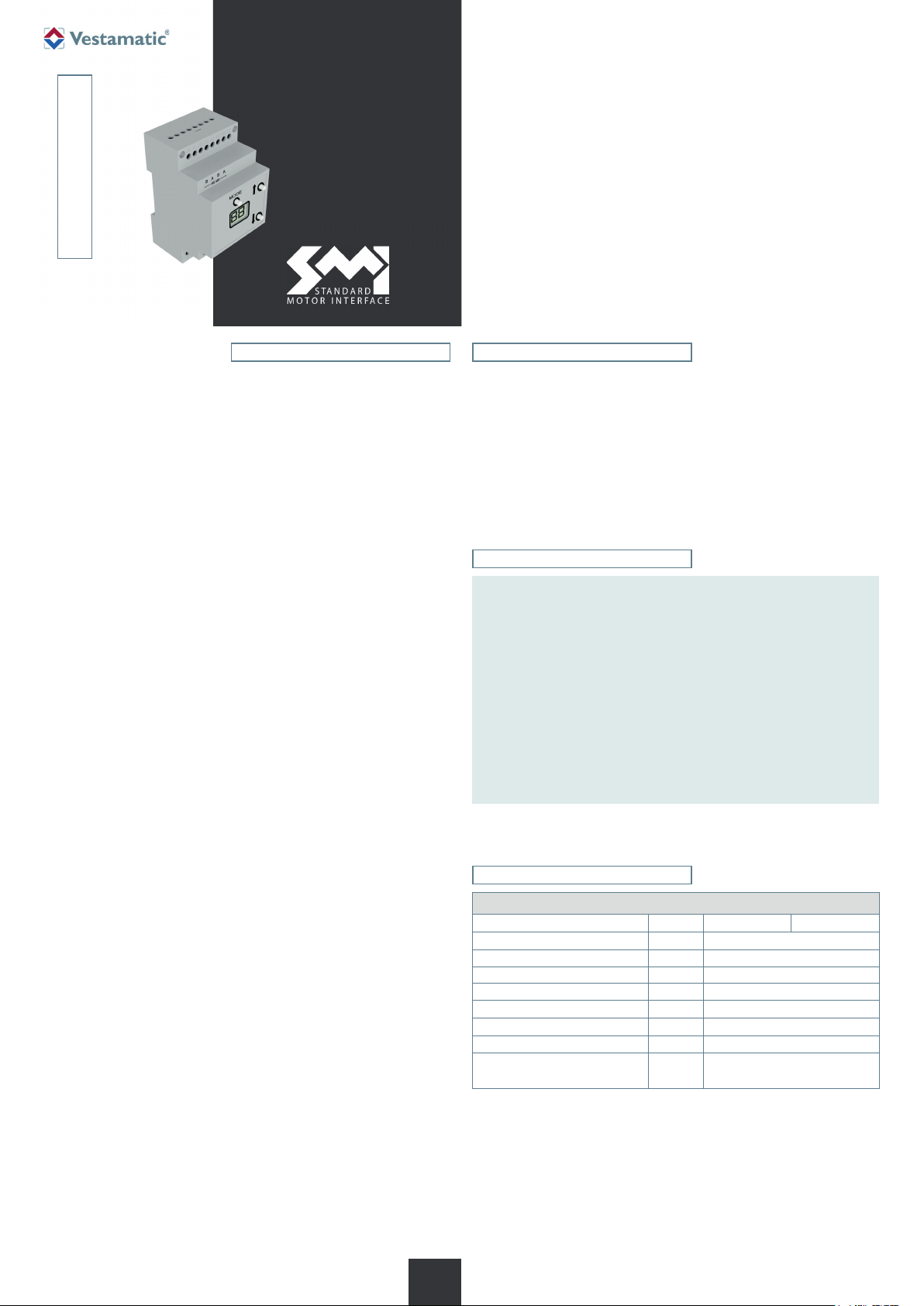

Vestamatic IF SMI RS-485 DIN RAIL Series, IF SMI RS-485 24 VDC-DIN, IF SMI RS-485 230 VAC-DIN Installation And Operating Instructions Manual

G

IF SMI RS-485 DIN

3060 001 GB 4518 A06

1. What is SMI?

2. Safety precautions

3. Technical data

4. Hardware

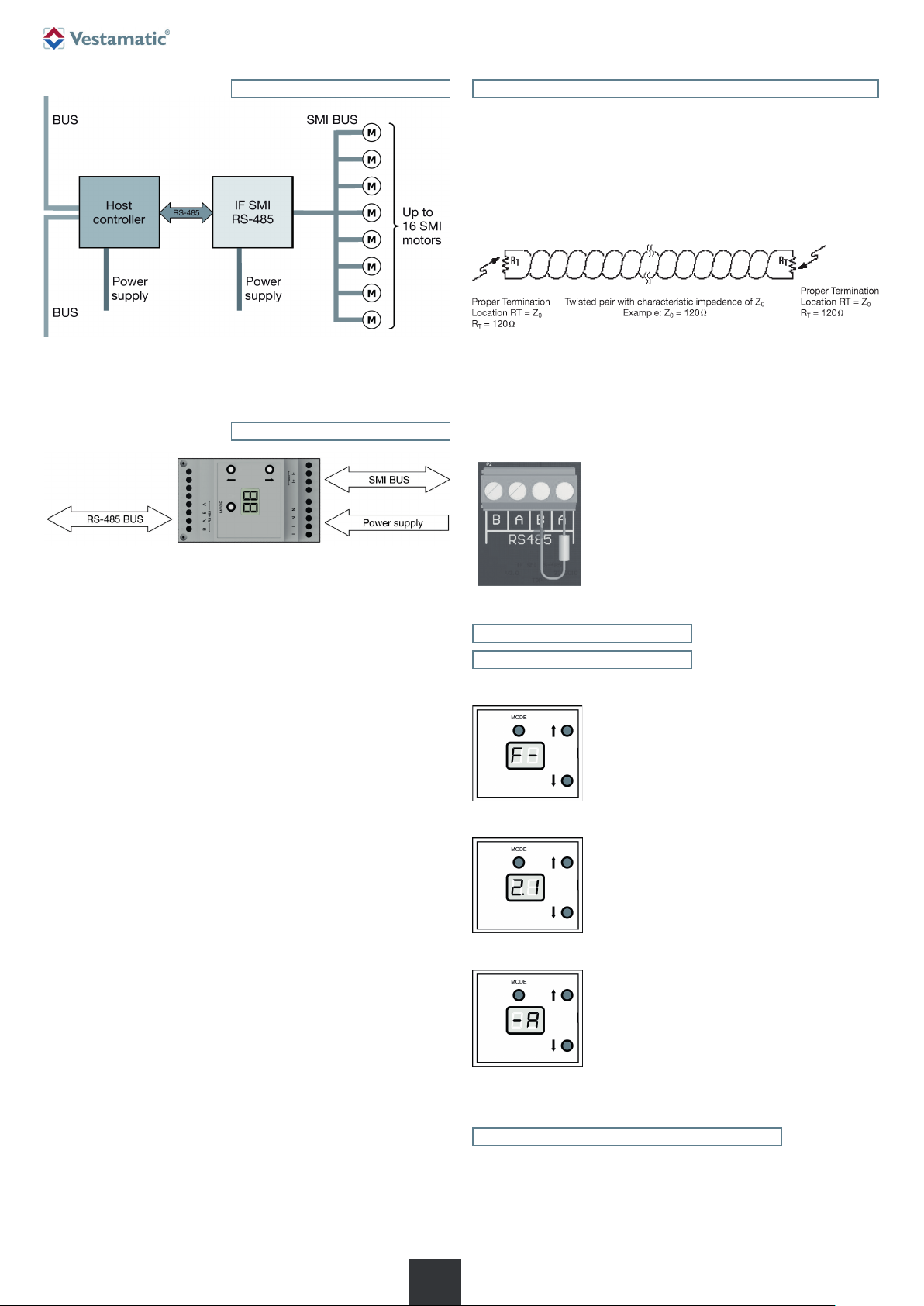

4.1 Overview IF SMI RS-485

4.1.1 RS-485 User interface

4.1.2 RS-485 BUS

4.1.3 Power supply

4.1.4 SMI BUS

4.1.5 Master Up/Down button

4.1.6 Base Address

4.2 Termination RS-485 BUS

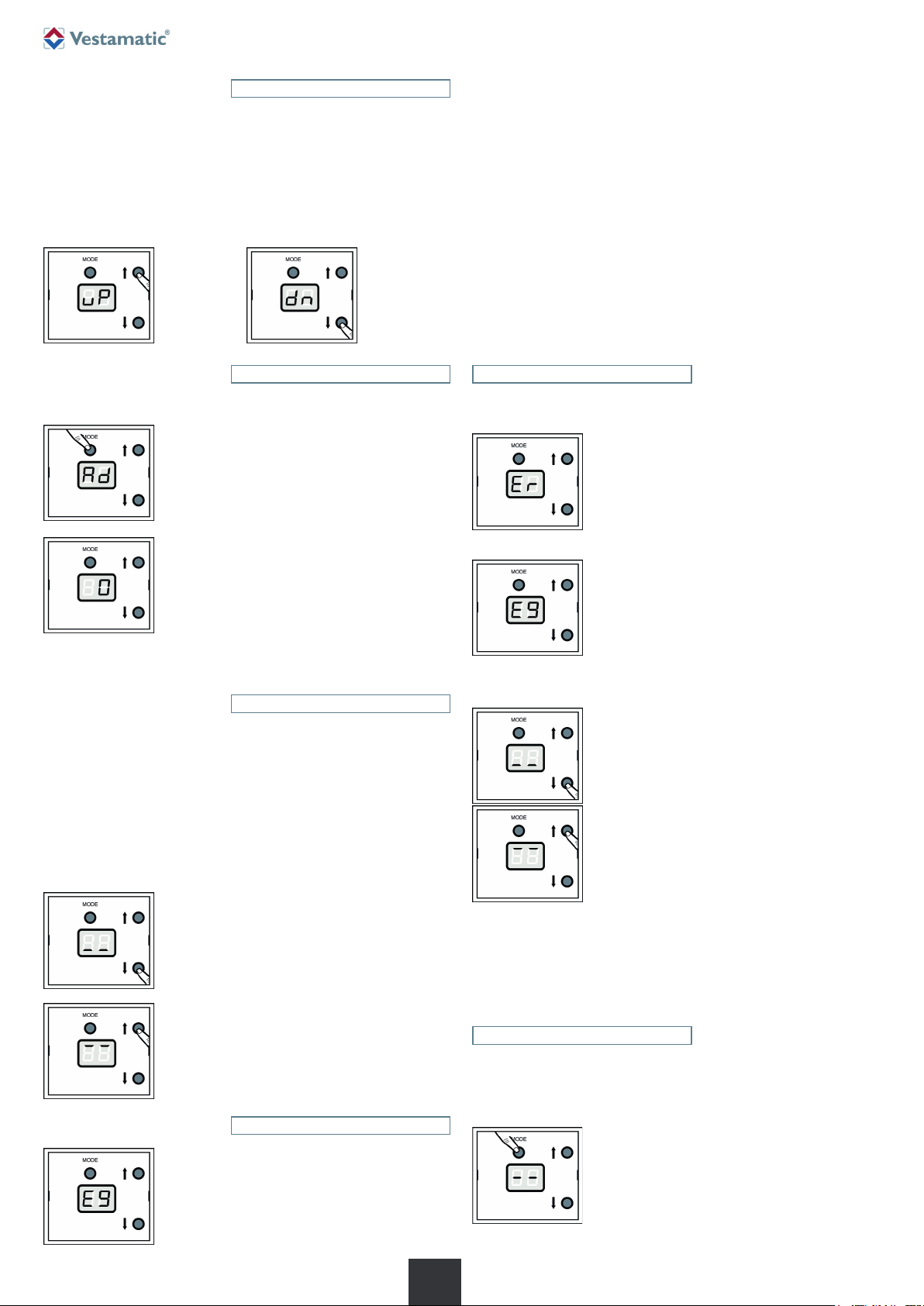

5. Menu navigation

5.1 Power-up

5.2 Main menu

5.3 Menu navigation

5.4 Address menu

5.5 Modify base address

5.6 Show error

5.7 Error log menu

5.8 Soft RESET

6. Protocol

6.1 Message structure

6.2 CRC16 Calculation

6.3 Steer commands

6.3.1 MSG_UP

6.3.2 MSG_DOWN

6.3.3 MSG_STOP

6.3.4 MSG_STEP_UP

6.3.5 MSG_STEP_DOWN

6.3.6 MSG_SET_POS

6.3.7 MSG_SET_TILT

6.3.8 MSG_SET_POS_STEP_UP

6.3.9 MSG_SET_POS_STEP_DOWN

6.3.10 MSG_GOTO_POS1

6.3.11 MSG_GOTO_POS2

6.3.12 MSG_GETMANID

6.3.13 MSG_SMI_TUNNEL

6.3.14 MSG_GW_OPTIONS

6.3.15 MSG_ERROR

6.4 Maintenance commands

6.4.1 MSG_VERSION

6.4.2 MSG_AUTO_ADDR

6.4.3 MSG_GET_SER

6.4.4 MSG_SET_SMIID

6.4.5 MSG_GET_PAR

6.4.6 MSG_GET_POS1

6.4.7 MSG_SET_POS1

6.4.8 MSG_GET_POS2

6.4.9 MSG_SET_POS2

6.5 Status commands

6.5.1 MSG_GETGENSTAT

6.5.2 MSG_GETDETSTAT

7. PC Test Software

7.1 Communication

7.2

General commands

7.3

Motor Mask based commands

7.4 Motor ID based commands

7.5 Send / Receive

8. Wiring diagrams

8.1 IF SMI RS-485 LoVo

8.2 IF SMI RS-485 230VAC

IF SMI RS-485 DIN RAIL

Contents

IF SMI RS-485 24 VDC-DIN

Motor control SMI RS-485 for top-hat rail

for control of 16 SMI motors 24 VDC.

Art.-no.: 01092124

IF SMI RS-485 230 VAC-DIN Art.-no.: 01092714

Motor control SMI RS-485 for top-hat rail

for control of 16 SMI motors 230 VAC.

Installation and Operating Instructions

1. What is SMI?

SMI is the abbreviation for Standard Motor Interface. SMI has been developed for the connection of intelligent drives for roller shutters and

sun protection systems. SMI enables to transmit telegrams from control

system to the drive and vice versa. With SMI it is possible to combine

products from different sources together. The SMI Interface should spread

high value solutions and promote drives and controls on the market. The

applications in roller shutters and sun protection systems require extreme

robustness and economic efficiency. SMI has been developed to meet

these requirements.

2. Safety precautions

– Contact a professional electrician for installation.

Ä

– Check the control system for signs of mechanical damage after

unpacking. If you notice any shipping damage, do not start up

the control system and notify your supplier imme di ately.

– The control system should only be used for the purpose speci-

– If the control unit cannot be operated without presenting a

– Turn off the power supply and prevent it from being switched

Article

Supply voltage: 230 VAC

Impulse voltage withstand level: kV 2.5

Rated power: W 2 W

Operating temperature: °C 0 °C (32 °F) to +40 °C (104 °F)

IP class: IP 20

Degree of contamination: 2

Dimensions (H × W × D): mm 90 × 52 × 60 (3 HP)

Conformity:

fied by the manufacturer (refer to the operating instructions).

Any changes or modifications thereof are not permissible and

will result in loss of all warranty claims.

hazard, it must be switched off and prevented from being

switched on unintentionally.

on unintentionally before performing work on any windows,

control or sunshades driven by the control system.

3. Technical data

IF SMI RS-485 DIN

Art.-no.: 01092124 01092714

p

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

1/10

G

Subject to modifications.© Vestamatic GmbH

IF SMI RS-485 DIN

4. Hardware

The IF SMI RS-485 can be used for SMI (230VAC) or SMI LoVo applications.

Important: It is not allowed to use a combination of SMI (230VAC) and

SMI LoVo on the same SMI BUS.

4.1 Overview IF SMI RS-485

4.2 Termination RS-485 BUS (Optional)

If you experience problems, please read this section.

The device usually has sufficient base termination. In exceptional cases

(e.g. with long or untwisted lines) we recommend to use a terminating

resistor of 120 Ω at both ends of the bus line.

This is to be installed between terminals A and B of the RS-485 signal line.

A terminating resistor is simply a resistor placed at the extreme end or

ends of a cable. The value of the terminating resistor is ideally the same

value as the characteristic impedance of the cable.

As a general rule moreover, termination resistors should be placed at both

far ends of the cable. Although properly terminating both ends is absolute ly critical for most system designs, it can be argued that in one special

case only one termination resistor is needed. This case occurs in a system

when there is a single transmitter and that single transmitter is located at

the far end of the cable. In this case there is no need to place a termination

resistor at the end of the cable with the transmitter, because the signal is

intended to always travel away from this end of the cable.

There is a Terminating resistor with a value of 120B

delivered by every IF SMI RS-485 module. If the Terminating resistor is recommended than he must be

placed between the A and B from the connector on

the PCB.

The IF SMI RS-485 module is an intelligent module that translates RS-485

commands to SMI commands.

4.1.1 RS-485 User interface

MODE button

– Short press Show current base address for 5 sec.

– Long press Modify current base address

– Double press Show error log

UP/DOWN button

– In main menu Steer all attached SMI motors UP/DOWN.

– In address menu Increase/Decrease base address

– Error log menu Show next/previous error

4.1.2 RS-485 BUS

The communication BUS between Host controller and IF SMI RS-485 module is RS-485. The following configuration is used:

Baud rate: 19200

Data bits: 8

Stop bits: 1

Parity: None

Signal: -7V to +10V Common-Mode Input Voltage Range

Maximum allowed pause Byte-to-Byte: 5 milliseconds

4.1.3 Power supply

The IF SMI RS-485 module needs the following power supply signals:

L, N (230VAC/50Hz)

4.1.4 SMI BUS

The SMI bus exists out of the following signals:

I+ (SMI BUS)

I

-

(SMI BUS)

5. Menu navigation

5.1 Power-up

During power-up, the firmware version is shown in 3 stages:

Step 1

Display shows “F-“ for 2 sec as indication that firmware version follows.

Step 2

Display shows firmware version (major.minor) for

3 seconds.

Step 3

Display shows firmware revision for 2 seconds.

4.1.5 Master Up/Down button

The IF SMI RS-485 has an master UP/DOWN button, to operate all

connected SMI motors at simultaneously.

4.1.6 Base Address

The IF SMI RS-485 is selected by its base address. Each IF SMI RS-485

module connected to a shared RS-485 BUS must have an unique base

address. A maximum of 16 IF SMI RS-485 modules can be connected to

the same RS-485 BUS, which makes it possible to control 16 x 16 = 256

SMI motors.

2/10

G

5.2 Main menu

The main menu is the default menu that is being shown when no other

user actions take place. The main menu shows:

A counter – counting the number of correctly received RS-485 frames

from 0 up to 99 and then starts at 0 again.

A blinking dot in the right bottom corner with a blink-frequency of 1 Hz

to indicate a running application.

Subject to modifications.© Vestamatic GmbH

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

IF SMI RS-485 DIN

5.3 Menu navigation

When the UP or DOWN buttons in the main menu are pressed, all attached

SMI motors will move UP or DOWN (depends on the pressed button) as

long as the button is pressed. This feature is useful during commissioning

to check:

– if the SMI communication is working

– if all attached motors are running in the correct direction

– if the limit positions are set correctly

Display shows the following as a visual feedback:

UP button

pressed

5.4 Address menu

The current RS-485 base address is shown when the MODE button is

pressed shortly (< 5 sec).

As long as the MODE button is pressed shortly,

“Ad” is shown on the display.

DOWN button

pressed

Error code description:

E0 = no error

E1 = RS-485 framing error

E2 = RS-485 timing error

E3 = RS-485 data overflow error

E4 = RS-485 CRC error

E5 = RS-485 command error (not supported or invalid length)

E6 = RS-485 busy (not able to process new command)

E7 = SMI format error

E8 = SMI checksum error

E9 = SMI timing error

EA = SMI data overflow

EB = SMI echo error

EC = SMI queue full error

The error message is shown for 5 seconds. Pressing any buton returns to

main menu directly.

5.7 Error log menu

The error log keeps track of the 5 last occurred errors, and can be shown

be pressing the MODE button twice within 1 second.

The text “Er” is briefly visible to indicate that the error

log is shown.

When the MODE button is released, the current

RS-485 base address is shown for 5 sec.

To directly return to the main menu, the MODE button must be pressed

again.

5.5 Modify base address

The current RS-485 base address can be modified be pressing the

MODE button for more than 5 seconds (after 5 seconds the text “Ad” starts

blinking).

After the MODE button is released, the current RS-485 base address is

shown blinking.

– Pressing UP will increase the RS-485 base address.

– Pressing DOWN will decrease the RS-485 base address.

– Pressing MODE button – or wait for 5 seconds – will store the RS-485

base address and return to main menu.

The RS-485 base address can be modified from 0 to 15.

When pressing the DOWN button while base address is already 0, the following is shown to indicate

that the base address cannot be further decreased.

When pressing the UP button while the base address

is already 15, the following is shown to indicate that

the base address cannot be further increased.

5.6 Show error

Next, the last occurred error is shown blinking.

– By pressing the UP button, the previous occurred error will be shown.

– By pressing the DOWN button, the next occurred error will be shown.

When pressing DOWN button while first error in log

is currently being shown..

When pressing UP button while last error in log is

currently shown.

By briefly pressing MODE button – or waiting for a few seconds – you will

return back to main menu.

5.8 Soft RESET

The IF SMI RS-485 can be restarted (soft-reset) without interruption of the

power supply by pressing the MODE button for 10 seconds.

After 10 seconds pressing the MODE button, the soft-reset will be entered,

and display will briefly show the following:

When an error occurs,

this will be shown directly.

3/10

G

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

Subject to modifications.© Vestamatic GmbH

6. Protocol

This chapter describes the communication protocol between the IF SMI RS-485 module

and Host controller.

IF SMI RS-485 DIN

6.1 Message structure

[SID] [LEN] [CMD] [DATA] [CRC16]

SID Slave ID

LEN Message length (without CRC)

CMD Command byte

DATA Optional data bytes

CRC16 16 bits checksum (LSB first)

The IF SMI RS-485 module has 4

DIP switches, which represents the base

address of the module from 0 to 15 (decimal)

or 0 to F (hexadecimal). The base address

is part of the Slave ID:

Base address Slave ID

0 0xC0

1 0xC1

2 0xC2

3 0xC3

4 0xC4

5 0xC5

6 0xC6

7 0xC7

8 0xC8

9 0xC9

10 0xCA

11 0xCB

12 0xCC

13 0xCD

14 0xCE

15 0xCF

6.2 CRC16 Calculation

Example code CRC16 calculation in C-language:

6.3 Steer commands

#define MSG_UP 0x10

#define MSG_DOWN 0x11

#define MSG_STOP 0x12

#define MSG_STEP_UP 0x13

#define MSG_STEP_DOWN 0x14

#define MSG_SET_POS 0x15

#define MSG_SET_TILT 0x16

#define MSG_SET_POS_STEP_UP 0x17

#define MSG_SET_POS_STEP_DOWN 0x18

#define MSG_GOTO_POS1 0x19

#define MSG_GOTO_POS2 0x1A

#define MSG_GETMANID 0x2C

#define MSG_SMI_TUNNEL

#define MSG_GW_OPTIONS

#define MSG_ERROR

0x2D

0x50

0xE0

6.3.1 MSG_UP

This message is used to move all, or a set of sun blind, to the top position.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

When bit n in mask is set, SMI motor with address n is addressed and

executes a UP command.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

#define CRC_CONSTANT 0xA001

word Crc16 (byte* pb, byte len)

{

byte i;

word crc;

for (crc=0xffff; len--; pb++)

{

crc ^= (byte)*pb;

for (i=8; i--; )

if (crc & 0x01)

{

crc >>= 1;

crc ^= CRC_CONSTANT;

}

else

crc >>= 1;

}

// return crc result

return crc;

}

6.3.2 MSG_DOWN

This message is used to move all, or a set of sun blind, to the lower position.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

When bit n in mask is set, SMI motor with address n is addressed and

executes a DOWN command.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

6.3.3 MSG_STOP

This message is used to stop all, or a set of sun blind.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT. The IF SMI RS-485 module responds to

this request with a general status message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

4/10

G

Subject to modifications.© Vestamatic GmbH

IF SMI RS-485 DIN

6.3.4 MSG_STEP_UP

This message is used to relatively move all, or a set of sun blind, in UP

direction.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [NSTEP] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

[NSTEP]: Number of steps (1..255) in UP direction. 1 step is defined as

2° rotation of the output shaft of the SMI motor.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

6.3.5 MSG_STEP_DOWN

This message is used to relatively move all, or a set of sun blind, in DOWN

direction.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [NSTEP] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

[NSTEP]: Number of steps (1..255) in DOWN direction. 1 step is defined

as 2° rotation of the output shaft of the SMI motor.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

6.3.6 MSG_SET_POS

This message is used to move all, or a set of sun blind, to an absolute

position.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [POS0] / [POS1] /

[CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

[POS0]: LSB of 16-bit absolute position.

[POS1]: MSB of 16-bit absolute position.

The absolute position value is defined as below:

0x0000 is the top position (0%).

0x8000 is the middle position (50%).

0xFFFF is the bottom position (100%).

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

6.3.7 MSG_SET_TILT

This message is used to move all, or a set of venetian blinds, in a absolute

tilt orientation.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [TILT] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

[TILT]: Absolute tilt orientation (0..255).

Absolute tilt orientation is defined as follow:

127 (0x7F) slats completely closed in down direction

0 (0x00) slats completely open (horizontal)

-128 (0x80) slats completely closed in up direction

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

The position of each sun blind can be obtained by the detailed response

message MSG_GETDETSTAT.

REMARK: The MSG_SET_TILT message uses a manufacturer specific

SMI command, which is currently only supported by Vestamatic SMI motors.

6.3.8 MSG_SET_POS_STEP_UP

This message is used to move all, or a set of venetian blinds, to an absolute

position combined with an relative up command.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [POS0] / [POS1] /

[NSTEP] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

[POS0]: LSB of 16-bit absolute position.

[POS1]: MSB of 16-bit absolute position.

[NSTEP]: Number of steps (1..255) in UP direction. 1 step is defined as

2º rotation of the output shaft of the SMI motor.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT. The position of each sun blind can be

obtained by the detailed response message MSG_GETDETSTAT.

6.3.9 MSG_SET_POS_STEP_DOWN

This message is used to move all, or a set of venetian blinds, to an absolute

position combined with an relative down command.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [POS0] / [POS1] /

[NSTEP] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

[POS0]: LSB of 16-bit absolute position.

[POS1]: MSB of 16-bit absolute position.

[NSTEP]: Number of steps (1..255) in DOWN direction. 1 step is defined

as 2º rotation of the output shaft of the SMI motor.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT. The position of each sun blind can be

obtained by the detailed response message MSG_GETDETSTAT.

6.3.10 MSG_GOTO_POS 1

This message is used to move all, or a set of venetian blinds, to intermediate position 1.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT. The position of each sun blind can be

obtained by the detailed response message MSG_GETDETSTAT.

6.3.11 MSG_GOTO_POS 2

This message is used to move all, or a set of venetian blinds, to intermediate position 2.

Message: [SID] / [LEN] / [CMND] / [MSK0] / [MSK1] / [CRC16]

[MSK0]: LSB of 16-bit mask to select motor address 0..7.

[MSK1]: MSB of 16-bit mask to select motor address 8..16.

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT. The position of each sun blind can be

obtained by the detailed response message MSG_GETDETSTAT.

6.3.12 MSG_GETMANID

This message is used to request the manufacturer ID of a specific motor.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [CRC16]

[SMIID]: SMI address of motor (0..15).

Response: [SID] / [LEN] / [CMND] / [SMIID] / [MID] / [CRC16]

[MID]: bit3-0: Manufacturer ID. (See SMI-Group website for actual

list)

Bit7-4: Motor type. An indication from 0 to 15 which each

SMI motor manufacturer can freely use to identify

their SMI motor type.

REMARK: An Manufacturer ID of 0 indicates that an invalid SMI-ID is

used.

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

5/10

G

Subject to modifications.© Vestamatic GmbH

IF SMI RS-485 DIN

6.3.13 MSG_SMI_TUNNEL

This message is used to send a SMI message directly to the SMI bus.

Detailed knowledge in SMI protocol is required to use this command.

Message: [SID] / [LEN] / [CMND] / [SMIMSG0] /… / [SMIMSGn] /

[CRC16]

[SMIMSG0..n]: SMI message data to send directly to SMI bus. The [LEN]

parameter defines the number of SMIMSG data bytes expected.

Response: [SID] / [LEN] / [CMND] / [RTYP] / [SMI_CMND] / [DATA0]

/… / [DATAm] / [CRC16]

[RTYP]: Response type:

0xFF: SMI message send successfully and accepted by

addressed motor(s).

0xE0: Error occurred. [DATA0] contains error code:

0x01: checksum error

0x02: format error

0x03: echo error

0x04: data overflow

0x05: timeout error

0xEF: SMI message send successfully and

response is in [DATA0..m]

[SMI_CMND]: SMI command to which this response belongs.

[DATA0..m]: Additional data for response type 0xE0 and 0xEF.

6.3.14 MSG_GW_OPTIONS

This message is used to request current gateway options or to set the

gateway options.

Set gateway options

Message: [SID] / [LEN] / [CMND] / [OPTIONS] / [CRC16]

[OPTIONS]: Gateway options:

bit 0: RS485 error feedback enabled flag

bit 1: Cycle logging in EEPROM enabled flag

bit 2-3: –

bit 4: RS485 error feedback flag state after power-up

bit 5: Cycle logging enabled flag state after power-up

bit 6-7: –

Response: [SID] / [LEN] / [CMND] / [OPTIONS] / [CRC16]

[OPTIONS]: Stored gateway options. See gateway options layout as

described above.

REMARK: Cycle logging is by default disabled, meaning that the

gateway does not keep track of the number of motor

cycles performed by each SMI motor.

For RS485 error feedback, see chapter 6.3.15 MSG_ERROR.

6.3.15 MSG_ERROR

This message is used to request the error log or used as a feedback message to host, when an error occurred during RS485 communication.

Request error log

Message: [SID] / [LEN] / [CMND] / [CRC16]

Response: [SID] / [LEN] / [CMND] / [ERR0] / … / [ERR4] / [CRC16]

[ERR0..4]: Contents of error log, where [ERR0] is the most recent error

and [ERR4] is the oldest error in the log.

Error code description:

0x00 = no error

0x01 = RS485 framing error

0x02 = RS485 timing error

0x03 = RS485 data overflow error

0x04 = RS485 CRC error

0x05 = RS485 command error

(not supported or invalid length)

0x06 = RS485 busy (not able to process new command)

0x07 = SMI format error

0x08 = SMI checksum error

0x09 = SMI timing error

0x0A = SMI data overflow

0x0B = SMI echo error

0x0C = SMI queue full error

Error feedback

When during RS485 communication an error is detected by the gateway

and “RS485 error feedback” is enabled (see chapter 6.3.14 Set gateway

options), an error response is send to host.

Response: [SID] / [LEN] / [CMND] / [ERR] / [CRC16]

[CMND] MSG_ERROR (= 0xE0)

[ERR] Error code indicating the type of error occurred:

0x00 = no error

0x01 = RS485 framing error

0x02 = RS485 timing error

0x03 = RS485 data overflow error

0x04 = RS485 CRC error

0x05 = RS485 command error

(not supported or invalid length)

0x06 = RS485 busy (not able to process new command)

REMARK: An error feedback is send back, when an error is detected and

at least the first 2 bytes of the original RS485 message were

received correctly.

Request gateway options

Message: [SID] / [LEN] / [CMND] / [CRC16]

Response: [SID] / [LEN] / [CMND] / [OPTIONS] / [CRC16]

[OPTIONS]: Stored gateway options.

See gateway options layout as described above.

Default gateway options: 0x00

6/10

G

6.4 Maintenance commands

#define MSG_VERSION 0x20

#define MSG_AUTO_ADDR 0x21

#define MSG_GET_SER 0x22

#define MSG_SET_SMIID 0x23

#define MSG_GET_PAR 0x24

#define MSG_GET_POS1 0x28

#define MSG_SET_POS1 0x29

#define MSG_GET_POS2 0x2A

#define MSG_SET_POS2 0x2B

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

Subject to modifications.© Vestamatic GmbH

IF SMI RS-485 DIN

6.4.1 MSG_VERSION

This message is used to check to version number of the application.

Message: [SID] / [LEN] / [CMND] / [CRC16]

Response: [SID] / [LEN] / [CMND / [HARD] / [VMAJ] / [VMIN] / [REV] /

[CRC16].

[HARD]: An alphanumeric char to identify the hardware platform.

[VMAJ]: The major software version number (from 0 to 255).

[VMIN]: The minor software version number (from 0 to 255).

[REV]: An alphabetic char to identify the internal revision letter

(from A to V), X is reserved for specific test software version.

6.4.2 MSG_AUTO_ADDR

This message is used to start the SMI auto address procedure. Motor address conflicts will be solved and every motor becomes an unique address

(0..15). This procedure can take up to 60 seconds to solve all the address

conflicts.

Message: [SID] / [LEN] / [CMND] / [CRC16]

The IF SMI RS-485 module responds to this request with a general status

message MSG_GETGENSTAT.

6.4.3 MSG_GET_SER

This message is used to return the serial number and the SMI ID of a

specific sun blind.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [CRC16]

[SMIID]: SMI address of motor (0..15)

Response: [SID] / [LEN] / [CMND] / [SMIID] / [SER0] / … / [SER3] /

[CRC16]

[SMIID]: SMI address of motor (0..15)

[SER0..3]: The serial number of the specified SMI motor. The serial number

is always 4 bytes.

6.4.4 MSG_SET_SMIID

This message is used to set the SMI ID of a specific sun blind address by

its serial number.

Message: [SID] / [LEN] / [CMND] / [SER0] / … / [SER3] / [SMIID] / [MAN] /

[CRC16]

[SER0..3]: The serial number of the specified SMI motor.

The serial number is always 4 bytes.

[SMIID]: SMI address of motor (0..15) to set.

[MAN]: Manufacturer ID of SMI motor. Manufacturer ID for a Vestamatic

motor is 6.

Response: [SID] / [LEN] / [CMND] / [SER0] / … / [SER3] / [SMIID] / [MAN] /

[CRC16]

[SER0..3]: The serial number of the specified SMI motor.

[SMIID]: SMI address of motor (0..15). When high-nibble if SMI ID is

0xF0, an error occurred during SMI ID set.

[MAN]: Manufacturer ID of SMI motor.

It can take up to 60 seconds before the GETGENSTAT response is updated

with the new SMI ID.

6.4.5 MSG_GET_PAR

This message is used to get the value of any private protected parameters

of a specific motor.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [PAR0] / [PAR1] / [PLEN] /

[CRC16]

[SMIID]: SMI address of motor (0..15)

[PAR0..1]: Index of the motor parameter.

[PLEN]: Length of parameter (1, 2 or 4 bytes)

Response: [SID] / [LEN] / [CMND] / [SMIID] / [VAL0] / … / [VALn] /

[CRC16]

[SMIID]: SMI address of motor (0..15)

[VAL0..n]: Parameter value (1, 2 or 4 bytes in size)

6.4.6 MSG_GET_POS 1

This message is used to get (read) the stored intermediate position 1.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [CRC16]

[SMIID]: SMI address of motor (0..15)

Response: [SID] / [LEN] / [CMND] / [SMIID] / [POS0] / [POS1] / [CRC16]

[SMIID]: SMI address of motor (0..15).

When high-nibble of SMI address is 0xF0, an error occurred

during GET_POS1.

[POS0]: LSB of 16-bit intermediate position 1.

[POS1]: MSB of 16-bit intermediate position 1.

The intermediate position value is defined as below:

0x0000 is the top position (0%).

0x8000 is the middle position (50%).

0xFFFF is the bottom position (100%).

6.4.7 MSG_SET_POS 1

This message is used to set (write) intermediate position 1.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [POS0] / [POS1] / [CRC16]

[SMIID]: SMI address of motor (0..15)

[POS0]: LSB of 16-bit intermediate position 1.

[POS1]: MSB of 16-bit intermediate position 1.

Response: [SID] / [LEN] / [CMND] / [SMIID] / [POS0] / [POS1] / [CRC16]

[SMIID]: SMI address of motor (0..15).

When high-nibble of SMI address is 0xF0, an error occurred

during SET_POS1.

[POS0]: LSB of 16-bit intermediate position 1.

[POS1]: MSB of 16-bit intermediate position 1.

6.4.8 MSG_GET_POS 2

This message is used to get (read) the stored intermediate position 2.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [CRC16]

[SMIID]: SMI address of motor (0..15)

Response: [SID] / [LEN] / [CMND] / [SMIID] / [POS0] / [POS1] / [CRC16]

[SMIID]: SMI address of motor (0..15). When high-nibble of SMI address

is 0xF0, an error occurred during GET_POS2.

[POS0]: LSB of 16-bit intermediate position 2.

[POS1]: MSB of 16-bit intermediate position 2.

The intermediate position value is defined as below:

0x0000 is the top position (0%).

0x8000 is the middle position (50%).

0xFFFF is the bottom position (100%).

6.4.9 MSG_SET_POS 2

This message is used to set (write) intermediate position 2.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [POS0] / [POS1] /

[CRC16]

[SMIID]: SMI address of motor (0..15)

[POS0]: LSB of 16-bit intermediate position 2.

[POS1]: MSB of 16-bit intermediate position 2.

Response: [SID] / [LEN] / [CMND] / [SMIID] / [POS0] / [POS1] /

[CRC16]

[SMIID]: SMI address of motor (0..15). When high-nibble of SMI

address is 0xF0, an error occurred during SET_POS2.

[POS0]: LSB of 16-bit intermediate position 2.

[POS1]: MSB of 16-bit intermediate position 2.

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

7/10

G

Subject to modifications.© Vestamatic GmbH

IF SMI RS-485 DIN

6.5 Status commands

#define MSG_GETGENSTAT 0xA0

#define MSG_GETDETSTAT 0xA1

6.5.1 MSG_GETGENSTAT

This message requests the general status of the system.

Message: [SID] / [LEN] / [CMND] / [CRC16]

Response: [SID] / [LEN] / [CMND] / [PRES0] / [PRES1] / [RDY0] / [RDY1] /

[CRC16].

[PRES0]: The LSB mask of the 8 first motors present on the SMI BUS.

[PRES1]: The MSB mask of the 8 last motors present on the SMI BUS.

[RDY0]:

[RDY1]: The MSB mask of the 8 first motors ready to operate on the

Motor can always accept new commands; RDY0/RDY1 indicates if a motor is running (flag cleared) or motor is idle (flag set).

The LSB mask of the 8 first motors ready to operate on the SMI

BUS.

SMI BUS.

6.5.2 MSG_GETDETSTAT

This message is used to obtain the detailed status of a specified sunblind.

Message: [SID] / [LEN] / [CMND] / [SMIID] / [CRC16]

[SMIID]: SMI address of motor (0..15)

Response: [SID] / [LEN] / [CMND] / [SMIID] / [STATUS] / [POS0] /

[POS1] / [TILT] / [CYCLE0] / .. / [CYCLE3] / [CRC16]

[SMIID]: SMI address of motor (0..15)

[STATUS]: Status of the motor

[POS0..1]: 16-bits absolute position value

[TILT]: Orientation of the slats

REMARK: Tilt information uses a manufacturer specific SMI command,

[CYCLE0..3]:

which is currently only supported by Vestamatic SMI motors.

For non Vestamatic SMI-motors, TILT value 0x00 is returned.

32-bits cycle counter of the motor

7. PC Test Software

For testing your application, a freeware PC Software (Windows®) can be

downloaded from our website http://www.vestamatic.com.

Status Bit layout

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Meaning

X X X X 0 X X X

X X X X 1 0 0 0

X X X X 1 0 0 1

X X X X 1 0 1 0

X X X X 1 0 1 1

X X X X 1 1 0 0

X X X X 1 1 0 1

X X X X 1 1 1 0

X X X X 1 1 1 1

0 0 0 1 X X X X

1 1 1 1 X X X X

MOTOR ERROR OCCURED

UP + DOWN + STOP

DOWN + STOP

UP + STOP

ALL STOP

UP + DOWN

ALL DOWN

ALL UP

NOT VALID

TILT INFO:

NOT SUPPORTED BY MOTOR

INVALID SMI RESPONSE

7.1 Communication

In the “Communication” section, select the RS-485 communication port

of your PC, that is connected to the IF SMI RS-485 module. Also set the

RS-485 base address. This must correspond with the DIP switch settings

on the IF SMI RS-485 module. Press the “Open” button to open the communication channel.

7.2 General commands

On the “General” tab-sheet, you will find commands that don’t have additional parameters.

VERSION: Get software version of IF SMI RS-485 module.

GETGENSTAT: Get general status (motor present / motor ready).

AUTO_ADDR: Start the auto-address sequence, in case of address

conflicts.

8/10

G

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

Subject to modifications.© Vestamatic GmbH

IF SMI RS-485 DIN

7.3 Motor Mask based commands

On the “Motor Mask” tab-sheet, you will find the “motor mask” based

commands. With the checkboxes 15 to 0 you can select which motor(s)

you want to address, or simply select “All”, to address all motors. Next,

press a command button, like “UP”, “DOWN”, “STOP”, “STEP_UP”,

“STEP_DOWN”, “SET_POS”, “SET_TILT”, “SET_POS_STEP_UP”,

“SET_POS_STEP_DOWN”, “GOTO_POS1” or “GOTO_POS2”.

REMARK: Some commands need additional parameters. See section

“6. Protocol” for detailed information.

7.4 Motor ID based commands

On the “Motor ID” tab-sheet, you will find the “Motor ID” based commands. The motor you want to address, can be selected with the spin edit

box (in the dark gray part, behind Motor ID). Motor ID can be set from “0” to

“15”. Next, press a command button, like “GET_SERIAL”, “GET_PARAM”,

“SET_SMI_ID”, “GET_POS1”, “SET_POS1”, “GET_POS2”, “SET_POS2”

or “GETDETSTAT”.

REMARK: Some commands need additional parameters. See section

“6. Protocol” for detailed information.

7.5 Send / Receive

In the “Send/Receive” section, you can monitor the communication between PC and

IF SMI RS-485 module. You will see the Transmit and Receive data stream.

9/10

G

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

Subject to modifications.© Vestamatic GmbH

8. Wiring diagrams

8.1 Wiring diagram – IF SMI RS-485 24VDC DIN

IF SMI RS-485 DIN

8.2 Wiring diagram – IF SMI RS-485 230VAC DIN

10/10

G

Art.-Nr.: 3060 001 GB 4518 A06 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

Subject to modifications.© Vestamatic GmbH

Loading...

Loading...