5 of 26

Page 6

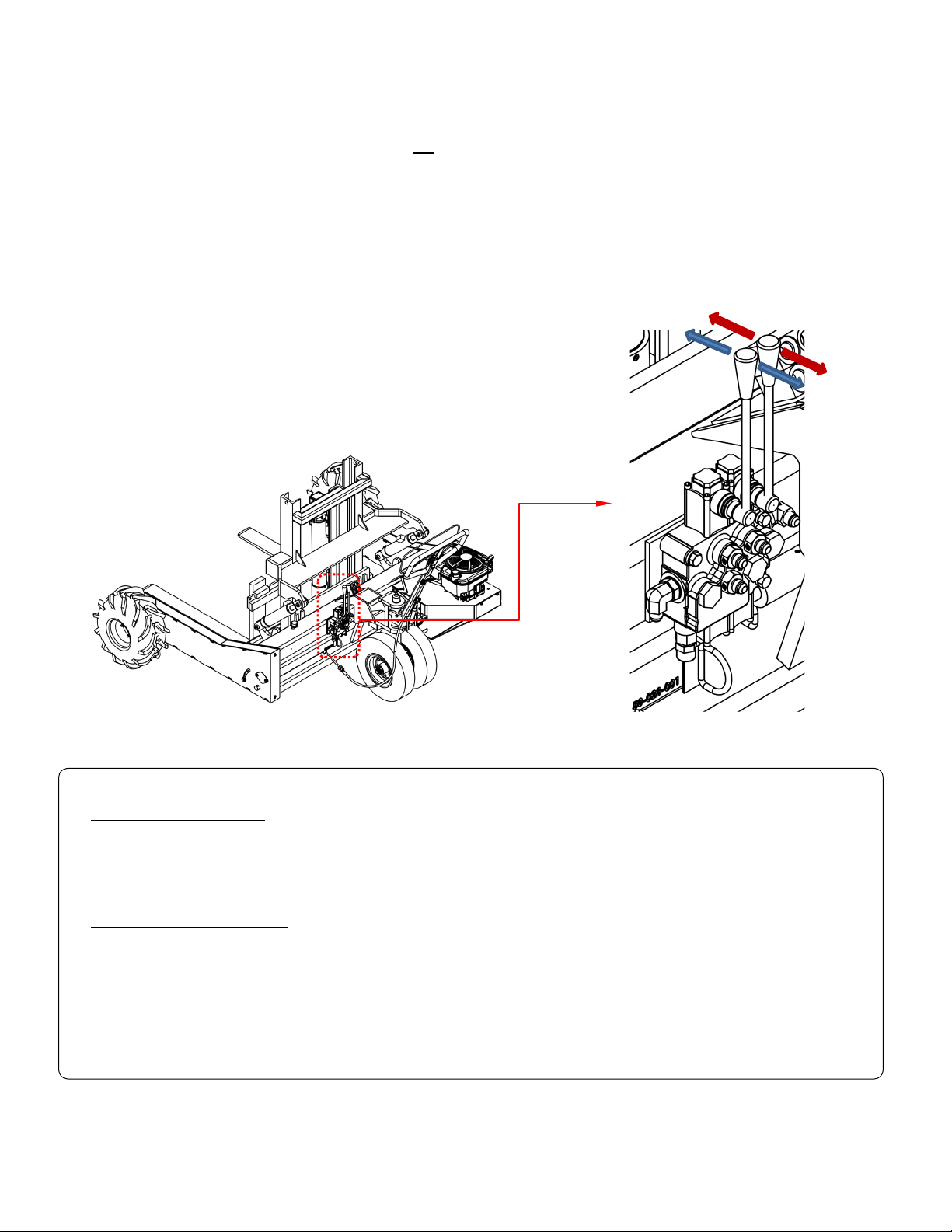

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

LIFTING AND TRANSPORTING LOADS

Lower

Raise

Tilt

Level

b. Releasing the lever causes to cylinder to stop extending. The cylinder maintains position wherever it stops.

Release the control lever as soon as the desired load elevation is achieved.

NOTE: Do not continue to hold the control lever when the cylinder is completely extended. The hydraulic

fluid could overheat and cause permanent damage to the hydraulic system.

2. Lower the fork carriage: The engine does not have to be running to lower the carriage.

a. Pull the control lever towards you.

b. The carriage descends at a controlled speed. Releasing the lever causes the carriage to stop. It maintains

position wherever it stops. Lowering speed is adjustable. However, the lowering speed is optimized at the

factory. Do not change the lowering speed without approval from, and guidance by, Technical Service.

If the carriage lowers too quickly, a safety device in the cylinder, called a velocity fuse, closes. When the

fuse is closed, hydraulic fluid cannot flow from the cylinder to the reservoir. The cylinder cannot retract and

the carriage does not lower. If this happens, you must reset the velocity fuse by raising the hitch.

B. Tilting the carriage

Units equipped with the powered tilt feature (“-PT” appears in the

model designation) have two control levers.

1. The lever on the left controls up-and-down movement.

2. The lever on the left controls carriage tilt.

a. Push the lever forward to activate a second cylinder. This

cylinder pushes the top of the carriage forward, which

causes the fork tips to drop.

b. Pull back the lever to raise the tips and level the forks.

Before engaging the load:

1. Release the direction control lever.

2. Adjust the engine throttle to mid-speed.

3. Align the forks (on the carriage) with the fork channels in the pallet. The forks must be centered on the carriage.

4. Adjust the elevation of the forks with the Raise/Lower lever.

Mount the pallet on the forks:

1. Drive forward and insert the forks through the pallet. Insert the forks all-the-way. Fork length should be at least 2/3’s

of the parallel dimension of the pallet.

2. Raise the forks to elevate the pallet a few inches above the ground. Do not raise the forks any higher than

necessary.

3. Drive the load to the desired location. Instructions for driving and steering the truck are provided in Operating the

Truck on p. 5.

4. Set the pallet on the ground by lowering the forks. When the pallet rests on the ground, extract the forks from the

pallet by driving the truck in reverse.

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 6 of 26

Page 7

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

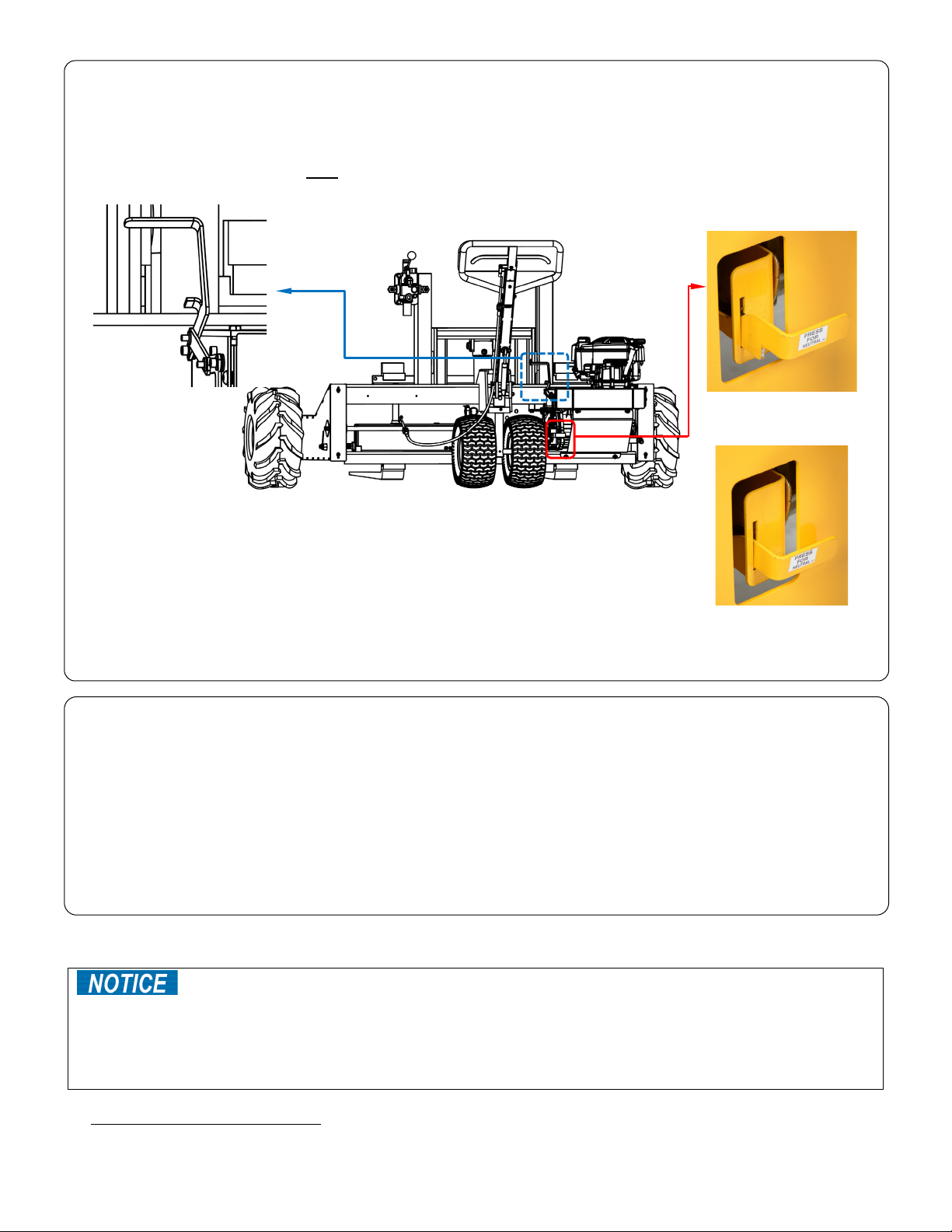

Parking brake lever

Transaxle release lever

PARKING BRAKE

This product is equipped with a parking brake. This brake should only be applied when the unit is stopped. Do not

use the parking brake to slow the unit.

1. To apply the brake pull the brake lever up until it locks.

2. To release the brake, push the lever downward.

NOTE: ONLY park the mover on level ground.

Unload the hydraulic system when you are finished using the truck by lowering the

carriage all the way.

Drive mode: axle engaged

Neutral mode: axle

disengaged

DISENGAGING THE TRANSMISSION (NEUTRAL MODE)

The unit can be moved manually by putting the transmission into neutral.

This decouples the drive wheels from the transaxle. To put the transmission

into neutral:

1. Locate the transaxle release lever.

2. Push the lever in and down until it seats inside the release bracket.

To put the transmission back into drive mode, lift the lever and pull it towards you.

RECORD OF SATISFACTORY CONDITION

Before using the product for the first time, make a record of its appearance and functions. Cycle the

carriage/forks up and down. Describe the motion (e.g. smooth and at a uniform rate). Drive the unit in forward and

in reverse. Describe the motion. Thoroughly photograph the unit from multiple angles including all labeling applied

to it. Each feature listed in Inspect the following components (below) should be photographed in detail. Describe

where each label is located. Collate all photographs and writings into a file. Mark the file appropriately to identify it.

This record documents the truck in satisfactory condition. Compare the results of all inspections to this record

to determine if the unit is in satisfactory condition. Do not use it unless it is in satisfactory condition. Purely cosmetic

changes, like damaged paint/powder coat do not constitute changes from normal condition. However, touchup paint

should be applied to all affected areas as soon as damage occurs. Contact Technical Service (contact information

appears on the cover page) if you have questions that are not addressed in these instructions.

INSPECTIONS AND MAINTENANCE

service life of the unit.

o DO NOT fill the hydraulic system with brake fluid or jack oils. Only use anti-wear hydraulic oil, viscosity grade

150 SUS at 100°F (ISO 32cSt at 40°C) or Dexron transmission fluid.

o Fill the engine with oil and gasoline as instructed in the manufacturer’s manual. Perform maintenance on the

engine as directed in that manual.

Inspect the following components:

1. Motor: Maintain the motor as instructed in the manufacturer’s manual. The manual is provided with the unit.

Proper maintenance is essential to keep this product in satisfactory condition and to maximize the

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 7 of 26

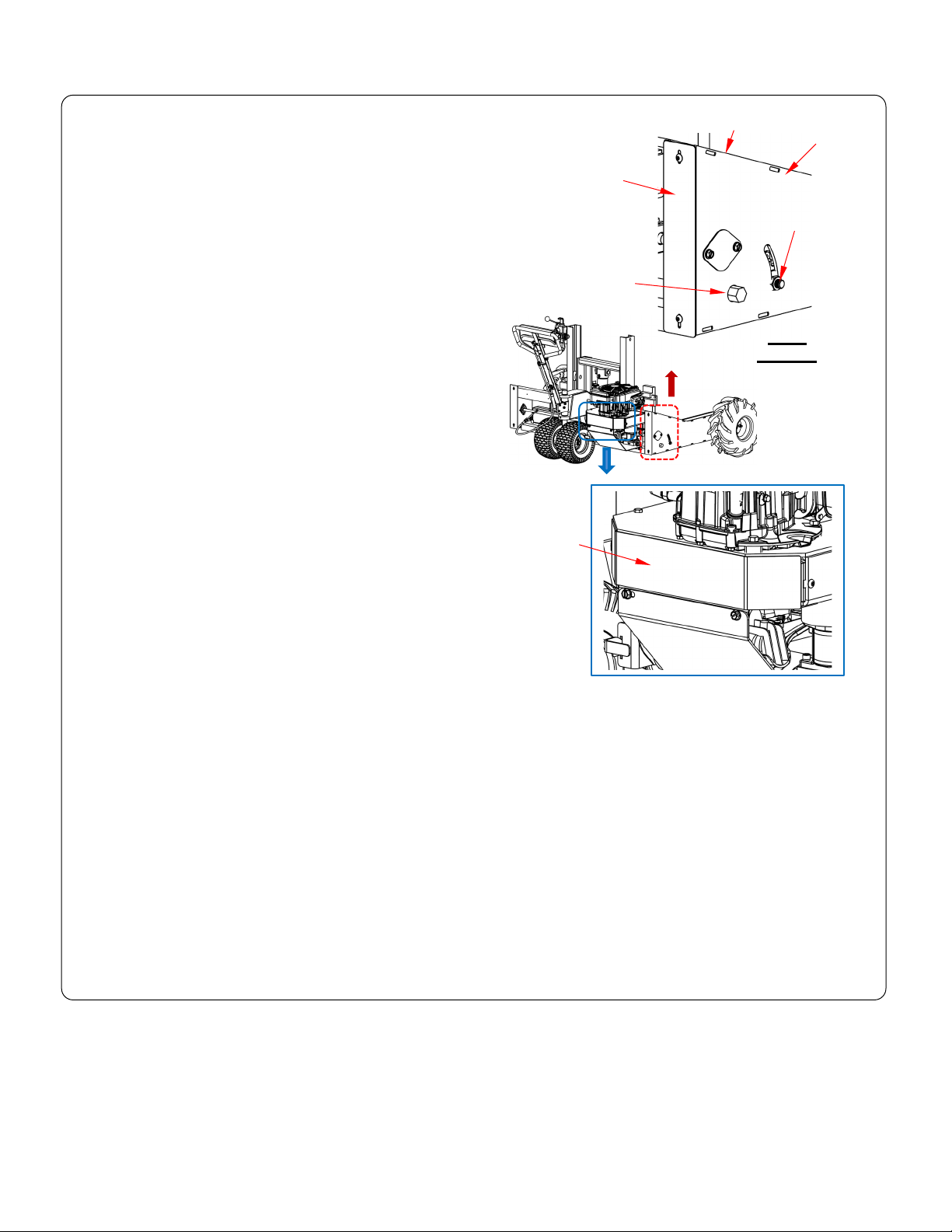

Page 8

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Drive belt

guard

Cover

plate

Cover

plate

Drive

housing

Chain guard

Hex

head

Lock

nut

2. Drive chain (one for each drive wheel): every other oil

change, inspect the chains. To access the chains, remove

the cover plates fastened to both ends of the drive housing.

Refer to the appropriate Sprocket Drive Subassembly on

pages 23 and 24.

A. Check the tension of both chains. They should not be

taut but also should not be so loose that they slap

against the housing or jump on the sprockets. Adjust

the chains by applying pressure to the hex head with a

wrench while loosening the lock nut.

B. Check set screws on the front and rear sprockets,

drive shaft coupling, motor pulley, and pump

pulley. Confirm that the set screws are tight. Tighten

all loose screws. Apply thread locker to keep

connections tight.

C. The front wheel sprocket should line up with the axle

sprocket

D. Lubricate the drive chains with spray grease as

needed, e.g. if the drive train becomes noisy.

3. At least once per month, remove the drive belt guard.

Determine the condition of the drive belt (Exploded Views on

pages 9-17; part number 50-042-008; 50-042-009; or 50-042-

010) and drive pulley (part number 50-027-003; or 50-027-

004). Unseat the belt from the drive pulleys to relieve belt

tension. Then, examine the pump assembly (part number 50643-012 or 50-643-001): Idler pulley on top of the pump as

well as the pump bearings and shaft. Look for damage and

significant wear. Replace any component that is significantly

worn, in particular, the belt.

4. Check the hydraulic system.

a. Before each use:

i. Cycle the carriage all the way up and then all the way down. Movement should be smooth in both

directions, i.e. no binding, jumps, skips.

ii. Check the hydraulic hoses for signs of wear, kinks, cuts, etc. Replace damaged hoses.

b. At least once per month, examine the hydraulic oil. The oil reservoir is located next to the hydraulic pump.

First, fully lower the carriage. Remove the brass fill plug from the top of the reservoir and examine the oil.

Change the oil if it darkens, becomes gritty, or has a milky appearance (indicating that water is present).

Replace the oil with AW-32 hydraulic fluid or its equivalent.

c. Before each use,

5. Before each use make sure all labels are in place & in readable condition. See Labeling diagram on p. 25.

6. Periodically clean dirt and debris from all surfaces to keep the finish in good condition. Store the unit indoors.

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 8 of 26

Page 9

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Bill of Materials continues on page 10

50-006-014

Complete Exploded View and Bill of Materials: ALL-T-2-GPT, ALL-T-4-GPT, ALL-

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

50-514-022

Weldment, frame assembly:

ALL-T-2-GPT-L & ALL-T-4-GPT-L

1

2

50-538-001

Weldment, carriage

1

13

50-540-009

Assembly, lever, brake

1

99-021-901-001

Cylinder, hydraulic:

ALL-T-4-GPT & ALL-T-4-GPT-L

2

•4

50-612-008

Assembly, axle, rear wheel (1)

1

15

50-024-012

Cover, lower belt, formed

1

5

50-612-006

Assembly, transaxle, 3/4” shaft

1

16

50-024-014

Cover, skid plate

1

••6

50-525-002

Weldment, steering handle

1

17

50-040-010

OR4 TA neutral lever

1

50-542-005

Subassembly, sprocket drive, left

ALL-T-2-GPT-L & ALL-T-4-GPT-L

50-542-006

Subassembly, sprocket drive,

ALL-T-2-GPT-L & ALL-T-4-GPT-L

9

50-145-002

Coupler, drive shaft

1

20

50-024-016

Cover, front leg

2

50-028-002

Fork:

ALL-T-4-GPT-L

2

11

15-527-004

Subassembly, roller

4

22

99-145-104

U-nut

2

T-2-GPT-L, & ALL-T-4-GPT-L

1

50-514-004

ALL-T-2-GPT & ALL-T-4-GPT

12

1

50-540-006 Weldment, shifter plate 1

3

99-021-906-001

ALL-T-2-GPT & ALL-T-2-GPT-L

14

2

50-024-011 Cover, rear belt 1

•••7

50-542-003

(exploded view on p. 18):

ALL-T-2-GPT & ALL-T-4-GPT

18

1

1

50-016-024 Bracket, neutral, formed 1

••••8

10

50-542-004

50-026-002 Shaft, drive 1

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 9 of 26

right (exploded view on p. 17):

ALL-T-2-GPT & ALL-T-4-GPT

19

1

1

21

50-024-006 Cover, rear leg 2

38-028-007

38-028-013

50-028-001

ALL-T-2-GPT

ALL-T-4-GPT

ALL-T-2-GPT-L

2

2

2

Page 10

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

23

29185

Screw, machine, truss head

13

*48

50-042-008

Belt, 1/2” x 38”

1

Screw, socket set, black

oxide, 1/4”-20 x 1/4”

Bolt, HHCS, #2, zinc-plated,

/8”-16 x 23/4”

Accessories, electrical, 9V

battery clip

Hex nut, gr. A, z-plated, 3/8”16

Accessories, Electrical, (V

battery snap

Adjustable yoke end,

2”x6/16”x5/8”x1/4”-28

Bolt, HHCS, #2, z-plated,

/16”-18 x 3/4”

Hex bolt, gr. A, z-plated,

/4”-20 x 4”

Cotter pin, z-plated, 1/16” x

/2”

Nylon lock nut, gr. 2, zfinish, 1/4”-20

Bolt, cylinder retaining, 1/2”13 x 2”

Hex bolt, gr. A, z-finish, 3/8”16 x 11/2”

Nylon insert lock nut, gr. 2,

zinc finish, 3/8”-16

Narrow machinery bushing,

plain, 13/4” x 18ga.

Hose, subassembly,

cylinder

External retaining ring,

phosphate finish, 11/8”

Subassembly, hose, valve

return

36

23203

Bolt, SHCS, 1/4”-20 x 3/4”

1

*61

50-623-010

Subassembly, hose, pump

1

Hex nut, gr. A, z-plated, 1/4”20

38

50-130-006

Pin, key, axle extension

1

*63

50-623-006

Subassembly, hose, suction

1

Thread-cutting screw,

/16”-18 x 3/4”

Bolt, #2, z-plated. 5/16”18UNC x 11/2”

Fitting, hydraulic, 06MJ12MP 90° elbow

Fitting, hydraulic, 06MJ08MP 90° elbow

*42

99-159-007

Engine, 190cc

1

*67

99-031-078

Accessories, pipe, 3/4” NPT

1

*43

50-638-002

Assembly, T3 valve

1

*68

01-031-005

Filter, reservoir, hydraulic

1

Subassembly, pump,

hydraulic gear

Accessories, clamp, 2 ear,

17/16”

Accessories, clamp, 2 ear,

11/8”

*47

50-540-003

Assembly, belt tensioner

1

24

25326

2

*49

99-034-134 Horn 1

25

26

11114

36106

3

4

4

*50

50-034-003

*51

50-139-001 Battery, 9V 1

27

50-145-009 Transaxle link, threaded rod 1

*52

50-034-002

28

29

43520

50-120-001 Nut, brake 1

1

*53

99-130-001 Pin, keystock 1

*54

11053

5

30

31

32

66026 Pin, clevis,

65012

01-118-001

1

1

/4” x 1” 1

2

1

*55

*56

*57

11019

37018

11109

1

33

15-112-002 Pin, cylinder bracket 1

34

33454

8

*58

*59

37024

50-623-009

35

68021

2

*60

50-623-008

37

36102

3

*62

50-623-007 Subassembly, hose, return 1

39

32416

slotted, type F, z-plated,

5

4

*64

50-623-011 Subassembly, hose, valve 1

40

11059

1

*65

99-116-074

41

99-145-105 U-nut, 1/4”-20 11

*66

99-116-073

*44

50-643-001

1

*69

99-031-094 Accessories, cap 3/4” 1

*45

*46

50-027-003 Pulley, engine 1

50-523-001 Subassembly, reservoir 1

*70

*71

99-031-095

99-031-096

• Item 4 shown in Rear Wheel Axle Assembly (1) Exploded View on p. 17.

•• Item 6 shown in Steering Handle Subassembly Exploded View on p. 18.

••• Item 7 shown in Sprocket Drive Subassembly, Left Side, Exploded Views on p. 24.

•••• Item 8 shown in Sprocket Drive Subassembly, Right Side, Exploded Views on p. 23.

* Components of Power Unit Subassembly 50-160-002 on p. 20.

1

1

3

1

1

3

3

1

1

2

2

1

1

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 10 of 26

Page 11

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Complete Exploded View and Bill of Materials: ALL-T-2-GPT-10HP, ALL-T-4-GPT-

Bill of Materials continues on page 12

50-006-015

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

Weldment, frame assembly:

10HP

2

50-538-001

Weldment, carriage

1

11

15-527-004

Subassembly, roller

4

10HP

•4

50-632-002

Assembly, axle, rear wheel (2)

1

13

50-540-009

Assembly, lever, brake

1 5 50-612-007

Assembly, transaxle, 1” shaft

1

14

50-024-006

Cover, rear leg

2

••6

50-525-002

Weldment, steering handle

1

15

50-024-016

Cover, front leg

2

Subassembly, sprocket drive, left

10HP

50-028-002

Fork:

ALL-T-4-GPT-L

2

Subassembly, sprocket drive, right

10HP

9

50-145-004

Coupler, drive shaft

1

18

29185

Screw, machine, truss head

13

10HP, ALL-T-2-GPT-L-10HP & ALL-T-4-GPT-L-10HP

1

50-514-024

50-514-025

ALL-T-2-GPT-10HP & ALL-T-4-GPT-10HP

ALL-T-2-GPT-L-10HP & ALL-T-4-GPT-L-

10

1

1

50-026-001 Shaft, drive 1

99-021-906-001

3

99-021-901-001

Cylinder, hydraulic:

ALL-T-2-GPT-10HP & ALL-T-4-GPT-10HP

ALL-T-2-GPT-L-10HP & ALL-T-4-GPT-L-

12

1

1

50-540-006 Weldment, shifter plate 1

•••7

50-542-007

50-542-009

50-542-008

•••8

50-542-010

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 11 of 26

(exploded view on p. 18):

ALL-T-2-GPT-10HP & ALL-T-4-GPT-10HP

ALL-T-2-GPT-L-10HP & ALL-T-4-GPT-L-

(exploded view on p. 17):

ALL-T-2-GPT-10HP & ALL-T-4-GPT-10HP

ALL-T-2-GPT-L-10HP & ALL-T-4-GPT-L-

1

1

1

1

38-028-007

16

38-028-013

50-028-001

17

99-145-105 U-nut,

ALL-T-2-GPT

ALL-T-4-GPT

ALL-T-2-GPT-L

1

/4”-20 9

2

2

2

Page 12

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

Bolt, HHCS, #2, zinc-plated,

/8”-16 x 23/4”

20

36106

Hex nut, gr. A, z-plated, 3/8”-16

5

*48

50-042-009

Belt, 1/2” x 40”

1

21

50-145-009

Transaxle link, threaded rod

1

*49

99-034-134

Horn

1

Adjustable yoke end,

2”x6/16”x5/8”x1/4”-28

Accessories, electrical, 9V

battery clip

23

50-120-001

Nut, brake

2

*51

50-139-001

Battery, 9V

1

Accessories, Electrical, (V

battery snap

25

*53

Bolt, cylinder retaining, 1/2”-13

x 2”

Bolt, HHCS, #2, z-plated,

/16”-18 x 3/4”

Hex bolt, gr. A, z-plated, 1/4”20 x 4”

Narrow machinery bushing,

plain, 13/4” x 18ga.

Nylon lock nut, gr. 2, z-finish,

/4”-20

External retaining ring,

phosphate finish, 11/8”

Hex bolt, gr. A, z-finish, 3/8”16 x 11/2”

Nylon insert lock nut, gr. 2,

zinc finish, 3/8”-16

31

36102

Hex nut, gr. A, z-plated, 1/4”-20

3

*59

50-623-009

Hose, subassembly, cylinder

1

Subassembly, hose, valve

return

Bolt, #2, z-plated. 5/16”-18UNC

x 11/2”

34

50-024-009

Guard, skid plate, 10HP

1

*62

50-623-007

Subassembly, hose, return

1

35

50-024-017

Guard, skid plate top, formed

1

*63

50-623-006

Subassembly, hose, suction

1

36

*64

Battery, 12V, sealed leadacid (AGM)

Thread-cutting screw, slotted,

type F, z-plated, 1/4”-20 x 3/4”

Accessories, motor contactor,

12V coil

Bracket, drive to neutral,

formed

Weldment, handle, drive to

neutral

Hex bolt, gr. A, z-finish, 1/4”20 x 3/4”

Hex bolt, gr. A, z-finish, 3/8”-16

x 3/4”

Accessories, battery box,

series 16

*42

99-659-001

Assembly, engine, 190cc

1

*70

99-031-078

Accessories, pipe, 3/4” NPT

1

*43

50-638-002

Assembly, T3 valve

1

*71

99-031-094

Accessories, cap 3/4”

1

Subassembly, pump, hydraulic

gear

Fitting, hydraulic, 06MJ-08MP

90° elbow

Fitting, hydraulic, 06MJ-12MP

90° elbow

19

11114

3

4

*47

50-540-005 Assembly, belt tensioner 1

22

43520

1

*50

50-034-003

24

26

66026 Pin, clevis,

65012 Cotter pin, z-plated, 1/16” x 1/2” 3

01-118-001

1

/4” x 1” 1

1

*52

50-034-002

99-130-003 Pin, keystock 1

*54

11053

5

27

15-112-002 Pin, cylinder bracket 1

28

33454

8

*55

*56

11019

37018

1

29

30

68021

23203 Bolt, SHCS,

1

/4”-20 x 3/4” 1

2

*57

*58

11109

37024

32

50-130-007 Pin, key, axle extension 1

33

11059

1

*60

50-623-008

*61

50-623-010 Subassembly, hose, pump 1

50-024-015 Guard, right side transaxle 1

37

50-514-005 Weldment, battery box 1

38

32408

2

50-623-011 Subassembly, hose, valve 1

*65

21-139-002

*66

99-034-028

39

40

50-016-008

50-525-001

1

1

*67

21-034-004 Circuit breaker 1

*68

11003

41

11103

1

*69

50-034-004

*44

50-643-001

1

*72

01-031-005 Filter, reservoir, hydraulic 1

*45

• Item 4 shown in Rear Wheel Axle Assembly (2) Exploded View on p. 17.

•• Item 6 shown in Steering Handle Subassembly Exploded View on p. 18.

••• Item 7 shown in Sprocket Drive Subassembly, Left Side, Exploded Views on p. 24.

•••• Item 8 shown in Sprocket Drive Subassembly, Right Side, Exploded Views on p. 23.

* Components of Power Unit Subassembly 50-160-003 on p. 20.

50-027-004 Pulley, engine 1

*46

50-523-001 Subassembly, reservoir 1

*73

*74

99-116-073

99-116-074

1

1

3

1

3

4

4

1

1

1

2

1

2

2

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 12 of 26

Page 13

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Bill of Materials continues on page 14

50-006-022

Complete Exploded View and Bill of Materials: ALL-T-2-GPT-PT, ALL-T-4-GPT-PT,

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

1

50-514-027

Subassembly, frame, tilt

1

16

50-026-002

Shaft, drive

1

2

50-514-023

Weldment, frame assembly

1

17

50-540-006

Weldment, shifter plate

1 3 50-538-002

Weldment, carriage

1

18

50-540-009

Assembly, lever, brake

1 4 50-514-012

Weldment, frame, tilt mast

1

19

50-024-017

Guard, skid plate, top, formed

1

5

15-527-004

Subassembly, roller

4

20

50-024-009

Guard, skid plate, 10HP

1

Assembly, cylinder, hydraulic, 2”x21/4”

hand port)

Assembly, cylinder, hydraulic, 2x21/4”

hand port)

8

03-612-002

Assembly, hinge pin

4

23

50-024-016

Cover, front leg

2

99-021-952

Cylinder, hydraulic

PT

ALL-T-4-GPT-PT & ALL-T-4-GPT-L-PT

1

•10

50-623-002

Assembly, axle, rear wheel (2)

1

25

99-145-105

U-nut, 1/4”-20

9

11

50-612-006

Assembly, transaxle, 3/4” shaft

1

26

29185

Screw, machine, truss head

13

Socket set screw, black oxide, 1/4”20x1/4”

Bolt, HHCS #2, z-plated, 3/8”16x23/4”

••••14

50-542-006

Subassembly, sprocket, drive, right

1

29

36106

Hex nut, gr. A, z-plated, 3/8”-16

4

15

50-145-002

Coupler, drive shaft

1

30

50-145-009

Transaxle link, threaded rod

1

ALL-T-2-GPT-L-PT, & ALL-T-4-GPT-L-PT

6

50-521-001

piston style with clevis mounts (right

21

1

50-016-024 Bracket, neutral, formed 1

7

50-521-002

piston style with clevis mounts (left

22

1

50-024-006 Cover, rear leg 2

9

99-021-909-001

••12 50-525-002 Weldment, steering handle 1 27

•••13 50-542-005 Subassembly, sprocket, drive, left 1

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 13 of 26

ALL-T-2-GPT-PT & ALL-T-2-GPT-L-

24

1

50-040-010 OR4 TA neutral lever 1

25326

28

11114

2

4

Page 14

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

Adjustable yoke end,

2”x7/16’x5/8”x1/4”-28

Accessories, 9V battery

snap

32

50-120-001

Nut, brake

1

*55

99-130-001

Pin, keystock

1

Bolt, HHCS, #2, z-plated,

/16”-18x2”

Cotter pin, z-plated,

/16”x1/2”

Hex bolt, gr. A, z-plated,

/4”-20x4”

Nylon lock nut, gr. 2, zfinish, 1/4”-20

Narrow machinery bushing,

plain, 13/4” x 18ga.

Hex bolt, gr. A, z-finish, 3/8”16x11/2”

External retaining ring,

phosphate finish, 11/8”

Nylon insert lock nut, gr. 2,

z-finish, 3/8”-16

Bolt, SHCS, utility grade,

/4”-20x3/4”

Subassembly, hose,

suction, tank-to-pump

Hex nut, gr. A, z-plated, 1/4”20

Subassembly, hose, return,

valve-to-tank

Subassembly, hose, bottom

bulkhead-to-cylinder

Bolt, #2, z-plated, 5/16”18UNCx11/2”

Subassembly,, hose, top

tilt, bulkhead-to-block

50-028-002

Fork

ALL-T-4-GPT-L-PT

Fitting, hydraulic,

06MJ08MA ORB 90° elbow

Fitting, hydraulic, 06MJ08MORB STRAIGHT

*45

50-638-001

Assembly, valve, double

1

*68

99-031-078

Accessories, pipe, 3/4” NPT

1

Subassembly, pump,

hydraulic gear

*47

50-027-003

Pulley, engine

1

*70

99-031-094

Accessories, cap, 3/4”

1

Subassembly, hose, tilt,

valve-to-bulkhead

Subassembly, hose, lift,

valve-to-bulkhead

Subassembly, hose, blockto-tilt-cylinder

Fitting, hydraulic, 06MJ08MP 90° elbow

Accessories, clamp, 2 ear,

17/16”

Accessories, clamp, 2 ear

11/8”

31

43520

33

66026 Pin, clevis,

34

35

65012

15-112-002 Pin, cylinder bracket 1

36

37

33454

68021

38

23203

39

36102

40

50-130-006 Pin, key, axle extension 1

41

11059

38-028-007

42

38-028-013

50-028-001

43

50-024-015 Guard, right side transaxle 1

*44

99-159-007 Engine 190cc 1

*46

50-643-001

*48

50-523-001 Subassembly, reservoir 1

*49

50-540-003 Assembly, belt tensioner 1

*50

50-042-010 Belt,1/2”x46” 1

*51

99-034-134 Horn, ALL-T 1

*52

50-034-003 Accessories, 9V battery clip 1

*53

1

• Item 10 shown in Rear Wheel Axle Assembly (2) Exploded View on p. 17.

•• Item 12 shown in Steering Handle Subassembly Exploded View on p. 18.

••• Item 13 shown in Sprocket Drive Subassembly, Left Side, Exploded Views on p. 24.

•••• Item 14 shown in Sprocket Drive Subassembly, Right Side, Exploded Views on p. 23.

* Components of Power Unit Subassembly 50-160-004 on p. 21.

50-139-001 Battery, 9V 1

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 14 of 26

1

/4”x1” 1

1

1

ALL-T-2-GPT-PT

ALL-T-4-GPT-PT

ALL-T-2-GPT-L-PT

1

2

8

2

1

3

1

2

1

*54

50-034-002

*56

*57

*58

*59

*60

*61

*62

*63

*64

*65

*66

*67

*69

*71

*72

*73

*74

*75

*76

11061

11019

37018

11109

37024

50-623-012

50-623-013

50-623-014

50-623-015

50-623-016

99-116-119

99-116-096

01-031-005 Filter, reservoir, hydraulic 1

50-623-017

50-623-019

50-623-018

99-116-073

99-031-095

99-031-096

5

1

tilt, bulkhead-to-block & lift,

Subassembly, hose, valveto-pump

1

3

1

1

3

3

1

1

2

1

1

2

3

2

1

4

1

1

1

Page 15

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Bill of Materials continues on page 16

50-006-026

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

1

50-514-026

Subassembly, frame, tilt

1

14

50-145-004

Coupler, drive shaft

1

2

50-538-002

Weldment, carriage

1

15

50-026-001

Shaft, drive

1 3 50-514-012

Weldment, frame, tilt mast

1

16

50-540-006

Weldment, shifter plate

1

4

15-527-004

Subassembly, roller

4

17

50-540-009

Assembly, lever, brake

1

Assembly, cylinder, hydraulic, 2”x21/4”

hand port)

Assembly, cylinder, hydraulic, 2x21/4”

hand port)

7

03-612-002

Assembly, hinge pin

4

20

50-024-006

Cover, rear leg

2

Cylinder, hydraulic

GPT-L-PT-10HP

•9

50-623-002

Assembly, axle, rear wheel (2)

1

22

99-145-105

U-nut, 1/4”-20

9

10

50-612-007

Assembly, transaxle, 3/4” shaft

1

23

29185

Screw, machine, truss head

13

Bolt, HHCS #2, z-plated, 3/8”16x23/4”

•••12

50-542-009

Subassembly, sprocket, drive, left

1

25

36106

Hex nut, gr. A, z-plated, 3/8”-16

4

••••13

50-542-010

Subassembly, sprocket, drive, right

1

26

50-145-009

Transaxle link, threaded rod

1

Complete Exploded View and Bill of Materials: ALL-T-2-GPT-PT-10HP; ALL-T-4GPT-PT-10HP; ALL-T-2-GPT-L-PT-10HP; & ALL-T-4-GPT-L-PT-10HP

5

50-521-001

piston style with clevis mounts (right

18

1

50-024-017 Guard, skid plate, top, formed 1

6

50-521-002

piston style with clevis mounts (left

19

1

50-024-009 Guard, skid plate, 10HP 1

99-021-909-001

8

••11 50-525-002 Weldment, steering handle 1 24

99-021-952

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 15 of 26

ALL-T-2-GPT-PT-10HP & ALL-T-2-

ALL-T-4-GPT-PT-10HP & ALL-T-4-

GPT-L-PT-10HP

21

1

1

50-024-016 Cover, front leg 2

11114

4

Page 16

Adjustable yoke end,

2”x7/16’x5/8”x1/4”-28

Bolt, HHCS, #2, z-plated, 5/16”18x2”

Hex bolt, gr. A, z-plated, 1/4”20x4”

Nylon lock nut, gr. 2, z-finish,

/4”-20

Nylon insert lock nut, gr. 2, zfinish, 3/8”-16

Narrow machinery bushing,

plain, 13/4” x 18ga.

Subassembly, hose, suction,

tank-to-pump

External retaining ring,

phosphate finish, 11/8”

Subassembly, hose, return,

valve-to-tank

Subassembly, hose, bottom tilt,

bulkhead-to-cylinder

Subassembly,, hose, top tilt,

bulkhead-to-block

Subassembly, hose, valve-topump

Bolt, #2, z-plated, 5/16”18UNCx11/2”

Fitting, hydraulic, 06MJ08MA

ORB 90° elbow

50-028-002

Fork

ALL-T-4-GPT-L-PT

39

50-024-015

Guard, right side transaxle

1

*67

99-031-078

Accessories, pipe, 3/4” NPT

1

40

50-016-008

Bracket, drive-to-neutral, formed

1

*68

01-031-005

Filter, reservoir, hydraulic

1

Weldment, handle, drive-toneutral

Subassembly, hose, tilt, valveto-bulkhead

Screw, thread cutting, 1/4”20x3/4”

Subassembly, hose, lift, valveto-bulkhead

Subassembly, hose, block-to-tiltcylinder

Fitting, hydraulic, 06MJ-08MP

90° elbow

Subassembly, pump, hydraulic

gear

*47

50-027-004

Pulley, motor

1

*75

99-031-096

Accessories, clamp, 2 ear 11/8”

1

*48

50-523-001

Subassembly, reservoir

1

*76

21-139-002

Battery, 12V, sealed lead-acid

1

Accessories, motor

contactor,12V coil

Accessories, electrical battery

box, series 16

Hex bolt, gr. A, z-finish, 3/8”16x11/2”

*53

*54

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Item Part no. Description Qty. Item Part no. Description Qty.

27

28

43520

50-120-001 Nut, brake 1

*55

1

99-130-003 Pin, keystock 1

*56

11061

29

30

66026 Pin, clevis,

65012 Cotter pin, z-plated,

1

/4”x1” 1

1

/16”x1/2” 2

*57

*58

11019

37018

1

31

15-112-002 Pin, cylinder bracket 1

32

33

34

33454

68021

23203

Bolt, SHCS, utility grade,

3

/4”

20x

1

/4”-

*59

*60

8

*61

2

*62

1

37024

50-623-012

50-623-013

50-623-014

bulkhead-to-block & lift,

35

36

36102 Hex nut, gr. A, z-plated,

50-130-007 Pin, key, axle extension 1

1

/4”-20 3

*63

*64

50-623-015

50-623-016

37

38

11059

38-028-007

38-028-013

50-028-001

ALL-T-2-GPT-PT

ALL-T-4-GPT-PT

ALL-T-2-GPT-L-PT

*65

1

2

*66

99-116-119

99-116-096

Fitting, hydraulic, 06MJ08MORB STRAIGHT

41

50-525-001

42

50-514-005 Weldment, battery box 1

*69

1

99-031-094 Accessories, cap, 3/4” 1

*70

50-623-017

43

*44

32408

99-659-001 Assembly, engine, 344cc 1

*71

2

*72

50-623-019

50-623-018

*45

50-638-001 Assembly, valve, double 1

*46

50-643-001

*73

99-116-073

*74

1

99-031-095 Accessories, clamp, 2 ear, 17/16” 1

*49

50-540-003 Assembly, belt tensioner 1

*50

50-042-008 Belt, 1/2”x38” 1

*51

99-034-134 Horn 1

*77

99-034-028

*78

21-034-004 Circuit breaker 1

*79

50-034-004

*52

1

• Item 9 shown in Rear Wheel Axle Assembly (2) Exploded View on p. 17.

•• Item 11 shown in Steering Handle Subassembly Exploded View on p. 18.

••• Item 12 shown in Sprocket Drive Subassembly, Left Side, Exploded Views on p. 24.

•••• Item 13 shown in Sprocket Drive Subassembly, Right Side, Exploded Views on p. 23.

* Components of Power Unit Subassembly 50-160-005 on p. 22.

50-034-003 Accessories, 9V battery clip 1

50-139-001 Battery, 9V 1

50-034-002 Accessories, 9V battery snap 1

*80

*81

11109

11003

Hex bolt, gr. A, z-plated, 1/4”20x3/4”

3

1

1

3

1

1

2

1

1

2

3

2

1

4

1

1

1

4

2

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 16 of 26

Page 17

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Item

Part no.

Description

Qty.

1

2

3

1

Machine bushing, low

carbon, plain, 3/4”x18ga.

Extended prong cotter pin,

z-finish, 1/8”x11/2”

7

22-110-001

Bearing, upper steering

1 8 50-113-017

Shim, bearing spacer

1 9 50-113-014

Spacer, rear steering

1

Specialty hardware, cap,

hex nut

11

Cotter pin, z-plated,

/16”x11/4”

Bearing, ball, low speed,

rear wheel

15

50-110-008

Bearing, seal

1

Rear Wheel Axle Assembly (2) Exploded View and Bill of Materials

Item

Part no.

Description

Qty. 1 50-612-001

Weldment, rear king pin

1 2 16-132-361

Foam filled tire, 4.80”x8”

2 3 22-110-001

Bearing, upper steering

1 4 50-113-017

Shim, bearing spacer

1

5

Specialty hardware, cap,

hex nut

7

50-110-005

Bearing, tapered

1 8 50-110-006

Bearing, cup

1

Wheel, rim for pneumatic

tire

Slotted jam nut, gr. 2,

plain, 1”-14

11

33444

Machine bushing, 1”x18ga.

2

Extended prong cotter pin,

z-finish, 1/8”x11/2”

13

50-110-007

Bearing, seal

1

Cotter pin, z-plated,

/16”x11/4”

Return to p. 9.

Return to p. 11; p. 13; or p. 15.

Rear Wheel Axle Assembly (1) Exploded View and Bill of Materials

ALL-T-2-GPT; ALL-T-4-GPT; ALL-T-2-GPT-L; ALL-T-4-GPT-L

50-612-008

50-112-013 Pin, rear, king pin 1

50-112-014 Axle, rear 1

64255

4

16-132-235 Tire, rear, foam filled 2

/4”x2” spring pin 1

5

6

10

33424

65078

50-145-010

50-110-002 Bearing, tapered 1

12

50-110-004 Bearing, cup 1

13

14

65124

50-110-003

3

ALL-T-2-GPT-PT; ALL-T-4-GPT-PT; ALL-T-2-GPT-L-PT; ALL-T-4-GPT-L-PT; ALL-T-2-GPT10HP; ALL-T-4-GPT-10HP; ALLT-2-GPT-L-10HP; ALL-T-4-GPT-L-10HP; ALL-T-2-GPT-PT10HP; ALL-T-4-GPT-PT-10HP; ALL-T-2-GPT-L-PT-10HP; ALL-T-4-GPT-L-PT-10HP

50-623-002

4

2

1

1

4

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 17 of 26

50-113-014 Spacer, rear steering 1

6

50-145-010

9

16-132-280

10

12

14

36870

65078

65124

3

1

2

2

2

1

Page 18

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Qty

.

Specialty hardware, shifter

cable

Hex bolt, gr. A, plain, 3/8”16x21/2”

Adjustable yoke end,

2”x7/16”x5/8”x1/4”-28

4

17

Specialty hardware, shock,

tension

Hex bolt, gr. A, zinc finish,

/8”-16x 11/2”

Nylon insert lock nut, gr. 2,

z-finish, 3/8”-16

Flat washer, USS, z-plated,

/4”

Bolt, HHCS, #2, z-plated,

/8”-16x31/2”

Hex bolt, gr. A, z-plated, 1/4”20x13/4”

Hex nut, gr. A, z-plated, 3/8”16

Switch, PB SPST, normally

closed

Bolt, HHCS, #2, z-plated,

/4”-20x21/2”

Switch, PB SPST, normally

open

Nylon lock nut, gr. 2, z-finish

/4”-20

Hex bolt, gr. A, z-plated,

/4”-16x11/2”

Weldment, frame, handle

mount

Return to p. 9; p. 11;

Steering Handle Subassembly Exploded View and Bill of Materials

50-525-002

p. 13; or p. 15.

Item Part no. Description Qty. Item Part no. Description

1

50-113-002 Spacer, air spring 2

14

50-145-003

2

50-113-03 Spacer, handle 2

3

50-525-003 Weldment, steering handle 1

15

16

11113

43520

1

2

1

50-540-004 Weldment, shifter lever 1

5

50-525-004 Weldment, safety bale 1

6

99-145-015

7

8

9

10

11

12

13

11109

37024

11117

36106

11013

37018

11009

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 18 of 26

50-120-001 Nut, brake 1

18

19

1

20

3

3

1

1

1

1

3

4

4

1

3

1

21

22

23

24

25

26

66026 Pin, clevis, 1/4”x1” 1

65012 Cotter pin, z-plated, 1/16”x1/2” 2

50-146-002 Spring, kill switch 1

33004

11010

50-022-001

50-022-002

50-034-001 Boot, switch 2

50-514-040

1

1

1

1

1

1

Page 19

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

ALL-T-(2 or 4)-GPT Power Unit Subassembly Exploded View and Bill of Materials

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

Engine

ALL-T-GPT-10HP

3

/8”-16 Nylon insert lock nut, gr. 2,

z-finish

Subassembly, pump, hydraulic,

gear

4

50-027-003

Pulley, engine

1

19

50-623-008

Subassembly, hose, valve return

1 5 50-523-001

Subassembly, reservoir

1

20

50-623-010

Subassembly, hose, pump

1 6 50-540-003

Assembly, belt tensioner

1

21

50-623-007

Subassembly, hose, return

1 7 15-042-003

Belt, 1/2”x55”

1

22

50-623-006

Subassembly, hose, suction

1 8 99-034-134

Horn, ALL-T

1

23

50-623-011

Subassembly, hose, valve

1

Accessories, electrical, 9V

battery clip

10

50-139-001

Battery, 9V

1

25

99-116-073

Fitting, hydraulic, 06MJ-08MP 90°

2

Accessories, electrical, 9V

battery snap

5/

16

14

11019

1/

4

”-20x4” hex bolt, gr. A, z-plated

1

29

99-031-095

Accessories, clamp, 2 ear, 17/16”

1

1

/4”-20 Nylon insert lock nut, gr. 2,

z-finish

Return to p. 10

50-160-002

1

2

3

9

11

12

13

99-159-007

ALL-T-GPT: 190cc

50-638-002 Assembly, T3 valve 1

50-643-001

50-034-003

50-034-002

99-130-001 Pin, keystock 1

11053

”-18x3/4”, HHCS, #2, z-plated 3

1

1

1

1

16

17

18

24

26

27

28

11109

37024

50-623-009 Subassembly, hose, cylinder 1

99-116-074 Fitting, hydraulic, 06MJ-12MP 90° 2

99-031-078 Accessories, pipe, 3/4” NPT

01-031-005 Filter, reservoir, hydraulic 1

99-031-094 Accessories, cap, 3/4” 1

3

/8”-16x11/2” hex bolt, gr. A, zinc

finish

3

3

15

37018

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 19 of 26

3

30

99-031-096 Accessories, clamp, 2 ear, 11/8” 1

Page 20

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

ALL-T-(2 or 4)-GPT-10HP and ALL-T-(2 or 4)-GPT-L-10HP

2

19

6

23

Accessories, motor contactor, 12V

coil

Accessories, electrical, 9V battery

clip

Accessories, electrical, 9V battery

snap

5/

1/

1

/4”-20 Nylon insert lock nut, gr. 2, z-

finish

3

/8”-16x11/2” hex bolt, gr. A, zinc

finish

3

/8”-16 Nylon insert lock nut, gr. 2, z-

finish

Return to p. 12

Power Unit Subassembly Exploded View and Bill of Materials

50-160-003

Item Part no. Description Qty. Item Part no. Description Qty.

1

99-659-001 Engine, 344cc 1

50-638-002 Assembly, T3 valve 1

3

50-643-001 Subassembly, pump, hydraulic, gear 1

4

50-027-004 Pulley, engine 1

5

50-523-001 Subassembly, reservoir 1

50-540-005 Assembly, belt tensioner 1

7

50-042-009 Belt, 1/2”x40” 1

8

99-034-134 Horn, ALL-T 1

9

50-034-003

10

50-139-001 Battery, 9V 1

11

50-034-002

12

99-130-003 Pin, keystock 1

13

14

15

11053

11019

37018

”-18x3/4”, HHCS, #2, z-plated 3

16

”-20x4” hex bolt, gr. A, z-plated 1

4

18

50-623-009 Subassembly, hose, cylinder 1

50-623-008 Subassembly, hose, valve return 1

20

50-623-010 Subassembly, hose, pump 1

21

50-623-007 Subassembly, hose, return 1

22

50-623-006 Subassembly, hose, suction 1

50-623-011 Subassembly, hose, valve 1

24

21-139-002 Battery, 12V sealed lead-acid AGM 1

25

99-034-028

26

1

1

3

21-034-004 Circuit breaker 1

27

28

29

30

31

32

11003 Hex bolt, gr. A, z-plated, 1/4”-20 x 3/4” 2

50-034-004 Accessories, battery box, series 16 1

99-031-078 Accessories, pipe, 3/4” NPT 1

99-031-094 Accessories, cap, 3/4” 1

01-031-005 Filter, reservoir, hydraulic 1

99-116-073 Fitting, hydraulic, 06MJ-08MP 90° 2

1

16

17

11109

37024

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 20 of 26

33

4

4

99-116-074 Fitting, hydraulic, 06MJ-12MP 90° 2

Page 21

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

ALL-T-(2 or 4)-GPT-PT and ALL-T-(2 or 4)-GPT-L-PT

Item

Part no.

Description

Qty.

Item

Part no.

Description

Qty.

Subassembly, pump, hydraulic,

gear

Subassembly, hose, bottom tilt, bulkhead

to block & lift, bulkhead to cylinder

Subassembly, hose, top tilt, bulkhead to

block

6

23

Accessories, electrical, 9V battery

clip

Accessories, electrical, 9V battery

snap

Subassembly, hose, tilt, hose to bulkhead

Subassembly, hose, lift, valve to

bulkhead

5/

1/

1

/4”-20 Nylon insert lock nut, gr. 2,

z-finish

3

/8”-16x11/2” hex bolt, gr. A, zinc

finish

3

/8”-16 Nylon insert lock nut, gr. 2,

z-finish

Return to p. 14

Power Unit Subassembly Exploded View and Bill of Materials

50-160-004

1

99-159-007 Engine, 190cc 1

2

50-638-001 Assembly, valve, double 1

3

50-643-001

4

50-027-003 Pulley, engine 1

5

50-523-001 Subassembly, reservoir 1

50-540-003 Assembly, belt tensioner 1

7

50-042-010 Belt, 1/2”x40” 1

8

99-034-134 Horn, ALL-T 1

9

50-034-003

10

50-139-001 Battery, 9V 1

11

50-034-002

12

99-130-001 Pin, keystock 1

13

14

15

16

11061

11019

37018

11109

”-18x2”, HHCS, #2, z-plated 3

16

”-20x4” hex bolt, gr. A, z-plated 1

4

18

50-623-012 Subassembly, hose, suction tank to pump 1

19

50-623-013 Subassembly, hose, return valve to tank 1

20

1

1

1

1

3

50-623-014

21

50-623-015

22

50-623-016 Subassembly, hose, valve to pump 1

99-116-119 Fitting, hydraulic, 06MJ-08MAORB 90° 2

24

99-116-073 Fitting, hydraulic, 06MJ-08MP 90° 1

25

99-031-078 Accessories, pipe, 3/4” NPT 1

26

01-031-005 Filter, reservoir, hydraulic 1

27

99-031-094 Accessories, cap, 3/4” 1

28

50-623-017

29

50-623-019

30

50-623-018 Subassembly, hose, block to tilt 4

31

99-116-096 Fitting, hydraulic, 06MJ-08MORB straight 3

32

99-031-095 Accessories, clamp, 2 ear, 17/16” 1

33

99-031-096 Accessories, clamp, 2 ear, 11/8” 1

2

1

2

1

17

37024

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 21 of 26

3

Page 22

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

Subassembly, hose, top tilt, bulkhead to

block

Subassembly, hose, tilt, hose to

bulkhead

Subassembly, hose, lift, valve to

bulkhead

Fitting, hydraulic, 06MJ-08MORB

straight

1

/4”-20 Nylon insert lock nut, gr. 2, z-

finish

3

/8”-16 Nylon insert lock nut, gr. 2, z-

finish

Subassembly, hose, suction tank to

pump

Subassembly, hose, return valve to

tank

Subassembly, hose, bottom tilt,

cylinder

ALL-T-(2 or 4)-GPT-PT-10HP & ALL-T-(2 or

Return to p. 16

4)-GPT-L-PT-10HP Power Unit Subassembly

Exploded View and Bill of Materials

50-160-005

Item Part no. Description Qty. Item Part no. Description Qty.

1 99-659-001 Engine, 344cc 1 20 50-623-015

2 50-638-001 Assembly, valve, double 1 21 50-623-016 Subassembly, hose, valve to pump 1

3 50-643-001 Subassembly, pump, hydraulic, gear 1 22 99-116-119 Fitting, hydraulic, 06MJ-08MAORB 90° 2

4 50-027-004 Pulley, engine 1 23 99-116-073 Fitting, hydraulic, 06MJ-08MP 90° 1

5 50-523-001 Subassembly, reservoir 1 24 99-031-078 Accessories, pipe, 3/4” NPT 1

6 50-540-003 Assembly, belt tensioner 1 25 01-031-005 Filter, reservoir, hydraulic 1

7 50-042-008 Belt, 1/2”x38” 1 26 99-031-094 Accessories, cap, 3/4” 1

8 99-034-134 Horn, ALL-T 1 27 50-623-017

9 50-034-003 Accessories, electrical, 9V battery clip 1 28 50-623-019

10 50-139-001 Battery, 9V 1 29 50-623-018 Subassembly, hose, block to tilt 4

11 50-034-002 Accessories, electrical, 9V battery snap 1 30 99-116-096

12 99-130-003 Pin, keystock 1 31 99-031-095 Accessories, clamp, 2 ear, 17/16” 1

13 11061

14 11019

15 37018

16 37024

17 50-623-012

5/

”-18x2”, HHCS, #2, z-plated 3 32 99-031-096 Accessories, clamp, 2 ear, 11/8” 1

16

1/

”-20x4” hex bolt, gr. A, z-plated 1 33 21-139-002 Battery, 12V, sealed lead-acid (AGM) 1

4

1

2

1

3

3 34 99-034-028 Accessories, motor contactor 12V coil 1

3 35 21-034-004 Circuit breaker 1

1 36 50-034-004 Accessories, battery box, series 16 1

18 50-623-013

19 50-623-014

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 22 of 26

bulkhead to block & lift, bulkhead to

1 37 11109 Hex bolt, gr. A, z-finish, 3/8”-16 x 11/2” 4

2 38 11003 Hex bolt, gr. A, z-plated, 1/4”-20 x 3/4” 2

Page 23

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

50-145-007

Chain:

ALL-T-4-GPT-L-10HP

1

Thread cutting screw, type F,

/16”-18 x 1/2”

Thread cutting screw, slotted,

type F, 5/16”-18 x 3/4”

Bolt, HHCS, z-plated, 5/16”-18 x

/4”

50-145-007

Chain:

ALL-T-2-GPT-L & ALL-T-4-GPT-L

1

Thread cutting screw, type F, 5/16”18 x 1/2”

Thread cutting screw, slotted, type

F, 5/16”-18 x 3/4”

Sprocket Drive Subassembly, Right Side Exploded View and Bill of Materials

ALL-T-2-GPT-10HP; ALL-T-4-GPT-10HP;

ALL-T-2-GPT-L-10HPL & ALL-T-4-GPT-L-10HP

(50-542-008 & 50-542-010 on p. 11 or p. 15)

Item Part no. Description Qty.

1 50-612-002 Assembly, front axle 1

2 15-110-001 Bearing, ball, front axle 1

3 16-132-229 Tire, front left, foam filled 1

4 50-110-001 Bearing, flange mount 2

5 50-042-005 Sprocket, roller chain, front wheel 1

6 50-540-008 Subassembly, chain tensioner 1

7 50-024-004 Cover, front axle skid plate 1

8 50-024-010 Cover, sprocket 1

50-145-006

9

50-145-006

50-145-007

10 20-042-002 Sprocket, driver, #50, 10 tooth 1

11 50-120-005 Nut, front lug 4

12 32415

13 32416

14 11053

15 36104 Hex nut, gr. A, z-plated, 5/16”-18 4

16 99-130-003 Pin, key stock 2

ALL-T-2-GPT-10HP

ALL-T-4-GPT-10HP

ALL-T-2-GPT-L-10HP

5

3

Sprocket Drive Subassembly, Right Side Exploded View and Bill of Materials

ALL-T-2-GPT; ALL-T-4-GPT;

ALL-T-2-GPT-L and ALL-T-4-GPT-L

(50-542-004 & 50-542-006 on p. 9 or p. 13)

Item Part no. Description Qty.

1 50-612-002 Assembly, front axle 1

2 15-110-001 Bearing, ball, front axle 1

3 16-132-229 Tire, front left, foam filled 1

4 50-042-004 Bearing, flanged, transaxle 1

5 50-110-001 Bearing, flange mount 1

6 50-042-005 Sprocket, roller chain, front wheel 1

7 50-540-008 Subassembly, chain tensioner 1

8 50-024-004 Cover, front axle skid plate 1

9 50-024-010 Cover, sprocket 1

1

1

1

2

2

4

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 23 of 26

10 50-145-006

11 20-042-007 Sprocket, driver, #50, 10 tooth 1

12 50-120-005 Nut, front lug 4

13 32415

14 32416

15 11053 Bolt, HHCS, z-plated, 5/16”-18 x 3/4” 4

16 36104 Hex nut, gr. A, z-plated, 5/16”-18 4

17 99-130-003 Pin, key stock 1

18 99-130-002 Pin, key stock 1

ALL-T-2-GPT & ALL-T-4-GPT

1

2

2

Page 24

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

50-145-007

Chain:

ALL-T-4-GPT-L-10HP

1

Thread cutting screw, type F,

/16”-18 x 1/2”

Thread cutting screw, slotted,

type F, 5/16”-18 x 3/4”

Bolt, HHCS, z-plated, 5/16”-18 x

/4”

50-145-007

Chain:

ALL-T-2-GPT-L & ALL-T-4-GPT-L

1

Thread cutting screw, type F, 5/16”18 x 1/2”

Thread cutting screw, slotted, type

F, 5/16”-18 x 3/4”

Sprocket Drive Subassembly, Left Side Exploded View and Bill of Materials

ALL-T-2-10HP; ALL-T-4-10HP; ALL-T-2-L-10HP and ALL-T-4-L-10HP

(50-542-007 & 50-542-009 on p. 11 or p. 15)

Item Part no. Description Qty.

1 50-612-002 Assembly, front axle 1

2 15-110-001 Bearing, ball, front axle 1

3 16-132-229 Tire, front left, foam filled 1

4 50-110-001 Bearing, flange mount 2

5 50-042-005 Sprocket, roller chain, front wheel 1

6 50-540-008 Subassembly, chain tensioner 1

7 50-024-004 Cover, front axle skid plate 1

8 50-024-010 Cover, sprocket 1

50-145-006

9

50-145-006

50-145-007

10 20-042-002 Sprocket, driver, #50, 10 tooth 1

11 50-120-005 Nut, front lug 4

12 32415

13 32416

ALL-T-2-GPT-10HP

ALL-T-4-GPT-10HP

ALL-T-2-GPT-L-10HP

5

14 11053

15 36104 Hex nut, gr. A, z-plated, 5/16”-18 4

16 99-130-003 Pin, key stock 2

3

Sprocket Drive Subassembly, Left Side Exploded View and Bill of Materials

ALL-T-2-GPT; ALL-T-4-GPT; ALL-T-2-GPT-L; and ALL-T-4-GPT-L

(50-542-003 & 50-542-005 on p. 9 or p. 13)

Item Part no. Description Qty.

1 50-612-002 Assembly, front axle 1

2 15-110-001 Bearing, ball, front axle 1

3 16-132-231 Tire, front left, foam filled 1

4 50-042-004 Bearing, flanged, transaxle 1

5 50-110-001 Bearing, flange mount 1

6 50-042-005 Sprocket, roller chain, front wheel 1

7 50-024-007 Sprocket, roller chain, axle 1

8 50-540-008 Subassembly, chain tensioner 1

9 50-024-004 Cover, front axle skid plate 1

10 50-024-010 Cover, sprocket 1

1

1

1

2

2

4

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 24 of 26

11 50-145-006

12 50-120-005 Nut, front lug 4

13 32415

14 32416

15 11053 Bolt, HHCS, z-plated, 5/16”-18 x 3/4” 4

16 36104 Hex nut, gr. A, z-plated, 5/16”-18 4

17 99-130-003 Pin, key stock 1

18 99-130-002 Pin, key stock 1

ALL-T-2-GPT & ALL-T-4-GPT

1

2

2

Page 25

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

D: Label 1110 on frame/oil tank

C: Label 206 on frame/oil tank close to oil fill cap

B: Label 1109 on back of carriage cross bar

J: Label 661

(not

diagrams)

transaxle

release lever

(p. 7)

G: Label 835 on

frame by parking

brake

F

H: Label 696 on frame by

motor

A: Label 220 on both legs and on drive belt guard (p. 8)

E: Label 834 on kill

switch

F: Label 662 on

handle by

direction

control lever

C

E

F

G

H

A

B

C

D

A

G

A

H

LABELING DIAGRAM

The unit should be labeled as shown in the diagrams. However, label content and location are subject to

change so your product might not be labeled exactly as shown. Thoroughly photograph the unit when you

first receive it as discussed in the Record of Satisfactory Condition portion of the Inspections and

Maintenance section on p. 7-8. Make sure that your record includes a photograph of each label. Replace all

labels that are, or later become, damaged, missing, or not easily readable (e.g. faded). To order

replacement labels, contact the technical service and parts department online at

http://www.vestilmfg.com/parts_info.htm. Alternatively, you may request replacement parts and/or service by

calling (260) 665-7586 and asking the operator to connect you to the Parts Department.

shown in

on

Table of Contents Copyright 2019 Vestil Manufacturing Corp. Page 25 of 26

Page 26

Table of Contents 2/28/2020 ALL-T-2/4-GPT MANUAL

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective, original part covered by the

warranty after we receive a proper request from the Warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

Definition of “original part”?

An original part is a part used to make the product as shipped to the Warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests by

one of the following methods:

US Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 info@vestil.com

2999 North Wayne Street, PO Box 507 Phone Enter “Warranty service request”

Angola, IN 46703 (260) 665-7586 in subject field.

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered. After Vestil receives your request for warranty service, an authorized representative will contact you to

determine whether your claim is covered by the warranty. Before providing warranty service, Vestil will require you to

send the entire product, or just the defective part (or parts), to its facility in Angola, IN.

What is covered under the warranty?

The warranty covers defects in the following original, dynamic parts: motors, hydraulic pumps, motor controllers, and

cylinders. It also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such as

bearings, hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 1 year. For wearing parts, the warranty period is 90 days. Both

warranty periods begin on the date Vestil ships the product to the Warrantee. If the product was purchased from an

authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its sole discretion, extend a

warranty period for products shipped from authorized distributors by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

The Warrantee (you) are responsible for paying labor costs and freight costs to return the product to Vestil for warranty

service.

Events that automatically void this Limited Warranty.

• Misuse;

• Negligent assembly, installation, operation or repair;

• Installation/use in corrosive environments;

• Inadequate or improper maintenance;

• Damage sustained during shipping;

• Collisions or other accidents that damage the product;

• Unauthorized modifications: Do not modify the product IN ANY WAY without first receiving written authorization from

Vestil.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty. Vestil makes