Vertiv Tech NetSure 2100 A31-S1 Installation And Commissioning Manual

Parameter

category

Parameter

Description

AC input

System Input

TN or TT, single-phase (L+N+PE)

Rated input line voltage

220Vac

Input phase voltage range

85Vac ~ 300Vac (output derating

below 176Vac)

Input frequency range

45Hz~65Hz

Rated input frequency

50Hz

Maximum input current

12.3A

DC output

Default output DC voltage

-53.5Vdc

Standard configuration

output current

0 ~ 34.4A

Mechanical

Dimension(W × D × H)

43.6mm × 482mm × 240mm

Subrack power system

weight(kg)

≤ 4kg (excluding rectifiers)

Rectifier weight (kg)

≤ 0.6kg

Environmental

Operating temperature

-5°C ~ +40°C

Relative humidity

≤ 90%RH (30°C)

Altitude

≤2000m (derating is necessary

above 2000m)

Over-voltage/pollution

degree

Over-voltage: II; Pollution degree:2

Load route rated

current

Max. output

current

Min. cable CSA

Max cable length ( volt drop:

0.5V with min. CSA)

30A

20A

4mm2

2.5m

20A

10A

1.5mm2

1.9m

10A

5A

1.5mm2

3.8m

Load route rated

current

Max. output

current

Min. cable CSA

Max cable length ( volt drop:

0.5V with min. CSA)

Note: The specs are applicable at ambient temperature of 25°C. If the temperature

is higher than this, the CSA of the cable should be increased. The maximal cable

CSA should not larger than 10mm2

32

20

Wall

465

Expansion pipe M6 65

×

Flat washer Ф6, spring washerФ6, nut M6 (4 group)

Danger

Danger

NetSure 2100 A31-S1 Subrack Power

System Installation And

Commissioning Manual

1 Technical Parameters

See Table 1-1 for the technical data of NetSure 2100 A31-S1 subrack power system

(power system for short).

Table 1-1 Technical data

The CSA of DC cable depends on the current flowing through the cable, the

allowable voltage drop and the load peak capacity. The recommended load peak

capacity is 1/2 to 2/3 of the MCB/fuse capacity.

The CSA of grounding cable should not less than 2.5mm2, and yellow-green double

color cable is recommended.

2.3 Installing Power System

The power system can be installed against the wall or installed into 19 inch rack.

Note

1. When installing the power system against the wall, make sure that the wall strength and

thickness meet the load-bearing and expansion bolt installation requirements.

2. The three brackets are fixed on both sides of the subrack power system before delivery.

1. If wall-mounting installation is used, firstly remove the three brackets, turn the

bracket with the grounding screw to make the grounding screw facing forward, and

then fasten the bracket to the front of the subrack left side wall, meanwhile,

respectively fix the other two brackets after rotation to the middle of the subrack left

and right side wall. The position of the bracket is shown in Figure 2-2.

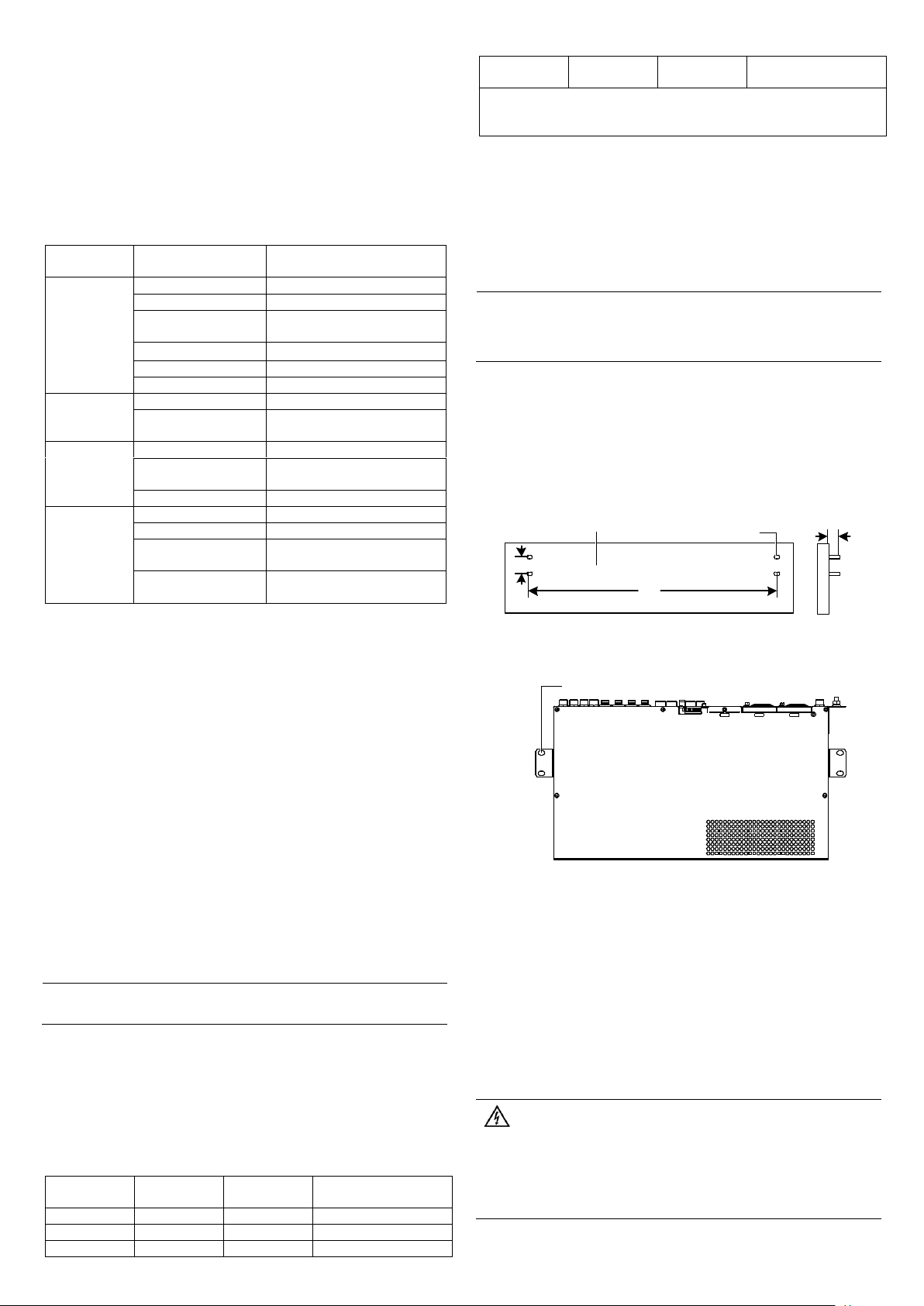

2. By referring to the dimension shown in Figure 2-1, mark the central points of the

installation holes on the floor. Use an electric drill (aiguille: Φ8) to dig holes (depth:

45mm) at the marked points. Clean the holes off dust. Put the four expansion pipes

(M6 × 65) into the holes and keep 20mm exposed.

2 Installation

2.1 Safety Regulations

1. Only the adequately trained personnel with satisfactory knowledge of the power

system can carry out the installation and maintenance.

2. Prevent fire disaster and personnel injury.

3. Provide AC power supply that meets the requirement to equipment.

4. Make sure the equipment is well grounding.

5. Keep the equipment clean and dry.

6. Avoid of touching the bare parts of the circuit.

7. In case of suspicious failure, only can carry out 'Off' operation, shall not carry out

'On' operation.

8. It is strictly forbidden to stand or place objects on the equipment body and

accessories.

2.2 Preparation

Unpacking inspection

To inspect the equipment, you should open the packing case, take out the packing

list and check against the packing list that the equipment is correct and complete.

Make sure that the equipment is delivered intact.

Note

The rectifiers were installed in the subrack power system before delivery.

Cables

The AC cable CSA should take into account the requirements like temperature rise,

voltage drop, mechanical strength and the cable design should meet relevant

industry standards. With cable length shorter than 30 meters, the CSA calculation

should be based on the current density of 2.5A/mm2. The suggested CSA value is

no less than 10mm2.

Select the DC load cable CSA according to the Table 2-1.

Table 2-1 DC load cable CSA selection

Figure 2-1 Installation dimension of cabinet base

3. As shown in Figure 2-2, use four groups of flat washer Ф6, spring washer Ф6 and

nut M6 to fix the power system on the wall.

Figure 2-2 Fixing the power system

4. After the installation, the cabinet should stand firmly no matter how it is shaken.

5. If rack mounting installation is used, firstly remove the three brackets, turn the

bracket with the grounding screw to make the grounding screw facing forward, and

then fasten the bracket to the front of the subrack left side wall, meanwhile, fix any

one of the other two brackets after rotation to the front of the subrack right side wall

(the rest bracket is no need to be fixed). The position of the bracket is shown in

Figure 2-2, use the fixing screws to fasten the subrack power system to the rack

through bracket.

2.4 Cable Connection

All the cables entering or outgoing the power system must be put into the metal pipe

for protection. The metal pipe should be connected to the PE bar reliably. Plastic

coated metal hoses are recommended.

1. Switch off all MCBs before the electrical connection.

2. Only the qualified personnel can do the mains cable connection.

3. Before electrical connection, make sure all the AC MCBs of the power system are

switched off, the AC 230/400V 20A double pole C type MCB is recommended.

4. There is a dangerous voltage in the primary circuit, disconnect the power supply before

maintenance.

1

AC input terminal L

AC input terminal N

Grounding terminal

Load output route 1-

Battery-

Battery+

Load output route 2Load output route 3-

Load output route 3+

Load output route 2+

Load output route 1+

RS232 port

DB9 port

1 (Tx)

2

2 (Rx)

3

3 (GND)

5

No.

Check content

1

Check that the power system is horizontally, vertically and steadily fixed

2

Check that all the bolts are tightened, especially those in electrical

connections. Check that the bolts have plain washers and spring

washers and are not reversed

3

Check that there are no unwanted materials inside the cabinet and clear

up the unwanted materials

4

Check that the power system is intact. If there are scratches, paint them

immediately with antirust paint to prevent corrosion

5

Check the correctness of all MCBs and cables specifications

6

Check the correctness of input and output cable connection, and

communication between the power system and the system grounding.

Make sure that all the cable connections are firm and reliable and the

cable binding is tidy and normative

7

Check the correctness of the battery strings polarities

8

Measure the resistance value between the positive terminal and

negative terminal and phase- to - phase resistance value in the AC loop.

Make sure that there is no short-circuit

9

Check the AC input and distribution. Check that the color of the AC

cables is normative, the cables are laid stably, and the safety labels are

complete

10

Check that the rectifiers are clipped tightly

11

Check that all the MCBs are switched off

Check item

OK

Remark

Make sure that all the MCBs are switched off.

Measure the AC input voltage. Make sure the input voltage

is within the allowable range.

Umin= V

Make sure that the communication and dry contact alarm

output cable are connected to the monitoring board

Make sure that the temperature sensor is installed correctly

Use a voltmeter to measure the battery string voltage and

make sure the battery polarities are correct

Umin= V

Check with an ohmmeter that there is no short circuit

between the positive & negative terminal of DC output,

between the positive & negative battery poles or AC input

terminals (Note: Pull out all modules before the check and

restore them after the check)

Check item

OK

Remark

Switch on the system AC output MCB, the green LED on the

rectifier will be on after a certain delay

Switch on the load MCB. Use a multimeter to check the

voltage of both ends of load, if it shows 53.5V ± 0.5V, the

voltage is normal

Switch on the battery MCB

2.4.1 Connecting Earth Cable

Connect one end of the earth cable to the grounding terminal (see Figure 2-3), and

solder the other end to the grounding metal base outside the power system.

2.4.2 Connecting AC Input Cables

1. The routing method of the AC input cables is the same as that of the earth cables.

Connect the live line (L) and neutral line (N) of the AC input cables respectively to

the lower terminals of the power system AC input terminal L and AC input terminal N,

as shown in Figure 2-3.

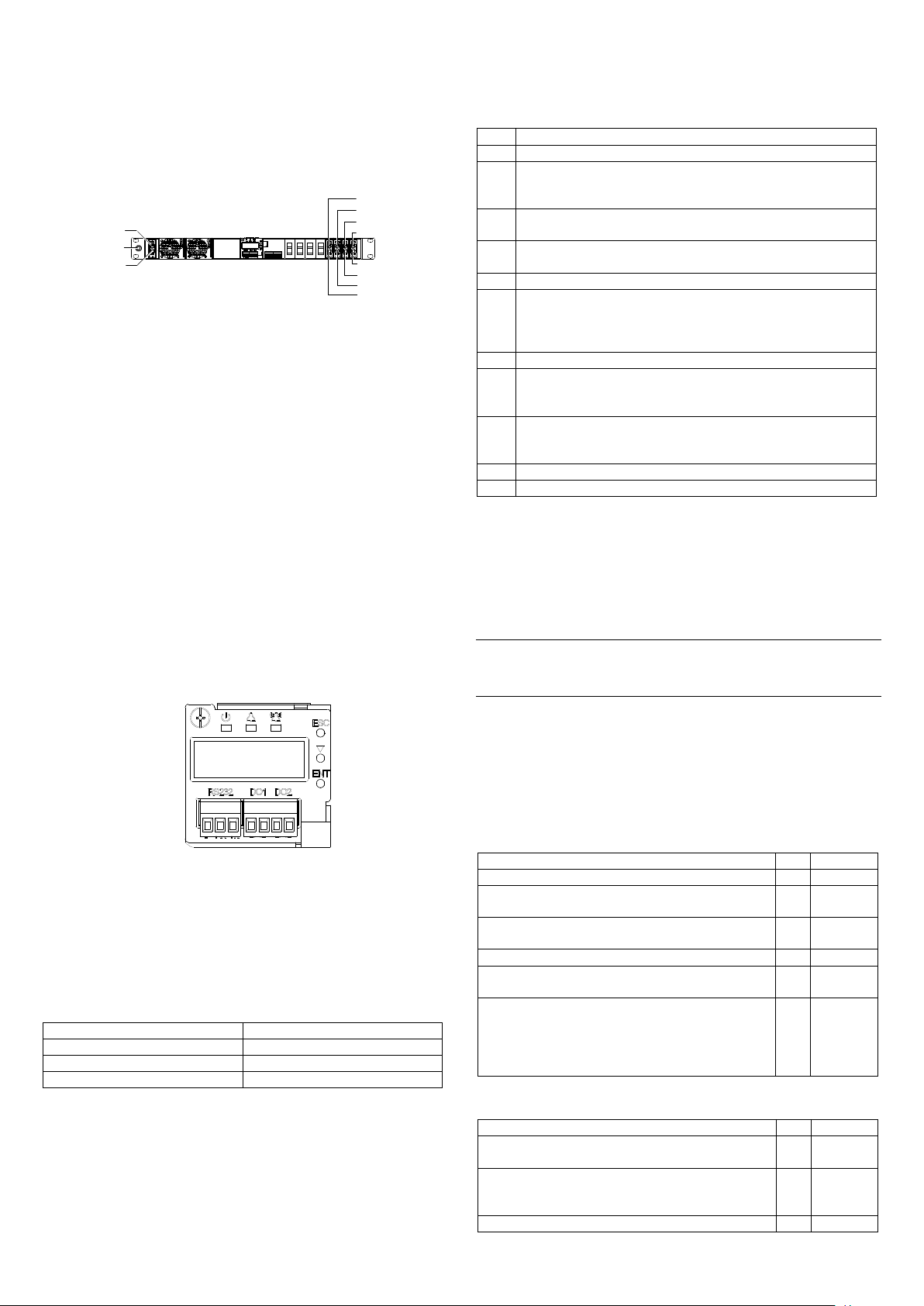

Figure 2-3 Illutration of connection terminal

2.4.3 Connecting DC Cables

The power system can be connected with three route of loads respectively

controlled by three MCBs, as shown in Figure 2-3. Connect the negative load cable

to the corresponding load '-' and then connect the positive load cable to the

corresponding load '+' (see Figure 2-3).

2.4.4 Connecting Battery Cable

The power system can be accessed in one group of batteries controlled by a battery

MCB, as shown in Figure 2-3. During connection, connect the negative battery

cable to the battery terminal '-' and then connect the positive battery cable to the

battery terminal '+' (see Figure 2-3).

2.4.5 Connecting Communication Cable

Connecting dry contact output port

The controller is configured with two pairs of alarm dry contact output (DO1 ~ DO2)

as standard configuration and four expanded outputs (DO3 ~ DO6) as optional. The

dry contact that generating corresponding alarm is normally closed, users can

connect according to actual needs. When wiring, take out the female of the 4-pin

phoenix terminal bound at the controller handle, connect the multi-core

communication cable with the pipe terminal to the corresponding female of the

phoenix terminal according to the dry contact silkprint on the controller, and then

insert the terminal into the controller front panel. The position of communication

terminal and port definition are shown in Figure 2-4 (Users need to prepare signal

cable themselves).

Figure 2-4 Illutration of controller front panel

Connecting RS232 port

The RS232 port is used for communication with the host. The correlation of the

RS232 and DB9 port on the host is shown in Table 2-2. When wiring, take out the

female of the 3-pin phoenix terminal bound at the controller handle, connect the

multi-core communication cable with the pipe terminal to the corresponding female

of the phoenix terminal according to the RS232 port silkprint on the controller, and

then insert the terminal into the controller front panel, as shown in Figure 2-4 (Users

need to prepare signal cable themselves).

Table 2-2 Correlation of ports

2.5 Installation Check

After the installation, you should carry out the inspection procedures given in

Table 2-3.

Table 2-3 Installation check list

3 Testing

During testing, the corresponding safety regulations must be observed, and the

testing procedures should be followed strictly. The system has been tested before

delivery, the user does not need to carry on the field testing.

3.1 Testing Distribution Unit And Rectifiers

Note

Before the test, inform the chief manufacturer representative. Only trained electrical

engineer can maintain and operate this equipment. In operation, the installation personnel

are not allowed to wear conductive objects such as watches, bracelets, bangles and rings.

During operation, parts of this equipment carry hazardous voltage. Misoperation

may result in severe or fatal injuries and property damage. Before the test, check

the equipment to ensure the proper grounding. Installation check must be done

before testing. Then the batteries can be charged for the first time.

Make sure that the AC output MCBs, rectifier MCBs and load MCBs are switched off.

Make sure that all the devices are properly installed.

Please check the power system according to below listed items.

Startup preparations

2.4.6 Connecting Temperature Compensation Cable

If the user selects the temperature compensation cable, first loosen the captive

screw in the upper left of the controller, and slowly pull the controller out of the

power system until the 3pin temperature sensing interface J2 is exposed on the

monitoring board. Then table out the temperature compensation cable and insert

the cable into the interface, and then slowly push the controller into the power

system and fix the captive screw.

Startup

2

Loading...

Loading...