Page 1

VESTEL STB

SERVICE MANUAL

SATELLITE STB

MODELS

SAT 3600

SAT 3700

SAT 3701

SAT 3702

SAT 3703

SAT 3800

SAT 3801

SAT 3802

Page 2

SERVICE MANUAL

SATELLITE STB MODELS

Rev 1.0 21.10.02 16:23 Page 2

Page 3

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 3

Page 4

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 4

Page 5

SERVICE MANUAL

SATELLITE STB MODELS......................................................................................................................................................2

REVISION HISTORY .................................................................................................................................................................6

GENERAL DESCRIPTION........................................................................................................................................................7

I5518 (IC100)........................................................................................................................................................................7

ST

SDRAM 8MB

F

LASH MEMORY 1 MBYTE (IC301)........................................................................................................................................23

EEPROM

YTE (IC300)......................................................................................................................................................23

S 128K (16,384 X 8) 2-WIRE SERIAL (IC302).........................................................................................................25

USED IC LISTS .......................................................................................................................................................................... 33

CONNECTORS..................................................................................................................... ..................................................... 34

P

OWER CONNECTOR..................................................................................................................................................................34

F

RONT PANEL CONNECTOR ....................................................................................................................................................... 34

5512 JTAG C

ONNECTORS.........................................................................................................................................................34

SCART CONNECTION........................................................................................................................................................... 35

TV S

CART SOCKET...................................................................................................................................................................35

CART SOCKET................................................................................................................................................................36

VCR S

RS232 S

RCA (A

ERIAL PORT..................................................................................................................................................................36

UDIO AND COMPOSITE VIDEO) CONNECTOR................................................................................................................. 36

POWER REQUIREMENTS......................................................................................................................................................37

PCB EXPLANATIONS..............................................................................................................................................................37

INTRODUCTION................................................................................................................................................................... 37

POWER BOARD (16PW07 E3) ............................................................................................................................................ 37

MAIN BOARD (16MB07 E3 ) ............................................................................................................................................... 38

FRONT PANEL BOARD (TK507-2)....................................................................................................................................39

SERVICE MENU INTERFACE...............................................................................................................................................40

RF M

ODULATOR SYSTEM :........................................................................................................................................................40

ODULATOR TYPE : ............................................................................................................................................................ 40

RF M

T

UNER TYPE :............................................................................................................................................................................40

S

CARTS :.................................................................................................................................................................................... 40

R

EBOOT :................................................................................................................................................................................... 40

C

LEAR DATABASE :...................................................................................................................................................................41

L/R: DBC

OWNLOAD PGM : ...................................................................................................................................................................42

D

R

EMOTE/FRONT TEST : .............................................................................................................................................................. 42

7-S

S

YSTEM DIAGNOSTIC :............................................................................................................................................................... 43

D

EVELOPMENT TEAM :..............................................................................................................................................................43

U

PLOAD DEFAULT SAT_XPDRS :...............................................................................................................................................43

OWNLOAD DEFAULT SAT_XPDRS :......................................................................................................................................... 43

D

R

S232 TEST :.............................................................................................................................................................................44

OPY – OK: UPLOAD PGM :....................................................................................................................................... 41

EGMENT DISPLAY TEST :......................................................................................................................................................43

SOFTWARE UPGRADE THROUGH RS232.........................................................................................................................45

SCHEMATICS............................................................................................................. ERROR! BOOKMARK NOT DEFINED.

BILL OF MATERIALS.............................................................................................................................................................48

BOARD LAYOUT.......................................................................................................ERROR! BOOKMARK NOT DEFINED.

Rev 1.0 21.10.02 16:23 Page 5

Page 6

SERVICE MANUAL

REVISION HISTORY

Rev 1.0 07/25/02 Tuncay Akkurt Initial Revision

Schematics

Rev 1.0 21.10.02 16:23 Page 6

Page 7

SERVICE MANUAL

GENERAL DESCRIPTION

Major functional blocks are discussed briefly in this section. A more detailed description is contained later in the

document.

STi5518 (IC100)

1. Introduction

The STi5518 integrates in a single chip: a transport dem ultiplex block; an ST20 32-bit system CPU; an

audio/video MPEG2 decoder; display and gr aphics features; a digi tal video encoder; and s ystem peripherals. The

Sti5518 integrates D irecTV and D VB desc ram blers in the tra nsport demultip lex block , allowin g it to be used in b oth

Digital Video Broadcasting (DVB) and Digital Satellite System (DSS) set-top box applications.

2. Technical Specification

Integrated 32-bit host CPU up to 81 MHz

2 Kbytes of Icache, 2 Kbytes of Dcache, and 4 Kbytes of SRAM configurable as Dcache.

Audio decoder

5.1 channel Dolby Digital® /MPEG-2 multi-channel decoding, 3 X 2-channel PCM outputs

IEC60958 -IEC61937 digit al out put

SRS®/TruSurround®

DTS® digital out and MP3 decoding

Alignment beep for satellite dishes.

Video decoder

Supports MPEG-2 MP@ML

Fully programmable zoom-in and zoom-out

NTSC to PAL conversion.

DVD and SVCD subpicture decoder

High performance on-screen display

2 to 8 bits per pixel OSD options

Anti-flicker, anti-flutter and anti-aliasing filters.

PAL/NTSC/SECAM encoder

RGB, CVBS, Y/C and YUV outputs with 10-bit DACs

Macrovision® 7.01/6.1 compatible (optional).

Shared SDRAM memory interface

1 or 2x16-Mbit, or 1x64-Mbit 125 MH

Programmable CPU memory interface for SDRAM, ROM, peripherals...

Front-end interface

DVD, VCD, SVCD and CD-DA compatible

Z SDRAM.

Rev 1.0 21.10.02 16:23 Page 7

Page 8

SERVICE MANUAL

Serial, parallel and ATAPI int er f ac es

Hardware sector filtering

Integrated CSS decryption and track buffer.

Hardware transport-stream demultiplexor

Parallel/serial input

DES and DVB descramblers

32 PID support.

Integrated peripherals

2 UARTs, 2 SmartCards, I

2C controller, 3 PWM outputs, 3 capture timers

Modem support

44 bits of programmable I/O

IR transmitter/receiver.

Professional toolset support

ANSI C compiler and libraries.

208 pin PQFP package.

The STi5518 is a hig hly integrated single-chip deco der, d es ig ned f or use in feature-rich mass-market set-top boxes.

It integrates a high-performance 32-bit CPU, a dedicated block for DVB/DirecTV transport demultiplexing and

descrambling, modules for MPEG-2 video and audio decoding with 3D-surround and MP3 support, advanced

display and graphics features, a digital video encoder and all of the system peripherals required in a typical low-cost

interactive receiv er. To cover t he needs of DVD-capable s et-top boxes , ST i5518 integr ation opt ions incl ude a CS S

decryption block, a Dolby Digital audio decoder and Macrovision copy protection. An ATAPI interface is built-in,

supporting the glueles s c onnection of s tandar d Hard Dis k Drives. I n this wa y, the ST i551 8 is id eal for set- top boxes

featuring trick modes such as live TV recording , pausing and time-shif ting. The STi5518 is backward compatible

with the popular STi5500 set-t op box deco der, all owing eas y migrat ion from the previous generation. T he high level

of integration in a single PQFP-2 08 pac kage makes the STi5518 ideally suited fo r lo w-c os t, h ig h-vol ume set-top box

applications.

Rev 1.0 21.10.02 16:23 Page 8

Page 9

SERVICE MANUAL

3. Architecture overview

The figure below shows the architecture of the Sti5518.

This chapter gives a brief overview of each of the functional blocks of the STi5518.

4. STi5518 functional modules

a. Central processor

The STi5518 Central Processing Unit is a ST20C2+ 32-bit processor core. It contains instruction processing logic,

instruction and data pointers, and an operand regist er. It directly accesses the high-s peed on-chip SRAM, which

can store data or programs and uses the cache to reduce access time to off-chip program and data memory.

The processor can access memory via the Programmable CPU Interface (often referred to as the EMI) or the

Shared Memory Interface (SMI), which is shared with the video, audio, sub-picture and OSD decoders.

Rev 1.0 21.10.02 16:23 Page 9

Page 10

SERVICE MANUAL

b. MPEG video decoder

This is a real-time video compression processor supporting the MPEG-1 and MPEG-2 standards at video rates up t

720 x 480 x 60 Hz and 720 x 576 x 50 Hz. Picture format conversion for display is performed by vertical and

horizontal filters. User- defined bitmaps can be super -impos ed on the d isplay pictur e b y using the on- screen d isplay

function. The display unit is part of the MPEG vide o decoder, it overla ys the f our displa y planes shown i n the figure

below. The display planes are norm ally overlaid in the ord er illustrated, with the background color at the back and

the sub-picture at the f ront (us ed as a curs or p lane). T he s ub-pic ture pla ne ca n a ltern ativel y be posi tioned bet ween

the OSD and MPEG video planes where it can be used as a second on-screen display plane.

c. Audio decoder

The audio decoder accepts: Dolby Digital, MPEG-1 layers I, II and III, MPEG-2 layer II 6-channel, PCM, CDDA data

formats; MPEG2 PES streams for MPEG-2, MPEG-1, Dolby Digital, MP3, and Linear PCM (LPCM). The audio

decoder supports DTS® digital out (DVD DTS and CDDA DTS). SPDIF input data (IEC-60958 or IEC-61937

standards) is accepted if an external circuitry extr acts the PCM clock from the str eam. Skip frame, repeat block s

and soft mute frame features can be used to synchronize audio and video data. PTS audio extraction is also

supported. The devic e outputs up to 6 channels of PCM data and appr opriate clocks for ex ternal digital-to-anal og

converters. Program mable downmix enables 1,2, 3 or 4 channel outputs. D ata can be output in either I²S f ormat or

Sony format. The decoder can form at output data according t o IEC-60958 s tandard (for non c ompress ed data: L/R

channels, 16, 18, 20 an d 24-bits) or IEC-6193 7 standar d (for com pres sed data), for F

or 32 kHz. Sampling frequenc i es of 96 kHz, 48 kHz, 44.1 kHz, 32 kHz and half sampling frequencies are supported.

A downsampling f ilter (9 6 kHz/48 kHz) is available. T he decoder supports dual mode for MPEG an d Do lby Digital. It

includes a Dolby surround compatible downmix and a ProLogic decoder. A pink noise generator enables the

accurate positioning of speakers for optim al surround sound s etup. PCM be ep tone is a s pecial m ode used for S et

Top Box. It generates a triangular signal of variable frequency and amplitude on the left and right channels. In

global mute mode, the decoder decodes the incoming bitstream normally but the PCM and SPDIF outputs are

softmuted. This mode is used to prepare a period of decoding mode, to synchronize audio and video data without

hearing the audio. S low-forward and fast-forward tr ick modes are available f or compressed and n on-compressed

data. The control interface of the decoder is activated via memory mapped registers in the ST20 address space.

S = 96 kHz, 48 kHz, 44.1 k Hz

d. IR transmitter/receiver

The STi5518 provides a pulse-position modulated signal for automatic VCR programming by the set-top box. The

signal is output to the IR blast pin and an accessory jack pin, simultaneously. The pulse frequency, number of

pulses (envelope length) and the total cycle time is controlled by registers.

e. Modem analog front-end interface

The Modem Analog Front- end interface is used to trans fer transmit and receive D AC and ADC samples bet ween

the memory and an external modem analog front-end (MAFE), using a synchronous serial protocol. DMA is used to

transfer the sample data between memory buffers and the MAFE interface module, with separate transmit and

receive buffer s and double buf fering of the buf fer pointer s. FIFOs are us ed to tak e into account the ac cess laten cy

to memory, in a worst c ase system and to all ow the use of bursts for m emory bandwidth eff iciency improvem ent.

The V22 bis standard is supported.

f. Memory subsystem

On-chip

The on-chip memory includes 2K bytes of instruction c ache, 2Kbytes of data cache and 4 Kbytes of SRAM th at can

be optionally configured as data cache. The subsystem provides 240M/bytes of internal bandwidth, supporting

pipelined 2- cycle internal m emory access. The instruction a nd data caches are direct-m apped, with a write-back

system for the data-c ache. The caches support bur st accesses to the external memories for refill and write-back.

Burst access increases the performance of pagemode DRAM memories.

Off-chip

There are two off-chip memory interfaces:

• The external memory interface (EMI) accessed by the ST20 is used for the transfer of data and programs

between the STi5518 and external peripherals, flash and additional SDRAM and DRAM.

Rev 1.0 21.10.02 16:23 Page 10

Page 11

SERVICE MANUAL

• Shared memory interface (SMI) controls the movement of data between the STi5518 and 16, 32 or 64 Mbits of

SDRAM. This external SDRAM stores the display data generated by the MPEG decoder and CPU and the C2+

code data.

The EMI uses minimal external support logic to support memory subsystems, and accesses a 32 Mbytes of physical

address space (greater if SDRAM or DRAM is used) i n four ge nera l purpos e m emor y banks of 8 or 16 b its wide, 21

or 22 address lines, an d byte select. F or applications req uiring extra m emory, the EMI su pports this extra memor y

with zero external support logic , even for 16-bit SDRAM devices. The EMI c an be configured for a wide variety of

timing and decode functions b y the conf igurat ion regis ters. The t im ing of each of the four m em or y banks c an be set

separately, with different device types being placed in each bank with no need for external hardware.

g. Serial communication

Asynchronous serial controllers

The Asynchronous Serial Controller (ASC), also referred to as the UART interface, provides serial communication

between the STi5518 and other microcontrollers, microprocessors or external peripherals. The STi5518 has four

ASCs, two of which are generally used by the SmartCard controllers.

Eight or nine bit data transfer, parity generation, and the number of stop bits are programmable. Parity, framing, and

overrun error detection increase data transfer reliability. Transmission and reception of data can be double-buffered,

or 16-deep FIFOs can be used. A mechanism to distinguish the address from the data bytes is included for

multiprocessor comm unication. Testing is supported by a loop-back option. A 16-bit baud-rate generator provides

the ASC with a separate serial clock signal.

Two ASCs support full-duplex and 2 half-duplex asynchronous communication, where both the transmitter and the

receiver use the same data fram e format and the sam e baud rate. Each A SC can be set to operate in SmartCard

mode for use when interfacing to a SmartCard.

Synchronous serial controller

Two Synchronous Serial Controllers (SSC) provide high-speed interfaces to a wide variety of serial memories,

remote control recei vers and other microcontrol lers. The SSCs support all of the features of the Serial Peripher al

Interface bus (SPI) a nd the I

SSCs share pins with the parallel input/output (PIO) ports, and support half-duplex synchronous communication.

h. Front-end interface

The STi5518 can be connected to a front-end through the following interfaces:

2C bus. The SSCs c an be program med to interf ace to other serial b us standar ds. The

• I2S interface;

• multi-format serial interface;

• multi-format parallel interface;

• ATAPI interface (for Hard Disk Drives and DVD-ROMs)

i. On-chip PLL

The on-chip PLL accepts 27 MHz input and generates all the internal high-frequency clocks needed for the CPU,

MPEG and audio subsystems.

j. Diagnostic controller (DCU)

The ST20 Diagnostic Controller Unit (DCU) is used to boot the CP U and to c ontro l a nd monitor the chip systems via

the standard IEEE 1194.1 Test Acc ess Port. The DCU includes on-chip hard ware with ICE (In Circuit Emulation)

and LSA (Logic State Analyzer) featur es to facilitate verificati on and debugging of softwar e running on the on-c hip

CPU in real time. It is an independent hardware module with a private link from the host to support real-time

diagnostics.

k. Interrupt subsystem

The interrupt system allows an on-chip module or external interrupt pin to interrupt an active process so that an

Rev 1.0 21.10.02 16:23 Page 11

Page 12

SERVICE MANUAL

interrupt handling process can be run. An interrupt can be signalled by one of the following: a signal on an external

interrupt pin, a signal from an internal peripheral or subsystem, software asserting an interrupt in the pending

register. Interrupts are im plemented by an on-chip interrupt controll er and an on-ch ip interrupt-level co ntroller. The

interrupt controller s upports eight prioritized inter rupts as inputs and manag es the pending interrupts. Th is allows

the nesting of pre-em ptive interrupts for real-time system design. Each interrupt can be programmed to be at a

lower or higher priority than the high priority process queue.

l. PAL/NTSC/SECAM encoder

The integrated digital encoder converts a multiplexed 4:2:2 or 4:4:4 YCbCr stream into a standard analog baseband

PAL/NTSC or SECAM signal and into RGB, YUV, Yc and CV BS components. The encoder can perform closedcaption, CGMS encoding, and a ll o ws M ac rovision

TM 7.01/6.1 copy protection. The DENC is able to encode Tele tex t

according to the “CCIR/ITU-R Broadcast Teletext System B” specification, also known as “World System Teletext”.

In DVB applicatio ns, Teletext data is em bedded within D VB stream s as MPEG d ata packets . It is the respons ibility

of the software to han dle incoming data p ackets and in partic ular to store T eletext packets in a buf fer, which the n

passes them to the DENC on request.

m. SmartCard interfaces

Two SmartCard interfaces support SmartCards compliant with ISO7816-3. Each interface is has a UART (ASC), a

dedicated programmable clock generator, and eight bits of parallel IO port.

n. PWM and counter module

The PWM and counter module provides three PWM encoder outputs, three PWM decoder (capture) inputs and four

programmable timer s. Each capt ure input can be programmed to detect r ising edge, falling edge, both edges or

neither edge (disabled) . These facilities are c locked by two indep endent clocks , one for PWM outputs and one for

capture inputs/timers. The PWM counter is 8-bit, with 8-bit registers to set the output-high time. The

capture/compare counter and the compare and capture registers are 32-bit. The module generates a single

interrupt signal.

o. Parallel I/O module

44 bits of parallel I/O are configured in 6 ports, and each bit is programmable as output or input. The output can be

configured as a totem-pole or open- drain driver. The input com pare logic can ge nerate an interr upt on any chan ge

of any input bit. Many parallel IO have alt ernate functions and can be connected to an int ernal peripheral signal

such as a UART or SSC.

Rev 1.0 21.10.02 16:23 Page 12

Page 13

SERVICE MANUAL

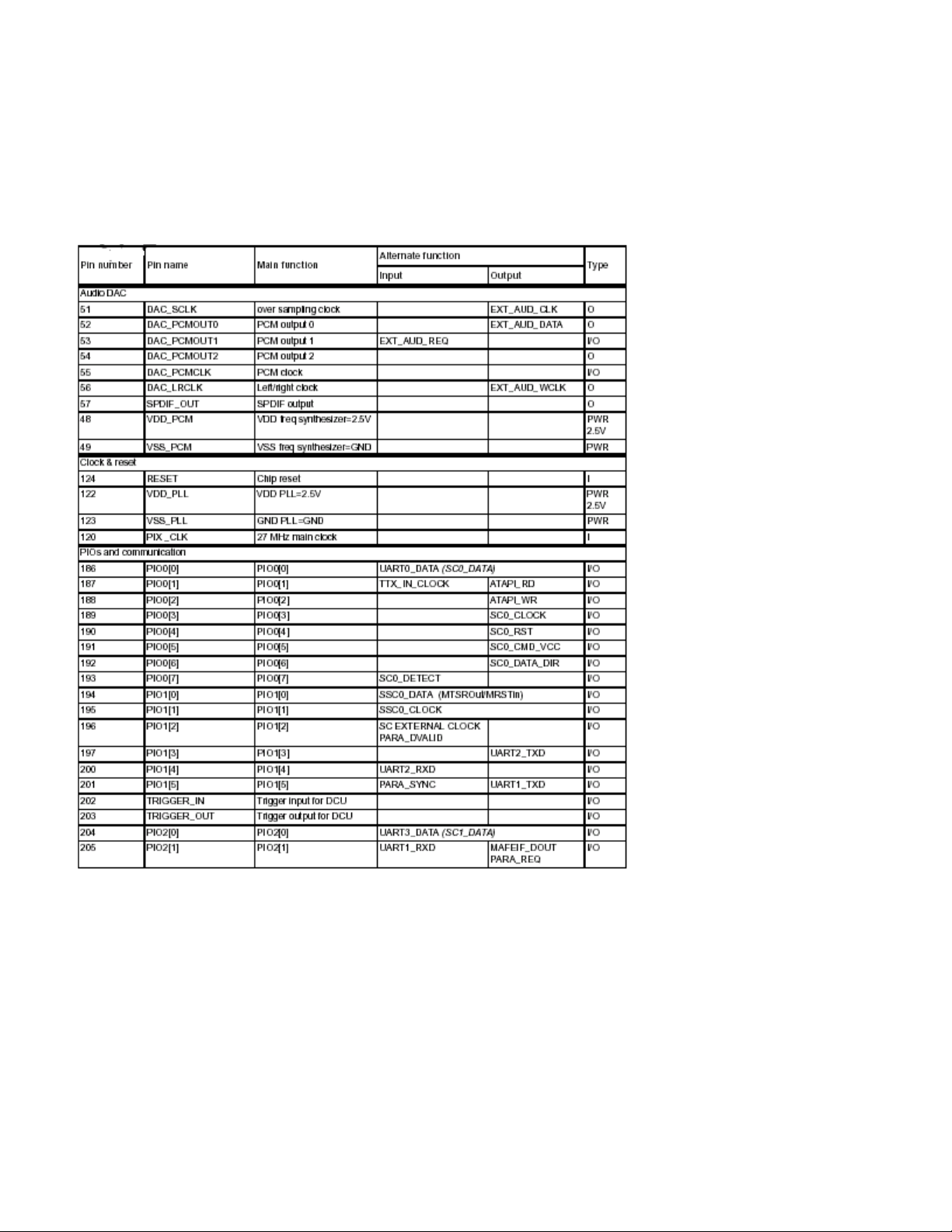

5. Pin list sorted by function

Alternate functions printed in Italic show a suggested use of the PIO; alternate functions not printed in Italic are

multiplexed with a specific hardware.

Rev 1.0 21.10.02 16:23 Page 13

Page 14

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 14

Page 15

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 15

Page 16

SERVICE MANUAL

1. FEI_CFG bits 8 and 9 must be programmed according to the required NRSS configuration.

2. The NRSS_IN and NRSS_OUT pins are swapped around on the STi5518 compared to the STi5508.

3. Register LNK_SDAV_CONF bit 22 (SDE) must be set to 1 to validate the output path.

4. Inverted. ATTENTION! the PIO input is also inverted.

5. The PIO must be configured in open drain.

6. BOOT_FROM_ROM is active during reset.

7. Tie low whenever JTAG is not used.

Rev 1.0 21.10.02 16:23 Page 16

Page 17

SERVICE MANUAL

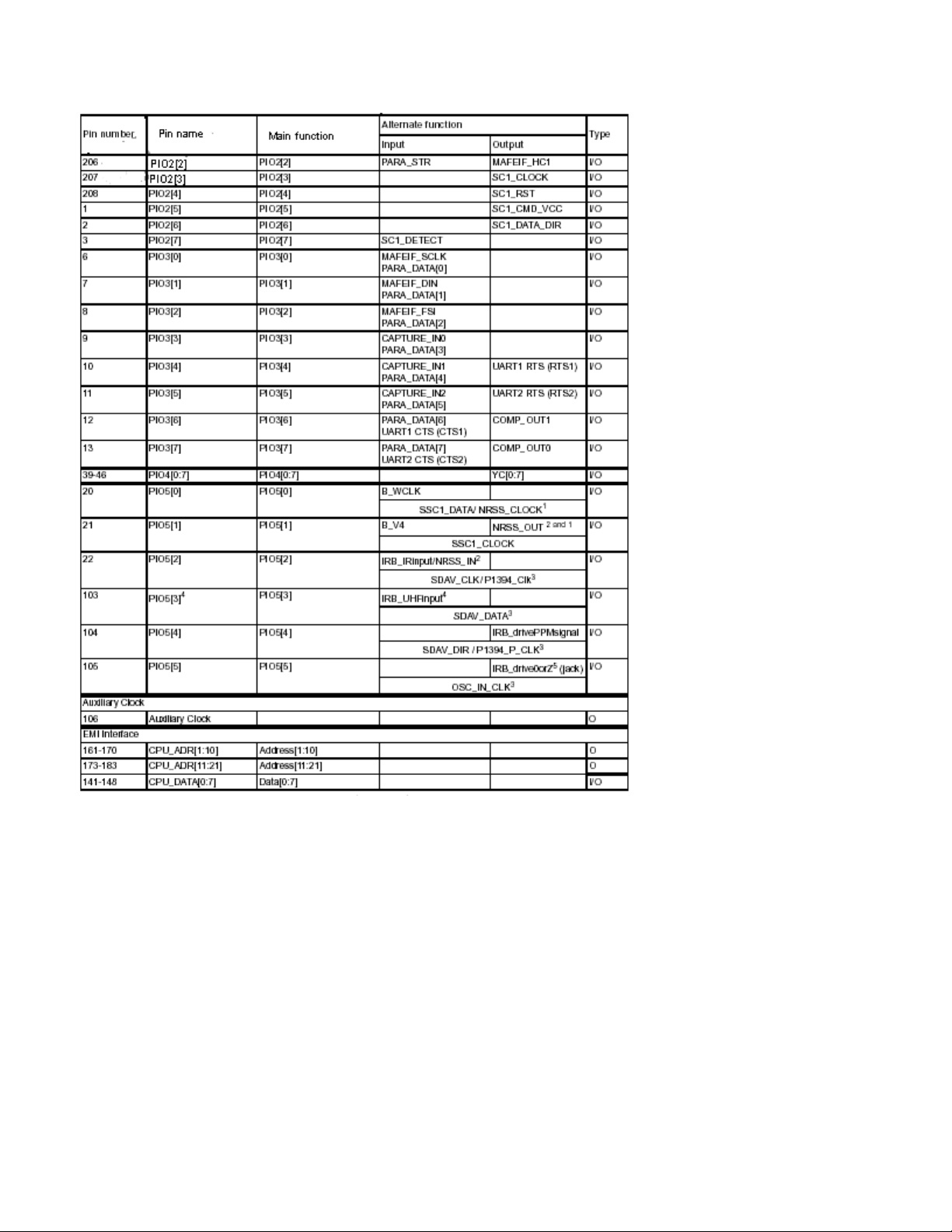

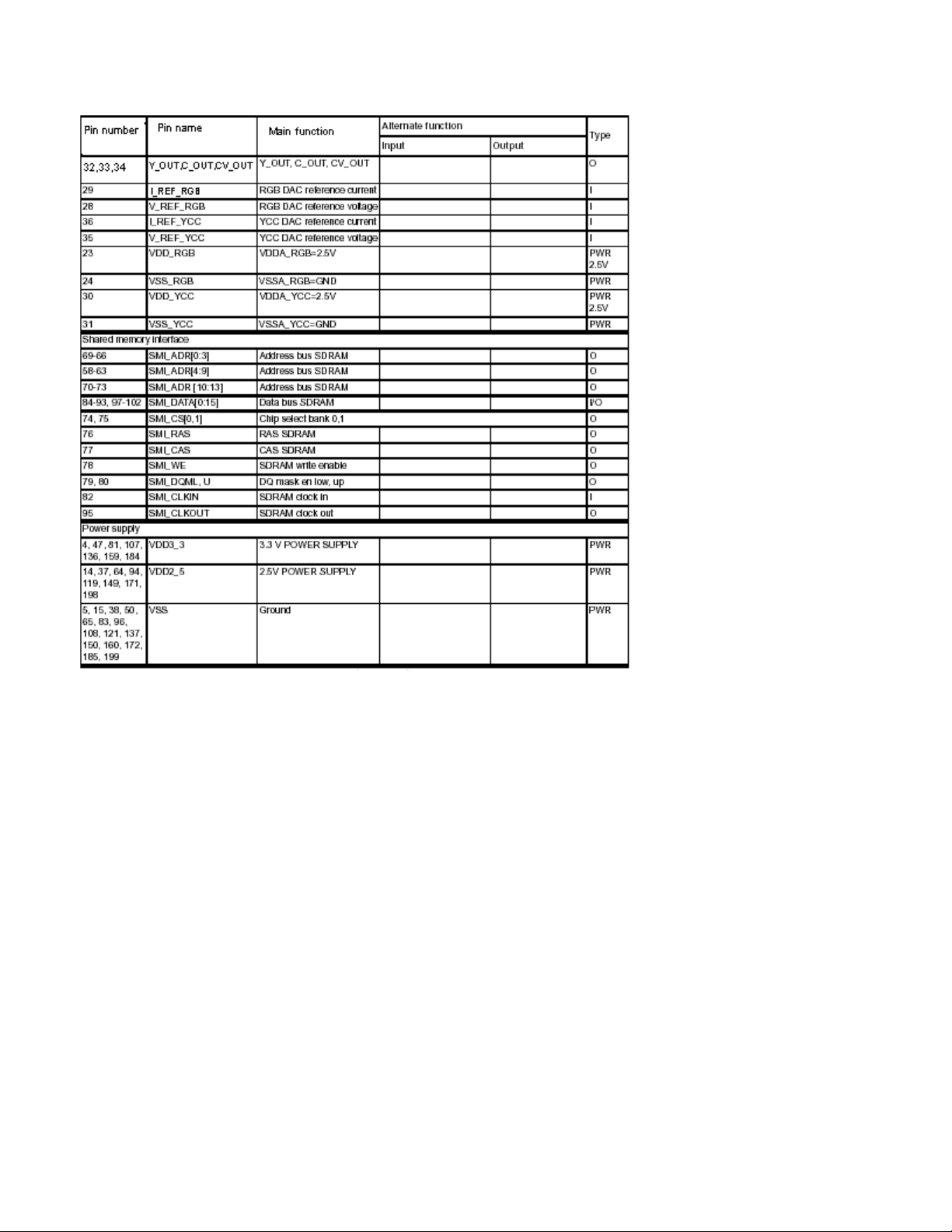

6. Pins sorted by pin number

Rev 1.0 21.10.02 16:23 Page 17

Page 18

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 18

Page 19

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 19

Page 20

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 20

Page 21

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 21

Page 22

SERVICE MANUAL

1. FEI_CFG bits 8 and 9 must be programmed according to the required NRSS configuration.

2. The NRSS_IN and NRSS_OUT pins are swapped around on the STi5518 compared to the STi5508.

3. Register LNK_SDAV_CONF bit 22 (SDE) must be set to 1 to validate the output path.

4. Inverted. ATTENTION! the PIO input is also inverted.

5. The PIO must be configured in open drain.

6. Tie low whenever JTAG is not used

7. BOOT_FROM_ROM is active during reset.

Rev 1.0 21.10.02 16:23 Page 22

Page 23

SERVICE MANUAL

SDRAM 8MByte (IC300)

FEATURES

• PC66-, PC100- and PC133-compliant

• Fully synchronous; all signals registered on positive edge of system clock

• Internal pipelined operation; column address can be

changed every clock cycle

• Internal banks for hiding row access/ precharge

• Programmable burst lengths: 1, 2, 4, 8 or full page

• Auto Precharge, includes CONCURRENT AUTO

PRECHARGE, and Auto Refresh Modes

• Self Refresh Modes: standard and low power

• 64ms, 4,096-cycle refresh

• LVTTL-compatible inputs and outputs

• Single +3.3V ±0.3V power supply

GENERAL DESCRIPTION

The 64Mb SDRAM is a high-speed CMOS, dynamic random-access memory containing 67,108,864 bits. It is

internally configured as a quad-bank DRAM with a synchronous interface (all signals are registered on the positive

edge of the clock signal, CLK). Each of the x4’s 16,777,216 -bit banks is organized as 4,096 rows by 1,024 columns by 4

bits. Each of the x8’s 16,777,216-bit banks is organized as 4,096 rows by 512 columns by 8 bits. Each of the x16’s

16,777,216-bit banks is organized as 4,096 rows by 256 columns by 16 bits. Read and write accesses to the

SDRAM are burst oriented; accesses start at a selected location and continue for a programmed number of

locations in a progr ammed sequenc e. Accesses begi n with the registr ation of an ACT IVE command, which is then

followed by a READ or WRITE

command. The address bits registered coincident with the ACTIVE command are used to select the bank and row to be

accessed (BA0, BA1 select the bank; A0-A11 select the row). The address bits registered coincident with the READ or

WRITE command are used to select the starting column location for the burst access.

The SDRAM provides for programmable READ or WRITE burst lengths of 1, 2, 4 or 8 locations, or the full page,

with a burst terminate option. An AUTO PRECHARGE function may be enabled to provide a self-timed row precharge that

is initiated at the end of the burst sequence. The 64Mb SDRAM uses an internal pipelined architecture to achieve highspeed operation. This architecture is compatible with the 2n rule of prefetch architectures, but it also allows the column

address to be changed on every clock cycle to achieve a high-speed, fully random access. Precharging one bank while

accessing one of the other three banks will hide the precharge cycles and provide seamless, high-speed, random-access

operation. The 64Mb SDRAM is designed to operate in 3.3V, lowpower memory systems. An auto refresh mode is

provided, along with a power-saving, power-down mode. All inputs and outputs are LVTTL-compatible. SDRAM’s offer

substantial advances in DRAM operating performance, including the ability to synchronously burst data at a high data rate

with automatic column-address generation, the ability to interleave between internal banks in order to hide precharge time

and the capability to randomly change column addresses on each clock cycle during a burst access.

Flash Memory 1 MByte (IC301)

Low Voltage Single Supply Flash Memory

2.7V to 3.6V SUPPLY VOLTAGEfor

PROGRAM, ERASE and READ OPERATIONS

FASTACCESS TIME: 90ns

FASTPROGRAMMING TIME

– 10µs by Byte / 20µs by Word typical

PROGRAM/ERASE CONTROLLER (P/E.C.)

– Program Byte-by-Byte or Word-by-Word

– Status Register bits and Ready/Busy Output

MEMORY BLOCKS

– Boot Block (Top or Bottom location)

– Parameter and Main blocks

Rev 1.0 21.10.02 16:23 Page 23

Page 24

SERVICE MANUAL

BLOCK, MULTI-BLOCK and CHIP ERASE

MULTI BLOCK PROTECTION/TEMPORARY

UNPROTECTION MODES

ERASE SUSPEND and RESUME MODES

– Read and Program another Block during

Erase Suspend

LOW POWER CONSUMPTION

– Stand-byand AutomaticStand-by

100,000 PROGRAM/ERASE CYCLES per

BLOCK

20 YEARSDATARETENTION

– Defectivity below 1ppm/year

ELECTRONIC SIGNATURE

– Manufacturer Code: 0020h

– Device Code, M29W800T: 00D7h

– Device Code, M29W800B: 005Bh

DESCRIPTION

The M29W800 is a non-volatile memory that may be erased electrically at the block or chip level and programmed

in-system ona Byte-by-Byteor Wordby-Word basis using only a single 2.7V to 3.6V V

CC supply. For Program and

Erase operations the necessary high voltages are generated internally. The device can also be programmed in

standard programmers. The array matrix organisation allows each block to be erased and reprogrammed without

affecting other blocks. Blocks can be protected against programing and erase on programming equipment, and

temporarily unprotected to make changes in the application. Each block can be programmed and erased over

100,000 cycles. Instructions for Read/Reset, Auto Select for reading the Electronic Signature or Block Protection

status, Programming, Blockand Chip Erase, Erase Suspend and Resume are written to the device in cycles of

commands to a Command Interface using standard microprocessor write timings. The device is offered in

TSOP48(12 x 20mm) and SO44 packages. Both normal and reverse pinouts are available for the TSOP48package.

Organisation

TheM29W800 is organised as 1 Mx8 or 512K x16 bits selectable by the BYTE signal. When BYTEis Low the Bytewide x8 organisation is selected and the address lines are DQ15A–1 and A0-A18. The Data Input/Output signal

DQ15A–1 acts as address line A–1 which selects the lower or upper Byte of the memory word for output on DQ0DQ7,DQ8-DQ14 remain at High impedance. When BYTEis High the memory uses the address inputs A0-A18 and

the Data Input/Outputs DQ0-DQ15. Memory control is provided by Chip Enable E, Output Enable G and Write

EnableW inputs. AReset/Block Temporary Unprotection RPtri-level input provides a hardware reset when pulled

Low,and when held High (atV

ID) temporarily unprotects blocks previously protected allowing them to be programed

and erased. Erase and Program operations are controlled by an internal Program/Erase Controller (P/E.C.). Status

Register data output on DQ7 provides a Data Polling signal, and DQ6 and DQ2 provide Toggle signals to indicate

the state of the P/E.C operations. A Ready/Busy RB output indicates the completion of the internal algorithms.

Memory Blocks

The devices feature asymmetrically blocked architecture providing system memory integration. Both M29W800Tand

M29W800Bdeviceshavean array of 19 blocks, one Boot Block of 16 KBytes or 8KWords, two Parameter Blocks of 8

KBytes or 4KWords, one Main Block of 32 KBytes or 16KWordsand fifteen Main Blocks of 64 KBytes or 32KWords.

The M29W800Thas the Boot Block at the top of the memory address space and the M29W800B locates the Boot

Block starting at the bottom. The memory maps are showed in Figure3. Each block can be erased separately, any

combination of blocks can be specified for multi-block erase or the entire chip may be erased. The Erase operations

are managed automatically by the P/E.C. The block erase operation can be suspended in order to read from or

program to any block not being ersased, and then resumed. Block protection provides additional data security. Each

block can be separately protected or unprotected against Program or Erase on programming equipment. All

previously protected blocks can be temporarily unprotected in the application.

Rev 1.0 21.10.02 16:23 Page 24

Page 25

SERVICE MANUAL

Bus Operations

The following operations can be performed using the appropriate bus cycles: Read(Array, Electronic Signature,

Block Protection Status), Write command, Output Disable, Standby, Reset, Block Protection, Unprotection,

Protection Verify, Unprotection Verify and Block Temporary Unprotection.

Command Interface

Instructions, made up of commands written in cycles, can be given to the Program/Erase Controller through a

Command Interface (C.I.). For added data protection, program or erase execution starts after4 or 6 cycles. The first,

second, fourth and fifth cycles are used to input Coded cycles to the C.I. This Coded sequence is the same for all

Program/Erase Controller instructions. The ’Command’ itself and its confirmation, when applicable, are given on the

third, fourth or sixth cycles. Any incorrect command or any improper command sequence will reset the device to

Read Array mode.

Instructions

Seven instructions are defined to perform Read Array, Auto Select (to read the Electronic Signature or Block

Protection Status), Program, Block Erase, Chip Erase, Erase Suspend and Erase Resume. The internal P/E.C.

automatically handles all timing and verification of the Program and Erase operations. The Status Register Data

Polling, Toggle, Error bits and the RB output may be read at any time, during programming or erase, to monitor

the progress of the operation. Instructions are composed of up to six cycles. The first two cycles input a Coded

sequence to the Command Interface which is common to all instructions The third cycle inputs the instruction setup command. Subsequent cycles output the addressed data, Electronic Signature or Block Protection Status for

Read operations. In order to give additional data protection, the instructions for Program and Block or Chip Erase

require further command inputs. For a Program instruction, the fourth command cycle inputs the address and data

to be programmed. For an Erase instruction (Block or Chip), the fourth and fifth cycles input a further Coded

sequence before the Erase confirm command on the sixth cycle. Erasure of a memory block may be suspended, in

order to read data from another block or to program data in another block, and then resumed. When power is first

applied or if V

CC falls below VLKO, the command interface is reset to Read Array.

EEPROMs 128K (16,384 x 8) 2-wire Serial (IC302)

Features

• Low-voltage and Standard-voltage Operation

– 5.0 (V

– 2.7 (VCC = 2.7V to 5.5V)

– 1.8 (V

• Internally Organized 16,384 x 8 and 32,768 x 8

• 2-wire Serial Interface

• Schmitt Trigger, Filtered Inputs for Noise Suppression

• Bidirectional Data Transfer Protocol

• 1 MHz (5V), 400 kHz (2.7V) and 100 kHz (1.8V) Compatibility

• Write Protect Pin for Hardware and Software Data Protection

• 64-byte Page Write Mode (Partial Page Writes Allowed)

• Self-timed Write Cycle (5 ms Typical)

• High Reliability

– Endurance: 100,000 Write Cycles

– Data Retention: 40 Years

– ESD Protection: > 4000V

• Automotive Grade and Extended Temperature Devices Available

• 8-pin JEDEC PDIP, 8-lead JEDEC and EIAJ SOIC, 14-lead TSSOP, and

8-pad Leadless Array Packages

Description

The AT24C128/256 provides 131,072/262,144 bits of serial electrically erasable and programmable read only

memory (EEPROM) organized as 16,384/32,768 words of 8 bits each. The device’s cascadable feature allows up to

four devices to share a common 2-wire bus. The device is optimized for use in many industrial and commercial

CC = 4.5V to 5.5V)

CC = 1.8V to 3.6V)

Rev 1.0 21.10.02 16:23 Page 25

Page 26

SERVICE MANUAL

applications where low-power and low-voltage operation are essential. The devices are available in space-saving 8pin JEDEC PDIP, 8-lead EIAJ, 8-lead JEDEC SOIC, 14-lead TSSOP, and 8-pad LAP packages. In addition, the

entire family is available in 5.0V (4.5V to 5.5V), 2.7V (2.7V to 5.5V) and 1.8V (1.8V to 3.6V) versions.

Pin Description

SERIAL CLOCK (SCL): The SCL input is used to positive edge clock data into each EEPROM device and negative

edge clock data out of each device.

SERIAL DATA (SDA): The SDA pin is bidirectional for serial data transfer. This pin is open-drain driven and may

be wire-O Red with any number of other open-drain or open collector devices.

DEVICE/PAGE ADDRESSES (A1, A0): The A1 and A0 pins are device address inpu ts that are hard wir ed or left not

connected for hardware compatibility with AT24C32/64. When the pins are hardwired, as many as four 128K/256K

devices may be addressed on a single bus system (device addressing is discussed in detail under the Device

Addressing section). When the pins are not hardwired, the default A

1 and A0 are zero.

WRITE PROTECT (WP): The write protect input, when tied to GND, allows normal write operations. When WP is

tied high to V

GND. Switching WP to V

CC, all write operations to the memory are inhibited. If left unconnected, WP is internally pulled down to

CC prior to a write operation creates a software write protect function.

Memory Organization

AT24C128/256, 128K/256K SERIAL EEPROM: The128K/256K is internally organized as 256/512 pages of 64-

bytes each. Random word addressing requires a 14/15-bit data word address.

Absolute Maximum Ratings

Operating Temperature.................................. -55°C to +125°C

Storage Temperature ..................................... -65°C to +150°C

Voltage on Any Pin

with Respect to Ground .....................................-1.0V to +7.0V

Maximum Operating Voltage .......................................... 6.25V

DC Output Current........................................................ 5.0 mA

Rev 1.0 21.10.02 16:23 Page 26

Page 27

SERVICE MANUAL

Tuner Alps (TU400)

Rev 1.0 21.10.02 16:23 Page 27

Page 28

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 28

Page 29

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 29

Page 30

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 30

Page 31

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 31

Page 32

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 32

Page 33

SERVICE MANUAL

USED IC LISTS

MAINBOARD (16MB07 E3)

MAX 232 (IC101) RS232 Driver/Receiver

Sti5518(IC100) Set Top Box Backend Decoder With Integrated Host Processor

TSH 22 (IC103) Dual Bipolar Operational Amplifier

M74HCU04 (IC102) Hex Inverter

MT48LC4M16A2 (IC300) 1 Mbyte x 16 x 4 banks SDRAM

M29W800T (IC301) Single Supply Flash Memory

M24C128 (IC302) 128Kbit Serial EEPROM

LM833 (IC501) Low Noise Dual Operational Amplifier

CS4335 (IC500) 8-Pin, 24 Bit, 96 KHz Stereo D/A Converter

DS1811 (IC400) Reset IC

NDS8947 (Q402) Dual P – Channel Enhancement Mode Field Effect Transistor

POWER BOARD (16PW07 E3)

TOP233Y (IC1) SMPS primary IC

SFH617A (IC2) Optocoupler

TL431(IC3) Programmable Precision Reference

LM358N (IC4) Low Power Dual Operantional Amplifier

LM7812 (IC5) 12V Voltage Regulator

Rev 1.0 21.10.02 16:23 Page 33

Page 34

SERVICE MANUAL

CONNECTORS

Power Connector

Power Connector – PL400

Pin Description

1LNB_SUPPLY_IN

2+30V

3+12 V

4GND

5GND

6+5 V

7+3V3

8+3V3

9H/V

10 LNB_POWER_ENABLE

11 DISEQC

Front Panel Connector

Front Panel Connector – PL401

Pin Description

1 STANDBY

2 SW3_STDBY

3GND

4 SW1_UP

5 SW1_DOWN

6GND

7IR_IN

85VFP

5512 JTAG Connectors

JTAG Connector – PL100

Pin Description Pin Description

1 ------ 11 TCK

2GND12GND

3 TRIGOUT 13 TDI

4GND14GND

5 TRIGIN 15 TDO

6GND16GND

7 ------ 17 JTAGRESET

8GND18GND

9TMS19TRST

10 GND 20 GND

Rev 1.0 21.10.02 16:23 Page 34

Page 35

SERVICE MANUAL

SCART CONNECTION

20 18 16 14 12 10 8 6 4 2

21 19 17 15 13 11 9 7 5 3 1

TV Scart Socket

TV Scart Socket – PL200

Pin Description Pin Description

1 Audio Right Output 12 No Connection

2 No Connection 13 GND

3 Audio Left Output 14 GND

4 GND 15 RED Output

5 GND 16 Fast Blanking Output

6 No Connection 17 GND

7

8 Function Switching Output 19 CVBS Output

9 GND 20 No Connection

10 No Connection 21 GND

11 GREEN Output

BLUE Output

18

GND

Rev 1.0 21.10.02 16:23 Page 35

Page 36

SERVICE MANUAL

VCR Scart Socket

VCR Scart Socket – PL200

Pin Description Pin Description

1

2 Audio Right Input 13 GND

3 Audio Left Output 14 GND

4 GND 15 No Connection

5 GND 16 No Connection

6 Audio Left Input 17 GND

7 No Connection 18 GND

8 Function Switching Input 19 CVBS Output

9 GND 20 CVBS Input

10 No Connection 21 GND

Audio

Right Output

12 No Connection

11

No Connection

RS232 Serial Port

RS232 Header – JK_DSUB_9

Pin Description Pin Description

1-2-

3TXD4CTS

5RXD6RTS

7-8-

9GND

RCA (Audio and Composite Video) Connector

A/V Connector – JK1

Pin Description

1 CVBS VIDEO

2 LEFT AUDIO

3 RIGHT AUDIO

Rev 1.0 21.10.02 16:23 Page 36

Page 37

SERVICE MANUAL

POWER REQUIREMENTS

Power measurements are for a board configured according to the included Bill of Materials while playing a

typical DVB channel.

16MB07 E3 Board

Power Consumption

Voltage Current mA Power

LNB_SUPPLY_IN (13V, 18V) ----- -----

+30V 1mA

+12V 30mA

STAND_BY

LNB_SUPPLY_IN (13V, 18V) 500mA (max)

POWER_ON

+5V 130mA

+3V3 ----- ----

Voltage Current mA Power

+30V 1mA

+12V 100mA

+5V 200mA

+3V3 960mA

Watts

Watts

PCB EXPLANATIONS

INTRODUCTION

DVB-S (digital satellite receiver) is designed with ST chipset. The technical information of

the receiver will be explained as three parts in the following pages: Power Board, Main Board

and Front Panel Board.

POWER BOARD (16PW07 E3)

The TOPSwitch concept is used for power supply. TOP 233Y (IC1) is designed to work

until 50 Watts in family of TOPSwitch_FX with 5 pins. The receiver works between 85 and 265

VAC mains voltage by using TOP 233Y in SMPS (Switch Mode Power Supply). The secondary

voltage regulation is adjusted by changing the duty cycle of drain signal according to the

feedback voltage, which is got from the secondary side of transformer. The feedback voltages

are 3.3V and 5V. This is connected to the comparator pin of TOP 233Y (IC1-pin1) via IC12

(Optocoupler). The comparator pin also protects the box against short circuits and overload. The

Vcc voltage of IC1 is between 2V –3V at pin2. The TOP 233Y works at a fixed frequency. This

frequency is fixed by RC oscillator at pin1. The pin3 and pin 4 are ground and the pin5 is drain

of MOSFET, which is inside the TOP 233Y.

Rev 1.0 21.10.02 16:23 Page 37

Page 38

SERVICE MANUAL

The switching of LNB supply voltage is done here. 18V and 22V outputs of transformer

switched by Q1, Q2 and H/V output of STV299 (TU400). By this way overheating and

unnecessary power consumption of Q5 (BD235) that regulates the LNB supply is prevented.

22kHz tone which is needed for DiSEqC signals, is generated at pin15 (Alps-TU400) or pin12

(Sharp-TU400) of STV0299 in tuner 22KHz is added to LNB supply here via LM358N (IC4).

16PW07-3 Power Board

Range of Voltage

Voltage Range of Voltage

LNB_SUPPLY_IN (13V, 18V) -----

+30V 31V – 34V

+12V 11.8V – 12.20V

+5V 4.7 V – 5.3V

STAND_BY

LNB_SUPPLY_IN (13V VER) 13 V – 14 V

LNB_SUPPLY_IN (18V HOR) 17V – 19V

POWER_ON

+3V3 3.6 V – 3.9V

Voltage Range of Voltage

+30V 31 V – 34 V

+12V 11.8 V – 12.2 V

+5V 4.8 V – 5.2 V

+3V3 3.3 V – 3.6V

+2V5 2.4 V – 2.7V

MAIN BOARD (16MB07 E3 )

The main board contains two parts: Front-end and Back-end. The digital signal is

demodulated in Front-end and then decoded in Back-end. Analog signals are processed in

different part.

The tuner (TU400 Alps or Sharp) is capable of getting both digital broadcasts. After the

modulated signals (I, Q outputs) receive from tuner, they go to STV0299 for demodulation

process in tuner. (TU400) In this IC, QPSK (Quadrated Phase Shift Keying) demodulation and

Forward Error Correction (FEC) are done which is necessary to demodulate DVB-S

transmission. TS (transport stream): The multiplexed digital stream which includes video, audio

and data information related to more than one channel (can be only one channel for SCPC

signals) and DVB tables. TS signals which are generated after demodulation, reach to Sti5518

(IC100) via 8 bits data bus. However, Byte Clock (TSIn_BCLK), Packet Clock (TSIn _STROUT)

signals are also sent to ST5518 (IC100) for demultiplexing process of TS. STV0299 is controlled

by I2C. In addition, 22kHz tone which is needed for DiSEqC signals, is generated at pin12 (Alps)

or pin10 (Sharp) of STV0299 in tuner.

LNB supply voltage (13/18V) is regulated via power board. Switching of supply voltage

between LOOP_IN and LNB_SUPPLY is done by Q402 transistors. The voltage on R403 is

proportional with the current of LNB supply. Overload on LNB supply increases the voltage on

R403, which results switching of Q400, Q401. By this way input LNB_OVERLOAD signal port of

Rev 1.0 21.10.02 16:23 Page 38

Page 39

SERVICE MANUAL

Sti 5518 (IC100) has the knowledge of LNB overload and then LNB supply is cut off for

protection of box via Sti 5518 port (P25).

At the backend part, there is a 32-bit CPU ST20 (in Sti 5518 embedded) that controls all

processes. Demultiplexer of the CPU provides the transmission of the desired channel’s

information from TS (Transport Stream) to MPEG Decoder section. The program that runs on

Sti5518 is in Flash memories (IC301). 8Mbits SDRAM (IC300) is used for data memory of this

program.

ST20 uses 32- bit data and 22- bit address buses for access to flash, DRAM and MPEG

decoder. It uses RAS, CAS etc. (read, write, enable) signals to activate related IC while

accessing them.

The clock which is needed by Sti 5518 (IC100), is generated at power on mode by

27MHz crystal (X100) and IC102 (74HCU04). The output of PWM outputs of Sti 5518 (IC100), is

filtered to have a DC level via R129 and C118. At the output of ICS3, the 27MHz clock can be

adjusted according to capacity of pins of 27MHz crystal to ground. This capacity is related with

DC value on D100 and D101 (BB133) at pins of crystal. This operation maintains

synchronization between audio-video that are coming from MPEG transport stream and PCR

clock.

Sti 5518 (IC100) can communicate any micro controller via RS232 by using IC101

(MAX232- RS232 level converter). The RS232 output of receiver is used for debug any problem

using Windows Hyper Terminal program.

MPEG decoder in Sti 5518 (IC100), is responsible for decoding of MPEG video and audio

signals. The video, which is compressed using MPEG2 and audio, which is compressed using

MPEG1 Layer 1-2, are processed here. After decoding, CCIR 601 formatted 8-bit video and

PCM formatted audio, are generated by mpeg decoder.

If digital broadcast has a teletext information, Sti 5518 (IC100) inserts teletext info into

VBI (vertical blanking interval) which can be watched on TV. Digital audio that is PCM formatted

on Sti 5518’ s output, is processed by CS4335 (IC500) and amplified by LM833 (IC501) and

then switched through IC200 (M74HC4052).

In digital mode, RGB signals are only delivered to TV scart. CVBS output is distributed

through IC201 (M74HC4052) to TV, AUX/VCR and VCR scarts. When VCR becomes active,

audio and video signals are driven to TV and VCR scarts, which is activated by pin8 of VCR

scart.

The program information is stored in 128Kbits EEPROM (24C128 – IC302) via I2C.

FRONT PANEL BOARD (TK507-2)

Rev 1.0 21.10.02 16:23 Page 39

Page 40

SERVICE MANUAL

To show program number, 4 digit 7 segment display (P2) is used on front panel board.

They are driven by 97C52 (IC502) which is controlled by MC. The functional keys are Standby,

Prog+, Prog-. IR module (IR01) is used for remote control.

FRONT PANEL PCBs

Functional Keys

Key Name Description

Standby

Prog +

Prog -

Standby

Program Up

Program Down

16FP05-2

Key Name

SW101

SW102

SW103

SERVICE MENU INTERFACE

There is a service menu for service person which is accessed by entering “MAIN MENU”

then pressing “9”, “2”, “9”, “5”, “2”, “6” keys on the remote control. You will see se rvice me nu

on the screen. This menu consists of fifteen active lines.

RF Modulator System :

You can control RF modulator system at this line. RF modulator system option can be

selected as Pal G or Pal I or Pal K type in software side by pressing left or right cursor key on

the remote control.

RF Modulator Type :

You can control RF modulator type at this line. RF modulator option can be selected as

Sharp or Samsung or LG type in software side by pressing left or right cursor key on the remote

control.

Tuner Type :

You can control Tuner type in software version at this line

Scarts :

You can control number of scarts in software version at this line

Reboot :

Rev 1.0 21.10.02 16:23 Page 40

Page 41

SERVICE MANUAL

You press OK button on the remote commander. Apparatus is restart.

Clear Database :

You press OK button on the remote commander. These settings reinitialize whole

EEPROM and store all programs erase.

L/R: DBCopy – OK: Upload PGM :

The object of this manual is to give necessary information and details to the user to

UPLOAD the program table to the receiver through RS232.

The list of the necessary equipment is as follows:

• Receiver and TV

• PC with “Hyper Terminal” function,

• RS232 serial communication cable (male to female modem cable).

Steps to be followed by the user are given below:

1. Connect the serial communication cable between the RS232 outport of the receiver and the

serial communication port (COM1 or COM2) of the PC.

2. Make sure that the PC is on and the receiver is in Power on mode.

3. Run “Hyper Terminal” program of the PC from Start / Programs / Accessories /

Communications / Hyper Terminal menu.

4. For a new connection, run Hypertrm.exe file.

5. Give a name and choose an icon for the connection. (You do not need to make a new

connection every time. You can use this name for the future connections.)

6. Choose communication port in the new coming window (COM1 or COM2) whichever you

have used in Step 1.

7. Port settings should be as follows:

Bits per second : 38400

Data Bits : 8

Parity : None

Stop bits : 1

Flow control : None

8. Now Hyper Terminal connection is established.

9. Go to “L/R: DBCopy – OK: Upload PGM” line on the service menu and press “LEFT” or

“RIGHT” keys of remote control (for copying database to the receiver). Please wait until the

print statements on the Hyper Terminal screen end.

10. From “Transfer” menu, choose “Receive File”.

11. Choose 1K Xmodem as protocol type.

12. “L/R: DBCopy – OK: Upload PGM” line on the service menu and press “OK” key of remote

control. Then Receive on of Hyper Terminal window and enter a file name like

(Program_table.pit) and press “OK” button. then You will see the progress on the PC

screen. Besides, on TV screen the receiver will count the downloaded packets.

Rev 1.0 21.10.02 16:23 Page 41

Page 42

SERVICE MANUAL

13. Wait for the transfer to be completed. Then, disconnect and exit from Hyper Terminal

window.

Download PGM :

The object of this manual is to give necessary information and details to the user to

upgrade the program table of the receiver through RS232.

The list of the necessary equipment is as follows:

• Receiver and TV

• PC with “Hyper Terminal” function,

• RS232 serial communication cable (male to female modem cable).

Steps to be followed by the user are given below:

1. Connect the serial communication cable between the RS232 outport of the receiver and the

serial communication port (COM1 or COM2) of the PC.

2. Make sure that the PC is on and the receiver is in Power on mode.

3. Go to “ Clear Database ” line and press “OK” key and then wait for twenty seconds (old

program table is deleted).

4. Run “Hyper Terminal” program of the PC from Start / Programs / Accessories /

Communications / Hyper Terminal menu.

5. For a new connection, run Hypertrm.exe file.

6. Give a name and choose an icon for the connection. (You do not need to make a new

connection every time. You can use this name for the future connections.)

7. Choose communication port in the new coming window (COM1 or COM2) whichever you

have used in Step 1.

8. Port settings should be as follows:

Bits per second : 38400

Data Bits : 8

Parity : None

Stop bits : 1

Flow control : None

9. Now Hyper Terminal connection is established. From “Transfer” menu, choose “Send File”.

10. Enter file name to be sent (program table).

11. Choose 1K Xmodem as protocol type.

12. Press Send button of Hyper Terminal window and then Go to “Download PGM” line on the

service menu and press “OK” key of remote control. You will see the progress on the PC

screen. Besides, on TV screen the receiver will count the downloaded packets.

13. Wait for the transfer to be completed. Then, disconnect and exit from Hyper Terminal

window.

Reset receiver by replugging in the mains cord of the set to the mains supply. Receiver will tune

to new program table.

Remote/Front Test :

Rev 1.0 21.10.02 16:23 Page 42

Page 43

SERVICE MANUAL

You press “OK” button remote commander to enter Remote/Front panel test then you can

see name of the button on the front panel or remote commander you pressed. By pressing Menu

button on the remote commander two times, you can exit.

7-Segment Display Test :

You press the OK key on the remote commander to start 7-segment display test. You

can see the test pattern on the display.

System Diagnostic :

You press the OK key on the remote commander and show your IC information in

apparatus main hardwar e

Development Team :

You press the OK key on the remote commander and Show your development team list

Upload Default Sat_Xpdrs :

This line can explain information under line

Download Default Sat_Xpdrs :

The object of this manual is to give necessary information and details to the user to

transmission the program table and preset table to the receiver through RS232.

The list of the necessary equipment is as follows:

• Receiver (master that sends the program table), TV

• Receiver (slave that receives the program table), TV

• RS232 serial communication cable (male to male modem cable).

Steps to be followed by the user are given below:

1. Connect the serial communication cable between the RS232 outport of the receiver to other

receiver.

2. Make sure that both receivers are in Power on mode.

3. Open the “main menu” and press “929526” keys sequentially for both of the receivers, you

will see service menu on the TV screens.

4. Go to “L/R: DBCopy – OK: Upload PGM” line on the service menu for master receiver and

press “LEFT” or “RIGHT” keys of remote control (for copying database to the receiver).

5. Go to “Download PGM” line on the service menu for slave receiver

6. “L/R: DBCopy – OK: Upload PGM” line on the service menu and press “OK” key of remote

control for master device. “Download PGM” line on the service menu and press “OK” key of

remote control for slave device. Besides, on TV screen the receiver will count the

downloaded packets.

7. Wait for the transfer to be completed the program table for both receivers.

8. Power off both receivers then power on them.

Rev 1.0 21.10.02 16:23 Page 43

Page 44

SERVICE MANUAL

9. Open the “main menu” and press “929526” keys sequentially for both of the receivers, you

will see service menu on the TV screens.

10. Go to “Upload default Sat_Xpdrs” line on the service menu for master receiver.

11. Go to “Download default Sat_Xpdrs” line on the service menu for slave receiver

12. “Upload default Sat_Xpdrs” line on the service menu and press “OK” key of remote control

for master device. “Download default Sat_Xpdrs” line on the service menu and press “OK”

key of remote control for slave device. Besides, on TV screen the receiver will count the

downloaded packets.

13. Wait for the transfer to be completed the preset table for both receivers.

Rs232 Test :

You connect the jumper to Rx output and Tx output. You press the “OK” key on the

remote commander then you can see “tESt” at the front display. You release the “OK” key on the

remote commander

then you can see “Err” at the front display.

You can return to main menu by pressing “Menu” keys on the remote control

Rev 1.0 21.10.02 16:23 Page 44

Page 45

SERVICE MANUAL

SOFTWARE UPGRADE THROUGH RS232 FOR HAVİNG 7-SEGMENT

DISPLAY MODELS

The object of this manual is to give necessary information and details to the user to

upgrade the software of the receiver through RS232.

The list of the necessary equipment is as follows:

Receiver and TV

PC with “Hyper Terminal” function,

RS232 serial communication cable (male to female modem cable).

Steps to be followed by the user are given below:

1. Connect the serial communication cable between the RS232 out port of the receiver and the

serial communication port (COM1 or COM2) of the PC.

2. Make sure that the PC is on and the receiver is in the Standby mode.

3. Run “Hyper Terminal” program of the PC from Start / Programs / Accessories /

Communications / Hyper Terminal menu.

4. For a new connection, run Hypertrm.exe file.

5. Give a name and choose an icon for the connection. (You do not need to make a new

connection every time. You can use this name for the future connections.)

6. Choose communication port in the new coming window (COM1 or COM2) whichever you

have used in Step 1.

7. Port settings should be as follows:

Bits per second : 115200

Data Bits : 8

Parity : None

Stop bits : 1

Flow control : None

8. Now Hyper Terminal connection is established. From “Transfer” menu, choose “Send File”.

9. Enter file name to be sent.

10. Choose Xmodem1K as protocol type.

11. Get the receiver out of standby mode using front panel keys just after pressing Send button

at the hyper terminal window. You will see the progress on the PC screen. Besides, front

panel display of the receiver will count the downloaded packets.

12. Wait for the transfer to be completed. Then, disconnect and exit from Hyper Terminal

window.

Receiver will automatically start to operate

Rev 1.0 21.10.02 16:23 Page 45

Page 46

SERVICE MANUAL

SOFTWARE UPGRADE THROUGH RS232 FOR HAVING LED MODELS

The object of this manual is to give necessary information and details to the user to

upgrade the software of the receiver through RS232.

The list of the necessary equipment is as follows:

Receiver and TV

PC with “Hyper Terminal” function,

RS232 serial communication cable (male to female modem cable).

Steps to be followed by the user are given below:

1. Connect the serial communication cable between the RS232 out port of the receiver and the

serial communication port (COM1 or COM2) of the PC.

2. Make sure that the PC is on.

3. Run “Hyper Terminal” program of the PC from Start / Programs / Accessories /

Communications / Hyper Terminal menu.

4. For a new connection, run Hypertrm.exe file.

5. Give a name and choose an icon for the connection. (You do not need to make a new

connection every time. You can use this name for the future connections.)

6. Choose communication port in the new coming window (COM1 or COM2) whichever you

have used in Step 1.

7. Port settings should be as follows:

Bits per second : 115200

Data Bits : 8

Parity : None

Stop bits : 1

Flow control : None

8. Now Hyper Terminal connection is established. From “Transfer” menu, choose “Send File”.

9. Enter file name to be sent.

10. Choose Xmodem1K as protocol type.

11. Plug in the mains cord of the set to the mains supply just after pressing Send button at the

hyper terminal window. You will see the progress on the PC screen. Besides, front panel

display of the receiver will count the downloaded packets.

12. Wait for the transfer to be completed. Then, disconnect and exit from Hyper Terminal

window.

Receiver will automatically start on standby mode. Af ter software initialisation(it takes 5 second)

finished you can turn on your digital set-top box by pressing one of the standby button, up/down

or numeric buttons on remote control or up/down/standby button on the front panel.

Rev 1.0 21.10.02 16:23 Page 46

Page 47

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 47

Page 48

SERVICE MANUAL

BILL OF MATERIALS

Ves.Code Description

20092206 MAINBOARD (MAN) SHARP

20092207 MAINBOARD (RAD) SHARP

20092208 MAINBOARD (SMD) SHARP

30000294 CAP SMD 100NF 50V K (0805) C427 C412 C413 C414 C244 C438 C265

30000814 RES SMD 1/10W 820R J R225 R233 R240 R246

30001734 JUMPER SMD (0805) S107 S108 S415 S416 S417 S418 S419

30001968 FERRITE BEAD (0805) BLM21B201S L106 L301 L302 L303 L304 L407 L400 L409

L410 L414 L208 L417 L418 L419 L420 L4 21 L422 L423

30007366 IC TSH22 (SO8) tape&reel IC103

30007378 IC LM 833(SO8) tape&reel IC501

30010689 DIODE VAR BB133 SMD D100 D101

30010780 IC 74HCU04 (SO14) tape&reel IC102

30010796 IC 24C128 SMD tape&reel IC302

30010817 IC MAX232 (SOIC16) IC101

30010822 IC M74HC4052 (SO16) tape&reel IC200 IC201

30012509 RES SMD 1/16W 100K J (0603) R502 R503

30012510 RES SMD 1/16W 100R J (0603) R108 R140 R147 R148 R254 R255 R411 R280 R281

30012551 TR BC847B SMD Q102 Q103 Q104 Q200 Q201 Q202 Q203 Q204 Q205 Q400 Q403

Q500 Q501 Q502 Q503 Q504 Q505 Q506 Q209 Q215 Q507 Q217

30012552 TR BC857B SMD Q100 Q101 Q105 Q206 Q207 Q208 Q212 Q401

30012559 CAP SMD 10PF 50V D COG (0603) C204 C208 C212 C216

30012560 CAP SMD 100PF 50V J (0603) C236 C220

30012564 CAP SMD 18PF 50V J (0603) C113 C116

30012567 CAP SMD 220PF 50V J (0603) C232 C234 C235 C243 C246

30012568 CAP SMD 270PF 50V J (0603) C502 C504

30012570 CAP SMD 330PF 50V J (0603) C119

30012573 CAP SMD 47PF 50V J (0603) C205 C206 C209 C210 C213 C214 C217 C218

30012581 CAP SMD 1NF 50V K R (0603) C221 C222 C228 C230 C238 C239 C241 C400 C401

C432 C433 C434 C435 C436 C240

30012582 CAP SMD 10NF 50V K R (0603) C100 C102 C104 C107 C114 C115 C409

30012583 CAP SMD 1.5NF 50V K (0603) C260

30012608 CAP SMD 27PF 50V J CH (0603) C515 C516

30012616 CAP SMD 2.7NF 50V K B (0603) C511 C512

30012641 RES SMD 1/16W 10K J (0603) R113 R114 R118 R119 R120 R121 R142 R300 R400

R401 R283 R512 R513 R514 R527 R292

30012650 RES SMD 1/16W 15K J (0603) R282

30012657 RES SMD 1/16W 1K J (0603) R134 R208 R211 R212 R213 R250 R251 R252 R253

R266 R267 R180 R518 R259 R214 R133 R135

30012658 RES SMD 1/16W 1M J (0603) R123

30012659 RES SMD 1/16W 2.2K J (0603) R110 R111 R402 R516 R539

30012667 RES SMD 1/16W 220K J (0603) R504 R510

30012668 RES SMD 1/16W 220R J (0603) R248 R519 R520 R521 R522 R523 R524 R525 R540

30012669 RES SMD 1/16W 22K J (0603) R128 R137 R138 R139 R218 R219 R220 R256 R257

R276 R277 R278 R279 R136 R287 R216 R273 R272 R271 R286 R290 R291

30012673 RES SMD 1/16W 270R J (0603) R249

30012677 RES SMD 1/16W 3.3K J (0603) R506 R509 R209

30012684 RES SMD 1/16W 330R J (0603) R224 R231 R238 R245

30012685 RES SMD 1/16W 33K J (0603) R404 R501 R507

30012692 RES SMD 1/16W 4.7K J (0603) R100 R109 R117 R505 R508 R526 R528 R529 R530

R531 R532 R533 R221 R228 R235 R242 R536 R537 R538 R541

Rev 1.0 21.10.02 16:23 Page 48

Page 49

SERVICE MANUAL

30012694 RES SMD 1/16W 470K J (0603) R124 R125

30012695 RES SMD 1/16W 470R J (0603) R227 R232 R241

30012696 RES SMD 1/16W 47K J (0603) R511 R500 R126

30012698 RES SMD 1/16W 5.6K J (0603) R515

30012702 RES SMD 1/16W 560R J (0603) R200 R201 R202 R203 R204 R205 R206 R207

30012707 RES SMD 1/16W 680R J (0603) R223 R229 R237 R243 R258 R222 R230 R236 R244

30012709 RES SMD 1/16W 7.5K J (0603) R217 R269 R270

30012712 RES SMD 1/16W 8.2K J (0603) R127 R129

30012713 RES SMD 1/16W 75R J (0603) R143 R226 R234 R239 R247

30012800 IC DAC CS4335 tape&reel IC500

30012982 RES SMD 1/16W 10R J 0603 R288 R289

30012985 JUMPER SMD 0603 S201 S203 S205 S300 S302 S304 S400 S401 S403 S404 S407

S411 S412 R116

30012986 RES SMD 1/16W 68R J 0603 R260

30014022 RES SMD 1/16W 47R J (0603) R103 R104 R105 R106 R130 R131 R144 R145 R517

30014088 IC SDRAM 4MX16 100MHZ tape&reel IC300

30014128 RES SMD 1/16W 33R J (0603) R112 R122 R132 R149 R151 R413 R414 R415 R184

R419 R420 R421 R422 R423 R424 R425 R416

30014342 IC TS87C52X2-MCB tape&reel IC502

30014344 TR NDS8947 IC402

30014442 RES SMD 1/16W 20K F(0603) R101 R102

30014714 IC DS1811(RESET IC) IC400

30014952 IC FLASH 8MB (TOP BOOT) tape&reel IC301

30016427 IC STI5518 IC100

30016654 CAP SMD 100NF 16V K R (0603) C108 C109 C110 C111 C112 C117 C120 C122

C123 C124 C125 C127 C128 C129 C130 C131 C133 C134 C135 C136 C138 C139 C201

C203 C223 C252 C253 C254 C255 C300 C302 C303 C305 C306 C307 C308 C309 C310

C311 C402 C403 C404 C405 C406 C407 C408 C410 C411 C418 C420 C421 C422 C423

C428 C506 C507 C509 C510 C225 C415C513 C430 C142 C269 C437 C233

30017143 COIL SMD 22UH (2520) L100 L101 L102 L103 L200 L201 L202 L203 L204 L207

L300 L405 L500 L501 L206

30017653 RES SMD NET 1/16W 47RX4 J (0603) R153 R154 R155 R156 R157 R158 R159 R160

R161 R162 R163 R164 R165 R166 R167 R168 R169 R170

30018776 PCB 16MB07E3

50010922 LABEL FRONT ''YESIL NOKTA'' (ÇAP 1 CM )

30000345 CAP EL 10UF 50V M C101 C103 C105 C106 C256 C257 C258 C301 C503 C505

30000352 CAP EL 100UF 16V M C118 C121 C126 C132 C304 C508

30000353 CAP EL 100UF 25V M C200 C245 C247 C248 C249 C250 C251 C207 C211 C215 C219

30000355 CAP EL 100UF 50V M C259 C261 C262

30000362 CAP EL 1UF 50V M C517 C518

30000375 CAP EL 220UF 16V M C202 C263 C264

30000384 CAP EL 2.2UF 50V M C500 C501

30000395 CAP EL 47UF 6.3V M (4*7MM) C416 C417 C429

30000400 CAP EL 47UF 50V M C424 C425 C426 C419 C514

30000407 CAP EL 470UF 16V M C312

30001452 TR BC327 Q216

30011011 COIL FIXED 22UH J RAD L401 L402 L403 L404 L415 L205

30000769 RES CF 1/2W 680R J R406

30001422 TR BD238 Q402

30001753 XTAL 8MHZ X500

30001851 CONN MALE 7P 2.5MM PL401

30006710 CONN MALE 11P TOP WHITE PL400

30007040 JACK D-SUB 9P JACK_D

30007367 XTAL 27MHZ R=20 OHM X100

30010700 DIODE BYV28-200 3.5A/200V 90A D400

30010902 HEADER 10X2(2,54MM) PL100

Rev 1.0 21.10.02 16:23 Page 49

Page 50

SERVICE MANUAL

30010921 DOUBLE-DECK SCART SOCKET PL200

30014089 MODULATOR RF TAMC_G001D TU200

30014123 TUNER NIM BS2F7VZ0180 TU400

30014191 CONN MALE 12P TOP WHITE PL500

30014195 JACK RCA 3P-DVB- JK1

30016742 RES MF 1/2W 0.82R J R403

35000006 SINGLE BATT.CONTACT (-) RC2000

50010759 LABEL SERIAL NO (UNIVERSAL)

20092367 POWERBOARD CHS.DVB-4 (MAN)

20092368 POWERBOARD CHS.DVB-4 (RAD)

20092369 POWERBOARD CHS.DVB-4 (AXI)

20092370 POWERBOARD CHS.DVB-4 (SEQ)

30000452 RES CF 1/4W 10R J R6

30000471 RES CF 1/4W 10K J R14 R23 R29 R30 R34 R35

30000477 RES CF 1/4W 100K J R43

30000583 RES CF 1/4W 220R J R10

30000590 RES CF 1/4W 2.2K J R26

30000599 RES CF 1/4W 220K J R42

30000712 RES CF 1/4W 470R J R5

30000718 RES CF 1/4W 4.7K J R13 R28 R31

30000736 RES CF 1/4W 51R J R11 R44

30000767 RES CF 1/4W 68R J R20

30000769 RES CF 1/2W 680R J R12

30000790 RES CF 1/4W 6.8R J R40

30000820 RES CF 1/4W 82K J R27

30000888 RES MF 1/4W 15K F R9

30000985 RES MF 1/4W 47K F R22 R24

30001028 RES MF 1/4W 82K G R25 R32

30001284 DIODE 1N4148 0.15A/100V 0.5A D5

30001303 DIODE BYD33M 1A/1000V 20A D9

30001318 DIODE BA159 1A/800V 20A D6

30001329 DIODE 1N4007 1A/1000V 30A D1 D2 D3 D4 D14

30001377 DIODE ZENER 33V UZT 33B D13

30002583 SHORT CIRCUIT # 0.6MM GR 0,875 J2 J4 J1 J3 J5 J6 D15

30007200 RES MF 1/4W 10K F R7 R8 R21

70000593 SEQUENCER TAPE 5.8mmx2700m M 0,810

30018871 PCB 16PW07E3

30000225 CAP CER 220PF 50V J SL C37

30000244 CAP CER 330PF 50V J SL C25

30000269 CAP CER 68PF 50V J CH C27

30000283 CAP CER 1NF 50V K B C26 C29

30000287 CAP CER 10NF 50V K B C28

30000295 CAP CER 100NF 50V Z F C12 C24 C32 C5 C30

30000352 CAP EL 100UF 16V M C10 C11 C33

30000371 CAP EL 22UF 50V M C13

30000400 CAP EL 47UF 50V M C34

30000431 CAP CER 100PF 1KV M C35 C36 C38

30001454 TR BC548B Q2 Q6 Q7 Q8 Q9 Q10

50010759 LABEL SERIAL NO (UNIVERSAL)

30000094 CAP MKT 220NF 275V M AC C1 C2

30000359 CAP EL 1000UF 16V M C8 C9

30000361 CAP EL 1000UF 35V M C19

30000377 CAP EL 220UF 35V M C15 C16

30000402 CAP EL 47UF 100V M C17

30000409 CAP EL 470UF 25V M C20

30000423 CAP EL 47UF 400V M C3

Rev 1.0 21.10.02 16:23 Page 50

Page 51

SERVICE MANUAL

30000440 CAP CER 2.2NF 4KV M C21

30000525 RES CF 1/2W 1.5K J R41

30000603 RES CF 1/2W 2.2M J (400V) R1

30001422 TR BD238 Q1

30001446 TR BD235 Q5

30001501 IC MC7812CT IC5

30001506 IC TL431 IC3

30001731 FUSE 2.5A 250V 5*20MM F1

30001792 CONN.MALE 2P MOLEX PL1

30002103 LINE FILTER 2*32MH (AK19) L6

30006710 CONN MALE 11P TOP WHITE PL2

30010700 DIODE BYV28-200 3.5A/200V 90A D8 D10 D11

30010708 DIODE ZENER 200V D16

30011450 COIL CHOKE 22UH RADIAL L1 L2 L3 L5

30012864 IC TOP233Y IC1

30013160 COIL ZBF116T-01A L7 L8

30014414 TRF SMPS DVB TR1

30015087 IC TCET1102G IC2

30015124 IC LM358N (ANALOG SAT) IC4

30017602 DIODE SCHOTTKY 3A D7

35000136 TK79-A (GRAY)

35000158 NUT C ZN BOTTOM M3

35000165 RONDELA C ZNSY 3*6*04 (M3)

35000181 C ZN YSMB M3*8

35002781 TR SOGUTUCU (10X19X35 MM)

50010759 LABEL SERIAL NO (UNIVERSAL)

20103681 TOUCH B.ASSY DVB-4 RED DS.

30000345 CAP EL 10UF 50V M CT01

30000459 RES CF 1/4W 100R J RT03

30001670 PREAMPLIFIER TFMS5360 IR01

30002178 SWITCH TACT SKHHLU X1 X2 X3

30002583 SHORT CIRCUIT # 0.6MM GR 0,250 J1 J2

30011017 DISPL.SEGMENT A-574E (H-96)B/W P2

30011068 PCB TK507-2

30018914 CONN ASSY 7P 15CM W/FERRITE P1

30018915 CONN ASSY 12P 13CM W/FERRITE KON04

20105468 R/C DVB2 SERVISAT (S) (SILVER)

20062060 UKV B.ASSY. (MAN)

20062061 UKV B.ASSY. (SMD)

30000464 RES SMD 1/10W 100R J R101

30000475 RES SMD 1/10W 10K J 0805 R104

30000499 RES SMD 1/10W 1.2K J (0805) R102

30000546 RES SMD 1/10W 1.5R J (0805) R106

30000727 RES SMD 1/10W 47K J (0805) R105

30000778 RES SMD 1/10W 6.8K J 0805 R100

30002731 RES SMD 1/10W 68R J R103

30002735 IC SAA3010T IC1

30015100 PCB 16UV04-1

30000395 CAP EL 47UF 6.3V M (4*7MM) C100

30001452 TR BC327 Q102

30001454 TR BC548B Q101

30002733 LED INFRARED IR333 D100

30011443 XTAL REZ 429KHZ (0.9MM) X100

35000006 SINGLE BATT.CONTACT (-) RC2000

35000007 SINGLE BATT.CONTACT (+) RC2000

35000003 DOUBLE BATTERY CONTACT UKV-900

Rev 1.0 21.10.02 16:23 Page 51

Page 52

SERVICE MANUAL

35000210 S C ZNSY YSMB 2.9*6.5

40006044 LENS RCDVB (I)

40008432 RUBBER PAD TRP38 (RCDVB) R01

40009550 BOTTOM COVER RCDVB (I) (SILVER)

40009561 BATTERY COVER RCDVB (I) (SILVER)

40011111 TOP CVR.RCDVB2 UK750 SERVISAT (S) (SLV)

50010561 NYLON (8CM *25CM ) KG 0,002

30011787 POWER CORD ASSY.(2.4MT W/FTZ)-SATELLITE30016831 CONN ASSY 11P 10CM W/FERRITE

35000228 C ZNSY YSMB 2.9*9.5

35002504 RONDELA DKP 14*9.5*0.6

35002530 C ZNSY YSMB 2.9*6

35002531 C ZNSY YSMB 2.9*8

35002560 3/8 UNEF-2A

35005664 TOP CVR.DVB-4(M.SLV)(LARGE)FF166/7837 ST

40005461 FOOT RUBBER RF-002 10*2.7

40005474 CABLE HOLDER 5RF-4

40010912 DVB 4 LARGE BOTTOM COVER

40011113 FRONTA.DVB-4 SERVISAT DSR 2003 3800(SLV)

50010560 NYLON (38CM *42CM ) KG 0,016

50010687 BIG CARTON BOX (OUT)(5'L#)

50010759 LABEL SERIAL NO (UNIVERSAL)

50010922 LABEL FRONT ''YESIL NOKTA'' (1 CM )

50010940 12MM TAPE

50013519 LABEL BARCODE (60x60) TRIPLE

50014939 LABEL BARCODE (80x30) OUTBOX

50018038 SNOW BOX RECEIVER LEFT

50018040 SNOW BOX RECEIVER RIGHT

50029712 PASTEBOARD DVB-4 STD

50029717 PROG.LIST DVB-4 SERVISAT/FRA

50029718 PROG.LIST.DVB-4 SERVISAT/ARABIC

50029719 PASTEBOARD ET#.DVB-4 SERVISAT DSR2003

50029720 USER_MAN.DVB-4 SERVISAT DSR 2003/FRA

50029721 USER_MAN.DVB-4 SERVISAT DSR 2003/ARABIC

50029722 TAG.DVB-4 SERVISAT DSR 2003/ENG

Rev 1.0 21.10.02 16:23 Page 52

Page 53

SERVICE MANUAL

Rev 1.0 21.10.02 16:23 Page 53

Loading...

Loading...