VESDA VLS-XXX Product Manual

Vision Fire & Security

LaserSCANNER

Product Guide

November 10, 2004

Part: 19147

VESDA

®

LaserSCANNER Product Manual

i

Copyright Information

This document is protected by copyright under the laws of Australia and other jurisd ictions t hroughout the world. It must not by any means,

either in whole or part, be reproduced, communicated to the public, adapted, distributed, sold, modified, published except as permitt ed by

any laws or statute or with prior written consent of VFS International Pty Ltd. Copyright© 2004 VFS In ter nat ional Pty Lt d ACN 100 259 381

Disclaimer

The manufacturer reserves the right to change designs or specifications without obligation and without further notice. VESDA,

LaserTEKNIC, LaserPLUS, LaserSCANNER, LaserCOMPACT, LaserFOCUS, VESDAnet, VESDAlink, ASPIRE, ASPIRE2, AutoLearn,

VSM, VConfig, InfoWORKS, PROACTIV, PRECISION, VSC, ADPRO, FastTrace, FastVu, FastScan, Axiom, PRO, Amux and Video

Central are brands and trade marks used under license by the distributor.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to rad io o r t ele vi sio n recept ion, the us er is e ncourag ed to t ry to cor rect t he i nt erferen ce by

one or more of the following measures, re-orientate or relocate the receiving antenna, increase the separation between the equipment and

receiver, connect the equipment to a power outlet which is on a different power circuit to the receiver or consult the dealer or an

experienced radio/television technician for help.

General Warning

This VESDA® Aspirating Smoke Detection System must only be installed, configured and used strictly in accordance with the General

Terms and Conditions and System Design Manual available from VFS International Pty Ltd. You acknowledge that you have read and

agree to those terms and conditions. All proper health and safety precautions must be taken during the installation, commissioning and

maintenance of the VESDA

®

Aspirating Smoke Detection System. The system should not be connected to a power source until all the

components have been installed. Proper safet y precautions must be taken during tests and maintenance of the VESDA

®

products when

these are still connected to the power source. Failure to do so or t amperi ng with the electronics insid e the product s can resul t in an electri c

shock causing injury or death and may cause equipment damage. VESDA

®

is not responsible and cannot be held accountable for any

liability that may arise due to improper use of the equipment and/or failure to take proper precautions. Only persons trained through a

VESDA

®

accredited training course can install, test and maintain the system.

Limitation of Liability

This VESDA® Aspirating / Air Sampling Smoke Detection System must only be installed, configured and used strictly in accordance with

the General Terms and Conditions, this manual and the System Design Manual available from VFS Internatio nal Pty Ltd (VFS). You

acknowledge that you have read and agree to those terms and conditions.

You acknowledge that you have been provided with a reasonable opportunity to appraise the VESDA

®

System and have made your own

independent assessment of the fitness or suitabilit y of the VES DA

®

System for your purpose. You acknowledge that you have no t relied on

any oral or written information, representation or advice given by or on behalf of VFS or its representatives.

VFS has no liability to you or any person for incidental or consequential loss, expense or damages including, without limitation, loss of

business, loss of profits or loss of data. You indemnify VFS for any claim, amount or liability brought against VFS in connection with the

VESDA

®

System.

You expressly agree that you assume the entire risk as to the results and performance of the VESDA

®

System resulting from the

configuration of the VESDA

®

System. VFS does not warrant, guarantee or make any representations, either expressly or implied,

regarding the current or future use, or the results of the use, of the VESDA

®

System, with respect to its correctness, accuracy, reliability,

completeness, interworking, functionality, currentness or otherwise resulting from the configuration of the VESDA

®

System.

T o t he full extent permit ted by law, VFS expressly excludes all conditions, warrant ies and liability, whether imposed or implied b y statute or

by rule of law or otherwise, which are not expressly set out in the General Terms and Conditions.

To the extent permitted by law, your sole recourse for any defect of, damage to, or performance standard of the VESDA

®

System will be

under the express warranties the General Terms and Conditions (if applicable) and VFS will in no event be liable to pay any amount or

damages resulting from or in connection with the VESDA

®

System.

To the extent by law that any limitation or exclusion can not apply, the tot al liability of VFS in relation to the VESDA

®

System is limited to:

(i) in the case of services, the cost of having the services supplied again; or

(ii) in the case of goods, the lowest cost of replacing the goods, acquir i ng equivalent goods or having the goods repaired.

To the extent permitted by law , VFS has no liability with respect to damage to or arising out of, or the condition or performance of, the

VESDA

®

System resulting from (i) negligence or improper use, storage, installation, configuration commission, service maintenance or

handling of the VESDA

®

System (where 'improper' includes treatment other than in accordance wit h the VES DA Manu al, these terms and

conditions or the information provided at a training session); (ii) accident , unforeseeable circumst ances or disaster ; (iii) mod ificati ons to the

VESDA

®

System other than in accordance with VFS's instructions; (iv) attachment of or interoperation with features, software or products

not approved by VFS in writing; or (v) where the VESDA

®

System has been serviced by persons not authorized by VFS in writing to

service the VESDA

®

System.

LaserSCANNER Product Manual VESDA

®

ii

VESDA Product Warranty Conditions

VFS International Pty Ltd (VFS) warrants that new VESDA products (excluding consumable items) will conform to its published

specifications and remain in good working order during the warranty period of 24 (twenty four) months from the date an invo ice is issued by

VFS to its distributor.

VFS also warrants that products serviced or repaired by it s service department will remain in good working order for a warranty period of

12 (twelve) months from the date of service. This service or repair warranty is only available on products less than 7 (seven) years old and

only covers those component parts of the products serviced, repaired or replaced.

Should product under warranty not be in good working order, VFS will, at its option, either repair or replace the product or its component

parts at no additional charge.

Spare parts and replacement product, covered under this warranty, will be furnished on an exchange basis and will, at the option of VFS

either be new, equivalent to new or reconditioned. Returned parts and products to VFS become the property of VFS.

This warranty does not cover the repair or damage to the product resulting from or arising out of (i ) negligence or improper use storage,

installation, configuration, commission, servi ce, maintenance or handling of the product (where 'improper' includes treatment other than in

accordance with any manual or instructions for use of the product); (ii) accident, unforeseeable circumstances or disaster; (iii)

modifications to the product other than in accordance with VFS's instructions; (iv) attachment of features or interoperation with features,

software or products not approved by VFS in writing; or (v) where the product has been serviced by persons not authorized by VFS in

writing to service the product.

Document Conventions

The following typographic conventions are used in this document.

The following icons are used in this document

Warranty service may be obtained by:

Notifying Vision Systems and giving full description of fault. Vision Systems will first attempt to rectify fault by supplying replacement

component parts. If rectification is not achieved by component part replacement then distributor is to return fa ulty product to Vision

Systems at Vision Systems cost once Vision Systems has gi ven approval to do so.

Convention Description

Bold Used to denote: emphasis

Used for names of menus, menu options, toolbar buttons

Italics Used to denote: references to other parts of this document or

other documents. Used for the result of an action

Convention Description

Caution: This icon is used to indicate that there is a danger to

equipment. The danger could be loss of data, physical damage,

or permanent corruption of configuration details.

Warning: This icon is used to indicate that there is a da nger of

electric shock. This may lead to death or permanent injury.

Warning: This icon is used to indicate that there is a da nger of

inhaling dangerous substances. This may lead to death or

permanent injury.

VESDA

®

LaserSCANNER Product Manual

iii

Contact Us

www.vesda.com www.adpro.com.au www.millbank.co.uk

Codes and Standards Information

We strongly recommend that this document is read in conjunction with the appropriate local codes and standards for smoke detection

systems and electrical connections. This document contains generic information and some sections may not comply fully with all local

codes and standards. In these cases, the local codes and standards must take precedence.

FM 3611 Hazardous Approval Warning

Exposure to some chemicals may degrade the sealing of relays used on the detector. Relays used on the detecto r are marked "TX2- 5V" or

"G6S-2-5V" or "EC2-5NU".

UL Warning

The fire alarm threshold (signal) that initi ates an evacuat ion proce dure via the Fire Al arm Panel must no t be se t highe r than 0.62 5%/f t. The

detector can send this signal either via the Fire Alarm Panel Output signal or the Pre-alarm output signal.

Safety Label

This VESDA product incorporates a laser device and is classified as a Class 1 laser product that complies with FDA regulations 21 CFR

1040.10. The laser is housed in a sealed detector chamber and contains no serviceable parts. This laser emits invisible light and can be

hazardous if viewed with the naked eye. Under no circumstances should the detector chamber be opened.

Document: 10279_01

This product complies with the following standards

SSL AS1603.8-1996

LPC & VdS GEI 1-048:Jan 1997

UL & CUL UL268 UL268A

FM FM3230-3250 FM3820

FDA 21 CFR 1010.2 21 CFR 1010.3

VESDA AS2211 EN60950

AS/NZS 3548 FCC Class B

EN 50081-1 EN 50130-4

UL and FM Compliancy

All installers must ensure that environments that require UL approved product must have the requirements of a remote display or FACP

connected to the detectors. Failure to do so will void product compliance for UL and FM certif ication th at is st a ted o n the det ect or approval

and rating label.

Approval Certification:

Vision Fire & Security have had this product tested and approve d by UL and FM. This product is fully listed and compliant as long as the

exception in UL268 is adhered to. Please see section 17.5 of UL268, 2003 Edition.

“17.5 A lamp or equivalent means shall be provide d on a spot -type detector head or ba se to identify it as the unit fro m which the alarm was

initiated”.

Exception: The alarm-indicating-means is not required on a detector whose use is restrict ed to a specific control unit that identifies

the individual detector in alarm.

As long as these models are connected to a remote di splay or to a Fire Alarm Control Pan el (FACP) that identifies if the detector is in alarm

then it is a compliant product.

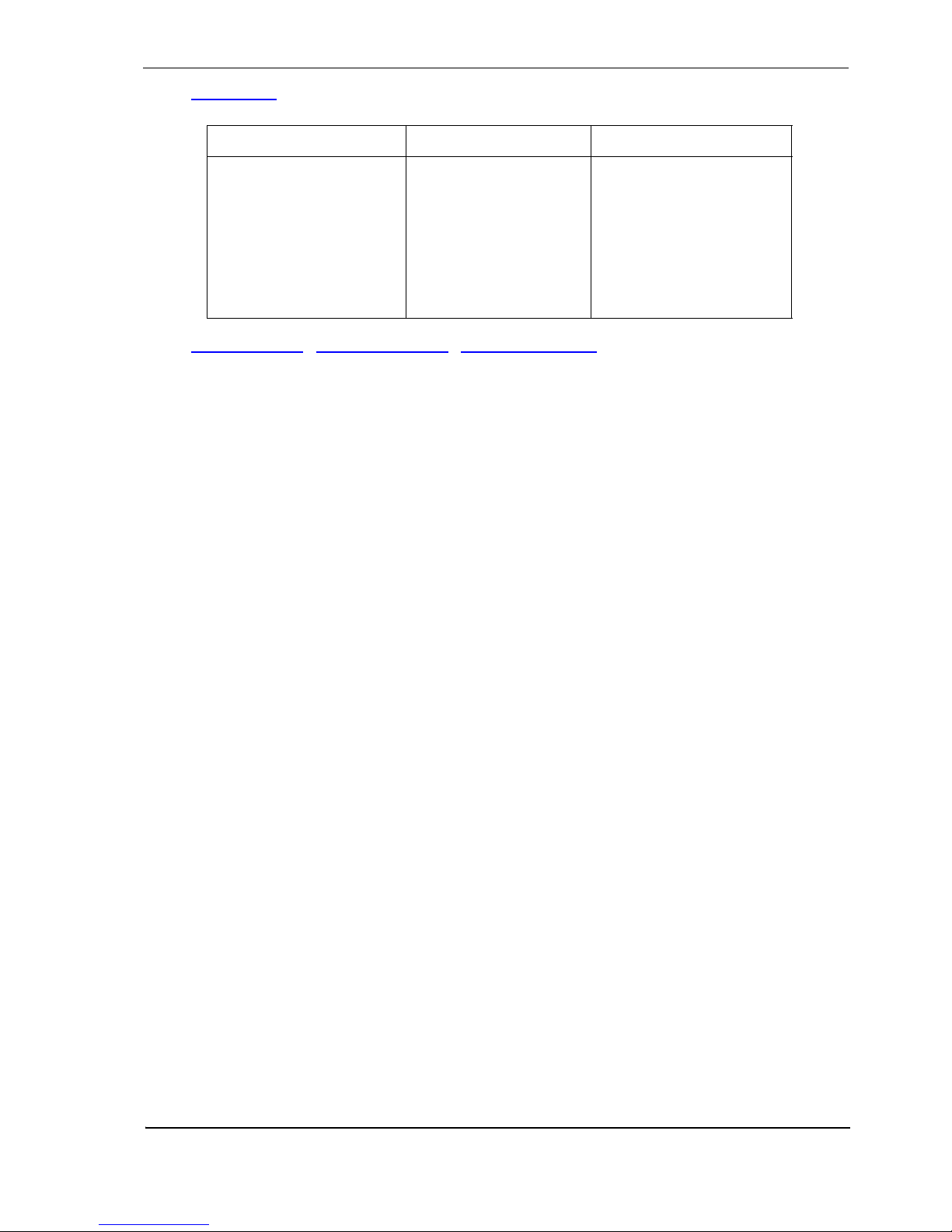

Australia and Asia The Americas Europe & Middle East

Vision Systems

Private Bag 215

495 Blackburn Road

Mount Waverley VIC 3149

Australia

Toll free: 1800 700 203

Tel: +61 (0) 3 9211 7200

Fax: +61 (0) 3 9211 7201

Vision Systems

700 Longwater Drive

Norwell,

Massachusetts, 02061

USA

Toll free: 800 229 4434

Tel: +1 78 740 2223

Fax: +1 78 740 4433

Vision Systems

Vision House, Focus 31,

Mark Road

Hemel Hempstead

Hertforshire HP2 7BW

United Kingdom

Tel: +44 (0) 1442 242 330

Fax: +44 (0) 1442 249 327

LaserSCANNER Product Manual VESDA

®

iv

VESDA

®

LaserSCANNER Product Manual

v

Contents

Scope ...............................................................................................................................................1

Introduction to the LaserSCANNER ..............................................................................................1

Features of the LaserSCANNER ............................................................................................1

Operation of the LaserSCANNER ..................................................................................................1

The Scanning Function ...........................................................................................................3

Scanning ....................................... ............................................................. .........................3

Adaptive scan threshold .....................................................................................................3

The Scanner Valve Test .....................................................................................................4

Sector Factor ...... ... ... .... .......................................... ... .......................................... ... ... .........4

LaserSCANNER Configurations: ............................................................................................5

Display Module ...................................................................................................................6

Display during the scan process ............ .............................................................................9

LCD Programmer .......... ... .......................................... ... .......................................... ... ... ......9

LaserSCANNER Components ..............................................................................................10

LaserSCANNER Product Information .........................................................................................11

Product Specifications ..........................................................................................................11

LaserSCANNER Dimensions ...............................................................................................13

Ratings and Approvals ..........................................................................................................14

Default Settings .....................................................................................................................15

Relays ..................................... ....................................................................... .......................16

Relay Settings and Conditions to Change States .............................................................17

Relay default settings .......................................................................................................18

First alarm sector relays: ...................................................................................................19

General Purpose Input (GPI) Functions ............................................................................20

Mounting the LaserSCANNER .....................................................................................................21

Securing the mounting bracket .............................................................................................21

Mounting the LaserSCANNER detector in Normal Orientation .........................................22

Mounting the LaserSCANNER in the inverted orientation ................................................ 22

Mounting the LaserSCANNER without mounting bracket ........................ ... ... ... .... ... ... ... ... ....22

Recess mounting kit .................................. ... ... ... .... ... .......................................... ... ... .......23

Connecting to the Pipe Network ..................................................................................................24

Inlet Pipes .............................................................................................................................24

Managing the Exhaust Air .....................................................................................................25

Wiring Connections ......................................................................................................................25

The Termination Card ...........................................................................................................25

VESDAnet Terminals ........................................................................................................26

Connections for GPI .........................................................................................................27

Power Source ................................................................................................................................28

Back Up Battery Power .................................................................................................................28

Starting Up .....................................................................................................................................30

Preliminary Systems Check .........................................................................................................30

Maintaining the VESDA LaserSCANNER ....................................................................................31

LaserSCANNER Product Manual VESDA

®

vi

Replacing the chassis/Air Inlet Pipe Manifold .......................................................................32

Internal Wiring for LaserSCANNER ......................................................................................34

Spare Parts ...........................................................................................................................36

VESDA

®

LaserSCANNER Product Manual

1

1.1 Scope

This manual is written to provide you with comprehensive knowledge of the detector.

This manual introduces you to the LaserSCANNER features, technical specifications and gives

an understanding of its components and their function. You will also find instructions on installing,

cabling and powering up the detector.

This manual is for anyone involved with the design, maintenance and purchasing of a VESDA

system. It is assumed that anyone using this manual has knowledge and the appropriate

certification from the local fire and electrical authorities.

1.2 Introduction to the LaserSCANNER

The LaserSCANNER can monitor and individually report on four sectors in the protected area.

The LaserSCANNER is an aspirating smoke detector providing very early warning of fire

conditions by drawing air samples through an air sampling pipe network. The detector chamber

can detect presence of smoke at very low concentrations. The embedded and PC software

complimenting the LaserSCANNER provides a wide range of user defined parameters and

reporting capabilities. The detector easily interfaces with fire warning and fire suppression

release systems, and can be easily integrated into a building management system.

Features of the LaserSCANNER

The LaserSCANNER features make it a versatile smoke detection product:

• Wide sensitivity range 0.005% obs/m to 20.0% obs/m (0.0015% obs/ft. to 6.24% obs/ft.)

• Each detector can cover an area of up to 2,0 0 0 m

2

(20,000 sq. ft.)

• Four programmable alarm thresholds (Alert, Action, Fire 1 and Fire 2)

• AutoLearn feature

• Four pipe inlets

• Individual pipe flow monitoring

• Scans individual sectors once smoke has been detected

• Replaceable air filter cartridge

• Option for inverted mounting

• Recessed mounting option

• Modular to meet site specific requirements

• Modular Display Module and LCD Programmer

• Programmable relays (option for 7 or 12 relays available)

• High efficiency aspirator

• Programmable General Purpose Input (GPI) to invoke operational modes

• PC programming and monitoring

• Multilingual displays

• Event Log for up to 18,000 events

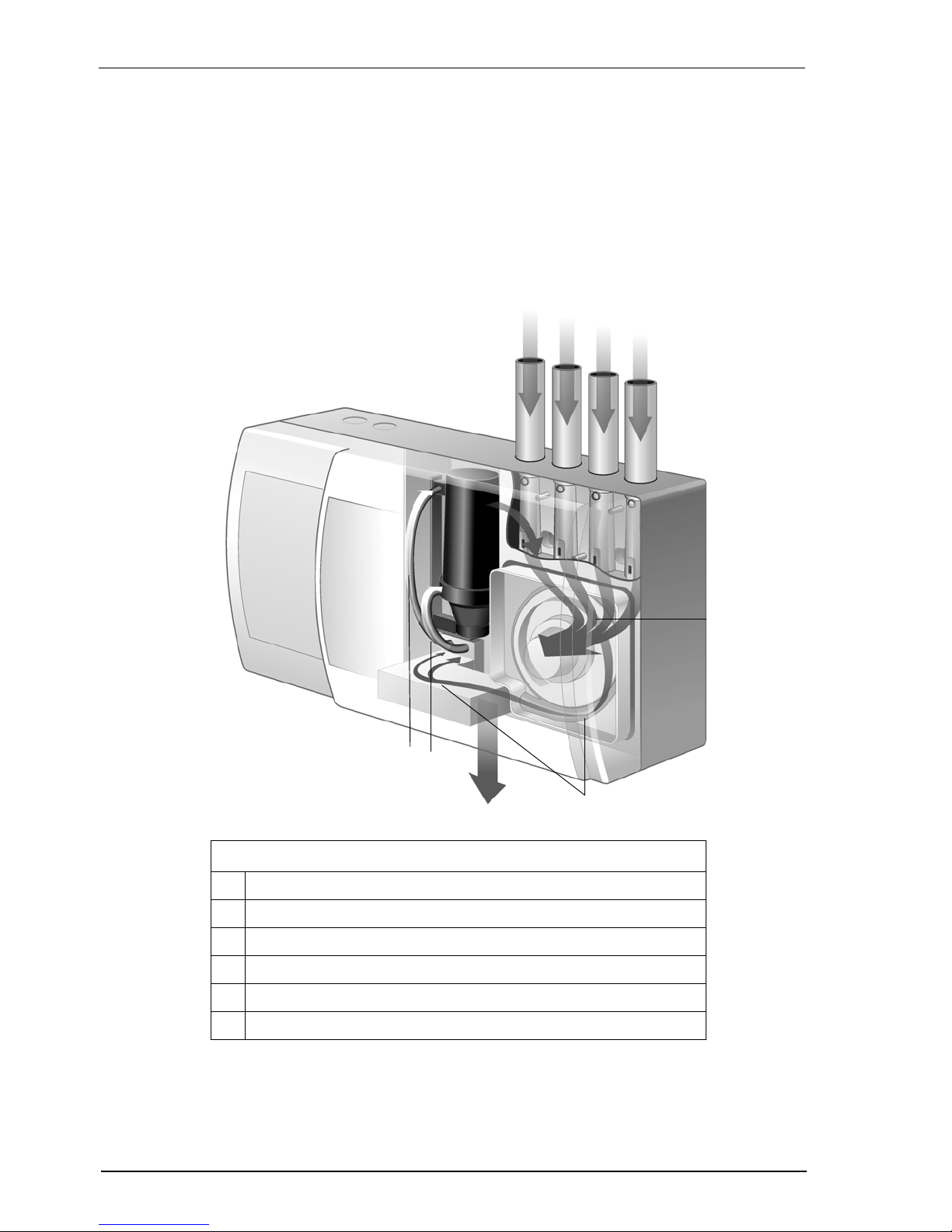

1.3 Operation of the LaserSCANNER

An air sampling pipe network with sampling holes at appropriate spacing collects air samples

from a protected area.

An integrated Aspirator draws air in the sampling pipes through a Pipe Inlet Manifold (up to four

pipes can be connected to a LaserSCANNER detector). For further information on air sampling

pipe network please see the Pipe Network Design and Installation Manuals.

LaserSCANNER Product Manual VESDA

®

2

Each pipe inlet in the manifold has a valve that can open or close the flow of air to the pipe. The

scan function controls the opening and closing of the valves to detect the smoke carrying pipe.

See The Scanning Function on page 3 for further information.

Some of the sampled air flows to the dual stage air filter. The first stage filtration removes dust

and dirt from the sampled air and a small percentage of this air then flows to the laser detector

chamber for detection smoke.

Any smoke detected in the laser detection chamber is signaled to the main processor card . If the

presence of detected smoke is higher than the set thresholds it will be reported as an alert,

action, fire 1 or fire 2 Alarm depending upon the set alarm thr esholds. The second stage filtration

further filters the air to make it ultra clean air. The ultra clean air is used to protect the optical

surfaces in the laser detector chamber.

Figure 1 - Operation and internal air flow of a LaserSCANNER

A

B

C

D

E

F

Legend

A Air inlets from pipe networks

B Air is drawn into the aspirator

C Some air is filtered and:

D -flows into the chamber for testing

E -is filtered a second time, then used to flush the chamber with ultra clean air

F All air is then exhausted

VESDA

®

LaserSCANNER Product Manual

3

The Scanning Function

The LaserSCANNER is designed to sample air from different sectors and to identify through a

scanning process the sector reporting presence of smoke.

Scanning

During normal operation the scanner valves remain open and the LaserSCANNER draws air

from all the pipes. When smoke is detected at a higher level than the scan threshold, for a period

exceeding the configured scan delay (0 to 10 seconds), the detector performs a fa st scan. During

the fast scan operation the LaserSCANNER samples air from e a ch sector (pipe) separately by

controlling the scanner valves in the inlet manifold. The fast scan sequence for each pipe is

approximately 4 seconds.

The sector reporting the highest level of smoke above the alert threshold is designated as the

first alarm sector. The display modules assigned to the detector reports this by illuminating the

first alarm and alert LEDs, and displaying the corresponding pipe number on the numeric screen.

Having identified the first alarm sector, the LaserSCANNER performs a slow scan using

intelligent sequencing. The sector with the highest level of smoke (the first alarm sector) is

scanned first. Each of the other sectors is scanned one at a time. Intelligent sequencing scans

the first alarm sector in every alternate scan (e.g. if all the pipes are in use and pipe 1

corresponds to the first alarm sector then intelligent sequencing will scan Pipe

1,2,1,3,1,4,1,2......). The time spent sampling air in each sector depends upon the configured

sector time.

Adaptive scan threshold

The scan threshold is the configured threshold at which the detector co mmences scan ning once

smoke has been detected at the threshold. The LaserSCANNER performs an adaptive scan

process to automatically set scan thresholds at the optimized level. The adaptive scan threshold

process is explained below:

• Typically separate scan thresholds are set for day and night periods.

• Scan thresholds are initially set to the lowest day or night alert threshold divided by the

number of pipes. If the threshold is set by AutoLEARN, the day or Night Alert Threshold is

divided by 2.

• The scan thresholds are then adapted automatically to eliminate unnecessary and

excessive scan cycles.

- Adapting the scan threshold u pwards - When the detected smok e level is lower than

the configured Alert Threshold, the scan threshold increases upwards by 0.005% obs/m

0.0016% obs/ft.) with every fast scan cycle. It will continue to do so until the scan threshold

is above the ambient smoke level or it equals the Alert Threshold. The scan threshold

cannot exceed the Alert Threshold

- Adapting the scan threshold downward s - At every changeover time (from Day to

night and from night to day) the detector determines if it is necessary to adapt the scan

threshold downwards. Thus, if the scan threshold has been adjusted upwards, then in the

following 24 hour period the detector begins a process of gradually lowering the scan

threshold downwards to an optimum setting. The detector maintains a record of the

maximum smoke readings measured in each day (or night) period. At the start of the next

day (or night) period the scan threshold is automatically scaled downwards by calculating

the difference between the current scan threshold and the ma xim um smo ke re adin g for the

previous day (or night) period.

LaserSCANNER Product Manual VESDA

®

4

The Scanner Valve Test

The VESDA LaserSCANNER performs a scanner valve test when first powered up. Thereafter a

valve test is performed every alternate T u esday at 12:00 hours. Duri ng the va lve test each val ve

is individually closed and opened to ensure its proper functioning. Any improper functioning is

reported as a fault (refer to the VESDA Tro ubleshooting Guide for fault descriptions and

troubleshooting). It is possible to simulate a valve scan test by pressing the Silence/Scan button

on the Display Module for two seconds, or selectin g th e sca n te st op tion un de r the dia g no stic s

menu on the LCD programmer or the device menu on the PC software.

Sector Factor

By setting appropriate sector factors it is possible to set differen t alarm thr esholds for each o f the

four sectors. The detector uses the sector factor to automatically calculate the alarm thresholds

appropriate for each sector based on the configured alarm thresholds. These are multiplied by

the sector factor to set the sector alarm thresholds.

Guidelines for setting sector factors:

• Sector factors range between 0.5 and 2.0

• Where more sensitive protection is desired for a sector (for example a critical server room

where there are relatively more sampling holes and re str icted access), set the se cto r factor

at less than 1.0

• Where less sensitive protection is desired for a sector (for example where there is a risk th at

a particular local process will generate nuisance alarms), set the sector factor at greater

than 1.0

• As a general rule, the difference between all pipes should not be greater than 1

Sector factors are generally optimized after a detector has been operational for a period and

sufficient historical data has been g athered in the event log to assist the decision. However, if it is

required to pre-determine the appropriate setting for sector factor the fo llowing methodo logy can

be used:

• Use ASPIRE Pipe Modelling Software to model the intended pipe layout

• Determine the appropriate fire sensitivity required for each sector to achieve the desired

hole sensitivity in each sector

• Select an appropriate median setting for the Fire 1 thre shold to be configured in th e detector

and calculate the appropriate sector factor which, when multiplied by the configured Fire 1

threshold, will give the desired fire sensitivity for each pipe

• Record the desired Fire1 threshold setting and sector factor setting for configuration into the

detector at commissioning.

VESDA

®

LaserSCANNER Product Manual

5

LaserSCANNER Configurations:

One or more devices can be integrated with the LaserSCANNER detector. These are normally

configured at the factory prior to shipping, but can also be installed at a later time. The st andard

LaserSCANNER comes with 7 relays or in an optional 12 relay versio n. The modules that ca n be

integrated are:

• Display Module

• LCD Programmer Module

• Fire and OK LEDs (FOK) Module

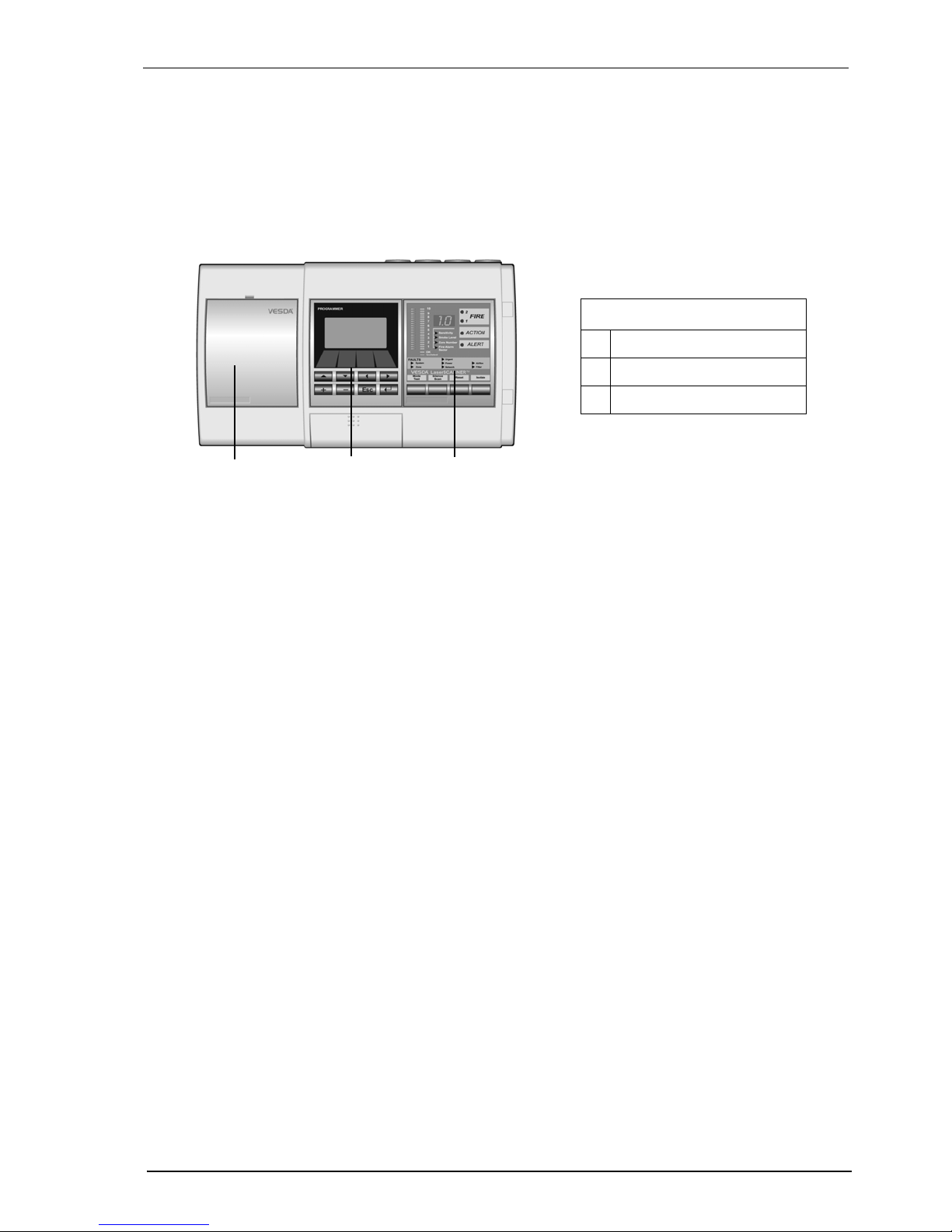

Figure 2 - VLS-214 VESDA LaserSCANNER with 7 relays, blank plate, LCD

Programmer and Display Module

Legend

A Blank Plate

B LCD Programmer

C LaserSCANNER Display Unit

A

B

C

LaserSCANNER Product Manual VESDA

®

6

Display Module

The LaserSCANNER Display Module is mounted either on the detector front cover or at a remote

location in a remote mounting box or a 19” subrack. It provides a visual representation of the

smoke levels and the four alarm stages for the a ssign ed detector. An array of fault LEDs light up

in different configurations to report Urgent, Minor, Zone and System faults. Up to 20 Display

Modules can be assigned to one detector, however the Display Module can be configured to

report the status of only one detector at a time.

Figure 3 - LaserSCANNER display module

OK LED

The OK LED stays lit during normal operation indicating the unit is functioning

normally. When this LED is off a warning beep sounds, indicating a Fault

condition is active.

Isolate LED

This LED is lit when the detector is Isolated and relays are de-activated

disabling alarm outputs of the detector. The display can be programmed to

beep every 60 seconds.

B

A

C

D

E

F

Legend

A Threshold Indicators

B Bar graph

C Numerical Display

D Alarm Level LEDs

E Fault LEDs

F Push Button Keys

VESDA

®

LaserSCANNER Product Manual

7

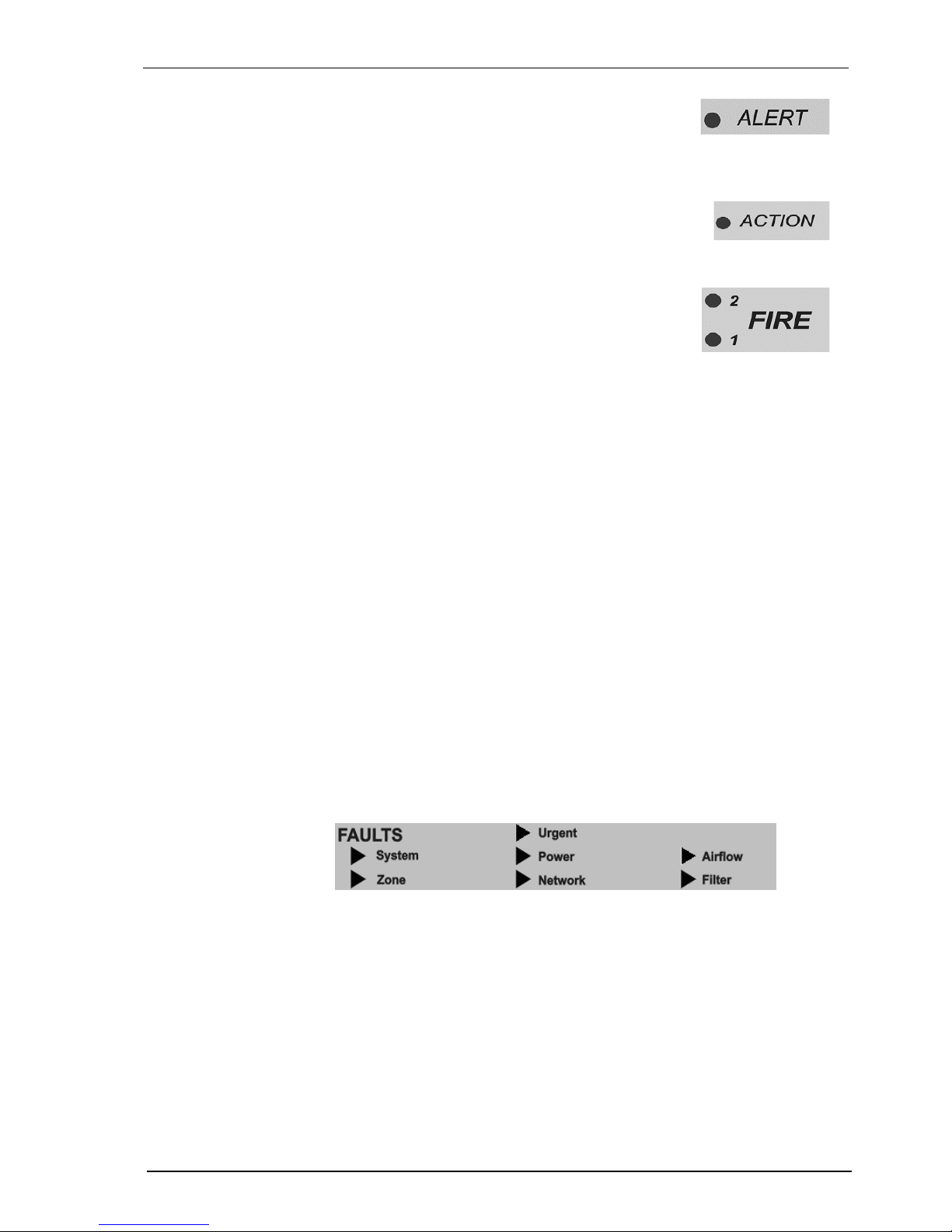

Alarm Levels

ALERT: When lit this LED indicates that the smoke

level is above the alert threshold. This means the

detector has identified very early stages of a fire

condition and/or that the smoke level in the area is

above normal.

ACTION: When lit this LED indicates that the detected

smoke level has passed the threshold value fixed for

Action, but is not intended to initiate a general fire alarm

response procedure.

FIRE 1: When lit this LED indicates that the detected

smoke level is above the threshold value set to initiate

a general fire alarm response procedure. This

indicates a fire may be imminent or is in progress.

When interfaced with a Fire Alarm Control Panel

(FACP) it can generate an automatic fire alarm.

FIRE 2: When lit this LED indicates a fire is in progress. The detector can be

interfaced with an FACP to activate automatic suppression systems and

evacuation procedures.

Bar graph

The Bar graph is a 20 step indicator where each indicator represents an

increase in the detected level of smoke, relative to the preset fire alarm level.

Threshold

Indicators

The illuminated LEDs represent visual settings for ALERT , ACTION, and FIRE

1 alarm levels. The FIRE 1 indicator is always at the top.

Fault LEDs

The Fault LEDs illuminate to indicate:

URGENT: A serious fault requiring immediate attention

SYSTEM: A fault affecting the network to which the Display module is

connected

ZONE: A fault in the VESDA Zone monitored by the Display module

POWER: A fault in the power supply if the GPI function is used

NETWORK: A communications fault on VESDAnet

AIRFLOW: Higher or lower than acceptable levels of air flow through the inlet

pipe(s)

FILTER: The air filter requires changing

Loading...

Loading...