Page 1

rev. 1/25/2013 AIR-2000-AIR, manual.doc

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail: sales@vestil.com

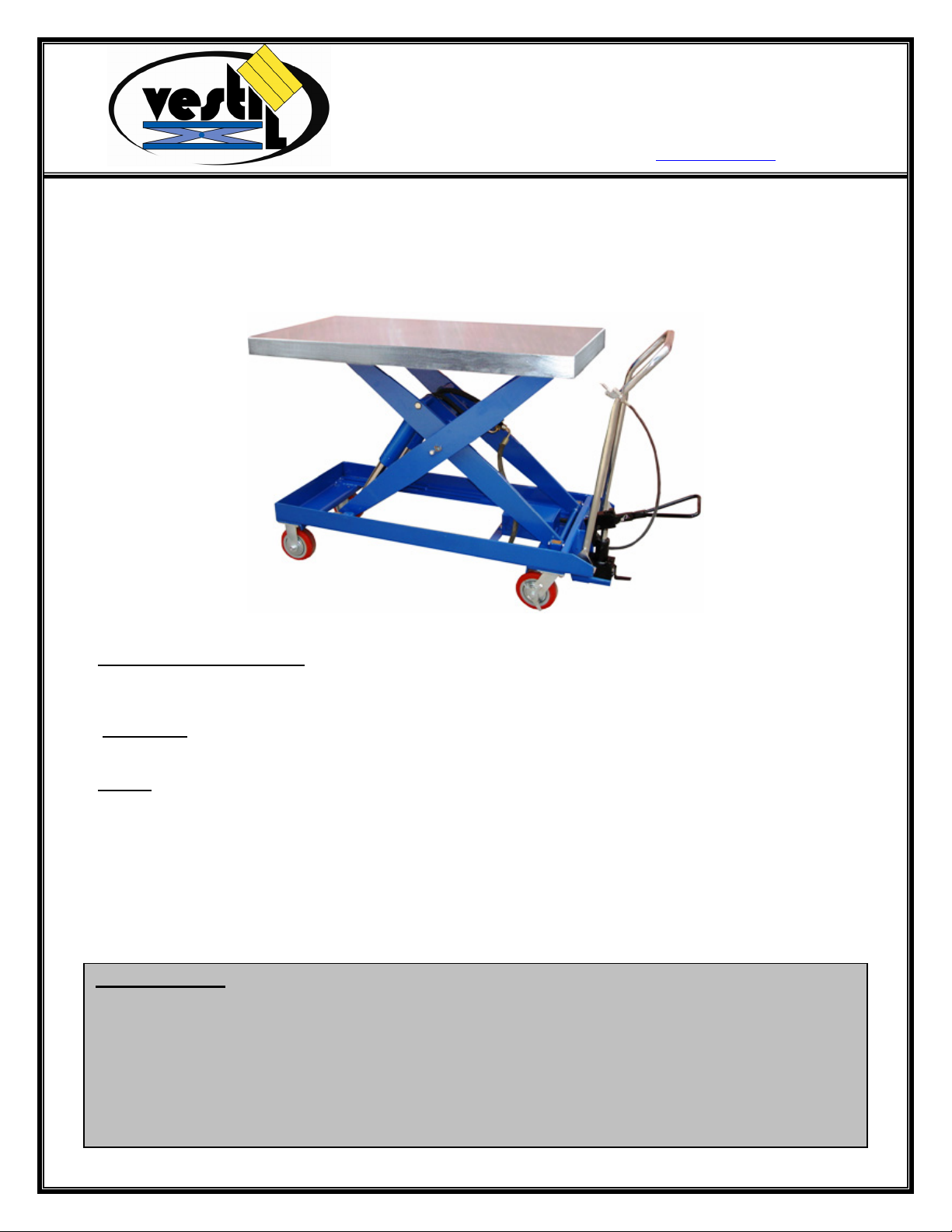

AIR-2000-AIR PNEUMATIC AND HYDRAULIC

DOUBLE-FUNCTION SCISSOR CART

INSTRUCTION MANUAL

RECEIVING INSTRUCTIONS

:

After delivery, IMMEDIATELY remove the packaging from the Hook-Base in a manner that preserves the

packaging and maintains the orientation of the product in the packaging; then inspect the product closely to

determine whether it sustained damage during transport. If damage is discovered during the inspection,

immediately

record a complete description of the damage on the bill of lading. If the product is

undamaged, discard the packaging.

NOTES

:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where the

product is used is exclusively the responsibility of the owner/end-user.

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply either:

a) Instructions in this manual; or

b) Information provided on labels affixed to the product. Neither is Vestil responsible for any consequential

damages sustained as a result of failing to exercise sound judgment while assembling, installing, using or

maintaining this product.

Table of Contents

Hazard identification: explanation of signal words…………………………………………………………………… 2

Safety Guidelines……………………………………………………………………………………………………….. 2

Product specifications by model……………………..………………………………………………………………… 3

Operation….………………………………… ………………………………………………………………………...3-4

Maintenance & Inspections……………………………………………………………............................................. 5

Troubleshooting……………………………………………………………………………………………………….. 6-7

Label placement diagram………………………………………………………………………………………………. 8

Limited warranty………………………………………………………………………………………………………9-10

Copyright 2013 Vestil Manufacturing Corp. Page 1 of 10

Page 2

rev. 1/25/2013 AIR-2000-AIR, manual.doc

Hazard Identification: Explanation of SIGNAL WORDS

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable seriousness

of those injuries, if the product is misused in the ways described. Other signal words call attention to uses of the product

likely cause property damage.

The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, UWILLU result in

DEATH or SERIOUS INJURY. Use of this signal word is limited to

Identifies a hazardous situation which, if not avoided, COULD result

Indicates a hazardous situation which, if not avoided, COULD result

Identifies practices likely to result in product/property damage, such as

Each person who assembles, installs, uses, or maintains this product should read the entire manual in advance

and fully understand the directions. If after reading the manual you do not understand an instruction, ask

your supervisor or employer for clarification, because failure to adhere to the directions in this manual

might result in serious personal injury.

SAFETY GUIDELINES

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, no manual can

address every conceivable risk. The end-user ultimately is responsible for exercising sound judgment at all times.

the most extreme situations.

in DEATH or SERIOUS INJURY.

in MINOR or MODERATE injury.

operation that might damage the product.

Electrocution might result if any part of the mezzanine ladder contacts electrified wires. Reduce the

likelihood of electrocution by applying common sense:

Do NOT assemble or use the cart in an area where it might contact electrified wires;

Do NOT contact electrified wires with the cart;

Before using the crane, always inspect the usage area for conditions that might require special precautions.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious

personal injuries or even be killed. ALWAYS use the product properly: Material handling is inherently dangerous.

Improper or careless operation might result in serious personal injuries sustained by user(s) and/or bystanders.

Always apply the following recommendations:

DO NOT attempt to service a loaded cart. Unload the cart and use the maintenance prop BEFORE working on the

cart. DO NOT work on the cart unless the maintenance prop is in place.

Keep clear of pinch points! As the deck rises and lowers, pinch points are created. NEVER reach, or put any part of

your body, into the scissors mechanism. ALWAYS use the maintenance prop before reaching under the deck. DO NOT

put hands or feet under the deck at any time UNLESS the maintenance props are in place.

DO NOT attempt to lift or transport loads that exceed the maximum rated load of the cart. Before transporting a load,

secure the load to the deck (if necessary) and then lower the deck.

DO NOT stand, sit or ride on the cart.

DO NOT use the cart UNLESS all safety labels are in place and readable.

DO NOT use the cart if you hear unusual sounds while raising or lowering the deck.

Always watch the load carefully while raising or lowering the deck.

ONLY use the cart on stable, improved surfaces.

DO NOT leave a loaded cart unattended. ALWAYS unload the cart, and return it to the designated storage location

BEFORE leaving the cart unattended.

DO NOT modify the cart without the express, written approval from Vestil. Unauthorized modifications

could make the cart unsafe to use. Unauthorized modification(s) automatically voids the warranty.

DO NOT modify the ladder in any way UNLESS you first obtain written approval from Vestil. Unauthorized

modifications automatically void the limited warranty (see p. 8) and might make the table unsafe to use.

Copyright 2013 Vestil Manufacturing Corp. Page 2 of 10

Page 3

rev. 1/25/2013 AIR-2000-AIR, manual.doc

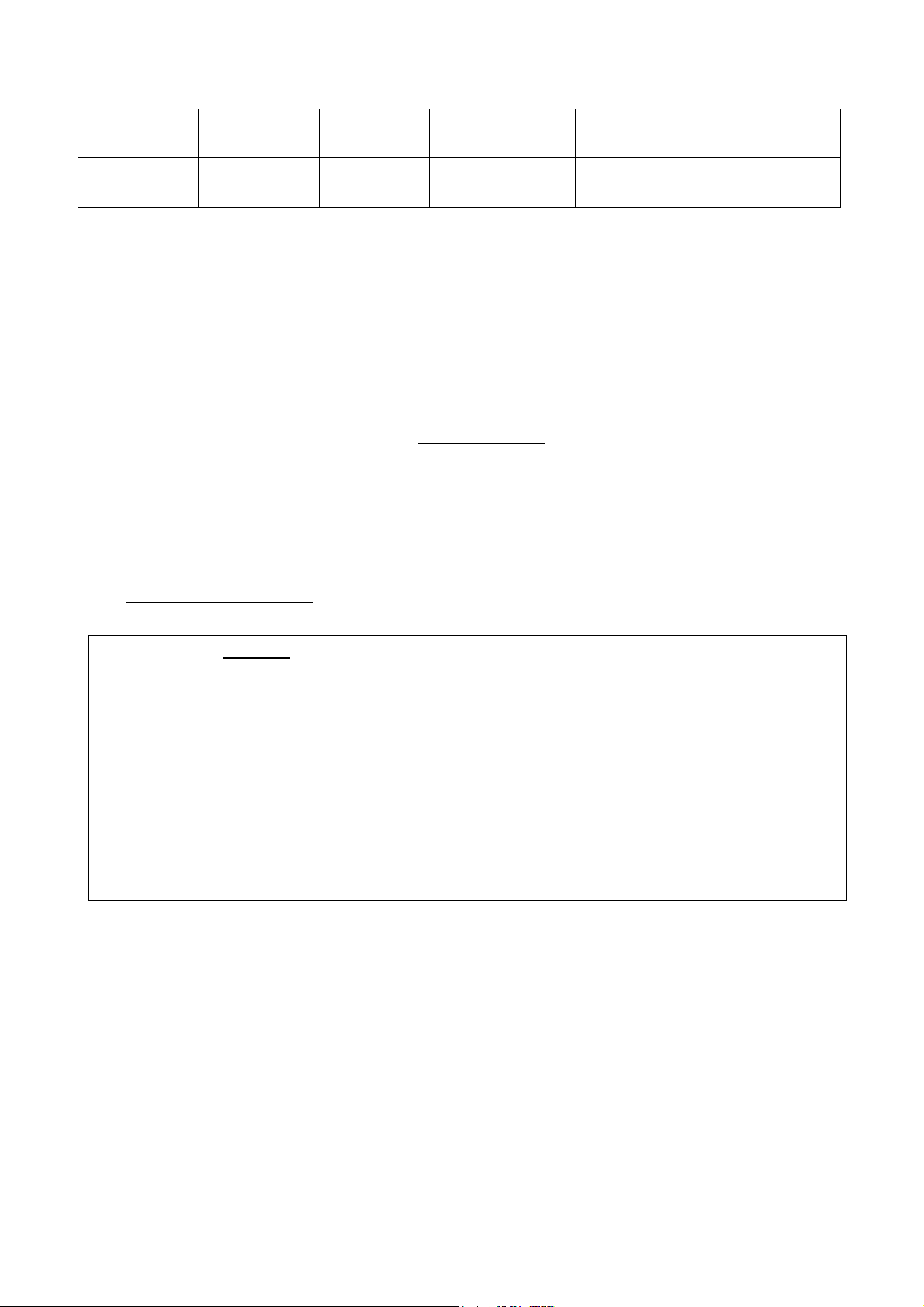

Product Specifications by Model:

Model

AIR-2000-AIR

Maximum Rated

Load

2,200 lbs.

(1,000kg)

Required air

pressure

80 - 100 p.s.i.

Deck dimensions

(W x L)

47¼ in. x 24 in.

1200 cm x 610 cm

Deck travel limits

Lower | Upper

15 in. 39.4in.

38 cm 100 cm

Net Weight in

Pounds (~kg)

lbs

(~kg)

The lifting mechanism of the AIR-2000 series of scissor lift cart will operate both pneumatically (using

factory air) and hydraulically by means of the manually-actuated foot pump. There are 2 swivel casters at

the back of the cart to provide 360 degree range of motion; two fixed casters at the front of the cart provide

stability while the cart travels. In operation, either pressurized air or pressurized hydraulic fluid causes a

cylinder to extend. Cylinder extension in turn causes the scissor leg assemblies to pivot and raise the deck.

OPERATION

This scissor lift cart is suitable for use indoors in most non-classified industrial locations as well as in

many commercial locations. Its intended use is to support and transport stable, evenly-distributed,

non-hazardous materials having dimensions or a footprint approximately equal to or smaller than the

platform.

Loading & Using the Cart:

WARNING: Improper use of this cart could result in serious injuries.

The platform rollers are not captured, which means that the platform pivots at the end near the handle.

The end of the platform opposite the handle can lift off of the rollers. Therefore, you must NOT position

any load on the platform at the hinged end of the platform because the roller end of the platform might

tip up and dump the load. Always center and evenly distribute the load on the platform. The load should

not overhang the platform, either.

Keep clear of the scissor/leg mechanisms while raising or lowering the platform.

Before raising the platform, always engage the caster lock (against the floor).

The load rating in pounds is shown on a label affixed to the cart. This label indicates the net capacity of

the scissor lift with a static load that is centered and evenly distributed on the platform.

The platform should be fully lowered whenever a load is transported with the cart. Failure to do so

could result in injury to personnel or damage to product or equipment due to the lift and its load becoming

unstable during transport.

- Unit is set up to use the foot pump when received.

- To use the air option, attach an air hose to the air-port & use the hand control to raise or lower the

platform.

- The foot pump can be used even if the air hose is plugged into the unit.

- The foot pump has 2 speeds – if the load is not going up or the foot pedal is hard to move, switch the foot

pump speed selection lever to the lower speed.

Copyright 2013 Vestil Manufacturing Corp. Page 3 of 10

Page 4

rev. 1/25/2013 AIR-2000-AIR, manual.doc

Foot Pump Operation

Your new cart is equipped with our exclusive 2-speed foot pump. Features of the pump include: 1)

primary pressure relief valve; 2) pressure compensated return flow control valve; and 3) integrated

lowering valve. Bushings, valve components, and seals are replaceable. Contact the factory for

replacement parts.

Pressing down on the pump pedal causes the platform to rise. Depressing the lowering valve will lower

the table at a constant rate of descent. If the platform is overloaded, the pressure relief valve will open

because of excessive pressure buildup in the hydraulic system. When the pressure relief valve opens, oil will

bypass into the reservoir. NEVER change the pressure relief setting. DO NOT exceed the rated capacity of

your lift equipment.

Speed Selection

This pump offers two "speeds". The “low” speed setting produces low volume/high pressure for fine

adjustments to the platform height. The high speed setting produces high volume/low pressure, which

produces the platform rapidly. The operator has the option of selecting the optimum pump speed for the

application at hand. Pump speeds are selected by sliding the "lock collar" (See below) in or out. An

occasional drop of oil will keep the collar working freely.

Procedure for Bleeding Air from the Hydraulic System

Whether your pump is new or recently serviced, the hydraulic system likely contains air. The design of

this pump includes an "air bleed screw" to facilitate removal of air from the foot pump. To remove air from

the system:

1. Check all fittings to be sure they are tight. Confirm that the oil level is adequate, i.e. within 1" of the

top of the reservoir when the lift is in the fully lowered position.

2. With the platform fully lowered, locate the "air bleed screw". Loosen the screw with an approximately

1/2 turn counterclockwise. As soon as you have loosened the screw, slowly depress the foot pedal to force

air out of the pump chamber. Do not let go of the foot pedal. Tighten the air bleed screw to prevent air from

reentering the pump chamber. Repeat the above procedure until the pump chamber is completely filled

with oil and a "spongy" feel is no longer present when the pedal is pressed. If the air bleeding procedure has

been successful, the feel of the pump pedal will be firm through the entire stroke, i.e. hydraulic fluid will

flow during the entire stroke.

Copyright 2013 Vestil Manufacturing Corp. Page 4 of 10

Page 5

rev. 1/25/2013 AIR-2000-AIR, manual.doc

MAINTENANCE

Make sure that Keep oil clean. Check the oil level in the reservoir before operate and replenish reservoir if oil

does not reach 2/3 of the capacity.

DO NOT use brake fluid or jack oils in the hydraulic system. Replace the oil with anti-wear

hydraulic oil having a viscosity of 150 SUS at 100°F (ISO 32 @ 40°C), or non-synthetic transmission fluid.

INSPECTIONS

To preserve the usefulness of the cart for the greatest period of time, the cart should be regularly

inspected and maintained.

(A) Daily inspections:

1.) Oil leaks.

2.) Pinched or chafed hoses.

3.) Damage to the casters.

4.) Damage or deformation of the structural members, cylinder brackets, etc.

5.) Unusual noise or binding, or evidence of grinding/binding.

(B) Monthly inspections:

1.) The oil level. Oil should be 1” to 1½” below the fill hole of the reservoir with the platform in the

fully lowered position. Add oil if necessary. [See “Yearly inspection” below for information about

the necessary properties of the hydraulic oil.]

2.) Worn or damaged hydraulic hoses.

3.) Significant wear at pivot point(s).

4.) Looseness and significant wear of roller(s).

5.) Integrity of hardware retaining each roller and fasteners at all pivot points.

6.) Loose, significantly worn or damaged caster bearings or mounting hardware.

7.) Accumulation of dirt or other material on the cart.

8.) Proper, normal function of all hand and/or foot-operated mechanisms.

9.) Unusual noises or movement during operation.

10.) All the information/safety/warning labels being in place and in good condition.

(C) Yearly inspection

Change the oil if it darkens, becomes gritty, or appears milky, which indicates the presence of water.

Replace the oil with anti-wear hydraulic oil having a viscosity grade of 150 SUS at 100°F, (ISO 32 at

40°C). Examples of acceptable replacement oils include AW 32 and HO 150 hydraulic oils and

non-synthetic transmission fluid.

Copyright 2013 Vestil Manufacturing Corp. Page 5 of 10

Page 6

rev. 1/25/2013 AIR-2000-AIR, manual.doc

TROUBLESHOOTING GUIDE

WARNING: Carelessness during maintenance could result in serious injury.

Identify all potential hazards and apply the safety procedures used at your work site before

beginning troubleshooting or repairs. Disconnect / disable all energy sources with proper

lock-out/tag-out procedures

Before performing any troubleshooting or repairs, the load must be removed from the platform;

then either raise the platform and install the maintenance props, or fully lower the platform.

Only qualified individuals trained to understand mechanical devices and their associated electrical

and hydraulic circuits, along with the hazards that could result from them, should attempt

troubleshooting and repair of this equipment.

Contact the factory for answers to questions not addressed in this manual

Problem: Possible cause(s): Action:

1. Platform does not raise

2. Foot pedal goes down hard

but platform does not rise

3. Platform rises only under no

load or when rapidly pumped

or

Pedal strokes without

being pumped.

4. Platform rises when the

pump is stroked but lowers

during the return stroke.

5. Platform rises but takes too

much effort

a. Load weight exceeds capacity

b. Oil is low

c. Pinched hose

d. Relief valve set too low

a. Particle of dirt under the pressure

relief

b. Particle of dirt under the inlet check

a. Pump is “air locked”.

b. Inlet check valve has foreign

material on seat

c. Relief setting is out of adjustment

d. Foreign material on relief valve set

a. Outlet check is leaking. a. Clean foreign material from ball

a. Switch pump displacement speed.

a. Remove part of the load

b. Fill oil to within on inch of the top

of the reservoir

c. Connect as necessary

d. Increase only as necessary

a. Lower platform – disassemble,

clean & reassemble pressure

relief.

b. Lower platform – disassemble

clean & reassemble inlet check

valve

a. Bleed air from system

b. Remove and clean inlet ball and

seat.

c. Adjust relief setting higher

d. Lower platform – disassemble

clean & reassemble inlet check

valve

and seat.

a. Slide locking collar back

Copyright 2013 Vestil Manufacturing Corp. Page 6 of 10

Page 7

rev. 1/25/2013 AIR-2000-AIR, manual.doc

6. Platform rises very slowly a. Change pump speed

b. Intake filter is clogged

c. Foreign material stuck under the

pressure relief valve or under the

inlet check valve

7. Under load, pump pedal

feels spongy or jerky

8. Platform lowers too slowly a. Pinched hose

9. Platform lowers too fast a. Pinched hose

10. Platform rises but does not

lower

a. Foreign material interfering with

rollers--stuck under the platform or

in the frame.

b. Oil is low

c. Air in the hydraulic system

b. Intake filter is clogged.

c. Foreign material lodged in velocity

fuse

d. Foreign material lodged in the

pressure compensated flow

control valve

a. Foreign material lodged in

pressure compensated flow

control value

b. Release pin bent or missing

c. Foreign objects blocking roller

travel

d. Velocity fuse is locked.

a. Slide locking collar forward

b. Lower platform – drain reservoir,

clean & flush debris, refill with

clean oil.

c. Lower platform – disassemble,

clean & reassemble pressure

relief

a. Clear / correct as necessary

b. Fill oil to within one inch of the

top of the reservoir

c. Bleed air from system

a. Correct as necessary

b. Lower platform – drain reservoir,

clean & flush debris, refill with

clean oil.

c. Lower platform – disassemble,

clean & reassemble

d. Lower platform – disassemble,

clean & reassemble

a. Lower deck – disassemble,

clean & reassemble

a. Lower deck – disassemble clean

& reassemble

b. Replace as necessary

c. Correct / remove as necessary

d. Remove air from the hydraulic

system to unlock & repressurize

the system.

Copyright 2013 Vestil Manufacturing Corp. Page 7 of 10

Page 8

rev. 1/25/2013 AIR-2000-AIR, manual.doc

LABEL PLACEMENT DIAGRAM

Periodically inspect each label affixed to the cart. Clean the labels if necessary for good legibility

from a reasonable viewing distance. Contact the manufacturer for a replacement(s) for any label that is

partially or entirely unreadable.

Copyright 2013 Vestil Manufacturing Corp. Page 8 of 10

Page 9

rev. 1/25/2013 AIR-2000-AIR, manual.doc

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a re

placement for a defective original part if the part is

covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped

to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice

shipping date; AND 2) a written request

for warranty service including your name and phone number. Send requests

that displays the

by any of the following methods:

Mail

Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the following

original

defects in original

dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It also covers

parts that wear under normal usage conditions (“wearing parts”), such as bearings, hoses, wheels,

seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original components is 90 days

. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not

covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty

:

Product misuse;

Copyright 2013 Vestil Manufacturing Corp. Page 9 of 10

Page 10

rev. 1/25/2013 AIR-2000-AIR, manual.doc

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive and/or

abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

: DO NOT modify the product IN ANY WAY without first receiving written

Copyright 2013 Vestil Manufacturing Corp. Page 10 of 10

Page 11

AIR-2000-AIR Double-function Table Truck

No. Description Q'ty No. Description Q'ty No. Description Q'ty

1 Table 1 55 O-ring 1 (27 Hex Cap Plug 2

2 Link Assembly 1 56 O-ring 1 (28 O-ring 2

3 Roller Guide 4 57 Plug 1 (29 Fix Shaft 1

4 C-ring 4 58 C-ring 1 (30 Spring Seat 1

5 C-ring 2 59 Switch Wrench 1 (31 Spring 1

6 Shaft 2 60 Set Nut 1 (32 Steel Ball 1

7 Middle Shaft 1 61 Screw 1 (33 Plug Cover 1

8 Flat Washer 1 62 Plug Tie-in 1 (34 Taper Spring 1

9 Spring 1 63 O-ring 1 (35 Steel Ball 1

10 Hex Cap Bolt 1 64 Enter Air Mouth 1 (36 Oil Pipe Tie-in 2

11 Hex Cap Bolt 4 65 Tie-in 1 (37 O-ring 2

12 Link Seat 4 66 C-ring 1 (38 Plug 1

13 Flat Washer 4 67 Air Pipe Tie-in 1 (39 Spring 1

14 Spring Washer 4 68 O-ring 2 (40 Steel Ball 1

15 Hex Cap Bolt 4 69 Plug 1 (41 C-ring 1

16 Handle 1 70 Spring Pin 2 (42 O-ring 2

17 Hex Cap Bolt 4 71 Lift Piston 2 (43 O-ring 1

18 Flat Washer 4 72 Dust Cover 2 (44 Plug 1

19 Spring Washer 4 73 O-ring 2 (45 Top Rod 1

20 Hex Cap Nut 4 74 Oil Seal 2 (46 Steel Ball 1

21 Seat 1 75 Top Nut 2 (47 Spring Seat 1

22 Flat Washer 8 76 O-ring 2 (48 Adjust Pressure Spring 1

23 Spring Washer 8 77 Cylinder 2 (49 O-ring 1

24 Hex Cap Bolt 8 78 Oil Pipe 2 (50 Adjust Pressure Spring 1

25 Fix Wheel Holder 2 79 Tie-in 1 (51 Plug 1

26 Set Nut 4 80 O-ring 8 (52 Lowering Valve 1

27 Wheel 2 81 Long Oil Pipe 1 (53 Spring Pin 1

28 Bearing 2 (54 Big Pump Piston 1

29 Dust Cover 2 (1 Valve 1 (55 Dust Cover 1

30 Shaft Cover 2 (2 Hex Cap Bolt 3 (56 Oil Seal 1

31 Hex Cap Bolt 2 (3 Spring Washer 3 (57 Big Spring 1

32 Dust Cover 2 (4 Top Nut 1 (58 Bushing 1

33 Bearing 1 (5 Rubber Cover 1 (59 O-ring 1

34 Semicircle Screw 2 (6 Piston Cover 1 (60 Hex Cap Bolt 1

35 Spring 2 (7 Small Piston 1 (61 Spring Pin 1

36 Flat Washer 2 (8 Oil Seal 1 (62 Screw 1

37 Protect Cover 2 (9 Big Piston 1 (63 Screw 1

38 Brake Slice 2 (10 O-ring 2 (64 Flat Washer 1

39 Brake Pedal 2 (11 Rubber O-ring 2 (65 Stop Block 1

40 Swivel Wheel Holder 2 (12 Cylinder Body 1 (66 Steel Ball 1

41 Hex Cap Screw 1 (13 Hex Cap Nut 1 (67 Spring 1

42 Flat Washer 2 (14 Spring Seat 1 (68 Link Block 1

43 Spring Washer 2 (15 Small Lift Piston 1 (69 Shaft 2

44 Hex Cap Nut 2 (16 Big Spring 1 (70 Bushing 1

45 Oil Box 1 (17 Plug Cover 1 (71 Bushing 1

46 Hex Cap Bolt 1 (18 Cylinder Body 1 (72 Shaft 1

47 Spring Washer 1 (19 Hex Cap Nut 1 (73 Press Wheel Seat 1

48 Hex Cap Nut 2 (20 Bushing 1 (74 Press Wheel 1

49 Oil Pipe 1 (21 Oil Seal 1 (75 Pin 1

50 Air Pipe 1 (22 Pump Cylinder Body 1 (76 Shaft 1

51 Enter Air 1 (23 O-ring 1 (77 Shaft 1

52 Spring 1 (24 Plug Cover 1 (78 Foot Pedal Petiole 1

53 Oil Seal 1 (25 Taper Spring 1

54 Valve Core 1 (26 Steel Ball 1

Page 12

Loading...

Loading...