Page 1

Vertiv™ SmartRow™ DCX

Installation Manual

Page 2

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv This document is the property of Vertiv and contains confidential and

proprietary information owned by Vertiv. Any copying, use or disclosure of it

without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.Vertiv.com/en-us/support/ for additional assistance.

(Undefined variable: Lg_3phase.1 - Company Name) | (Undefined variable: Lg_3phase.5 - Document Name)

Page 3

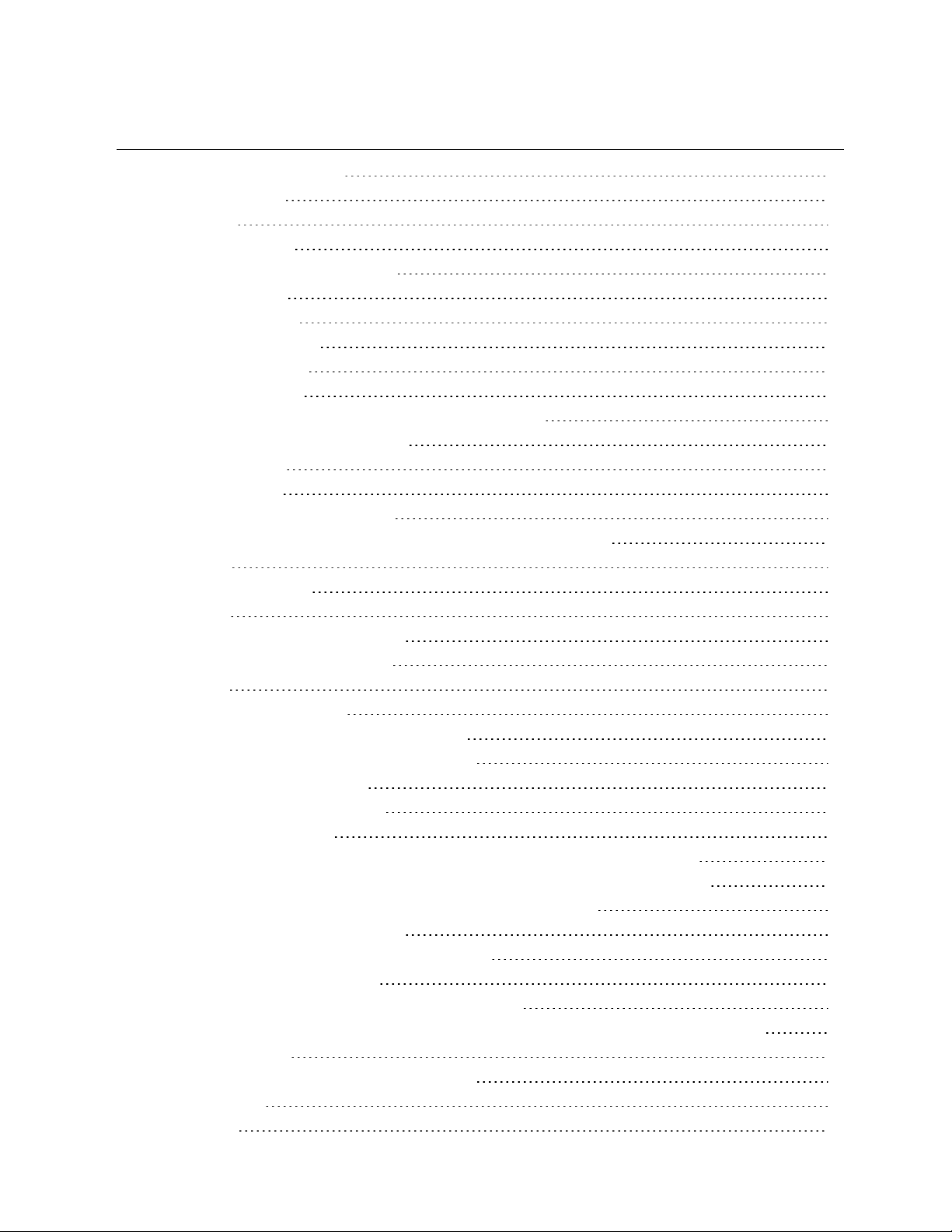

TABLE OF CONTENTS

1 Important Safety Instructions 5

2 Glossary of Symbols 7

3 Introduction 9

3.1 Operational Overview 9

3.2 Vertiv™ SmartRow™ DCX Components 9

3.3 Liebert® CRV Notes 10

4 Application Guidelines 11

4.1 Environmental Conditions 11

4.2 Cooling System Design 11

4.3 Heat Load Calculation 13

4.4 Vertiv™ SmartRow™ DCX Equipment Placement within the Row 14

4.4.1 Cooling Unit and Rack Placement 14

4.4.2 UPS System 14

4.4.3 Row Length 15

4.5 IT Equipment Deployment and Wiring 15

4.6 Settings for the Vertiv™ Liebert® iCOM™ on the Liebert® CRV Cooling Unit 16

5 Preparation 17

5.1 Clearance Requirements 17

5.2 Inspection 17

5.3 Unloading the Vertiv™ SmartRow™ DCX 18

5.4 Required Setup Tools and Equipment 18

6 Installation 19

6.1 Assembly Sequence Overview 19

6.1.1 Staging the Vertiv™ SmartRow™ Equipment 19

6.1.2 Installing the Vertiv™ SmartRow™ Equipment 19

6.1.3 Connecting the Equipment 20

6.1.4 Installing Expansion Channels 20

6.1.5 Finalizing Installation 20

6.2 Optional Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System—Overview 20

6.3 Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System Component Locations 21

6.3.1 Control Panel and Fire Suppression System Component Operation 22

6.4 Recovering from EPO Circuit Activation 24

6.5 Recovering from a Fire Suppression System Activation 24

6.6 System Set-up and Commissioning 24

6.7 Fire Detection and Suppression System Operation Overview 25

6.8 Restarting after Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System Has Shut Down 25

7 Installation Checklist 27

7.1 Cooling and Power Component Installation Checklist 27

8 Troubleshooting 29

9 Maintenance 31

Vertiv | SmartRow™ DCX Installation Manual | 3

Page 4

9.1 Liebert®CRV 31

9.2 UPSs and Rack PDUs 31

9.3 Electrical System 31

10 Technical Illustrations 33

Vertiv | SmartRow™ DCX Installation Manual | 4

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that must be closely followed during installation of this system to maintain

compliance with agency listings. Read all safety and operating instructions for all pieces of equipment before attempting to

operate the Vertiv™ SmartRow™ DCX. Adhere to all warnings on the system and in this manual. Follow all operating and

user instructions.

This product is designed for commercial/industrial use only. This product is not intended for use with life support or other

U.S. FDA designated “critical” devices. Maximum loads must not exceed those specified in this manual.

Install the equipment in a clean environment, free from moisture, flammable liquids, gases and corrosive substances. The

Vertiv SmartRow DCX must be deployed in an indoor environment that is maintained year-round between 50°F and 85°F

dry bulb (10°C and 30°C) and less than 60°F dew point (16°C). It is not suitable to install outdoors or in unconditioned

spaces (warehouses, garages, etc). This will avoid undesirable condensate formation and ensure there is air available at

suitable conditions for ventilating the SmartRow system if the Automatic Emergency Ventilation Fans activate. Additionally,

systems using a remote condenser must be operated within these parameters:

The control system provides refrigerant head-pressure control for outdoor ambient temperatures as low as -30°F (-35°C),

provided that the total design range (from minimum to maximum) is 125°F (70°C) or less. For traditional DX applications,

Vertiv™Liebert Lee-Temp kits are required only when the design temperature ranges exceed 125°F (70°C).

• Vertiv™ Liebert® MC condensers—above -20°F (-29°C)

• Liebert MC condensers with Liebert Lee-Temp kits—above -30°F (-35°C)

This product must be connected to and powered by suitable AC supplies, rated in accordance with the unit’s serial tag. It

must be properly grounded and protected by appropriately sized circuit breakers.

NOTE: The Vertiv SmartRow DCX must be installed on a flat, level surface for proper assembly and operation.

Vertiv recommends using shielded cables for all external communication interfaces.

Ensure that the Vertiv SmartRow DCX has proper ventilation. Never block or insert objects into the ventilation holes or other

openings. Maintain minimum clearances as specified in this manual (see Table 5.1 on page17).

WARNING! Risk of handling heavy unit. Can cause equipment damage, injury or death. Read all instructions

before beginning.

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment damage, injury or

death.

Only properly trained and qualified personnel wearing appropriate safety headgear, gloves, shoes and glasses should

attempt to move, lift, remove packaging from or prepare the unit for installation.

Read all instructions before attempting to move, lift, remove packaging from or preparing unit for installation.

Vertiv | SmartRow™ DCX Installation Manual | 5

Page 6

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 6

Page 7

2 GLOSSARY OF SYMBOLS

Hazardous VoltagePresent

Note following inst ructions

Consult user manual for additionalinformation

Indicates weight

Indicates ground connection

Indicates alternating c urrent

Vertiv | SmartRow™ DCX Installation Manual | 7

Page 8

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 8

Page 9

3 INTRODUCTION

The Vertiv™ SmartRow™ DCX is part of the SmartRow™ platform from Vertiv. The system includes integrated cooling and

power systems. Assembly is a matter of connecting the expansion channels and cabinets, then making electrical and piping

connections.

The basic configuration of the Vertiv SmartRow DCX is a dual-expansion-channel, closed-loop system that provides a roomneutral solution.

The Vertiv SmartRow DCX must be installed in an indoor, climate-controlled environment. The unit will not protect

electronic equipment if it is installed in an environment subject to extreme temperatures or humidity.

This manual is to be used in conjunction with existing Vertiv product manuals for each component and with site-specific

documentation and drawings. User and installation manuals ship with the equipment and are also available at

www.vertiv.com.

The Vertiv SmartRow DCX is a flexible system that allows customization of rack, power and cooling systems within the

limits of the component parts.

3.1 Operational Overview

The Vertiv SmartRow DCX is an enclosed system to house and cool electronic equipment. The Vertiv SmartRow DCX racks

may house critical IT equipment, optional rack power distribution units and optional, rack-mounted UPS units.

Cooling air is supplied in the row by Liebert® CRV thermal-management units and conveyed to the racks via front

expansion channels. Heated exhaust air from the racks returns to the Liebert CRV through rear expansion channels. An

automatic, emergency ventilation fan system is included to exhaust air in the event of a loss of primary mechanical cooling.

UPS-protected conditioned power is provided to each equipment rack using the Vertiv™ Liebert® MBX mounted overhead

and by rack PDUs mounted inside each rack.

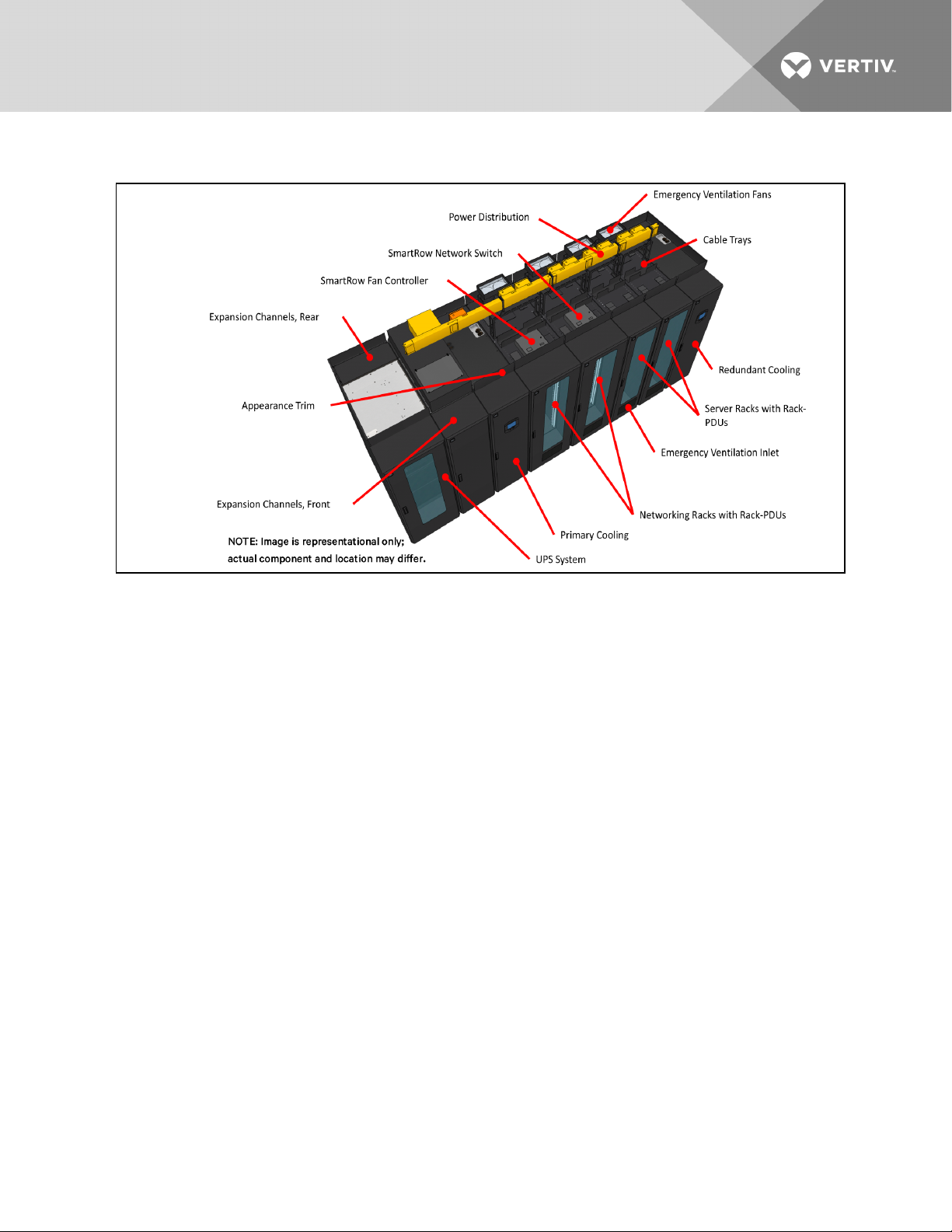

3.2 Vertiv™ SmartRow™ DCX Components

Required components differ based on whether the Vertiv SmartRow DCX includes power and/or redundancy options.

• Vertiv SmartRow DCX Expansion Channels—for each Vertiv™ DCX rack, Liebert® CRV and UPS.

• Liebert® MBX—power-distribution system.

• Liebert® EXM UPS—modular, scalable, with wrap-around BDC and internal or external batteries.

• Liebert® CRV—in-row cooling unit specially configured for use in the Vertiv SmartRow DCX.

• Vertiv™ DCE Rack—network (800mm wide) and server (600mm wide) rack configurations.

• Fire Detection and Suppression —integrated fire detection and suppression cabinet that is sized per design

(optional).

Vertiv | SmartRow™ DCX Installation Manual | 9

Page 10

Figure 3.1 Vertiv™ SmartRow™ DCX components

3.3 Liebert® CRV Notes

• Does not include reheat or humidifier

• Includes a condensate pump, drain field-installed.

• Factory-installed leak detection

Vertiv | SmartRow™ DCX Installation Manual | 10

Page 11

4 APPLICATION GUIDELINES

The pre-engineered Vertiv™ SmartRow™ DCX micro-data center delivers highly predictable, repeatable performance in a

variety of applications. This platform maximizes the flexibility in equipment configuration to meet the requirements of a

given application without complicating the overall selection, design or deployment process.

The Vertiv SmartRow DCX system architecture eases the dependence on the site, allowing it to be deployed on raised and

non-raised floors within traditional data centers and in non-traditional IT spaces. When tailoring and deploying a Vertiv

SmartRow DCX for a given application, be sure to follow all of the following guidelines.

When selecting a Vertiv SmartRow DCX system, be sure to exceed the minimum heat-load requirements for the row, do not

exceed the maximum UPS and cooling capacities and select a UPS and busway that offer capacity expansion that is

sufficient to support future growth, if desired. Also, be sure that the initial placement of the cooling units within the row

allows for additional racks and cooling units to be added without having to relocate the existing equipment.

4.1 Environmental Conditions

The Vertiv SmartRow DCX must be deployed in an indoor environment that is maintained year round between 50°F and

85°F (10°C and 30°C) dry bulb and less than 60°F dew point (16°C). It is not suitable for installation outdoors or in

unconditioned spaces (loading docks, unconditioned warehouses, garages, etc). A properly conditioned environment avoids

undesirable condensate formation and ensures that there is air available at suitable conditions for ventilating the SmartRow

system if the Automatic Emergency Ventilation Fans activate.

4.2 Cooling System Design

Adhere to the following guidelines when tailoring a Vertiv™ SmartRow™ DCX cooling system for a particular application.

The automatic, emergency backup ventilation fans are nominally rated for 1,000 cfm. They are designed to provide time to

perform an orderly shutdown of the protected system. Duration of this time is dependent on the size and environmental

conditions of the room external to the Vertiv SmartRow DCX.

NOTICE: If the Vertiv SmartRow DCX is installed in a dedicated room and the airflow inlet and outlet openings are not

provided, the effectiveness of the ventilation system will degrade as the room warms. Providing fresh air relief to the room

and ducting the fan exhaust out of the space will extend run time. Large rooms may be able to run for the full duration of the

UPS battery run time before elevating the room temperature, not requiring the heat to be ducted out.

The Liebert® CRV 600 Series row-based cooling units are 600mm wide and includes 20kW, CRV 35-kW and 40-kW

models.

Vertiv | SmartRow™ DCX Installation Manual | 11

Page 12

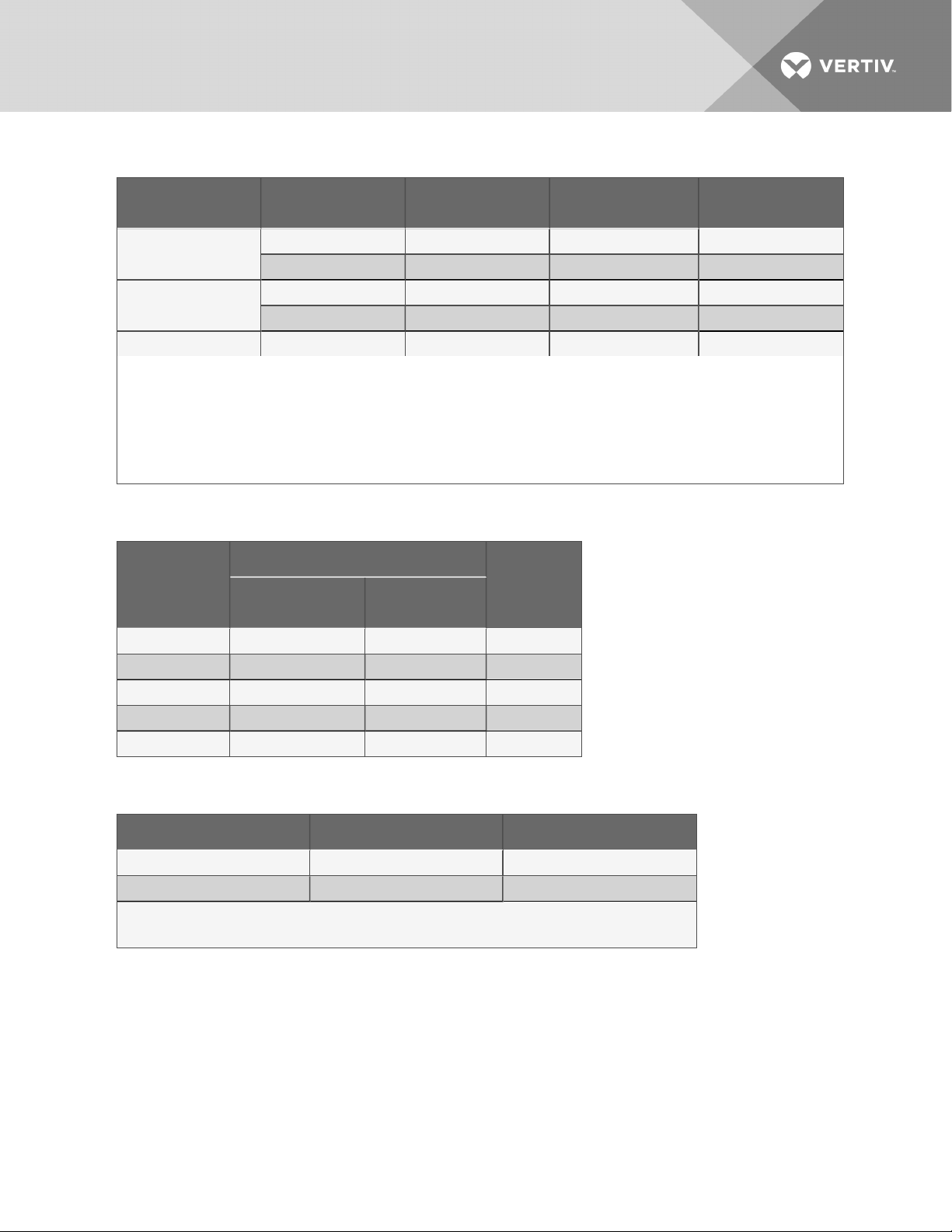

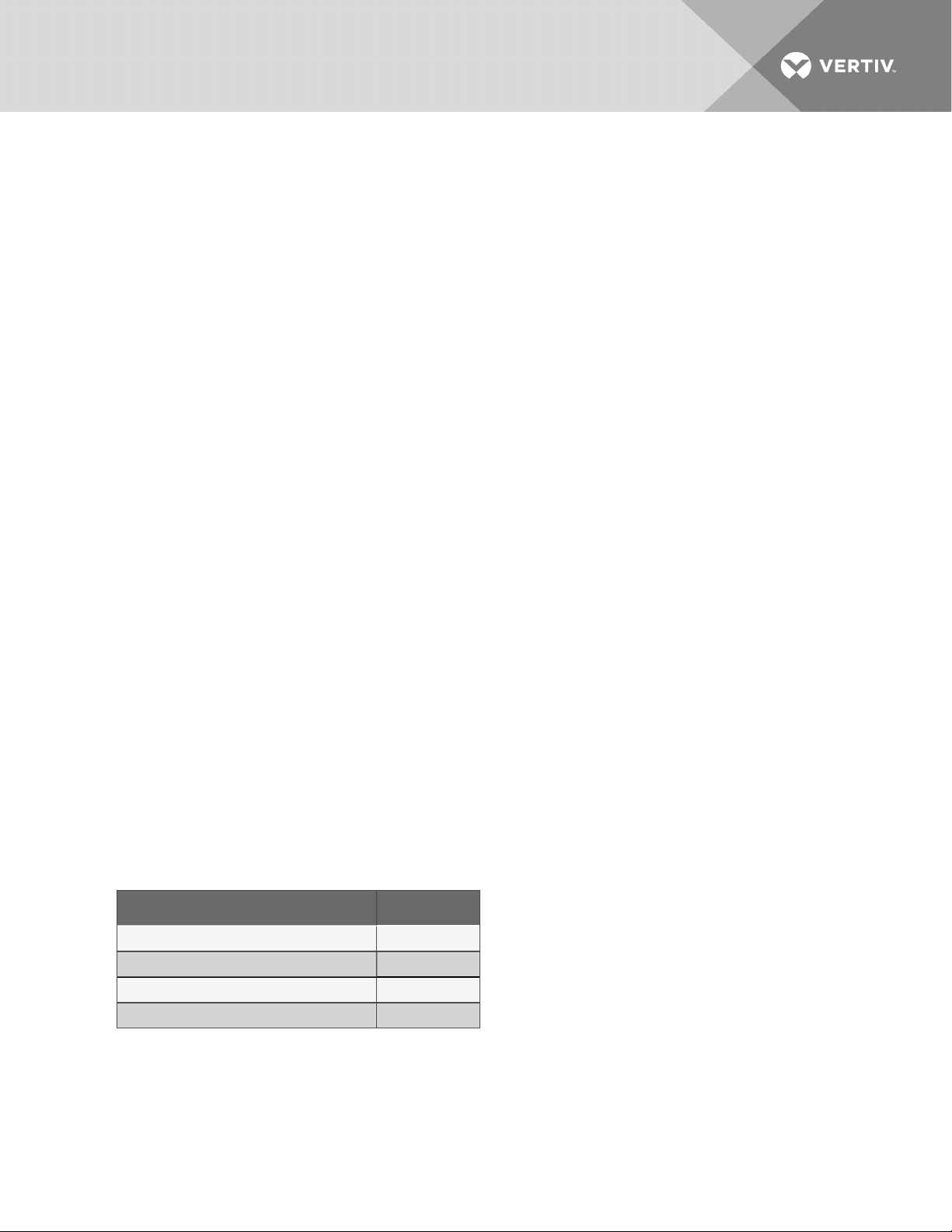

Table 4.1 Vertiv™ SmartRow™ DCX quick-reference cooling-unit capacities

System Type Liebert® C RV Mod el Nomin al C oo ling C apacity

Air-Cooled

Water/Glycol

Chilled Water

3

1. Minimum heat load based on 20% net sensible coolingcapacity at 80°F (27°C) return air temperature, 52°F dew point (11°C).

2. Maximum capacity based on 100% net sensible cooling capacity at 100°F (38°C) return air temperature, 52°F dew point (11°C).

3. Air-cooled c apacities based on 105°F (41°C) outdoor Liebert® MC condenser matchup.

4. Water-gylcol capacities based on 10% propylene-glycol concentration with matching 105°F (41°C) outdoor drycooler matc hup and

5. Chilled-water capacities based on 45°F (8°C) enteringwater conditions with 10°F (6°C) rise, always use site-specific water conditions

4

5

pump package.

when determining coolingunit net sensible capacity .

CR020RA 20 kW 4.8 kW 24.8kW

CR035RA 35 kW 9 k W 39.7 k W

CR020RW 20 kW 4.7 kW 22.9 k W

CR035RW 35 kW 8.7 kW 37.0 k W

CR040RC 40kW 6.0 kW 46.6 kW

Minimum Heat Lo ad

percooling u nit

Table 4.2 Liebert® EXM UPS quick-reference heat dissipation and air flow

Heat Dissipation (kWh)

UPS Capacity

Liebert EXM 100kVA 5.5 8.6 339

Liebert EXM 80kVA 4.4 7.2 271

Liebert EXM 60kVA 3.3 5.3 203

Liebert EXM 40kVA 2.2 3.8 136

Liebert EXM 20kVA 1.1 1.8 68

208V 4W+G UPS inpu t

without input transformer

480V 3W+G UPS inpu t

w \input transformer

Cooling Air F low

(CFM)

1

Maximum Capacity

percooling u nit

2

Table 4.3 Minimum and Maximum Number of Racks per Liebert CRV Cooling Unit

Numb er o f Racks* per Liebert C RV Minimum (Rmin) Maximum (Rmax)

CRV 600: 20 kW 2 7

CRV 600: 35/40 kW 3 8

*Server (600mm wide) and Networking (800mm wide) racks are t reated equally and are generically referred toas“racks.”

Consult the factory if you needto deviate from these limits.

Vertiv | SmartRow™ DCX Installation Manual | 12

Page 13

4.3 Heat Load Calculation

When determining the number of cooling units required to support the SmartRow, make sure to include the total IT

equipment and UPS heat dissipation, along with parasitic room losses. The amount of heat that an IT device rejects may be

very different than the power it consumes. This is common with PoE (Power over Ethernet) switches. Always reference the

heat-dissipation value, not power consumed, on the IT device's specification sheet.

When a UPS system is located within the Vertiv SmartRow DCX and conditioned by the row-based air conditioners, all of

the power leaving the UPS should be fed to the rack-mounted IT equipment. Consult the factory before using the integral

UPS system to power equipment outside of the row.

Figure 4.1 Capacity calculation template

1.) Rack Mounted Heat Load* _______ kW

2.) UPS Heat Load _______ kW

3.) Room Heat Load _______ kW

4.)

5.) Maximum Capacity per Cooling Unit _______ kW (From Table 4.1 on the previous page)

6.) Minimum Quantity of Liebert® CRV Cooling Units, = ______ Cooling units (Round up to whole number)

7.) Add 1 if desire N+1 cooling redundancy, + ______ (Enter 0 or 1)

8.)

9.) Minimum Heat Load per Liebert CRV, x _______ kW (From Table 4.1 on the previouspage)

10.)

11.)

12.) Minimum number of racksper CRV (Rmin), x ______ Racks(From Table 4.3 on the previous page)

13.)

14.)

If designing for N+1 cooling redundancy, be sure that all racksare within the region of influence of 2 or more Liebert CRVs.

*Enter heat dissipation, not power consumption. Contact factory if powering IT equipment outside of the Vertiv SmartRow DCX.

Total Quantity of Liebert CRV Cooling Unitsin Vertiv

Minimum Constant Rack Mount Heat Load, =

Total Quantity of Liebert CRV Cooling Units in Vertiv

Minimum number of Vertiv SmartRow DCX racks, =

Consult T able 4.3 on the previous page for Maximum Rack

Total Heat Load, S

SmartRow DCX, =

SmartRow DCX

Limitations.

_______ kW

______ Cooling units

_______ kW (UPS heat load does not count toward

minimum)

______ Cooling units (F rom Row 8 above)

______ Racks

______

Vertiv | SmartRow™ DCX Installation Manual | 13

Page 14

4.4 Vertiv™ SmartRow™ DCX Equipment Placement within the Row

4.4.1 Cooling Unit and Rack Placement

• Server (600mm wide) and Networking (800mm wide) racks are treated equally and generically referred to as

“racks.”

• When determining the location for Liebert® CRVs within the row, they should be evenly spaced within the rack

lineup to maintain uniform airflow distribution, assuming that the heat-load density is fairly uniform across all of

the racks. If there are a couple of racks within the row with a higher concentration of heat, Liebert® CRVs may

be placed closer to that equipment.

• Do not place two Liebert CRV cooling units next to each other.

• UPS placement does not influence the placement of the cooling units due to the relatively low heat and air-flow

demands of the UPS system.

• If the cooling system is designed for N+1 redundancy, be sure that each rack is within the region of influence of

2 or more Liebert CRVs with sufficient capacity. This will ensure that if any cooling unit fails, another unit will be

able to condition the IT equipment.

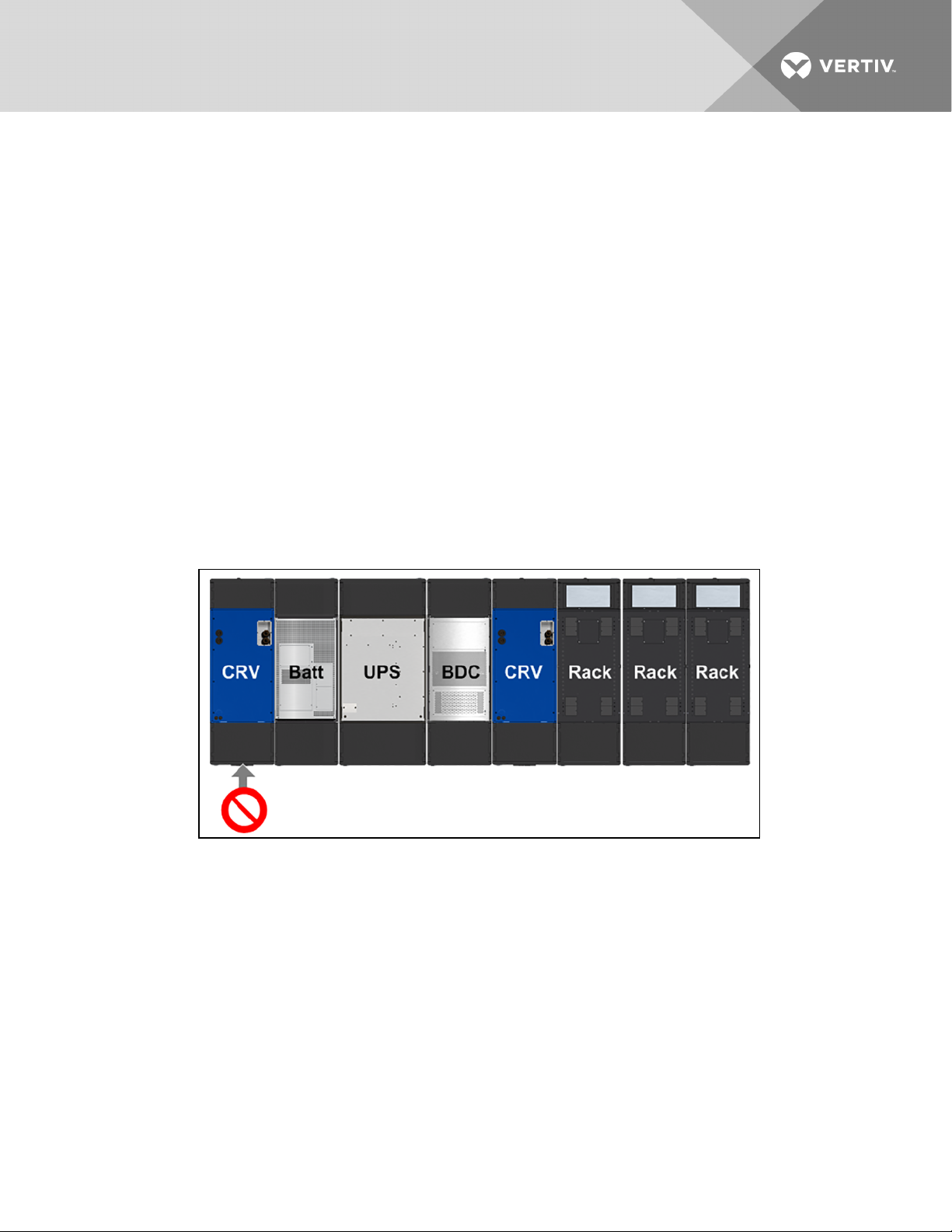

• Do not place a Liebert CRV at the end of a row next to a UPS because this would put the Liebert CRV too far

from the rack-mounted IT equipment (see Do not locate Liebert CRV at end of row next to UPS system below).

Figure 4.2 Do not locate Liebert CRV at end of row next to UPS system

4.4.2 UPS System

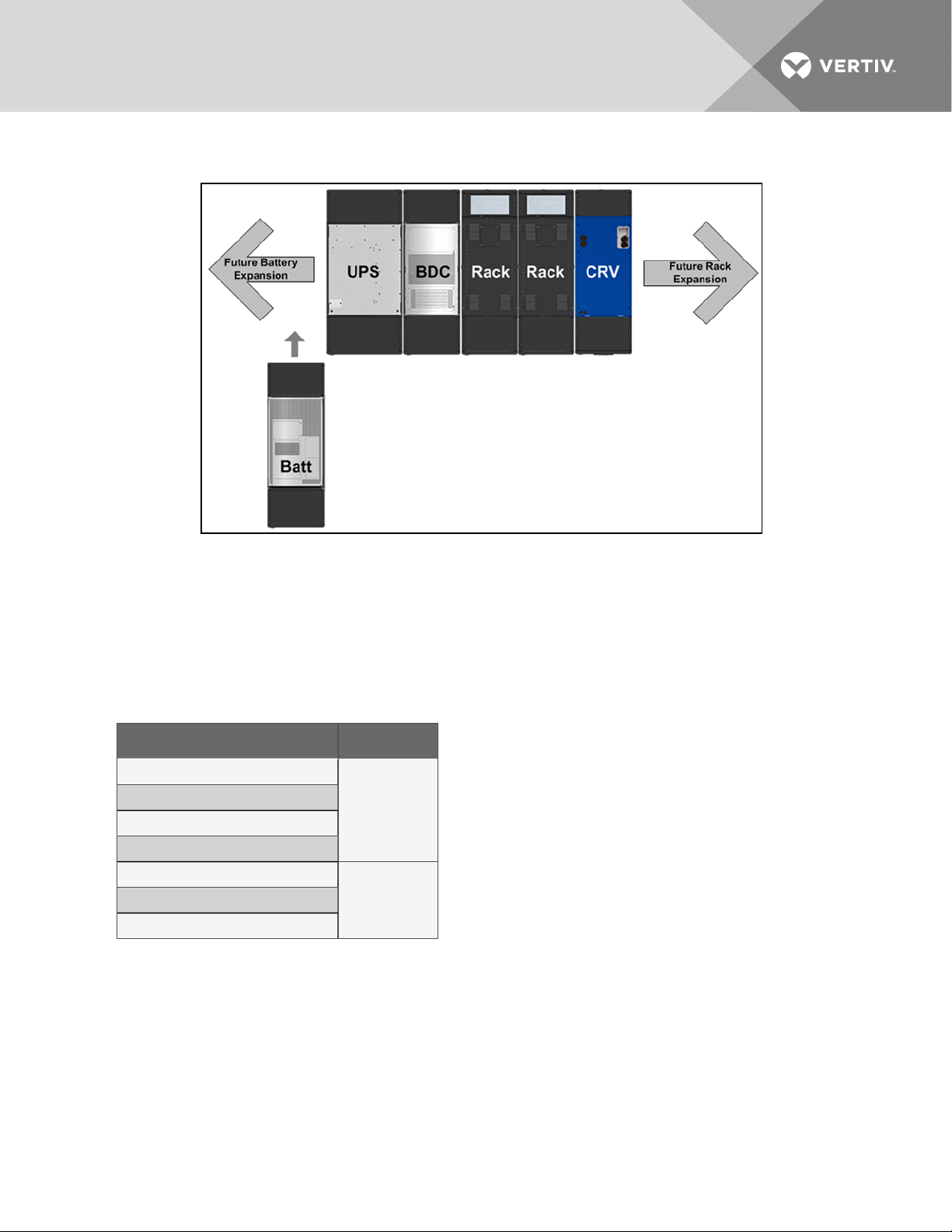

• Two UPS systems can be located next to each other.

• Three-phase, row-based UPS systems must be placed at the left end of the row (when viewed from the front,

cold side) to ease addition of battery cabinets to the UPS system in the future.

• Battery cabinets can be remotely located, but they will not be conditioned by the row-based cooling system.

Vertiv | SmartRow™ DCX Installation Manual | 14

Page 15

Figure 4.3 Recommended: UPS system at left-end of row

4.4.3 Row Length

When calculating the row length of the Vertiv™ SmartRow™ DCX, include the following distances between the various pieces

of row-based equipment to accurately account for the gasketing and baying brackets. Refer to the Submittals for complete

clearance requirements.

Table 4.4 Included spacing between system

equipment

Neighbo ring Equ ipment Distance Between

Rack - Rack

Rack - Liebert® CRV

Rack - UPS, BDC or Battery cabinet

Liebert CRV - UPS, BDC or Battery Cabinet

UPS - BDC

Redundant UPS Systems

10mm (0.40 in)

28mm (1.10 in)UPS - Battery Cabinet

4.5 IT Equipment Deployment and Wiring

• Follow industry best practices when deploying IT equipment within the Vertiv™ SmartRow™ DCX.

• To maintain good cold-hot air separation, use blanking panels in all unoccupied RU space.

• Neatly manage all fiber and Ethernet cabling to avoid air-flow restrictions.

• Never route any type of cable within or through the front or rear expansion channels (ECs). Doing so will restrict

air flow and prevent the ECs from being removed from the row equipment.

• When loading IT equipment in the racks, try to distribute the load evenly throughout the row. If there is a higher

density rack, that rack should be closest to a Liebert® CRV.

Vertiv | SmartRow™ DCX Installation Manual | 15

Page 16

4.6 Settings for the Vertiv™ Liebert® iCOM™ on the Liebert® CRV Cooling Unit

• All of the Liebert CRV cooling units are to be configured in Teamwork Mode 3 with the controlling sensors set

to use the 2T rack-inlet temperature readings.

• The low end of the Liebert CRV fan-speed modulation range is raised at the factory. Do not field-adjust.

• Do not run the Liebert CRV in a staged (staggered) or stand-by configuration. All Liebert CRVs must be

operational at the same time. Ensure your IT equipment dissipates the minimum heat load required by the

entire cooling system on day one.

• For questions on navigating the Liebert iCOM control system call 800-543-2778 for Liebert® Environmental

Technical Support.

Vertiv | SmartRow™ DCX Installation Manual | 16

Page 17

5 PREPARATION

The application and installation location should be determined and prepared before the Vertiv™ SmartRow™ DCX is

delivered. Proper planning will permit installation of the required power and coolant connections and ensure proper

clearances. The installation location must have:

• An indoor, climate-controlled environment with the ambient temperature year round between 50°Fand85°F

dry bulb (10°C and 30°C) and less than 60°F (16°C) dew point.

• Sufficient height and clearance from ceilings, walls, fixtures and overhead sprinkler nozzles for the Vertiv

SmartRow DCX, including its emergency fans and power distribution.

IMPORTANT! The Vertiv SmartRow DCX must be installed on a flat, level surface to maintain proper spacing and

provide tight seals. Leaving gaps in the field-applied gaskets will reduce cooling efficiency and increase energy use.

• Suitable location for outdoor Liebert® MC condenser, where the equivalent refrigerant piping length will not

exceed values listed in the Liebert® CRV Installation Manual (air-cooled systems).

• Adequate heat rejection coolant supply for the Liebert CRV (chilled water or water/glycol-cooled systems).

• Input power sufficient for:

• Each Liebert CRV—each requires a separate input-power feed.

• Liebert® EXM - ships as single-input configuration, but may be wired as dual-input.

NOTE: For details about any component’s requirements, refer to that unit’s user manual:

• Liebert® CRV Installation Manual is SL-11975.

• Liebert CRV with Liebert® iCOM™ User Manual is SL-11987.

• Liebert iCOM User Manual is SL-11987.

• Liebert® EXM 208V User Manual is SL-25650

• Vertiv™ DCE Rack System User Manual is SL-11992

• Liebert MBX Busway Track System User Manual is SL-70371

These are delivered with the unit and are available at http://www.vertiv.com/en-us/support/.

5.1 Clearance Requirements

See Vertiv SmartRow DCX dimension details in submittal drawings contained in Technical Illustrations on page33.

Table 5.1 Vertiv SmartRow DCX system clearances

Clearances Minimum, in. (mm )

Liebert EXM UPS syst em front and back 36 (915)

Liebert CRV cooling unit front and back 36 (915)

Closest building sprinkler to any surface 18 (458)

Between emergency fan module and parallel surface 16 (407)

5.2 Inspection

Upon receiving a Vertiv™ SmartRow™ DCX, examine the packaging for any signs of mishandling or damage. If any damage

is found, notify your local Vertiv™ representative and the carrier immediately.

Vertiv | SmartRow™ DCX Installation Manual | 17

Page 18

5.3 Unloading the Vertiv™ SmartRow™ DCX

Before unloading the Vertiv SmartRow DCX, refer to the manual for each component, particularly the Liebert® CRV, Liebert®

EXM and Liebert® DCE Racks. These manuals are shipped with the Vertiv SmartRow DCX and are available at

www.vertiv.com.

Read each manual thoroughly. They include handling instructions and safety notices that must be followed when unpacking,

installing, operating and maintaining the Vertiv SmartRow DCX.

Adhere to all warnings, cautions and installation, operating and safety instructions on the units and in their manuals. Only

properly trained and qualified personnel should move, install, operate or service this equipment.

5.4 Required Setup Tools and Equipment

The following tools are needed to set up a Vertiv SmartRow DCX:

• Standard and metric socket sets

• Phillips-head screwdriver

• Flat-blade screwdriver

• Forklift or pallet jacks

• Utility knife

• Carpenter’s level, 3 feet long or longer

• Battery-powered drill with T30, Phillips, and Flat-blade bits

• Sheet-metal hole saw or punch kit (for conduit entries)

Vertiv | SmartRow™ DCX Installation Manual | 18

Page 19

6 INSTALLATION

6.1 Assembly Sequence Overview

1. Equipment is delivered and de-trashed by Vertiv™ SmartRow™ Delivery Service Provider.

2. Stage equipment for installation.

3. Place and level all row-based equipment in the lineup you want according to the user/installation manuals.

4. Install Liebert® MBX system.

5. Install expansion channels.

6. Make all Vertiv™ SmartRow™ DCX connections as required.

6.1.1 Staging the Vertiv™ SmartRow™ Equipment

1. Thoroughly inventory the equipment received.

2. Place each piece of row equipment in its designated location.

3. Stage the expansion channels (ECs) around the perimeter of the room taking care to position the ECs with the

equipment they will be attached to.

4. Each EC contains a box of hardware specific to each EC. Take care to keep the hardware boxes with their

respective EC.

6.1.2 Installing the Vertiv™ SmartRow™ Equipment

1. Refer to the user/installation manual for all row-based equipment for specific installation instructions.

2. Referring to the Vertiv™ SmartRow™ DCX submittal drawings and starting with the UPS (if applicable), install

the equipment in the lineup.

3. For proper alignment, install the gasketing and spacers included with the UPS equipment.

Tip: Adjust all equipment leveling feet until the casters are just off the floor. This will ensure proper fit of the

skirting, installed later if supplied. This will also assist in leveling if the floor is uneven.

4. Use the provided hardware, included in the Vertiv SmartRow DCX spacer kit, to bolt together the 3-phase UPS,

BDC and battery cabinet.

5. Use the provided power- and control-wiring harnesses for the cabinet cabling.

6. Install any top plenums required by the UPS cabinets.

7. Install the Liebert® CRV and Liebert® DCE racks in the order shown on the submittal drawings. Use the

gasketing and cluster kits for proper alignment.

8. After all cabinets are installed, level the tops from end to end, and then front to back. Make sure the cabinets

are completely level in both directions when finished.

9. Install the Liebert® MBX mounting brackets on top of each Vertiv™ DCE rack. Consider locations of BDC

cabling, busplug rack cabling and Liebert CRV connections during bracket installation.

10. Assemble and mount the Liebert MBX according to the Liebert MBX installation manual SL-70371.

11. Mount the Vertiv SmartRow network switch (vNSA) and Vertiv SmartRow DCX and fan control box and make

control wiring connections.

Vertiv | SmartRow™ DCX Installation Manual | 19

Page 20

6.1.3 Connecting the Equipment

Refer to the user/install manuals for each piece of equipment as required.

1. Make all connections to the UPS BDC cabinets (input power and Liebert® MBX).

• The UPS requires an upstream over-protection device (a circuit breaker or manual isolation switch.

• Install the protection device per local codes and agency requirements.

2. Make all power, coolant and drain connections to the Liebert® CRV equipment.

3. Connect the Liebert® MC Condenser (if applicable) control wire to the Liebert CRVs and route the wire to the

condenser based on the site-specific application.

4. Using the provided adapter cables, connect power to the Vertiv™ SmartRow™ vNSA and Vertiv™ SmartRow™

fan controller from the Liebert MBX busplug.

NOTICE

Risk of improper power input.

Improper power input can cause equipment damage or degrade performance.

6.1.4 Installing Expansion Channels

Refer to Technical Illustrations on page33 for detailed expansion channel installation instructions.

6.1.5 Finalizing Installation

1. Install busplugs into the overhead Liebert MBX and align them with the Vertiv™ DCE racks that they power.

2. Connect the rack PDU plugs into the busplugs.

3. The 2T temperature sensors are pre-wired to each rack. Connect the sensors to the Liebert® CRVs in the row

and correctly set the 2T sensor DIP switches per the supplied instructions.

4. Cable the Liebert CRV iCOM and monitoring card to the Vertiv™ SmartRow™ network switch.

5. Cable the UPS monitoring card to the Vertiv SmartRow network switch.

NOTICE

Do not run any cables in the expansion channels. Doing so will reduce the airflow and eliminate the ability to

remove the expansion channels. The expansion channels should not be removed unless absolutely necessary.

6.2 Optional Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System—Overview

The Vertiv SmartRow DCX must be installed in compliance with all applicable national, state and local fire codes. An

emergency power off (EPO) switch is provided as one means of meeting regulations. Additional field-supplied connections

to the system may be required, depending on the applicable regulations, the equipment configuration and the user’s

operational preference.

The optional Vertiv SmartRow DCX Control Panel and Fire Suppression System has been fully tested and certified at the

factory.

The Vertiv SmartRow DCX Control Panel and Fire Suppression System is shipped with wiring that, if required by local fire

code, must be field-connected to the shutdown circuits of the Liebert® CRV and any connected UPS systems.

Under NFPA regulations, systems protected by a clean fire-suppression agent can be left with the UPS and HVAC systems

operational at the discretion of the owner and local fire officials.

Vertiv | SmartRow™ DCX Installation Manual | 20

Page 21

The Vertiv SmartRow DCX Control Panel and Fire Suppression System should be field-connected as a separate zone to the

building fire detection and alarm system.

If the Vertiv SmartRow DCX is installed in a dedicated room, an additional strobe and horn may be installed at the entrance

to the room. Contact your local authorized service representative if required.

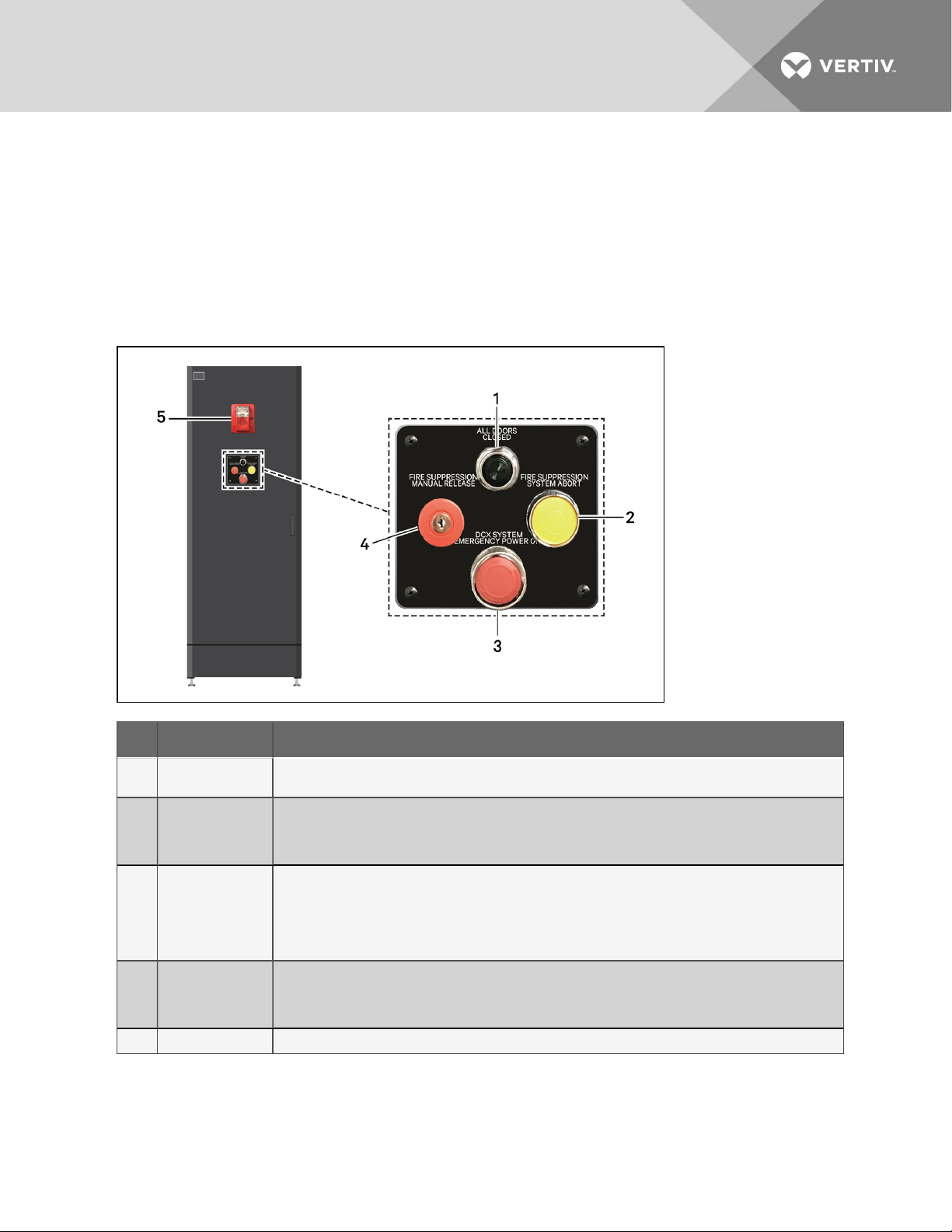

6.3 Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System Component Locations

Figure 6.1 Vertiv SmartRow DCX Control Panel and Fire Suppression System, exterior features

Item Component Description

ALL DOORS

1

CLOSED indicator

FIRE

SUPPRESSION

2

SYSTEM ABORT

button

DCX SYSTEM

EMERGENCY

3

POWER OFF

latching butt on

FIRE

SUPPRESSION

4

MANUAL RELEASE

button

5 Horn and strobe Alarm sounds and strobe illuminates when the f ire-suppression system is act ivated.

Illuminates when all rack doors are closed.

Prevents the fire-suppression sy stem from dumping due to a false alarm.

To engage t he Emergency Power Off (EPO), press the button until it latches and the system shuts down.

To disengage t he EPO, pull out the EPO button.

When engaged, all cooling units, UPSs (if wired into t he EPO circuit), f ire-suppression and emergency ventilation fans

power down. There are multiple ways to configure the EPO circuit per t he electrical s chematic to comply with local

codes, so your operationmay vary. All equipment can be wired to shut down.

If equipped, the shunt trip breaker in t he load panel can be wired to open as well.

Turn t he key to activate the manualfire-suppression release. If you see smoke and/or f ire in the Vertiv™ SmartRow™

DCX sys tem, but the s moke detector is malfunct ioning, you can manually discharge the fire-suppression material into

the Vertiv SmartRow DCX system.

Vertiv | SmartRow™ DCX Installation Manual | 21

Page 22

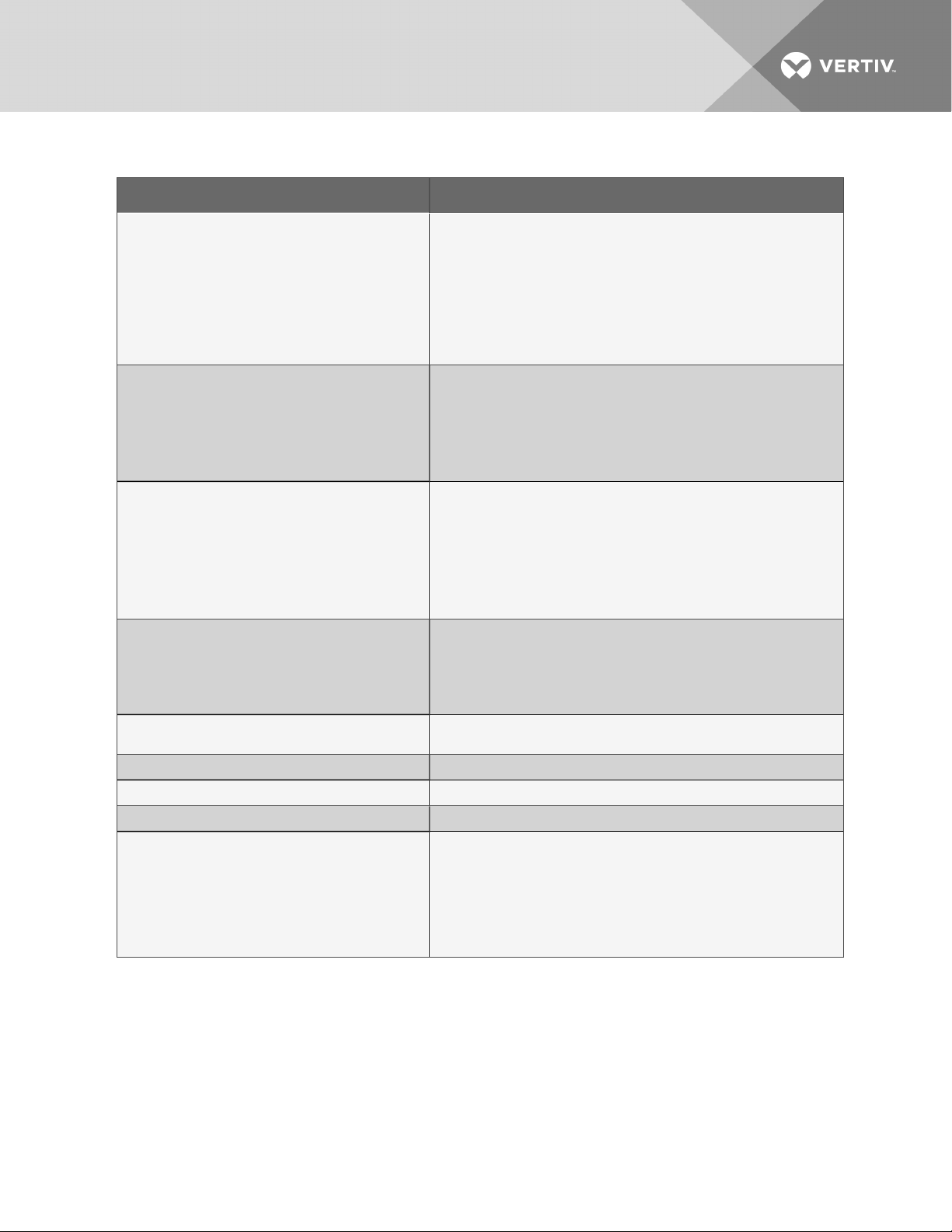

Figure 6.2 Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System internal features

Item Description

EMERGENCY

POWER OFF

OVERRIDE TIMER

EMERGENCY

SUPPRESSION

BYPASS TIMER

Turning this timer temporarily bypasses the EPO circuit. This allows for a manual restart of the UPS after an EPO event. You can

turn the t imer up to a maximum of two hours, if necessary, to perform maintenance. T o continue the bypass operation, turn the

timer again to add t ime when it gets low.

Turning this timer temporarily suspends fire detect ion s o that maintenance can be performed on the system.

This timer provides a normally closed circuit bypassing the internal, normally closed relays in the fire suppression panel. Once

the timer expires, the circuit returns to the Off position.

You can turn the timer up to a maximum of 2 hours, if necessary, to perform maintenance. To continue the bypass operation,

turn the t imer againto add time when it gets low.

IMPORTANT! Risk of accidental fire suppression system activation. Can cause equipment and property damage.

Do not attempt to bypass the fire suppression system on the Vertiv SmartRow DCX. Attempting to bypass the fire

suppression system can cause the system to discharge.

6.3.1 Control Panel and Fire Suppression System Component Operation

Component operation for the Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System on the facing page

shows each component, describes what each one does, and how to use it.

Vertiv | SmartRow™ DCX Installation Manual | 22

Page 23

Table 6.1 Component operation for the Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System

Action Operation

Emergency power-off.

Press the EPO button on t he front door of the Control Paneland

Fire Suppression Sys tem.

Press the Remote EPO (REPO) butt on(s) if they are connected

to the system.

Note: Systems manufactured and shipped after August 26,

2016, have the latching EPObutton.

Resetting emergency ventilation fans.

Push t he H igh Temp Reset button after an event in which the

fans have activated and lowered the return air temperature to

89°F ±3°F or lower

Turning the fire-suppression c ontrol bypass timer.

Turn t he timer past the 1-hour position

Turning the Vertiv™ SmartRow™ DCX emergency power-off

override timer.

Turn t he timer past the 1-hour position.

Turning the key to activate the manual fire-suppression

release.

Fire-suppression sy stem abort Prevents the fire-suppression sy stem from dumping due to a false alarm.

Control Power Available light illuminated (green) Control syst em is powered via TB1 positions (1 & 2) or (3 & 4).

Control Power Available light is NOT illuminated Green LED indicates all doors are c losed.

Main Circuit Breaker with Shunt Trip Assembly (If applicable)

• To enable power flow to the control panel, flip

the breaker swit ch to the UP position

(On/Closed).

• To disable power flow to the c ontrol panel, flip

the breaker swit ch to the DOWN position

(Off/Open)

The EPObutton is a latching button.

To engage t he EPO: Press the button until it latches and the s yst em shuts down.

To disengage t he EPO: Pull-out the EPO button.

When engaged, all cooling units, UPS(s) (if wired into EPO circuit), Fire suppression

and emergency ventilation fans (if running) power down. There are multiple w ays to

configure the EPO circuit per t he electrical schematic to c omply with local codes, so

your operation may vary. However, all equipment can be wired to shut down.

If equipped, the Shunt trip breaker in the load panel can be wired to open as well.

Deactivates the emergency v entilation f ans after the safe temperature is reached.

Allows coolingunit to reactivate when possible (Utility power restored, alarm cleared,

etc.).

Resets t he control logic for the Emergency Ventilation Fans for future activation.

Note: Do not reset emergency ventilation fans for at least 2 minutes after they

activate t o ensure that the t hermal unit’s 2 minute restart delay has expired.

Suspend the fire-detection so that maintenance can be performed on the system.

The timer provides a normally-closed circuit bypassing the internal, normally closed

relays in the f ire-suppression panel.

Once t he t imer expires, the circuit is returned to its normal setting (Off).

Note: You can t urn t he timer up to a maximum of two hours if necess ary to perform

maintenance.

To continue the bypass operation, just t urn t he timer againwhen t ime gets low.

Temporarily bypass the EPO circuit. This allows manual restart of t he UPS aft er an

EPO event.

Note: You can t urn t he timer up to a maximum of two hours if necess ary to perform

maintenance.

To continue the bypass operation, just t urn t he timer againwhen t ime gets low.

If you see smoke and/or fire in the sys tem, but the s moke detector is malfunct ioning,

you can manually discharge the f ire s uppression material into the system.

Eliminates power to all loads connected to and downstream of t he loaddistribution

center both locally and remotely.

IMPORTANT! The shun t trip assembly requires a dedicated, field-sup plied source of 120V

power to TB1 Pins 9 & 10.

If the breaker is tripped (EPO act ivation), you must reset the breaker before beginning

the restart protocols. See Recovering from a Fire Suppression System Act ivation on

the next page, f or details.

Vertiv | SmartRow™ DCX Installation Manual | 23

Page 24

6.4 Recovering from EPO Circuit Activation

If the EPO circuit is activated by the local EPO button on the Vertiv™ SmartRow™ DCX or by a field-supplied REPO button

and the system is shut down, the following steps must be taken to recover:

1. If a Shunt-Trip Main Circuit Breaker is being used, reset the Shunt-Trip Main Circuit Breaker.

2. Disengage the EPO circuit.

NOTE: You must reset the EPO or REPO button that activated the circuit to reset the circuit. Pressing a button that did

not trigger the circuit will not reset the circuit.

a. If the local EPO button on the Vertiv SmartRow DCX activated the circuit:

• Pull the latching button back to disengage the circuit.

b. If a remote EPO (REPO) button activated the circuit, reset the REPO button that activated the circuit

using the reset function of the field-supplied button.

Once cleared, the thermal management units in the Vertiv SmartRow DCX automatically start via their

dedicated power supply.

3. Turn the Local Emergency Power Off Override Timer past the half-hour position.

NOTE: If needed, you may turn the timer to a maximum of 2 hours. If time is running low, turn the timer past the halfhour mark again to continue the bypass.

4. Reset the UPS that powers the Vertiv SmartRow DCX control circuit and fire-suppression control circuit.

• If the Vertiv SmartRow DCX is powered by a stand-alone Liebert® UPS, refer to the corresponding

procedure in the manual for the UPS to start the UPS. If it will not restart, put the UPS in bypass and

restart the remaining equipment.

For assistance putting a Liebert three-phase UPS in bypass and for service support, call 800-543-2378.

For a Liebert single-phase UPS, call 800-222-5877, option #1.

The Fire Suppression System is protected from commercial power failures by an integrated battery and battery charger. In

the event of a commercial power failure, the fire-suppression system continues to operate in idle mode from this battery for

up to 48 hours. Upon restoration of commercial power, the battery charger automatically recharges the battery to float

state.

6.5 Recovering from a Fire Suppression System Activation

In the event of a Fire Suppression System activation, contact your local fire-suppression representative for guidance on

bringing your system back online.

6.6 System Set-up and Commissioning

1. Perform UPS startup.

2. Perform Liebert® CRV startup.

3. Perform fire suppression startup.

4. Set up PDU networking.

Vertiv | SmartRow™ DCX Installation Manual | 24

Page 25

6.7 Fire Detection and Suppression System Operation Overview

The Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System monitors the air in the Vertiv SmartRow DCX for

evidence of combustion. If the smoke detector, mounted in the rear expansion channels down the entire row of equipment,

senses combustion products, the system activates the audible horn and visual strobe on the upper right corner of the Vertiv

SmartRow DCX Control Panel and Fire Suppression System panel (see Figure 6.1 on page21).

After a 30-second delay, the system releases fire-suppression agent into the cabinets, locks out the Emergency Fans and

shuts down any connected UPS’s and the Liebert® CRV. This sequence may differ if NFPA 2001 is applicable and

coordinated with the local fire officials.

NFPA 2001 authorizes discretion of the owner and local fire officials to leave UPS and cooling systems operational when the

system is protected by a clean fire-suppression agent.

The Vertiv SmartRow DCX Control Panel and Fire Suppression System should be field-connected as a separate zone to the

building fire detection system.

6.8 Restarting after Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System Has Shut Down

If the Vertiv SmartRow DCX Control Panel and Fire Suppression System Rack Supply has shut down:

1. Turn Emergency Power Off Override timer beyond the 1/2 hour position (see Figure 6.2 on page22 and Vertiv

SmartRow DCX Control Panel and Fire Suppression System timers).

2. Confirm that input power is available.

a. If the Vertiv SmartRow DCX is powered by a stand-alone Liebert UPS and will not restart, put the UPS in

bypass and restart the remaining equipment. Call 800-543-2378 for assistance in putting the UPS in

bypass and for service support. For a Liebert three-phase UPS, call 800-543-2378 and for a Liebert

single-phase UPS, call 800-222-5877, option #1.

b. If the Vertiv SmartRow DCX controls, emergency fans and emergency-fan controls are connected to

rack-mounted UPSs, manually restart the UPSs.

The Vertiv SmartRow DCX Control Panel and Fire Suppression System have an internal battery for the fire suppression

system. The system will continue operating on this battery up to 48 hours unless power is restored earlier.

The Liebert® CRV is set up to restart when power is restored.

Fire Suppression Control Bypass Timer

To allow servicing the Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression System, this timer is turned to its

maximum position by a qualified service representative. The timer provides a normally closed circuit bypassing the

internal, normally closed relays in the fire suppression panel. Once the timer expires, the circuit is returned to its normal

setting (Off).

Vertiv | SmartRow™ DCX Installation Manual | 25

Page 26

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 26

Page 27

7 INSTALLATION CHECKLIST

7.1 Cooling and Power Component Installation Checklist

1. All cabinets and expansion channels have been installed.

2. All gaskets and edge guards are installed.

3. All external cable and piping entrances are sealed.

4. All electrical and piping connections have been made.

5. All cabinet doors close and seal securely.

6. Verify that the All doors closed light illuminates.

7. All Emergency Power Off interlocks to the UPSs and to the Liebert® CRV are connected.

8. All rack power strips are installed and connected to the Liebert® MBX for UPS power.

9. 2T temperature sensors are installed at the top, front of each Vertiv™ SmartRow™ DCX rack and their DIP

switches set.

10. Make sure that no cables are routed through any of the expansion channels.

11. Liebert CRV has been started-up and factory-commissioned.

12. Liebert® EXM UPS has been started up and factory-commissioned.

13. Emergency Power Off has been tested and verified to shut-down systems as designed.

14. Test Emergency backup fan operation by turning Off all Liebert CRV units.

15. The Liebert® iCOM™ displays the supply air temperature.

16. All monitoring points are communicating to the Network Management System.

17. Computer equipment is installed so that the heat load is evenly distributed among the Vertiv DCX Racks.

18. Power and temperature monitoring are fully operational.

19. Perform all installation checks as stated in manuals for Vertiv SmartRow DCX components.

Vertiv | SmartRow™ DCX Installation Manual | 27

Page 28

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 28

Page 29

8 TROUBLESHOOTING

Table 8.1 Troubleshooting

Problem/Alarm Recommend ed Action

Ensure that the Liebert® CRVs are operating.

Cabinet

Overheating

Liebert® CRV

in alarm

UPS s ystem

has shutdown

Liebert CRV

has shutdown

Adjust cooling setpoints to increase cooling.

Check for proper cooling air flow.

Check that the load is evenly distributed between racks and that individual racks arenotoverloaded.

Refer a properly-trained and qualified s ervice representative or consult t he Liebert® CRV operation and maintenance manual, SL19800, shipped with the Vertiv™ SmartRow™ DCX and available at htt p:// www.vertiv.com/en-us/support/.

For assistance c all 800-543-2378.

If the 3-phase Liebert UPS and will not restart, put the UPS in bypass and restart the remaining equipment.

Call 800-543-2738 f or assistance in putting the UPS in bypass and for service support

The Liebert CRV will restart automatically once power has been rest ored.

For assistance c all 800-543-2378.

Vertiv | SmartRow™ DCX Installation Manual | 29

Page 30

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 30

Page 31

9 MAINTENANCE

9.1 Liebert®CRV

The air conditioning system should be checked quarterly by a Vertiv™-certified technician. The trained technician who

started your system is available to provide maintenance and on-site support.

9.2 UPSs and Rack PDUs

The UPSs should be checked at least twice a year. Vertiv™ Services can be contacted at 800-543-2378.

For single-phase Liebert® UPS, rack power strips and Vertiv™ DCX racks, call 800-222-5877,option #1. Outside North

America call +00800 1155 4499; or e-mail: liebert.upstech@vertiv.com.

For three-phase UPS and power systems, call 800-543-2378; outside North America call 614-841-6598. For information

about the warranty, contact your local Vertiv representative or go to www.vertiv.com.

9.3 Electrical System

All electrical components, including the load-distribution center breakers, should be inspected at least twice a year by a

licensed electrical contractor. Any loose connections should be tightened.

Vertiv | SmartRow™ DCX Installation Manual | 31

Page 32

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 32

Page 33

10 TECHNICAL ILLUSTRATIONS

The illustrations on the following pages are provided to assist with installation.

Vertiv | SmartRow™ DCX Installation Manual | 33

Page 34

Figure 10.1 Vertiv™ SmartRow™ DCX System Submittal Overview, typical

Vertiv | SmartRow™ DCX Installation Manual | 34

Page 35

Figure 10.2 Vertiv™ SmartRow™ DCX 40kW One-Line N+1 Redundant with Power

Vertiv | SmartRow™ DCX Installation Manual | 35

Page 36

Figure 10.3 Vertiv™ SmartRow™ DCX 40kW One-Line 2N Redundant with Power

Vertiv | SmartRow™ DCX Installation Manual | 36

Page 37

Figure 10.4 Vertiv™ SmartRow™ DCX System Submittal Dimensions, typical

Vertiv | SmartRow™ DCX Installation Manual | 37

Page 38

Figure 10.5 Vertiv™ SmartRow™ DCX System Submittal Clearances, typical

Vertiv | SmartRow™ DCX Installation Manual | 38

Page 39

Figure 10.6 Vertiv™ SmartRow™ DCX System Submittal One-Line, typical

Vertiv | SmartRow™ DCX Installation Manual | 39

Page 40

Figure 10.7 Vertiv™ SmartRow™ DCX System, typical

Vertiv | SmartRow™ DCX Installation Manual | 40

Page 41

Figure 10.8 Vertiv™ SmartRow™ DCX Assembly 1, typical

Vertiv | SmartRow™ DCX Installation Manual | 41

Page 42

Figure 10.9 Vertiv™ SmartRow™ DCX Assembly 2, typical

Vertiv | SmartRow™ DCX Installation Manual | 42

Page 43

Figure 10.10 Vertiv™ SmartRow™ DCX Assembly 3, typical

Vertiv | SmartRow™ DCX Installation Manual | 43

Page 44

Figure 10.11 Vertiv™ SmartRow™ DCX Assembly 4, typical

Vertiv | SmartRow™ DCX Installation Manual | 44

Page 45

Figure 10.12 Vertiv™ SmartRow™ DCX Fan Control/vNSA

Vertiv | SmartRow™ DCX Installation Manual | 45

Page 46

Figure 10.13 Vertiv™ SmartRow™ DCX Fan Control/vNSA Cabling

Vertiv | SmartRow™ DCX Installation Manual | 46

Page 47

Figure 10.14 Vertiv™ SmartRow™ DCX UPS Spacer Kit

Vertiv | SmartRow™ DCX Installation Manual | 47

Page 48

Figure 10.15 Vertiv™ SmartRow™ DCX Liebert® EXM Installation, Pg. 1

Vertiv | SmartRow™ DCX Installation Manual | 48

Page 49

Figure 10.16 Vertiv™ SmartRow™ DCX Liebert® EXM Installation, Pg. 2

Vertiv | SmartRow™ DCX Installation Manual | 49

Page 50

Figure 10.17 Vertiv™ SmartRow™ DCX Liebert® EXM Installation, Pg. 3

Vertiv | SmartRow™ DCX Installation Manual | 50

Page 51

Figure 10.18 Vertiv™ SmartRow™ DCX Liebert® EXM Installation, Pg. 4

Vertiv | SmartRow™ DCX Installation Manual | 51

Page 52

Figure 10.19 Vertiv™ SmartRow™ DCX Liebert® EXM Installation, Pg. 5

Vertiv | SmartRow™ DCX Installation Manual | 52

Page 53

Figure 10.20 Vertiv™ SmartRow™ DCX Rack Expansion Channels Install, pg. 1

Vertiv | SmartRow™ DCX Installation Manual | 53

Page 54

Figure 10.21 Vertiv™ SmartRow™ DCX Rack Expansion Channels Install, pg. 2

Vertiv | SmartRow™ DCX Installation Manual | 54

Page 55

Figure 10.22 Vertiv™ SmartRow™ DCX Liebert® CRV600 Expansion Channels Install, pg. 1

Vertiv | SmartRow™ DCX Installation Manual | 55

Page 56

Figure 10.23 Vertiv™ SmartRow™ DCX Liebert® CRV600 Expansion Channels Install, pg. 2

Vertiv | SmartRow™ DCX Installation Manual | 56

Page 57

Figure 10.24 Vertiv™ SmartRow™ DCX Liebert® CRV600 Expansion Channels Install, pg. 3

Vertiv | SmartRow™ DCX Installation Manual | 57

Page 58

Figure 10.25 Vertiv™ SmartRow™ DCX Dimensions - Fire Detection and Suppression, 35# Cylinders

Vertiv | SmartRow™ DCX Installation Manual | 58

Page 59

Figure 10.26 Vertiv™ SmartRow™ DCX Component Layout - Fire Detection and Suppression, 35# Cylinders

Vertiv | SmartRow™ DCX Installation Manual | 59

Page 60

Figure 10.27 Vertiv™ SmartRow™ DCX Connections - Fire Detection and Suppression, 35# Cylinders

Vertiv | SmartRow™ DCX Installation Manual | 60

Page 61

Figure 10.28 Vertiv™ SmartRow™ DCX Racks with Expansion Channels

Vertiv | SmartRow™ DCX Installation Manual | 61

Page 62

Figure 10.29 Vertiv™ SmartRow™ DCX Liebert® CRV600 with Expansion Channels

Vertiv | SmartRow™ DCX Installation Manual | 62

Page 63

Figure 10.30 Vertiv™ SmartRow™ DCX Dimensions-Liebert® EXM (208V &480V) with Expansion Channels

Vertiv | SmartRow™ DCX Installation Manual | 63

Page 64

Figure 10.31 Vertiv™ SmartRow™ DCX Dimensions-Liebert® EXM BDC (208V &480V) with Expansion Channels

Vertiv | SmartRow™ DCX Installation Manual | 64

Page 65

Figure 10.32 Vertiv™ SmartRow™ DCX Dimensions-Liebert® EXM Battery Cabinet (600mm) with Expansion Channels

Vertiv | SmartRow™ DCX Installation Manual | 65

Page 66

Figure 10.33 Vertiv™ SmartRow™ DCX Server Rack Isometric Drawing

Vertiv | SmartRow™ DCX Installation Manual | 66

Page 67

Figure 10.34 Vertiv™ SmartRow™ DCX Server Rack Outline Drawing

Vertiv | SmartRow™ DCX Installation Manual | 67

Page 68

Figure 10.35 Vertiv™ SmartRow™ DCX Network Rack Isometric Drawing

Vertiv | SmartRow™ DCX Installation Manual | 68

Page 69

Figure 10.36 Vertiv™ SmartRow™ DCX Network Rack Outline Drawing

Vertiv | SmartRow™ DCX Installation Manual | 69

Page 70

Figure 10.37 Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression Control Logic

Vertiv | SmartRow™ DCX Installation Manual | 70

Page 71

Figure 10.38 Vertiv™ SmartRow™ DCX Control Panel and Fire Suppression Power Connections

Vertiv | SmartRow™ DCX Installation Manual | 71

Page 72

This page intentionally left blank.

Vertiv | SmartRow™ DCX Installation Manual | 72

Page 73

Page 74

Vertiv.com | Vertiv Headquarters, 1050 Dearborn Drive, Columbus, OH, 43085, USA

© 2020 Vertiv GroupCorp. All rights reserved. Vertiv™ and the Vertiv logo are trademarks or registered trademarks of Vertiv Group Corp. All other nam es and logos referred to are

trade names, trademarks or registered tradem arks of their respective owners. While every precaution has been taken to ensure accuracy a nd completeness herein, Vertiv Group

Corp. assumes no responsibility, and disclaims all liability, for damages resulting from use of this information or for any errors or omissions. Specifications are subject to change without

notice.

SL-11469_REV5_04-20

Loading...

Loading...