VESDA VLQ-100 Product Manual

VESDA VLQ

Product Guide

VLQ-100

February 2014

Document: 26104_03

Part Number: 30320

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com i

Intellectual Property and Copyright

This document includes registered and unregistered trademarks. All trademarks displayed are the trademarks of

their respective owners. Your use of this document does not constitute or create a licence or any other right to use

the name and/or trademark and/or label.

This document is subject to copyright owned by Xtralis AG (“Xtralis”). You agree not to copy, communicate to the

public, adapt, distribute, transfer, sell, modify or publish any contents of this document without the express prior

written consent of Xtralis.

Disclaimer

The contents of this document is provided on an “as is” basis. No representation or warranty (either express or

implied) is made as to the completeness, accuracy or reliability of the contents of this document. The manufacturer

reserves the right to change designs or specifications without obligation and without further notice. Except as

otherwise provided, all warranties, express or implied, including without limitation any implied warranties of

merchantability and fitness for a particular purpose are expressly excluded.

General Warning

This product must only be installed, configured and used strictly in accordance with the General Terms and

Conditions, User Manual and product documents available from Xtralis. All proper health and safety precautions

must be taken during the installation, commissioning and maintenance of the product. The system should not be

connected to a power source until all the components have been installed. Proper safety precautions must be taken

during tests and maintenance of the products when these are still connected to the power source. Failure to do so

or tampering with the electronics inside the products can result in an electric shock causing injury or death and may

cause equipment damage. Xtralis is not responsible and cannot be held accountable for any liability that may arise

due to improper use of the equipment and/or failure to take proper precautions. Only persons trained through an

Xtralis accredited training course can install, test and maintain the system.

Liability

You agree to install, configure and use the products strictly in accordance with the User Manual and product

documents available from Xtralis.

Xtralis is not liable to you or any other person for incidental, indirect, or consequential loss, expense or damages of

any kind including without limitation, loss of business, loss of profits or loss of data arising out of your use of the

products. Without limiting this general disclaimer the following specific warnings and disclaimers also apply:

Fitness for Purpose

You agree that you have been provided with a reasonable opportunity to appraise the products and have made

your own independent assessment of the fitness or suitability of the products for your purpose. You acknowledge

that you have not relied on any oral or written information, representation or advice given by or on behalf of Xtralis

or its representatives.

Total Liability

To the fullest extent permitted by law that any limitation or exclusion cannot apply, the total liability of Xtralis in

relation to the products is limited to:

1. in the case of services, the cost of having the services supplied again; or

2. in the case of goods, the lowest cost of replacing the goods, acquiring equivalent goods or having the goods

repaired.

Indemnification

You agree to fully indemnify and hold Xtralis harmless for any claim, cost, demand or damage (including legal costs

on a full indemnity basis) incurred or which may be incurred arising from your use of the products.

Miscellaneous

If any provision outlined above is found to be invalid or unenforceable by a court of law, such invalidity or

unenforceability will not affect the remainder which will continue in full force and effect. All rights not expressly

granted are reserved.

VESDAVLQ Product Guide VESDA by Xtralis

ii www.xtralis.com

Scope

The VESDA VLQ Product Guide provides a comprehensive description of the VLQdetector.

This guide introduces the VESDA VLQ features, technical specifications and gives an understanding of its

components and their function. You will also find instructions on installing, cabling and powering up the

detector.

This guide is for anyone involved with the design, maintenance and purchasing of a VESDA VLQ system. It is

assumed that anyone using this product has the knowledge and appropriate certification from local fire and

electrical authorities.

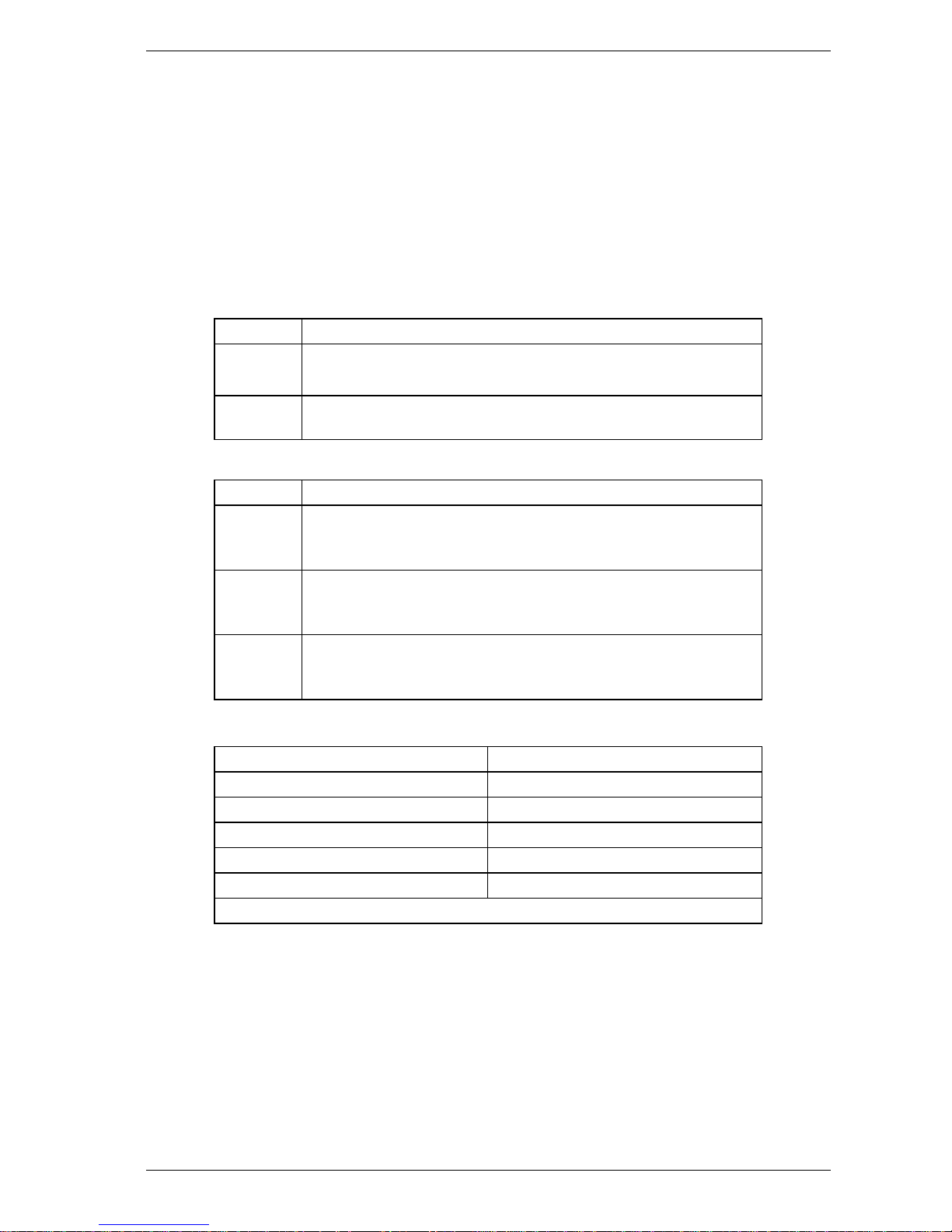

Document Conventions

The following typographic conventions are used in this document:

Convention Description

Bold Used to denote: emphasis.

Used for names of menus, menu options, toolbar buttons

Italics Used to denote: references to other parts of this document or other

documents. Used for the result of an action.

The following icons are used in this document:

Convention Description

Caution: This icon is used to indicate that there is a danger to

equipment. The danger could be loss of data, physical damage, or

permanent corruption of configuration details.

Warning: This icon is used to indicate that there is a danger of electric

shock. This may lead to death or permanent injury.

Warning: This icon is used to indicate that there is a danger of inhaling

dangerous substances. This may lead to death or permanent injury.

Contact Us

UKand Europe +44 1442 242 330

D-A-CH +49 431 23284 1

The Americas +1 781 740 2223

Middle East +962 6 588 5622

Asia +86 21 5240 0077

Australia and New Zealand +61 3 9936 7000

www.xtralis.com

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com iii

Codes and Standards Information for Air Sampling Smoke Detection

We strongly recommend that this document is read in conjunction with the appropriate local codes and standards

for smoke detection and electrical connections. This document contains generic product information and some

sections may not comply with all local codes and standards. In these cases, the local codes and standards must

take precedence. The information below was correct at time of printing but may now be out of date, check with your

local codes, standards and listings for the current restrictions.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, the user is encouraged to try to correct the interference by one

or more of the following measures; re-orientate or relocate the receiving antenna, increase the separation between

the equipment and receiver, connect the equipment to a power outlet which is on a different power circuit to the

receiver or consult the dealer or an experienced radio/television technician for help.

FDA

This Xtralis product incorporates a laser device and is classified as a Class 1 laser product that complies with FDA

regulations 21 CFR 1040.10. The laser is housed in a sealed detector chamber and contains no serviceable parts.

The laser emits invisible light and can be hazardous if viewed with the naked eye. Under no circumstances should

the detector chamber be opened.

The laser chamber is identified by the label shown below:

DANGER

DO NOT OPEN

NO SERVICEABLE

PARTS

Laser Radiation when Open

AVOID DIRECT EXPOSURE TO BEAM

NE PAS OUVRIR

DISPOSITIFS/PIECES

NON ECHANGEABLES

Rayonnement Laser en cas d’ouverture

EVITEZ TOUTE EXPOSITION DIRECTEAU FAISCEAU

Product Listings

l UL

l ULC

l VNIPPO

l EN 54-20 and other agencies (pending)

Document: 26104_03

Part Number: 30320

VESDAVLQ Product Guide VESDA by Xtralis

iv www.xtralis.com

This page is intentionally left blank.

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com 1

Table of Contents

1 Introduction 3

1.1 Features 4

2 Product Information 5

2.1 How it Works 5

2.2 Detector Overview 6

2.3 Specifications 9

2.4 Dimensions 10

3 Air Sampling Pipe Network 11

3.1 Installation Considerations 11

3.2 Pipe Inlets 11

3.3 Exhaust Air 11

3.4 Air Sampling Configurations 12

4 Installation 15

4.1 Mounting 16

4.2 Wiring 22

4.3 Specify Backup Battery for Power Supply 25

4.4 Installation Checklist 26

4.5 Powering Up 27

4.6 Preliminary System Check 27

5 Configuration 29

5.1 Logging on using the Display Panel 29

5.2 Setting the time using the Display Panel 29

5.3 DIP Switch Configuration 30

6 Commissioning 31

6.1 AutoLearn Smoke 31

6.2 Commissioning Smoke Test 31

7 Xtralis QSCSoftware 33

7.1 Installation 33

7.2 Functions 33

7.3 Configuration 34

7.4 Device Information 35

8 Maintenance 37

8.1 Replacing the Filter 37

9 Troubleshooting 41

9.1 Fault Codes 41

VESDAVLQ Product Guide VESDA by Xtralis

2 www.xtralis.com

This page is intentionally left blank.

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com 3

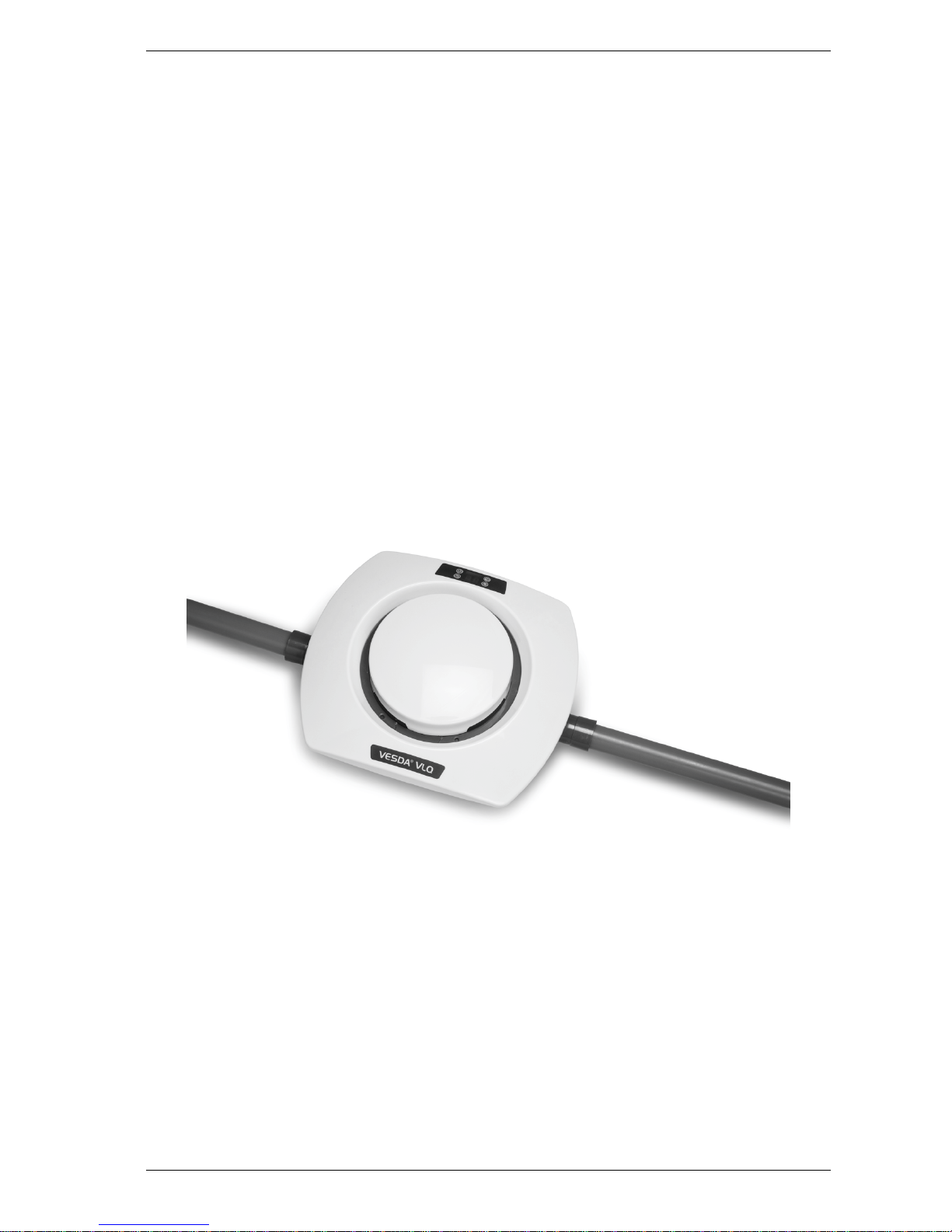

1 Introduction

The VESDA VLQ is an Aspirating Smoke Detector (ASD) that provides very early warning of fire conditions

by drawing air samples through sampling holes located in an air sampling pipe network.

The VESDA VLQ detector is specifically designed to cater for small areas up to 100m² (1000ft²). VESDA

VLQ is suited to several applications, including but not limited to:

l Telecommunications land line remote offices

l Base station controllers (BSC)

l Base transceiver stations (BTS)

l Server rooms

l Datacenter containers

l IT/equipment cabinets

l Controlled environmental vaults (CEV)

l Semi-conductor tools

l Modular laboratories

l Anechoic chambers

l Flight simulators

l Generator enclosures

l Signaling huts

l Pump houses

l Ammunitions holding areas

l Hyperbaric chambers

l Barracks self-contained units

Connection to the detector using Xtralis QSC software is available via the USB interface.

Figure 1-1: VESDA VLQ

The detector contains dry-contact relays which allow connectivity to fire warning and fire suppression release

systems, and integration into a building management system (BMS).

VESDAVLQ Product Guide VESDA by Xtralis

4 www.xtralis.com

1.1 Features

The VESDA VLQ detector provides the following features:

l Laser-based absolute smoke detection

l Clean air barriers for optics protection

l Up to 100 m² (1000 ft²)coverage

l Up to 2 x 6m (2 x 20ft) pipes (straight), up to 2 x 9m (2 x 30ft) pipes (branched)

l 2 or 4 VEWFD / EWFD (NFPA76), or 2 or 4 Class A / Class B (EN 54-20) sample holes

l Metric/Imperial pipe inlets

l Pre-alarm, Alarm and Fault Relays

l 5 LEDs: Pre-alarm, Fire-alarm, Fault, Power, Filter replacement

l Monitored on-board filter

l AutoLearn Smoke

l General Purpose Input (GPI)

l IP30 enclosure

l Xtralis QSC software support

l USB for direct PC connection

l Event log

l Low power consumption

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com 5

2 Product Information

2.1 How it Works

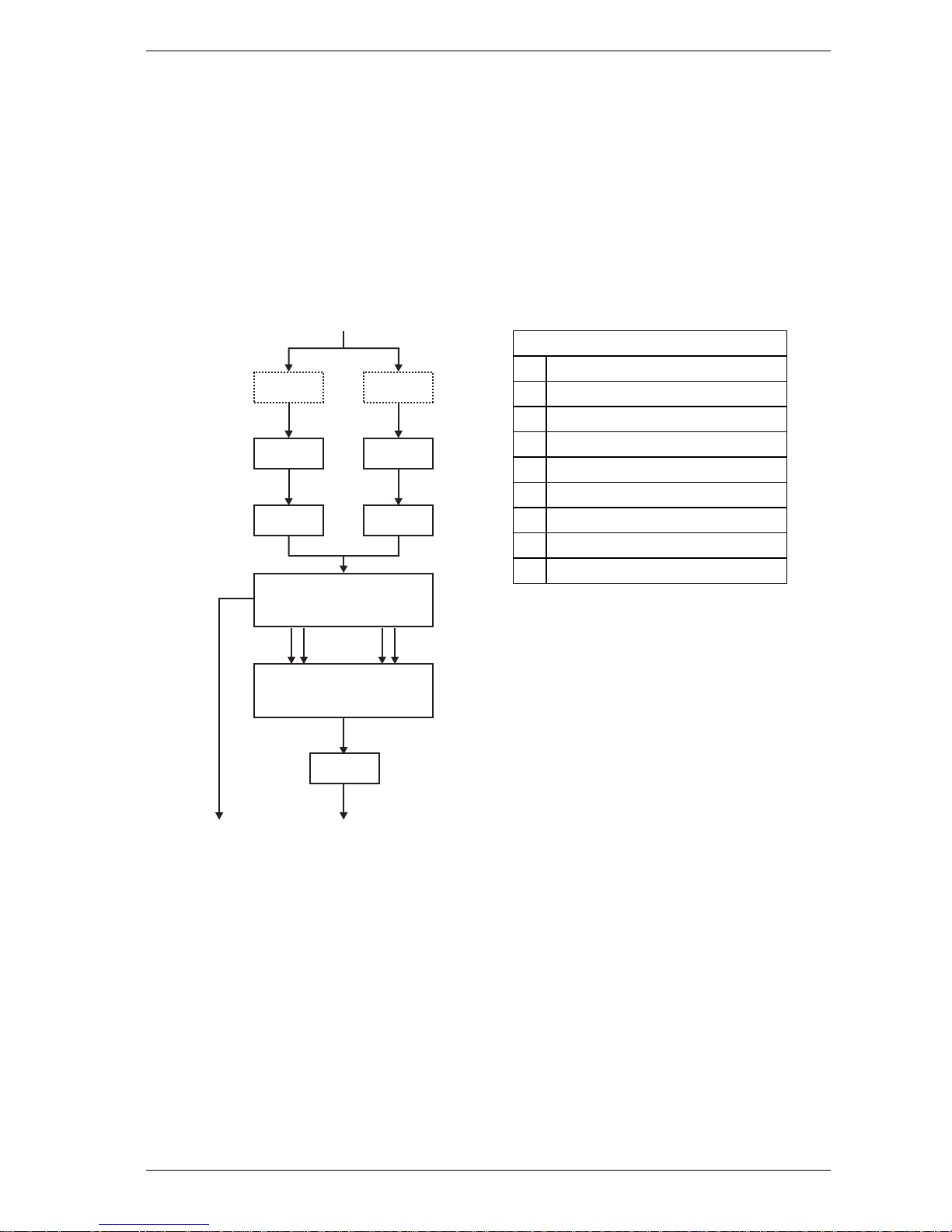

The VESDA VLQ detector continually samples air from the protected environment via two pipe inlets for the

sampling pipes on each side of the pipe inlets (A1, A2). Upon entering the detector, the air passes through

respective inlet manifolds (B1, B2) and the aspirators (C1, C2). The sampled air then enters the filter (D)

where the majority is exhausted out through filter exhaust (I2) and a portion from each inlet is separated into

two pathways, one pathway enters as clean air (E1,E2) and the other pathway enters as sampled air (F1,F2)

into the detection chamber (G). Sampled air is used for smoke detection and the clean air used for optics

protection. After smoke detection the air is exhausted out of the chamber exhaust (I1). Flow measurement is

performed at the chamber exhaust (H).

D

G

E1

F2

B1

A1

B2

A2

C1 C2

F1 E2

H

Legend

A PipeInlets

B Manifolds

C Aspirators

D Filter

E Clean Air

F Sample Air

G Detection Chamber

H Flow Sensor

I Exhaust

Figure 2-1: Air Path

VESDAVLQ Product Guide VESDA by Xtralis

6 www.xtralis.com

2.2 Detector Overview

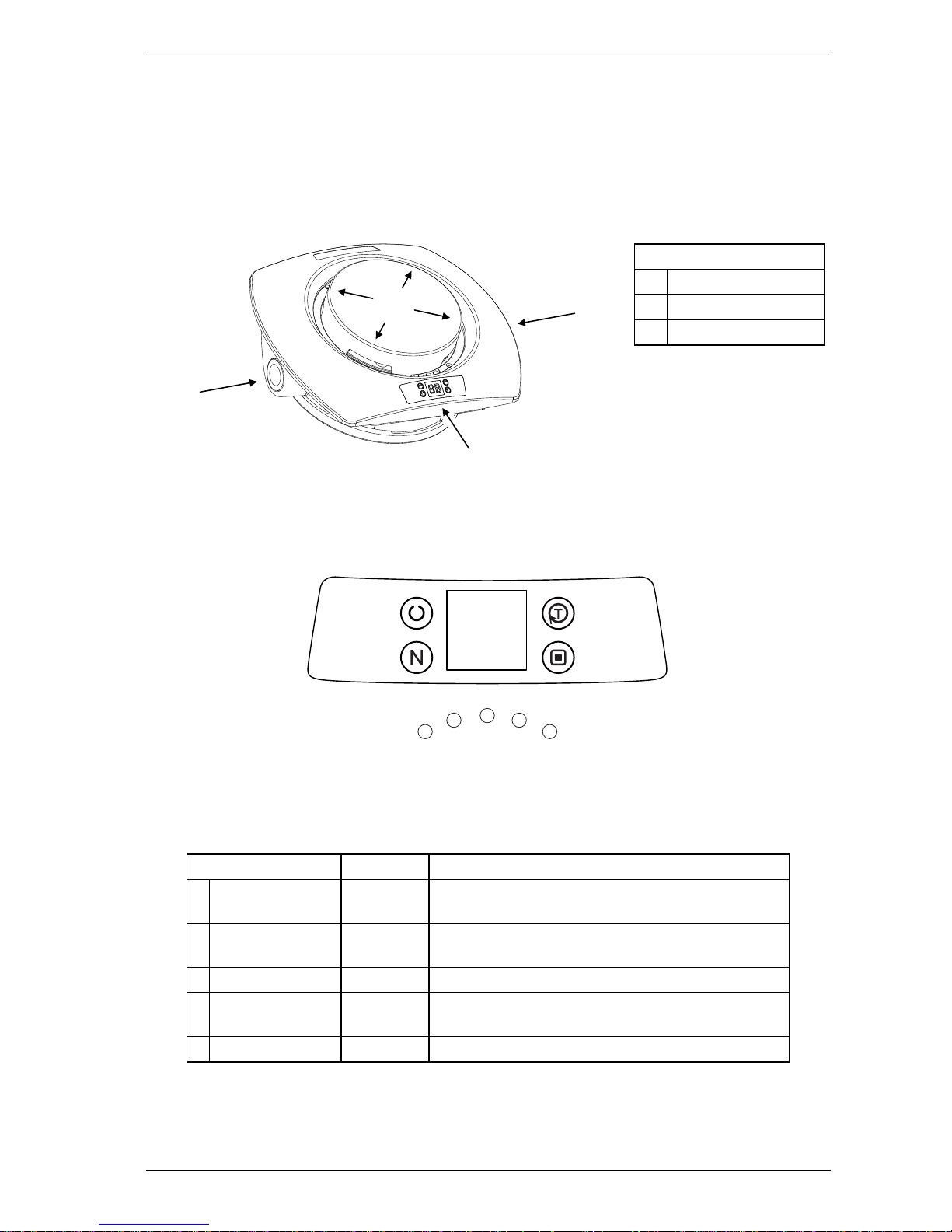

The VESDA VLQdetector is a lightweight unit designed to be ceiling or wall mounted and operates with a

simple sampling pipe network. The detector unit features two sampling pipe inlets, unobtrusive exhaust vents,

a simple control panel and display, and a buzzer to provide audio notifications.

AUSBport, described below in Section 2.2.3, provides the ability to interface with a computer, which allows

configuration with the Xtralis QSC software. Configuration DIPswitches and wiring terminals are located

beneath the detector and are accessible by removing the detector base..

A

A

B

C

Legend

A Sampling Pipe Inlets

B ExhaustVents

C Front Panel

Figure 2-2: VESDA VLQ Detector Overview

2.2.1 Front Panel

The VESDA VLQ front panel contains a series of indicators and buttons. These are described below.

88

A

B

C

D

E

Figure 2-3: VESDA VLQ Front Panel and Status LEDs

Indicators

The VESDA VLQ detector provides information via a series of Status LEDs.

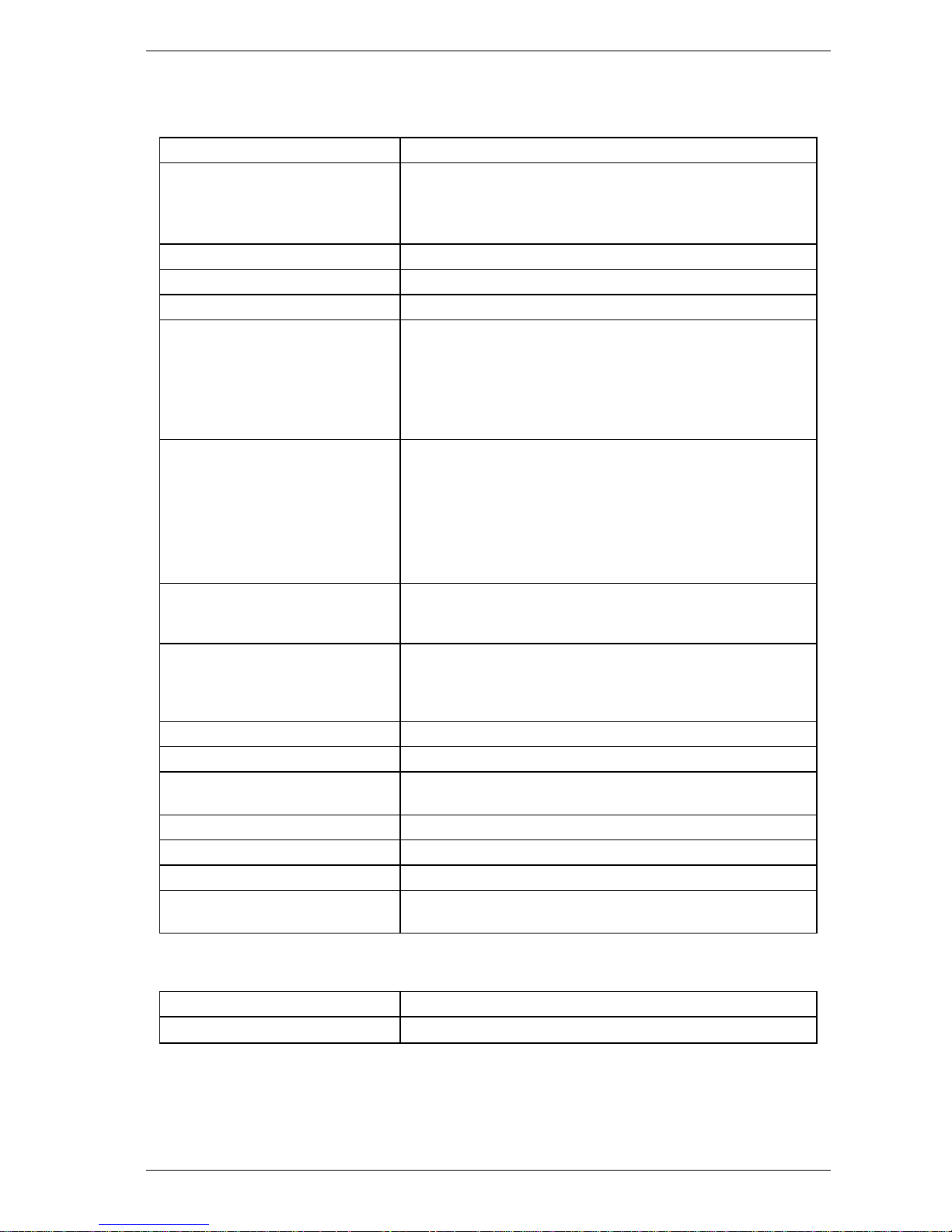

LED Color Description

A Power Green The Power LED illuminates when the detector is

powered up.

B Filter Replacement Yellow The Filter Replacement LEDis lit when the filter is due

for replacement.

C Fault Yellow The Fault LED is lit when a fault condition is detected.

D Pre-Alarm Red The Pre-Alarm LED is lit when the Pre-Alarm threshold

is reached.

E Fire-Alarm Red The Fire LED is lit when the Fire threshold is reached.

Table2-1: LEDIndicators

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com 7

Buttons

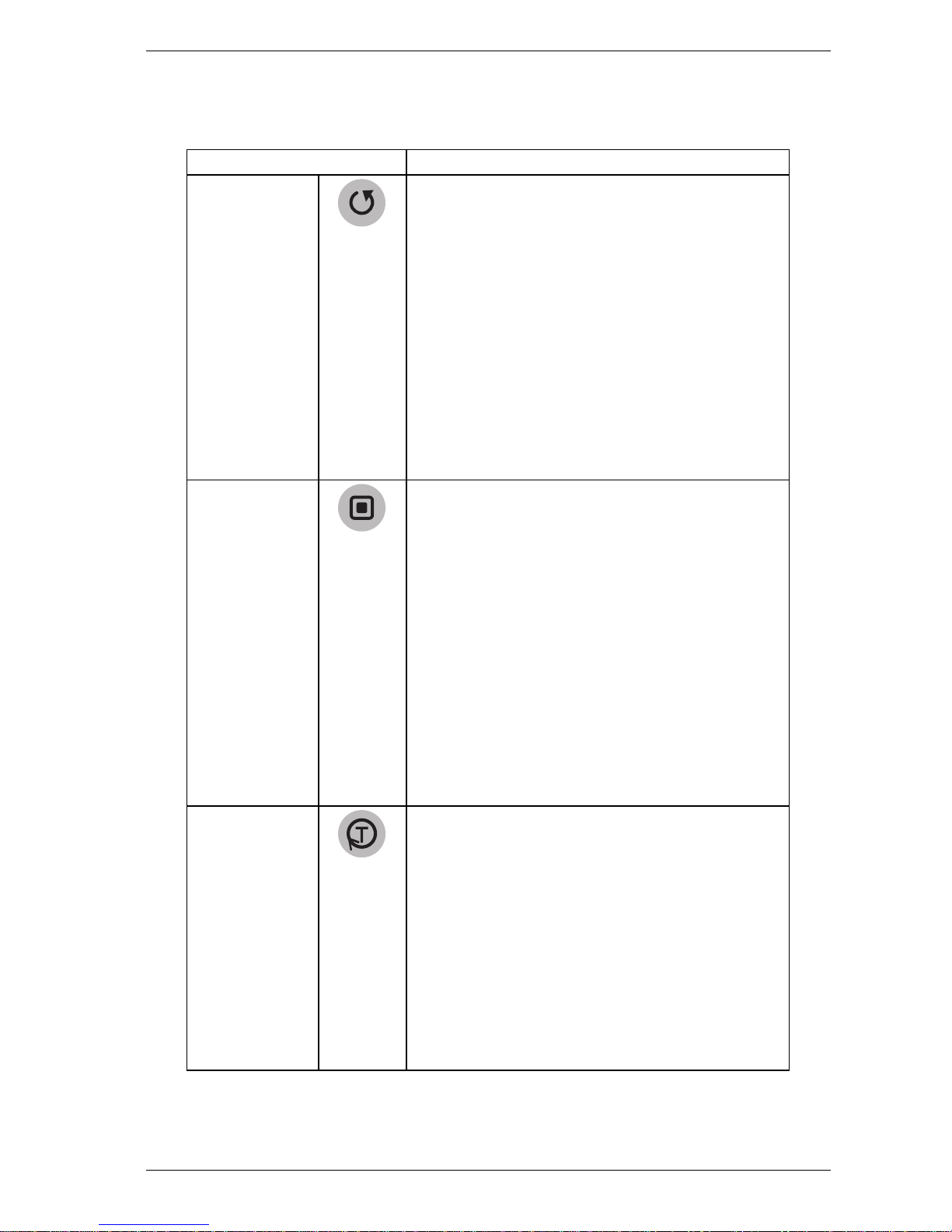

The VESDA VLQ detector provides accessibility to a range of functions via a set of control buttons.

Button Description

Reset / Silence Resetting the detector unlatches all latched alarms and

faults, returns relays to their normal state and clears the

active event list.

Silencing silences the buzzer for the current fault.

l To reset the detector, press this button once, 'rs' is

displayed on the panel.

l To silence the buzzer, press and hold this button till

"SI" is displayed on the panel (5 to 10 seconds). SI is

displayed alternately with the highest priority fault

code. The buzzer will remain silent unless another fault

is reported.

l To take detector out of Silence mode, press this button

once while detector is displaying "SI".

While the filter is removed, pressing the Reset / Silence

button once will reset the filter use percentage value.

Disable / Standby Disabling the detector disables all relay outputs with the

exception of the fault relay. The aspirator remains active.

Standby shuts down the aspirator and puts the detector

standby mode. There is no smoke detection during standby,

and the fault relay is activated.

l To disable the detector, press this button once.

l To re-enable the unit, press the button while "db" is

displayed on the panel.

l To place the detector in standby mode, press and hold

this button until "Sb" is displayed on the panel (5 to 10

seconds). To take detector out of standby mode, push

and hold this button when "Sb" is displayed on the

panel (5 to 10 seconds).

Note: You must be logged on to the detector through

front panel to use this button. Refer to Section 5.1

for further information.

Test Two Test modes are available:

l Lamp and Buzzer Test: Press this button to ensure

that all LEDs,display segments and buzzer operate

correctly. "Lt" is displayed momentarily when the

button is pressed.

l Alarm and Fault Test:Press and hold this button until

"At" is displayed on the front panel (5 to 10 seconds). It

activates alarm and fault relays. To stop the test press

and hold this button when "At" is displayed on the

panel.

Note: You must be logged on to the detector through

front panel to use this button. Refer to Section 5.1

for further information.

Table2-2: Control Buttons

VESDAVLQ Product Guide VESDA by Xtralis

8 www.xtralis.com

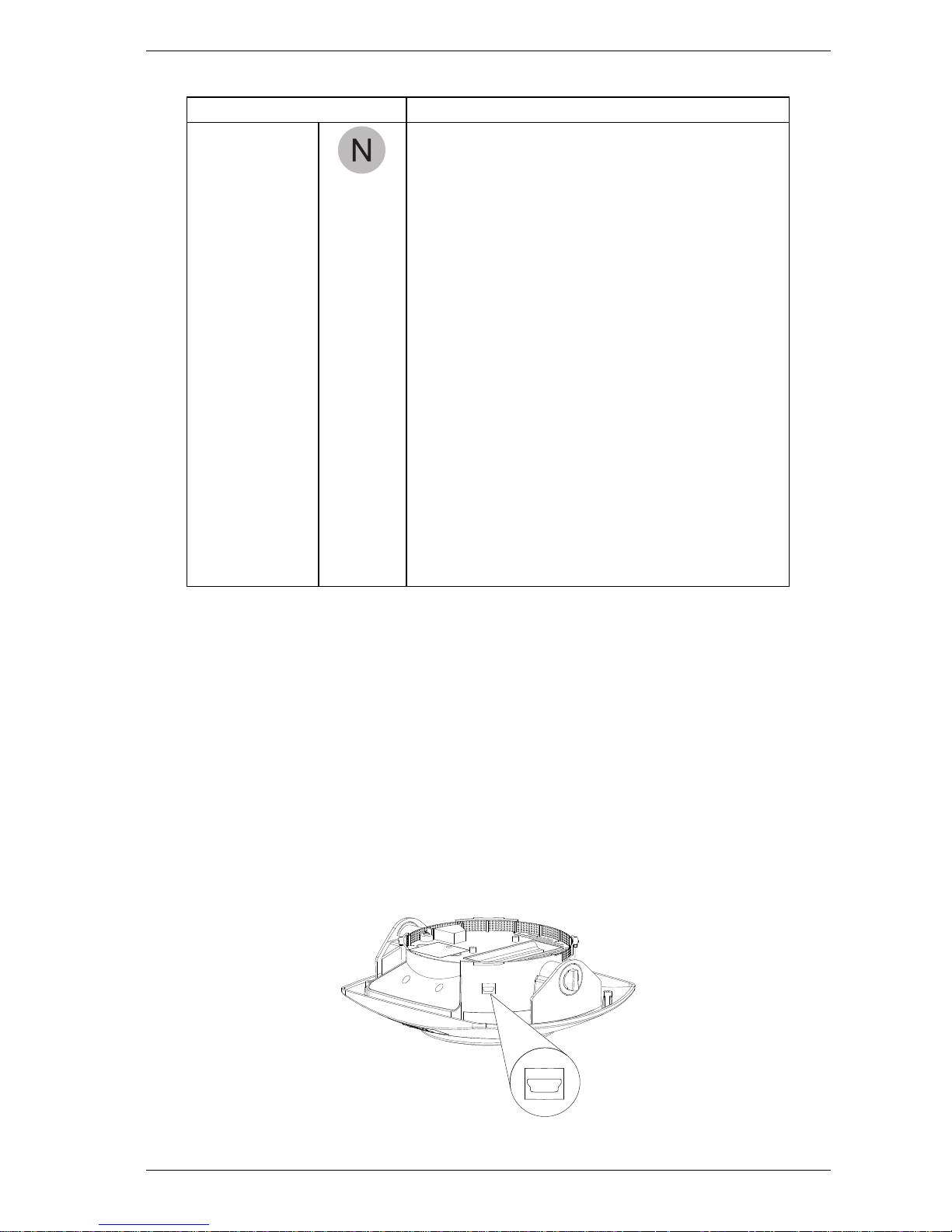

Button Description

Normalize Airflow /

AutoLearn Smoke

Airflow Normalization sets the reference point for airflow

thresholds based on ambient operating conditions.

AutoLearn Smoke sets the alarm thresholds based on the

environmental conditions.

l Press this button once to start the flow normalization,

'no' is displayed on the panel. Normalization takes

between 5 to 10 minutes. To cancel normalization

press this button while 'no' is displayed.

l To start the AutoLearn smoke press and hold this

button till "AL" is displayed on the panel. AutoLearn

takes 15 minutes to complete when started from the

panel. To cancel the AutoLearn press and hold this

button when "AL" is displayed.

Notes:

l AutoLearn Smoke thresholds are volatile, therefore if

thresholds are set using AutoLearn smoke then it must

be run each time the detector is powered up.

l AutoLearn Smoke over-rides the DIPswitch settings

within the smoke threshold range. Refer to Section 5.3

for further information.

l You must be logged on to the detector through the front

panel to use this button. Refer to Section 5.1 for further

information.

Table2-2: Control Buttons (continued...)

2.2.2 Buzzer

The buzzer will sound under the following conditions:

l During power up self testing.

l When a Pre-Alarm is raised, the buzzer will alternate between on and off until the detector is silenced or

the smoke is no longer present.

l When a Fire alarm is raised, the buzzer will beep continuously until the detector is silenced or the smoke

is no longer present.

l When a Fault is detected, the buzzer will alternate between on and off until the detector is silenced or the

fault condition is corrected.

l During a manually initiated system test.

2.2.3 USB Port

Detector configuration can be performed using the Xtralis QSC software installed on a computer connected to

the detector via the USB port. The USB port is located on the outside of the detector, beneath the shroud. It is

necessary to remove the rubber grommet in order to access this port.

Figure 2-4: USBPort

VESDA by Xtralis VESDAVLQ Product Guide

www.xtralis.com 9

2.3 Specifications

Specification Value

Supply Voltage 24 VDC nominal (18 to 30 VDC), externally supplied from UL1481

/ EN54-4 listed power supply (as appropriate to meet local

codes). Ensure that the power supply is installed in accordance

with local electrical codes.

Current Consumption 170 mA (quiescent), 190 mA (alarm)

Dimensions 260 mm x 228 mm x 110 mm (10.24in x 8.98in x 4.35in)

Weight 1.2 Kg (2.65 lbs)

Operating Conditions

(To operate the VESDA VLQ detector outside

these parameters please contact your

nearest XtralisOffice.)

Temperature:

l Tested to: -10°C to 55°C (14°F to 131°F) *

l Recommended Ambient: 0°C to 39°C (32°F to 103°F)

Humidity:

l 0-95% RH, non-condensing

Sampling Pipe Network Pipe Length:

l Linear: Up to 2 x 6 m (2 x 20 ft.)

l Branched:Up to 2 x 9 m (2 x 30 ft.)

Sampling Holes:

l 2 or 4 (1 or 2 per pipe)

Refer to Section 3.4 on page 12 for further information.

Pipe Size Accepts both metric and American standard pipe sizes:

l Metric: 25 mm (1.05 in.)

l American Pipe: IPS 21 mm (¾ in.)

Relays l 3 relays. Pre-Alarm, Fire and Fault

l Contacts rated 2A @ 30 VDC

l Programmable to latch or non-latch states

l Programmable 0 - 60 sec delay for each relay

IPRating IP30

Mounting Surface or flush mounting with optional mounting brackets.

Cable Access l Two cabling inlet points from top

l Side entry through removable partition

Cable Termination Screw terminal blocks (0.2-2.5 sq mm, 30-12 AWG)

PCConnection USB (Type 2)

Sensitivity Range 0.005% - 3% obs/m (0.0015% - 0.915% obs/ft)

Threshold Setting Range l Fire Alarm: 0.15%/m - 3%/m (0.046%/ft - 0.915%/ft)

l Pre-Alarm: 0.1%/m - 1.5%/m (0.03%/ft - 0.457%/ft)

Table2-3: VLQ Detector Specifications

* Product UL listed between 0° to 39°C (32° F to 103° F)

Specification Value

Event Log Up to 1,000 events

Table2-4: Software Features

Loading...

Loading...