Vespa GTS300 Service manual

MANUALE STAZIONE DI SERVIZIO

********

Vespa GTS Super 300 ie (2008)

MANUALE

STAZIONE DI

SERVIZIO

Vespa GTS Super 300 ie (2008)

The descriptions and illustrations given in this publication are not binding. While the basic specifications

as described and illustrated in this manual remain unchanged, PIAGGIO-GILERA reserves the right, at

any time and without being required to update this publication beforehand, to make any changes to

components, parts or accessories, which it considers necessary to improve the product or which are

required for manufacturing or construction reasons.

Not all versions/models shown in this publication are available in all countries. The availability of single

versions should be checked at the official Piaggio sales network.

"© Copyright 2007 - PIAGGIO & C. S.p.A. Pontedera. All rights reserved. Reproduction of this publication

in whole or in part is prohibited."

PIAGGIO & C. S.p.A. - After-Sales

V.le Rinaldo Piaggio, 23 - 56025 PONTEDERA (Pi)

MANUALE STAZIONE DI

SERVIZIO

Vespa GTS Super 300 ie (2008)

This service station manual has been drawn up by Piaggio & C. Spa to be used by the workshops of

Piaggio-Gilera dealers. It is assumed that the user of this manual for maintaining and repairing Piaggio

vehicles has a basic knowledge of mechanical principles and vehicle repair technique procedures. Any

significant change to vehicle characteristics or to specific repair operations will be communicated by

updates to this manual. Nevertheless, no mounting work can be satisfactory if the necessary equipment

and tools are unavailable. It is therefore advisable to read the sections of this manual concerning special

tools, along with the special tool catalogue.

N.B. Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle

to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

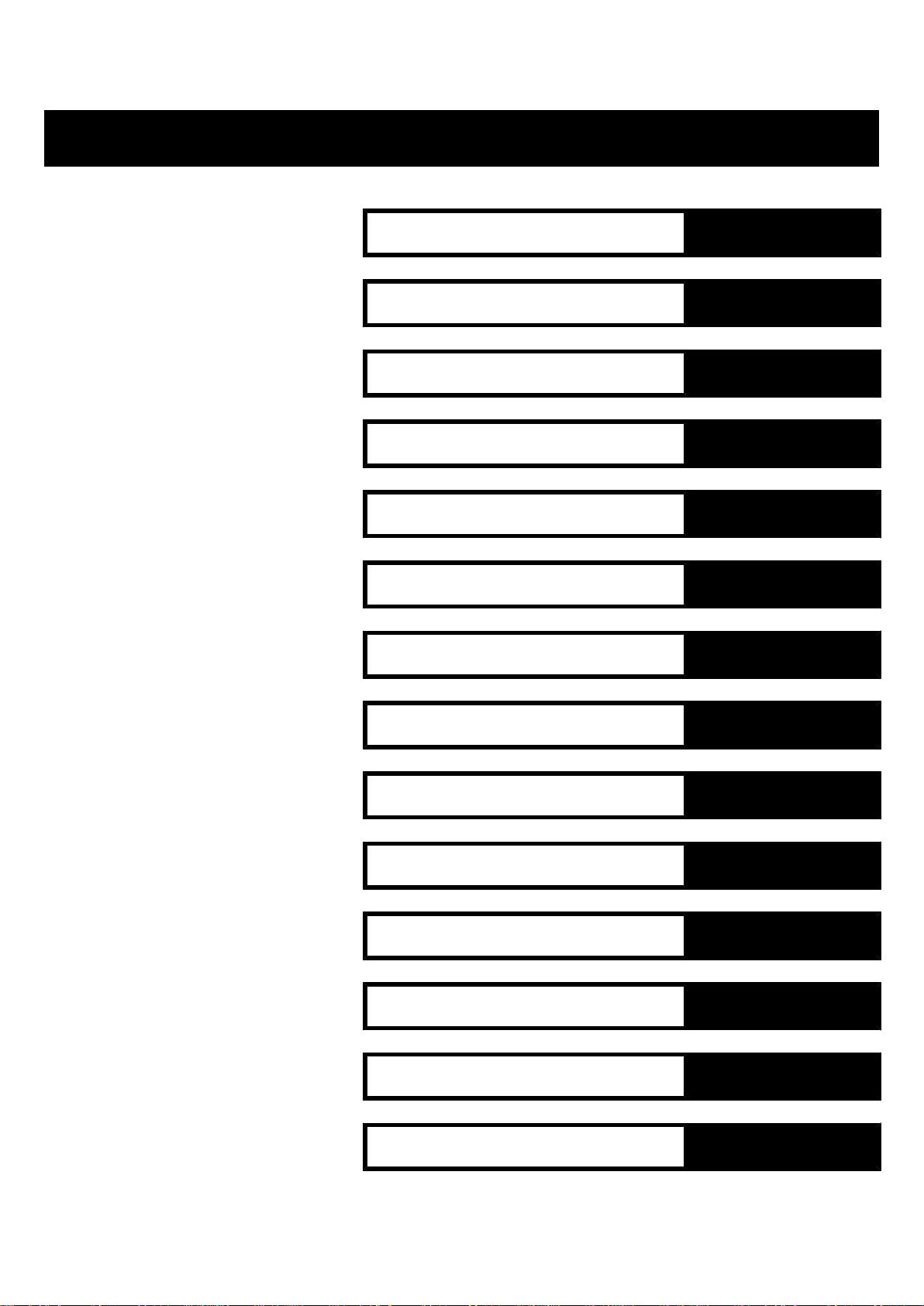

INDEX OF TOPICS

CHARACTERISTICS CHAR

TOOLING TOOL

MAINTENANCE MAIN

TROUBLESHOOTING TROUBL

ELECTRICAL SYSTEM ELE SYS

ENGINE FROM VEHICLE ENG VE

ENGINE ENG

INJECTION INJEC

SUSPENSIONS SUSP

BRAKING SYSTEM BRAK SYS

COOLING SYSTEM COOL SYS

CHASSIS CHAS

PRE-DELIVERY PRE DE

TIME TIME

INDEX OF TOPICS

CHARACTERISTICS CHAR

Vespa GTS Super 300 ie (2008) Characteristics

This section describes the general specifications of the vehicle.

Rules

This section describes general safety rules for any maintenance operations performed on the vehicle.

Safety rules

- If work can only be done on the vehicle with the engine running, make sure that the premises are wellventilated, using special extractors if necessary; never let the engine run in an enclosed area. Exhaust

fumes are toxic.

- The battery electrolyte contains sulphuric acid. Protect your eyes, clothes and skin. Sulphuric acid is

highly corrosive; in the event of contact with your eyes or skin, rinse thoroughly with abundant water

and seek immediate medical attention.

- The battery produces hydrogen, a gas that can be highly explosive. Do not smoke and avoid sparks

or flames near the battery, especially when charging it.

- Fuel is highly flammable and it can be explosive given some conditions. Do not smoke in the working

area, and avoid naked flames or sparks.

- Clean the brake pads in a well-ventilated area, directing the jet of compressed air in such a way that

you do not breathe in the dust produced by the wear of the friction material. Even though the latter

contains no asbestos, inhaling dust is harmful.

Maintenance rules

- Use original PIAGGIO spare parts and lubricants recommended by the Manufacturer. Non-original or

non-conforming spares may damage the vehicle.

- Use only the appropriate tools designed for this vehicle.

- Always use new gaskets, sealing rings and split pins upon refitting.

- After removal, clean the components using non-flammable or low flash-point solvents. Lubricate all

the work surfaces, except tapered couplings, before refitting these parts.

- After refitting, make sure that all the components have been installed correctly and work properly.

- For removal, overhaul and refit operations use only tools with metric measures. Metric bolts, nuts and

screws are not interchangeable with coupling members with English sizes. Using unsuitable coupling

members and tools may damage the scooter.

- When carrying out maintenance operations on the vehicle that involve the electrical system, make

sure the electric connections have been made properly, particularly the ground and battery connections.

CHAR - 7

Characteristics Vespa GTS Super 300 ie (2008)

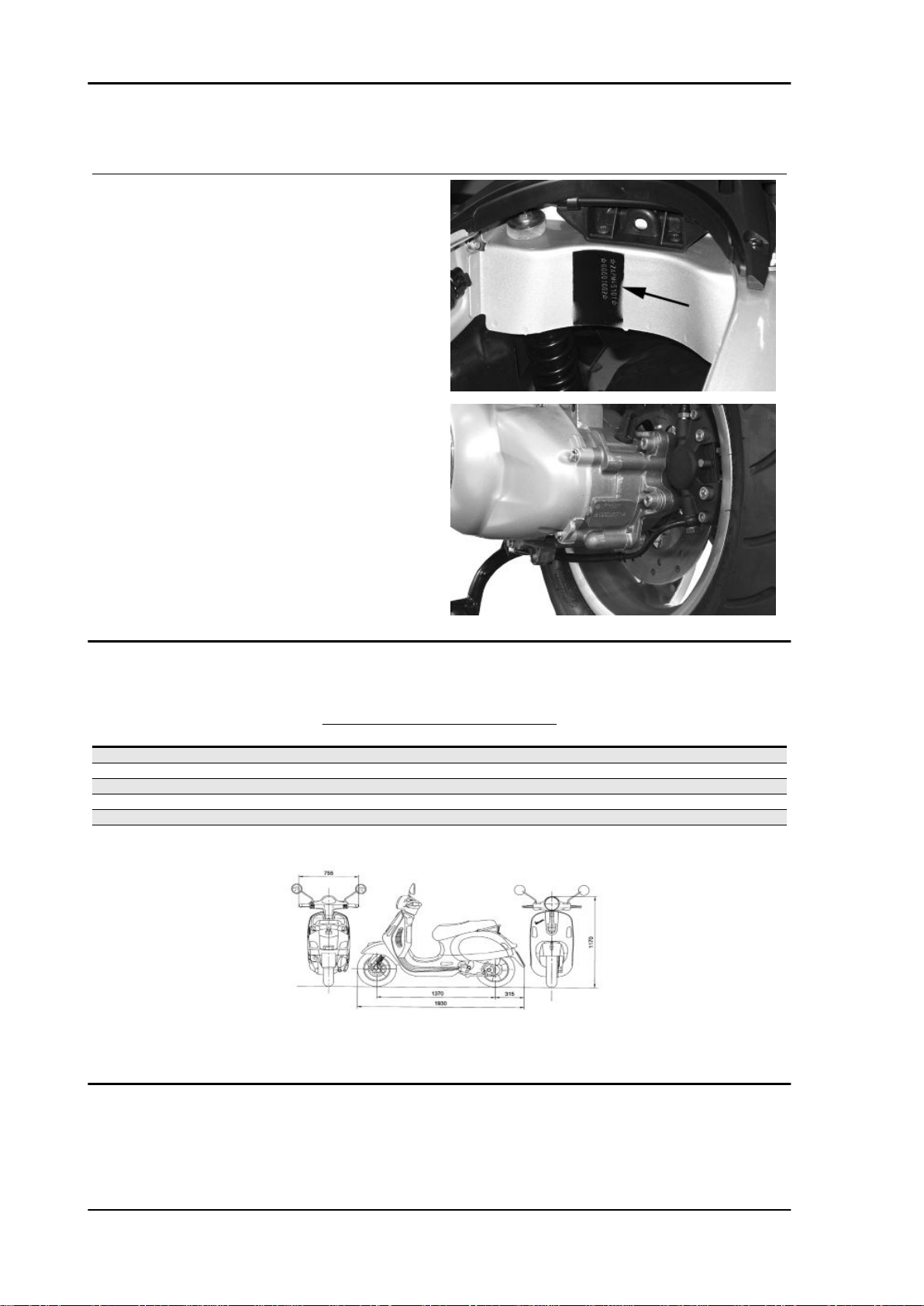

Vehicle identification

Chassis prefix: ZAPM45100000 ÷ 1001

Engine prefix: M451M ÷ 1001

Dimensions and mass

Specification

Kerb weight 158 ± 5 kg

Maximum weight allowed 340 kg

Maximum height 1170 mm

Overall width 755 mm

Overall length 2230 mm

Wheelbase 1370 mm

WEIGHTS AND DIMENSIONS

Desc./Quantity

CHAR - 8

Vespa GTS Super 300 ie (2008) Characteristics

Engine

DATA

Specification Desc./Quantity

Type single-cylinder, four-stroke and four liquid-cooled valves

Cubic capacity 278.3 cm³

Stroke 63 mm

Bore 75 mm

MAX. torque 22 Nm at 6500 rpm

Max. Power 16.4 kW at 7500 rpm

Timing system single overhead camshaft chain driven on the left-hand side, 3-

Compression ratio 10.5 ÷ 11.5

Engine idle speed 1650 ± 50 rpm

Air filter sponge, impregnated with mixture (50% petrol and 50% oil)

Starting system electric starter motor with freewheel

Lubrication with lobe pump (inside the crankcase) controlled by a chain and

Fuel supply Electronic injection with electric fuel pump

valve clearance intake: 0.10 mm - discharge: 0.15 mm

Minimum lubrication pressure (100° C) 0.8 bar

Lubrication pressure 3.5 ÷ 4 bar

Cooling Forced liquid circulation cooling.

arm rocking levers set up with set screw

double filter: mesh and paper

OIL PUMP

Specification

Type Trochoidal

Distance between the rotors Admissible limit clearance: 0.12 mm

Axial rotor clearance Limit values admitted: 0.09 mm

Distance between the outer rotor and the pump body Admissible limit clearance: 0.20 mm

Levelness 0.1 mm

Desc./Quantity

BY-PASS

Specification

Type With piston

Plunger diameter Ø 13.9 - 0.039 -0.057 mm

By-pass check up: Standard length 54.2 mm

Calibration pressure 4.5 bar

Desc./Quantity

OIL FILTER

Specification

Type Paper with pressure relief and anti-drain back by-pass valves

Desc./Quantity

OIL MINIMUM PRESSURE INDICATOR LIGHT SWITCH

Specification

Calibration 0.3 - 0.6 bar

Desc./Quantity

HEAD LUBRICATION CONTROL JET

Specification

Diameter 1 ± 0.05 mm *

* Tightening torque 5÷7 N·m

Desc./Quantity

COOLING SYSTEM

Specification

Cooling system capacity ~ 2.100 ÷ 2.150 l

Prescribed fluid AGIP PERMANENT SPEZIAL

Sealing pressure Cap calibrated at 0.9 bar

Desc./Quantity

CHAR - 9

Characteristics Vespa GTS Super 300 ie (2008)

THERMOSTAT

Specification Desc./Quantity

Type Wax-type, with deviator

Starts opening 85±2°C

ELECTRIC VENTILATION

Specification Desc./Quantity

Electric ventilation starts at 102°C

Electric ventilation stops at 96°C

WATER PUMP

Specification Desc./Quantity

Type Centrifugal

Control Coaxial to crankshaft

RADIATOR

Specification Desc./Quantity

Type Made of aluminium in two sections

Transmission

Specification

Transmission Automatic expandable pulley variator with torque server, V belt,

Capacities

Specification

Fuel tank (including a ~ 2 l reserve) ~ 9.2 l

Cooling system fluid ~ 2.100 ÷ 2.150 l

Engine oil approx. 1300 cc

Electrical system

Specification

Ignition/advance Electronic, with inductive discharge and variable advance with

Spark plug CHAMPION RG 4 PHP

Generator alternating current

TRANSMISSION

Desc./Quantity

automatic clutch, gear reduction unit and transmission housing

with forced air circulation cooling

CAPACITY

Desc./Quantity

Rear hub 250 cc

ELECTRICAL COMPONENTS

Desc./Quantity

three-dimensional mapping

Battery 12V-12Ah

Fuses One 30A fuse - One 15A fuse - Three 10A fuses - Four 7.5A

fuses - One 3A fuse

CHAR - 10

Vespa GTS Super 300 ie (2008) Characteristics

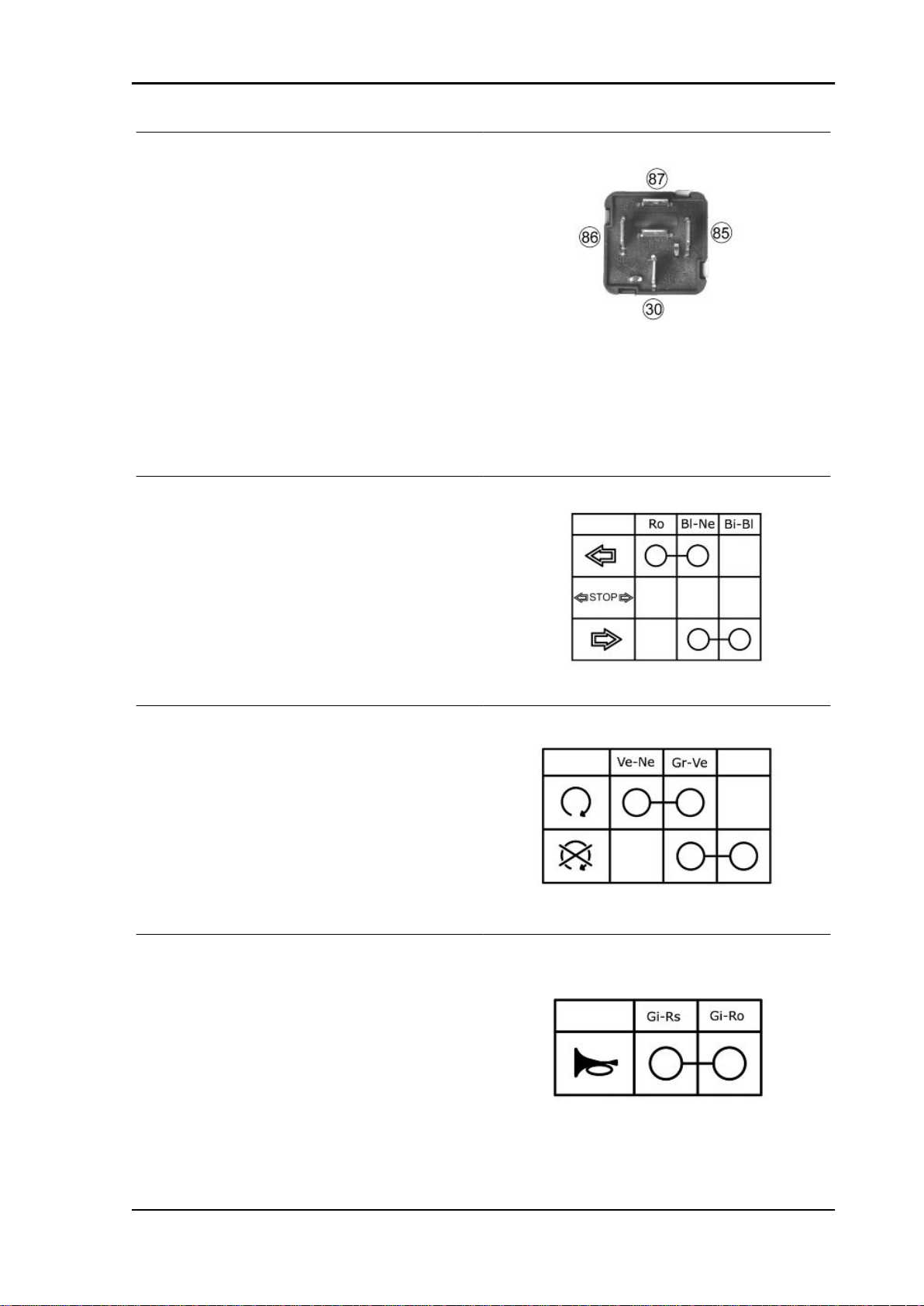

CHECKING REMOTE CONTROLS «A» OPERATING AS CIRCUIT BREAKERS

1) Check that, given regular conditions, there is no

continuity between terminals 30 and 87.

2) Apply 12V voltage to power terminals 85 and 86

of the remote control.

3) With the remote control powered, check that

there is continuity between terminals 30 and 87.

4) If these conditions are not fulfilled, the remote

control is damaged and must be replaced.

To check buttons and switches, check that, according to their position, the continuity of contacts is

correct as indicated in the following charts.

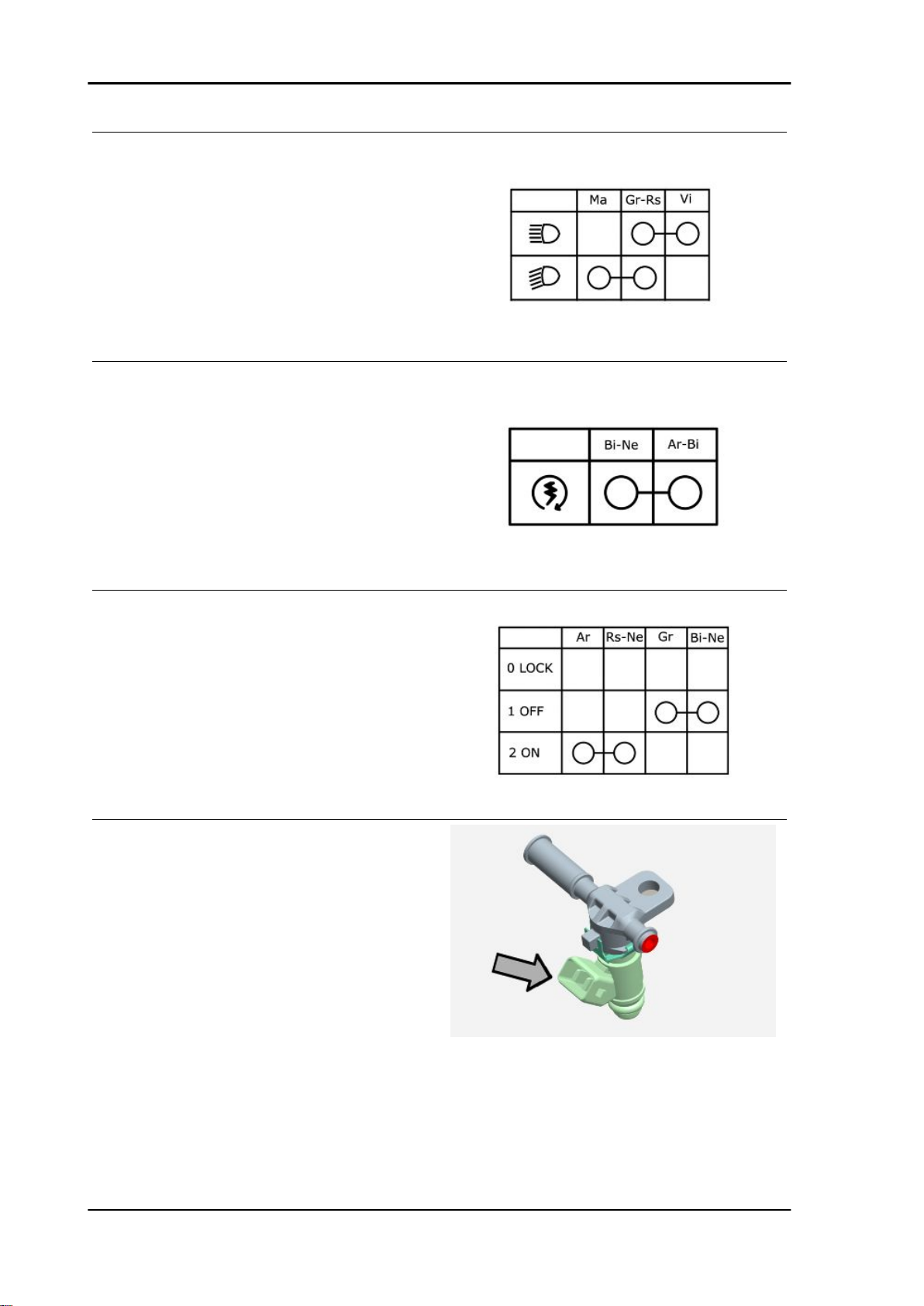

TURN INDICATOR SWITCH

ENGINE STOP SWITCH

HORN BUTTON

CHAR - 11

Characteristics Vespa GTS Super 300 ie (2008)

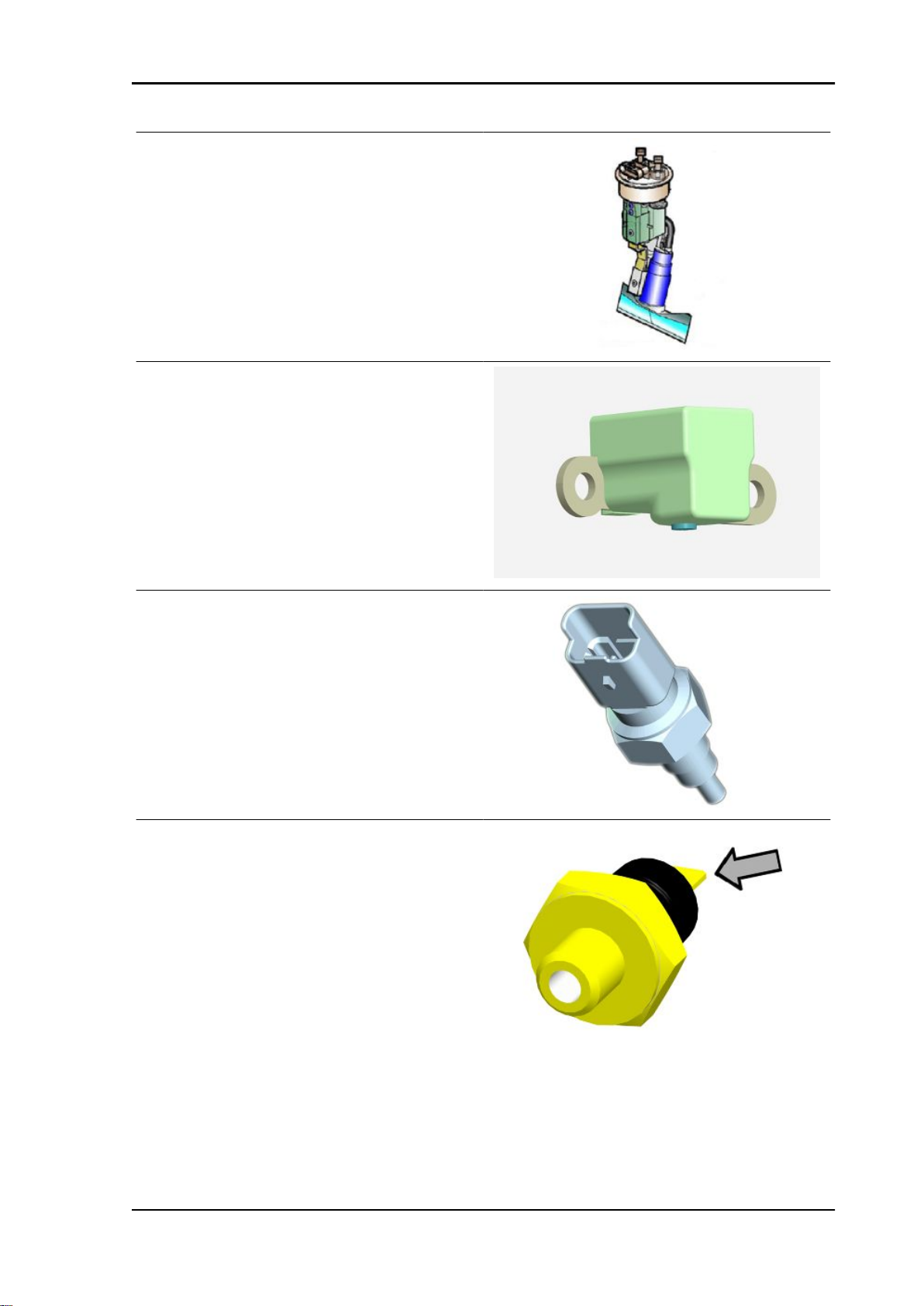

LIGHT SWITCH

STARTER BUTTON

KEY SWITCH

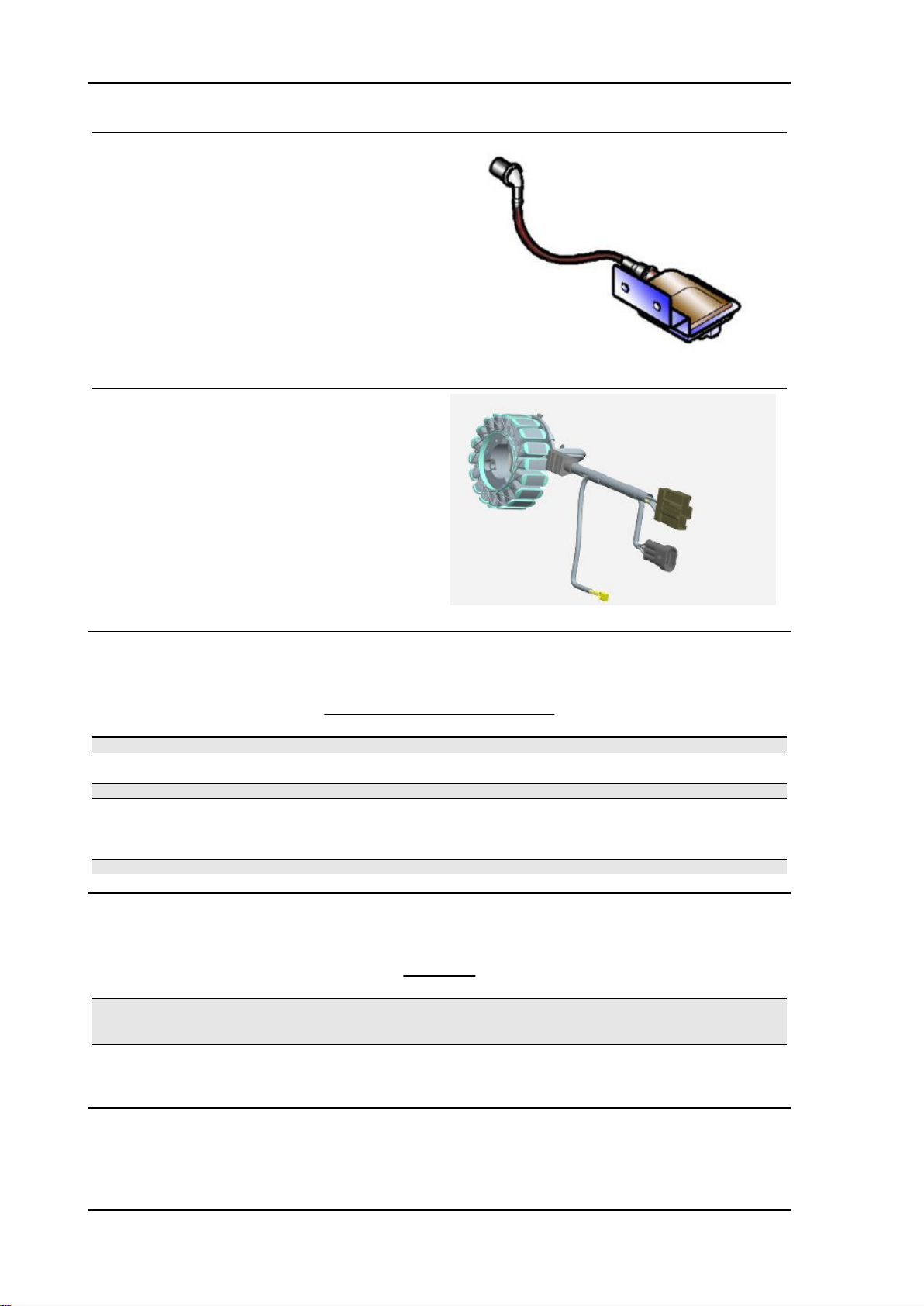

FUEL INJECTOR

Type: 3 holes

Conicity of the nozzle: 20°

Resistance at terminals: 13.7 ÷ 15.2 Ohm

CHAR - 12

Vespa GTS Super 300 ie (2008) Characteristics

FUEL PUMP UNIT

Mechanical type pressure regulator operating at a

pressure of 2.5 BAR

Pump winding resistance: ~ 1.5 Ohm

Input current during regular functioning: 1.4 - 1.8

A

REVOLUTION TIMING SENSOR

Resistance between pins 13 and 15: 100 ÷ 150

Ohm at approx. 20°

ENGINE TEMPERATURE SENSOR

0° = 5900 Ohm

+10° = 3800 Ohm

+20° = 2500 Ohm

+30° = 1700 Ohm

+80° = 300 Ohm

MINIMUM OIL PRESSURE SENSOR

Normally closed switch

Activation threshold: 0.3 - 0.6 bar

With the engine off: continuity between terminal

and ground

CHAR - 13

Characteristics Vespa GTS Super 300 ie (2008)

HV COIL

- Resistance of the primary = 0.5 Ohm ± 8%

- Resistance between primary and ground = infinite

- Resistance between primary and HV output = 3.1

KOhm ± 9%

- Presence of battery voltage between pins 22 and

26 of the interface cable harness upon

shifting to ON and for 2 sec.

STATOR

Power: 450 W

Resistance between terminals: 0.2 ÷ 1 Ohm

terminal insulation from ground

Frame and suspensions

Specification

Type Unitised body made of stamped plate

Front suspension Single arm suspension (cantilever wheel) fitted with a double-

Front shock absorber axial travel 86.5 mm

Rear suspension Engine with swinging fork articulated to frame by means of an

Rear shock absorber axial travel 89.5 mm

Brakes

Specification

Front Ø 220 disc brake and floating calliper with Ø 25 mm twin plung-

Rear Ø 220 disc brake and calliper with two Ø 30 mm counteracting

FRAME AND SUSPENSIONS

Desc./Quantity

acting hydraulic shock absorber with coaxial spring

arm with 2 degrees of freedom Pair of double-acting hydraulic

shock absorbers and coaxial springs with preloading adjust-

ment in 4 positions.

BRAKES

Desc./Quantity

ers and hydraulic control (lever on the far right end of the

handlebar)

plungers and hydraulic control (lever on the far left end of the

handlebar)

CHAR - 14

Vespa GTS Super 300 ie (2008) Characteristics

Wheels and tyres

WHEELS AND TYRES

Specification Desc./Quantity

Front wheels - light alloy rims 3.00x12

Rear wheels - light alloy rims 3.00x12

Front tyres 120/70-12" Tubeless

Rear tyres 130/70-12" Tubeless

TYRE PRESSURE

Specification Desc./Quantity

Front tyre pressure (when cold) 1.8 bar

Rear tyre pressure (when cold) 2 bar

Tyre pressure (when cold) with passenger 2.2 bar

N.B.

CHECK AND ADJUST TYRE PRESSURE WITH TYRES AT AMBIENT TEMPERATURE. REGULATE PRESSURE ACCORDING TO THE WEIGHT OF THE RIDER AND ACCESSORIES

Tightening Torques

STEERING ASSEMBLY

Name

Upper steering ring nut 35 ÷ 40

Steering lower ring nut 12 ÷ 14

Handlebar fixing screw 45 ÷ 50 (The two screws must be tightened to the prescribed

torque after having done so with the rear wheel axle nut. Safety

locks: see «Pre-delivery Operations» )

Fixing screws for handlebar control assembly U-bolts 7 ÷ 10

FRAME ASSEMBLY

Name

Engine-swinging arm bolt 64 - 72

swinging arm bolt - body shell 76 ÷ 83

Engine and vehicle side swinging arm junction bolt 33 ÷ 41

Bolt of the Silent block support plate 42 ÷ 52

Centre stand bolt 32 ÷ 40

Side stand fixing bolt 35 ÷ 40

FRONT SUSPENSION

Name

Screw fixing the shock absorber to the shock absorber - calliper

attachment plate

Wheel axle nut 74 ÷ 88

Wheel screw 20 ÷ 25

Screw fixing rear mudguard to steering 5 ÷ 6.5

shock absorber upper clamp 20 ÷ 30

Torque in Nm

Torque in Nm

Torque in Nm

20 ÷ 27

FRONT BRAKE

Name

Brake fluid pump-hose fitting 20 ÷ 25

Brake fluid pipe-calliper fitting 19 ÷ 24

Screw fixing calliper to the shock absorber - calliper plate at-

tachment

Disc tightening screw 6 (Apply LOCTITE 242 threadlock, medium strength)

Oil bleed screw 12 - 16

Pad fastening pin 19.6 ÷ 24.5

Brake pump reservoir screws 1.5 ÷ 2

Brake disc screws 8 ÷ 10

Torque in Nm

24 ÷ 27

CHAR - 15

Characteristics Vespa GTS Super 300 ie (2008)

REAR SUSPENSION

Name Torque in Nm

Retainer for left shock absorber to crankcase support plate 20 ÷ 25

Shock absorber lower fitting 40 ÷ 45

Shock absorber upper fitting 20 ÷ 25

Rear wheel axle 104 ÷ 126

Screw fixing wheel to hub 20 ÷ 25

Screws for muffler - shock absorber support arm on engine 20 ÷ 25 (The two screws must be tightened to the prescribed

Engine- and vehicle-side swinging arm junction bolt 40 ÷ 45

torque after having done so with the rear wheel axle nut. Safety

locks: see «Pre-delivery Operations» )

REAR BRAKE

Name Torque in Nm

Brake fluid pump-hose fitting 20 ÷ 25

Brake fluid pipe-calliper fitting 20 ÷ 25

Rear disc tightening bolt 11 ÷ 13

Oil bleed screw 12÷16

Calliper to engine tightening screw 20 ÷ 25

Brake pump reservoir screws 1.5 ÷ 2

Calliper coupling screw 30 ÷ 33

MUFFLER

Name Torque in Nm

Muffler heat guard fixing screw 4 ÷ 5

Screw for fixing muffler to the support arm 20 ÷ 25

Lambda probe clamp on exhaust manifold 40 ÷ 50

Exhaust manifold-muffler joint clamp 12 ÷ 13

Manifold - muffler diaphragm tightening clamp 16 ÷ 18

LUBRICATION

Name

Hub oil drainage plug 15 ÷ 17

Oil filter on crankcase fitting 27 ÷ 33

Engine oil drainage plug/mesh filter 24 ÷ 30

Oil filter 4 ÷ 6

Oil pump cover screws 7 ÷ 9

Screws fixing oil pump to crankcase 5 - 6

Oil pump control crown screw 10 ÷ 14

Oil pump cover plate screws 4 ÷ 6

Oil sump screws 10 ÷ 14

Minimum oil pressure sensor 12 ÷ 14

Torque in Nm

CYLINDER HEAD

Name

Spark plug 12 ÷ 14

Head cover screws 6 ÷ 7

Nuts fixing head to cylinder 7±1 + 10±1 + 270°

Head fixing side screws 11 ÷ 12

Starter ground screw 7 ÷ 8.5

Tappet set screw lock nut 6 ÷ 8

Inlet manifold screws 11 ÷ 13

Timing chain tensioner slider screw 10 ÷ 14

Starter ground support screw 11 ÷ 15

Timing chain tensioner support screw 11 ÷ 13

Timing chain tensioner central screw 5 - 6

Camshaft retention plate screw 4 ÷ 6

Torque in Nm

CHAR - 16

TRANSMISSION

Name

Belt support roller screw 11 ÷ 13

Clutch unit nut on driven pulley 45 ÷ 50

Torque in Nm

Vespa GTS Super 300 ie (2008) Characteristics

Name Torque in Nm

Drive pulley nut 75 ÷ 83

Transmission cover screws 11 ÷ 13

Driven pulley shaft nut 54 ÷ 60

Rear hub cap screws 24 ÷ 27

FLYWHEEL

Name Torque in Nm

Flywheel cover screw 11 ÷ 13

Stator assembly screws 3 - 4 (Apply LOCTITE 242 medium-strength threadlock)

Flywheel nut 94 ÷ 102

Pick-Up clamping screws 3 ÷ 4

Screw fixing freewheel to flywheel 13 ÷ 15

CRANKCASE AND CRANKSHAFT

Name Torque in Nm

Internal engine crankcase bulkhead (transmission-side half

shaft) screws

Engine-crankcase coupling screws 11 ÷ 13

Starter motor screws 11 ÷ 13

Crankcase timing cover screws 3.5 - 4.5 (Apply LOCTITE 242 medium-strength threadlock)

4 ÷ 6

Name Torque in Nm

Water pump rotor cover 3 ÷ 4

Thermostat cover screws 3 ÷ 4

Bleed screw 3

Overhaul data

Assembly clearances

Cylinder - piston assy.

COOLING

CHAR - 17

Characteristics Vespa GTS Super 300 ie (2008)

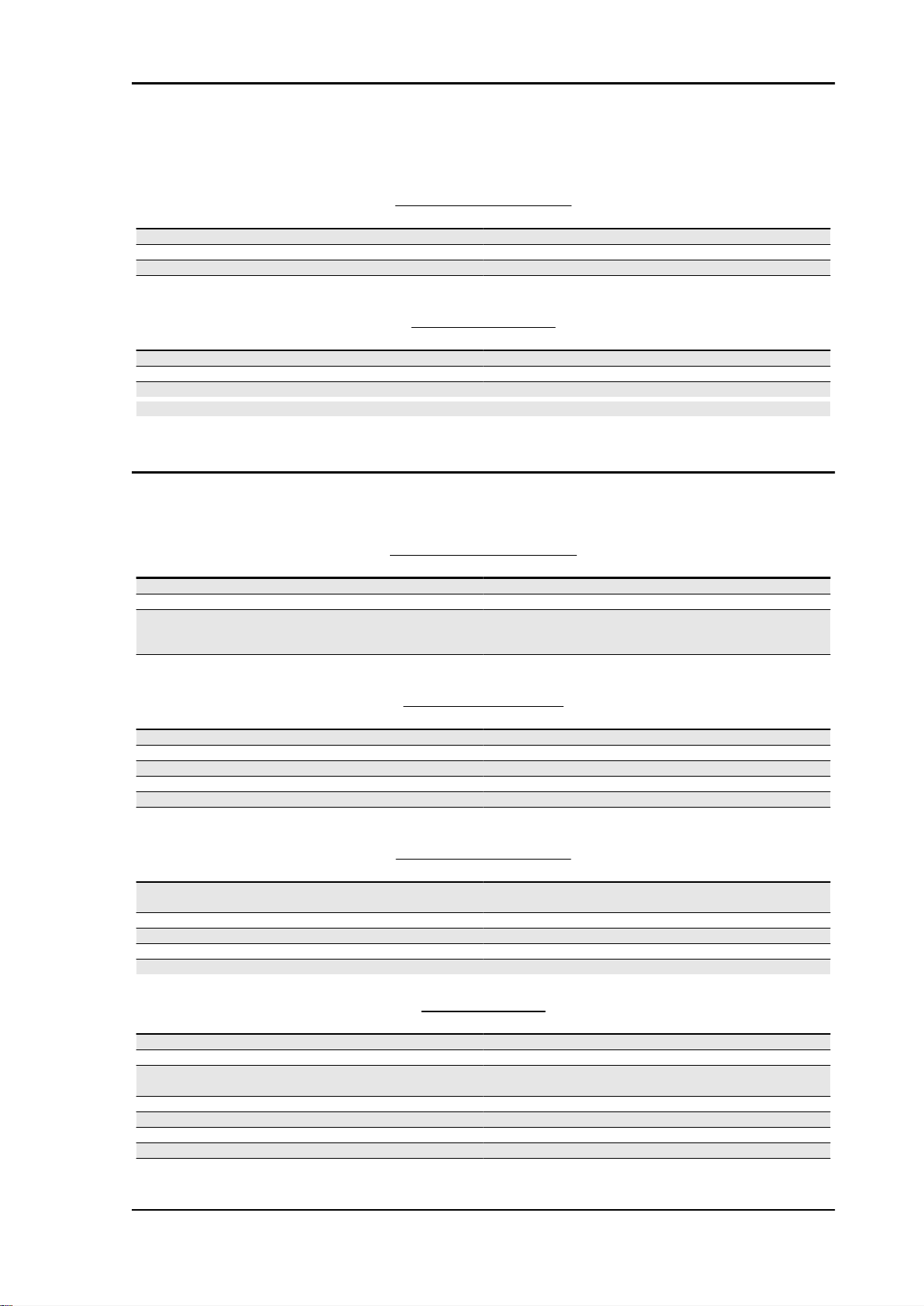

CYLINDER - PISTON

Specification Desc./Quantity

Plunger diameter 74.967 +0.014 -0.014 mm

Cylinder diameter 75 +0.038 +0.01 mm

COUPLING CATEGORIES

Name Initials Cylinder Piston Play on fitting

cylinder-piston M 75.01 ÷ 75.017 74.953 ÷ 74.960 0.050 ÷ 0.064

cylinder-piston N 75.017 ÷ 75.024 74.960 ÷ 74.967 0.050 ÷ 0.064

cylinder-piston O 75.024 ÷ 75.031 74.967 ÷ 74.974 0.050 ÷ 0.064

cylinder-piston P 75.031 ÷ 75.038 74.974 ÷ 74.981 0.050 ÷ 0.064

N.B.

THE PISTON MUST BE INSTALLED WITH THE ARROW FACING TOWARDS THE EXHAUST SIDE,

THE PISTON RINGS MUST BE INSTALLED WITH THE WORD «TOP» OR THE STAMPED MARK

FACING UPWARDS.

- Measure the outside diameter of the gudgeon

pin.

Characteristic

Pin outside diameter

16 +0 -0.004 mm

- Measure the diameter of the bearings on the piston.

Characteristic

Standard diameter

16 +0.006 +0.001 mm

- Calculate the piston pin coupling clearance.

N.B.

THE PIN HOUSINGS HAVE 2 LUBRICATION CHANNELS. FOR THIS REASON, MEASUREMENT

MUST BE MADE ACCORDING TO THE PISTON AXIS.

Characteristic

Standard clearance:

0.001 ÷ 0.010 mm

CHAR - 18

Vespa GTS Super 300 ie (2008) Characteristics

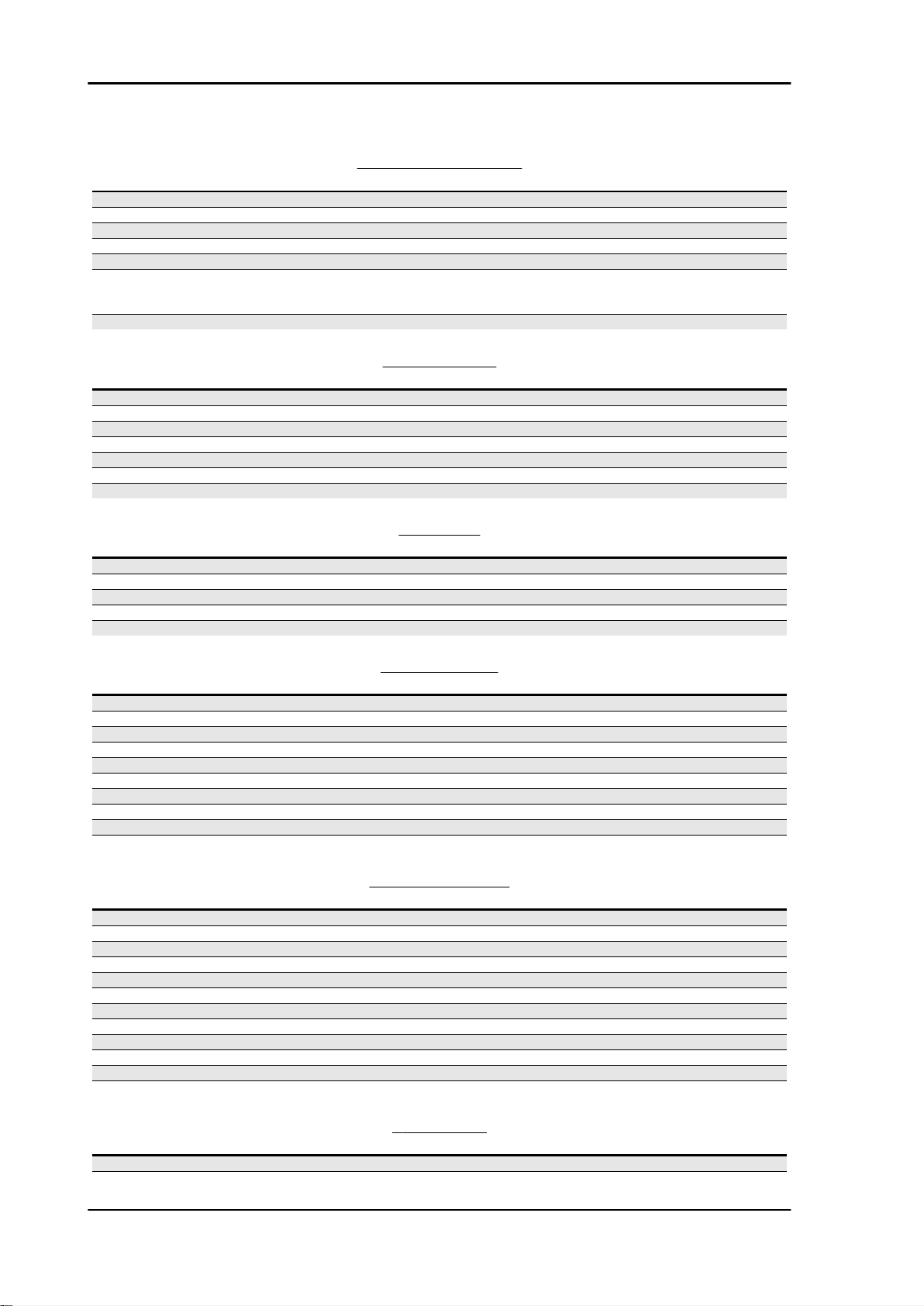

- Carefully clean the sealing ring housings.

- Measure the coupling clearance between the

sealing rings and the grooves using suitable sensors, as shown in the diagram.

- If the clearance is greater than that indicated in

the table, replace the piston.

N.B.

MEASURE THE CLEARANCE BY INSERTING THE BLADE

OF THE FEELER THICKNESS GAUGE FROM THE SECOND

SEAL SIDE.

Fitting clearance

Top piston ring - standard coupling clearance

0.015 - 0.06 mm Top piston ring - maximum clear-

ance allowed after use 0.07 mm Middle piston

ring - standard coupling clearance 0.015 - 0.06 mm

Middle piston ring - maximum clearance allowed after use 0.07 mm oil scraper ring - standard coupling clearance 0.015 - 0.06 mm oil scraper

ring - maximum clearance allowed after use

0.07 mm

- Check that the head coupling surface is not worn

or misshapen.

- Pistons and cylinders are classified according to

diameter. The coupling must be made with those

of the same type (M-M, N-N, O-O, P-P).

Characteristic

Maximum allowable run-out:

0.05 mm

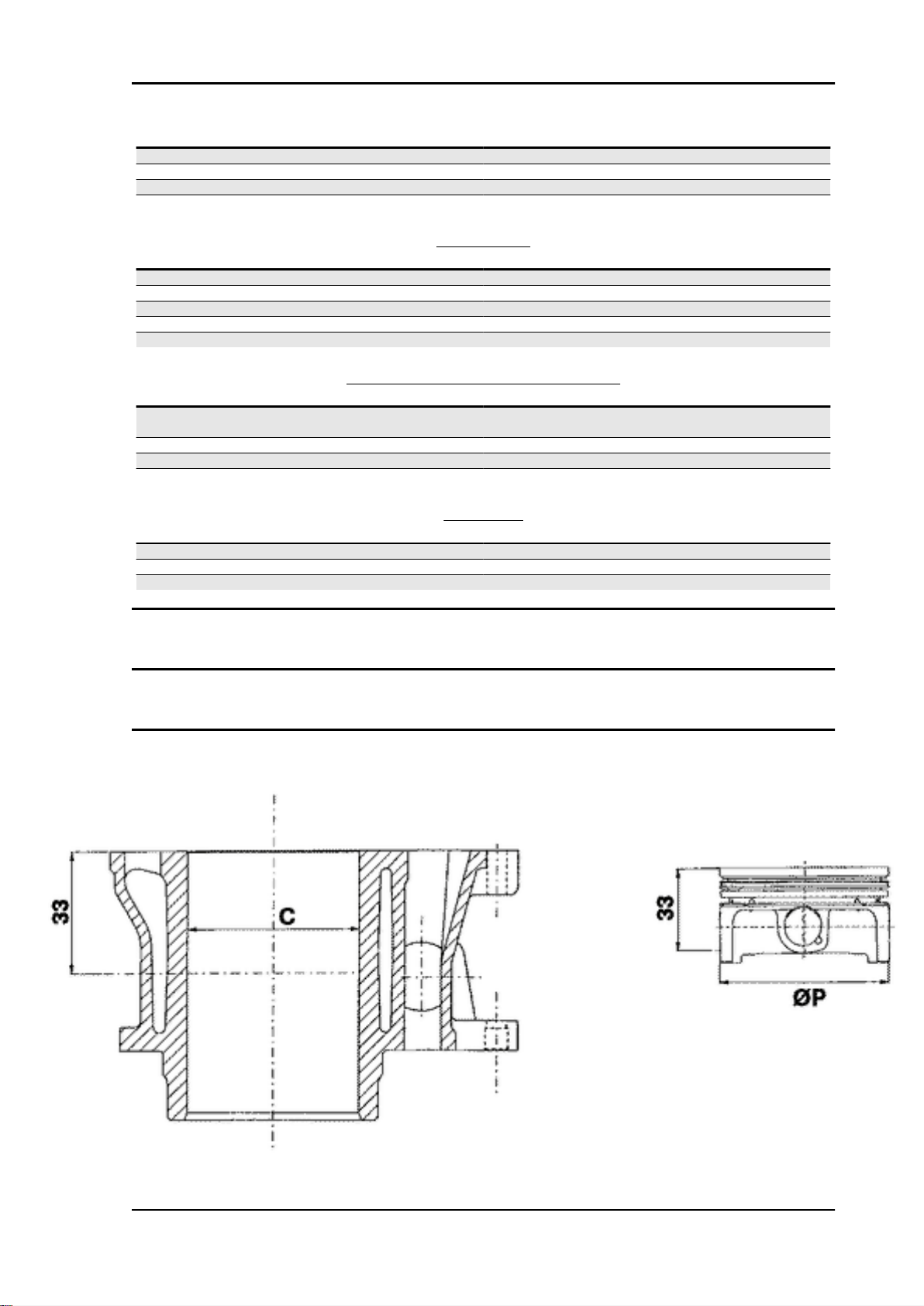

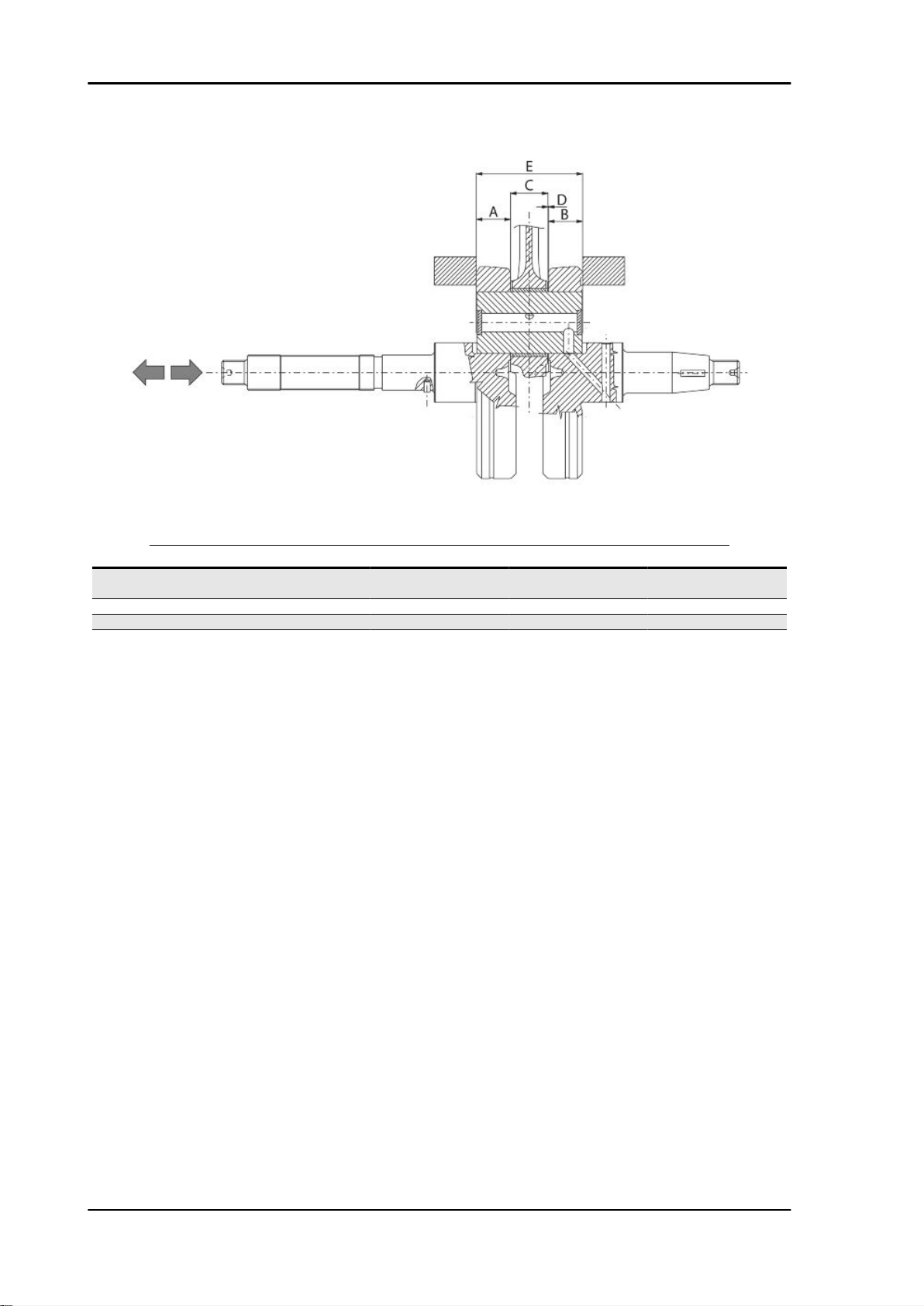

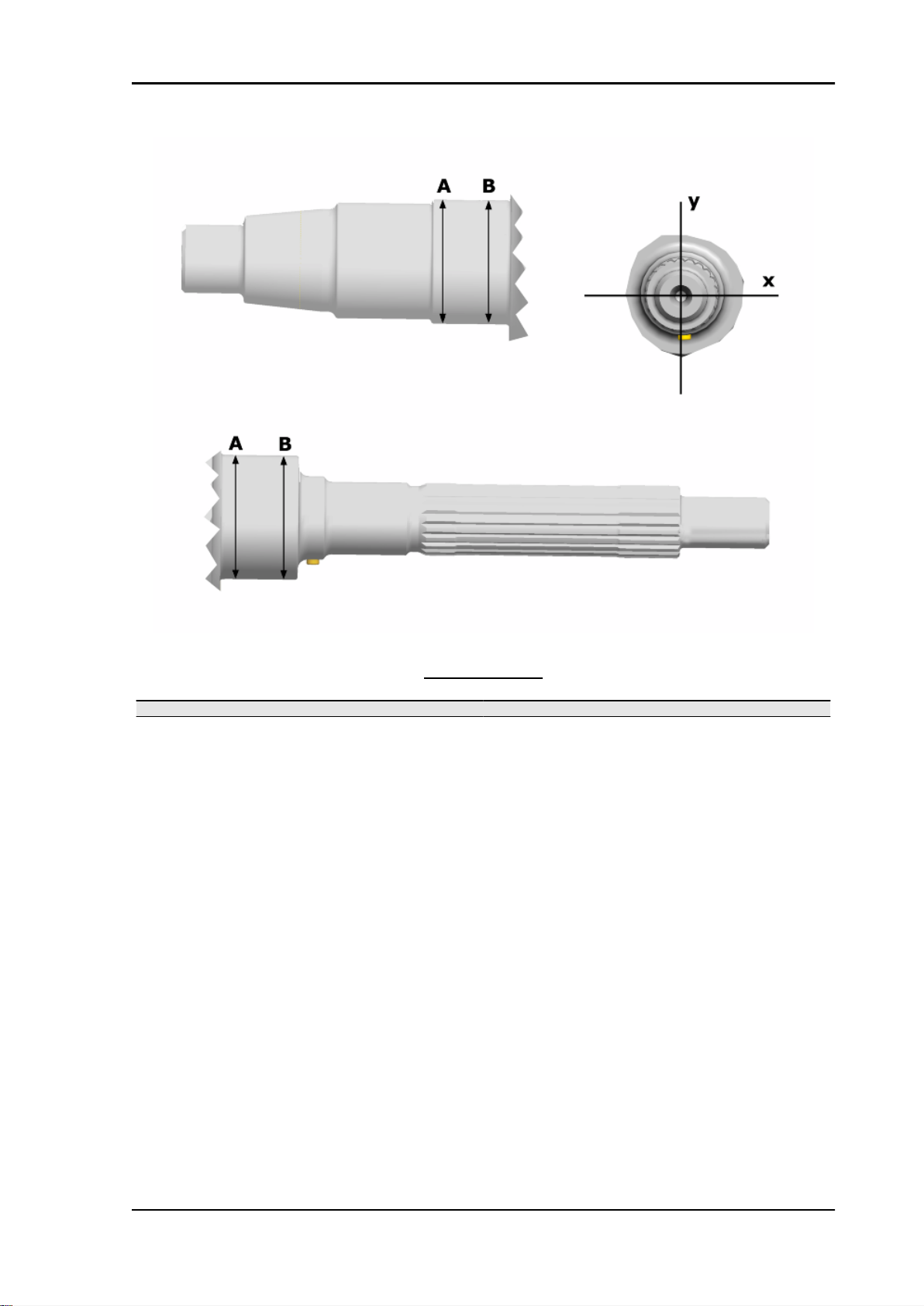

Crankcase - crankshaft - connecting rod

CRANKSHAFT

Titolo

Crankshaft Crankshaft to crankcase axial

Crankshaft to crankcase axial clearance

Durata/Valore Testo Breve (< 4000 car.) Indirizzo Immagine

clearance

CHAR - 19

Characteristics Vespa GTS Super 300 ie (2008)

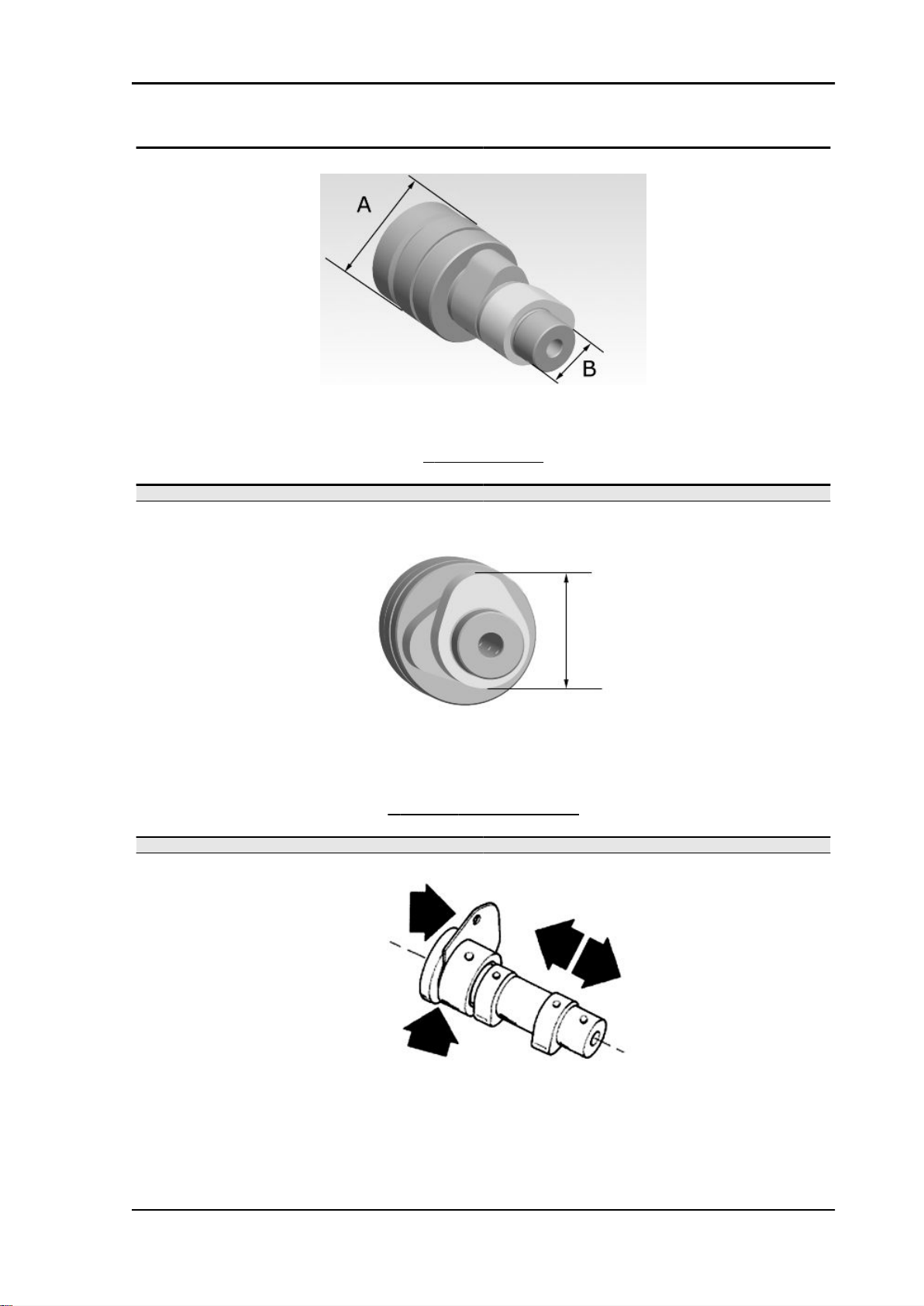

AXIAL CLEARANCE BETWEEN CRANKSHAFT AND CONNECTING ROD

Name

Half-shaft, transmission

side

Flywheel-side half-shaft 16.6 +0-0.05 B D = 0.20 - 0.50

Connecting rod 18 -0.10 -0.15 C D = 0.20 - 0.50

Spacer tool 51.4 +0.05 E D = 0.20 - 0.50

Diameter of crankshaft bearings.

Measure the bearings on both axes x-y.

Description Dimensions Initials Quantity

16.6 +0-0.05 A D = 0.20 - 0.50

CHAR - 20

Vespa GTS Super 300 ie (2008) Characteristics

CRANKSHAFT

Specification

Crankshaft bearings: Standard diameter: Cat. 1 28.998 ÷ 29.004 mm

Crankshaft bearings: Standard diameter: Cat. 2 29.004 ÷ 29.010 mm

Desc./Quantity

CHAR - 21

Characteristics Vespa GTS Super 300 ie (2008)

MAX. ADMISSIBLE DISPLACEMENT

Specification

A = 0.15 mm

B = 0.010 mm

C = 0.010 mm

D = 0.10 mm

Desc./Quantity

CHAR - 22

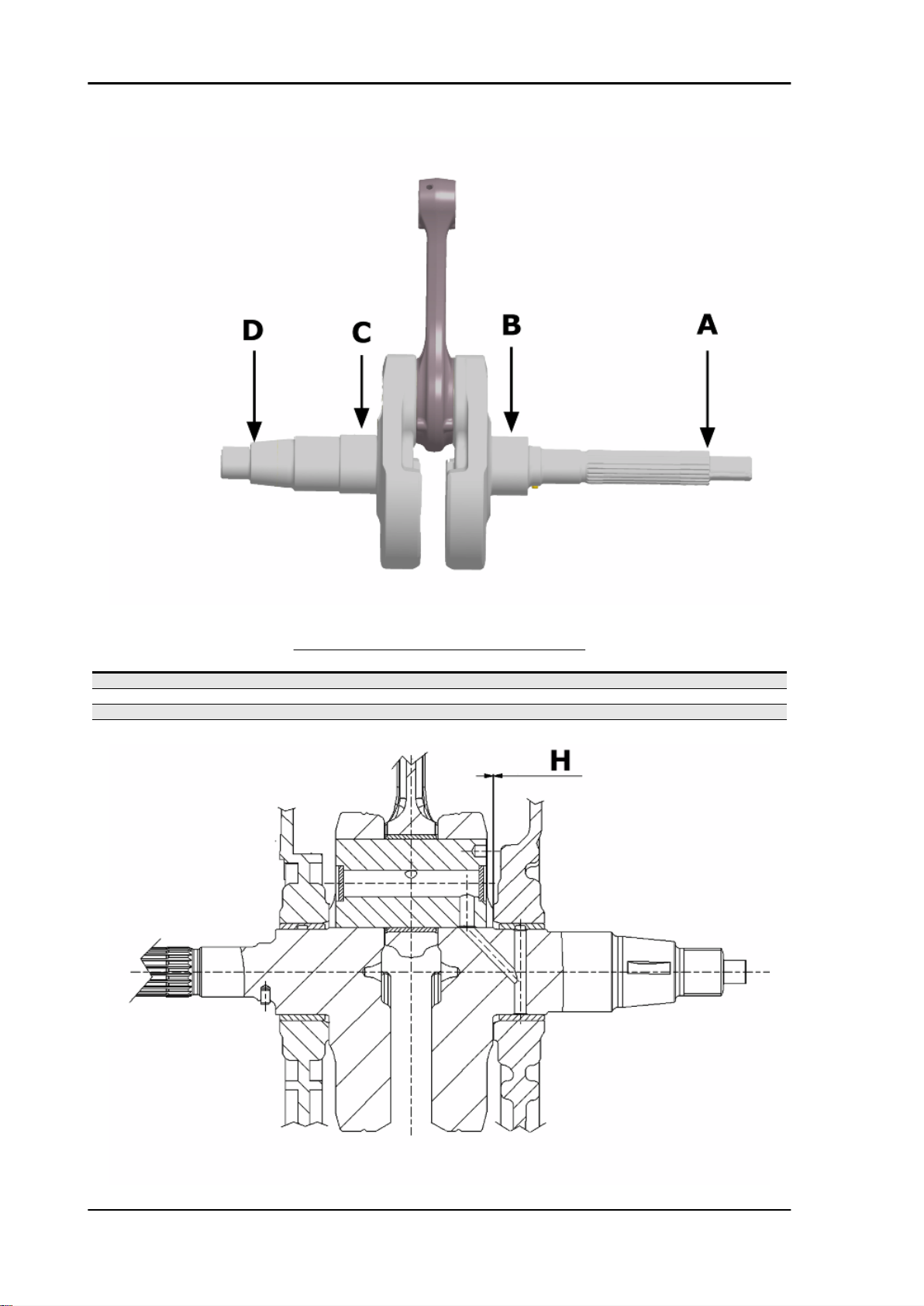

Vespa GTS Super 300 ie (2008) Characteristics

Characteristic

Crankshaft-crankcase axial clearance (H)

0.15 ÷ 0.43 mm

- Using a bore gauge, measure the connecting rod

small end diameter.

N.B.

IF THE CONNECTING ROD SMALL END DIAMETER EX-

CEEDS THE STANDARD DIAMETER, EXHIBITS WEAR OR

OVERHEATING, PROCEED TO REPLACE THE CRANKSHAFT AS DESCRIBED IN THE CRANKCASE AND

CRANKSHAFT CHAPTER.

Characteristic

Standard diameter

16 +0.025 +0.015 mm

- To obtain a good bushing lubrication it is necessary to have both an optimal lubricating pressure and

a good oil flow rate; the bushings must be correctly positioned so as not to obstruct the oil supply

channels.

- The main bushings are comprised of two half-bearings, one with holes and channels for lubrication

whereas the other is solid.

- The solid half-bearing is intended to stand the thrusts caused by combustion, and for this reason it is

arranged opposite the cylinder.

- To prevent obstructions in the oil feeding channels, the matching surface of the two half-bearings must

be perfectly perpendicular to the cylinder axis, as shown in the figure.

- The oil feeding channel section is also affected by the bushings driving depth compared with the

crankshaft axial clearance of the limiting surface.

- Check the inside diameter of the main bushings in the three directions indicated in the diagram.

- Repeat the measurements for the other bushing half. see diagram.

- There are three crankcase versions: with BLUE bushings, with YELLOW bushings and with GREEN

bushings.

- There is only one type of main bushing housing hole in the crankcase. The standard bushing diameter

after driving is variable on the basis of a coupling selection.

- The bushing housings in the crankcase are classified into 2 categories - Cat. 1 and Cat. 2 - just like

those for the crankshaft.

- The main bushings are available in three thickness categories, identified by colour markings, as shown

in the table below.

BUSHINGS

TYPE

B BLUE 1.973 ÷ 1.976

C YELLOW 1.976 ÷ 1.979

E GREEN 1.979 ÷ 1.982

IDENTIFICATION CRANKSHAFT HALF-BEARING

CHAR - 23

Characteristics Vespa GTS Super 300 ie (2008)

COUPLINGS

BUSHING CATEGORY CRANKCASE

HALVES CATEGORY

B 2 29.024 ÷ 29.054

C 1 29.024 ÷ 29.054

2 29.018 ÷ 29.048

E 1 29.018 ÷ 29.048

Combine the shaft with two category 1 crankwebs with the category 1 crankcase (or cat. 2 with cat. 2).

Furthermore a spare crankcase cannot be matched with a crankshaft with mixed categories. The spare

crankshaft has half-shafts of the same category.

BUSHING INSIDE DIAMETER AFTER FITTING

CATEGORIES

CRANKCASE HALVES ENGINE HALF-SHAFT BUSHING

Cat. 1 Cat. 1 E

Cat. 2 Cat. 2 B

Cat. 1 Cat. 2 C

Cat. 2 Cat. 1 C

N.B.

DO NOT TAKE THE MEASUREMENT ON THE TWO HALF-

SHELL COUPLING SURFACE SINCE THE ENDS ARE RELIEVED TO ALLOW BENDING DURING THE DRIVING

OPERATION.

N.B.

CRANKCASES FOR REPLACEMENTS ARE SELECTED

WITH CRANKCASE HALVES OF THE SAME CATEGORY

AND ARE FITTED WITH CATEGORY C BUSHINGS (YELLOW)

Characteristic

Crankshaft-bushing maximum clearance admitted:

0.08 mm

Diameter of crankcase without bushing

CAT. 1: 32.959 ÷ 32.965 mm

CAT. 2: 32.953 ÷ 32.959 mm

Cylinder Head

Before performing head service operations, thoroughly clean all coupling surfaces. Note the position of

the springs and the valves so as not to change the original position during refitting

- Using a trued bar and a feeler thickness gauge

check that the cylinder head surface is not worn or

distorted.

Characteristic

Maximum allowable run-out:

0.1 mm

- In case of irregularities, replace the head.

CHAR - 24

Vespa GTS Super 300 ie (2008) Characteristics

- Check the sealing surfaces for the intake and exhaust manifold.

- Check that the bearings of the camshaft and the rocker pins exhibit no wear.

- Check that the head cover surface is not worn.

- Check that the coolant sealing pad exhibits no oxidation.

- Insert the valves into the cylinder head.

- Alternatively check the intake and exhaust

valves.

- The test is carried out by filling the manifold with

petrol and checking that the head does not ooze

through the valves when these are just pressed

with the fingers.

Measure the camshaft bearing seats and rocking

lever support pins with a bore meter

HEAD BEARINGS

Specification

bearing «A» Ø 12.000 - 12.018 mm

bearing «B» Ø 20.000 ÷ 20.021 mm

bearing «C» Ø 37.000 - 37.025 mm

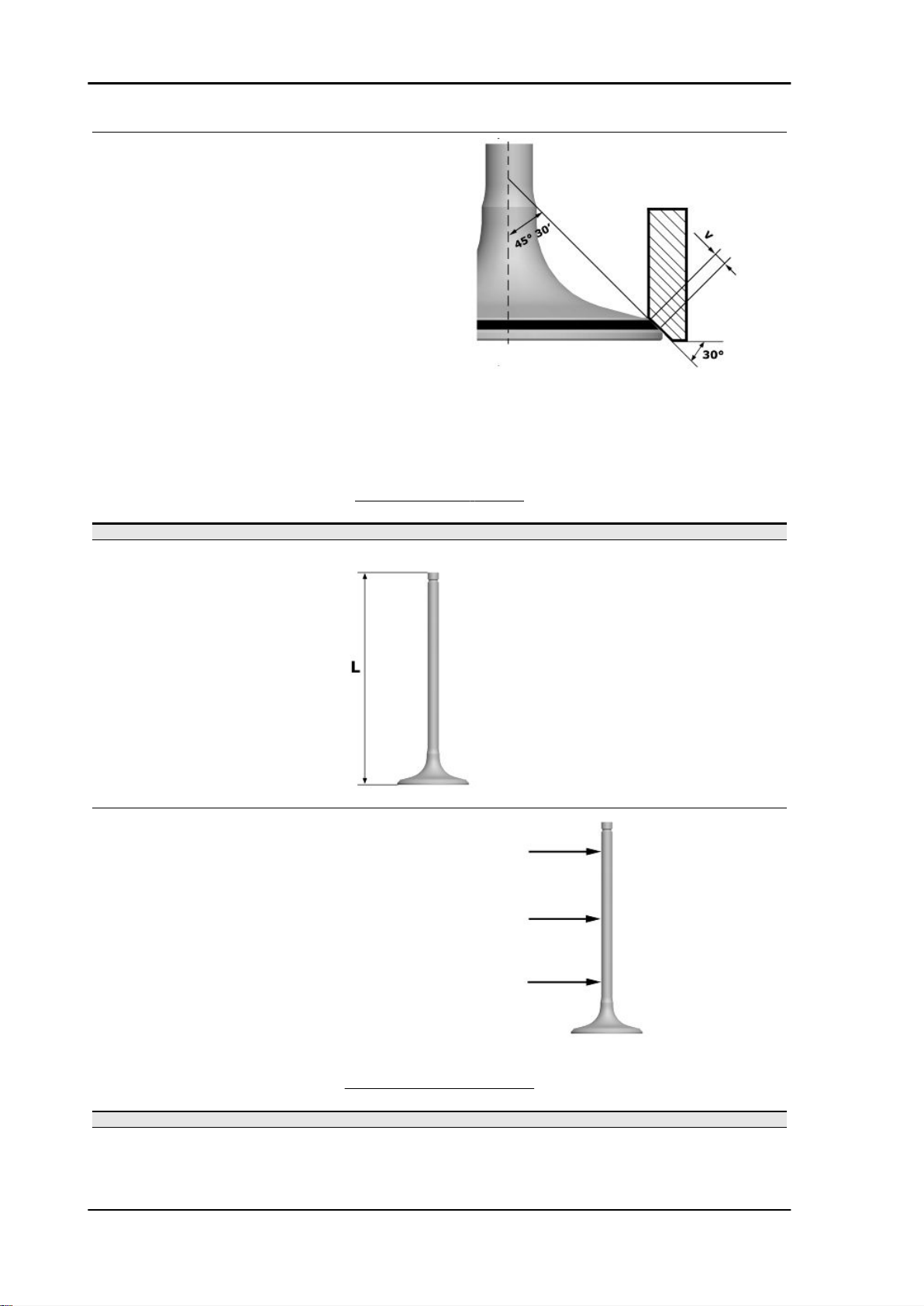

Measure the unloaded spring length

Characteristic

Standard length

40.2 mm

Desc./Quantity

Allowable limit after use:

38.2 mm

CHAR - 25

Characteristics Vespa GTS Super 300 ie (2008)

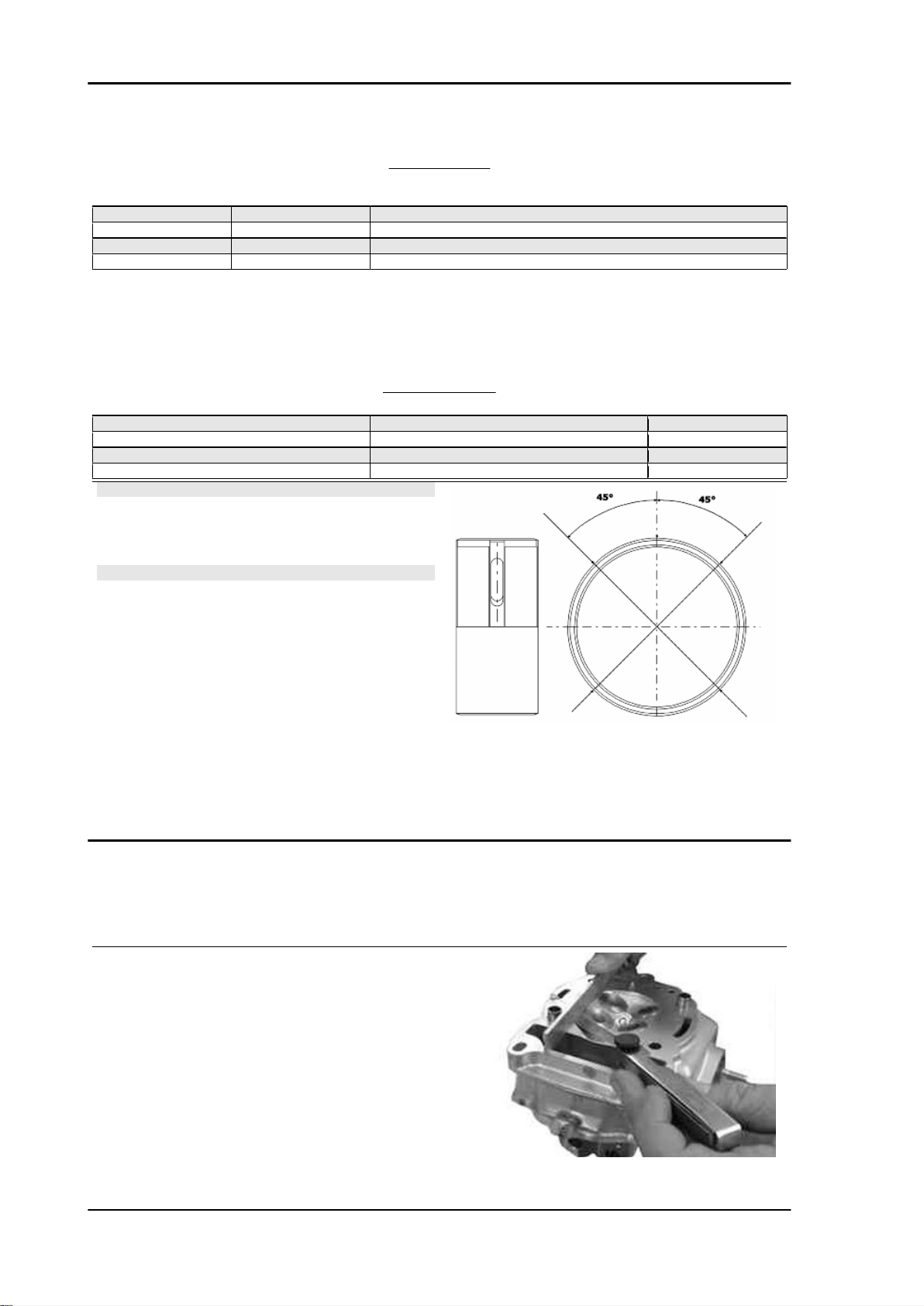

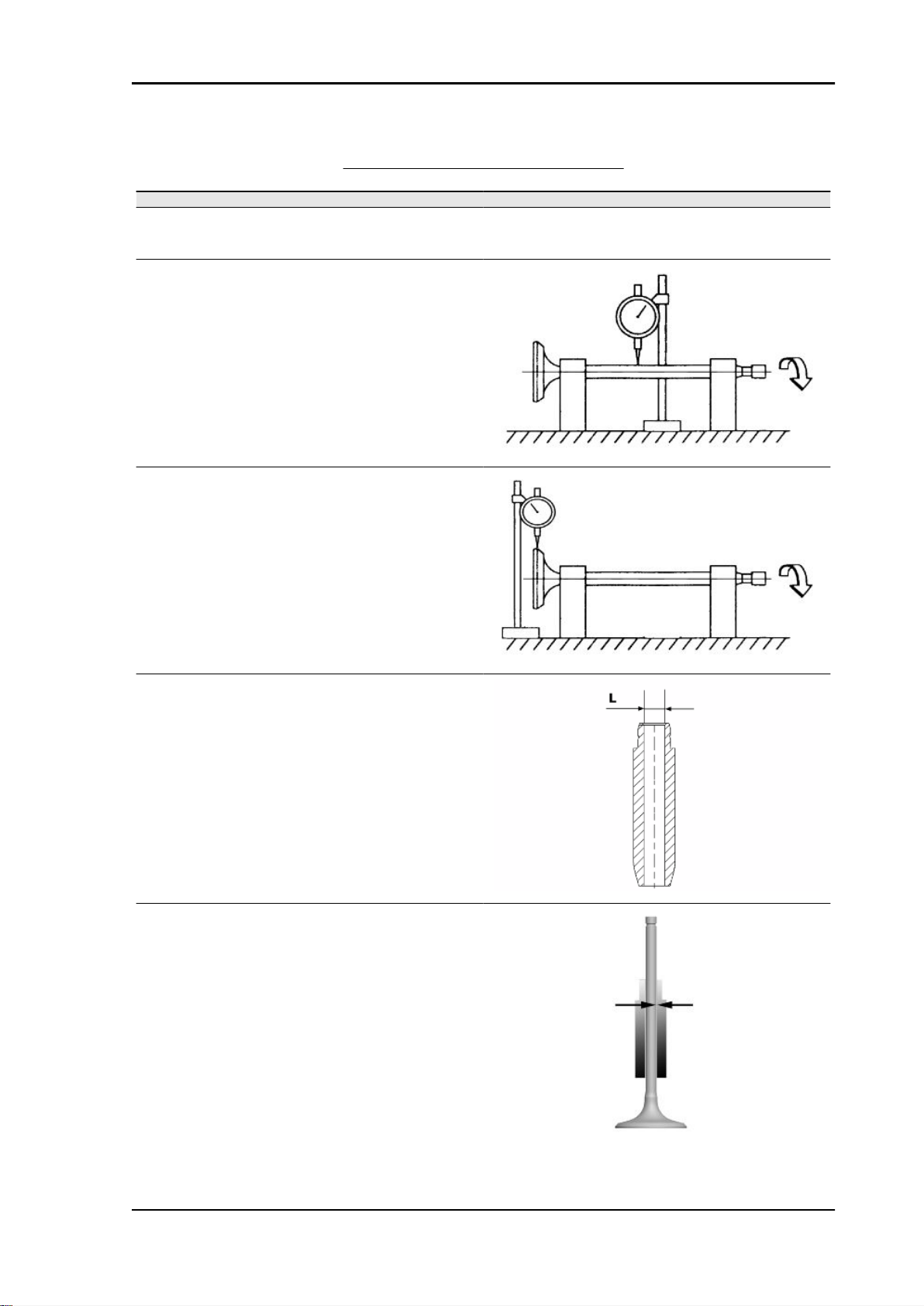

- Clean the valve seats of any carbon residues.

- Using the Prussian blue, check the width of the

impression on the valve seat "V".

Characteristic

Standard value:

1 - 1.3 mm

Admissible limit:

1.6 mm

- If the impression width on the valve seat is larger than the prescribed limits, true the seats with a 45°

mill and then grind.

- In case of excessive wear or damages, replace the head.

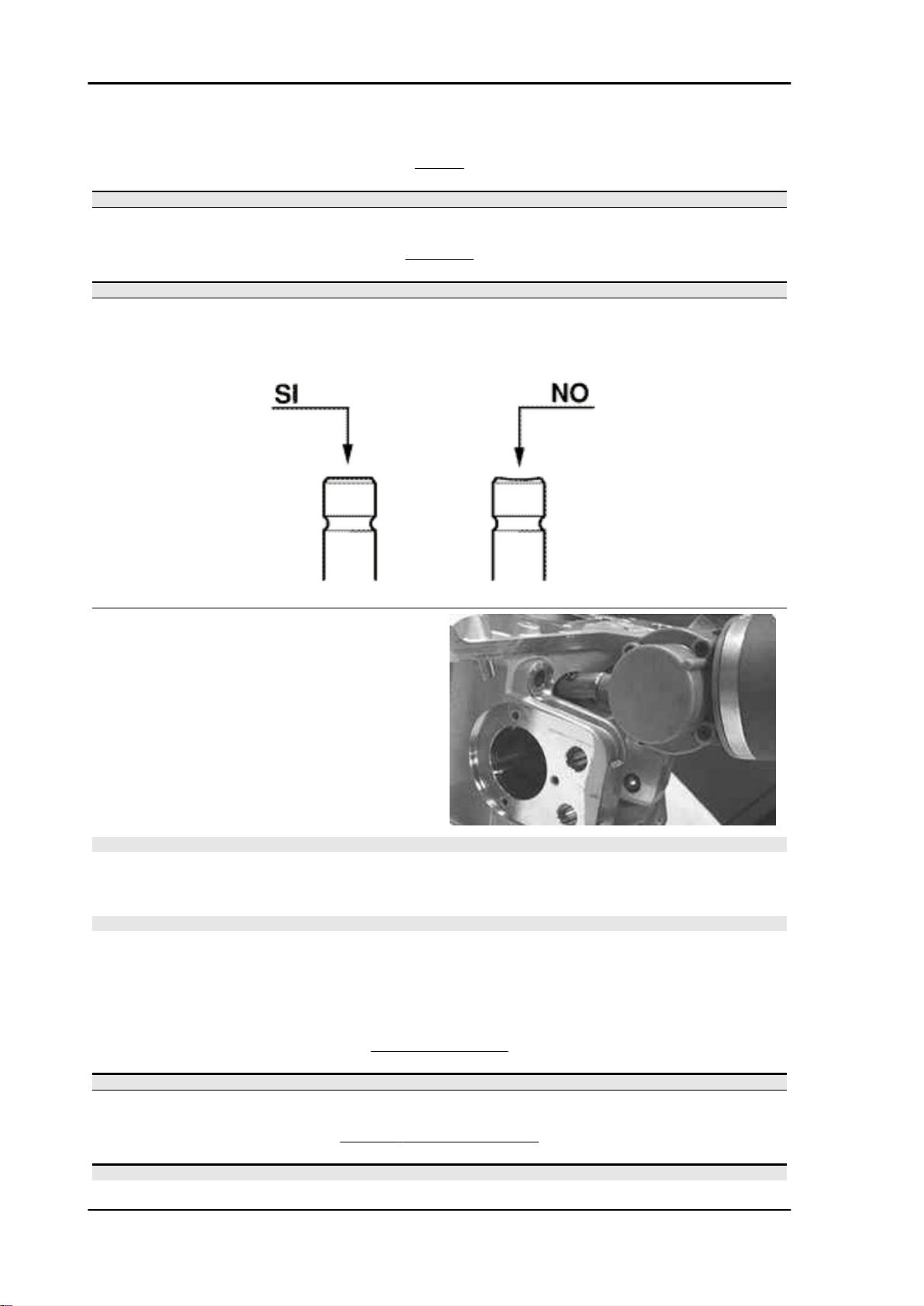

STANDARD VALVE LENGTH

Specification Desc./Quantity

Valve check standard length Inlet: 94.6 mm

Valve check standard length Outlet: 94.4 mm

- Measure the diameter of the valve stems in the

three positions indicated in the diagram.

STANDARD DIAMETER

Specification

Inlet: 4.987 - 4.972 mm

Outlet: 4.975 - 4.960 mm

CHAR - 26

Desc./Quantity

Vespa GTS Super 300 ie (2008) Characteristics

MINIMUM ADMISSIBLE DIAMETER

Specification Desc./Quantity

Inlet: 4.96 mm

Outlet: 4.945 mm

- Calculate the clearance between valve and valve guide.

- Check the deviation of the valve stem by resting

it on a "V" shaped abutment and measuring the

extent of the deformation with a comparator.

Characteristic

Limit values admitted:

0.1 mm

- Check the concentricity of the valve head by arranging a comparator at right angle relative to the

valve head and rotate it on a "V" shaped abutment.

Characteristic

Admissible limit:

0.03 mm

Measure the valve guide.

Characteristic

Valve guide:

5 +0.012 mm

- After measuring the valve guide diameter and the

valve stem diameter, check the clearance between guide and stem.

CHAR - 27

Characteristics Vespa GTS Super 300 ie (2008)

INLET

Specification Desc./Quantity

Standard clearance: 0.013 - 0.04 mm

Admissible limit: 0.08 mm

OUTLET

Specification Desc./Quantity

Standard clearance: 0.025 ÷ 0.052 mm

Admissible limit: 0.09 mm

- Check that there are no signs of wear on the surface of contact with the articulated register terminal.

- If the checks above give no failures, you can use

the same valves. To obtain better sealing performance, grind the valve seats. Grind the valves gently

with a fine-grained lapping compound. During the

grinding, keep the cylinder head with the valve axes in a horizontal position. This will prevent the

lapping compound residues from penetrating between the valve stem and the guide (see figure).

CAUTION

TO AVOID SCORING THE FAYING SURFACE, DO NOT KEEP ROTATING THE VALVE WHEN NO

LAPPING COMPOUND IS LEFT. CAREFULLY WASH THE CYLINDER HEAD AND THE VALVES

WITH A SUITABLE PRODUCT FOR THE TYPE OF LAPPING COMPOUND BEING USED.

CAUTION

DO NOT REVERSE THE FITTING POSITIONS OF THE VALVES (RIGHT - LEFT).

- Check that the camshaft bearings exhibit no scores or abnormal wear.

- Using a micrometer, measure the camshaft bearings.

STANDARD DIAMETER

Specification

Cam shaft check: Standard diameter Bearing A Ø: 36.95 ÷ 36.975 mm

Cam shaft check: Standard diameter Bearing B diameter: 19.959 ÷ 19.98 mm

Desc./Quantity

MINIMUM DIAMETER PERMITTED

Specification

Cam shaft check: Minimum admissible diameter Bearing A Ø: 36.94 mm

CHAR - 28

Desc./Quantity

Vespa GTS Super 300 ie (2008) Characteristics

Specification Desc./Quantity

Cam shaft check: Minimum admissible diameter Bearing B diameter: 19.950 mm

-Using a gauge, measure the cam height.

STANDARD HEIGHT

Specification Desc./Quantity

Cam shaft check: Standard height Inlet: 30.285 mm

Cam shaft check: Standard height Outlet: 29.209 mm

Check the axial clearance of the camshaft

CAMSHAFT AXIAL CLEARANCE

Specification

Cam shaft check: Standard axial clearance: 0.11 - 0.41 mm

Cam shaft check: Maximum admissible axial clearance 0.42 mm

- Measure the outside diameter of the rocking lever pins

- Check the rocking lever pins do not show signs of wear or scoring.

- Measure the inside diameter of each rocking lever.

Desc./Quantity

CHAR - 29

Characteristics Vespa GTS Super 300 ie (2008)

Check there are no signs of wear on the pad from contact with the cam and on the jointed adjustment

plate.

ROCKING LEVERS AND PIN DIAMETER:

Specification Desc./Quantity

Internal rocker arm diameter: Standard diameter Diameter 12.000 - 12.011 mm

Rocking lever pin diameter: Standard diameter Diameter 11.977 - 11.985 mm

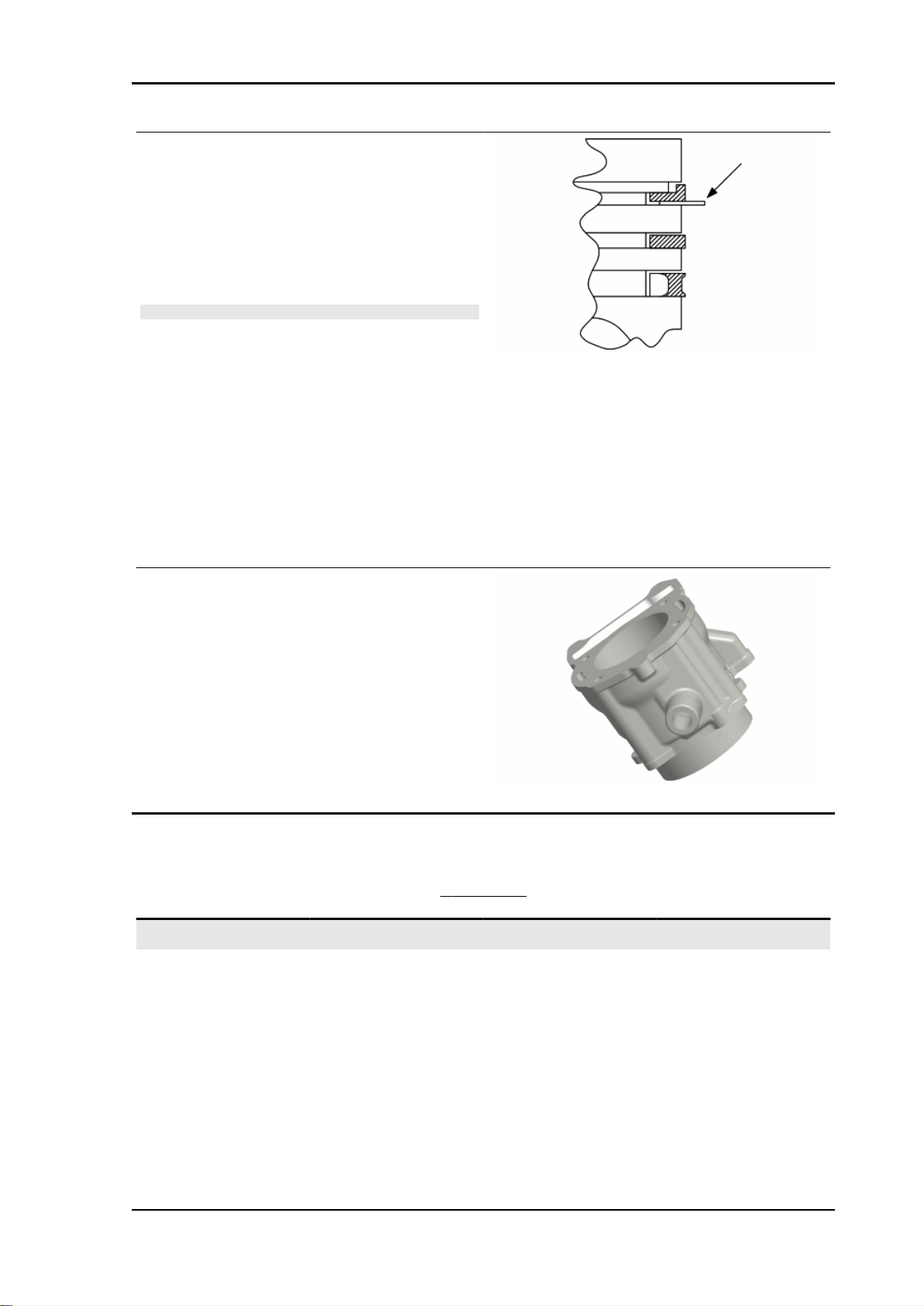

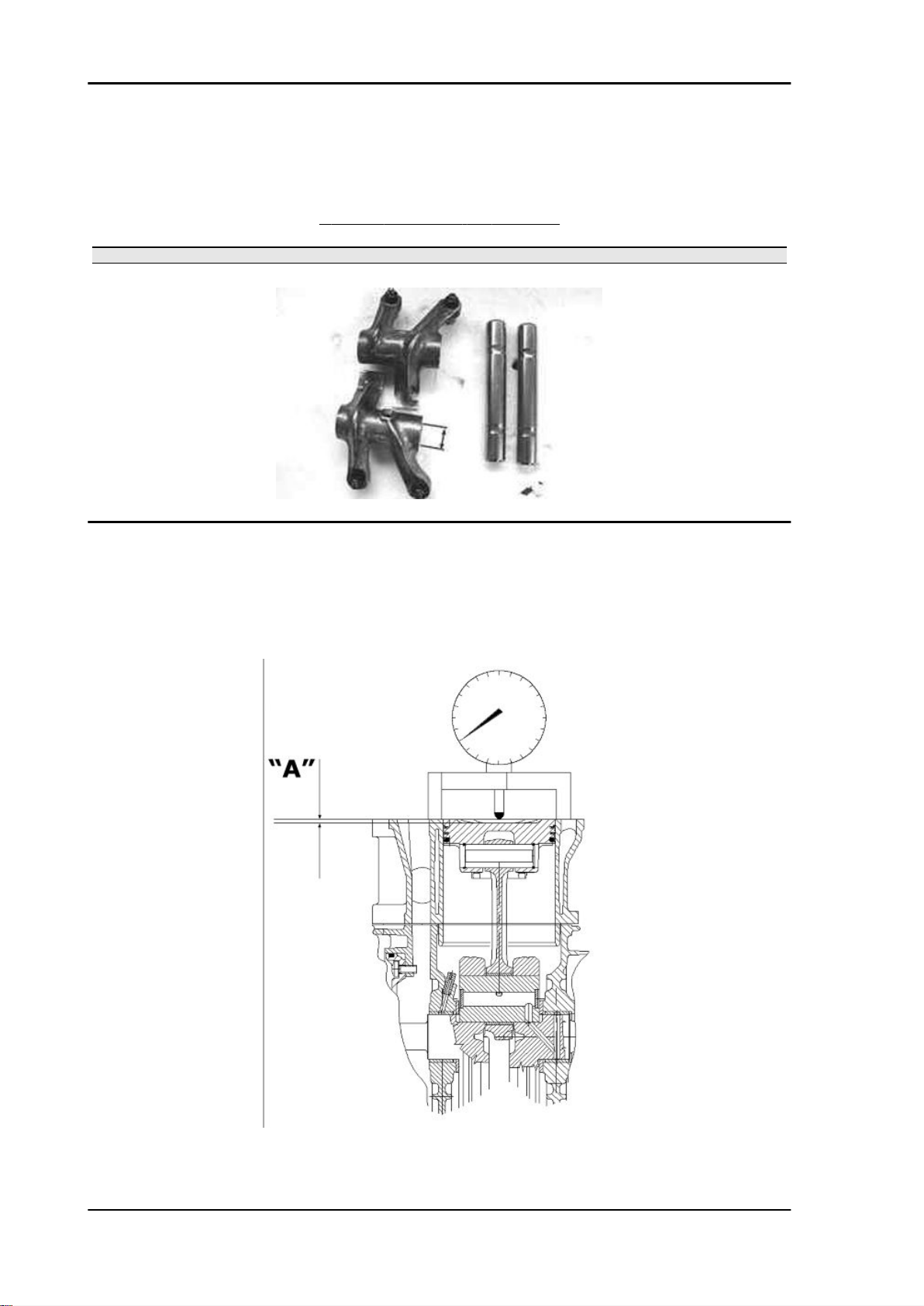

Slot packing system

Characteristic

Compression ratio

10.5 ÷ 11.5 : 1

Measurement "A" to be taken is a value of piston re-entry, it indicates by how much the plane formed

by the piston crown falls below the plane formed by the top of the cylinder. The further the piston falls

CHAR - 30

Loading...

Loading...