Vestil A-LIFT User Manual

rev. 1/16/2013 A-Lift, manual.doc

y

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail:

HUsales@vestil.comU

A-LIFT SERIES HAND WINCH LIFT TRUCKS

INSTRUCTION MANUAL

A-LIFT-S

UReceiving instructionsU:

A-LIFT-R A-LIFT-CB

After delivery, IMMEDIATELY remove the packaging from the Hook-Base in a manner that preserves the

packaging and maintains the orientation of the product in the packaging; then inspect the product closely to

determine whether it sustained damage during transport. If damage is discovered during the inspection,

UimmediatelyU record a complete description of the damage on the bill of lading. If the product is

undamaged, discard the packaging.

UNOTESU:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where the

product is used is exclusively the responsibility of the owner/end-user.

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply

either:

a) Instructions in this manual; or

b) Information provided on labels affixed to the product. Neither is Vestil responsible for any consequential

damages sustained as a result of failing to exercise sound judgment while assembling, installing, using or

maintaining this product.

UTable of Contents

Hazard identification: explanation of signal words………………………………………………………………… 2

Safety Guidelines…………………………………………………………………………………………………….. 2

Product specifications by model……………………..……………………………………………………………… 3

FIG 1A: HP & EHP models have telescoping mast frame……………………………………………………….. 3

FIG. 1B: Diagram of Assembled A-Lift……………………………………………………………………………... 4

Assembly Instructions…………………………………………………………………… …………………………… 5-7

Operation Instructions……………………………………………………………………………… ………………… 7-9

Inspections & Maintenance…………………………………………………………….......................................... 10

Label placement diagram………………………………………………………… …………………………………. 11

Limited warrant

……………………………………………………………………………………………………….12

Copyright 2012 Vestil Manufacturing Corp. Page 1 of 12

rev. 1/16/2013 A-Lift, manual.doc

Hazard Identification: Explanation of SIGNAL WORDS

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable

seriousness of those injuries, if the product is misused in the ways described. Other signal words call attention to uses

of the product likely cause property damage.

The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, UWILLU result in

DEATH or SERIOUS INJURY. Use of this signal word is limited to the

Identifies a hazardous situation which, if not avoided, COULD result in

Indicates a hazardous situation which, if not avoided, COULD result in

Identifies practices likely to result in product/property damage, such as

Each person who assembles, installs, uses, or maintains this product should read the entire manual in advance

and fully understand the directions. If after reading the manual you do not understand an instruction, ask

your supervisor or employer for clarification, because failure to adhere to the directions in this manual

might result in serious personal injury.

SAFETY GUIDELINES

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, no manual

can address every conceivable risk. The end-user ultimately is responsible for exercising sound judgment at all times.

most extreme situations.

DEATH or SERIOUS INJURY.

MINOR or MODERATE injury.

operation that might damage the product.

Electrocution might result if any part of the mezzanine ladder contacts electrified wires. Reduce the

likelihood of electrocution by applying common sense:

Electrocution Risk: DO NOT contact electrical wires with the winch lift or load! Be aware of all overhead

obstacles and take precautions to avoid contact with them.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious

personal injuries or even be killed. ALWAYS use the product properly:

Failure to read and understand the entire manual before assembling, installing, using or servicing the

product Uconstitutes misuseU. Read the manual to refresh your understanding of proper use and maintenance

procedures.

ALWAYS inspect the Lifter before each use according to the inspection instructions on p. 10. DO NOT use the

Lifter unless it passes the inspection.

Prior to each use, ALWAYS inspect the area where you intend to use the lifter. Inspect the area for unusual

conditions that might require special precautions. See “Notice” on p. 7-8.

DO NOT use a malfunctioning lifter. Always perform the “Function Test” described in the Notice on p. 8 before each

use.

Regardless of whether the lifter is loaded or unloaded, DO NOT stand or travel under the forks and DO NOT allow

any other person to stand or travel under the forks.

Inform all persons in the area that you are going to use the Lifter, and instruct them to stay clear of the device and

the supported load during operation.

ALWAYS make sure that your clothing and body do not contact the mast structure, lifting mechanisms, or carriage

during operation. ONLY operate the lifter from the “Operator’s Position,” shown in Step 2 on p. 8. DO NOT move the

lifter or raise or lower the forks unless you are in the operator’s position.

DO NOT allow people to ride the lifter.

ALWAYS load the A-lift according to the list of recommendations that appears below. Failure to properly position a

load on the forks (or platform) might cause the lifter to tip over and you could be injured as a consequence.

1. DO NOT exceed the A-Lift’s maximum rated load. The rated load (capacity) of your Lifter is posted on a

product label as shown in “Label placement diagram” on p. 11.

2. ONLY move loads using the forks or the optional deck platform (“load-engaging means”).

3. DO NOT handle off-center loads or loads that cannot be centered. ALWAYS properly center the load.

4. Start and stop gradually to avoid upsetting the load from the forks/platform.

5. NEVER tilt the lifter while carrying a load. All four castors must maintain contact with the ground when a

load is on the forks/platform.

DO NOT modify the ladder in any way UNLESS you UfirstU obtain written approval from Vestil. Unauthorized

modifications automatically void the limited warranty (see p. 12) and might make the table unsafe to use.

Copyright 2012 Vestil Manufacturing Corp. Page 2 of 12

rev. 1/16/2013 A-Lift, manual.doc

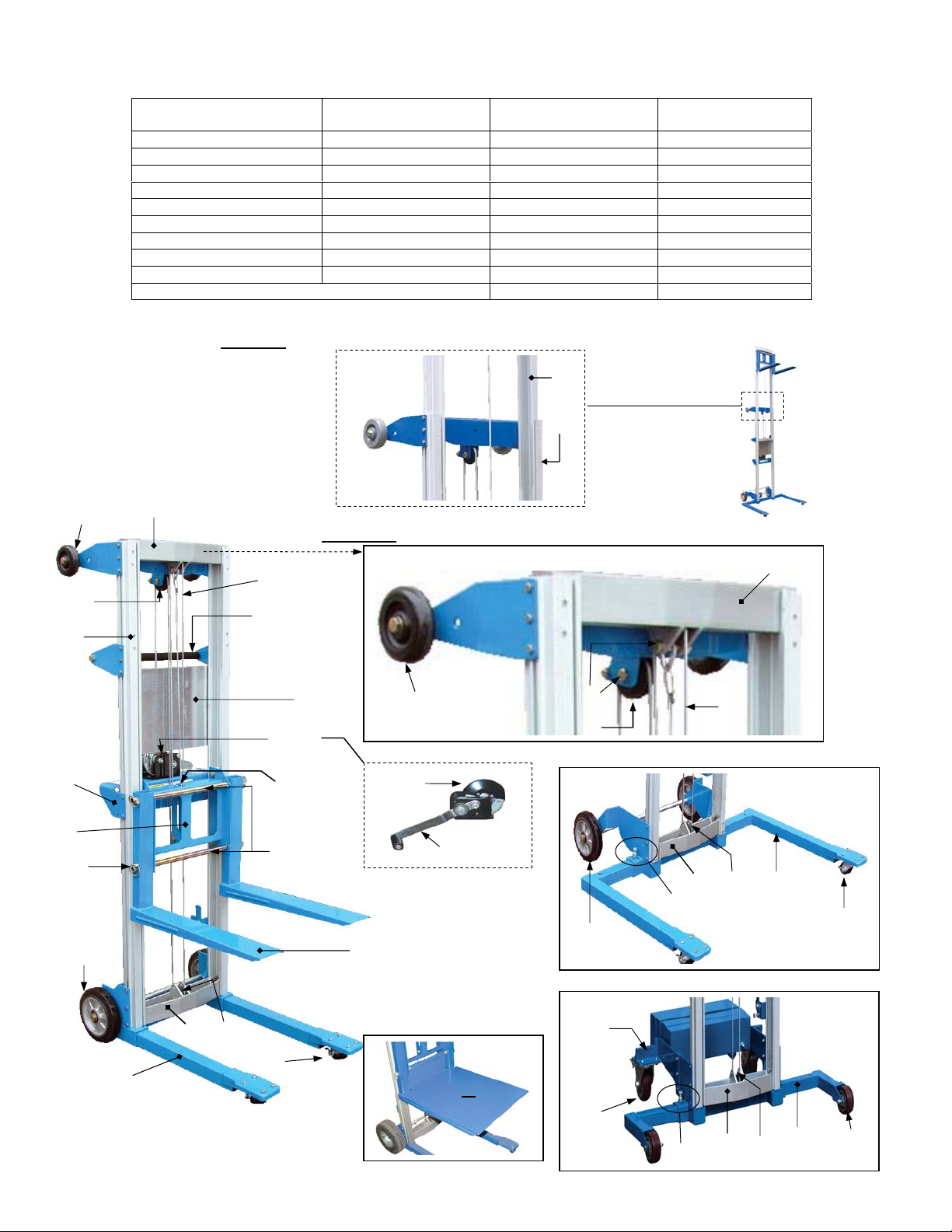

Product Specifications by Model:

Model

A-Lift-R 24 x 35 x 68 500 (~227kg) 136 (~62kg)

A-Lift-R-HP 24 x 35 x 68 400 (~182kg) 140 (~64kg)

A-Lift-S 29 x 43 x 68 500 (~227kg) 140 (~64kg)

A-Lift-S-HP 29 x 43 x 68 400 (~182kg) 145 (~66kg)

A-Lift-S-EHP 29 x 43 x 79 350 (~159kg) 154 (~70kg)

A-Lift-CB 29 x 47 x 68 500 (~227kg) 396 (~180kg)

A-Lift-CB-HP 29 x 47 x 68 400 (~182kg) 418 (~190kg)

A-Lift-CB-EHP 29 x 47 x 79 350 (~159kg) 449 (~204kg)

A-Lift-DK (Deck Platform) 20-1/2 x 24-1/4 25 (~11kg)

A-Lift-PN: 10in. pneumatic rear wheels 20 (~9kg)

UFIG. 1AU: HP & EHP models have telescoping mast frame

Overall Size in Inches

3

2

UFIG. 1BU: Diagram of Assembled A-Lift

(W x L x H)

Maximum Rated

Load in Pounds

6

7

Net Weight in

Pounds (~kg)

4 & 4a

7

26

10

25

23

5

1

8

27

(Winch)

33 & 33a

11

12

2

27

27a

14 4a

4a

4

14 4a

15

9 or 23

or 30

20

3

5

-S Models

13

16

-CB Models

22

Copyright 2012 Vestil Manufacturing Corp. Page 3 of 12

21

29

19

15

14

4a

18

17

rev. 1/16/2013 A-Lift, manual.doc

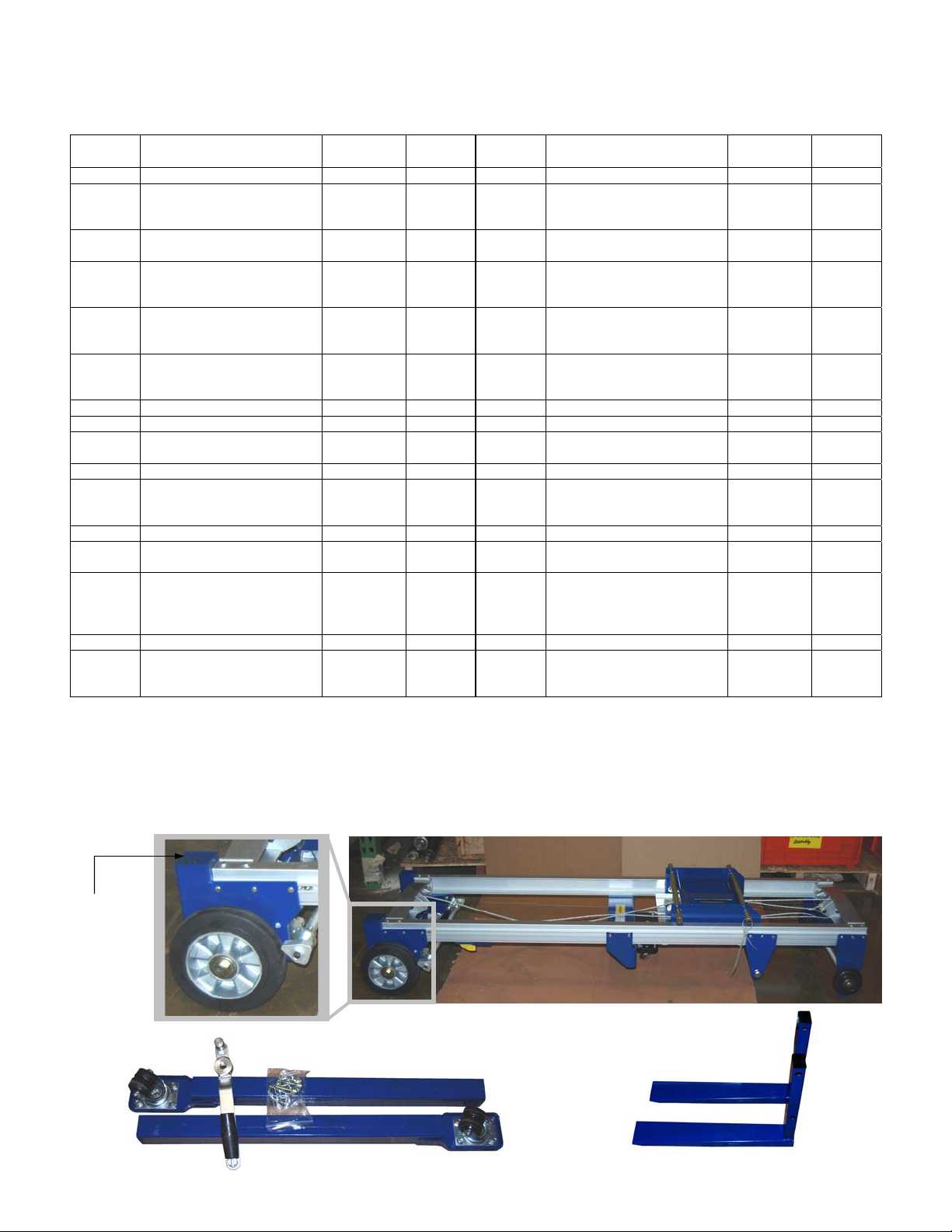

A

Parts List

“Standard Units” refers to A-Lift-R, -S, & -CB models; “HP Units” means A-Lift-R-HP, -S-HP, and -CB-HP models; “EHP

Units” indicates A-Lift-S-EHP and –CB-EHP models.

Diagram

Number Description

1 Operator Handle A-Lift-1 1 17 4 inch Fixed Wheel A-Lift-CB-17 2

2 Loading Wheels A-Lift-2 2 18 Adjustable Leg (-CB

3 Upper Inner Frame Pulley

(casting)

4

4a

10 Carriage A-Lift-10 1 26 Winch Mounting Bracket A-Lift-26 1

11 Fork Mounting Tube A-Lift-11 2 27

12 Fork A-Lift-12 2 28 Not Available nNA N/A

13 Adjustable Leg (Straddle

14

15 Leg Lock Pin A-Lift-CB-15 2 31-32 Not Available N/A N/A

16 Caster: either 2in. (option A)

Large Pulley

Large cable anchor bolt &

nut

5

Cable (Standard Units)

Cable (HP Units)

Cable (EHP Units)

6 Telescoping Inner Mast

Frame (only HP & EHP

Units)

7 Mast Frame A-Lift-7 1 23 Solid Rubber Wheel A-Lift-23 2

8 Decal Plate A-Lift-8 1 24 Brake (optional) A-Lift-24 1

9 10 in. Pneumatic wheel

(optional)

base)

Lower Inner Frame Pulley

(casting)

or 2½ in. (option B)

Part

Number Quantity

A-Lift-3 1 19 5 inch Swivel Castor A-Lift-CB-19 2

A-Lift-4

A-Lift-4a

A-Lift-5

A-Lift-HP-5

A-Lift-EHP-5

A-Lift-6 1 22 Legs - Standard base (R

A-Lift-9 2 25 Fork Lock Pin A-Lift-25 4

A-Lift-S-13 2 29 Deck Platform (optional) A-Lift-Deck 1

A-Lift-14 1 30 [-S models with 4-point

A-Lift-S-16 2 33

Diagram

Number Description

counterweight base

models)

3 20 Counterweight Base A-Lift-CB-20 1

1 21 Caster: 2in. double wheel A-Lift-R-21 2

models)

27a

27-SPG

33a

Winch

Winch Handle

Winch Spring

casters]

4in. caster – option A

5in. caster – option B

Small pulley

Cmall Cable Anchor Bolt &

Nut

Part

Number Quantity

A-Lift-CB-18 2

A-Lift-R-22 2

A-Lift-27

A-Lift-27a

-Lift-27-SPG

A-Lift-29A

A-Lift-29B

A-Lift-33

A-Lift-33a

1

1

1

1

1

Assembly Instructions

Vestil ships winch lifts to its customers in a mostly assembled form. The minimal assembly that is required differs by

model, so follow the directions that correspond to your lifter.

If you purchased an A-Lift-R or A-Lift-S, you will receive 3 pieces:

1). Main Assembly

Support leg

openings

2). Box 1 contains: standard support legs (2),

fork retaining pins (4), winch handle (1).

U

Copyright 2012 Vestil Manufacturing Corp. Page 4 of 12

3). Box 2 contains:

forks (2).

Loading...

Loading...