Vertiv XTE 802 Installation Manual

XTE 802 Series

Walk-In-Cabinet (WIC)

Description and Installation Manual

Specification Number: F2018009

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

The information contained in this document is subject to change without

notice and may not be suitable for all applications. While every precaution has

been taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in

this document.

The products covered by this instruction manual are manufactured and/or

sold by Vertiv. This document is the property of Vertiv and contains

confidential and proprietary information owned by Vertiv. Any copying, use or

disclosure of it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark

names should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.vertiv.com/en-us/support/ for additional assistance.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

iii

TABLE OF CONTENTS

Admonishments Used in this Document ......................................................................................................................... vi

Important Safety Instructions ........................................................................................................................................... vii

Static Warning ....................................................................................................................................................................... xiv

1 About this Document ........................................................................................................................................................ 1

2 Product Description .......................................................................................................................................................... 1

2.1 General ..................................................................................................................................................................................................................................................................................... 1

2.2 Part Numbers .................................................................................................................................................................................................................................................................... 2

2.3 Application .......................................................................................................................................................................................................................................................................... 4

2.4 Standards Compliance ............................................................................................................................................................................................................................................. 4

2.5 Safety Listed AC or DC Components......................................................................................................................................................................................................... 5

2.6 Commercial AC Service........................................................................................................................................................................................................................................... 5

2.7 WIC Dimensions, Weights, and Physical Specifications ............................................................................................................................................................ 7

2.8 WIC Features and Options ................................................................................................................................................................................................................................ 14

3 Sequence of Procedures ............................................................................................................................................... 30

3.1 General ................................................................................................................................................................................................................................................................................ 30

4 Front Door .......................................................................................................................................................................... 31

4.1 Safety Precautions ..................................................................................................................................................................................................................................................... 31

4.2 Locking Mechanism ................................................................................................................................................................................................................................................. 31

4.3 Securing Mechanism ............................................................................................................................................................................................................................................... 31

4.4 Intrusion Alarm Switch Operation ............................................................................................................................................................................................................... 31

5 Installation Considerations .......................................................................................................................................... 32

5.1 Important Safety Instructions ......................................................................................................................................................................................................................... 32

5.2 Installation Overview ............................................................................................................................................................................................................................................... 32

5.3 Tools and Test Equipment Required for Installation ................................................................................................................................................................ 33

6 WIC and Generator Placement .................................................................................................................................... 34

6.1 Overview ............................................................................................................................................................................................................................................................................ 34

6.2 Site Selection ................................................................................................................................................................................................................................................................ 34

6.3 WIC Foundation Kit Installation .................................................................................................................................................................................................................... 35

6.3.1 WIC Helical Foundation Kit Installation (P/N D1000-0000-0101) ........................................................................................................ 35

6.3.2 WIC Concrete Pier/Pad Foundation Kit Installation (P/N D1007-0000-0012) ........................................................................ 39

6.3.3 WIC On The Ground (Gravity) Foundation Kit Installation (P/N D1000-0000-0103) ....................................................... 41

6.4 Generator Foundation Kit Installation .................................................................................................................................................................................................... 42

6.4.1 All Generators up to 20 KW Helical Foundation Kit Installation (P/N D1000-0010-0109)........................................... 42

6.4.2 All Generators up to 30 KW Helical Foundation Kit Installation (P/N D1000-0010-0109, Two

Required) .................................................................................................................................................................................................................................................... 44

6.4.3 All Generators up to 30 KW On the Ground (Gravity) Foundation Kit Installation (P/N D1001-0020-

0062) ............................................................................................................................................................................................................................................................. 46

6.5 WIC and Generator Combo Platform Installation ......................................................................................................................................................................... 47

6.5.1 WIC and Generator Combo Helical Platform Installation (P/N D1000-0010-0122) .............................................................. 47

6.5.2 WIC and Generator Combo Concrete/Gravity Platform Installation (P/N D1000-0010-0123) ................................. 50

6.5.3 Generator Wings Installation (P/N D1000-0020-0032) ................................................................................................................................. 52

6.5.4 Elevated WIC and Generator Platform Installation (P/N D1000-0010-0089-04, P/N D1000-0010-

0089-06, P/N D1000-0010-0089-08, P/N D1000-0010-0089-10, P/N D1000-0010-0089-12) ............................ 55

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

iv

6.6 Transportation and Storage ............................................................................................................................................................................................................................. 57

6.7 Unpacking and Preparing the WIC at the Installation Site ................................................................................................................................................. 58

6.8 Preparing to Lift the WIC ................................................................................................................................................................................................................................... 59

6.9 Lifting the WIC .............................................................................................................................................................................................................................................................. 61

6.10 Placing the WIC .......................................................................................................................................................................................................................................................... 63

6.10.1 On Approved Foundation Kit ................................................................................................................................................................................................... 63

7 Installing GPS Antennae Mounting Bracket Kit .................................................................................................... 65

8 Sealing Cable Entries ..................................................................................................................................................... 67

9 Grounding the WIC ......................................................................................................................................................... 68

9.1 Important Safety Instructions ........................................................................................................................................................................................................................ 68

9.2 Safety Precautions ................................................................................................................................................................................................................................................... 68

9.3 General ................................................................................................................................................................................................................................................................................ 68

9.4 Exterior Ground Bars ............................................................................................................................................................................................................................................. 68

9.5 Master Ground Bar (MGB) ............................................................................................................................................................................................................................... 68

10 AC Power ........................................................................................................................................................................... 77

10.1 Important Safety Instructions ......................................................................................................................................................................................................................... 77

10.2 Safety Precautions .................................................................................................................................................................................................................................................... 77

10.3 General ................................................................................................................................................................................................................................................................................. 77

10.4 WIC AC Schematic .................................................................................................................................................................................................................................................... 77

10.5 AC Input Connections to Power Transfer Load Center (PTLC) E/W Automatic Transfer Switch (ATS) .............................. 78

11 DC Power ........................................................................................................................................................................... 82

11.1 Important Safety Instructions ......................................................................................................................................................................................................................... 82

11.2 Safety Precautions .................................................................................................................................................................................................................................................... 82

11.3 General ................................................................................................................................................................................................................................................................................. 82

11.4 DC Power Cabling Color Scheme ............................................................................................................................................................................................................... 82

11.5 Battery Installation and Wiring ...................................................................................................................................................................................................................... 82

11.6 External DC Generator Wiring........................................................................................................................................................................................................................83

11.6.1 Procedure ...................................................................................................................................................................................................................................................83

11.7 Operating the Power System ..........................................................................................................................................................................................................................83

12 OSP Cables ........................................................................................................................................................................ 87

12.1 Important Safety Instructions ......................................................................................................................................................................................................................... 87

12.2 Safety Precautions .................................................................................................................................................................................................................................................... 87

12.3 Sealing Cable Entries .............................................................................................................................................................................................................................................. 87

12.4 Installing Fiber Cables ............................................................................................................................................................................................................................................ 87

13 Alarm Wiring ..................................................................................................................................................................... 88

13.1 Connecting External Alarms ........................................................................................................................................................................................................................... 88

14 Initial Power Up ............................................................................................................................................................... 90

14.1 Important Safety Instructions ........................................................................................................................................................................................................................ 90

14.2 Safety Precautions ................................................................................................................................................................................................................................................... 90

14.3 Prerequisite .................................................................................................................................................................................................................................................................... 90

14.4 Initial Power Up Sequence ................................................................................................................................................................................................................................ 91

15 Direct Air Cooling (DAC) and HVAC ......................................................................................................................... 92

15.1 Description .......................................................................................................................................................................................................................................................................92

15.2 General Operation .....................................................................................................................................................................................................................................................92

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

v

15.3 Controller .......................................................................................................................................................................................................................................................................... 95

15.3.1 General ......................................................................................................................................................................................................................................................... 95

15.3.2 LCD Message Display

................................................................................................................................................................................................................... 95

15.3.3 Connecting to the Controller via a Smart Phone .................................................................................................................................................. 95

15.4 WIC Environmental Control Quick Start Guide ............................................................................................................................................................................. 95

16 DC Power, Outdoor Enclosure & Service Contacts .............................................................................................. 98

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

vi

DANGER

in death or serious injury if not avoided

WARNING

result in

death or serious injury if not avoided

a risk only to equipment, software, data, or service

CAUTION

result in minor or moderate injury if not avoided

used for situations that pose a risk only to equipment, data, or service, even i

appears to be permitted in some of the applicable standards

ALERT

equipment, software, data, or service

ALERT

equipment damage, software corruption, data loss, or service interruption

FIRE SAFETY

or policies, or of the locations of

SAFETY

policies not related to a particular source of hazard or to fire safety

Admonishments Used in this Document

! Warns of a hazard the reader

! Warns of a potential hazard the reader

! Warns of a potential hazard the reader

! Alerts the reader to an action that

will

be exposed to that will

. (ANSI, OSHA)

may

be exposed to that

. This admonition is not used for situations that pose

. (ANSI)

may

be exposed to that

. (ANSI, OSHA) This admonition is not

. (OSHA)

must be avoided

. (ISO)

in order to protect

likely

result

could

could

f such use

! Alerts the reader to an action that

! Informs the reader of fire safety information, reminders, precautions,

! Informs the reader of general safety information, reminders, precautions, or

fire-fighting and fire-safety equipment. (ISO)

must be performed

in order to prevent

. (ISO)

. (ISO, ANSI, OSHA)

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

vii

Important Safety Instructions

Safety Admonishments Definitions

Definitions of the safety admonishments used in this document are listed under “Admonishments Used in this Document” on page vi.

You Must Follow Approved Safety Procedures

DANGER! Performing the following procedures may expose you to hazards. These procedures should be performed by

qualified technicians familiar with the hazards associated with this type of equipment. These hazards may include shock,

energy, and/or burns. To avoid these hazards:

a) The tasks should be performed in the order indicated.

b) Remove watches, rings, and other metal objects.

c) Prior to contacting any uninsulated surface or termination, use a voltmeter to verify that no voltage or the expected

voltage is present. Check for voltage with both AC and DC voltmeters prior to making contact.

d) Wear eye protection.

e) Use certified and well maintained insulated tools. Use double insulated tools appropriately rated for the work to be

performed.

Voltages

AC Input Voltages

DANGER! This system may operate from AC input voltage capable of producing fatal electrical shock. AC input power must

be completely disconnected from the branch circuits wiring used to provide power to the system before any AC electrical

connections are made. Follow local lockout/tagout procedures to ensure upstream branch circuit breakers remain de-

energized during installation. DO NOT apply AC input power to the system until all electrical connections have been

completed and checked.

DC Output and Battery Voltages

DANGER! This system may produce DC power and may have a battery source connected to it. Although the DC voltage is

not hazardously high, the rectifiers and/or battery can deliver large amounts of current. Exercise extreme caution not to

inadvertently contact or have any tool inadvertently contact an output terminal or battery terminal or exposed wire

connected to an output terminal or battery terminal. NEVER allow a metal object, such as a tool, to contact more than one

termination or battery terminal at a time, or to simultaneously contact a termination or battery terminal and a grounded

object. Even a momentary short circuit can cause sparking, explosion, and injury.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

viii

Battery

Refer to the battery manufacturer documentation for specific battery safety instructions. The following are general guidelines.

WARNING! Correct polarity must be observed when connecting battery leads.

WARNING! Special safety precautions are required for procedures involving handling, installing, and servicing batteries.

Observe all battery safety precautions in this manual and in the battery instruction manual. These precautions should be

followed implicitly at all times.

WARNING! A battery can present a risk of electrical shock and high short circuit current. Servicing of batteries should be

performed or supervised only by properly trained and qualified personnel knowledgeable about batteries and the required

precautions.

The following precautions should be observed when working on batteries:

• Follow the recommended PPE requirements per the SDS for the battery to be used.

• Batteries are an energy source that can produce high amounts of electrical current.

• Remove watches, rings, and other metal objects.

• Eye protection should be worn to prevent injury from accidental electrical arcs.

• Use certified and well maintained insulated tools. Use double insulated tools appropriately rated for the work to be

performed. Ensure that wrenches with more than one working end have only one end exposed.

• Do not lay tools or metal parts on top of batteries.

• Verify that no current will flow when the battery is connected or disconnected by opening battery disconnects (if

available) or adjusting the system to match battery voltage.

• Risk of explosion if battery is replaced with an incorrect type or if polarity is reversed. Recommended to replace

batteries with the same manufacturer and type, or equivalent.

• Dispose of used batteries according to the instructions provided with the batteries. Do not dispose of batteries in a fire.

They may explode.

• Batteries may generate explosive gases during normal operation. Systems containing batteries should never be installed

in an airtight room or space. Only install in a ventilated environment.

• Batteries may contain sulfuric acid. If battery acid enters your eye, immediately flush your eye with running cold water

for at least 15 minutes. Get medical attention immediately. If battery acid contacts skin or clothing, wash immediately

with soap and water.

• Do not open or mutilate batteries.

• ALWAYS FOLLOW THE BATTERY MANUFACTURER’S RECOMMENDATIONS AND SAFETY INSTRUCTIONS.

ALERT! Performing maintenance and/or troubleshooting procedures may interrupt power to the loads, if battery reserve is

not sufficient.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

ix

Buried Utilities

CAUTION! When installing the WIC, ensure the site is free of any buried utilities. Call 811 before installation. Severe damage,

serious injury, or death can occur if buried utilities are not identified prior to installation.

Personal Protective Equipment (PPE)

DANGER! ARC FLASH AND SHOCK HAZARD.

Appropriate PPE and tools required when working on this equipment. An appropriate flash protection boundary analysis

should be done to determine the “hazard/risk” category, and to select proper PPE.

Only authorized and properly trained personnel should be allowed to install, inspect, operate, or maintain the equipment.

Do not work on LIVE parts. If required to work or operate live parts, obtain appropriate Energized Work Permits as required

by the local authority, per NFPA 70E “Standard for Electrical Safety in the Workplace”.

Hazardous Voltage

DANGER! HAZARD OF ELECTRICAL SHOCK.

More than one disconnect may be required to de-energize the system before servicing.

Handling Equipment Containing Static Sensitive Components

ALERT! Installation or removal of equipment containing static sensitive components requires careful handling. Before

handling any equipment containing static sensitive components, read and follow the instructions contained on the Static

Warning Page.

Maintenance and Replacement Procedures

CAUTION! When performing any step in procedures that requires removal or installation of hardware, use caution to ensure

no hardware is dropped and left inside the unit; otherwise service interruption or equipment damage may occur.

NOTE!

When performing any step in procedures that requires removal of existing hardware, retain all hardware for use in

subsequent steps, unless otherwise directed.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

x

General Safety Precautions

The following precautions shall be observed at all time when handling and installing the WIC:

• Observe all safety precautions against personal injury and equipment damage.

• The procedures outlined in this manual are only recommended guidelines. Ensure that all NEC (National Electric Code) and

local codes for safety and wiring are followed.

- Use listed two-hole compression connectors (lugs) to terminate all ground connections. Selected lug shall match wire

and type, and crimped applied as specified by the lug manufacturer.

- Apply NO-OX-ID-A to all ground connections.

- Insulation of field-wire conductors should be rated no less than 90 °C, and sized in a manner that is consistent with the

NEC and local codes.

• Always use an approved voltage detector, when approaching the WIC, to verify no leaks or shorts are presents on the

external body.

• Read “Specific Safety Precautions” starting on page xi in its entirety prior to attempting to handle or secure the WIC.

• A minimum of two persons are required to safely install the WIC.

• Hard hats and steel-toed boots should be worn while maneuvering the WIC.

• Safety glasses should always be on while on-site.

• Safety gloves should be on when working in temperature extremes, with batteries, or with sharp objects.

• All electricians, operators, and technicians have been trained for the task at hand.

• Keep bystanders away.

• Ensure that all personnel on site are familiar with the first-aid kit location and emergency procedures in the event of an injury.

• Never leave the WIC unattended. If leaving the site, close and secure the WIC.

xi

Specific Safety Precautions

DANGER! ELECTRICAL HAZARD

The equipment shall be installed and serviced by trained service personnel in accordance with the applicable requirements of

the current edition of the American National Standards Institute (ANSI) approved National Fire Protection Association's

(NFPA) National Electrical Code (NEC) (NFPA 70) or Canadian Electrical Code; and the applicable sections of the National

Electrical Safety Code (NESC) (ANSI C2). For operation in countries where the NEC or NESC is not recognized, follow

applicable codes.

All electrical procedures should be performed by a licensed electrician.

Observe all safety precautions as specified by local building codes. If local building codes specify procedures different from

those in this section, follow local codes.

DANGER! RISK OF ELECTRICAL SHOCK, GENERAL

All WIC grounding and ground ring must be installed and verified prior to connecting any power cables (AC or DC) and

turning-up of the WIC.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

When connecting any discrete power connection, make the connection first with the ground/return and break last with

ground/return.

Do not install equipment showing any physical damage.

If packaging is damaged, do not accept receipt from the shipper.

DANGER! RISK OF ELECTRICAL SHOCK, AC

Proper actions, include, but not limited to:

a) Verify before contacting the WIC that no current leakage or ground fault condition is present.

b) Verify a proper ground is in place.

c) Verify for AC hook-up, all WIC circuit breakers are OFF and the utility incoming feed is OFF.

DANGER! RISK OF ELECTRICAL SHOCK, OSP CABLES

If joint buried cables are used, check the cable sheath for voltage in accordance with local standards. If voltage is detected,

do not proceed with the installation. Contact the supervisor and do not proceed until the voltage hazard is eliminated.

DANGER! RISK OF ELECTRIC SHOCK

The DC bus may be powered by DUAL power sources – rectifiers and DC batteries.

To properly work on the system, de-energize by disconnecting BOTH power sources. Even with the batteries turned off by

using a local battery (circuit breaker) disconnect, batteries are still “LIVE” and hazardous, including a voltage >50 VDC, and a

source of high short circuit current.

Use extreme caution around the batteries and terminals.

WARNING! RISK OF INJURY TO EYES AND SKIN, FROM OPTIC DEVICES

Do not look into a fiber cable or device, nor hold such cable or device against body, fabric or other material.

WARNING! RISK OF HAZARDOUS SUBSTANCES

After handling of the WIC or any such component, such as batteries, cables, busbars, etc., always wash hands immediately

after.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

xii

DANGER! RISK OF CHEMICAL EXPOSURE

A battery can present harmful chemicals. Refer to the battery installation manuals and MSDS supplied with the batteries.

Work in a ventilated area and follow all safety procedures.

At a minimum, wear safety glasses and gloves when working with batteries.

Do not smoke.

CAUTION! PREVENT EQUIPMENT DAMAGE, PROPER HANDLING

Do not stack nor lay the WIC on its side.

Similarly, do not stack batteries or lay them on their side. Do not tip batteries -- keep in upright position at all times.

CAUTION! TO AVOID EQUIPMENT DAMAGE:

DO NOT REMOVE the exterior packaging or wrap from the WIC until the WIC is transported to the installation site. Control

moisture and condensation inside the WIC until it is turned up for service.

CAUTION! PREVENT EQUIPMENT DAMAGE, FROM CONDENSATION

Until the WIC is turned up for service, the bags of desiccant shipped with the WIC must remain in the WIC to prevent

condensation.

Once service is in-place, remove the desiccant.

DANGER! PREVENT EQUIPMENT DAMAGE, MAINTAIN VENTILATION

To optimize the service life of this equipment, make sure there are no obstructions in front of the ventilation openings.

WARNING! RISK OF EXPLOSION

For safety reasons, never restrict or block the airflow through the door or entry panel ventilation openings.

CAUTION! PREVENT EQUIPMENT DAMAGE, OPERATING TEMPERATURE

The WIC is approved for operation in an environment with an expected temperature range of -40 °F

+46 °C) and 0% to 95% relative humidity range, condensing. Do not use at temperatures or humidity exceeding these ranges.

The WIC is not for indoor use.

WARNING! PREVENT INJURIES, FROM LIFTING THE WIC

Follow all local safety practices while lifting the WIC. Safety equipment, signage, traffic control and all required Personal

Protective Equipment (PPE) shall be used.

Keep unnecessary personnel and bystanders clear of work areas at all times.

Do not lift the WIC over people. Do not let anyone work, stand, or pass under a lifted WIC.

Do not move or lift the WIC with a door open.

to +115 °F (–40 °C to

Only properly trained and certified operators shall operate any crane or lifting equipment.

Do not allow the lifting equipment or WIC to touch any electrical wiring or equipment.

Operate all lifting equipment within safety constraints, as defined by the manufacturer and local practices; for example, do not

exceed the capacity of reach.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

xiii

Crane Operation:

Only properly trained operators shall operate the crane.

Do not operate the crane until all stabilizers are extended. The stabilizers must be in firm contact with the ground or other

adequate support structure. Do not retract or extend the stabilizers when the WIC is suspended from the crane.

Only the crane rigging crew should set up the crane and rigging.

Do not exceed the lifting capacity of the crane.

Use all four (4) provided lifting points (eyes) at the top corners of the WIC to lift the WIC.

Use crane spreader frames to prevent WIC framework warping due to side loading.

Never route straps, cables or chains through the fork-lift channels in the base for a vertical crane lift.

Do not use slings, clevises or shackles of insufficient capacity.

Forklift Operation:

Only properly trained operators shall operate the forklift.

Do not exceed the lifting capacity of the forklift.

Forklifts shall have a minimum fork length of 72 inches.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

xiv

Static Warning

This equipment contains static sensitive components. The warnings listed below must be observed to prevent damage to

these components. Disregarding any of these warnings may result in personal injury or damage to the equipment.

1. Strictly adhere to the procedures provided in this document.

2. Before touching any equipment containing static sensitive components, discharge all static electricity from yourself by

wearing a wrist strap grounded through a one megohm resistor. Some wrist straps have a built-in one megohm resistor;

no external resistor is necessary. Read and follow wrist strap manufacturer’s instructions outlining use of a specific wrist

strap.

3. Do not touch traces or components on equipment containing static sensitive components. Handle equipment

containing static sensitive components only by the edges that do not have connector pads.

4. After removing equipment containing static sensitive components, place the equipment only on static dissipative

surfaces such as conductive foam or ESD bag. Do not use ordinary Styrofoam or ordinary plastic.

5. Store and ship equipment containing static sensitive components only in static shielding containers.

6. If necessary to repair equipment containing static sensitive components, wear an appropriately grounded wrist strap,

work on a conductive surface, use a grounded soldering iron, and use grounded test equipment.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

1

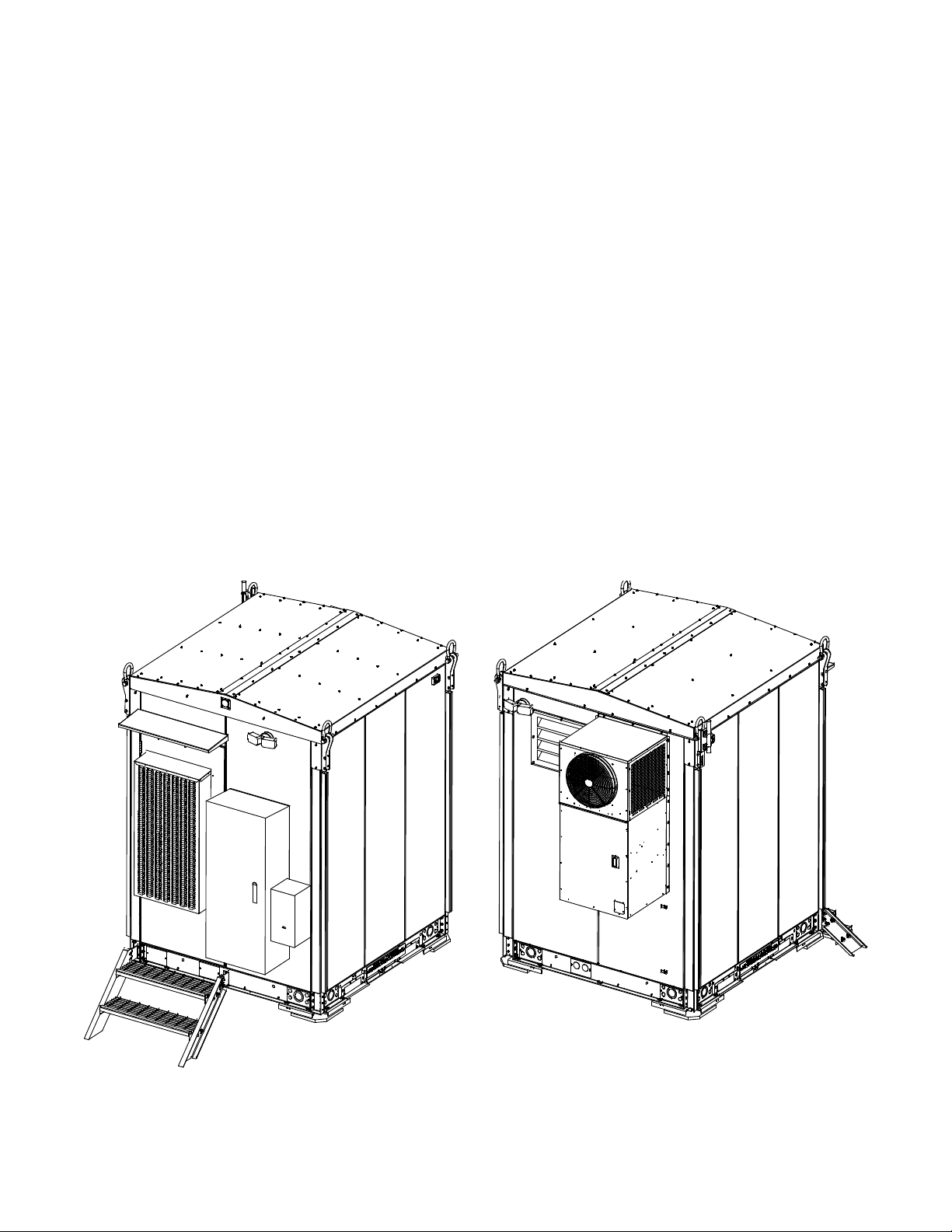

Front Rear

1 About this Document

This document provides description and installation instructions for the XTE 802 Series Walk-In-Cabinet (WIC); Spec. No. F2018009,

including associated foundation kits and platforms.

When using this document, consider the footprint for the XTE 802 Series Walk-In-Cabinet (WIC) you are installing as well as any

installed options when determining which procedures contained within this document will be applicable for your installation.

Procedures related to the provisioning, start-up, and acceptance of associated telecom equipment are not covered in this document.

Documents that supplement the information in this document are referenced in “Sequence of Procedures” on page 30.

2 Product Description

2.1 General

The XTE 802 Series Walk-In-Cabinet (WIC) ensures vital electronic equipment is protected from vandalism and environmental

damage. The XTE 802 Series Walk-In-Cabinet (WIC) may be equipped with a NetSure™ 7100 Power System (-48 VDC at 1000 amps,

+24 VDC at 500 amps, 3 row distribution). The XTE 802 Series Walk-In-Cabinet (WIC) offers an array of climate control, remote

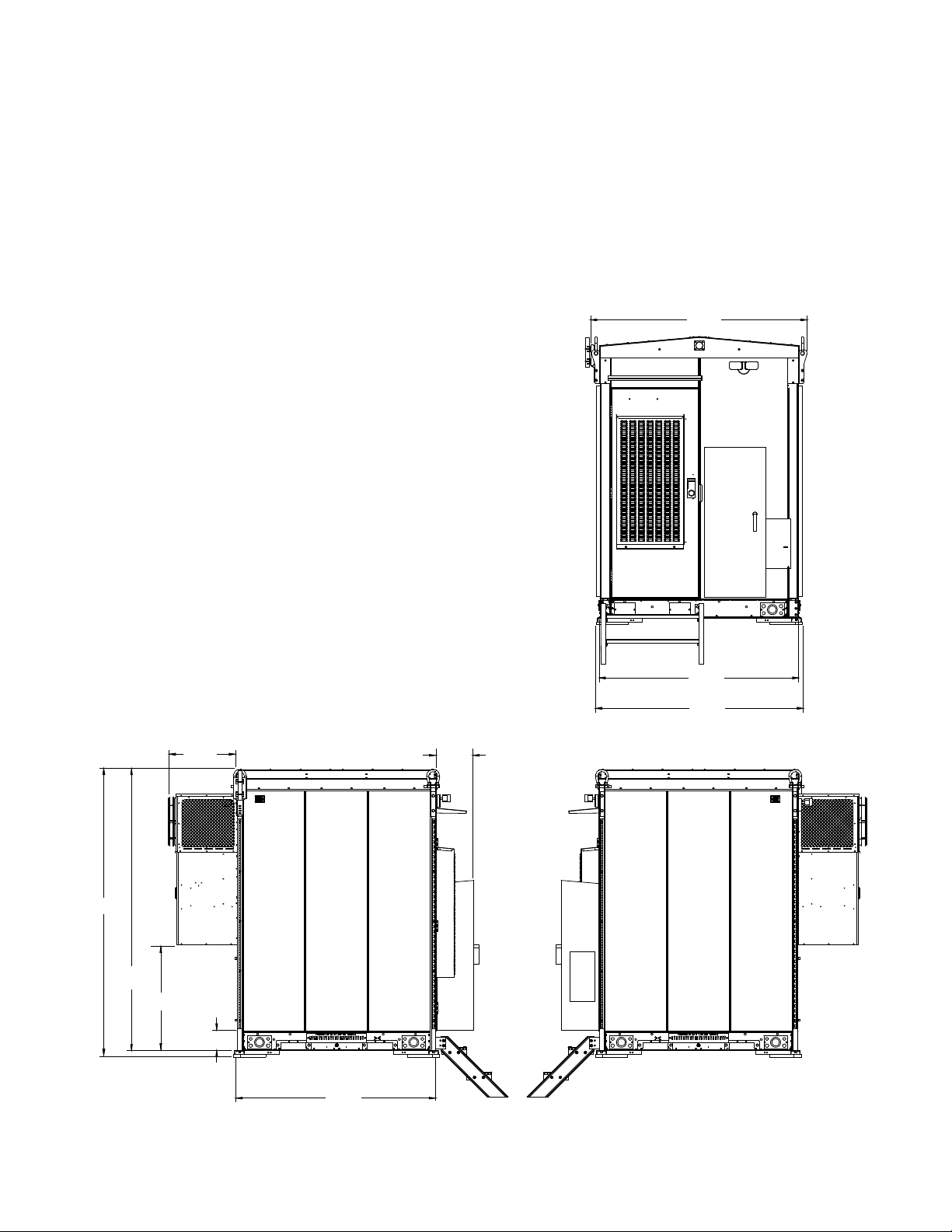

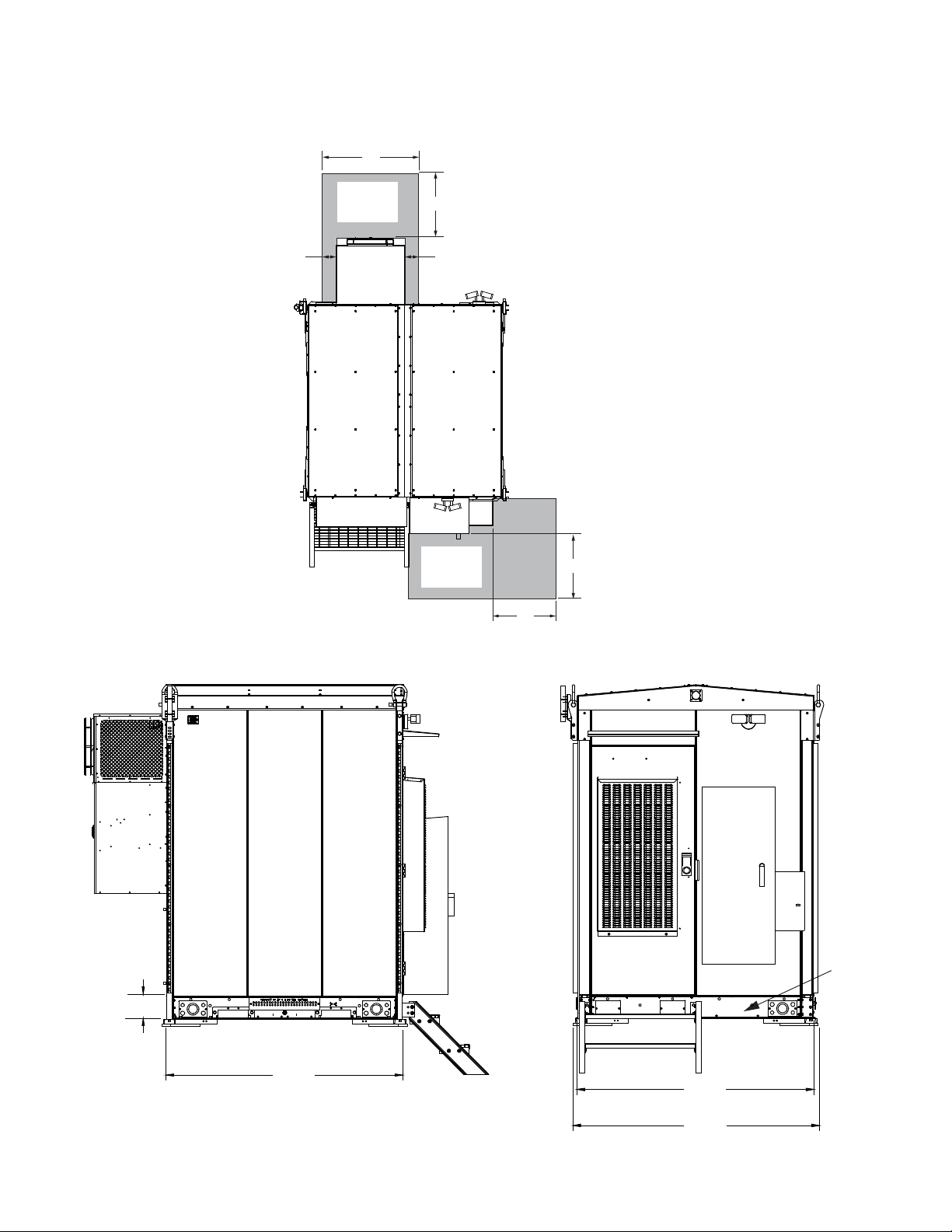

monitoring and control, power, mounting and configuration options. See Figure 2-1 for overall views of the XTE 802 Series Walk-InCabinet (WIC).

Figure 2-1: Overall Views of XTE 802 Series Walk-In-Cabinet (WIC)

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

2

2.2 Part Numbers

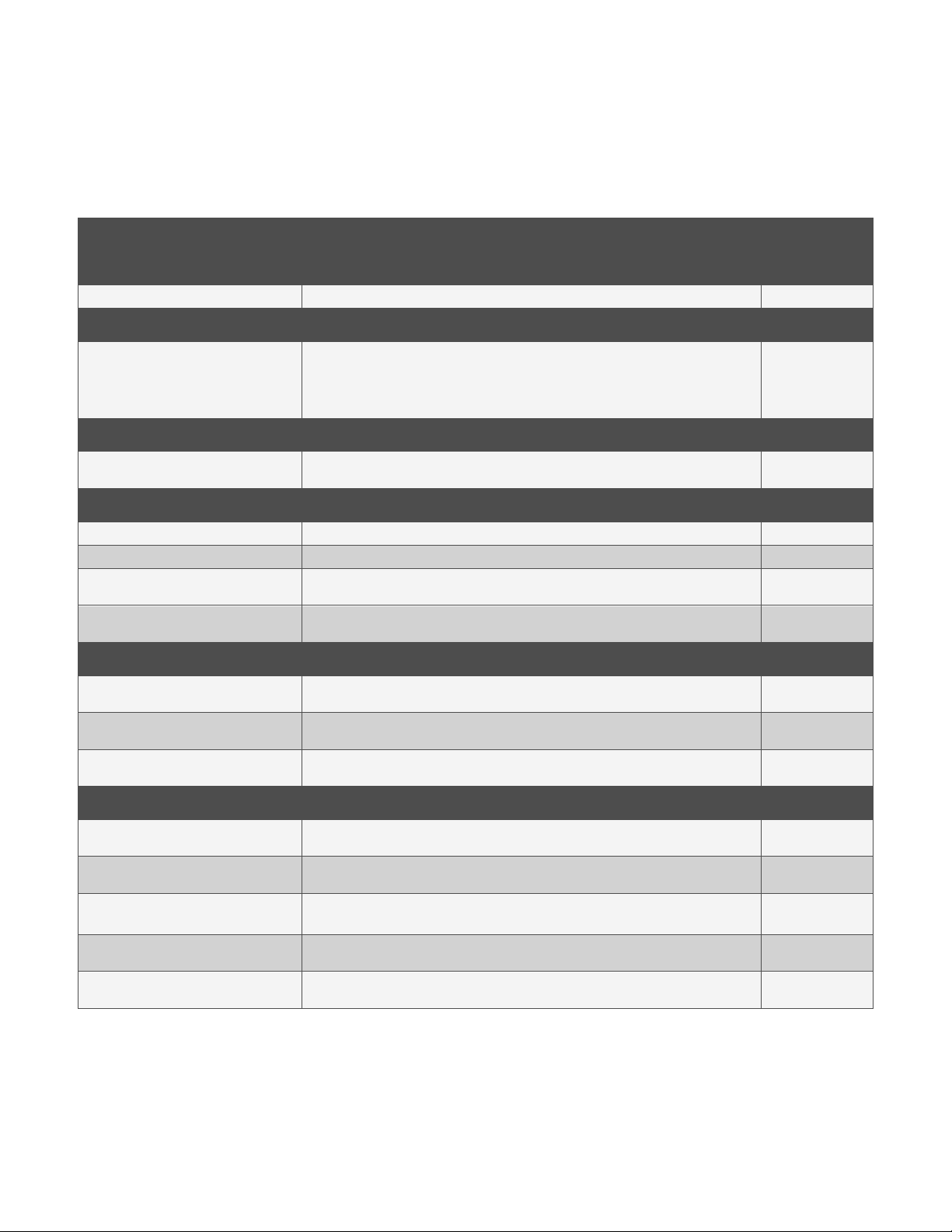

Refer to Table 2-1 for applicable product part numbers.

Table 2-1: XTE 802 Series Walk-In-Cabinet (WIC) Part Numbers and Descriptions

Part Number Description NEQ

XTE 802 Series Walk-In-Cabinet (WIC)

F2018009 ATT 6X6 WIC e/w as detailed below. NEQ.20060

Electrical Service Entrance

PTLC-ATS-3S-12200-CL_ATT UL 891 Listed, 32x22*x10 cabinet with CamLok Connector Panel, 240 VAC / 120 VAC, 200 A

Power Transfer Load Center with automatic transfer between Utility and an Alternative Power

Source permanently connected or temporarily connected via CamLok style connectors. PTLC

includes ASCO 510 Series TVSS surge protection, a 30-position Square D NQ panelboard, and

an alarm monitor for utility power loss SPD fail, and generator. (Vertiv P/N 151840.)

DC Power System

582127000203 NetSure™ 7100 SERIES -48V DC Power System sized at 1,000 Amp on the -48 VDC side and

500 A on the +24 VDC side with 3 factory-installed and wired battery trays.

Additional Equipment

PTS 3703-WIC WOF Rack CommBay-WIC-without Fiber Panel. NEQ.19678

PTS3704-WIC-WF Rack CommBay-WIC-with Fiber Panel. NEQ.19679

DAC2000S000-299-VAR-0013 Direct Air Cooling (DAC) system. Dual Fan -48 VDC powered fresh air cooling kit with HVAC

control for low voltage (24 VAC) controlled HVAC unit. (Vertiv P/N 151903.)

ECUA18 MAA1018 1.5 TON WALL MOUNTED HVAC, with controller, supply and return grills and remote sensor

(Vertiv P/N 10011724).

WIC Foundation Options

D1000-0000-0101 WIC Helical Foundation Kit – (4) WIC Corner Plates, (1) Two Step Stair, and (4) 6” x 7’ Helical

Piers with Leveling Hardware.

D1007-0000-0012 WIC Concrete Pier/Pad Foundation Kit - (4) WIC Corner Plates, (1) Two Step Stair, and (4) 11"

Extensions with Leveling Hardware.

D1000-0000-0103 WIC On The Ground (Gravity) Foundation Kit - (1) Frame, (1) Two Step Stair, and (9) 11"

Footers with Leveling Hardware.

Generator Foundation Kits

NEQ.20110

NEQ.20068

N/A

N/A

NEQ.19785

NEQ.20061

NEQ.20140

D1000-0010-0075 Vertical Polar Generator Helical Foundation Kit - (1) Frame, (2) 6" x 7' Helical Piers with

Leveling Hardware.

D1000-0010-0109 All Generators Up To 20KW Helical Foundation Kit - (1) 5' x 6' platform, (2) 6" x 7' Helical Piers

with Leveling Hardware.

D1000-0010-0109 All Generators Up To 30KW Helical Foundation Kit - Order two of these platforms and bolt

together. All material provided.

D1000-0000-0115 Vertical Polar Generator Concrete Pier/Pad Foundation Kit - (1) Frame, (2) Leveling Plates

with Leveling Hardware.

D1001-0020-0062 All Generators Up To 30KW On the Ground (Gravity) Foundation Kit - (1) 4' x 9' Platform, (9)

Feet with Leveling Hardware.

NEQ.20046

NEQ.20047

NEQ.20047

x2

NEQ.20297

NEQ.20186

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

3

Part Number Description NEQ

WIC Generator Combo Platforms

D1000-0010-0122 WIC Generator Combo Helical Platform - (1) Platform, (2) Stairs, (4) 8" x 7' Helical Piers with

Leveling Hardware, and Rodent Barrier.

D1000-0010-0123 WIC Generator Combo Concrete/On the Ground Platform - (1) Platform, (2) Stairs, (3) Skis

with Leveling Hardware, and Rodent Barrier.

D1000-0020-0032 Generator Wings - (2) 12" x 38" Extensions for Combo Platforms to accommodate Generac

30KW Diesel Generator.

D1000-0010-0089-04 Elevated WIC and Generator Platform 4' - (1) Platform, (1) Stairs, (1) Stairs Landing, (5) 10" x 2'

Extensions with Leveling Hardware, and (5) 10" x 10' Helical Piers with Leveling Hardware.

D1000-0010-0089-06 Elevated WIC and Generator Platform 6' - (1) Platform, (1) Stairs, (1) Stairs Landing, (5) 10" x 4'

Extensions with Leveling Hardware, and (5) 10" x 10' Helical Piers with Leveling Hardware.

D1000-0010-0089-08 Elevated WIC and Generator Platform 8' - (1) Platform, (1) Stairs, (1) Stairs Landing, (5) 10" x 6'

Extensions with Leveling Hardware, and (5) 10" x 10' Helical Piers with Leveling Hardware.

D1000-0010-0089-10 Elevated WIC and Generator Platform 4' - (1) Platform, (1) Stairs, (1) Stairs Landing, (5) 10" x 8'

Extensions with Leveling Hardware, and (5) 10" x 10' Helical Piers with Leveling Hardware.

D1000-0010-0089-12 Elevated WIC and Generator Platform 4' - (1) Platform, (1) Stairs, (1) Stairs Landing, (5) 10" x 10'

Extensions with Leveling Hardware, and (5) 10" x 10' Helical Piers with Leveling Hardware.

Custom Item Elevated WIC Generator Platform - This foundation kit is used in flood zones and areas where

the site needs to be elevated.

NEQ.20323

NEQ.20324

NEQ.20732

CEQ.24448

NEQ.20721

CEQ.24454

CEQ.24455

NEQ.20734

Request quote for

elevations over 12'

up to 20'.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

4

2.3 Application

The XTE 802 Series Walk-In-Cabinet (WIC) is designed to house and protect environmentally sensitive electronics at

telecommunications sites including cellular, microwave radio, BBU pools for CRAN, and edge applications with virtualized networks.

• The XTE 802 Series Walk-In-Cabinet (WIC) is designed to provide secure and water-tight housing for equipment, power and

batteries supporting wireless and wireline telecommunications applications.

• The XTE 802 Series Walk-In-Cabinet (WIC) depends upon a proven structural system and integrated mechanical

components.

• The XTE 802 Series Walk-In-Cabinet (WIC) has several mounting options, primarily helical and concrete pier.

2.4 Standards Compliance

The XTE 802 Series Walk-In-Cabinet (WIC) is designed to meet the following standards where applicable:

• CSA Certificate of Compliance #70096774.

- CLASS - C321111 - INDUSTRIAL CONTROL EQUIPMENT - Enclosures for Electrical Equipment

- CLASS - C321191 - INDUSTRIAL CONTROL EQUIPMENT - Enclosures for Electrical Equipment – US

- Enclosure Type 3R

NOTE!

APPLICABLE REQUIREMENTS

• National Building Code - Canada, 2005.

• National Building Code - USA, 2012.

• ASTM A653 - Galvanized Steel.

• Welding Conformance to CWB - CSA Standard W47.1 and AWS – D1.2, D1.3 and D1.6.

• Designed to Meet Seismic Zone 4.

• Telcordia GR487 compliant for corrosion, water intrusion, ultraviolet radiation, and impact resistance.

The WIC is intended for industrial and/or power distribution equipment applications. These components are

intended for the installation of industrial electrical equipment and/or power distribution equipment where the complete

assembly is approved for installation in non-hazardous locations in accordance with the National Electric Code (NEC) and

Canadian Electric Code (CEC).

a) CSA C22.2 No, 94.1-07 / UL 50 12th Ed (Harmonized) Enclosures for Electrical Equipment, Non-Environmental

Considerations.

b) CSA C22.2 No. 94.2-07 / UL 50E 1st Ed (Harmonized) Enclosures for Electrical Equipment, Environmental

Considerations.

• DC Power System - UL Listed 1801, cUL, NEBS Level 3.

• Power Transfer Load Center (PTLC) – constructed in accordance with UL 67 Standard for Panelboards. Suitable for use as

Service Entrance.

• Automatic Power Transfer Switch: UL Listed to UL 1008, Standard for Transfer Switching Equipment.

• UL/CSA Compliant Climate and other miscellaneous electrical equipment.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

5

• Electrical certification as per CSA and NFPA70 (NEC) requirements.

• Installation method compliant to AT&T TP76300.

2.5 Safety Listed AC or DC Components

A typical XTE 802 Series Walk-In-Cabinet (WIC) only utilizes listed or recognized components for the United States and/or Canada.

The following examples of these may or may not be included in the WIC:

• AC Terminal Blocks

• Liquid Tight Flexible Metallic Conduit

• GFI AC Receptacle

• AC-DC Rectifiers

• AC or DC Circuit Breakers

2.6 Commercial AC Service

AC power to be provided by customer via an upstream power source load center or power pedestal. Only load circuits to be brought

into AC entry facility. Overcurrent devices are not provided in the WIC. Load circuits in the WIC requiring power as per the WIC AC

schematic.

• Power Service Required: 120 VAC / 240 VAC, 1 phase, 60 Hz with upstream fuse protection and upstream surge protection.

The service entrance system will consist of the following:

• Power Transfer Load Center constructed in accordance with UL 67 Standard for Panelboards.

Suitable for use as service equipment.

• Automatic Power Transfer Switch: ASCO D3ATS, 2 Pole, 200 Amp, 240 VAC maximum. UL Listed to UL 1008, Standard for

Transfer Switching Equipment.

- Transfer Controller – ASCO Group G Automatic Transfer Switch Controller including:

Automatic Engine Starting Contacts.

Single Phase voltage sensing of Normal and Emergency sources.

Frequency sensing of Emergency source.

• Short Circuit Ratings:

- Main (Normal Source): Utility main disconnect circuit breaker, 2 pole, 200 amp at 240 VAC maximum, 22kA – Square-D

Type QD.

- Main (Normal Source): Utility main disconnect circuit breaker, 2 pole, 200 amp at 240 VAC maximum, 42kA – Square-D

Type QG.

- Permanent Emergency Source: Permanent emergency source circuit breaker, 2 pole, 200 amp at 240 VAC maximum,

10kA – Square-D Type QB.

- Temporary Emergency Source: Temporary emergency source circuit breaker, 2 pole, 200 amp at 240 VAC maximum,

10kA – Square-D Type QB.

- Branch: Branch ratings as follows when used with the specified branch devices and in combination with selected

optional normal and emergency source short-circuit ratings.

42kA using Square-D QH or QHB rated: 1 pole 15-30A, 2 pole 15-30A, 3 pole 15-30A.

22kA using Square-D QO-VH or QOB-VH rated: 2 pole 150A, 3 pole 35-150A.

10kA using Square-D QO or QOB rated: 1 pole 15-70A, 2 pole 15-125A, 3 pole 15-30A.

• Panelboard: Square-D NQ, 200 Amp maximum, 240 VAC maximum, single phase with 100% rated neutral. 30 circuits,

accepts bolt-on or plug-in branch devices.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

6

• Square-D QO120GFI, 20 Amp, 120 VAC Ground Fault Circuit Interrupter (GFCI) circuit breaker, wired to a duplex outlet.

• Transient Surge Protection: Connected to line side of panelboard for L-N (and L-G if used as service equipment) mode

protection. ASCO 510 Series TVSS with phase monitoring, alarm module, and load phase voltage availability indicator’s (LED)

on front of swing panel.

• Enclosure:

- Type 3R Listed to UL 50/50E. Single compartment wall mount compartment provides Type 1 protection with exterior

open and swing panels closed.

- Box and Doors: Constructed of 0.095 think aluminum alloy (5052-H32).

- Finish (all interior and exterior surfaces): Textured polyester powder coat, pebble gray (RAL 7032).

• Alarms – Utility Loss Alarm Monitoring, SPD Fail, and generator.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

7

2.7 WIC Dimensions, Weights, and Physical Specifications

Standard Racks

The XTE 802 Series Walk-In-Cabinet (WIC) may be equipped with two 19” wide equipment bays and each provides 45 rack units (RU).

One (1) rack comes equipped with a fiber patch panel and the other does not.

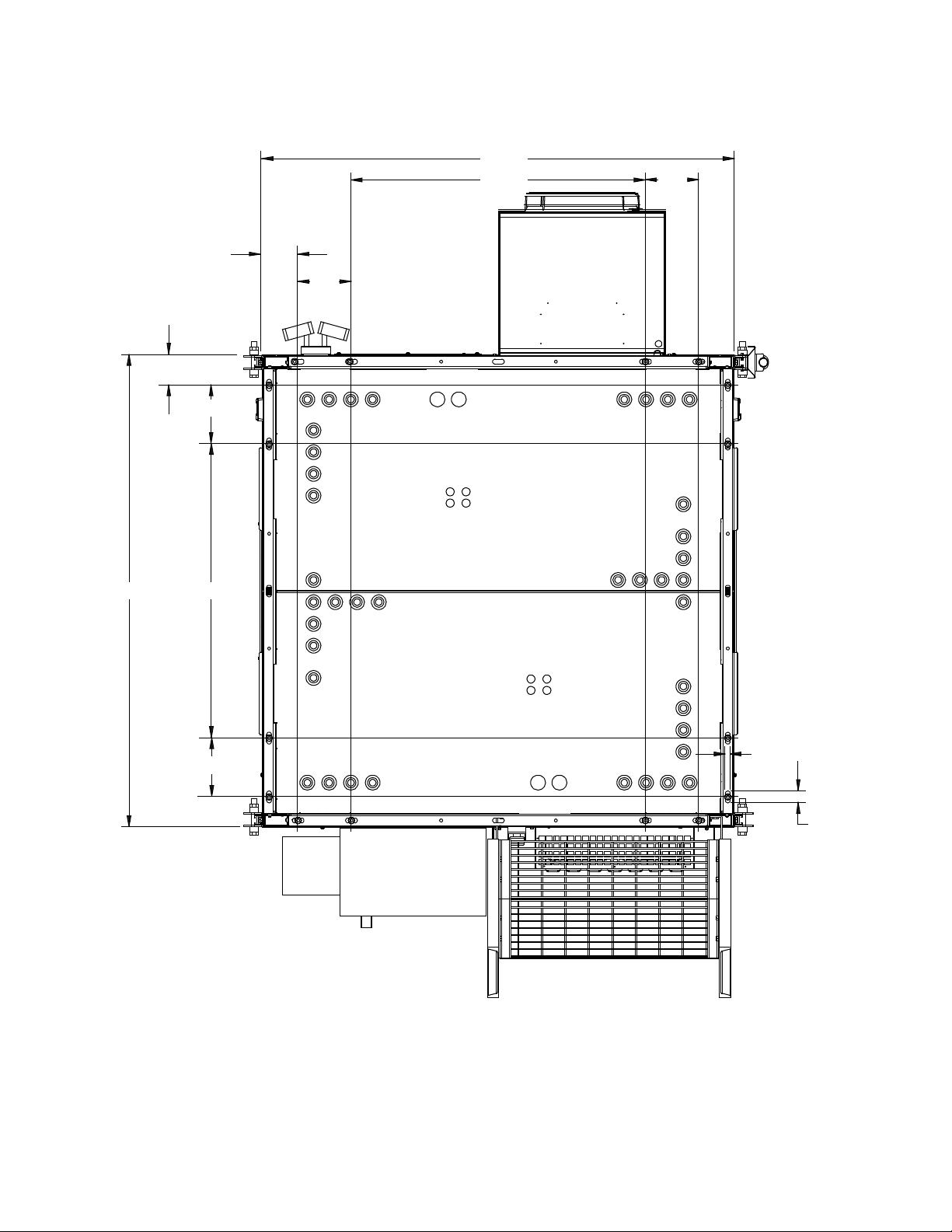

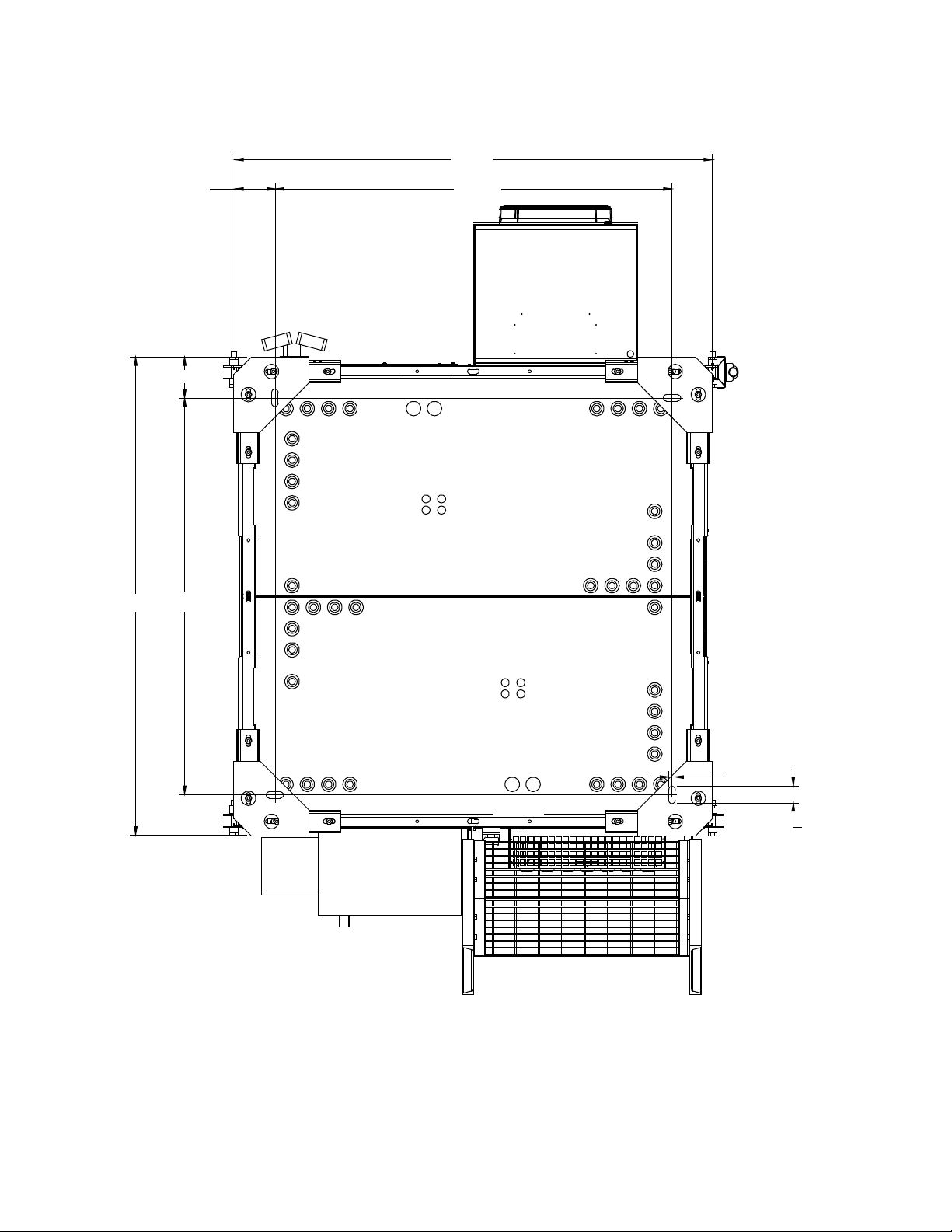

Dimensions

• See Figure 2-2 for overall dimensions.

• See Figure 2-3 for mounting hole dimensions without corner plates and Figure 2-4 for mounting hole dimensions with corner

plates.

• See Figure 2-5 for working space clearances.

• See Figure 2-6 for base dimensions.

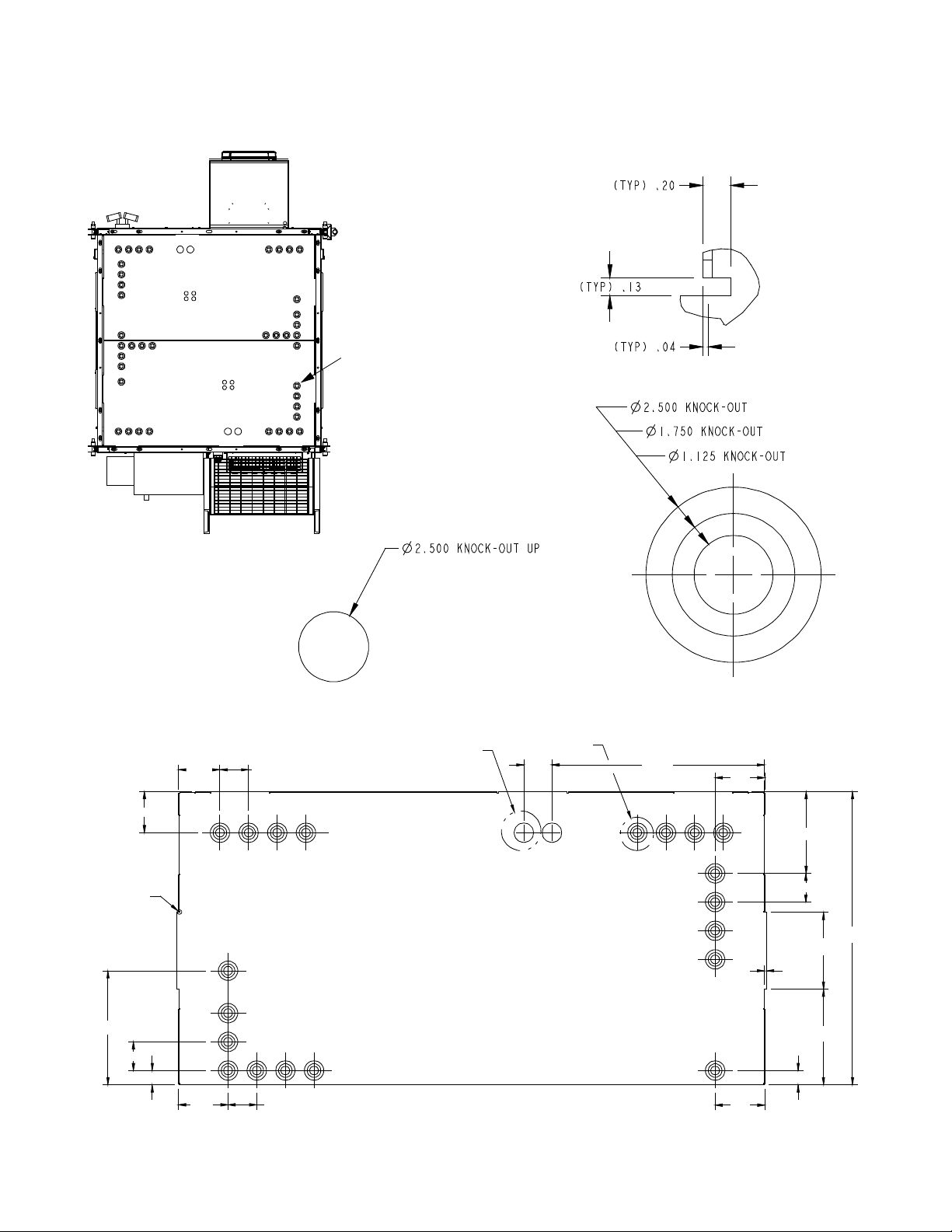

• See Figure 2-7 and Figure 2-8 for conduit knockout locations and dimensions.

Specifications

• External Dimensions – 80” x 80” x 113”

• Internal Height – 96.5"

• Internal Width – 71.4"

• Internal Length – 71.4"

• Weight – Empty: 4,500 lbs.

As Installed: 6,500 lbs.

• R13 Insulation for walls and ceiling.

• One (1) hour fire rating.

• Common equipment kit (lighting, cable rack, etc.).

• Primary DC powered high efficiency thermal management system.

• 1.5 ton backup air conditioner.

• Heater system.

• 200 A AC electrical system with power transfer and Cam-lock generator connection.

• Fully integrated internal grounding system.

• Thermal management and HVAC control.

• 66 type contact alarm consolidation point.

• Fold down laptop desk.

• Externally mounted color matched unistrut channels on each lifting strap for mounting external equipment.

• Externally mounted GPS antenna mounting brackets.

• Color – Pebble-Gray, RAL7032.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

8

Notes:

1. All dimensions are in inches,

unless otherwise specified.

79.76

82.99

86.50

Front

79.74

115.67

7.59

15.13

27.52

113.00

42.49

Left Side Right Side

• Finish – Standard finish is multistage dry powder polyester paint for maximum durability and performance against corrosion.

Optional exterior finishes also available upon request.

• NetSure™ 7100 DC Power System in 23" rack with three (3) battery trays (Third Party Integrated).

• NCU system and generator control (Third Party Integrated).

• Two (2) 19" equipment welded frames installed. One with fiber patch panel and the other without. (Third Party Integrated.)

Figure 2-2: WIC Overall Dimensions

9

Figure 2-3: Mounting Hole Dimensions (without corner plates)

2.00

80.26

80.26

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

5.14

10.00

49.97

6.07

9.06

50.00

Bottom View

9.06

10.00

0.81

Notes:

1. All dimensions are in inches,

unless otherwise specified.

Front

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

10

unless otherwise specified.

82.99

82.99

Figure 2-4: Mounting Hole Dimensions (with corner plates)

7.07

7.07

68.85

68.85

Bottom View

1.13

2.43

Front

Notes:

1. All dimensions are in inches,

11

Figure 2-5: Working Space Clearances

HVAC

ATS

36

Top View

6

6

Notes:

1. All dimensions are in inches,

unless otherwise specified.

36

Working

Space

Working

Space

36

42

Notes:

1. All dimensions are in inches,

unless otherwise specified.

Base

79.76

82.99

Front

79.74

7.59

Left Side

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

Figure 2-6: Base Dimensions

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

12

Bottom Cover Panel Conduit Knockout Locations and Dimensions

Bottom View

Typ. Conduit Knockout

(see Detail B)

Front

Notes:

1. All dimensions are in inches,

unless otherwise specified.

20X Detail B

2x

5.35

3x 5.30

6x 3.70

14.73

2x 3.70

1.85

6.40 3x 3.70

1.85

6.40

3x 3.70

2x 9.92

2x 12.34

2x 0.29

37.84

10.55

6.40

3.63 27.43

See Detail C

See Detail B

See Detail A

Detail A

2X Detail C

Figure 2-7: Conduit Knockout Locations in WIC Base Pan

13

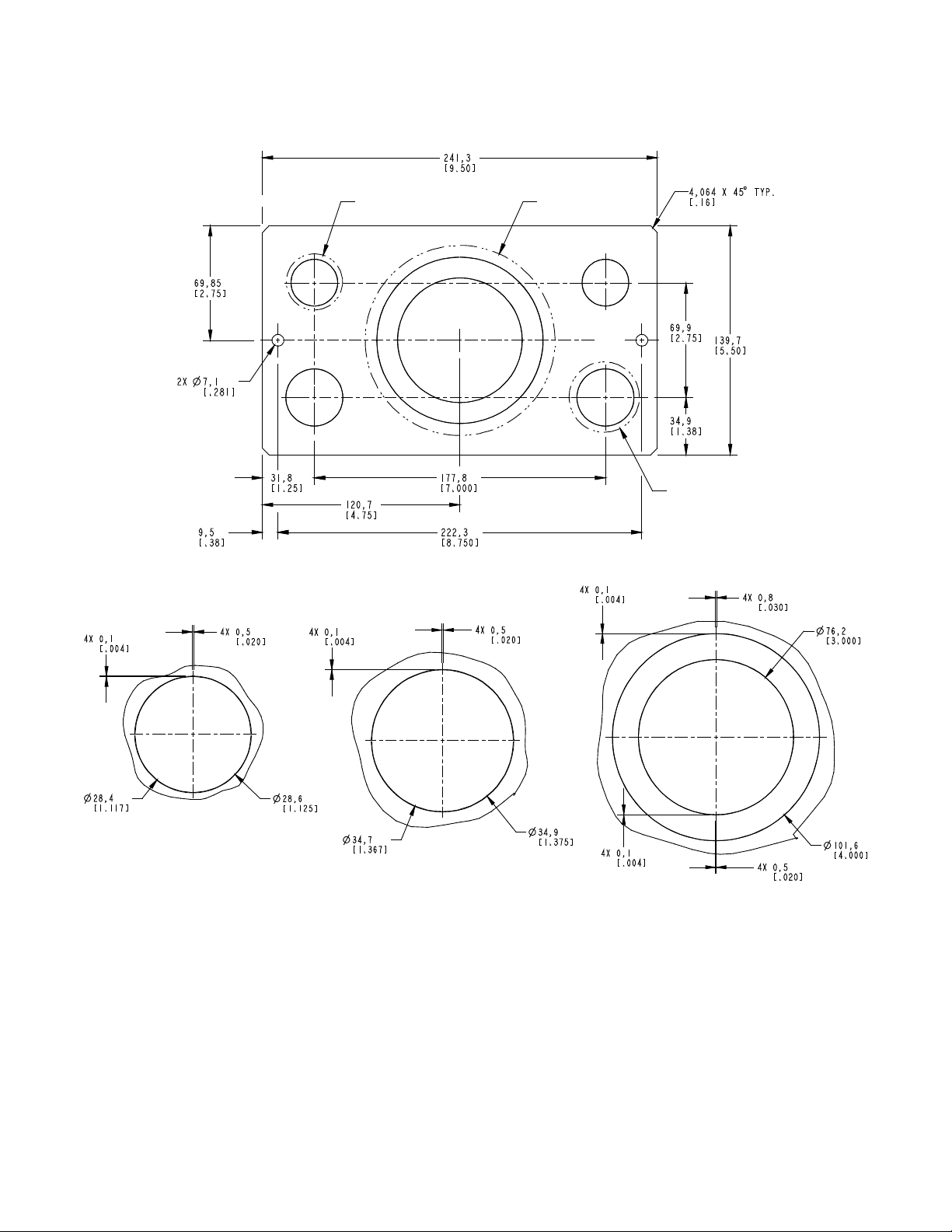

Figure 2-8: WIC Base Side Plate Conduit Knockout Dimensions

Notes:

1. All dimensions are in mm [inches].

2. All dimensions are to outside surface.

See Detail A

See Detail C

See Detail B

2X Detai l A

2X Detail B

Detail C

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

14

2.8 WIC Features and Options

Perspective Views

For illustrations of the WIC, refer to the following.

• Refer to Figure 2-9 and Figure 2-10 for WIC perspective views with major features identified.

• Refer to Figure 2-11 for WIC wall detail views.

• Refer to Figure 2-12 for top view of WIC floor.

• Refer to Figure 2-13 for WIC AC conduit routing.

• Refer to Figure 2-14 for WIC DC wireway locations.

• Refer to Figure 2-15 for door intrusion switch and fold down laptop desk locations.

• Refer to Figure 2-16 for floor cable entry ports locations.

Construction

Welded galvanized steel construction with outstanding impact and corrosion resistance.

• Interlocking steel panels construction.

• Walls, floor and ceiling are made of 14 gauge steel.

• Ceiling joists with 12 gauge steel.

• Floor Load: 200 pounds per square foot minimum (uniform with full-support foundation).

• Roof Live and Impact Load: 300 PSF (maximum).

• Wind Speed: 180 mph.

Protection

Powder coat finish. Meets GR487 Telcordia mechanical and environmental standards for telecom cabinets.

• Protects against rain, sleet, snow, splashing water and damage from external ice formation.

• Optional exterior finishes including brick, stone and exposed aggregate are available upon request.

Mounting Base

Cable mounting base with 360 degree access to floor penetrations for easy conduit and cable entries into the XTE 802 Series WalkIn-Cabinet (WIC). See

• Fork lift tubes on front and back.

• Base includes steel cover plates front and back to accommodate cabling.

Figure 2-6 on page 11.

Interior Finish

• Walls: White-textured Melamine panels over 5/8" gypsum board (1-hour fire-rated).

Insulation

• Walls: R-13 Thermax foam with vapor barrier in wall cavities.

• Roof: R-13 Thermax foam with vapor barrier in cavities between ceiling and roof.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

15

Common Equipment Kit

• Motion Controlled 70 W Outside Light

• Interior -48 VDC Lights

• Door Contacts

• Halo ground, interior isolated copper ground bar with ground cables to equipment rack, H taps for ground terminal and

external isolate ground bar with 2/0 ground cable, ground entry / exit plate as per ATT grounding specification.

Access Doors and Hardware

• Type: 16 gauge galvanized steel commercial grade insulated door.

• Size: 36" x 84" outward opening.

• Frame: 16 gauge galvanized steel frame.

• Door Lock: KABA Simplex L1000 Series, Model 1021B, Mechanical w/Best core.

• Hinges: (3) stainless steel with non-removable pin (per door).

• Door Holder: positive engagement latch with bumper stop.

• Closer: adjustable-hydraulic.

• Drip Cap: 12" drip cap above doorway.

Convenience Outlet

The WIC is equipped with two 20 A convenience outlets on the interior left side wall and one 20 A GFCI on the exterior PTLC-ATS.

Ground Bar

The WIC contains one (1) 24-position galvanized steel ground bar mounted to the outside of both the right and left sides of the base

assembly and one (1) 1/4” x 4” copper Master Ground Bar (MGB) located on the interior. The all-metal structure of the WIC is bonded

together using the PANI method for grounding.

Door Intrusion Switch

A door intrusion switch is provided, factory wired to the alarm blocks. See Figure 2-15 for location and “Intrusion Alarm Switch

Operation” on page 31 for operation.

Lifting

The XTE 802 Series Walk-In-Cabinet (WIC) is equipped with one lifting lug at the top of each corner that allow it to be lifted and

lowered into position. The base is also equipped with fork lift pockets that allow the use of a forklift to offload and lower to the

mounting base at the site.

Alarms

• The XTE 802 Series Walk-In-Cabinet (WIC) is equipped with intrusion, HVAC, various commercial AC power and DC power

alarms.

• Two alarm blocks are provided on the Telco Board inside the WIC for alarm connections.

• An alarm pinout is specified in the schematic drawings shipped with the WIC.

• The intrusion alarm triggers whenever the door is opened. It can be disabled by pulling the alarm plunger completely

forward.

Vertiv™ XTE 802 Series Walk-In-Cabinet (WIC) Description and Installation Manual

16

Light Switch

Located to the right of the door as you enter. A light switch is provided for the three (3) interior ceiling mounted LED lights.

Rack Sizes

Accommodates 19" width equipment racks with EIA hole spacing.

Fold Down Laptop Desk with Document Holder

The XTE 802 Series Walk-In-Cabinet (WIC) is equipped with a fold down laptop desk with document holder. See Figure 2-15 for

location.

Cable Entry Ports

The WIC contains wall and floor cable entrances.

The WIC has one (1) cutout in each of the left and right side walls which are equipped with Roxtec 4/4 EzEntry ports. See Figure 2-9

for the location of the cable entry ports.

The WIC has five (5) cutouts in the floor which are all equipped with Roxtec 24/24 EzEntry ports. See Figure 2-16 for the location of

the cable entry ports. See Figure 2-7 on page 12 for conduit knockout locations in WIC base pan.

Climate Control

The XTE 802 Series Walk-In-Cabinet (WIC) is offered with the climate control options listed in Table 2-2.

HVAC Units

AC heaters are included with each air conditioning unit to maintain internal WIC temperatures during cold climate conditions. Air

conditioners are AC powered, and are refrigerant-based vapor compression devices. The heaters are electric strip type, integral to the

a/c unit.

Thermal Controller

Marvair CoolLink.

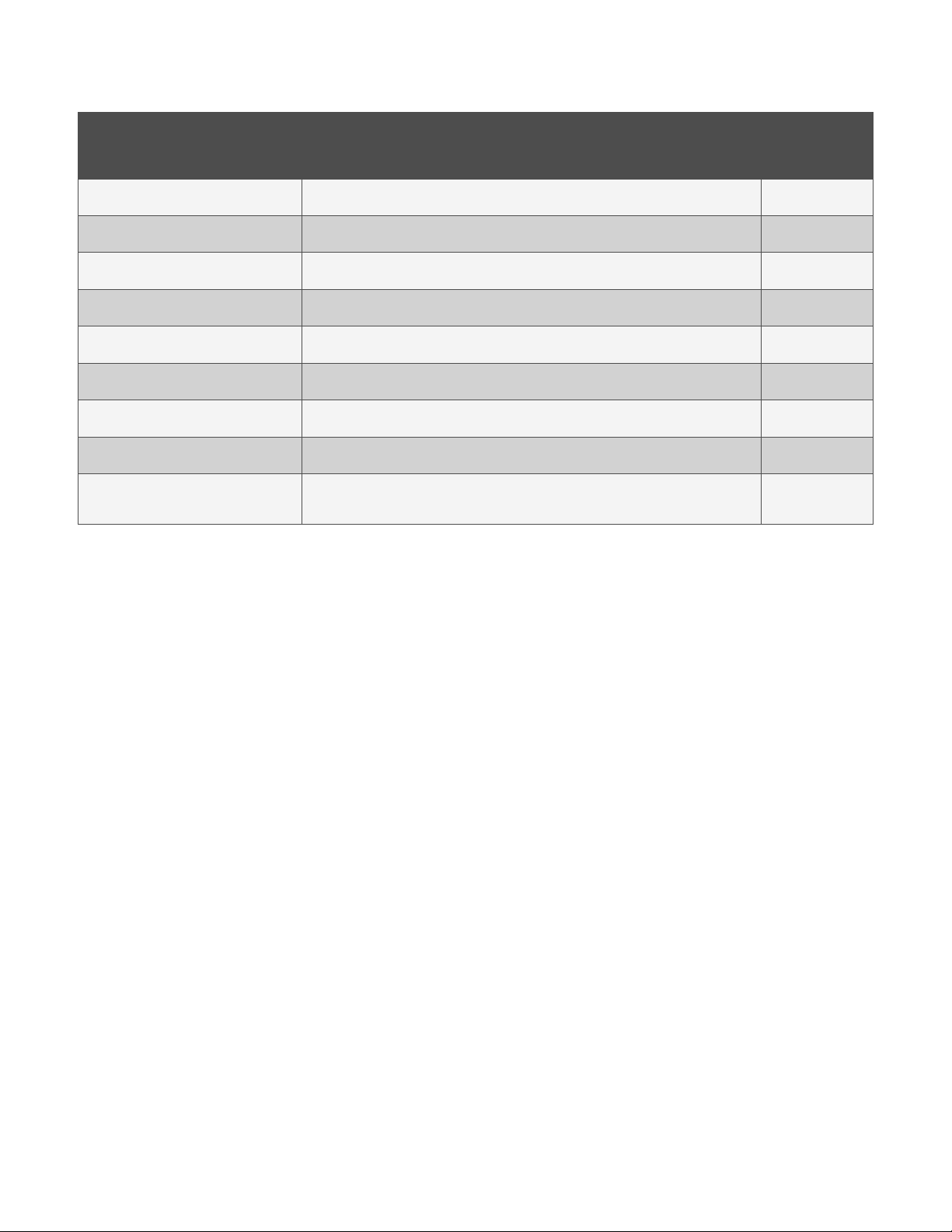

Table 2-2: Climate Control Configuration

Thermal System Element Mounting Power Controls

Primary Cooling System: Filtered Vent Fans (2 Radial Fans) / Power

Louver Exhaust Vent Free Air Cooling

Secondary / Back-Up System: HVAC Unit

- Cooling, 1.5 Ton

-

Integral Electric Heat Elements

Door /

Rear Wall

Rear Wall 240 VAC Circuit

48 VDC Power / ECU Marvair CoolLink

Marvair CoolLink and

Thermostat

-48 VDC Battery Option

The -48 VDC NetSure 7100 power bay contains three (3) battery shelves equipped with three (3) strings of -48 VDC batteries

connected in parallel.

Rack Units

Accommodates up to two 84" tall, 45 RU relay racks for 19" wide equipment mounting.

Loading...

Loading...