Vertiv Tech NetSure 731 C62 Series, NetSure 731 C62-X2, NetSure 731 C62-X1, NetSure 731 CC2-X4, NetSure 731 C62-X3 User Manual

...

NetSure 731 CC2、NetSure 731

C62 系列电源系统

用户手册

NetSure 731 CC2, NetSure 731 C62

Series Power Supply System

User Manual

资料版本 V2.0

归档时间 2017-12-31

BOM 编码 31013521

Version V2.0

Revision date December 31, 2017

BOM 31013521

维谛技术有限公司为客户提供全方位的技术

支持,用户可与就近的维谛技术有限公司办事

处或客户服务中心联系,也可直接与公司总部

联系。

维谛技术有限公司

版权所有,保留一切权利。内容如有改动,恕

不另行通知。

维谛技术有限公司

地址:深圳市南山区学苑大道 1001 号南山智

园 B2 栋

邮编:518055

公司网址:www.vertivco.com

客户服务热线:4008876510

E-mail: vertivc.service@vertivco.com

Vertiv Tech provides customers with technical

support. Users may contact the nearest Vertiv local

sales office or service center.

Copyright © 2017 by Vertiv Tech Co., Ltd.

All rights reserved. The contents in this document

are subject to change without notice.

Vertiv Tech Co., Ltd.

Address: Block B2, Nanshan I Park, No.1001

Xueyuan Road, Nanshan District, Shenzhen,

518055, P.R.China

Homepage: www.vertivco.com

E-mail: overseas.support@vertivco.com

Declaration

This is a Class A UPS product. In a residential environment, this product may nevertheless cause radio

interference, in which case, the user is required to take additional measures to reduce the interference.

Safety Precautions

To reduce the chance of accident, please read the safety precautions very carefully before operation. The

'Caution, Note, Warning, Danger' in this book and on the product do not represent all the safety points to be

observed, and are only supplement to various safety points. Therefore, the installation and operation personnel

must receive strict training and master the correct operations and all the safety points before operation.

When operating Vertiv products, the operation personnel must observe the safety rules in the industry, the

general safety points and special safety instructions provided by Vertiv.

Electrical Safety

I. Hazardous voltage

Danger

Danger

Some components of the power system carry hazardous voltage in operation. Direct contact or

indirect contact through moist objects with these components will result in fatal injury.

Observe safety rules in the industry when installing the power system. The installation personnel must be

licensed to operate high voltage and AC power.

In operation, the installation personnel are not allowed to wear conductive objects, such as watches, bracelets,

bangles and rings.

When you spot the cabinet with water or moisture, turn off the power immediately. In moist environment,

precautions must be taken to keep moisture out of the power system.

’Prohibit’ warning label m ust be attached to the switches and buttons that are not permi tted to operate during

installation.

Danger

Danger

High voltage operation may cause fire and electric shock. The connection and w iring of AC cables

must be in compliance with the local rules and regulations. Only those who are licensed to operate

high voltage and AC power can perform high voltage operations.

II. Tools

Warning

In high voltage and AC operation, specialized tools must be used.

III. Thunderstorm

Danger

Danger

Never operate on high voltage, AC, iron tower or mast in the thunderstorm.

In thunderstorms, a strong electromagnetic field will be generated in the air. Therefore the equipment should be

well earthed in time to avoid damage by lightning strikes.

IV. ESD

Note

The static electricity generated by the human body will damage the static sensitive elements on PCBs,

such as large-scale ICs. Before touching any plug-in board, PCB or IC chip, ESD w rist strap must be

worn to prevent body static from damaging the sensitive components. The other end of the ESD w rist

strap must be w ell earthed.

V. Short circuit

Danger

Danger

During operation, never short the positive and negative poles of the DC distribution unit of the

power system or the non-grounding pole and the earth. The power system is a constant-voltage

DC power device, short circuit will result in equipment burning and endanger human safety.

Check the polarity of the cable and connection terminal when performing DC live operations.

As the operation space in the DC distribution unit is very tight, please carefully select the operation space.

Never wear a watch, bracelet, bangle, ring, or other conductive objects during operation.

Use insulated tools.

In live operation, keep the arm, wrist and hand tense, so that when the tool in operation slips, the movement of

the human body and tool is reduced to a minimum.

Battery

Danger

Danger

Before any operation on battery, read carefully the safety precautions for battery transportation and

the correct battery connection method.

Note

If the power system does not connect with mains power for a long time, to prevent battery

over-discharge, users should cut batteries off from the pow er system thoroughly, for example, pulling

out battery fuses or switching off battery MCBs. Before putting the power system into operation, insert

all the battery fuses or switch on all the battery MCBs.

Non-standard operation on the battery will cause danger. In operation, precautions should be taken to prevent

battery short circuit and overflow of electrolyte. The overflow of electrolyte will erode the metal objects and PCBs,

thus causing equipment damage and short circuit of PCBs.

Before any operation on battery, pay attention to the following points:

1. Remove the watch, bracelet, bangle, ring, and other metal objects on the wrist.

2. Use specialized insulated tools.

3. Use eye protection device, and take preventive measures.

4. Wear rubber gloves and apron to guard against electrolyte overflow.

5. In battery transportation, the electrode of the battery should always be kept facing upward. Never put the

battery upside down or slanted.

LLVD And BLVD

The power system has battery low voltage disconnection (BLVD) function and load low voltage disconnection

(LLVD) function. LLVD means that the mains fail and batteries supply power, the controller cuts the non-priority

load off when the battery voltage drops down to below 44V. In this way, the battery remaining capacity can

sustain the priority load longer. BLVD means that the controller cuts the load off when the battery voltage drops

down to 43.2V to prevent over-discharge.

The factory setting is enabling LLVD and BLVD, which means that if power outage lasts for a long time or the

power system fails, there might be LLVD and BLVD. Users should classify the loads and connect the nonpriority loads to LLVD routes, and connect the priority loads to BLVD routes. For vital loads, users can disable

BLVD of these loads to insure reliability of the power supply.

The method of disabling BLVD is:

1. Hardware disabling: unplug the signal cable in J10 interface of the controller. Tag the BLVD-disabled label.

The position of the controller and the interface description are given in 2.4.2 Connecting Signal Cables.

2. Software disabling: set ‘BLVD Enable’ item of the controller to ‘N’.

Note

The advantage of enabling BLVD is protecting the batteries from over-discharge when the battery

voltage is low. The disadvantage of enabling BLVD is that when the battery voltage drops down to a

certain value, all the loads (including non-priority loads and priority loads) will be cut off due to battery

disconnection.

The advantage of software disabling BLVD is prolonging the power supply of priority loads. The

disadvantage is that software disabling cannot prevent unwanted power failure due to misoperation or

power system failure.

The advantage of hardware disabling BLVD is preventing unwanted power failure due to misoperation

or power system failure, and ensuring the continuity of vital loads’ power supply.

Others

I. Sharp object

Warning

When moving equipment by hand, wear protective gloves to avoid injury by sharp object.

II. Power cable

Note

Please verify the cable labels before connection.

III. Signal cables

Note

The signal cables should be routed at least 150mm aw ay from power cables.

Note

Note

To preserve the environment, the busbar of the power system may use tinning technique or

passivation technique. The busbar may become dark due to long-term operation, w hich does not

influence the performance or use of the power system.

Contents

Chapter 1 Overview ................................................................................................................................................................................1

1.1 Model Description ...................................................................................................................................................................1

1.2 Composition And Configuration ............................................................................................................................................1

1.3 Features....................................................................................................................................................................................6

1.4 Operating Principle .................................................................................................................................................................6

1.5 Functions ..................................................................................................................................................................................6

1.5.1 Lightning And Surge Protection ...............................................................................................................................6

1.5.2 LLVD And BLVD .........................................................................................................................................................8

1.5.3 Fault Alarm And Protection .......................................................................................................................................8

1.5.4 AC And DC Distribution .............................................................................................................................................8

1.5.5 Earthing Design ..........................................................................................................................................................9

Chapter 2 Installation Instruction ....................................................................................................................................................... 10

2.1 Safety Regulations............................................................................................................................................................... 10

2.2 Preparation............................................................................................................................................................................ 10

2.3 Mechanical Installation ........................................................................................................................................................ 11

2.3.1 Installing Power Cabinet......................................................................................................................................... 11

2.3.2 Installing Rectifiers .................................................................................................................................................. 12

2.4 Electrical Installation ............................................................................................................................................................ 12

2.4.1 Connecting Power Cables ..................................................................................................................................... 12

2.4.2 Connecting Signal Cables...................................................................................................................................... 14

2.4.3 Bottom Cabling Cabinet ......................................................................................................................................... 17

Chapter 3 Testing................................................................................................................................................................................. 19

3.1 Installation Check And Startup .......................................................................................................................................... 19

3.2 Basic Settings ....................................................................................................................................................................... 20

3.3 Alarm Check And System Operation Status Check ....................................................................................................... 20

3.4 Final Steps ............................................................................................................................................................................ 21

Chapter 4 Use Of The Controller....................................................................................................................................................... 22

4.1 Operation Panel ................................................................................................................................................................... 22

4.2 Main LCD Screens............................................................................................................................................................... 22

4.2.1 System Information Screen ................................................................................................................................... 22

4.2.2 Password Confirmation Screen............................................................................................................................. 23

4.2.3 MAINMENU Screen ................................................................................................................................................ 23

4.2.4 STATUS Screen ...................................................................................................................................................... 24

4.2.5 Settings Screen ....................................................................................................................................................... 24

4.2.6 Maintenance Screen ............................................................................................................................................... 24

4.2.7 Energy Saving Screen ............................................................................................................................................ 25

4.2.8 Fast Settings Screen............................................................................................................................................... 25

4.3 Querying System Main Information................................................................................................................................... 25

4.4 Querying Rectifier Status .................................................................................................................................................... 27

4.5 Querying Alarm Information ............................................................................................................................................... 27

4.5.1 Querying Active Alarm ............................................................................................................................................ 27

4.5.2 Querying History Alarm .......................................................................................................................................... 29

4.6 Maintenance ......................................................................................................................................................................... 29

4.7 Setting Parameters .............................................................................................................................................................. 30

4.7.1 Alarm Settings.......................................................................................................................................................... 30

4.7.2 Battery Settings ....................................................................................................................................................... 32

4.7.3 AC Settings............................................................................................................................................................... 37

4.7.4 DC Settings .............................................................................................................................................................. 37

4.7.5 Rectifier Settings ..................................................................................................................................................... 38

4.7.6 System Settings....................................................................................................................................................... 39

4.7.7 Communication Settings ........................................................................................................................................ 39

4.8 Energy Saving Settings....................................................................................................................................................... 40

4.9 Fast Settings ......................................................................................................................................................................... 41

Chapter 5 Technical Parameters of Rectifier .................................................................................................................................. 42

5.1 Appearance and Structure.................................................................................................................................................. 42

5.2 Functions And Features ...................................................................................................................................................... 43

5.3 Technical Parameters ......................................................................................................................................................... 46

Chapter 6 Troubleshooting ................................................................................................................................................................. 48

6.1 Handling Alarms ................................................................................................................................................................... 48

6.2 Handling Rectifier Fault....................................................................................................................................................... 49

6.3 Handling Controller Fault .................................................................................................................................................... 51

Appendix 1 Technical Data................................................................................................................................................................. 54

Appendix 2 Engineering Diagram...................................................................................................................................................... 57

Appendix 3 Parameter Setting Of The Controller ........................................................................................................................... 61

Appendix 4 Menu Structure Of The Controller ................................................................................................................................ 65

Appendix 5 Schematic Diagram ........................................................................................................................................................ 67

Appendix 6 Wiring Diagram................................................................................................................................................................ 69

Chapter 1 Overview 1

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Chapter 1 Overview

This chapter introduces the model description, composition and configuration, features, operating principle and

functions of the NetSure 731 CC2 and NetSure 731 C62 series power system (power system for short).

1.1 Model Description

Taking NetSure 731 CC2 power system as an example, the model description is given in Figure1-1.

Power system brand

Rectifier specification: G3 50A

Region: China

Max number of the rectifier: 12

Cabinet configuration type

System version: 2

NetSure

731

C

C

2

-

X1

Figure 1-1 Model description

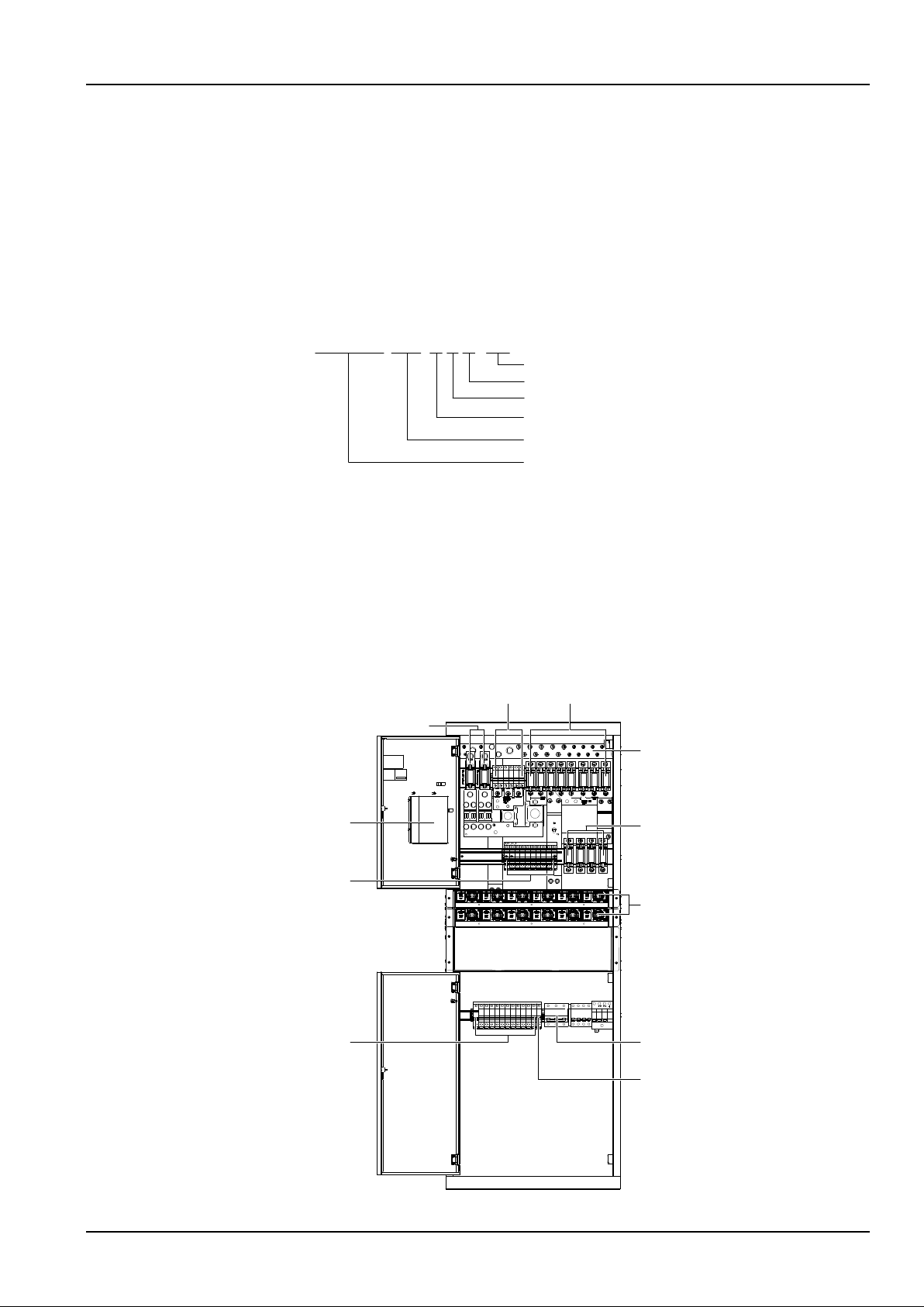

1.2 Composition And Configuration

Composition

The NetSure 731 CC2 power system has four models: NetSure 731 CC2-X1, NetSure 731 CC2-X2, NetSure 731

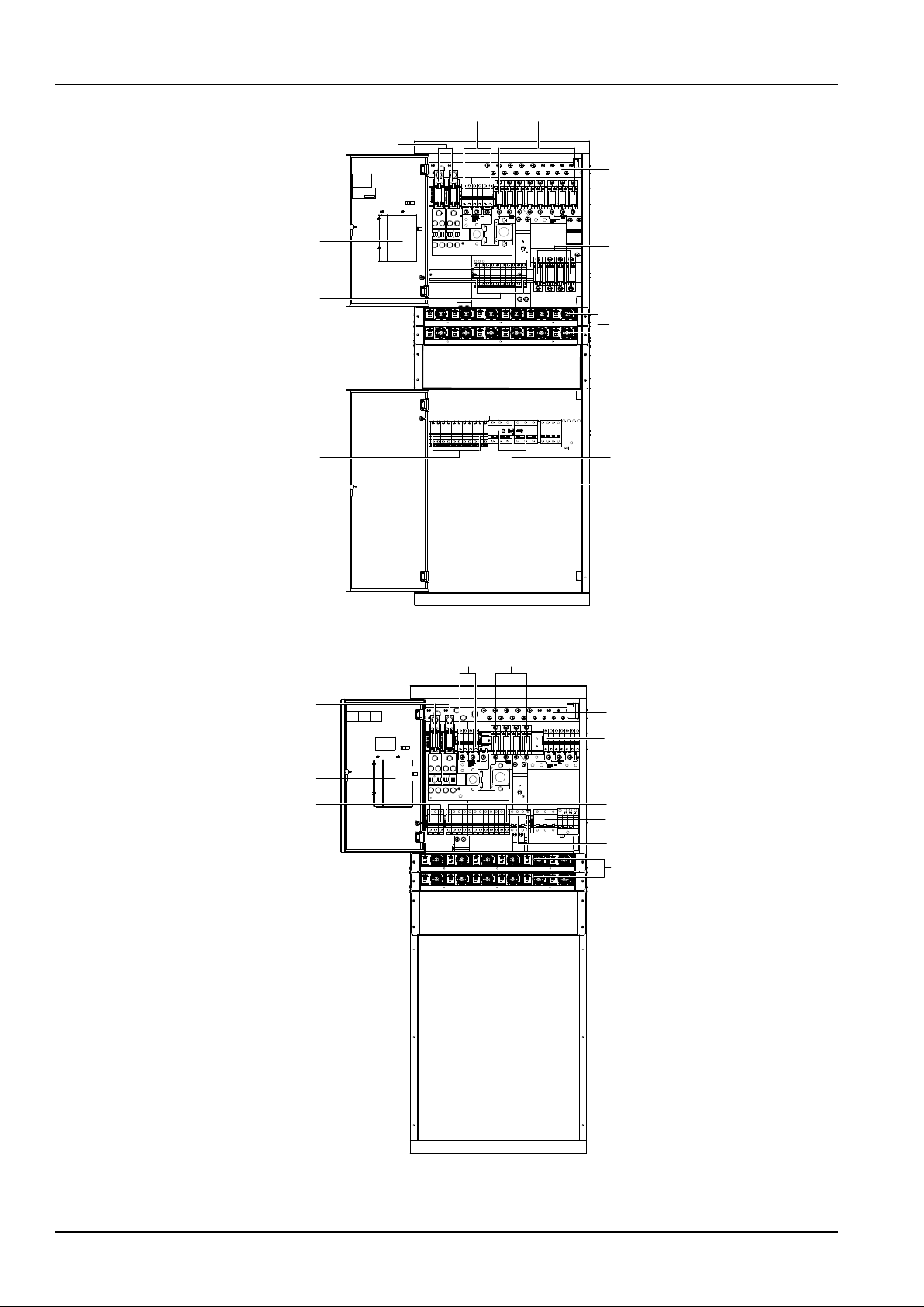

CC2-X3 and NetSure 731 CC2-X4. Figure 1-2 to Figure 1-5 illustrate the structure of the four models. NetSure 731

C62 has three models: NetSure 731 C62-X1, NetSure 731 C62-X2 and NetSure 731 C62-X3, the structure of this

model are shown in Figure 1-6 and Figure1-8.

Battery fuse

Priority load MCB Non- priority load fuse

DC output positive busbar

Rectifier

AC input MCB

controller

Non- priority load MCB

Rectifier MCB

Non- priority load fuse

AC output MCB

Figure 1-2 NetSure 731 CC2-X1 power system structure

2 Chapter 1 Overview

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Priority load MCB Non- priority load fuse

Battery fuse

controller

Non- priority load MCB

Rectifier MCB

DC output positive busbar

Rectifier

AC input MCB

Non- priority load fuse

AC output MCB

Figure 1-3 NetSure 731 CC2-X2 power system structure

Battery fuse

Controller

Priority load MCB

Non-priority load fuse

Non-priority load MCB

Rectifier

Rectifier MCB

AC output MCB

AC input MCB

DC output positive busbar

Non-priority load MCB

Figure 1-4 NetSure 731 CC2-X3 power system structure

Chapter 1 Overview 3

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Battery fuse

Controller

Priority load MCB

Non-priority load fuse

DC output positive busbar

Non-priority load MCB

Rectifier

Non-priority load MCB Rectifier MCB

AC output MCB

AC input MCB

Figure 1-5 NetSure 731 CC2-X4 power system structure

Priority load MCB Non- priority load fuse

Battery fuse

DC output positive busbar

Controller

Non- priority load MCB

Rectifier MCB

Rectifier

AC input MCB

AC output MCB

Figure 1-6 NetSure 731 C62-X1 power system structure

4 Chapter 1 Overview

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Battery fuse

Priority load MCB Non- priority load fuse

DC output positive busbar

Controller

Non- priority load MCB

Rectifier MCB

AC input MCB

Rectifier

AC output MCB

Figure 1-7 NetSure 731 C62-X2 power system structure

Priority load MCB

Battery fuse

controller

Non- priority load MCB

DC output positive busbar

AC input MCB

Non- priority load fuse

AC output MCB

Module MCB

Rectifier MCB

Figure 1-8 NetSure 731 C62-X3 power system structure

Chapter 1 Overview 5

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Configuration

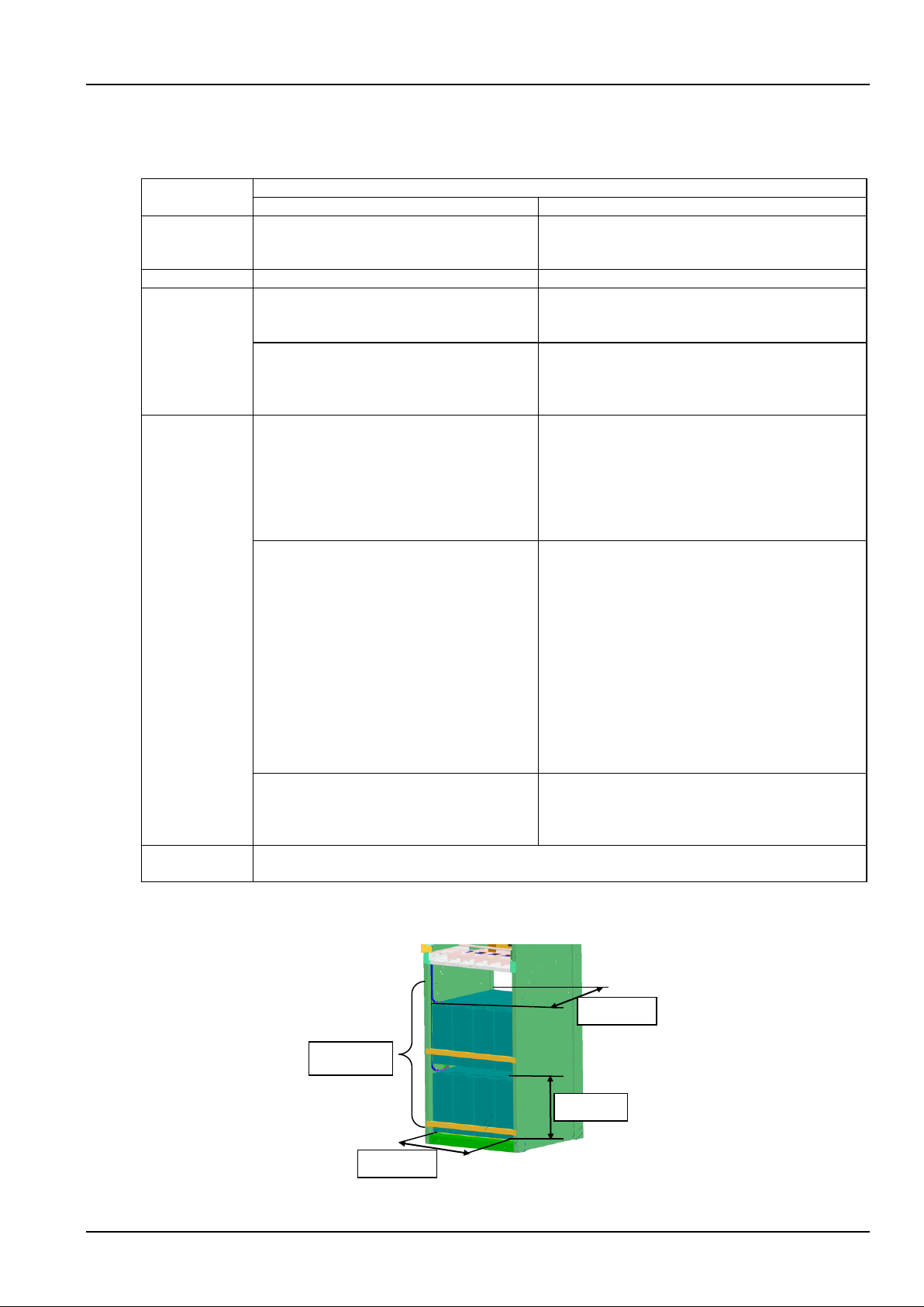

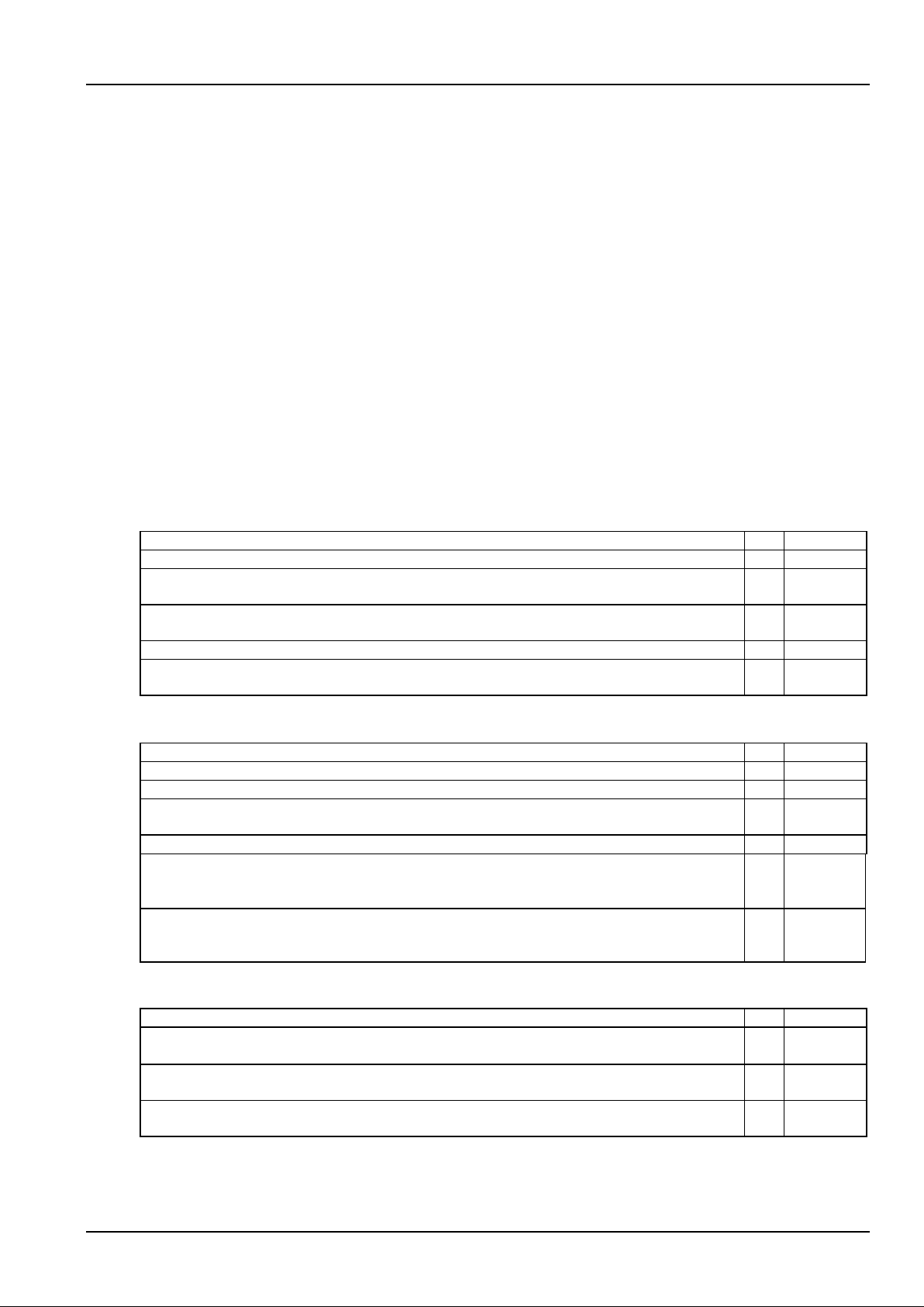

(1) The configuration of the power system is listed in Table 1-1.

Table 1-1 Power system configuration

Component

Configuration

NetSure 731 C62

NetSure 731 CC2

Rectifier

Model: R48-3000e3

Standard: 6 pcs

Optional: 2 ~ 6 pcs

Model: R48-3000e3

Standard: 12 pcs

Optional: 2 ~ 12 pcs

Controller

Model: M522S; Standard: 1 pcs

Model: M522S; Standard: 1 pcs

AC distribution

AC input:

NetSure 731 C62-X1, X2, X3: 1 × 63A/3P MCB

AC input:

NetSure 731 CC2-X1, X3, X4: 1 × 100A/3P MCB

NetSure 731 CC2-X2: 2 × 100A/3P MCB

AC output:

NetSure 731 C62-X1, X2: 1 × 16A/1P MCB

NetSure 731 C62-X3: 1 × 16A/1P MCB, 1 ×

16A/3P MCB

AC output:

NetSure 731 CC2- X1, X2: 1 × 16A/1P MCB

NetSure 731 CC2- X3, X4: 1 × 16A/3P MCB,

1 × 16A/1P MCB

DC ditribution

Priority load output:

NetSure 731 C62-X1: 2 × 32A/1P MCB,

2 × 10A/1P MCB

NetSure 731 C62-X2: 2 × 32A/1P MCB,

2 × 10A/1P MCB

NetSure 731 C62-X3: 2 × 32A/1P MCB,

2 × 16A/1P MCB

Priority load output:

NetSure 731 CC2-X1/X2: 2 × 32A/1P MCB, 4 × 10A/1P

MCB

NetSure 731 CC2-X3: 4 × 16A/1P MCB

NetSure 731 CC2-X4: 2 × 63A/1P MCB, 2 × 32A/1P

MCB,

2 × 10A/1P MCB

Non-priority load output:

NetSure 731 C62-X1:

4 × 100A fuse, 4 × 63A/1P fuse,

4 × 32A/1P MCB,

2 × 10A/1P MCB

NetSure 731 C62-X2:

4 × 100A fuse, 4 × 63A fuse,

4 × 32A/1P MCB,

2 × 10A/1P MCB

NetSure 731 C62-X3:

4 × 100A fuse,

4 × 63A/1P MCB,

6 × 32A/1P MCB

Non-priority load output:

NetSure 731 CC2-X1/X2:

6 × 100A fuse, 6 × 63A fuse, 6 × 32A/1P MCB,

4 × 16A/1P MCB

NetSure 731 CC2-X3:

4 × 100A fuse, 4 × 63A/1P MCB, 6 × 32A/1P MCB

NetSure 731 CC2-X4:

4 × 100A fuse, 6 × 63A fuse, 2 × 32A/1P MCB,

2 × 16A/1P MCB

Battery branch circuit:

NetSure 731 C62-X1: 2 × 250A fuse

NetSure 731 C62-X2: 2 × 250A fuse

NetSure 731 C62-X3: 2 × 250A fuse

Battery branch circuit:

2 × 500A fuse

Optional parts

Top cover, temperature sensor and modem, front and back cover plate (NetSure 731 C62-X2), Battery cable

(NetSure 731 C62-X2)

(2) NetSure 731 C62-X2 power system is configured with two layers of battery rack, the battery compartment space is

shown in Figure 1-9.

Figure 1-9 Battery compartment structure

330mm

570mm

535mm

Tw o layers

6 Chapter 1 Overview

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

1.3 Features

The rectifier uses the active Power Factor Compensation (PFC) technology, raising the power factor to 0.99

The power supply system has wide AC input voltage range: 90Vac ~ 300Vac

The rectifier uses soft switching technology, raising the efficiency up to 95%

The rectifier is of High power density

The rectifier is hot pluggable. It takes less than 1min to replace a rectifier

The rectifier has two optional over-voltage protection methods: hardware protection and software protection. The

latter one also has two optional modes: lock-out at the first over-voltage and lock-out at the second over-voltage

The power system has perfect battery management function. The management functions include BLVD, LLVD,

temperature compensation, auto voltage regulation, stepless current limiting, battery capacity calculation and

on-line battery test, etc

The power system can save up to 200 pieces of historical alarm records, and 10 sets of battery test data records

The power system is of network design. Providing multiple communication ports (such as RS232, modem and

dry contacts), which enables flexible networking, remote monitoring and unmanning

The power supply system has perfect lightning protection at both AC side and DC side

The power supply system has complete fault protection and fault alarm functions

1.4 Operating Principle

The AC mains comes out from the AC distribution unit and is distributed to each rectifier. After rectification, the -48V

DC current from each rectifier flows to the DC distribution unit through busbar, and then multiple outputs of the DC

distribution unit provide power for communication equipment. Normally, the system operates in parallel float charge

state, that is, the rectifiers, load and batteries work in parallel; besides powering the communication equipment, the

rectifiers provide float charge for the batteries. In case of mains failure, the rectifiers will stop working, and the

batteries begin to supply power to communication equipment. When the AC mains recovers, the rectifiers will resume

supplying power to communication equipment and charging the batteries.

Using centralized monitoring mode, the controller module manages the AC distribution unit and DC distribution unit. It

also receives the operating data of the rectifiers and controls them accordingly through CAN mode. The controller can

be connected to a local computer using the RS232 port. The power system can be connected to the monitoring

center through connecting a modem or other transmission resources (such as PSTN and so on) to achieve remote

monitoring.

For the detailed schematic diagram of the power system, see Appendix 5 Schematic Diagram.

1.5 Functions

Main functions of the power system include:

Lightning and surge protection.

LLVD and BLVD.

Fault alarm and protection.

AC and DC distribution.

Perfect earthing design.

1.5.1 Lightning And Surge Protection

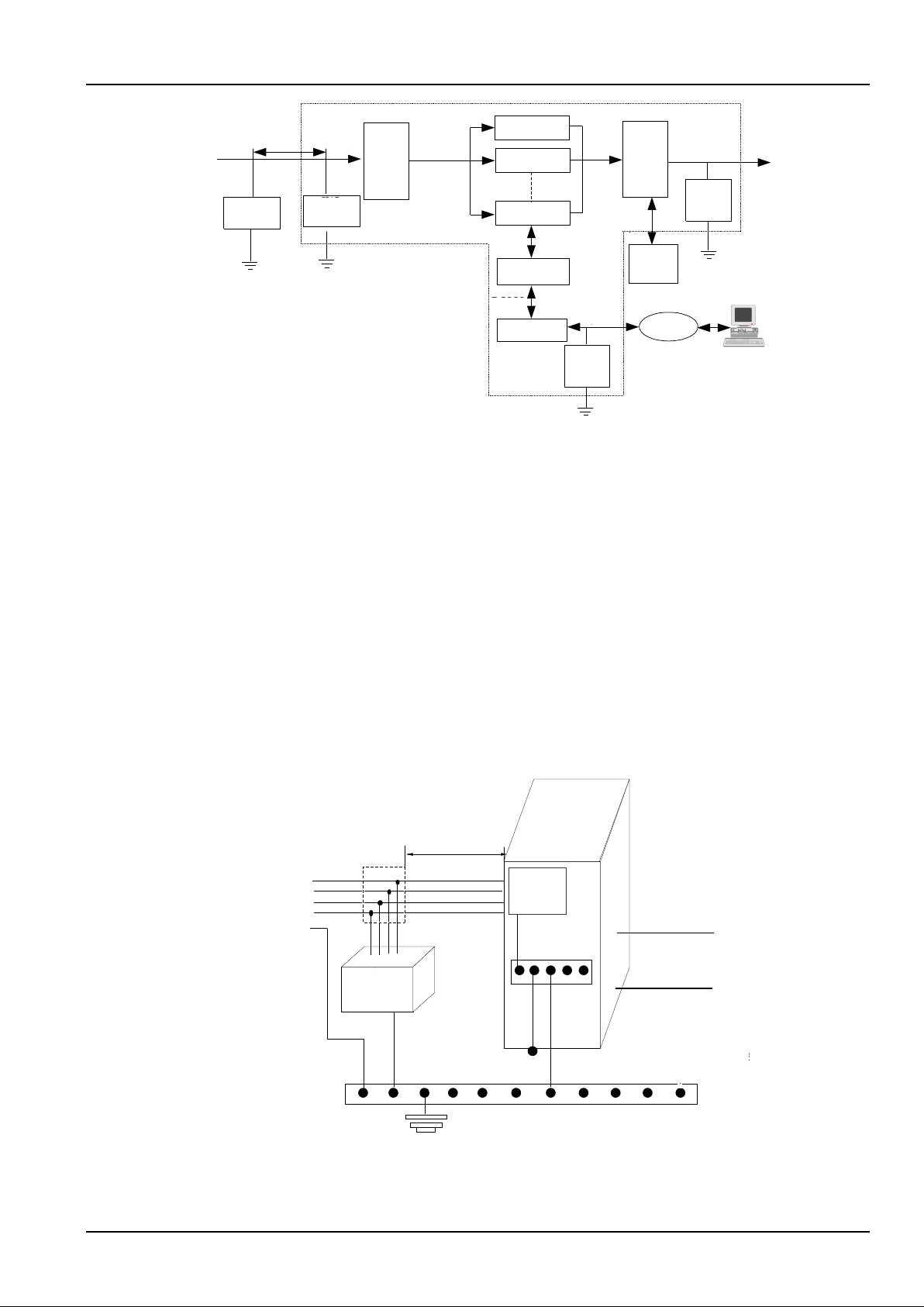

The power system is equipped with lightning protection at both the AC side and the DC side. The lightning protection

system is shown in Figure 1-10.

Chapter 1 Overview 7

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

交流输入

整流模块

整流模块

整流模块

交流

配电

单元

直流

配电

单元

监控模块

电池组

1、2

I/B

防雷器

DC

防雷器

Modem

RJ11

防雷器

-48V输出

RS232

RJ11

5m~10m

PSTN

远程后台监控

注:I,II,III级是IEC标准的分类方法

B,C,D级是德国VDE标准的分类方法

II/C

防雷器

AC input

5m ~ 10m

I/B SPD

II/C SPD

AC

distribution

unit

Rectifier

Rectifier

Rectifier

Controller

RS232

Modem

RJ11

RJ11

SPD

DC

distributi

on unit

DC

SPD

Battery

string

1, 2

PSTN

Remote host

- 48V output

Note:Classes I,II,III are IEC atandard,

classes B, C, D are VDE Geman standards.

Figure 1-10 Lightning protection system

The power system is equipped with a Class II/C SPD. Meanwhile, each module of the system has perfect lightning

protection circuit. The system can withstand simulated lightning surge currents of 20kA at 8/20μs five times, and

40kA at 8/20μs once. To prevent higher lightning strikes from damaging the equipment, it is recommended to install a

higher protective Class I/B SPD in the cable inlet of the equipment room (lightning surge current is at least 60kA, refer

to YD/T5098-2001 Signal station lightning overvoltage protection engineering design standard).

To prevent lightning strikes at the DC side from damaging the equipment, an effective lightning protection device is

provided, which can withstand simulated lightning surge currents of 10kA and 15kA at 8/20μs once respectively. To

prevent conductive lightning strike from damaging the modem port of the controller, the power system provides

lightning protection (optional) for the modem port. The SPD can withstand a 5kA lightning surge current at 8/20s and

a 4kV lightning surge voltage at 10/700s.

The power system has perfect lighting protection at both AC side and DC side. The power system is equipped with a

Class II/C SPD at AC side and SPD at DC side. To achieve better lightning protection at AC side, it is recommended

to mount a Class I/B SPD, lightning surge current is at least 60kA. The Class I/B SPD should be purchased by the

user. Refer to YD/T5098-2001 Signal station lightning overvoltage protection engineering design standard for the

detailed technical rules. The Class I/B SPD installation is shown in Figure 1-11.

48Vdc

+

-

A

B

C

N

PE

5m ~ 10m

Class-B

SPD

SPD

DC earth

Protective earth cable

User earth bar

System earth bar

Protective earth

Power supply

system

SPD earth

SPD earth

DC earth cable

240Vdc

Class-C

SPD

240Vdc

First

Class-B

SPD

Power system

-48Vdc

+

-

lever 1 SPD

(Class B)

Lever

Class

Lever 1

(Class B)

SPD

Lever 2

(Class C)

SPD

Level 1

Level 2

Figure 1-11 Diagram of Class I/B SPD mounting & system earthing

The Class I/B SPD should be purchased and mounted by the user. If condition permits, it is recommended that the

cable length between the Class I/B SPD and the power system meet the following rules: if a voltage limiting type SPD

8 Chapter 1 Overview

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

is used, then the cable length should be longer or equal than 5m; if a switching type SPD is used, then the cable

length should be longer or equal than 10m. The cable between the Class I/B SPD and the input terminals of the AC

distribution unit of the power system should be routed indoors to avoid direct lightning strike. The output cable CSA of

the Class I/B SPD and the grounding cable CSA should not be less than 16mm2. For the cable length, the shorter the

better.

The power system has lighting protection at DC side, which can meet YD/T5098 requirements. There’s no need to

design lighting protection at DC side.

1.5.2 LLVD And BLVD

In case of mains failure, the rectifiers will stop working and the batteries will begin to discharge and power the load.

When the battery voltage falls to the low voltage alarm point 45.0V (adjustable), the system will give audible/visual

alarm. When the battery voltage continues to fall and reaches the LLVD point 44.0V (adjustable), the LLVD contactor

will open, cutting off the power supply for the non-priority loads connected to the LLVD output branches thus the

power supply to priority load can be prolonged. As the batteries discharge, the battery voltage continues to fall. When

it reaches the BLVD point 43.2V (adjustable), the BLVD contactor will open, and the battery discharge will come to an

end. Thus the power supply to all loads is stopped, protecting the battery from being damaged due to over-discharge.

When the mains recovers and the rectifier output resumes normal functioning, the LLVD and BLVD contactors will

automatically close, and the system will resume normal operation.

1.5.3 Fault Alarm And Protection

The power system provides perfect fault alarm and protection functions. The system operating data can be collected

and the states of the load MCBs, load fuses, battery fuses and Level 2 (class C) SPD can be detected by the

controller. The alarm level can be set and audible/visual alarms can be selected for the system alarms, such as AC

input over/under voltage, DC output over/under voltage, fuse alarm, float charge and equalized charge status, rectifier

fault and protection alarm. The alarm type can be configured to correspond to dry contact relay output.

1.5.4 AC And DC Distribution

The functions of AC distribution are as follows:

The AC input uses 3-pole MCB, and has short circuit and over-current protection.

The AC input has overvoltage and undervoltage protection.

See Table 1-2 for the functions of the AC input and output interfaces of the power system.

Table 1-2 Functions of AC input and output interfaces

Interface

Functions

AC input MCB

To AC power supply; switchable

AC output MCB

Provides phase line terminal of AC; used to power other AC equipment

AC input neutral line busbar

To the neutral line of the 3-phase AC input

Earth terminal

The junctions of the protection earth, SPD earth, operation earth of the power system; need

connect to the earth bar of the equipment room

The functions of DC distribution are as follows:

Output load branch has short circuit and over-current protections, and branch capacity can be adjusted

according to user requirements.

Battery input uses fuse which has functions like short circuit, over-current protection, alarm and fault status

detection.

Battery current detection.

DC output overvoltage, undervoltage alarm functions.

See Table 1-3 for the functions of the DC input and output interfaces of the power system.

Table 1-3 Functions of DC input and output interface functions

Interface

Functions

Battery 1 fuse

To negative terminal of the battery string 1

Chapter 1 Overview 9

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Interface

Functions

Battery 2 fuse

To negative terminal of the battery string 2

DC output positive busbar

To positive terminal of battery string 1 and 2, and load output positive terminal

Priority load MCB

Negative terminal of 48V supply for priority load. Cut off the priority load output when the battery

voltage drops to the BLVD point

1.5.5 Earthing Design

Protective earth, SPD earth, and DC operation earth of the power system have been connected to the earth bar

before it is delivered. During the installation, user should connect the grounding terminal to the user earth bar of the

equipment room, as shown in Figure 1-11.

The protective earth cable of 3-phase 5-line system can be directly connected to the earth bar of the equipment room.

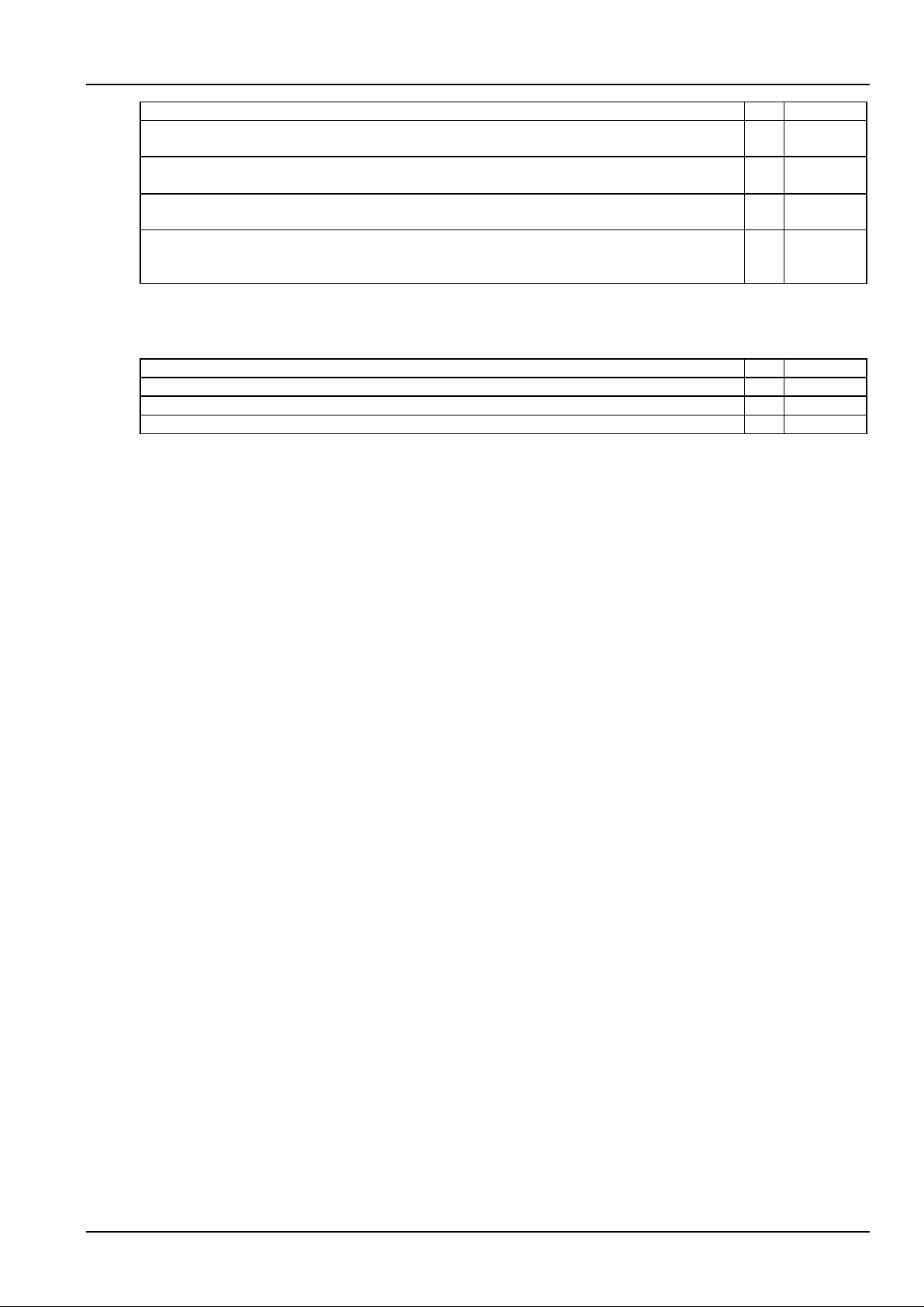

The earth resistance should be in accordance with the specifications listed in Table 1-4.

Table 1-4 Earth resistance requirements for communication station

Earth

resistance

Application range

Basis

< 1Ω

Integrated building, international telecom bureau, tandem station, SPC sw itching

office above 10000 lines, toll office above 2000 lines

YDJ20-88 Provisional

technical regulations of

computerized telephone

sw itching equipment

installation and design

< 3Ω

SPC switching office above 2000 lines and below 10000 lines, toll office below

2000 routes

< 5Ω

SPC switching office with less than 2000 lines, optical cable terminal station,

carrier w ave repeating station, earth station, microwave junction center, mobile

communication machine station

< 10Ω

Microwave relay station, optical cable relay station, small-sized earth station

YD2011-93 Microwave station

lightning protection and

grounding design

specifications

< 20Ω

Microwave passive relay station

< 10Ω

Suitable for those w hose earth resistance rate is less than 100Ω·m, SPD earth in

the interface between electric cable and aerial electric line

GBJ64-83 Industrial and civil

electrical device overvoltage

protection design specification

< 15Ω

Suitable for those whose earth resistance rate is 100-500Ω·m, SPD earth in the

interface between electric cable and aerial electric line

< 20Ω

Suitable for those whose earth resistance rate is 501-1000Ω·m, SPD earth in the

interface between electric cable and aerial electric line

10 Chapter 2 Installation Instruction

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Chapter 2 Installation Instruction

This chapter introduces installation and cable connection. Before installation, please read through the safety

regulations, and then follow the instructions in this chapter to carry out the installation and connection.

2.1 Safety Regulations

Certain components in this power system carry hazardous voltage and current. Always follow the instructions below:

1. Only adequately trained personnel with satisfactory knowledge of the power supply system can carry out the

installation. The Safety Precautions listed before the Contents of this manual and local safety rules in force shall be

adhered to during the installation.

2. All external circuits that are below -48V and connected to the power system must comply with the requirements of

SELV defined in IEC 60950.

3. Make sure that the power (mains and battery) to the power system is cut off before any operations can be carried

out within the cabinet.

4. The power system shall be kept locked and placed in a locked room. The key keeper should be the one

responsible for the power system.

5. The wiring of the power distribution cables should be arranged carefully so that the cables are kept away from the

maintenance personnel.

2.2 Preparation

Unpacking Inspection

The equipment should be unpacked and inspected after it arrives at the installation site. The inspection shall be done

by representatives of both the user and Vertiv Tech Co., Ltd. To inspect the equipment, you should open the packing

case, take out the packing list and check against the packing list that the equipment is correct and complete. Make

sure that the equipment is delivered intact.

Note

1. When delivered with the cabinet, the rectifier should be placed at the bottom of the cabinet subrack.

2. If the system need to configure fuse extractor, it should be strapped at the he bottom of the cabinet subrack.

Cable Preparation

The cable should be selected in accordance with relevant industry standards.

It is recommended to use the RVVZ cables as AC cables. The cable should reach at least 70°C temperature

durability. Select the AC cable CSA according to Table 2-1.

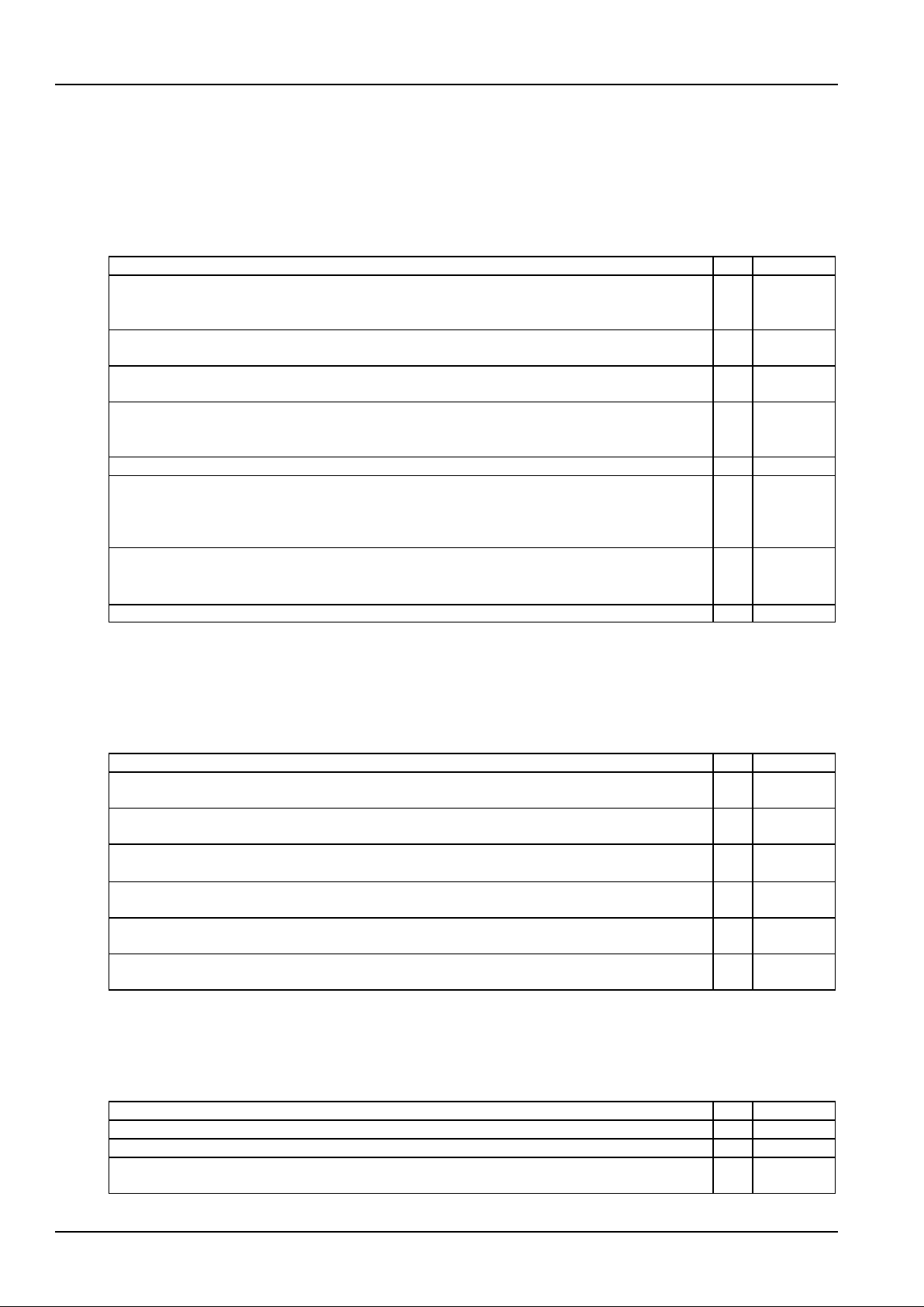

Table 2-1 AC cable CSA selection

Connector

Specifications

AC cable CSA

AC input MCB

1 × 63A/3P MCB, 3 H-shape tubal terminals

≤ 35mm2

AC input neutral busbar

1 M8 tubal OT terminal

≤ 25mm2

AC output MCB

1 × 16A/1P MCB, one H-shape tubal terminal

(CC2-X1/X2, C62-X1/X2)

≤ 10mm2

1 × 16A/3P MCB and 1 × 16A/1P MCB, 4 H-shape tubal terminals

(CC2-X3/X4, C62-X3)

AC output neutral busbar

2 M6 screws

Note: With cable length shorter than 30m, the CSA calculation should be based on the current density of 2.5A/mm2. The

suggested CSA value is not smaller than 15mm2

The CSA of DC cable depends on the current flowing through the cable, the allowable voltage drop and load peak

current. The recommended load peak current is 1/2 to 2/3 as large as the MCB or fuse capacity.

Chapter 2 Installation Instruction 11

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Select the battery cable CSA according to Table 2-2. Select the load cable CSA according to Table 2-3.

Table 2-2 Battery cable CSA selection

Battery fuse

rated current

Max. battery

current

Min. CSA

Max. cable

length (voltage

drop: 0.5V)

Max. cable

CSA

Max. cable length (volt

drop: 0.5V, with max.

CSA)

500A

400A

95mm2 (two) or 185mm2

14m

240mm2

20m

300A

200A

70mm2

9m

120mm2

15m

250A

160A

70mm2

10m

120mm2

15m

Note:

1. The specs are applicable at ambient temperature of 25°C. If the temperature is too high, the CSA should be increased.

2. The battery cable should reach at least 90°C heat durability. It is recommended to use double-insulated copper-core

flame-retardant cable as battery cable

Table 2-3 Load cable CSA selection

Load route

rated current

Max. output

current

Min. CSA

Max. cable length (volt

drop: 0.5V, with min.

CSA)

Max. CSA

Max. cable length (volt

drop: 0.5V, with max.

CSA)

160A

120A

50mm2

9m

95mm2

17m

100A

50A

25mm2

14m

50mm2

25m

63A

32A

16mm2

7m

25mm2

11m

32A

16A

16mm2

14m

25mm2

22m

10A

5A

6mm2

17m

25mm2

71m

Note: The specs are applicable at ambient temperature of 25°C. If the temperature is too high, the CSA should be increased

The CSA of the system grounding cable should be the same as that of the largest power distribution cable and not

less than 35mm2. The grounding terminal of the grounding busbar is M10 screw.

2.3 Mechanical Installation

2.3.1 Installing Power Cabinet

The power cabinet must be installed directly onto the cement floor, and kept far away from combustible materials.

1. Mark the specific installation position of the cabinet

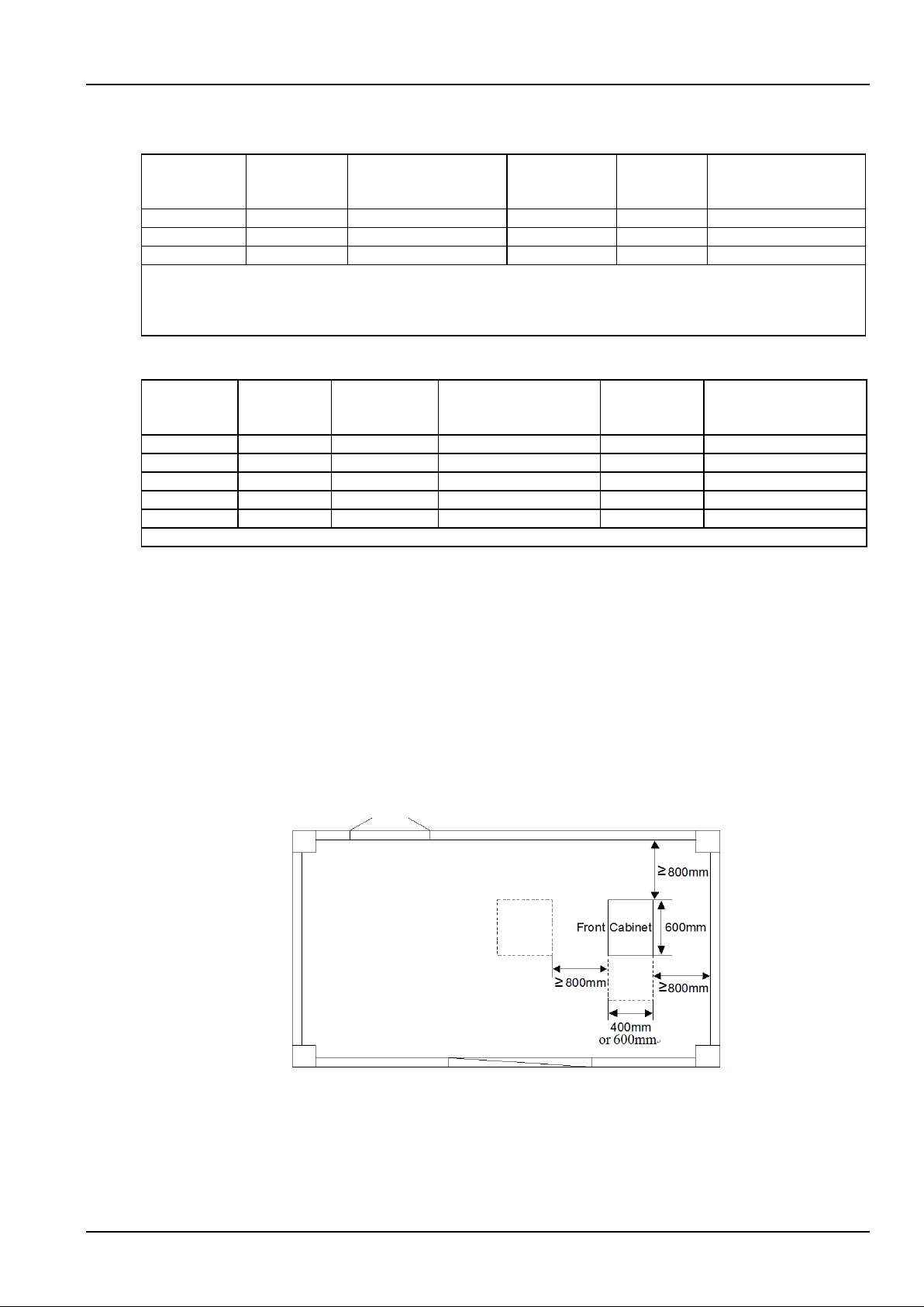

Determine the installation position of the power cabinet in the equipment room according to Figure 2-1. (the depth of

NetSure 731 C62-X2 cabinet is 600mm)

Figure 2-1 Locating power cabinet

12 Chapter 2 Installation Instruction

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

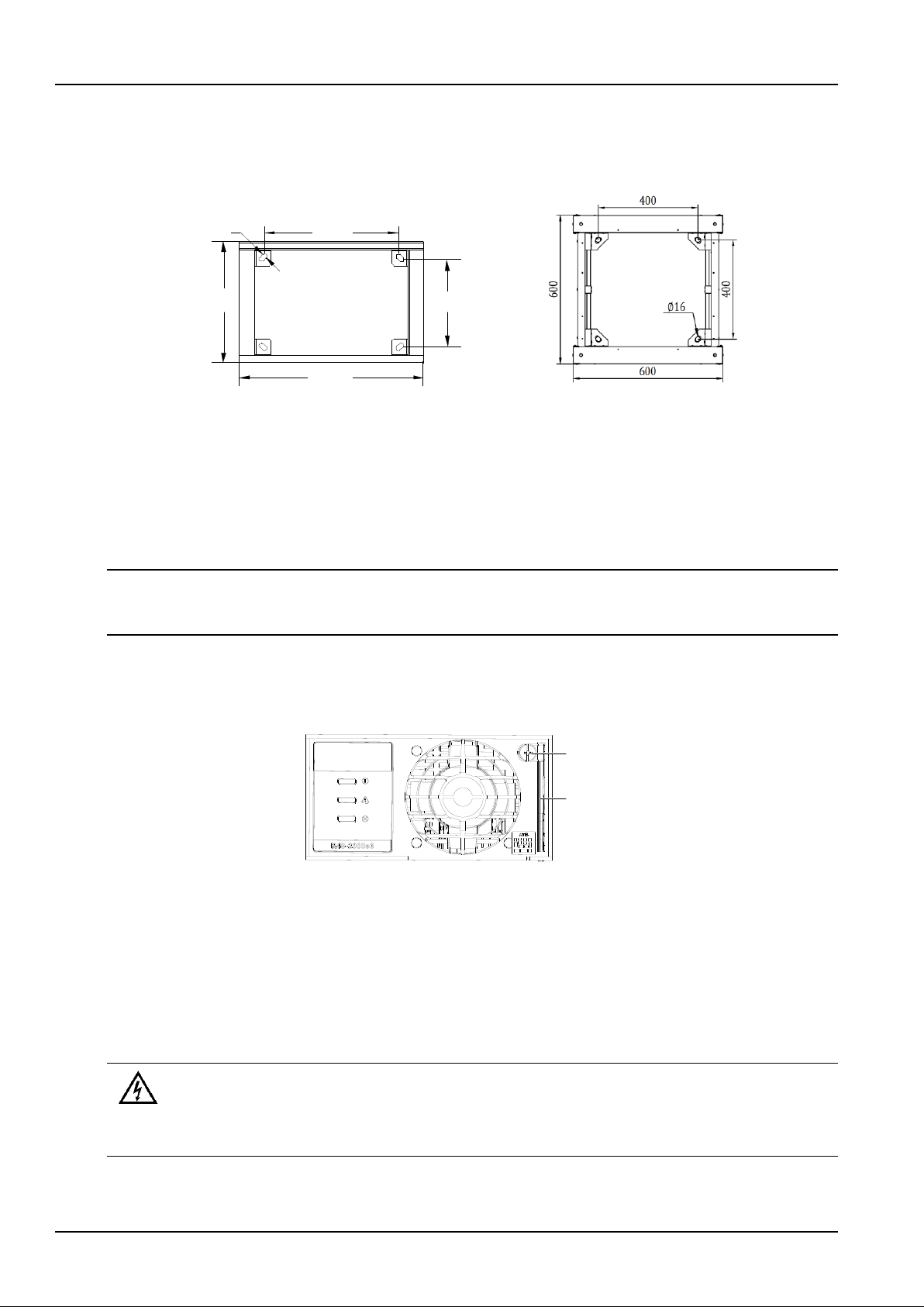

2. Install expansion pipe

According to Figure 2-2, determine the exact central points of the installation holes on the floor, and mark them with a

pencil or oil pen. Use the electric drill (aiguille: Φ14) to drill holes (depth: 70mm) at the marked points. Clean the

drilled hole of dust. Put the expansion pipe into the hole and knock it with a hammer till it is totally in.

18

436

400 300

600

NetSure 731 CC2 & NetSure 731 C62-X1/X3 NetSure 731 C62-X2

Figure 2-2 Installation size of the cabinet base (unit: mm)

3. Fix the cabinet

Move the cabinet to the installation position. Align the installation holes on the cabinet with the expansion pipes in the

floor. Secure the cabinet with bolts.

2.3.2 Installing Rectifiers

Note

1. In the non-full-configuration, install dummy plates at empty slots.

2. When installing the rectifier, hold the handle and push the rectifier into the slot gently, otherwise the slot may be damaged.

The procedures for installing rectifiers are as follows:

1. After loosing the fixing screw of the handle on the front panel of the rectifier, press the handle (see Figure 2-3) to

pop it up.

Handle

Fixing screw

Figure 2-3 Handle of the rectifier

2. Put the rectifiers in the slot. Push the rectifier completely into the cabinet. Close the handle and tighten the fixing

screw to lock the rectifiers onto the cabinet.

2.4 Electrical Installation

2.4.1 Connecting Power Cables

Danger

Danger

1. Switch off all MCBs and pull out all fuses before the electrical connection.

2. Only qualified personnel shall do the power cable connection.

The power systems uses top cabling, and all the cables should be introduced in or led out along the cable binding

beam in the side wall of the cabinet.

Chapter 2 Installation Instruction 13

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Connecting grounding cable

Connect one end of the grounding cable to the user earth bar of the equipment room, and the other end to the

grounding terminal of the power system. Put the cable through the fixing holes at the top of the cabinet. Use the cable

ties to fix the modem on the top of the cabinet, as shown in Figure 2-8. Taking NetSure 731 CC2-X3/X4 and NetSure

731 C62-X1 power system as an example, the grounding terminal is shown in Figure 2-4. The grounding terminal and

neutral busbar of the NetSure 731 CC2-X1、X2 power system are located under the rectifier subrack. The grounding

terminal position of NetSure 731 C62- X2 and NetSure 731 C62-X1/X3 is same as that of the neutral line busbar.

接地端子

零线母排

Neutral line busbar

Earth terminal

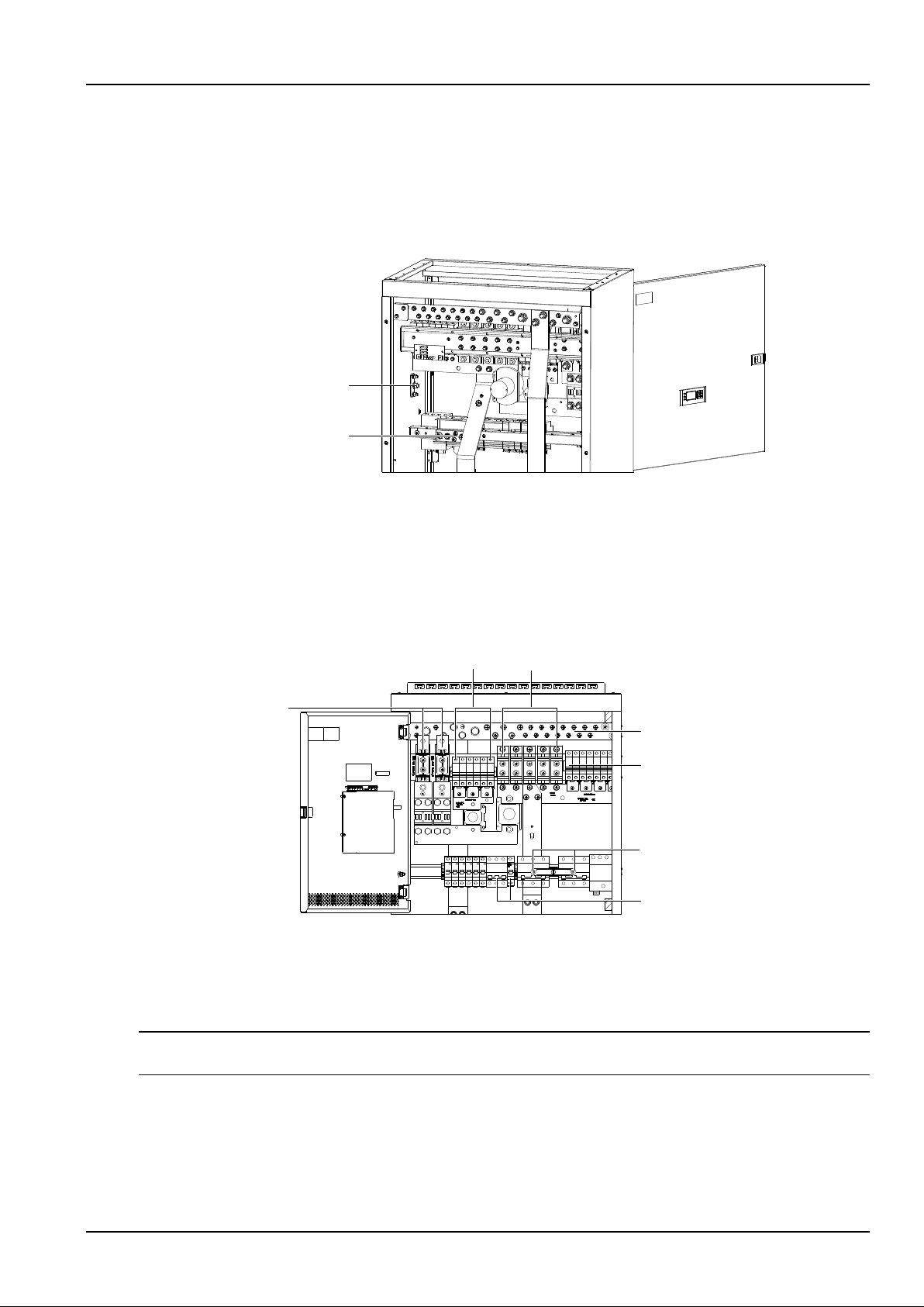

Figure 2-4 Connection terminals (rear view, rear plate removed)

Connecting AC cables

1. Connect the AC input phase cables to the AC input MCBs, as shown in Figure 2-5.

The figure shows the two routes of mains input MCB configuration. NetSure 731 CC2-X3, X4 and NetSure 731

C62-X1, X2, X3 power system only configure one route of mains input MCB, the AC input MCB is shown in Figure

2-5. The AC input MCB, AC output MCB and rectifier MCB of the NetSure 731 CC2-X1, X2 power system are located

in the distribution room below the rectifier subrack.

非重要负载熔断器

重要负载空开

直流输出正母排

电池熔断器

交流输出空开

交流输入空开

非重要负载空开

Priority load MCB

Non-priority load fuse

DC output positive busbar

Non-priority load MCB

AC input MCB

AC output MCB

Battery fuse

Figure 2-5 Connection terminals (front view)

2. If the power system is configured with AC output MCB, connect the AC out cables to the AC output MCB, and

connect the AC out neutral line to the neutral busbar, as shown in Figure 2-4 and Figure 2-5.

Connecting load cables

Note

The total capacity of the priority loads should not exceed 100A.

Connect the negative load cable to the upper terminal of the load MCB or load fuse. Connect the positive load cable

to the DC positive busbar, as shown in Figure 2-5. The specifications of the positive busbar connection screw are ¢

8mm and ¢6mm. Please connect the load cable according to the priority load and non-priority load labels.

14 Chapter 2 Installation Instruction

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Connecting battery cables

Note

1. The batteries may have dangerous current. Before connecting battery cables, make sure that the battery fuses at the system side

and the battery MCBs at the battery side are switched off. If there are no battery MCBs at the battery side, users should

disconnect any one of the connectors between battery cells to avoid live state of the power system after installation.

2. Be careful not to reversely connect the battery. Otherwise, both the battery and the power system will be damaged!

3. When the load capacity exceeds 200A, it is recommended to connect two routes of batteries.

1. Connect one end of the negative battery cable to the upper terminal of the battery fuse. Connect one end of the

positive battery cable to the DC positive busbar. The positions of the connection terminals are shown in Figure 2 -5.

The specifications of the positive busbar connection screw is ¢10mm.

2. Connect OT lugs to the other end of the two battery cables. Wrap all the bare parts with insulating tape, and put

them beside the battery. Do not connect the cables to the battery until the DC distribution unit is to be tested.

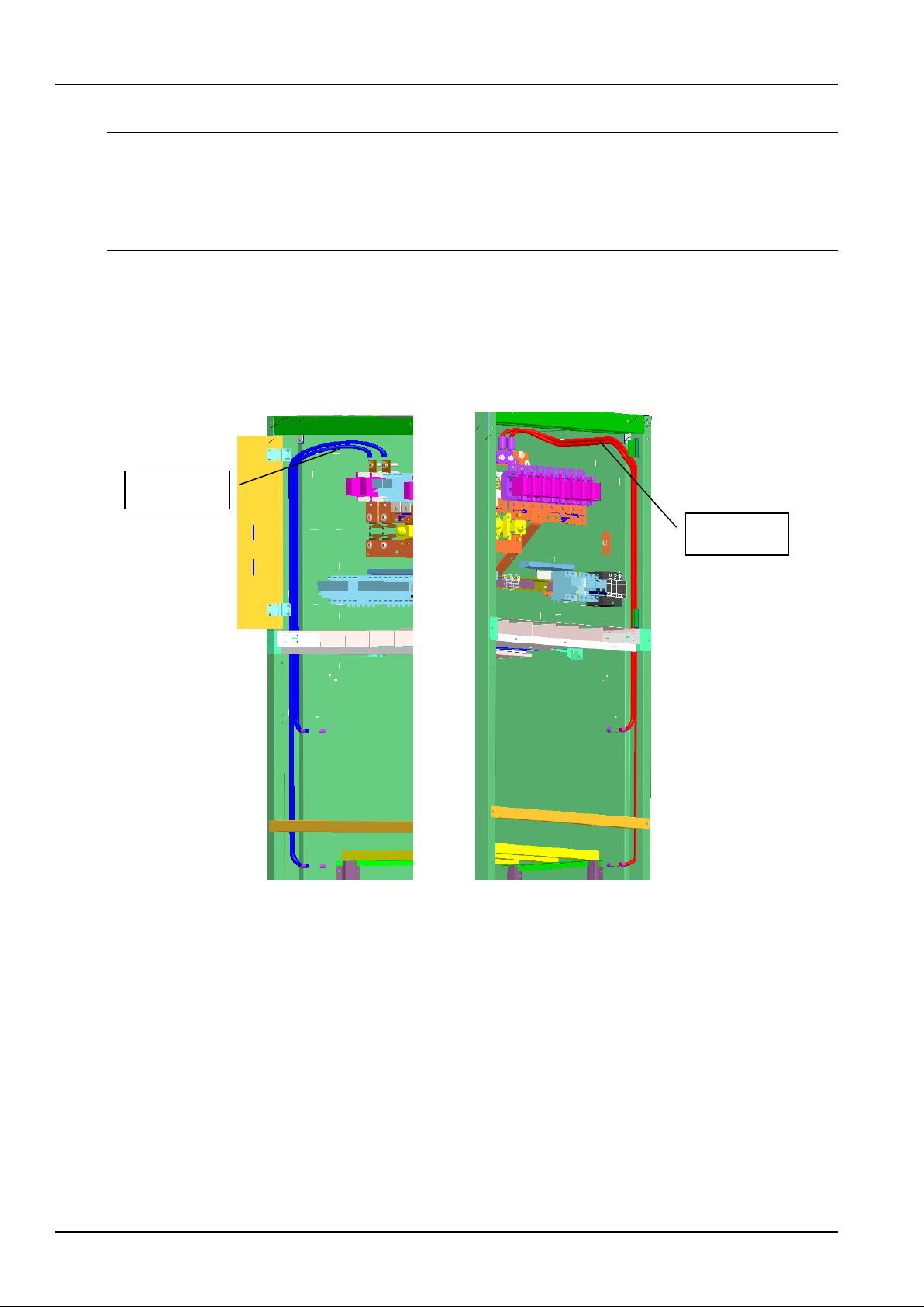

3. The wiring path of battery cable configured in NetSure 731 C62-X2 is shown in Figure 2-6.

Figure 2-6 Battery cable wiring path of NetSure 731 C62-X2

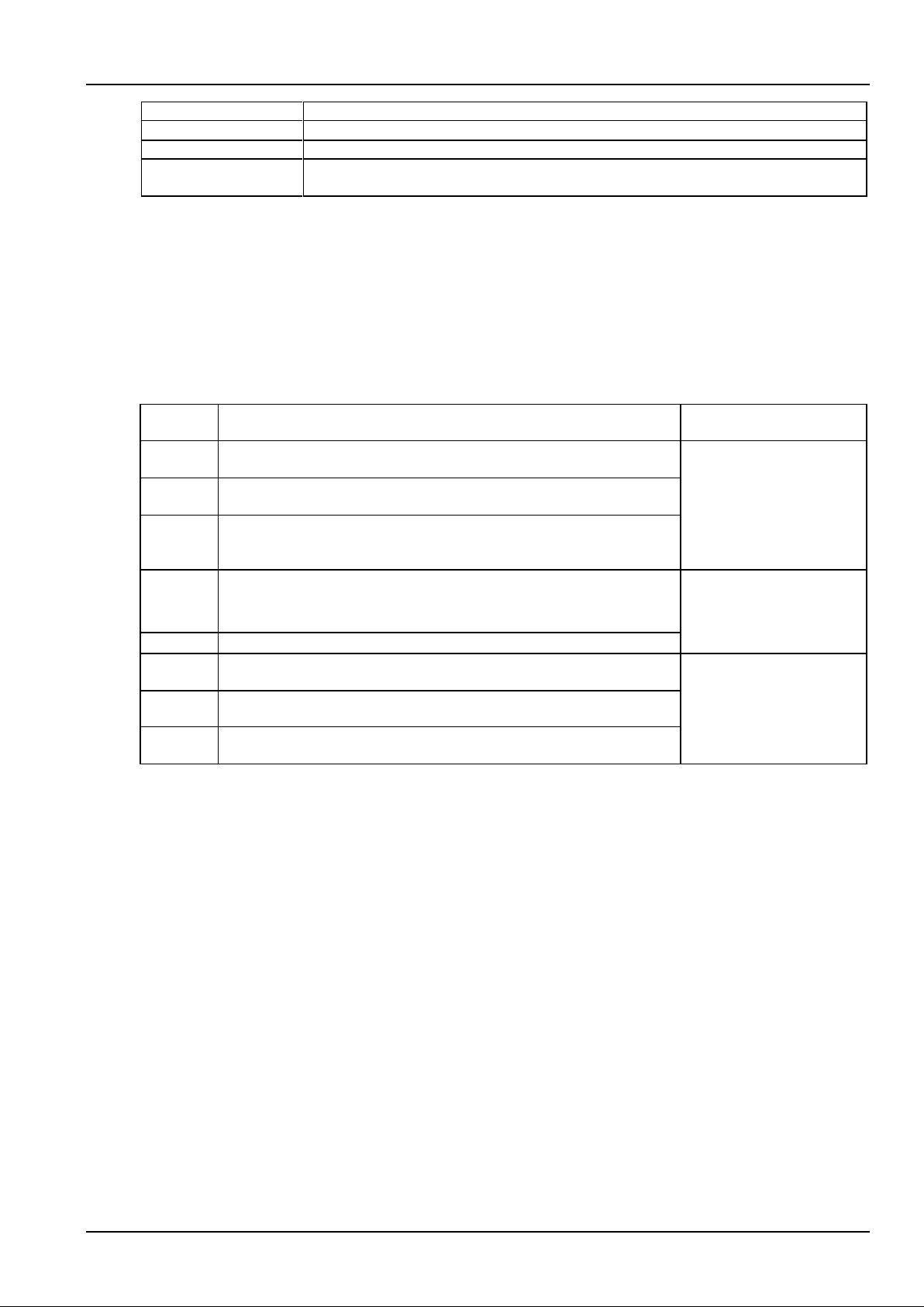

2.4.2 Connecting Signal Cables

All the signal cables are connected to the controller. The position of the controller is shown in Figure 1-2 and Figure

1-3.

The interfaces of the controller are shown in Figure 2-7. The functions of the interfaces are listed in Table 2-4.

Battery

negative cable

Battery

positive cable

Chapter 2 Installation Instruction 15

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

1

5

9

6

J1 J2

J3

J4 J5

J6

J9

J10

J12J11

T

emp

RS232

M522S

J7

J8

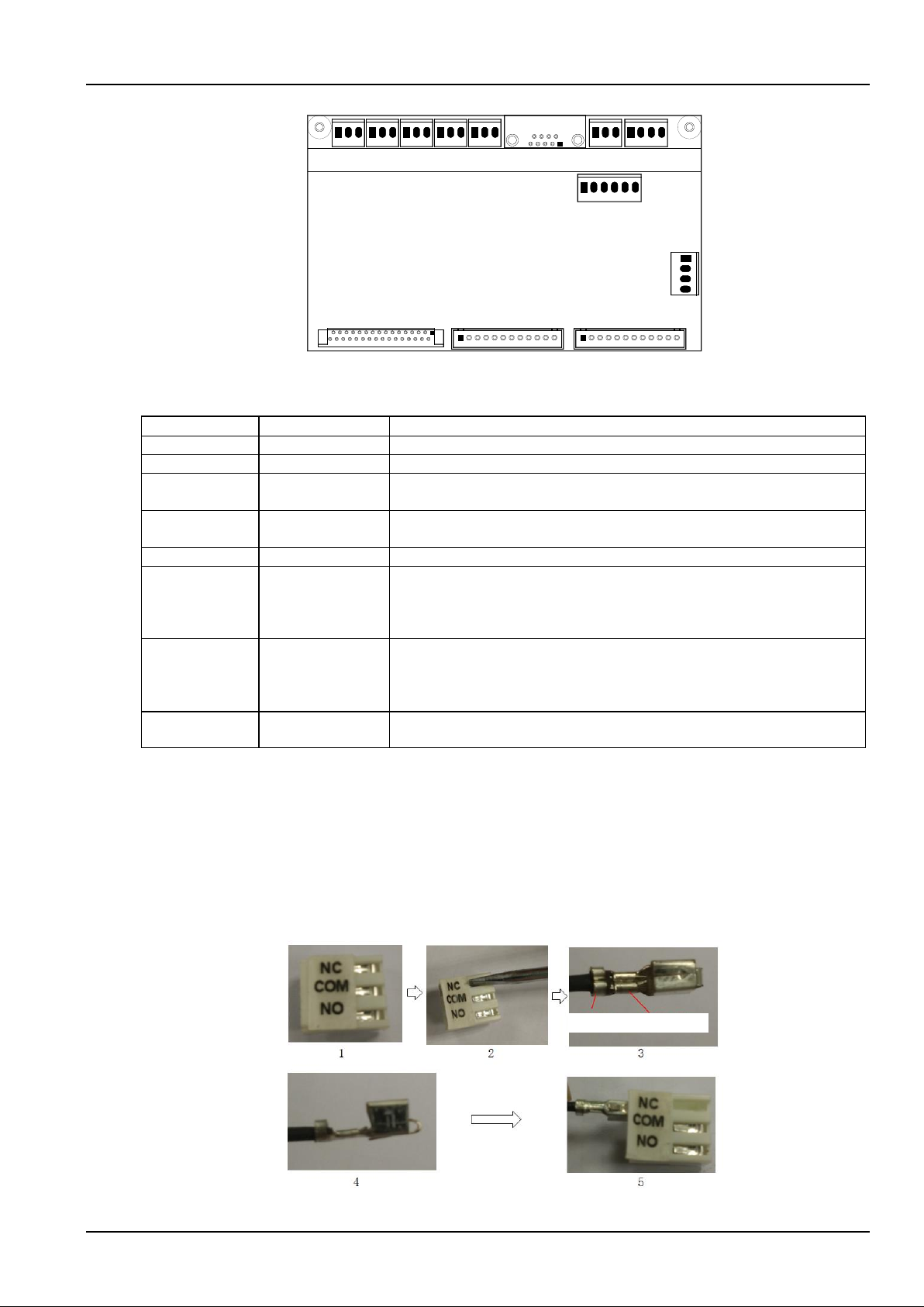

Figure 2-7 Interfaces of the controller

Table 2-4 Interface functions

Interface

Definition

Connection

J1 ~ J5

Dry contact output

To signal cables

J6

RS232 port

To modem or host

J7

Battery temperature

sensor interface

Connected before delivery

J8

Pow er interface of

the controller

Connected before delivery

J9_1 and J9_2

CAN interface

Connected before delivery

J10_1 and J10_2

LLVD

normally-closed

contact

The signal terminal has been connected to the PCB before delivery

LLVD normally-closed contact, when this interface is connected, the LLVD contactor

is controlled by the controller. Refer to 4.7.2 Battery Settings for the method of

controlling LLVD contactor

J10_3 and J10_4

BLVD

normally-closed

contact

The signal terminal has been connected to the PCB before delivery

BLVD normally-closed contact, w hen this interface is connected, the LLVD contactor

is controlled by the controller. Refer to 4.7.2 Battery Settings for the method of

controlling BLVD contactor

J11 and J12

Detect and alarm

interface

To battery shunt sampling, battery fuse and alarm cables of output routes

Procedures for connecting signal terminal J1 ~ J5:

Step 1: Unplug the signal terminal connector from the monitoring board;

Step 2: Use a slotted screwdriver, press the raised part of the terminal hardly, and push it out from the shell.

Step3: Peel off the insulation outer layer (about 3mm), as shown in Figure 2-8. Then press the naked wire and

insulation out layer.

Step 4: The well-compacted terminal is shown in Figure 2-8.

Step 5: Plug the terminal into the terminal shell, as shown in Figure 2-8.

Press insulation

out layer

Press naked

wire

Figure 2-8 Connecting J1-J5 signal terminal

16 Chapter 2 Installation Instruction

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Connecting temperature sensor

The temperature sensor is an optional accessory.

Probe operating voltage: 12V.

Measurement range: -5°C ~ +100°C.

Measurement precision: ± 2°C.

When installing the temperature sensor, put the temperature probe in the battery room that best represents the

battery temperature, far away from other heat-generating equipment. When the batteries are placed outside the

cabinet, the temperature probe shall not be placed inside the cabinet.

Installing modem

Modem is an optional accessory, suitable for those who have purchased the modem remote monitoring system.

The following expounds the modem installation and connection, taking e-TEK TD-5648DCII modem for example.

1. Fix the modem

Put the cable ties through the fixing holes at the top of the cabinet. Use the cable ties to fix the modem on the top of

the cabinet, as shown in Figure 2-9.

Modem

Cable tie

Figure 2-9 Position for placing modem

2. Connect modem with the controller

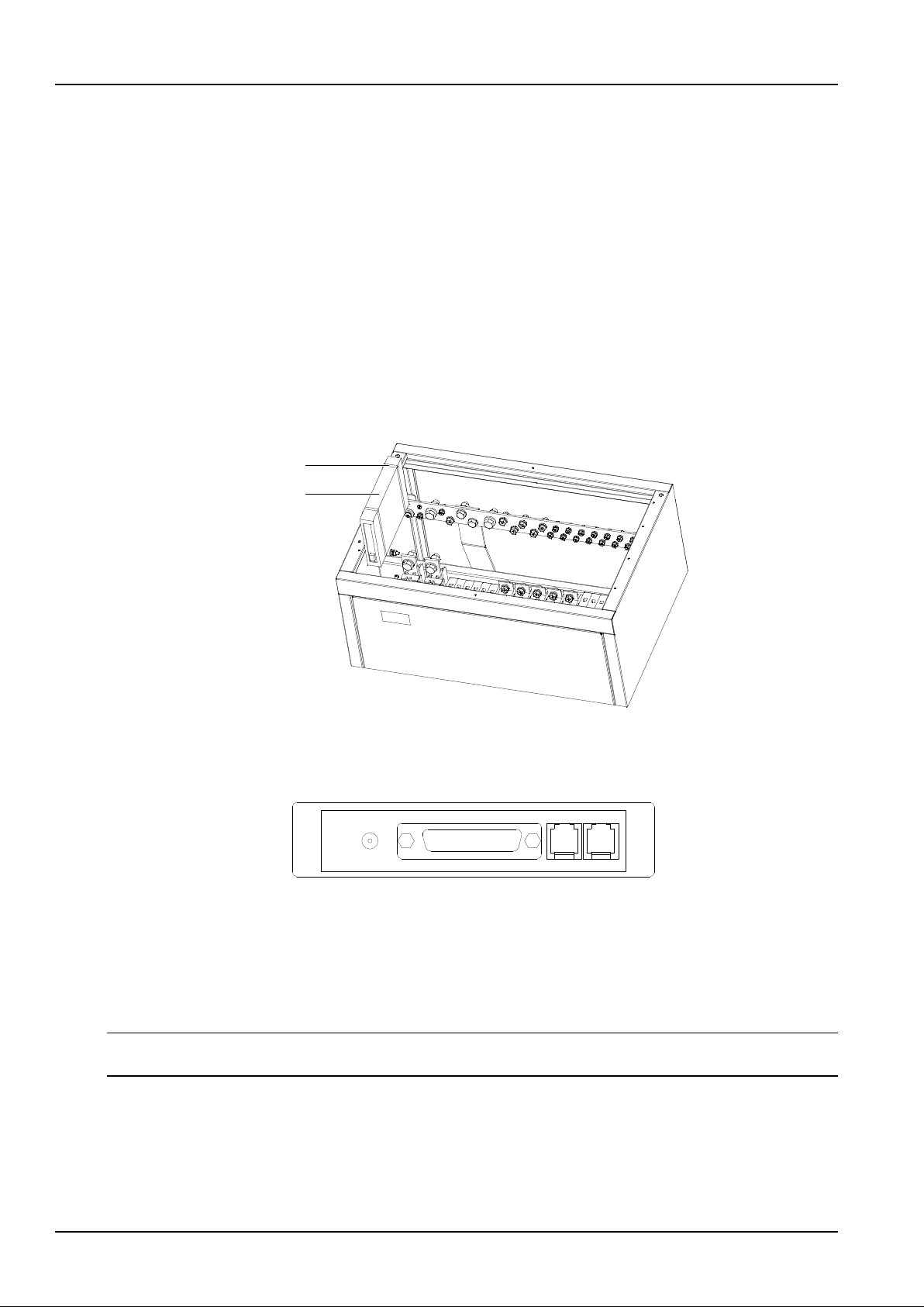

The input and output interfaces of the modem are shown in Figure 2-10.

RS-232

LINE

PHONE

POWER

Figure 2-10 Input & output interfaces of TD-5648DCII Modem

1) Connect a telephone line to the ‘LINE’ interface on the modem.

2) Use a power cable to connect the positive and negative power terminals (screenprint: POWER) of the modem to

the DC positive busbar and negative busbar (below the battery fuse) of the power system respectively.

3) Use a communication cable to connect the communication interface of the modem (DB25 female, screenprint:

RS-232) to the J6 interface (DB9 male) of the controller.

Note

During system testing, set the parameter ‘M odem’ of the controller to ‘Y’.

Connecting dry contacts

The controller provides five pairs of dry contacts, which are J1 ~ J5 interfaces shown in Figure 2-7. Peel one end of

the signal cable (optional) and insert it into the J1 ~ J5 sockets. The functions of the dry contacts are given in Table

2-5.

Chapter 2 Installation Instruction 17

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Table 2-5 Dry contact functions

Interface

Function

Interface

Function

J1

AC mains failure

J4

LLVD

J2

DC over/undervoltage

J5

BLVD

J3

Rectifier failure

Note: The above functions are default settings. Users can change them through the controller

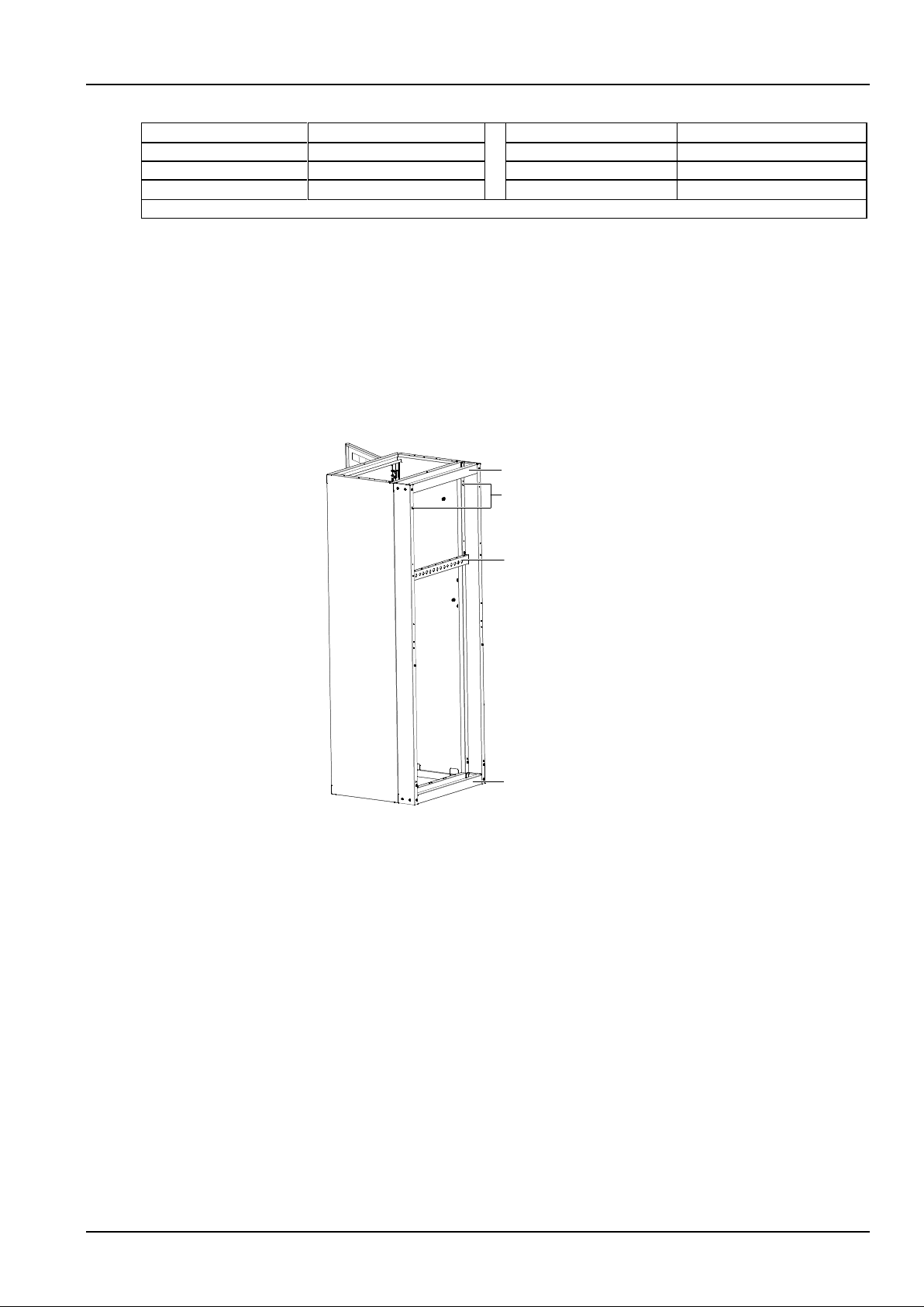

2.4.3 Bottom Cabling Cabinet

If the cabinet must use bottom cabling method, a rear cover plate should be installed at the rear of the cabinet. User

should follow the procedures below to install the cover plate. (Note: The bottom cabling method is not applicable to

NetSure 731 C62-X2.)

1. Remove the original rear cover plate of the cabinet, and then install the new rear cover plate (100mm thickness) in

the main frame of the cabinet. First install one screw on both of the right and left vertical pole of the new rear cover

plate respectively. Then fix the upper and lower beam, and the cable binding beam in the middle of the cabinet.

Finally, install the other screws on both of the right and left vertical pole, as shown in Figure 2-11.

Beam

screw on the left and right column

Cable bindong beam

Beam

Figure 2-11 Rear cover plate installation for bottom cabling method (1)

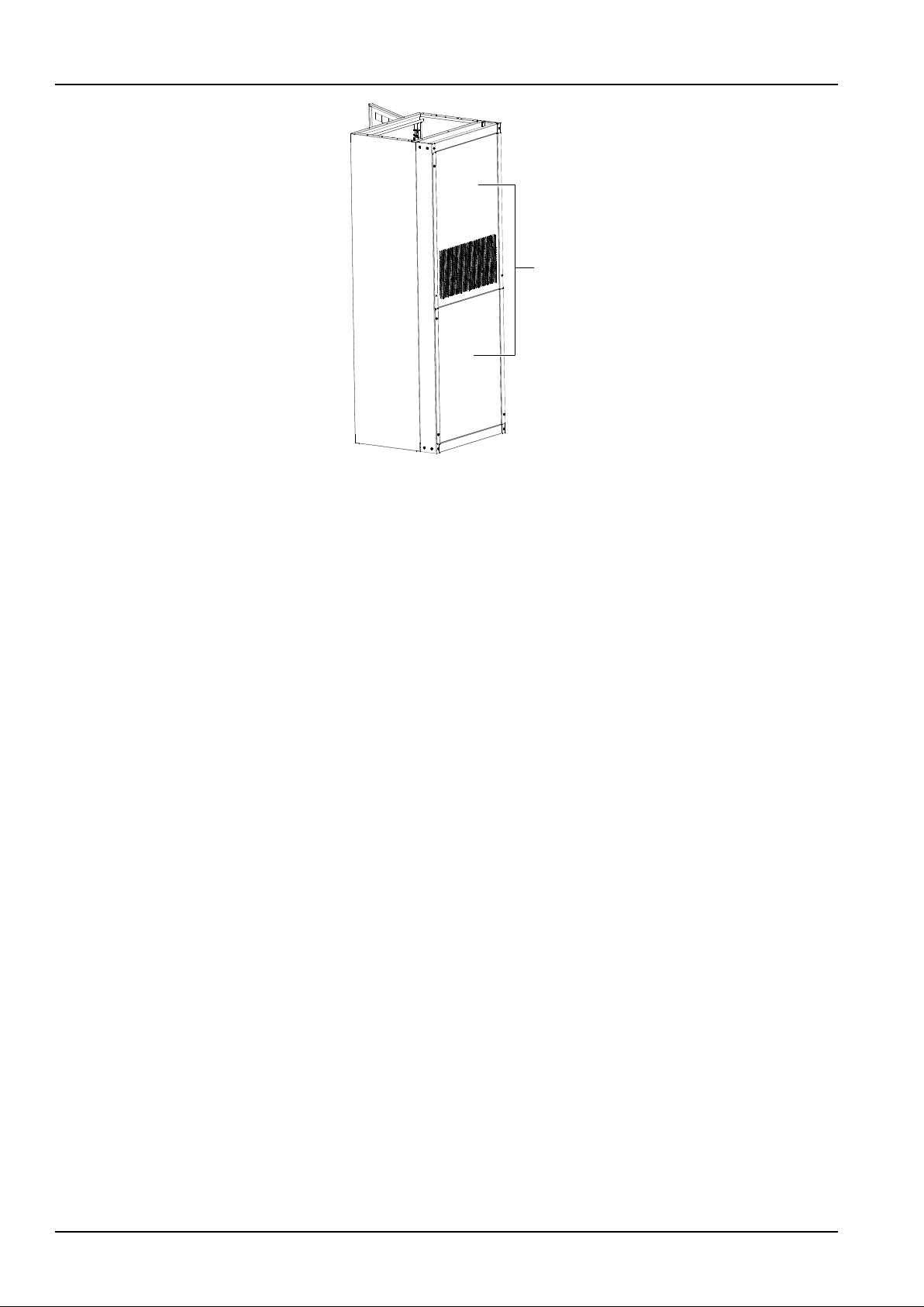

2. Install the original rear cover plate on the outside of the new one, as shown in Figure 2-12.

18 Chapter 2 Installation Instruction

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

后盖板

Back cover

Figure 2-12 Rear cover plate installation for bottom cabling method (2)

Chapter 3 Testing 19

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Chapter 3 Testing

This chapter introduces the testing procedures after installation. The corresponding safety rules shall be adhered to in

the test.

3.1 Installation Check And Startup

Before the test, inform the chief manufacturer representative. Only trained electrical engineers shall maintain and

operate the power system. In operation, the installation personnel are not allowed to wear conductive objects such as

watches, and rings.

During operation, parts of this power system carry hazardous voltage. Misoperation can result in personnel injury and

property loss. Before the test, check the equipment to ensure the proper earthing. Installation check must be done

before testing. Then the batteries can be charged for the first time.

Make sure that the AC input MCBs, rectifier MCBs and load MCBs are switched off. Make sure that all the devices

are properly installed.

Check the power system step by step according to the following listed items.

Installation check

Check item

OK

Comments

Check all the models of MCBs, fuses and cables are correct

Check the busbar connections, input and output cable connection, and connection between the power

system and the system grounding are correct

Check whether the number and connections of the batteries are correct; check the polarity of the battery

string are correct

Make sure all the connections are solid and reliable

Make sure all the communication cables and alarm cables are connected to the controller. Check that the

temperature sensor, if any, has been installed

Startup preparations

Check item

OK

Comments

Make sure that all the MCBs are sw itched off and all the fuses are removed

Measure the AC input voltage. Make sure the input voltage is within the allowable range

Umin= V

Check that at least one short-circuit copper bar in battery string circuit is not connected before installation,

prevent short-circuit caused by positive and negative short-connect

Connect the disconnected batteries to the battery string circuit

Measure with a voltmeter across the connection points of each battery and make sure that the polarity is

right. For a lead-acid battery with 24 cells, the voltmeter should read 2.0V ~ 2.1V/cell or 48V ~ 51V/battery.

If the voltage of certain cell is lower than 2.0V, that cell must be replaced

Umin= V

Check with an ohmmeter that there is no short circuit between the positive & negative distribution busbars,

or between the positive & negative battery poles (Note: Pull out all the rectifiers before the check and

restore them after the check)

Startup

Check item

OK

Comments

Switch on the AC input MCB. Switch on one rectifier MCB. The green LED on the rectifier w ill be on and the

fan w ill start running after a certain delay. The controller will show that the pow er supply voltage is 53.5V

Check the voltage and busbar polarity with a voltmeter. The voltage difference between the measured value

and displayed value should be less than ±0.3V

Start and stop each rectifier of the power system by switching on and sw itching off the rectifier MCBs.

Check their output voltages

20 Chapter 3 Testing

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

3.2 Basic Settings

When the power system is put into service for the first time, the parameters of controller must be set based on the

actual system configuration, such as battery string number, capacity, user’s charge current limi t and other functional

requirements. Only after that can the controller display system operation information and control the output.

Select the main menu Settings (password: 1) Battery Settings Basic Settings. Set the ‘Mode’ parameter to

‘Manual’. Return to the Settings menu to set the parameters in relative submenus. Refer to 4.7 Setting Parameters.

Check item

OK

Comments

The power supply system model has been set correctly in factory before delivery, check that the setting

agrees with the actual situation. (The system models are: NetSure 731 C62: 48V/300; NetSure 731 CC2:

48V/500)

The battery string number set at the controller should be the same as the number actually connected. By

default: 2

Set the battery capacity at the controller according to the actual capacity of the battery connected to the

power supply system. By default: 300Ah

Configure the temperature compensation coefficient at the monitoring module according to the battery

manufacturer’s requirement. Setting range: 0 ~ 500mV/°C. By default: 72mV/°C. (if no temperature sensor is

installed, do not set this parameter)

Set the charge current limiting point. Setting range: 0.1C10 ~ 0.25C10. By default: 0.1C10

Set the monitoring module according to the voltage suggested by the battery supplier.

Floating Charge (FC) voltage range: 42V ~ Boost Charge (BC) voltage. By default: 53.5V.

BC voltage range: FC voltage ~ 58V. By default: 56.4V.

For batteries that do not need BC, set the BC voltage to FC voltage plus 0.1V

Measure the battery voltage w ith a multimeter and record it. Enter Main menu Maintenance (password: 1)

RectTrim submenu. Set the output voltage of the rectifier to the value of the battery voltage. Insert the

battery fuse. Set the output voltage of the rectifier to 53.5V

Enter the Basic Parameters submenu. Set the ‘Mode’ parameter to ‘Auto’

3.3 Alarm Check And System Operation Status Check

Alarm check

Check that all functional units can trigger alarms that can be displayed on the controller.

Check item

OK

Comments

Pull out one rectifier. The ‘Rect N Com Failure’ alarm should be triggered. Insert the rectifier in. The alarm

should disappear. Repeat the same procedures on other rectifiers

Remove battery fuse 1. The ‘Batt1 Failure’ alarm should be triggered. Put on the fuse. The alarm should be

cleared. Repeat the same on battery fuse 2

Switch off a load MCB connected to a load route. The alarm ‘Load Fuse N Failure’ should be triggered.

Switch on the MCB, and the alarm should be cleared. Repeat the same on the other load MCBs

Remove all the battery input fuses. Keep only one rectifier in operation. Through the controller, adjust the

rectifier FC voltage to make it lower than the alarm point. The alarm ‘DC Voltage Low ’ should be triggered

Pull out the varistor of the AC SPD. The ‘SPD fault’ alarm should be triggered. Insert the varistor, the alarm

should be cleared

Note: When the preceding alarms are generated, the controller will give alarms after approximately 3s. For

querying the alarm information in the controller, please refer to 4.5 Quering Alarm Information

System operation status check

There’s no alarm if the system works normally. User can check whether the system runs normally through the

controller. For querying the controller parameters, please refer to 4.3 Querying System Main Information and 4.4

Querying Rectifier Status.

Check item

OK

Comments

The system models are NetSure 731 C62: 48V/300; NetSure 731 CC2: 48V/500

The controller should display the correct AC voltage

The controller should be able to display the DC voltage. The difference between the displayed voltage and

that measured at the busbar with should be less than ± 0.3V

Chapter 3 Testing 21

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Check item

OK

Comments

The controller should display the battery current. The difference between the displayed and measured

battery current should be less than 1%

Check the number of the rectifier through the controller. The number should be consistent with the settings

and actual values

Check the voltage, current, current limiting point of rectifiers through the controller. They should agree with

the actual parameters

For the power system configured with temperature sensor, the battery and ambient temperature displayed

by the controller should be normal. Hold the probe of the temperatures sensor and the displayed

temperatures should change

3.4 Final Steps

Check item

OK

Comments

Make sure that materials irrelevant to the equipment have been all removed

Fill in the installation report and hand it over to the user

Fill in the parameter table at the cabinet door

If any defect is found in this equipment, inform the personnel responsible for the contract.

If repairing is needed, please fill in the FAILURE REPORT and send the report together with the defective unit to the

repairing center for fault analysis.

22 Chapter 4 Use Of The Controller

NetSure 731 CC2, NetSure 731 C62 Series Power Supply System User Manual

Chapter 4 Use Of The Controller

This chapter introduces the operation panel indicators and functional keys of the controller briefly, and expounds the

main screen contents, access method, system controlling, information querying and parameter setting.

When the controller is powered on, the language selection screen will appear. The default language is Chinese, and

you do not need to do any operation. Then the controller will be initialized. After the initialization, the first system

information screen will appear.

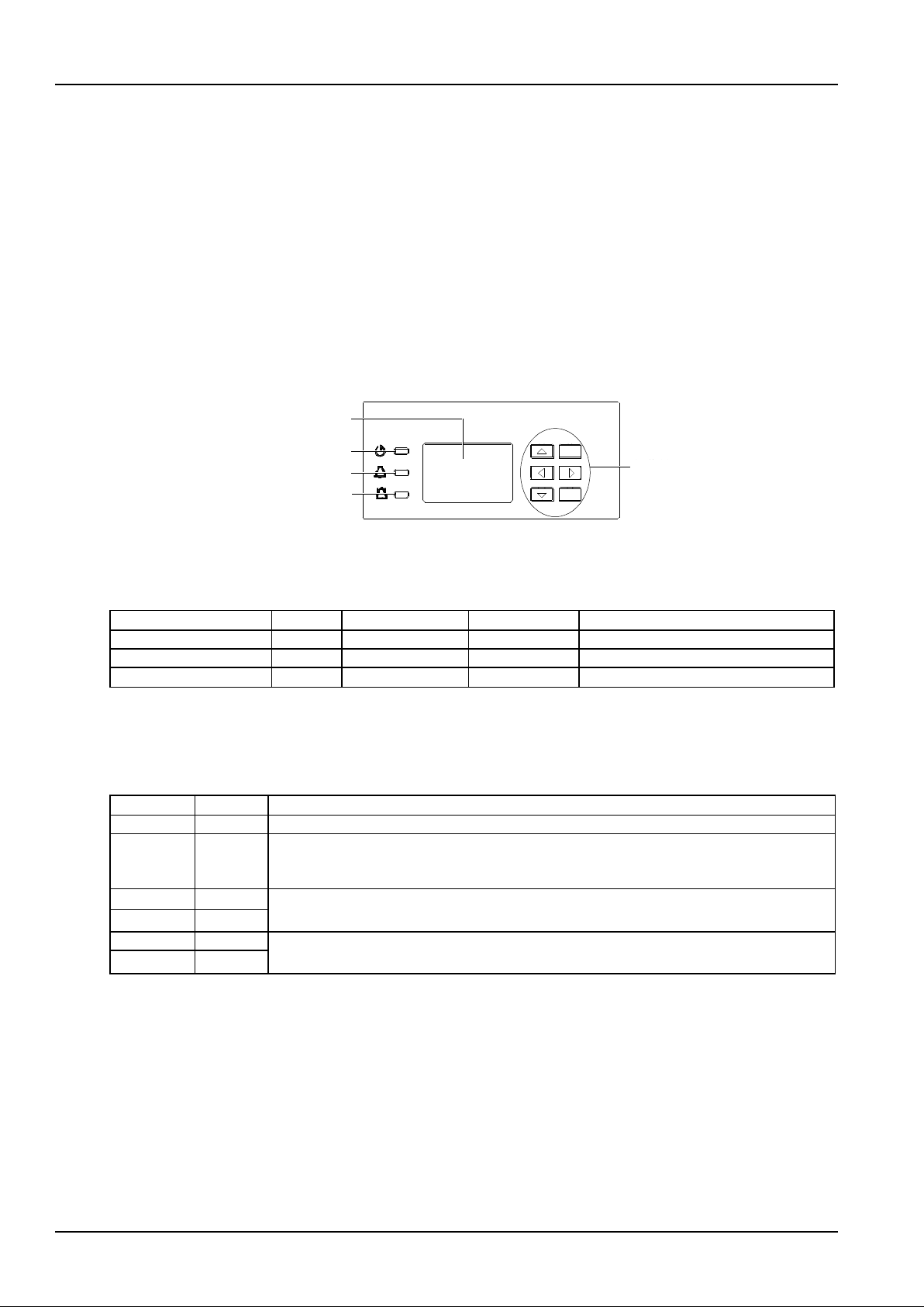

4.1 Operation Panel

The operation panel of the controller provides the backlit LCD, functional keys and indicators, as shown in Figure 4-1.

ESC

ENT

运行指示灯

告警指示灯

紧急告警指示灯

操作键

液晶显示屏

操作面板

监控单元前面板

Functional keys

LCD

Run indicator

Alarm indicator

Critical alarm indicator

Figure 4-1 Operation panel of the controller

Description of the indicators on the operation panel is given in Table 4-1.

Table 4-1 Description of the controller indicators

Indicator

Color

Normal state

Fault state

Fault cause

Run indicator

Green

On

Off

No operation power supply

Alarm indicator

Yellow

Off

On

There are observation alarms

Critical alarm indicator

Red

Off

On

There are major or critical alarms

The controller uses a 128 × 64 LCD unit, and a keypad with six functional keys. The interface language is

Chinese/English optional (8 × 4 Chinese characters can be displayed). Table 4-2 shows the description of the

controller functional keys.

Table 4-2 Description of the controller functional keys

Screenprint

Name

Function

ESC

Escape

Return to the upper level menu. When the audible alarm is generated, press this key to cancel it

ENT

ENT

Enter the lower level menu or confirm the menu operation. When changing or inputting parameters,

press this key to get into editing state. After any change is made, press this key to validate the

change

▲

Up

Shift among parallel menus. For a character string, these two keys can be used to change values

▼

Down

Left

In value setting interface, these two keys can be used to change values. These two keys can move

the cursor, only w hen one LCD screen requires character string to be input

Right

4.2 Main LCD Screens

The following LCD screens will be mentioned in this chapter for many times. This section is a centralized introduction

about the contents and access methods of these LCD screens.

4.2.1 System Information Screen

When the controller is powered on, the language selection screen will appear. The default language is English, and

you do not need to do any operation. Then the controller will be initialized. After the initialization, the first system

information screen will appear.

Loading...

Loading...