Page 1

NetSure™ IPE Series

Rectifier

Installation and User Manual

Specification Number: 561664, 561665, 561666

Model Number: R48-1000C

Page 2

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

The information contained in this document is subject to change without

notice and may not be suitable for all applications. While every precaution has

been taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in

this document.

The products covered by this instruction manual are manufactured and/or

sold by Vertiv. This document is the property of Vertiv and contains

confidential and proprietary information owned by Vertiv. Any copying, use or

disclosure of it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark

names should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.vertiv.com/en-us/support/ for additional assistance.

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Page 3

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

iii

TABLE OF CONTENTS

Admonishments Used in this Document .......................................................................................................................... v

Important Safety Instructions ............................................................................................................................................ vi

Static Warning ....................................................................................................................................................................... viii

1 Introduction ......................................................................................................................................................................... 1

1.1 Ordering Structure ........................................................................................................................................................................................................................................................ 1

1.1.1 Configurations ............................................................................................................................................................................................................................................ 1

1.1.2 Circuit breaker option ......................................................................................................................................................................................................................... 1

1.1.3 GMT fuse option ....................................................................................................................................................................................................................................... 1

1.1.4 What is in the box ................................................................................................................................................................................................................................... 2

1.1.5 Replacement components ............................................................................................................................................................................................................. 3

1.2 Rectifier Overview ........................................................................................................................................................................................................................................................ 4

1.3 Rectifier Specifications ............................................................................................................................................................................................................................................ 4

1.3.1 DC output ratings ................................................................................................................................................................................................................................... 4

1.3.2 AC input ratings ....................................................................................................................................................................................................................................... 6

1.3.3 Environmental ratings ..................................................................................................................................................................................................................... 10

1.3.4 Compliance information

1.3.5 Standard features ................................................................................................................................................................................................................................. 11

1.3.6 Mechanical specifications ............................................................................................................................................................................................................ 12

2 Installation ......................................................................................................................................................................... 14

2.1 General Requirements ........................................................................................................................................................................................................................................... 14

2.2 Tools and Test Equipment Required for Installation ................................................................................................................................................................ 14

2.3 Installing the Rectifier .............................................................................................................................................................................................................................................15

2.3.1 General ...........................................................................................................................................................................................................................................................15

2.3.2 Front door ....................................................................................................................................................................................................................................................15

2.3.3

Pole installation

2.3.4 Wall installation procedure

2.4 Installing GMT Fuses (P/N 561666 [R48-1000C-6] Only) ................................................................................................................................................. 20

3 Making Electrical Connections ................................................................................................................................... 20

3.1 Important Safety Instructions ........................................................................................................................................................................................................................ 20

3.2 Wiring Considerations........................................................................................................................................................................................................................................... 20

3.3 Frame Ground Connection ............................................................................................................................................................................................................................... 20

3.4 Customer Wiring to the Mating Connectors ..................................................................................................................................................................................... 21

3.5 Electrical Connections Diagrams ................................................................................................................................................................................................................26

3.6 External Alarm and Control Connections ........................................................................................................................................................................................... 30

3.6.1 General ......................................................................................................................................................................................................................................................... 30

3.6.2 Alarm and Control Connections ........................................................................................................................................................................................... 30

3.6.3 Changing the Alarm Relay Configuration for the Rectifier Fail Alarm and AC Fail Alarm ................................................ 31

3.7 Nominal 120 VAC / 208 VAC / 220 VAC / 230 VAC / 240 VAC Input and AC Input Equipment Grounding

Connections .................................................................................................................................................................................................................................................................... 32

3.8 -48 VDC Output Connections ........................................................................................................................................................................................................................ 32

3.9 -48 VDC Input Connections ............................................................................................................................................................................................................................. 32

3.10 Paralleling Rectifiers ................................................................................................................................................................................................................................................ 32

............................................................................................................................................................................................................... 10

proc

edure

........................................................................................................................................................................................................15

........................................................................................................................................................................................................ 18

Page 4

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

iv

3.10.1 Two Paralleled Rectifiers or One Plus One with Redundancy ................................................................................................................... 32

3.10.2 Three Paralleled Rectifiers or Two Plus One with Redundancy ............................................................................................................. 34

3.11 Final Step ........................................................................................................................................................................................................................................................................... 35

4 Initially Starting and Checking Rectifier Operation ............................................................................................. 36

4.1 Initially Starting the Rectifier .......................................................................................................................................................................................................................... 36

4.2 Checking System Status .................................................................................................................................................................................................................................... 36

5 Operation ........................................................................................................................................................................... 37

5.1 Local Indicators ........................................................................................................................................................................................................................................................... 37

5.2 Rectifier High Voltage Shutdown and Lockout Restart ........................................................................................................................................................ 37

6 Troubleshooting and Repair ........................................................................................................................................ 38

6.1 Contact Information .................................................................................................................................................................................................................................................38

6.2 Troubleshooting ..........................................................................................................................................................................................................................................................38

6.3 Repair ...............................................................................................................................................................................................................................................................................38

7 DC Power, Outdoor Enclosure & Service Contacts ............................................................................................. 40

Page 5

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

v

DANGER!

in death or serious injury if not avoided. (ANSI, OSHA)

WARNING!

result in

death or serious injury if not avoided. This admonition is not used for situations that pose a

risk only to equipment, software, data, or service. (ANSI)

CAUTION!

result in minor or moderate injury if not avoided. (ANSI, OSHA) This admonition is not

used for situations that pose a risk only to equipment, data, or service, even if such use

appears to

ALERT!

equipment, software, data, or service. (ISO)

ALERT!

equipment damage, software corruption, data loss, or service interruption. (ISO)

FIRE SAFETY!

or policies, or of the locations of fire

SAFETY!

policies not related to a particular source of hazard or to fire safety. (ISO, ANSI, OSHA)

Admonishments Used in this Document

Warns of a hazard the reader

Warns of a potential hazard the reader

Warns of a potential hazard the reader

be permitted in some of the applicable standards. (OSHA)

Alerts the reader to an action that

will

be exposed to that will

may

be exposed to that

may

be exposed to that

must be avoided

likely

result

could

could

in order to protect

Alerts the reader to an action that

Informs the reader of fire safety information, reminders, precautions,

Informs the reader of general safety information, reminders, precautions, or

-fighting and fire-safety equipment. (ISO)

must be performed

in order to prevent

Page 6

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

vi

Important Safety Instructions

Safety Admonishments Definitions

Definitions of the safety admonishments used in this document are listed under “Admonishments Used in this Document” on page v.

General Safety

DANGER! YOU MUST FOLLOW APPROVED SAFETY PROCEDURES.

Performing the following procedures may expose you to hazards. These procedures should be performed by qualified

technicians familiar with the hazards associated with this type of equipment. These hazards may include shock, energy,

and/or burns. To avoid these hazards:

a) The tasks should be performed in the order indicated.

b) Remove watches, rings, and other metal objects.

c) Prior to contacting any uninsulated surface or termination, use a voltmeter to verify that no voltage or the expected

voltage is present. Check for voltage with both AC and DC voltmeters prior to making contact.

d) Wear eye protection.

e) Use certified and well maintained insulated tools. Use double insulated tools appropriately rated for the work to be

performed.

Voltages

AC Input Voltages

DANGER! This system operates from AC input voltage capable of producing fatal electrical shock. AC input power must be

completely disconnected from the branch circuits wiring used to provide power to the system before any AC electrical

connections are made. Follow local lockout/tagout procedures to ensure upstream branch circuit breakers remain de-

energized during installation. DO NOT apply AC input power to the system until all electrical connections have been

completed and checked.

DC Output and Battery Voltages

DANGER! This system produces DC power and may have a battery source connected to it. Although the DC voltage is not

hazardously high, the rectifiers and/or battery can deliver large amounts of current. Exercise extreme caution not to

inadvertently contact or have any tool inadvertently contact an output terminal or battery terminal or exposed wire

connected to an output terminal or battery terminal. NEVER allow a metal object, such as a tool, to contact more than one

termination or battery terminal at a time, or to simultaneously contact a termination or battery terminal and a grounded

object. Even a momentary short circuit can cause sparking, explosion, and injury.

DANGER! Follow local lockout/tagout procedures to ensure DC branch circuit protection devices remain de-energized

during installation at loads, as required.

Page 7

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

vii

Personal Protective Equipment (PPE)

DANGER! ARC FLASH AND SHOCK HAZARD.

Appropriate PPE and tools required when working on this equipment. An appropriate flash protection boundary analysis

should be done to determine the “hazard/risk” category, and to select proper PPE.

Only authorized and properly trained personnel should be allowed to install, inspect, operate, or maintain the equipment.

Do not work on LIVE parts. If required to work or operate live parts, obtain appropriate Energized Work Permits as required

by the local authority, per NFPA 70E “Standard for Electrical Safety in the Workplace”.

Hazardous Voltage

DANGER! HAZARD OF ELECTRICAL SHOCK.

More than one disconnect may be required to de-energize the system before servicing.

Handling Equipment Containing Static Sensitive Components

ALERT! Installation or removal of equipment containing static sensitive components requires careful handling. Before

handling any equipment containing static sensitive components, read and follow the instructions contained on the Static

Warning Page.

Page 8

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

viii

Static Warning

This equipment contains static sensitive components. The warnings listed below must be observed to prevent damage to

these components. Disregarding any of these warnings may result in personal injury or damage to the equipment.

1. Strictly adhere to the procedures provided in this document.

2. Before touching any equipment containing static sensitive components, discharge all static electricity from yourself by

wearing a wrist strap grounded through a one megohm resistor. Some wrist straps have a built-in one megohm resistor;

no external resistor is necessary. Read and follow wrist strap manufacturer’s instructions outlining use of a specific wrist

strap.

3. Do not touch traces or components on equipment containing static sensitive components. Handle equipment

containing static sensitive components only by the edges that do not have connector pads.

4. After removing equipment containing static sensitive components, place the equipment only on static dissipative

surfaces such as conductive foam or ESD bag. Do not use ordinary Styrofoam or ordinary plastic.

5. Store and ship equipment containing static sensitive components only in static shielding containers.

6. If necessary to repair equipment containing static sensitive components, wear an appropriately grounded wrist strap,

work on a conductive surface, use a grounded soldering iron, and use grounded test equipment.

Page 9

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

1

1 Introduction

The NetSure IPE SERIES provides a rectifier mounted inside an environmentally protective enclosure. The NetSure IPE SERIES

rectifier can be wall or pole mounted.

1.1 Ordering Structure

1.1.1 Configurations

The NetSure IPE SERIES rectifier can be provided in three (3) configurations.

• Bulk Output: Spec. No. 561664 (R48-1000C-4).

• Output Fed through an Internal 30 A Circuit Breaker:

Spec. No. 561665 (R48-1000C-5).

• Output Fed through an Internal 6-Position GMT Fuse Block: Spec. No. 561666 (R48-1000C-6).

1.1.2 Circuit breaker option

Spec. No. 561665 (R48-1000C-5): A 30 A internal circuit breaker is provided.

1.1.3 GMT fuse option

Spec. No. 561666 (R48-1000C-6): An internal 6-position GMT fuse block is provided.

Specify fuses from Table 1-1.

• Maximum GMT fuse size is 10 A.

• At +65 °C (+149 °F), a space is required between GMT fuses greater than 5 A.

• When used for power distribution, load should not exceed 80% of device rating, except 10 A fuses, for which load should not

exceed 70% of device rating.

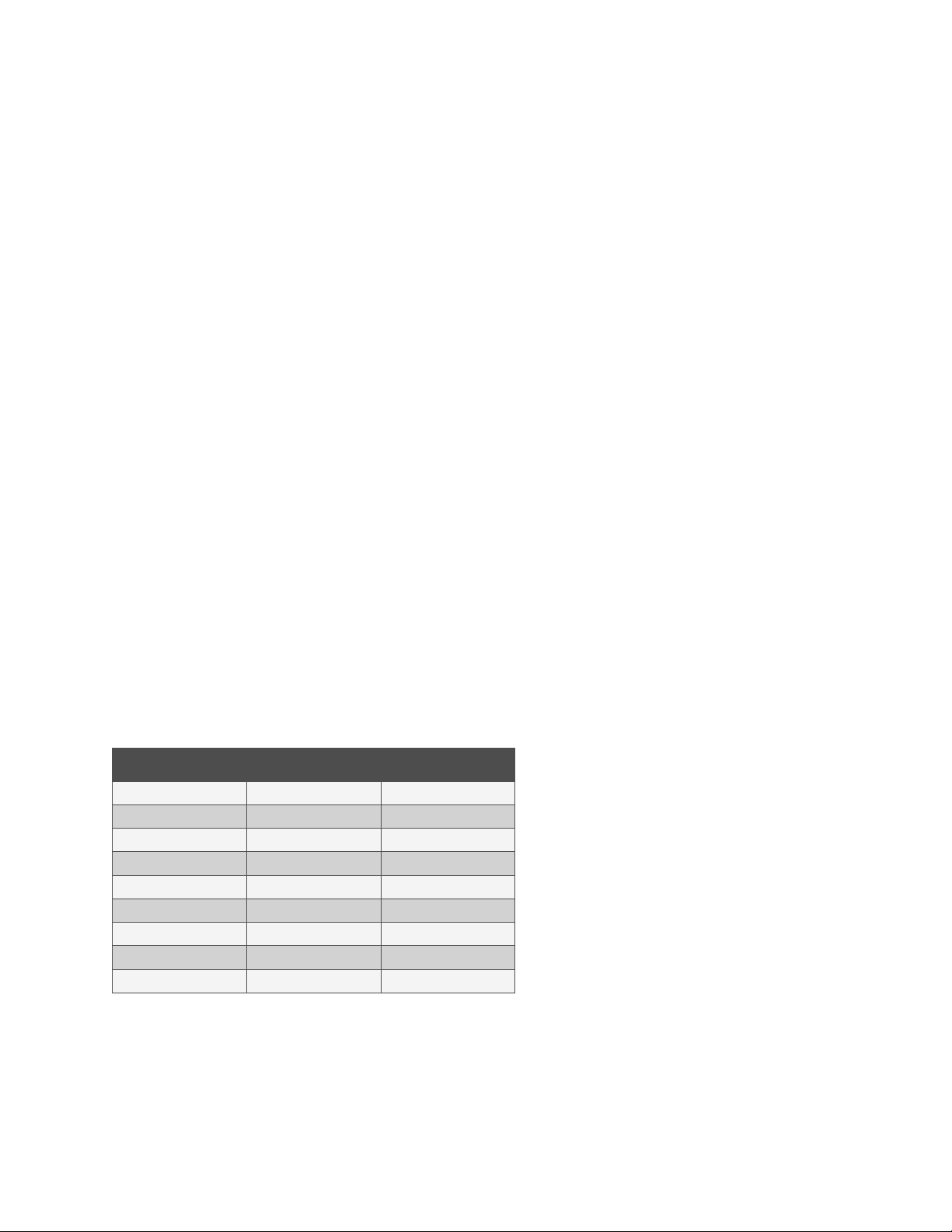

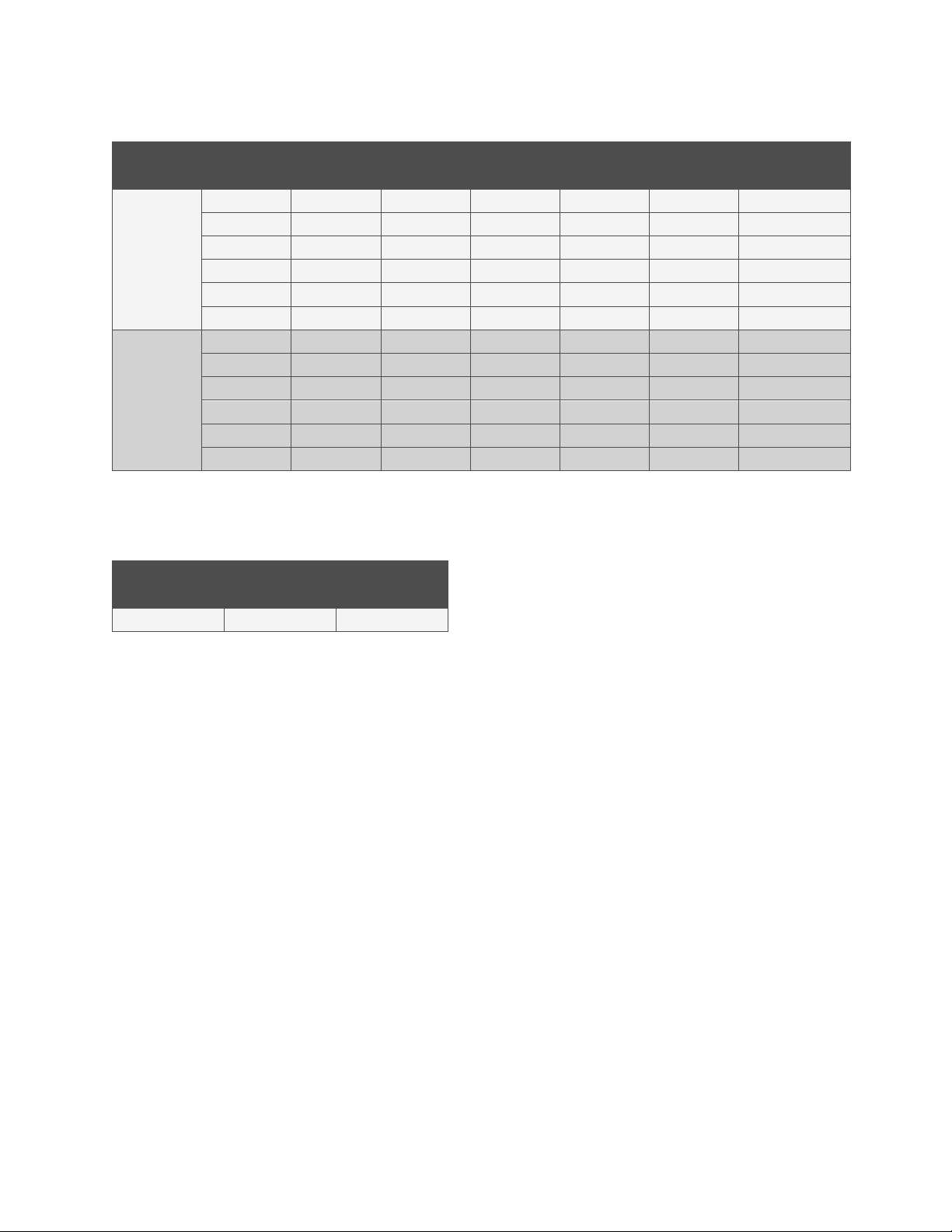

Table 1-1: GMT Fuses

Ampere Rating Part Number Fuse Color

1/4 248610200 Violet

1/2 248610300 Red

3/4 248610500 Brown

1-1/3 248610700 White

2 248610800 Orange

3 248610900 Blue

5 248611000 Green

7-1/2 248611300 Black-White

10 248611200 Red-White

Page 10

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

2

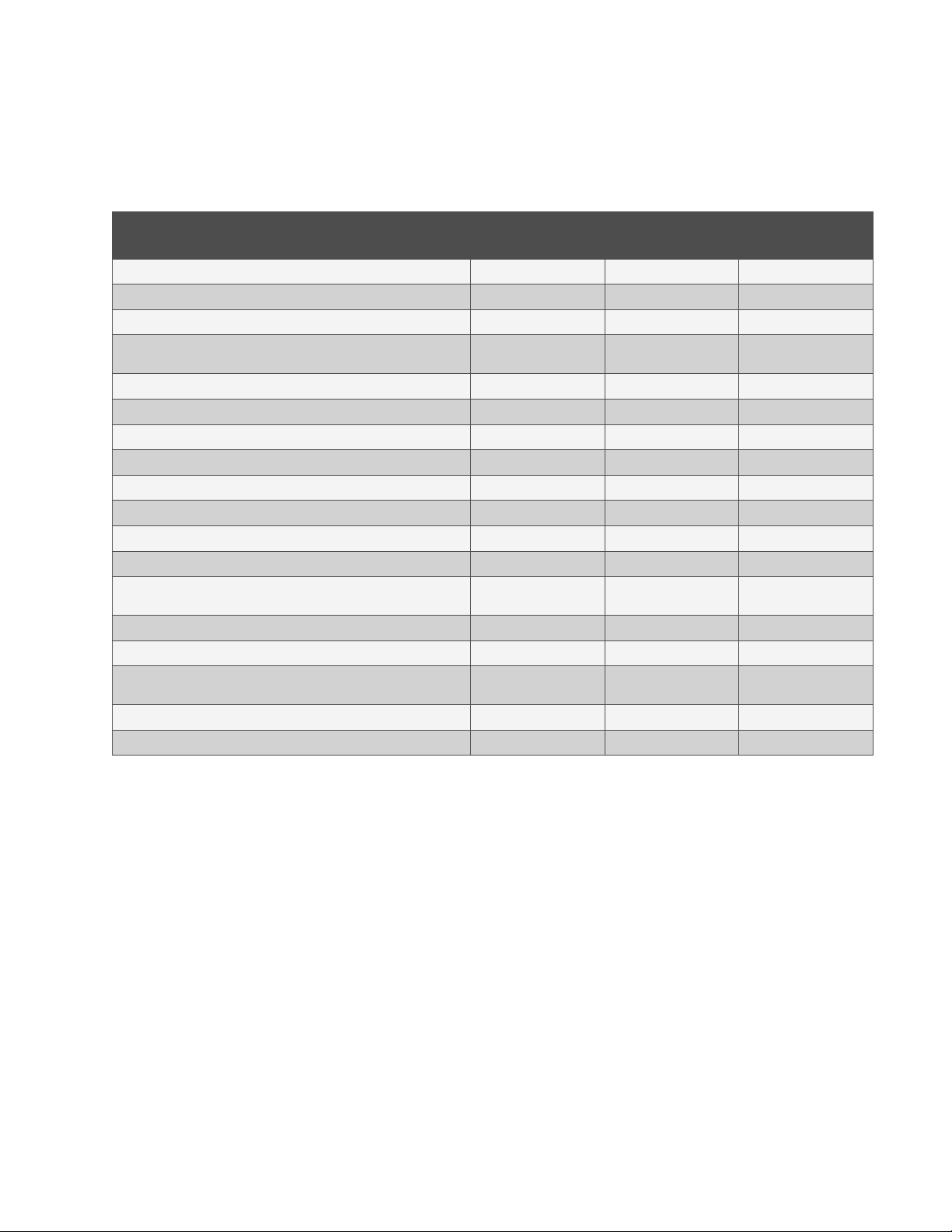

1.1.4 What is in the box

Refer to Table 1-2.

Table 1-2:

Item

(1) 21503878 Mounting Bracket Kit X X X

(2) 632404V1 Mounting Bracket (Big) X X X

(1) 632404V2 Mounting Bracket (Small) X X X

(2) 21101742 Sealing Cable Adapter (Single Large) (DC Input, Bulk DC

Output, 30 A Breaker Output, AC Input)

(1) 21101743 Sealing Cable Adapter (Single Small) (AC Input) X X X

(3) 21101744 Sealing Cable Adapter (Three Cables) (Alarm, GMT Output) X X X

(1) 63126350 Door Hardware Tool X X X

(2) 26011153 M8 Bolts w/ Flat Washer and Lock Washer X X X

(4) 26011018 M5 Bolts w/ Flat Washer and Lock Washer X X X

(2) 26011356 M5 Flat Head Screws X X X

(2) 63126330 Pole Mount Band X X X

(1) 14190607 AC Input Connector (Customer Side) X X X

(2) 14190609 DC Output Connector for GMT Fuse Option (Customer

Side)

(1) 14190611 Alarm Connector (Customer Side) X X X

(1) 14190615 DC Input Connector (Customer Side) X X X

(1) 14190623 DC Output Connector for Bulk Output or Internal Circuit

Breaker Option (Customer Side)

(6) 21101745 Sealing Pin for Unused Holes in Sealing Cable Adapters X X X

(1) UM1R481000CNA Installation and User Manual X X X

P/N 561664

(R48-1000C-4)

X X X

-- -- X

X X --

P/N 561665

(R48-1000C-5)

P/N 561666

(R48-1000C-6)

Page 11

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

3

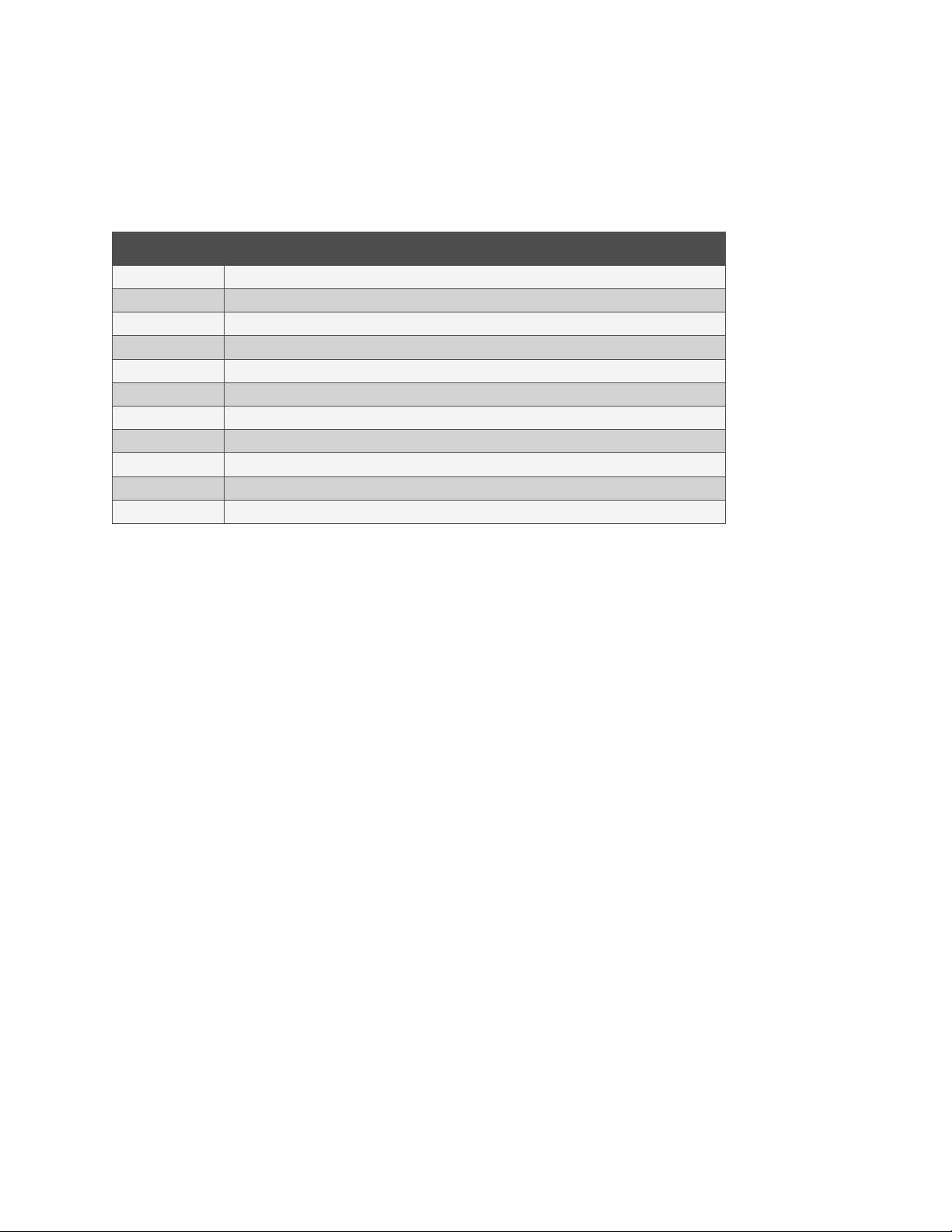

1.1.5 Replacement components

The input/output terminations are connectorized. For a replacement mating connector, order from Table 1-3. Refer also to Table 1-3

for other replacement components.

Table 1-3: Replacement Components

Part Number Description

14190607 AC Input Connector (Customer Side)

14190609 DC Output Connector for GMT Fuse Option (Customer Side)

14190611 Alarm Connector (Customer Side)

14190615 DC Input Connector (Customer Side)

14190623 DC Output Connector for Bulk Output or Internal Circuit Breaker Option (Customer Side)

63126330 Pole Mount Band

21101742 Sealing Cable Adapter (Single Large) (DC Input, Bulk DC Output, 30 A Breaker Output, AC Input)

21101743 Sealing Cable Adapter (Single Small) (AC Input)

21101744 Sealing Cable Adapter (Three Cables) (Alarm, GMT Output)

21101745 Sealing Pin for Unused Holes in Sealing Cable Adapters

21101755 Door Gasket

Page 12

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

4

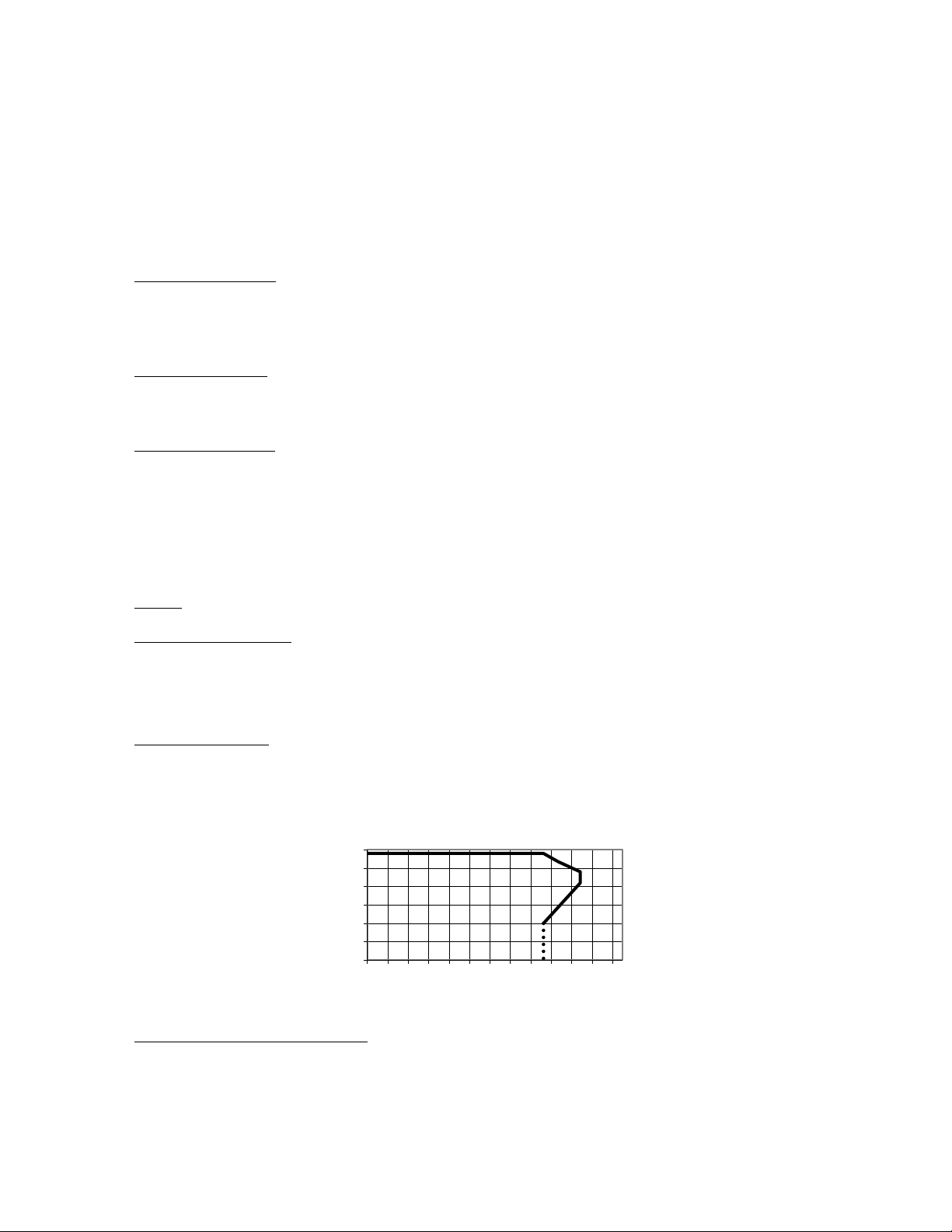

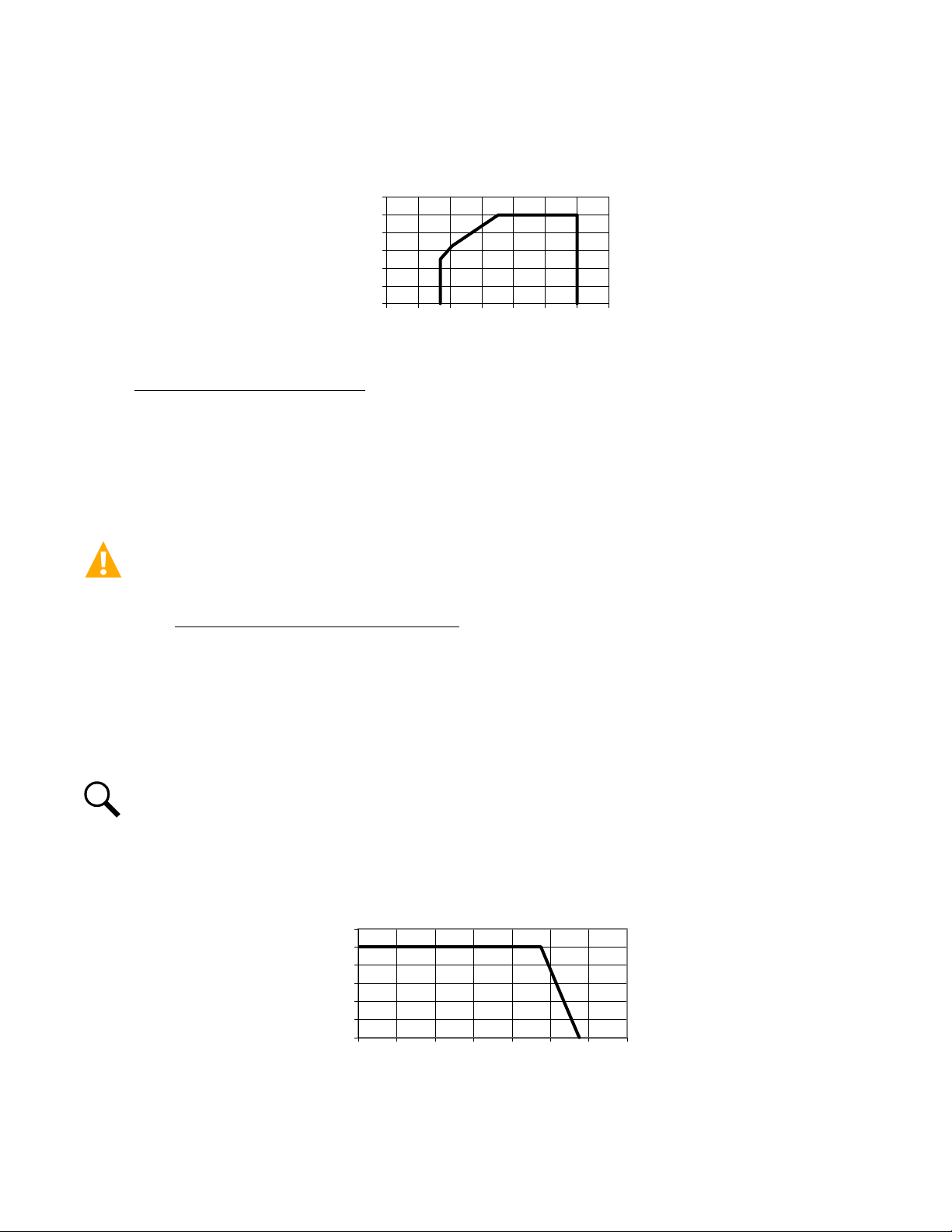

Output Voltage (V)

Output Current (A)

1.2 Rectifier Overview

The rectifier provides load power during normal operating conditions. The rectifier is a constant power design. The rectifier is rated

at its maximum output power. This means that, within the normal operating ambient temperature range and input voltage range, the

maximum available output power is a constant 1000 W. Within these ranges, the rectifier operates in one of three modes, depending

upon load demands. Transition between modes is completely automatic. If ambient temperature rises above or input voltage falls

below acceptable values, the rectifier continues to operate but at derated output power levels.

• Constant Voltage Mode: For any initial output voltage setting from -42 VDC to -58 VDC (factory set at -54 VDC), output

voltage remains constant regardless of load. This is the normal operating condition, in which loads are being supplied. The

rectifier operates in the Constant Voltage Mode unless load increases to the point where the product of load current and

output voltage is approximately 1000 W.

• Constant Power Mode: As load increases above approximately 1000 W (non-adjustable), output current continues to

increase, but output voltage decreases as required to maintain constant output power. The rectifier operates in the Constant

Power Mode unless load continues to increase to the point where the current limit setting is reached.

• Constant Current Mode: If load increases to the current limit setting, output voltage decreases linearly to maintain output

current at the current limit setting.

1.3 Rectifier Specifications

The specifications are for a single unit only, unless otherwise noted.

1.3.1 DC output ratings

1. Voltage: -42 VDC to -58 VDC, positive ground. Output voltage is factory set at -54 VDC.

2. Output Power and Current:

a) 1000 W (20.83 A) @ 200 VAC to 250 VAC input and -48 VDC output.

b) 700 W (14.58 A) @ 120 VAC input and -48 VDC output.

3. Output Characteristics: Refer to Figure 1-1 for a graph of output voltage vs. output current.

Figure 1-1: Output Voltage vs. Output Current

Output Voltage vs. Output Current

at Maximum Power 1000 W

60

50

40

30

20

10

0

0 2 4 6 8 10 12 14 16 18 20 22 24

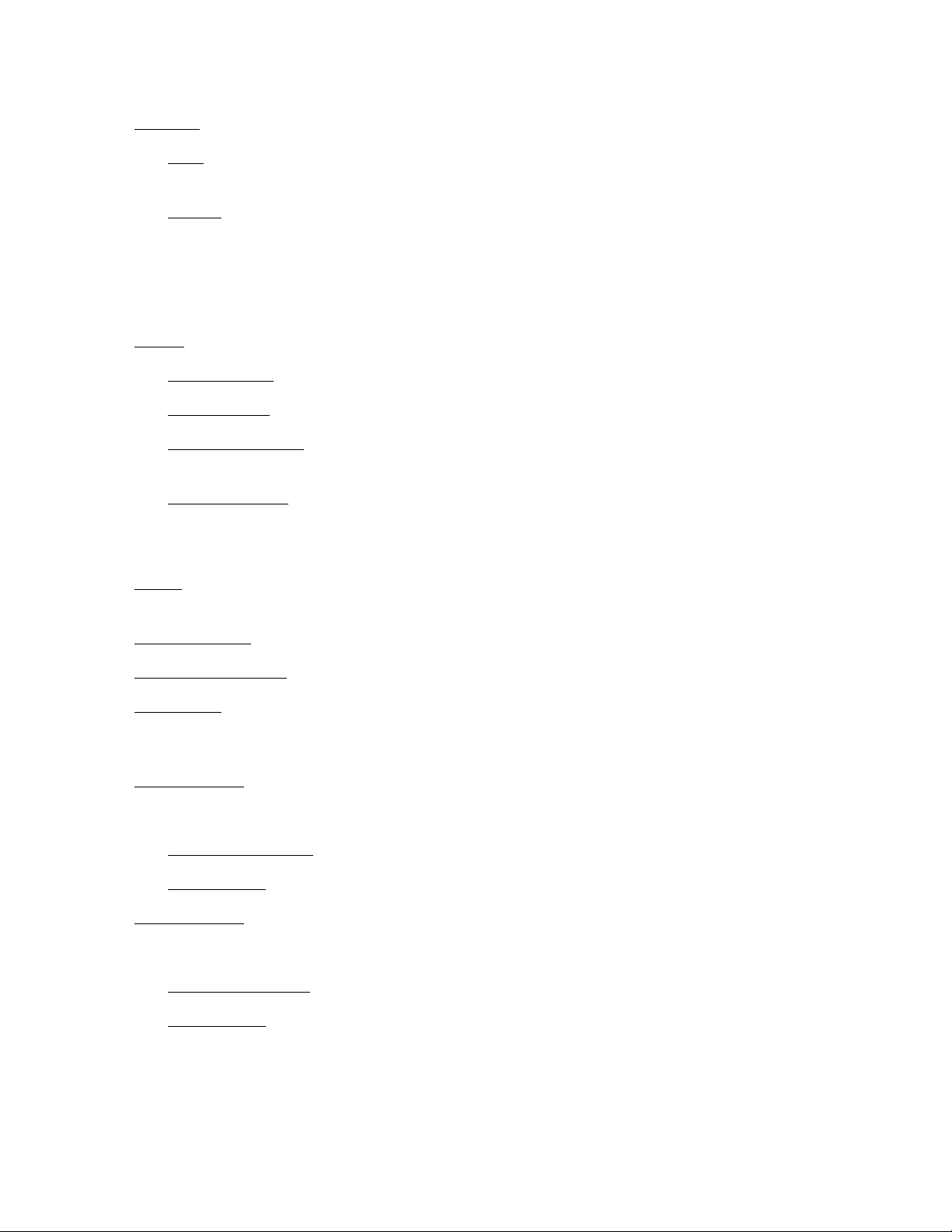

4. Power Derating Based on Input Voltage: The rectifier power varies with changes in input voltage. It uses an advanced power

limitation method. The lower input threshold is 85 VAC. The rectifier can provide its maximum rated power (1000 W) as long

as the input voltage is within the range of 176 VAC to 300 VAC. Below 176 VAC, and down to 85 VAC, the rectifier will

continue to operate normally but will be in a power derating mode. The relationship between the output power and input

voltage is illustrated in Figure 1-2.

Page 13

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

5

% of Output Power

Input Voltage (Vac)

% of Output Power

Temperature (℃)

Figure 1-2: Power Derating Based on Input Voltage

Output Power vs. Input Voltage

and Vo >48 V at Temp ≤55℃

120.0%

100.0%

80.0%

60.0%

40.0%

20.0%

0.0%

0 50 100 150 200 250 300 350

5. Power Derating Based on Temperature: The rectifier delivers full power when operating at an ambient temperature of +55 °C

(+131 °F) or below. The rectifier continuously monitors the ambient temperature surrounding the power conversion circuit. If

this temperature for any reason (such as a high ambient temperature) increases above approximately +55 °C (+131 °F), the

rectifier will not shut down. Rather, the rectifier limits its maximum output power to maintain the temperature of the power

conversion circuit within design parameters. Operation between +55 °C (+131 °C) and +75 °C (+167 °F) will result in output

power being decreased. Full power capability is restored when the temperature decreases to below approximately +55 °C

(+131 °F). Refer to Figure 1-3 to view the relationship between the output power and the ambient temperature.

WARNING! The module is rated for continuous operation at full output power up to +55 °C (+131 °F). Operation between

+55 °C (+131 °F) and +75 °C (+167 °F) will result in output power decrease. Operation above +75 °C (+167 °F) is considered

abnormal and should be used on a temporary

1

Temporary Operation at Abnormal Temperature: Temporary operation is defined as a period of not more than eight

1

basis only.

consecutive hours per day, and a total of not more than 15 days in a year. (This refers to a total of 120 hours in any

given year, but no more than 15 occurrences in that one-year period.)

Other power rating values are as follows (refer to Figure 1-3):

a) At an ambient temperature of +65 °C (+149 °F), the power delivered by the rectifier is 500 W.

b) At an ambient temperature of +75 °C (+167 °F), the power delivered by the rectifier is 0 W.

NOTE!

If used outdoors under full solar radiation, in an ambient of 46 °C the product is rated for 561 W per Telcordia GR-

487-CORE.

Figure 1-3: Power Derating Based on Temperature

Output Power vs. Temperature

at 290 Vac ≥ Vin ≥ 176 Vac

120

100

80

60

40

20

0

-40 -20 0 20 40 60 80 100

Page 14

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

6

6. Regulation:

a) Static: Steady state regulation is ±0.6% as controlled within the rectifier for any and all combinations of load from no

load to full load, input voltage, and input frequency at a constant ambient temperature.

b) Dynamic: Response time ≤200 us and overshoot ≤5% for load changes at 50% - 25% - 50%

and 50% - 75% - 50% at rated output current.

For any step load change within the range of 10% to 90% of full load within 50 us, per Telcordia GR-947-CORE, the

maximum voltage transient will not exceed 5% of the initial steady state voltage within 50±10 us. Recovery to within 1%

of the initial steady state voltage does not exceed 1 milliseconds.

7. Filtering:

a) Voice Band Noise: Peak-peak voltage is ≤200 mV at 0 MHZ to 20 MHZ and normal output voltage.

b) Wide Band Noise: Wideband noise voltage is ≤50 mV at 3.4 kHz to 150 kHz and ≤20 mV at 0.15 MHz to 30 MHz.

c) Discrete Noise Voltage: Discrete noise voltage is ≤5 mV at 3.4 kHz to 150 kHz, ≤3 mV at 150 kHz to 200 kHz, ≤2 mV at

200 kHz to 500 kHz, and ≤1 mV at 500 kHz to 30000 kHz.

d) Psophometric Noise: Psophometric noise is ≤2 mV typical at 220 VAC input, 53.5 VDC output, and 30% to 90% of rated

load for more than one rectifier.

1.3.2 AC input ratings

1. Voltage: Nominal 120 VAC / 208 VAC / 220 VAC / 230 VAC / 240 VAC, single phase, 3-wire, 50 Hz / 60 Hz, with an operating

range of 85 VAC to 300 VAC. Acceptable input frequency range is 45 Hz to 65 Hz.

Permitted Variation: 85 VAC to 300 VAC.

2. Harmonic Content (THD): Meets EN61000-3-2. ≤5% from 50% to 100% of rated output current at 220 VAC.

3. Inrush Current: Peak does not exceed 1.5 times of the peak value of the maximum steady-state input current at full load, 220

VAC input voltage, and for any duration of AC input interrupts. Under the above conditions, standard AC distribution circuit

breakers will not trip.

4. Typical Input Data: 50 Hz input.

a) Refer to Table 1-4.

b) Maximum Input Current: Refer to Table 1-5.

c) Efficiency Curve: Refer to Figure 1-4.

5. Typical Input Data: 60 Hz input.

a) Refer to Table 1-6.

b) Maximum Input Current: Refer to Table 1-7.

c) Efficiency Curve: Refer to Figure 1-5 and Figure 1-6.

Page 15

7

Table 1-4: Typical Input Data with 50 Hz Input

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Nominal

Input Voltage

208

240

Note:

System output is initially adjusted to 54 volts DC as measured at the system sense point at 50% of full load

Percent

of Full Load

0 0.286 55.84 4.73 0.10023 -- 16.137

25 1.26 258.754 245.374 0.9 48 57 90.79 77.1101

50 2.34 485.81 479.1 4 0.98624 94.33 92.6646

75 3.489 725.77 721.56 0.99407 94.81 127.7476

100 4.66 970. 24 967.15 0.99682 94.76 172.9354

110 5.01 1041.68 1038.95 0.99725 94.70 187.9968

0 0.33 73.4 4.908 0.06636 -- 16.745

25 1.12 265.36 244.52 0.92218 91.16 73.7573

50 2.02 482.99 477.956 0.9897 7 94.59 88.2566

75 3.015 724.2 719.46 0.99357 95.10 120.301

100 4.033 969.3 966.68 0.99727 95.09 161.8856

110 4.32 1037.32 103 5.1 0.99778 95.05 174.7991

Input Current

(Amperes)

and nominal input. “Percent of Full Load” refers to percent of 17.24 amperes.

Table 1-5: Maximum Input Current with 50 Hz Input

Nominal Input

Voltage

Input

Voltage

Input Current

(Amperes)

Input

VA

Input

Watts

Power

Factor

Efficiency

%

Heat Dissipation

BTU/Hr

208/240 176 7.5

Note:

At 100% of full load with output adjusted to 58 volts DC as

measured at the output terminals.

Page 16

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

8

Table 1-6: Typical Input Data with 60 Hz Input

Nominal

Input Voltage

120

208

240

Percent

of Full Load

0 0.233 28.132 4.863 0.17286 -- 16.59

25 2.175 262.037 256.726 0.97973 90.76 80.96

50 4.185 503.75 499.92 0.99241 93.09 117.85

75 6.278 754.97 751.24 0.99505 92.94 181.02

100 -- -- -- -- -- --

110 -- -- -- -- -- --

0 0. 34 67.243 4.713 0.07574 -- 16.08

25 1.284 263.654 245.112 0.92942 90.80 76.95

50 2.35 487.82 478.89 0.98189 94.35 92.36

75 3.49 726.85 721.46 0.99271 94.81 1 27.7 7

100 4.66 970. 53 966.92 0.99636 94.78 172.29

110 5.006 1042 .06 1038.81 0.99693 94.70 187.70

0 0.381 87.67 4.728 0.05362 -- 16.13

25 1.155 272.863 244.46 0.89528 91.15 73.79

50 2.027 4 84.678 478.99 0.98601 94.37 91.97

75 3.02 725.35 719.45 0.9919 95.10 120.31

100 4.023 966.79 963.65 0.99679 95.12 160.58

110 4.31 1037.7 2 1035.15 0.99752 95.05 174.97

Input Current

(Amperes)

Input

VA

Input

Watts

Power

Factor

Efficiency

%

Heat Dissipation

BTU/Hr

Note:

System output is initially adjusted to 54 volts DC as measured at the system sense point at 50% of full load

and nominal input. “Percent of Full Load” refers to percent of 17.24 amperes.

Table 1-7: Maximum Input Current with 60 Hz Input

Nominal Input

Voltage

208/240 176 7.5

Note:

At 100% of full load with output adjusted to 58 volts DC as

Input

Voltage

Input Current

(Amperes)

measured at the output terminals.

Page 17

9

Figure 1-4: Efficiency Curve (@ 230 VAC, 50 Hz)

Efficiency (%)

98

96

94

92

90

88

86

84

0 10 20 30 40 50 60 70 80 90 100

Figure 1-5: Efficiency Curve (@ 240 VAC, 60 Hz)

98

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Efficiency Curve

Load (% of rated load)

Efficiency Curve

96

94

92

90

88

Efficiency (%)

86

84

0 10 20 30 40 50 60 70 80 90 100 110 120

Figure 1-6: Efficiency Curve (@ 120 VAC, 60 Hz)

98

96

94

92

90

Load (% of rated load)

Efficiency Curve

88

Efficiency (%)

86

84

0 10 20 30 40 50 60 70 80 90 100 110 120

Load (% of rated load)

Page 18

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

10

1.3.3 Environmental ratings

1. Operating Ambient Temperature Range:

a) -40 °C (-40 °F) to +55 °C (+131 °F) with full power performance.

b) +55 °C (+131 °F) to +75 °C (+167 °F) with derating output.

c) Temperature Coefficient: 0.02% per degrees Celsius.

2. Storage Ambient Temperature Range: -40 °C (-40 °F) to +70 °C (+158 °F).

3. Relative Humidity: This rectifier is capable of operating in an ambient relative humidity range of 0% to 95%.

4. Altitude: -200 feet (- 61 m) to 13000 feet (3900 m).

5. Surge Protection: EN61000-4-5 up to level 4, Telcordia GR-1089-Core, IEEE C62.41-2002, YD/T 731-2002.

Performance Criteria B.

AC Power Terminals

Test Level

Line to Line Line to Ground

± 4 kV ± 4 kV 2 ohms B

NA ± 6 kV 12 ohms B

Source

Impedance

Performance

Criteria

DC Power Terminals:

Test Level

Line to Line Line to Ground

± 500 V ± 500 V 2 ohms B

± 800 V ± 800 V 2 ohms B

Source

Impedance

Performance

Criteria

The test method is described in EN 61000-4-5. In this test the DC-cables shall

be 5 m long.

6. High Voltage Category (per UL60950): III

7. Power Distribution System: TN/TT/IT

8. EMI/RFI Suppression:

a) The rectifier conforms to the requirements of FCC rules Part 15, Class B for radiated and conducted emissions limits.

b) The rectifier conforms to the requirements of European Norm, EN55022, Class B for radiated and conducted emissions

limits.

1.3.4 Compliance information

1. EMC: ETSI EN 300 386, FCC CFR 47 Part 15 class B, Telcordia GR-1089-CORE.

2. EMI Load Range: 10% to 100%.

3. Safety: IEC 60950, EN 60950.

Page 19

11

4. Product is GR-3108 Class 4 compliant.

1.3.5 Standard features

1. Type of Power Conversion Circuit: High frequency.

2. Input Protection:

a) Input Over/Under Voltage Protection: The rectifier will shut down at low or high voltage input; based on the following

voltage levels:

Low Voltage Disable Point: 80 VAC, ±5 V; hysteresis is at least 15 VAC for restart.

High Voltage Disable Point: 305 VAC, ±5 V; hysteresis is at least 10 VAC for restart.

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

b) Between 85 VAC and 176 VAC the output power will be

derated linearly based on the input voltage as

follows:

At input voltage of 85 VAC with output >48 VDC, maximum output power is 500 W.

At input voltage of 176 VAC with output >48 VDC, maximum output power is 1000 W.

3. Output Protection:

a) Overload / Reverse Current: The rectifier has a 28 A fuse wire in the negative output DC bus. This fuse is not customer

replaceable.

b) Current Limiting: The rectifier has a current limit function. The current limit point is factory set at 20.83 A. The current

limit accuracy is ±1.5 A when the output voltage ranges from 42 VDC to 48 VDC.

c) Advanced Current Limit Function: The rectifier has an advanced Current Limit Function. When a short circuit occurs

at the rectifier output terminals, the rectifier will keep its output current at a constant value (factory set at 17 A ± 6 A).

This function effectively protects the rectifier and the equipment connected to the rectifier. When the short circuit fault

is cleared, the rectifier will automatically restore back to normal operation.

d) High Voltage Shutdown:

• Fixed Control: If rectifier output voltage exceeds a factory set value of 59.5 VDC and the rectifier is delivering more

than 10% of its rated current, the rectifier shuts down. (The restart hysteresis is 0.5 V ±0.2 V.)

The rectifier then restarts and a HVSD restart timer starts (factory set at 5 minutes). If output voltage again

exceeds the high voltage shutdown value before the HVSD restart timer expires, the rectifier shuts down and locks

out. Manual restart is then required (by turning power to the rectifier off , waiting until the LEDs on the rectifier

extinguish, then turning power to the rectifier on). If the rectifier does not experience a high voltage condition

before the HVSD restart timer expires, the restart circuit is reset.

If two or more rectifiers are paralleled, only the rectifier causing the high voltage condition shuts down.

• Backup: If rectifier output voltage exceeds 59.5 VDC ±0.5 V (non-adjustable), the rectifier shuts down. The

rectifier then restarts and a HVSD restart timer starts (factory set at 5 minutes). If output voltage again exceeds

the high voltage shutdown value before the HVSD restart timer expires, the rectifier shuts down and locks out.

Manual restart is then required (by turning power to the rectifier off, waiting until the LEDs on the rectifier

extinguish, then turning power to the rectifier on).

4. Over-Temperature Protection: The rectifier provides over temperature protection by derating output power and recovers

automatically.

Page 20

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

12

5. Active Load Sharing: The rectifier uses advanced digital active load sharing technology that maintains balancing to within 5%

of rated current.

6. Paralleling: Up to three (3) rectifiers can be connected in parallel in one system. Do not exceed the load rating of a single

rectifier. See “Paralleling Rectifiers” on page 32.

7. Rectifier Output Current Imbalance:

a) When the average current of all rectifier modules is greater than 20% of full rated current, and the difference between

local rectifier current and average current is greater than 16% of full rated current, the yellow protection indicator will

illuminate.

b) When the average current of all rectifier modules is greater than 10% of full rated current, and local rectifier current is

less than 2% of full rated current, then the red fault indicator will illuminate.

8. Monitoring Function: The rectifier has a built-in advanced DSP that monitors and controls the operation of the rectifier.

1.3.6 Mechanical specifications

1. Dimensions and Weight:

Refer to

2. Indicators (located behind door):

a) Power (Green LED)

b) Protection (Yellow LED)

c) Alarm (Red LED)

Figure 1-7.

Page 21

13

Figure 1-7: Overall Dimensions

Notes:

1. Dimensions are in inches,

unless otherwise specified.

2. Finish: Aluminum with

Powder Painted.

3. Weight:

Bottom View

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Net: 5 kg (11 lbs.)

Shipping:

Rear View

7.68

Top View

3.66

14.17

4.61

17.05

Front View

Right Side ViewLeft Side View

Page 22

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

14

2 Installation

2.1 General Requirements

CAUTION! PREVENT EQUIPMENT DAMAGE, FROM CONDENSATION

Until the product is turned up for service, the top cover of the product should remain closed as delivered from the factory. If

the top cover of the product is opened when in storage, it shall be placed in its sealed protective packaging with the provided

desiccant bags to prevent condensation. Once the product is in service, the heat generated by the product is sufficient to

prevent humidity build up.

• This product is intended for installation in network telecommunications facilities (CO, vault, hut or other electronic equipment

enclosure) or as an outside plant cabinet.

• This product is intended to be connected to the common bonding network in a network telecommunications facility (CO,

vault hut or other equipment enclosure).

• The DC return connection to this system can remain isolated from system frame and chassis (DC-I). The DC return is not

connected to the power supply chassis from the factory.

• This product is suitable for installation as part of the Common Bonding Network (CBN).

2.2 Tools and Test Equipment Required for Installation

The following tools, test equipment and materials are required for the physical installation of the product:

• Non-Contact Voltage Detector

• Digital Multimeter (DMM), 0 VDC to 200 VDC, 0 VAC to 300 VAC

• Torque Wrench

• Ratchet, 1/2”, 3/8” and 1/4” Drives

• Socket Set Range from M4 to M13

• 3” and 6” Extensions, 1/4” and1/2” Drive

• Carpenters Level

• Lineman’s Scissors

• Lineman’s Strippers

• Lineman’s Cutters

• Crimping Tool with Dies for 6 AWG to 14 AWG

• Electrician’s Insulated Screwdrivers, Phillips, No. 1 and 2

• Electrician’s Insulated Screwdrivers, Flat Blade, Small and Large

• NO-OX-ID or Approved Equivalent

Page 23

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

15

Front View Front

1

3

2.3 Installing the Rectifier

2.3.1 General

The rectifier can be pole mounted or secured to a suitable wall.

For mounting; use a corrosion inhibiting compound (CIC) that is conductive inside the tapped mounting holes to keep water away, or

use organically plated stainless steel bolts. See Figure 2-3 and Figure 2-7.

2.3.2 Front door

If the front door is opened during installation, perform the following procedure to properly close and secure the door.

Procedure

1. Close the door.

2. Hand tighten each screw, ensuring the screw and washer beneath it are centered in the mounting hole.

3. Torqued each screw in the following order (Figure 2-1) to 29 Kgf cm (2.9 Nm) (25 in-lbs).

Figure 2-1: Torque Sequence

2

4

1

23

4

2.3.3 Pole installation procedure

NOTE!

1. Unpack the rectifier and mounting accessories.

2. Install the mounting bracket (big) in the appropriate top position on the pole with the supplied pole mount band. Tighten the

Torque all hardware to the values shown in the illustrations.

pole mount band to the pole (torque to 45 in-lbs). The pole mount band accommodates poles from 6” to 12” in diameter.

Refer to Figure 2-2.

3. Install mounting brackets to the rear panel of the rectifier with the supplied hardware. Refer to Figure 2-3.

4. Secure the top of the rectifier to the pole by securing the mounting bracket (small) to the mounting bracket (big) with the

supplied M8 bolts. Refer to Figure 2-4.

Page 24

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

16

Pole

Mounting Bracket (Big)

P/N: 632404V1

Pole Mount Band

P/N: 63126330

Torque to 5.08 Nm (45 in-lbs).

M5 Flat Head Screws (2)

P/N: 26011356

Torque to

2.02 to 2.69 Nm

(18 to 24 in-lbs).

M5 Bolts (2)

P/N: 26011018

Torque to

2.02 to 2.69 Nm

(18 to 24 in-lbs).

For mounting; use a corrosion inhibiting

compound (CIC) that is conductive inside

the tapped mounting holes to keep water

away, or use organically plated stainless

steel bolts.

Mounting Bracket (Small)

P/N: 632404V2

Mounting Bracket (Big)

P/N: 632404V1

5. Secure the bottom of the rectifier to the pole by securing the mounting bracket (big) to the pole with the supplied pole

mount band. Torque to 45 in-lbs . Refer to Figure 2-5.

Figure 2-2: Installing the Mounting Bracket to the Pole with the Pole Mount Band

Figure 2-3: Installing the Mounting Brackets to the Rectifier

Page 25

17

Figure 2-4: Securing the Rectifier to the Pole at the Top

M8 Bolts

(2 places)

P/N: 26011153

Torque to

13 to 16 Nm

(115 to 141 in-lbs).

Door hardware (4X)

torque is 29 Kgf cm

(2.9 Nm) (25 in-lbs).

Pole Mount Band

P/N: 63126330

Torque to 5.08 Nm (45 in-lbs).

Mounting Bracket (Big)

P/N: 632404V1

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Figure 2-5: Securing the Rectifier to the Pole at the Bottom

Page 26

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

18

5

(0.2)

Mounting Bracket (Big)

P/N: 632404V1

Mounting Bracket (Big)

P/N: 632404V1

M5 Bolts (4)

P/N: 26011018

Torque to

2.02 to 2.69 Nm

(18 to 24 in-lbs).

For mounting; use a corrosion inhibiting

compound (CIC) that is conductive inside

the tapped mounting holes to keep water

away, or use organically plated stainless

steel bolts.

2.3.4 Wall installation procedure

1. Drill appropriately sized holes for the customer provided M5 wall anchors being used into the wall as shown in Figure 2-6.

Note that the rectifier can be mounted horizontal or vertical. Figure 2-6 shows horizontal mounting. Install the M5 wall

anchors into the holes.

2. Install mounting brackets to the rear panel of the rectifier. Refer to Figure 2-7.

3. Secure the rectifier to the wall using the wall anchors previously installed. Refer to Figure 2-8.

Figure 2-6: Wall Mounting Hole Positions

80

Dia.

(3)

mm

(inch)

405

(16)

Figure 2-7: Installing the Mounting Brackets to the Rectifier

Page 27

19

Figure 2-8: Securing the Rectifier to the Wall

Wall

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Page 28

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

20

GMT Fuses

2.4 Installing GMT Fuses (P/N 561666 [R48-1000C-6] Only)

If the rectifier is equipped with an optional internal 6-position GMT fuse block, install appropriately sized GMT fuses into this fuse

block.

Procedure

1. Loosen the screws on the rectifier front door (four) and open the front door, as show in Figure 2-9.

2. Install the GMT fuses. Record fuse information on the label next to the fuse block.

3. Close the rectifier front door by following the procedure in “Front door” on page 15.

Figure 2-9: Installing GMT Fuses (P/N 561666 [R48-1000C-6] Only)

3 Making Electrical Connections

3.1 Important Safety Instructions

DANGER! Adhere to the “Important Safety Instructions” presented at the front of this document.

3.2 Wiring Considerations

All wiring and branch circuit protection should follow the current edition of the American National Standards Institute (ANSI)

approved National Fire Protection Association's (NFPA) National Electrical Code (NEC), and applicable local codes. For operation in

countries where the NEC is not recognized, follow applicable codes.

3.3 Frame Ground Connection

For grounding requirements, refer to the current edition of the American National Standards Institute (ANSI) approved National Fire

Protection Association’s (NFPA) National Electrical Code (NEC), applicable local codes, and your specific site requirements.

Captive fasteners (for M8 bolts) for frame ground lugs are located on each mounting bracket. Holes are spaced on 1-inch centers.

Refer to Figure 3-1 for location.

Page 29

21

Figure 3-1: Frame Grounding Location

Captive Fasteners

for Frame Ground Lugs

(M8 on 1-inch centers)

Rear

Captive Fasteners

for Frame Ground Lugs

(M8 on 1-inch centers)

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

3.4 Customer Wiring to the Mating Connectors

Procedure

NOTE!

NOTE!

inside the connector housing as the sleeve is tightened to the connector housing. Perform these steps in the correct order to

prevent this from happening.

1. Strip 7.5 ± 0.5 mm (0.3 ± 0.02 inch) of insulation off the wires.

2. With the dust cap installed, unscrew the sleeve from the connector housing to expose the wiring terminals.

3. Remove the rear pressing nut.

4. Separate the sleeve from the sealing cable adapter housing.

5. Slide the cable(s) through the rear pressing nut, then through the appropriate opening(s) in the sealing cable adapter

NOTE!

6. Slide the appropriate wires into the appropriate pins of the connector housing. Tighten the screw in the connector housing

Refer to

Figure 3-2

through

Figure 3-6

as this procedure is performed.

If the sleeve and sealing cable adapter housing are not separated before installing the cable, the cable may twist

installed in the sealing cable adapter housing, and finally through the sleeve.

If multiple sealing cable adapters are furnished, select and install the appropriate sealing cable adapter.

to secure the wire. Torque to 0.8 Nm (7 in-lbs).

7. Tighten the sleeve to the connector housing.

8. Slide the sealing cable adapter housing into the sleeve.

9. Tighten the rear pressing nut to the sleeve. Torque to 6.5 Nm (58 in-lbs).

Page 30

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

22

Sealing

Cable

Adapter

P/N 14190611 (Alarm Cable)

Dust

Cap

Connector

Housing

Sleeve

Rear

Pressing

Nut

Sealing

Cable

Adapter

Housing

NOTE! If the sleeve and sealing cable adapter housing

are not separated before installing the cable, the cable

may twist inside the connector housing as the sleeve is

tightened to the connector housing. Perform these steps

in the correct order to prevent this from happening.

1. Strip 7.5 ± 0.5 mm (0.3 ± 0.02 inch)

of insulation off the wires.

2. With the dust cap installed, unscrew the sleeve from

the connector housing to expose the wiring terminals.

3. Remove the rear pressing nut.

4. Separate the sleeve from the sealing cable adapter

housing.

5. Slide the cable(s) through the rear pressing nut,

then through the appropriate opening(s) in the

sealing cable adapter installed in the sealing cable

adapter housing, and finally through the sleeve.

NOTE: If multiple sealing cable adapters are

furnished, select and install the appropriate sealing

cable adapter.

6. Slide the appropriate wires into the appropriate pins

of the connector housing. Tighten the screw in the

connector housing to secure the wire.

Torque to 0.8 N m (7 in-lbs).

7. Tighten the sleeve to the connector housing.

8. Slide the sealing cable adapter housing into the

sleeve.

9. Tighten the rear pressing nut to the sleeve.

Torque to 6.5 N m (58 in-lbs).

Sealing cable adapter provided.

Maximum cable diameter is 6.1 mm to 8.1

mm (0.24” to 0.32”).

Insert provided plug into any empty cable

hole. If this connector is not used, place

dust cap onto connector.

The following are some cable choices that

fit this connector:

Alarm Contact Cabling:

Belden Waterdog 5504G1 (6/C) 22AWG,

300V

CAN Bus Cabling:

Belden Waterdog 5502G1 (4/C) 22AWG,

300V

Note: Cable choices should be based on

the environment that the power system is

located as well as any National Electrical

Code and local regulations. Choices

above are just examples of cables that will

fit.

3

4 5

1 8

2

6

7

Rectifier Fail to terminals 1 and 2.

AC Fail to terminals 3 and 4.

Fuse or Circuir Breaker Alarm to

terminals 7 and 8 (if available).

CAN_H to terminal 5.

CAN_L to terminal 6.

ALARM

Pins for wire connections.

Accepts 22 AWG wires maximum.

Figure 3-2: Customer Wiring to the Mating Connector P/N 14190611 (Alarm Connector)

(Mates to Connector Labeled Y in Figure 3-7 to Figure 3-9)

Page 31

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

23

P/N 14190607 (AC Input)

Dust

Cap

Connector

Housing

Sleeve

Rear

Pressing

Nut

NOTE! If the sleeve and sealing cable adapter housing

are not separated before installing the cable, the cable

may twist inside the connector housing as the sleeve is

tightened to the connector housing. Perform these steps

in the correct order to prevent this from happening.

1. Strip 7.5 ± 0.5 mm (0.3 ± 0.02 inch)

of insulation off the wires.

2. With the dust cap installed, unscrew the sleeve from

the connector housing to expose the wiring terminals.

3. Remove the rear pressing nut.

4. Separate the sleeve from the sealing cable adapter

housing.

5. Slide the cable(s) through the rear pressing nut,

then through the appropriate opening(s) in the

sealing cable adapter installed in the sealing cable

adapter housing, and finally through the sleeve.

NOTE: If multiple sealing cable adapters are

furnished, select and install the appropriate sealing

cable adapter.

6. Slide the appropriate wires into the appropriate pins

of the connector housing. Tighten the screw in the

connector housing to secure the wire.

Torque to 0.8 N m (7 in-lbs).

7. Tighten the sleeve to the connector housing.

8. Slide the sealing cable adapter housing into the

sleeve.

9. Tighten the rear pressing nut to the sleeve.

Torque to 6.5 N m (58 in-lbs).

Sealing

Cable

Adapter

Housing

Two sealing cable adapters provided.

Maximum cable diameter is 8.92 mm to 9.45 mm

(0.35” to 0.37”) for small cable adapter.

Maximum cable diameter is 12.5 mm to 16 mm

(0.49” to 0.63”) large cable adapter.

The following are some cable choices that fit this

connector:

Southwire Royal SJ00W, 14/3, 300V

General Cable HF360 Carolprene SJ00W, 14/3,

300V

Note: Cable choices should be based on the

environment that the power system is located as

well as any National Electrical Code and local

regulations. Choices above are just examples of

cables that will fit.

Sealing

Cable

Adapter

GND

GND

L2/N

L2/N

L1

L1

AC INPUT

Line to terminal L1.

Line/Neutral to terminal L2/N.

Ground to terminal GND.

Pins for wire connections.

Accepts wires in the range

of 22 AWG to 11 AWG.

Figure 3-3: Customer Wiring to the Mating Connector P/N 14190607 (AC Input Connector)

(Mates to Connector Labeled X in Figure 3-7 to Figure 3-9)

Page 32

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

24

P/N 14190623 (-48 VDC Output)

Dust

Cap

Connector

Housing

Sleeve

Sealing

Cable

Adapter

Sealing

Cable

Adapter

Housing

Rear

Pressing

Nut

NOTE! If the sleeve and sealing cable adapter housing

are not separated before installing the cable, the cable

may twist inside the connector housing as the sleeve is

tightened to the connector housing. Perform these steps

in the correct order to prevent this from happening.

1. Strip 7.5 ± 0.5 mm (0.3 ± 0.02 inch)

of insulation off the wires.

2. With the dust cap installed, unscrew the sleeve from

the connector housing to expose the wiring terminals.

3. Remove the rear pressing nut.

4. Separate the sleeve from the sealing cable adapter

housing.

5. Slide the cable(s) through the rear pressing nut,

then through the appropriate opening(s) in the

sealing cable adapter installed in the sealing cable

adapter housing, and finally through the sleeve.

NOTE: If multiple sealing cable adapters are

furnished, select and install the appropriate sealing

cable adapter.

6. Slide the appropriate wires into the appropriate pins

of the connector housing. Tighten the screw in the

connector housing to secure the wire.

Torque to 0.8 N m (7 in-lbs).

7. Tighten the sleeve to the connector housing.

8. Slide the sealing cable adapter housing into the

sleeve.

9. Tighten the rear pressing nut to the sleeve.

Torque to 6.5 N m (58 in-lbs).

Sealing cable adapter provided.

Maximum cable diameter is 12.5 mm to

16 mm (0.49” to 0.63”).

The following are some cable choices

that fit this connector:

WR-VG102ST-BRDA, 10/2, 600V from

Rosenberger

HF382 Carolprene SJ00W, 10/2, 300V

from General Cable

Note: Cable choices should be based on

the environment that the power system is

located as well as any National Electrical

Code and local regulations. Choices

above are just examples of cables that

will fit.

Pins for wire connections.

Accepts wires in the range

of 22 AWG to 10 AWG.

3+

4+ 4-

1+ 1-

2+

3-

2-

-48 VDC OUTPUT

Return to terminal 3+

-48 VDC to terminal 3-.

Figure 3-4: Customer Wiring to the Mating Connector P/N 14190623 (-48 VDC Output Connector)

(Mates to Connector Labeled Z in Figure 3-7 and Figure 3-8) (this connector is not used with Spec. No. 561666)

Page 33

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

25

Sealing cable adapter provided.

Maximum cable diameter is 6.1 mm to 8.1 mm

(0.24” to 0.32”)”.

Insert provided plug into any empty cable hole.

The following are some cable choices that fit this

connector:

General Cable HF312 Carolprene SJ00W, 16/2,

300V

Belden Waterdog 5240U1 (2/C) 16AWG, 300V

Note: Cable choices should be based on the environment that the power system is located as well as

any National Electrical Code and local regulations.

Choices above are just examples of cables that will

fit.

Dust

Cap

Connector

Housing

Sleeve

Sealing

Cable

Adapter

Rear

Pressing

Nut

P/N 14190609

(-48 VDC GMT Fuse Output)

3+

4+ 4-

1+ 1-

2+

3-

2-

3+

4+ 4-

1+ 1-

2+

3-

2-

-48 VDC OUTPUT 1

Load 1: Return to terminal 1+, -48 VDC to terminal 1-.

Load 2: Return to terminal 3+, -48 VDC to terminal 3-.

Load 3: Return to terminal 4+, -48 VDC to terminal 4-.

-48 VDC OUTPUT 2

Load 4: Return to terminal 1+, -48 VDC to terminal 1-.

Load 5: Return to terminal 3+, -48 VDC to terminal 3-.

Load 6: Return to terminal 4+, -48 VDC to terminal 4-.

Pins for wire connections.

Accepts wires in the range

of 22 AWG to 16 AWG.

NOTE! If the sleeve and sealing cable adapter housing

are not separated before installing the cable, the cable

may twist inside the connector housing as the sleeve is

tightened to the connector housing. Perform these steps

in the correct order to prevent this from happening.

1. Strip 7.5 ± 0.5 mm (0.3 ± 0.02 inch)

of insulation off the wires.

2. With the dust cap installed, unscrew the sleeve from

the connector housing to expose the wiring terminals.

3. Remove the rear pressing nut.

4. Separate the sleeve from the sealing cable adapter

housing.

5. Slide the cable(s) through the rear pressing nut,

then through the appropriate opening(s) in the

sealing cable adapter installed in the sealing cable

adapter housing, and finally through the sleeve.

NOTE: If multiple sealing cable adapters are

furnished, select and install the appropriate sealing

cable adapter.

6. Slide the appropriate wires into the appropriate pins

of the connector housing. Tighten the screw in the

connector housing to secure the wire.

Torque to 0.8 N m (7 in-lbs).

7. Tighten the sleeve to the connector housing.

8. Slide the sealing cable adapter housing into the

sleeve.

9. Tighten the rear pressing nut to the sleeve.

Torque to 6.5 N m (58 in-lbs).

Sealing

Cable

Adapter

Housing

Figure 3-5: Customer Wiring to the Mating Connector P/N 14190609 (-48 VDC GMT Output Connector)

(Mates to Connector Labeled Z in Figure 3-9) (this connector is not used with Spec. No. 561664 or Spec. No.

561665)

Page 34

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

26

-48 VDC INPUT

Return to terminal 3+.

-48 VDC to terminal 3-.

3+

4+ 4-

1+ 1-

2+

3-

2-

Pins for wire connections.

Accepts wires in the range

of 22 AWG to 10 AWG.

Sealing cable adapter provided.

Maximum cable diameter is 12.5 mm to

16 mm (0.49” to 0.63”).

The following are some cable choices

that fit this connector:

WR-VG102ST-BRDA, 10/2, 600V from

Rosenberger

HF382 Carolprene SJ00W, 10/2, 300V

from General Cable

Note: Cable choices should be based on

the environment that the power system is

located as well as any National Electrical

Code and local regulations. Choices

above are just examples of cables that

will fit.

P/N 14190615 (-48 VDC Input)

Dust

Cap

Connector

Housing

Sleeve

Sealing

Cable

Adapter

Rear

Pressing

Nut

NOTE! If the sleeve and sealing cable adapter housing

are not separated before installing the cable, the cable

may twist inside the connector housing as the sleeve is

tightened to the connector housing. Perform these steps

in the correct order to prevent this from happening.

1. Strip 7.5 ± 0.5 mm (0.3 ± 0.02 inch)

of insulation off the wires.

2. With the dust cap installed, unscrew the sleeve from

the connector housing to expose the wiring terminals.

3. Remove the rear pressing nut.

4. Separate the sleeve from the sealing cable adapter

housing.

5. Slide the cable(s) through the rear pressing nut,

then through the appropriate opening(s) in the

sealing cable adapter installed in the sealing cable

adapter housing, and finally through the sleeve.

NOTE: If multiple sealing cable adapters are

furnished, select and install the appropriate sealing

cable adapter.

6. Slide the appropriate wires into the appropriate pins

of the connector housing. Tighten the screw in the

connector housing to secure the wire.

Torque to 0.8 N m (7 in-lbs).

7. Tighten the sleeve to the connector housing.

8. Slide the sealing cable adapter housing into the

sleeve.

9. Tighten the rear pressing nut to the sleeve.

Torque to 6.5 N m (58 in-lbs).

Sealing

Cable

Adapter

Housing

Figure 3-6: Customer Wiring to the Mating Connector P/N 14190615 (-48 VDC Input Connector)

(Mates to Connector Labeled W in Figure 3-7 to Figure 3-9)

3.5 Electrical Connections Diagrams

Refer to Figure 3-7 through Figure 3-9.

Page 35

27

Figure 3-7: Electrical Connections Diagram - External, P/N 561664 (R48-1000C-4)

Customer Wiring

DC OUTPUT

Return -48 VDC

LOAD 1

3+

3-

3+

4+ 4-

1+ 1-

2+

3-

2-

DC INPUT

+ -

DC Input

DC INPUT

3+ 3-

3+

4+ 4-

1+ 1-

2+

3-

2-

ALARM

Rect Fail AC Fail CAN

1 65432 87

3

4 5

1 8

2

6

7

DC OUTPUT

DC INPUT

NO

CONNECTION

ALARM

AC INPUT

Connectors Inf ormation

Designation

Vertiv P/N

AC Input 14190607

Alarm 14190611

Vertiv P/N

14190611

No Connection No Connection

DC Input 14190615

Vertiv P/N

14190615

DC Output 14190623

Mfgr P/N

CT93-3TK1X

Mfgr P/N

CT93-3TK1X

CT93-8TK1Y

Mfgr P/N

CT93-8TK1Y

No Connection

CT93-8TK1W A001

Mfgr P/N

CT93-8TK1W A001

CT93-8TK1Z A001

Mfgr P/N

CT93-8TK1Z A001

Vertiv P/N

14190623

AC INPUT

AC Input

L1 L2/N GND

GND

GND

L2/N

L2/N

L1

L1

Vertiv P/N

14190607

SINGLE PHASE

120 VAC or 208 VAC to 240 VAC

CAN_H CAN_L

X

(X)

Y

(Y)

W

(W)

Z

(Z)

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Page 36

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

28

Customer Wiring

DC OUTPUT

Return -48 VDC

LOAD 1

3+

3-

3+

4+ 4-

1+ 1-

2+

3-

2-

DC INPUT

+ -

DC INPUT

DC INPUT

3+ 3-

3+

4+ 4-

1+ 1-

2+

3-

2-

ALARM

Rect Fail AC Fail CAN

1 65432 87

CB Alarm

3

4 5

1 8

2

6

7

DC OUTPUT

DC INPUT

NO

CONNECTION

ALARM

AC INPUT

Connectors Inf ormation

Designation Vertiv P/N

AC Input 14190607

Alarm 14190611

No Connection No Con nection

DC Input 14190615

DC Output 14190623

Mfgr P/N

CT93-3TK1X

CT93-8TK1Y

No Connection

CT93-8TK1W A001

CT93-8TK1Z A001

CAN_H CAN_L

Vertiv P/N

14190611

Vertiv P/N

14190615

Vertiv P/N

14190623

AC INPUT

AC Input

L1 L2/N GND

GND

GND

L2/N

L2/N

L1

L1

Vertiv P/N

14190607

SINGLE PHASE

120 VAC or 208 VAC to 240 VAC

X

YW

Z

(X)(Y)(W)(Z)

Mfgr P/N

CT93-3TK1X

Mfgr P/N

CT93-8TK1Y

Mfgr P/N

CT93-8TK1W A001

Mfgr P/N

CT93-8TK1Z A001

Figure 3-8: Electrical Connections Diagram - External, P/N 561665 (R48-1000C-5)

Page 37

29

Figure 3-9: Electrical Connections Diagram - External, P/N 561666 (R48-1000C-6)

DC OUTPUT 2

DC INPUT

ALARM

AC INPUT

DC OUTPUT 1

Connectors I nfor mation

Designat ion Vertiv P/N

AC Input 14190607

Alarm 14190611

DC Output 1 14190609

DC Input 14190615

DC Output 2 14190609

Mfgr P/N

CT93-3TK1X

CT93-8TK1Y

CT93-8TK1Z

CT93-8TK1W A001

CT93-8TK1Z

Customer Wiring

DC INPUT

+ -

DC INPUT

CAN_H CAN_L

DC INPUT

3+ 3-

ALARM

Rect Fail AC Fail CAN Fuse Alarm

1 2 3 4 5 6 7 8

3

4 5

1 8

2

6

7

3+

4+ 4-

1+ 1-

2+

3-

2-

DC OUTPUT 1

Return -48 VDC

LOAD 4

DC OUTPUT 2

Return -48 VDC

OUTPUT2 OUTPUT2OUTPUT2

1+ 1- 3-3+ 4+ 4-

LOAD 5

LOAD 6

OUTPUT1 OUTPUT1OUTPUT1

1+ 1- 3-3+ 4+ 4-

LOAD 1

LOAD 2

LOAD 3

3+

4+ 4-

1+ 1-

2+

3-

2-

3+

4+ 4-

1+ 1-

2+

3-

2-

Vertiv P/N

14190611

Vertiv P/N

14190615

Vertiv P/N

14190609

Vertiv P/N

14190609

AC INPUT

AC Input

L1 L2/N GND

GND

GND

L2/N

L2/N

L1

L1

Vertiv P/N

14190607

SINGLE PHASE

120 VAC or 208 VAC to 240 VAC

X

YW

Z Z

(X)

(Y)(W)

(Z)(Z)

Mfgr P/N

CT93-3TK1X

Mfgr P/N

CT93-8TK1Y

Mfgr P/N

CT93-8TK1Z

Mfgr P/N

CT93-8TK1Z

Mfgr P/N

CT93-8TK1W A001

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

Page 38

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

30

3.6 External Alarm and Control Connections

3.6.1 General

The rectifier is equipped with plug-in alarm connectors located on the bottom of the enclosure. Mating connectors are provided.

Customer must provide wiring to the mating connector. Maximum wire size is 22 AWG. See Figure 3-2. Refer also to Figure 3-7

through Figure 3-9. See also “Customer Wiring to the Mating Connectors” starting on page 21.

Contact Ratings (UL / CSA Rating):

NOTE!

• Maximum Switching Power: 60 W, 125 VA.

• Maximum Switching Voltage: 220 VDC, 250 VAC.

• Maximum Switching Current: 2 A.

• Maximum Carrying Current: 2 A.

To remain NEBS compliant, the alarm contacts must remain below 60 volts and 100 VA.

3.6.2 Alarm and Control Connections

Rectifier Fail Alarm

A rectifier fail alarm activates if any of the conditions listed in Table 5-1 on page 37 under “Red (Alarm)” indicator occur.

Contacts close between terminals 1 and 2 on the alarm connector during a rectifier fail alarm condition (factory default).

There is an option to change the alarm relay contact configuration to indicate an alarm when the contacts open.

Refer to “Changing the Alarm Relay Configuration for the Rectifier Fail Alarm and AC Fail Alarm” on page 31.

AC Fail Alarm

An AC fail alarm activates if AC input voltage is lost.

Contacts close between terminals 3 and 4 on the alarm connector during an AC fail alarm condition (factory default).

There is an option to change the alarm relay contact configuration to indicate an alarm when the contacts open.

Refer to “Changing the Alarm Relay Configuration for the Rectifier Fail Alarm and AC Fail Alarm” on page 31.

CAN

Terminal 5 on the Alarm Connector: CAN_H.

Terminal 6 on the Alarm Connector: CAN_L.

Circuit Breaker Alarm (P/N 561665 [R48-1000C-5] only)

A circuit breaker alarm activates if the internal circuit breaker opens.

Contacts close between terminals 7 and 8 on the alarm connector during a circuit breaker alarm condition.

Fuse Alarm (P/N 561666 [R48-1000C-6] only)

A fuse alarm activates if any of the internal GMT fuses open.

Contacts close between terminals 7 and 8 on the alarm connector during a fuse alarm condition.

Page 39

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

31

J10

1

1

3

3

1

1

3

3

J12

J10

J12

Jumper Positions for

Alarm when Contact

Closes

Jumper Positions for

Alarm when Contact

Opens

J10 Rectifier Fail Alarm

Contact Configuration

1

1

3

3

J12 AC Fail Alarm

Contact Configuration

J10

J12

3.6.3 Changing the Alarm Relay Configuration for the Rectifier Fail Alarm and AC Fail

Alarm

By default, the rectifier fail alarm and AC fail alarm relay contacts close during an alarm condition. A jumper option is available to

change these to indicate an alarm when the relay contact opens. Refer to the following procedure.

Procedure

1. Loosen the screws on the rectifier front door (four) and open the front door.

2. Locate the J10 and J12 jumpers. See Figure 3-10. J10 jumper is associated with the rectifier fail alarm. J12 jumper is

associated with the AC fail alarm.

3. Refer to Figure 3-10 and set the J10 and J12 jumpers per site requirements.

4. Close the rectifier front door by following the procedure in “Front door” on page 15.

Figure 3-10: J10 and J12 Jumpers

Page 40

Vertiv™ NetSure™ IPE Series Rectifier Installation and User Manual

32