Vessel IPC40-E Instruction Manual

Quality does it.

Instruction Manual

ION/ PARTS CLEANER

No. IPC40-E

Application

This product is used to remove fine powder and dust attracted by static electricity and to remove static

electricity from parts that are negatively affected by static electricity.

A powerful air blower in an ionized space blows off the debris. The blown off debris is forcefully

collected by a dust collector.

Table of Contents

■For Your Safety ································ P.2

■Product Overview ···························· P.6

■Dimensions ······································ P.9

■Component Functions ····················· P.10

■Installation ······································· P.13

■Operation ········································· P.19

■Maintenance ···································· P.27

■Storage &Troubleshooting ··········· P.33

■Removing, Disposing of,

and Replacing Parts ······················ P.34

■Notice of CE Marking ···················· P.35

For Your Safely

Safety Precautions

Please read this manual carefully before using this product.

Use this manual to take responsibility to ensure everyone that is using this product is doing so safely.

After carefully reading this manual, keep it in a protected place where it can be used at any time.

●The precaution items shown here are divided into two levels according to the level or risk.

WARNING

CAUTION

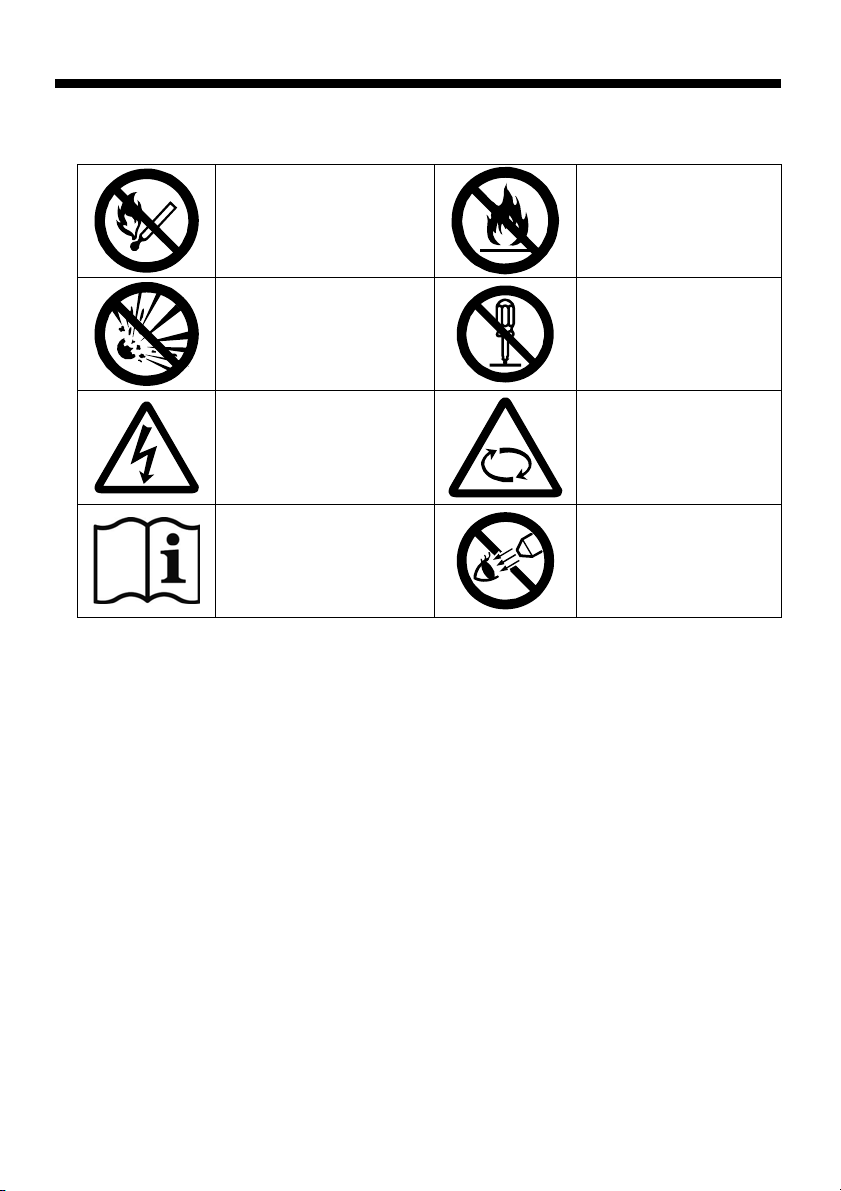

○Example Pictorial Displays

Indicates that improper handling can lead to serious injury or even death.

Indicates that improper handling can lead to minor injury and property

damage.

This symbol indicates a WARNING or CAUTION.

Prohibited

Vacuuming Up Prohibited

This symbol indicates a prohibited action.

This symbol indicates a mandatory required action

WARNING

Do not use IPC40-E for anything other than static erasure or dust

removal.

To prevent fires, absolutely do not vacuum up flames, explosive

dust, or liquid mist containing dust such as the following.

- Items that are on fire: Cigarette butts, matches, and other

sources of fire.

- Things containing sparks: A large amount of sparks from

grinding, dust that includes cinders, etc.

- Flammable substances: Gasoline, thinner, benzene,

kerosene, materials adhered with or containing oils, cleaning

fluids, or flammable substances.

- Explosive substances: Explosive dust, such as aluminum,

magnesium, titanium, and epoxy resin; explosive materials

and dust or explosive liquids that can make dust explode

depending on the conditions such as particle diameter and

concentration; liquid mists or substances adhered with or

containing explosive substances.

- Combustible substances: Combustible dust, combustible

liquid mist, or materials adhered with or containing

combustible materials, etc.

2

Vacuuming Up Prohibited

Vacuuming Up Prohibited

Joint Use Prohibited

Remember

Remember

Remember

Remember

For Your Safely

WARNING

- Detrimental substances: Corrosive substances, adhesive

substances, liquids containing adhesive substances, gases

Take into consideration the conditions surrounding the installation area.

・ Install the unit in an indoor location not subject to wind, rain, or direct

sunlight.

・ Where possibly wet by water, oil, chemicals, etc.

・ Where exposed to marked vibrations or shock

・ The temperature range should be 0°C to 40°C. Use the unit in a humidity

range of 20 to 80%.

To prevent fires, conduct an inspection after work is completed.

Be sure to correctly install the components.

Leaks from defective installation could overload the motor and cause it to

burn out.

Store this manual close to the product where it can be referenced easily.

containing large quantities of detrimental substances, etc.

- Liquids and liquid mists: Dust containing moisture such as

that generated by machine tools, etc.

To prevent an accident or malfunction, absolutely do not

vacuum up damp dust or any moisture such as water or oil.

Damp dust could clog the filter and make recovery impossible.

Further, the product is not moisture or oil resistant, so an

unforeseen malfunction or accident could occur due to

corrosion, leaking, and dust accumulating in the internal duct.

To prevent fires, absolutely do not make joint use of the

following.

・ When the dust could transform into a hazardous substance

when mixed inside the unit.

CAUTION

Prohibited

Do not install, use, or service this product until you understand this manual.

3

For Your Safely

WARNING

Prohibited

Painting Prohibited

Peering Prohibited

Disassembly Prohibited

Acceleration Prohibited

Remember

To prevent fires, only use the specified rated power source.

Use as a painting booth is prohibited. Do not perform painting

work in it.

Do not peer into the end of the air nozzle. The sensor will

detect your presence and blast out compressed air, which

could strike your eyes or face.

WARNING

Do not remove components, or modify or unreasonably

disassemble or assemble the product.

・ This product is manufactured in accordance with safety and

performance standards, so removing components or

modifying the product is dangerous.

・ Depending on the type of trouble, the customer might not be

able to handle it, so always contact the store where the

product was purchased.

Do not use an inverter to accelerate operation.

Acceleration could overload the motor and pose a hazard in

terms of the strength of rotating parts, etc. In addition,

deceleration could cause a drop in blow volume, which could

result in insufficient motor cooling.

Be sure to observe the following to prevent electrical shock

accidents.

・ Be sure to unplug the power cord from the outlet before

performing any wiring.

Remember

Remember

Remember

WARNING

Be sure to turn off the power when the thermal protector operates and the

operation stops.

When the motor becomes overloaded, the thermal protector automatically

operates to stop the motor, but since this is an automatic recovery type motor,

if the power is left on, the motor could suddenly automatically restarting

operating and leads to an accident.

Turn off the power switch and main power supply before looking for the cause

of the problem.

Do not restart operation before identifying and eliminating the cause of the

problem.

Perform the processing quickly without letting dust accumulate.

Depending on the conditions, dust could present a fire or explosion hazard.

Be sure to unplug the power cord from the outlet before performing any

maintenance or inspection work.

4

To Use this Product Safely

The following prohibition and caution symbols are displayed on the product.

○Example Pictorial Displays

Sucking up sparks or

flames is prohibited

Sucking up explosive

substances is prohibited

Be careful of electric shock

Carefully read the

instruction manual

5

Sucking up flammable or

combustible substances

is prohibited

Disassembly Prohibited

Be careful of rotating

parts

No Peeking for Air Nozzle

Product Overview

Features

●Dust collecting unit with a static eraser

・This is a separate type static eraser dust collector where the work hood and dust collector are

connected by a duct and a connection cord.

・The work hood and dust collector can be installed in separate, freely selected locations to make

effective use of limited working space.

・The dust collector can be placed under the bench or in another location to muffle the noise.

●Work hood

・The entire top of the hood is made of transparent acrylic. This lets in light to provide good visibility.

・The wide opening makes it easy to insert and remove long pieces of work.

・Connecting electrical power and the drive source to the static eraser dust collector maintains an

environment filled with ions inside the hood.

・The sensor detects when work held by hand is placed inside the hood and automatically turns on the

air blower.

・The dust is instantly removed from even large pieces of work by the two air nozzles that blow air from

the left and right.

●Dust collecting unit

・ Built-in high-performance filter for removing fine, dry dust. The exhaust does not dirty the room air.

・ A closable clear acrylic window is provided in the front of the hood to block flying material and provide

good visibility.

・ The opening has been optimally designed to allow the work to be smoothly put in and removed.

・ The dust collector filter can be easily replaced by removing the front cover.

●Safety

・ The static eraser has a problem monitoring function that can be checked by looking at the illuminated

indicators, etc.

・ Equipped with a control circuit that first vents the air from inside the dust collector hood before turning

on the static eraser power.

CE Marking

We have certified our manufactured IPC40-E are designed and manufactured under the

requirement of EU directive with following conditions:

○Low voltage Directive (73/23/EEC)

REQUIREMENTS : IEC/EN60335-1, IEC/EN60335-2-80, IEC/EN55014-1,

IEC/EN55014-2, IEC/EN61000-3-2, IEC/EN61000-3-3, IEC/EN60204-1

○POLLUTION DEGREE : II

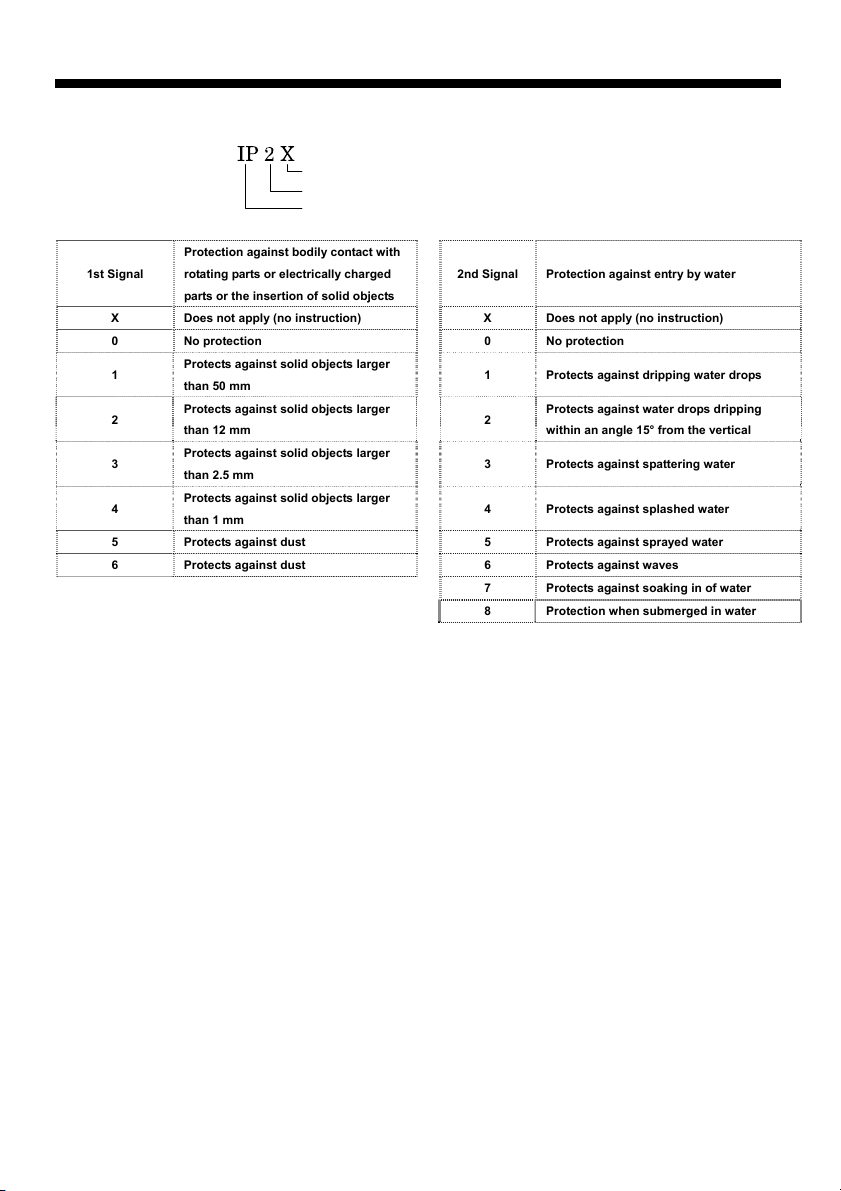

○IP Code : IP2X

6

Product Overview

Protection Classification (IP) Labeling Examples

Protection against bodily contact with

1st Signal

X Does not apply (no instruction) X Does not apply (no instruction)

0 No protection 0 No protection

1

2

3

4

5 Protects against dust 5 Protects against sprayed water

6 Protects against dust 6 Protects against waves

7 Protects against soaking in of water

8 Protection when submerged in water

rotating parts or electrically charged

parts or the insertion of solid objects

Protects against solid objects larger

than 50 mm

Protects against solid objects larger

than 12 mm

Protects against solid objects larger

than 2.5 mm

Protects against solid objects larger

than 1 mm

2nd signal

1st signal

Character signal

2nd Signal Protection against entry by water

1 Protects against dripping water drops

2

3 Protects against spattering water

4 Protects against splashed water

Protects against water drops dripping

within an angle 15° from the vertical

7

Product Overview

Model No. : IPC40-E

Dust Collection Method : Cylindrical Cartridge Filter

Input Voltage : Single-phase AC 230V (50/60Hz)

Power Output : 200W

Consumption Current : 1.2A (50Hz) 1.4A (60Hz)

Air Flow : 3.3 m

Static Pressure : 0.88kPa (50Hz) 1.23kPa (60Hz)

Wind Pressure : 0.4 m/sec (50Hz) 0.5 m/sec (60Hz)

Dust Collection : 1.2L

Air Pressure/Air Hose : 0.4~0.7MPa (Use clean air) /φ6mm x φ4mm

Air Consumption : 355 ℓ / min. (0.7MPa, actual measurement))

Working Temperature/ Humidity Range : 0~+40℃ / 20~80%RH (No dewing or freezing)

Noise : Hood Front 63dB(A) (50Hz) 66dB(A) (60Hz)

Dust Collector Front 62dB(A) (50Hz) 65dB(A) (60Hz)

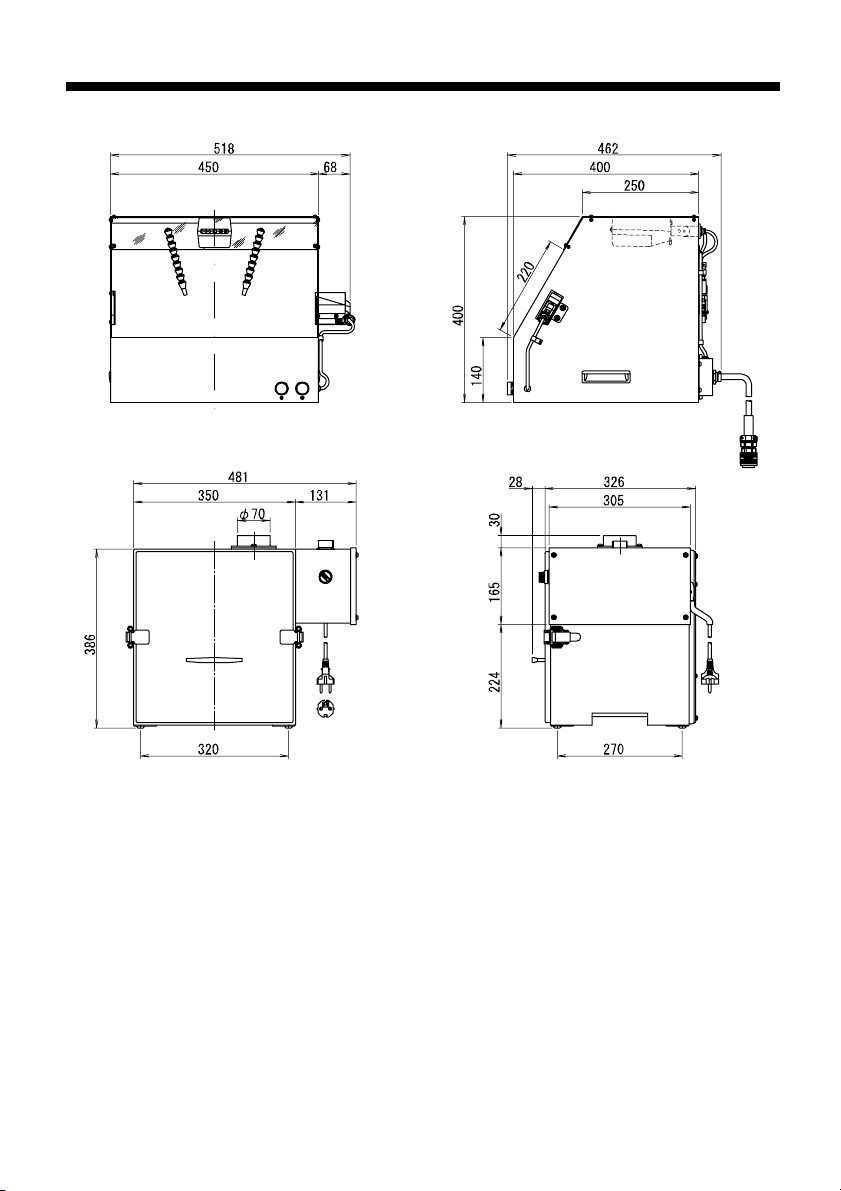

Dimensions :Hood 518W×462D×402H(mm)

Dust Collector 481W×354D×416H(mm)

Weight : Hood 12kg

Dust Collector 30kg

Connection cord

Accessories

Option :High-brightness LED unit This optional LED unit lights up the

workspace, helping workers to detect dust.

●Specifications (Static Eraser)

Model No. : SDJ-08

Ion Generation Method : High voltage AC corona discharge

Output voltage :±3.5 KV AC

Input voltage : 24V DC ±5%

Consumption Current : 200mA (typ.)

Air Flow : 0.8 ㎥/ min. (max.) ⇔ 0.4 ㎥/ min.

Warning output : NPN transistor / open collector, max. rating: 100 mA/ 50V

high voltage alarm (Red LED), fan lock alarm (Red LED)

Protective function : Over current protection fuse (1.8 A/50 V)

Reverse-current connector protection diode (1.0 A/ 400 V)

Fan motor rotation monitoring function (Detecting rotation lock)

High-voltage output drooping (Detecting overload)

Working temperature/ Humidity Range: 0 ~+40℃ 20~80%RH (No dewing or freezing)

Ozone generation : 0.007 ppm or less (As measured at 300 mm, 30 sec.)

Static electricity removal time : About 2.9 sec. from ±1,000 V ⇔ ±100 V

Ion balance : Within ±10 V (At 300 mm, maximum air flow)

3

/min (50Hz) 4.0 m3/min (60Hz)

:Connector type Length 1.6 m

:Instruction Manual (this manual) 1cop.

Static eraser dust remover adjustment tool 1pc

Sensor plastic adjustment tool 1pc

Dangerous use prohibited card 1pc

Clear acrylic sheet 1pc

Thumbscrews (M4-6) 6pcs

Dust collection duct hose (1.6 m) 1pc

(At 300 mm, maximum air flow)

8

■Dimensions

9

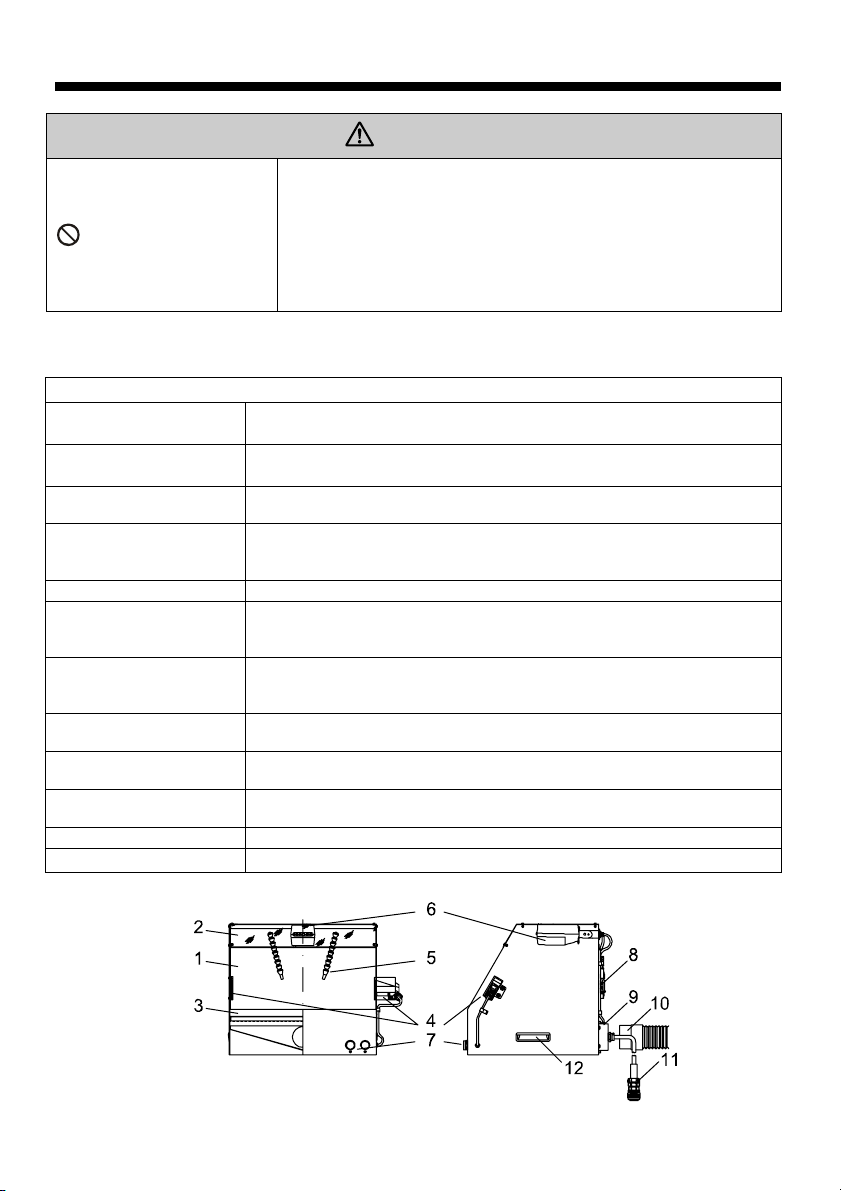

■Component Functions

CAUTION

Absolutely do not replace the hood or dust collector with another

device or use a substitute device.

Do not remove components, or modify or unreasonably disassemble

Disassembly Prohibited

Please be sure to understand the components and functions of the dust collector work platform and to

operate the unit safely and to work safely.

1. Work hood

2. Clear acrylic sheet

3. Perforated plate

4. Sensor + reflection

plate

5. Air nozzles Two flexible nozzles that can be pointed in any direction.

6. Static eraser

7. Operation button

8. Air solenoid valve

9. Duct connection port

(exhaust)

10. Dust collection duct

hose

11. Connection cord This is a 1.6 m long connection cord for connecting to the dust collector.

12. Handle This is used to hold the hood when moving it.

or assemble the product.

This product is manufactured in accordance with safety and

performance standards, so removing components or modifying the

product is dangerous.

Work Hood

This is a booth that improves the dust collection effectiveness of the dust

removal work.

This plate keeps dust from dispersing during the dust removal work. It

also lets in light from the top to allow the work surface to be clearly seen.

This is a work plate for use during the work. It prevents large objects from

falling inside the chamber.

This senses when work is put in or removed and sends a signal to the air

solenoid valve. For information about the sensitivity and timer, refer to

the “Sensor” item under “Operation” in this manual.

This removes electrostatic charge. For information regarding the detailed

operation of the SDJ-08 Static Eraser, refer to the “Static Eraser” item

under “Operation” in this manual.

This button is located close to the dust collector and is used to start and

stop the operation. A push button type main switch is attached to the dust

collector.

This supplies or stops the compressed air in response to the sensor

signal.

This connects the duct to the dust collector.

Bellows type with a length of 1.6 m when extended.

10

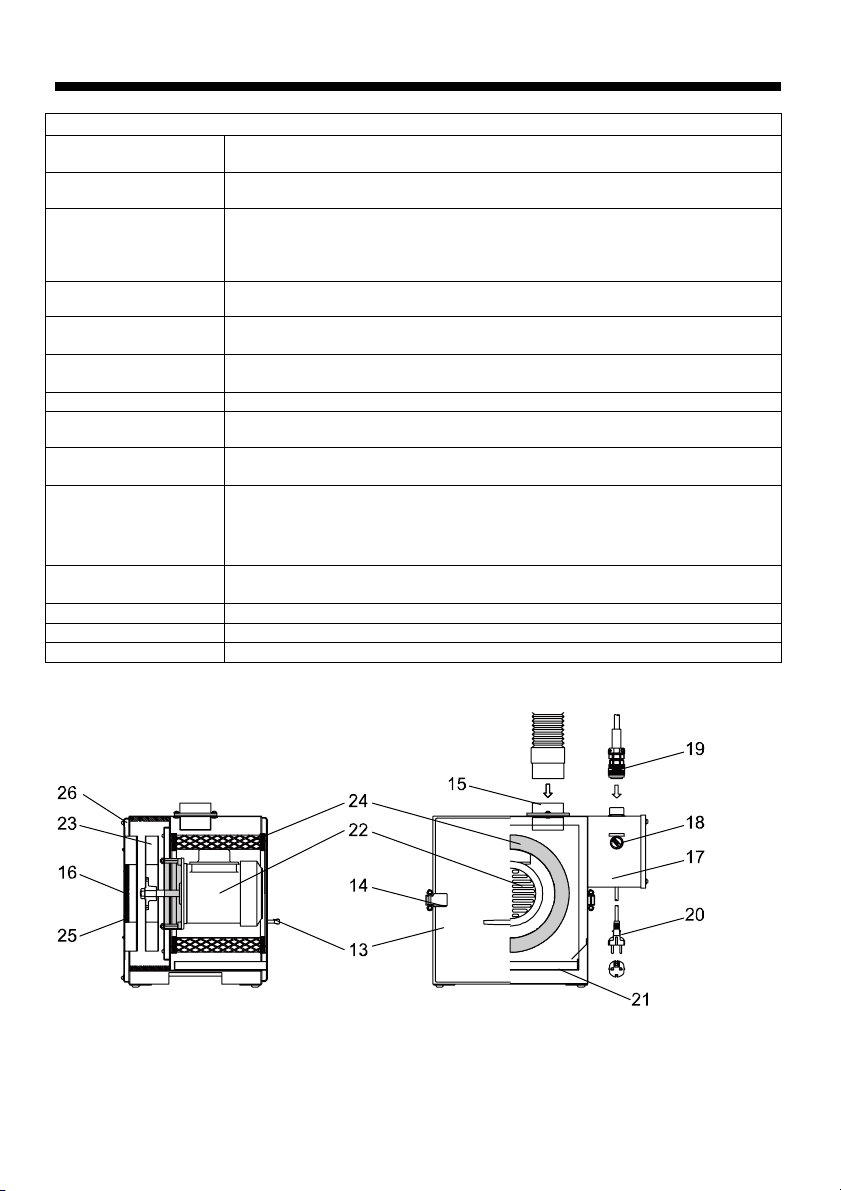

■Component Functions

13. Front cover

14. Thumb lock This lock is used to fasten the front cover.

Removable opening through which the filter unit can be installed and

removed.

Dust Collector

15. Duct connection

port (suction)

16. Exhaust port This is from where the clean air is exhausted.

17. Control box

18. Main switch

19. Connector This connector is for a connection cord that connects to the work hood.

20. Power cord Cabtyre cord with insertion plug.

21. Draw tray

22. Fan motor

23. Fan

24. Filter unit The filter unit removes dust.

25. Rear filter This is installed in the rear cover as the unit’s final filter.

26. Rear cover This covers the area containing the fan.

This connects the duct to the work hood.

This contains a circuit that turns on the static eraser dust collector about 7

sec after the operation switch is turned on.

This switch turns the power to the control box on and off. It is a selector type

switch.

This tray collects the removed dust or dropped powder dust.

The draw in the front cover is removed to dispose of the dust.

This is the drive unit that turns the fan. It has a built-in thermal protector.

When the temperature inside the motor reaches approximately 120°C, the

motor automatically stops, and when it cools again to approximately 80°C

after stopping, it automatically restarts.

This generates speed and pressure in the air and provides vacuum force to

the dust collector.

11

Loading...

Loading...