Vertysystem Apolix Instructions For Use Manual

Instruction for use

Apolix

Electronic and automatic polymerizer

1. DESCRIPTION

This instrument is used to polymerize acrylic material. It was engineered for work in the dental laboratory.

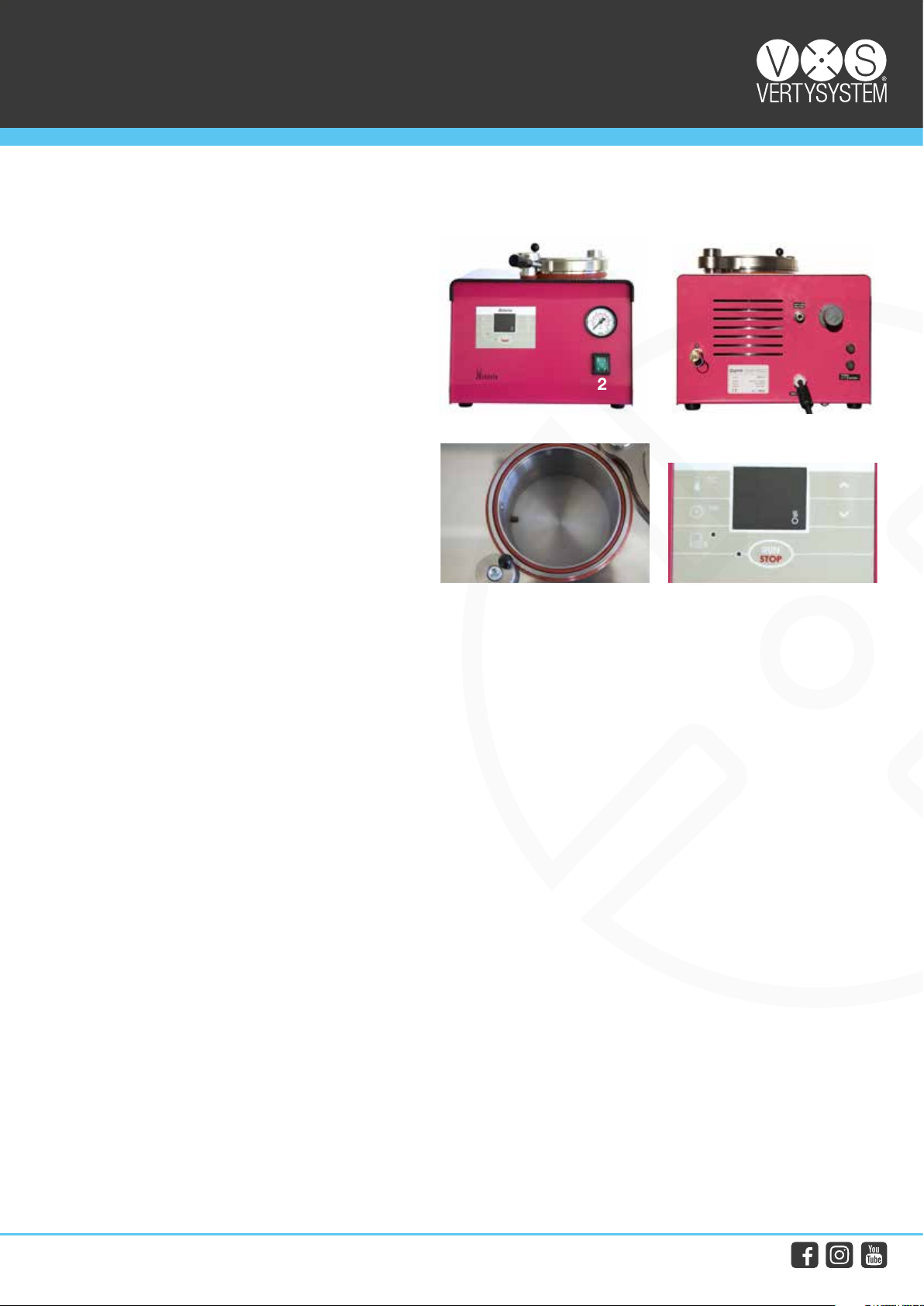

1. Front panel

2. ON/OFF switch

3. Manometer

4. Lid

5. Handle for closing/opening

6. Nozzle for water

7. Nozzle for air

8. Socket

9. Power cord

10. Fusibles

11. Pressure adapter

12. Latch for closing/opening

13. Filter

14. Temperature button

15. Timer button

16. Water release button

17. RUN/STOP button

18. Selection arrows

19. Display

5

4

3

1

2

6

14

13

15

16

19

12

11

7

10

8

9

18

17

2. INSTALLATION AND FIRST USE

OPENING

• Carefully remove the machine from the wrapping

• Make sure the electric tension is 230 V

• Set the machine so that the plug is accessible

SET UP

Connect the main air to the terminal labelled INPUT AIR on the back panel. The input hole has a 6 ø. Pressure must not

exceed 6 bars.

Connect the 8 ø hose to the OUT output and unwind it to a water drain or a water collecting container. This hole is on the

left side of the side lid.

IMPORTANT

Do not soak this hose into any liquid as to not damage the unit. The safety valve is on the back panel.

Put the instrument in such a position as to not damage anything if the valve is activated. Do not direct it towards

combustibles.

3. MODE OF USE AND CHARACTERISTICS

• APOLIX has a total of ten programs, four of which are pre-set for VERTYSYSTEM® acrylic

• materials

• A work cycle consists of the necessary time and temperature settings

• Use the selection arrows (e) to set timing and temperatures

• After using the selection arrows, you will see the current setting flashing on the display (f)

• When the setting is flashing, you can change its value by using the selection arrows (e)

• To save the setting, you must once again push the corresponding selection button

• You will then exit the parameter setup mode

Rev. 10/2019

a.gree srl

Via Retrone 14, Altavilla Vicentina 36077 (VI) Italy

+39 0444 960 991 info@vertysystem.com

1/7

vertysystem.com

Instruction for use

Apolix

Electronic and automatic polymerizer

3. MODE OF USE AND CHARACTERISTICS

• Put the Furbo Alu Big/Small flask in the machine. Pour the necessary water in the tank (leaving at least a 2-cm gap to

the top)

• Close the lid until it latches. Start the process using the RUN/STOP button (17)

• The process can be stopped at any time using the RUN/STOP button (17)

• Once the process is started, it’s necessary to push the water release button (16). The LED will flash, and water and air

will be automatically released at the end of the process.

• In case of need, you can manually release the water by pushing and holding the water release button (16) for 5 seconds. The machine will automatically release the water.

• In case of extreme need, you can manually drain the water using the nozzle for water (6). This can only be done while

the machine isn’t running a program. Before emptying the water, push the RUN/STOP button (17).

• Once the machine has been emptied, you must press on the nozzle (6) again to close the electromagnetic valve.

IMPORTANT NOTES

• Before the first use of the day, it’s necessary to wet the orange gasket with a little water before closing the lid, to protect it from accidental damage.

• Once the pressure setting is memorized, it will stay so for all other programs as well

• Do not set the pressure at values exceeding 6 bars

• If the dierence between the set temperature and the actual chamber temperature is below 10° C, it’s necessary to

hold the RUN/STOP button (2) for a few seconds to start a new cycle. The new cycle will start after an acoustic signal.

• Pressure will stay active until you manually release it. Do not open the machine lid until the temperature has gone below 100°C, as to not risk burns with boiling water.

• The machine is engineered for use in places up to 2000 m above sea level

• Maximum air humidity has to be below 80% for temperatures up to 31°, and goes down to 50% for temperatures from

40° C.

• If the machine is used with accessories that were not provided by the manufacturer, safety is compromised.

4. SAFETY RULES

• The following precautions must be observed to avoid damages to personnel or to the machine:

• The machine musn’t be used by an operator who hasn’t read the instructions

• Before plugging the machine in, make sure that the grid tension is the same as the work tension. In case of dicrepancy,

consult a specialist

• Under no circumstance tamper with and/or modify the machine

• The stickers and warnings must be kept in legible conditions and must not be removed

• In case of damages the machine must not be activated, in order to protect the user or bystanders.

• Keep the power cord away from sources of heat, oils or damaging objects

• When moving the machine, do not hold it by the cord

• Do not use spare parts that don’t come from the manufacturer

• Prevent the machine from falling or receiving hits

• To function correctly, the machine has to be heated. Be mindful of the possible explosion hazard, or toxic/combustible

gas emission hazard that derive from heating

This symbol warns you that there is dangerously high tension

This symbols guarantees that the machine conforms to the Low Tension and

Electromagnetic Compatibility Directive, and related norms

Rev. 10/2019

a.gree srl

Via Retrone 14, Altavilla Vicentina 36077 (VI) Italy

+39 0444 960 991 info@vertysystem.com

2/7

vertysystem.com

Instruction for use

Apolix

Electronic and automatic polymerizer

5. MAINTENANCE

• Avoid placing the machine next to sources of heat

• Don’t place objects on the machine

• Clean with a dampened cloth

• Change the safety fuses using only the following values: 6,3 A/250 V Class T

• Have only manufacturer authorized technicians perform any maintenance operation

• Lifting and transport of the machine must be done by picking it up manually

• Load or transport exclusively with the machine set vertically

6. THERMAL SAFETY

This machine has a thermal safety. If the temperature in the tank goes above 150° C a special component will stop any heating processes.

To reset to normal function one must:

1. Unplug the machine

2. Remove the left lateral lid

3. Push the red button on the thermal safety

4. Replace the lid and resume the work

7. TECHNICAL DATA

1. Power supply: 230 V, ±10%, 50Hz

2. Energy consumption: 1220 W

3. Tension category: II

4. Actual chamber volume: 1, 5 l

5. Inside dimensions: ø 140 – h 145 mm

6. Maximum pressure: 6 bars

7. Working temperature limits: 40° C – 120° C

8. Temperature and functioning areas: 2

9. Time limits: 1 min – 99 mins

10. Weight: 9,3 kg

11. Working temperature: 0° C – 40° C

12. Pollution level: 2

13. Outside dimensions: Depth: 300 mm

Width: 330 mm

Height: 240 mm

8. CONTENT

1. APOLIX polymerizer 1 pc

2. Flexible water release hose 1 pc

3. Spare fuses T 6,3 A/250 V 2 pcs

4. Instruction manual 1 pc

9. WARRANTY

a.gree srl guarantees to the customer the correct functioning of all the components and materials of this product for 12

months after the date of purchase. During this lapse of time a.gree srl or authorized personnel will repair any defect or

malfunction of the machine.

Any damage caused during transport, storing or handling of the product, or due to malfunction of the electric grid are the

user’s responsibility. This warranty is voided if any unauthorized personnel tries to make any repair or modification to the

machine.

Thank you for purchasing APOLIX!

This machine has been designed according to the latest industrial standards.

We wish you a pleasant working experience using APOLIX!

Rev. 10/2019

a.gree srl

Via Retrone 14, Altavilla Vicentina 36077 (VI) Italy

+39 0444 960 991 info@vertysystem.com

3/7

vertysystem.com

Loading...

Loading...