Vertiv Liebert STS2 User Manual

Liebert® STS2 /PDU

User Manual—250A-800A, Three-Phase, 60 Hz

™

CONTACTING VERTIV™ FOR SUPPORT

To contact Vertiv Services for information or repair service in the United States, call 800-543-2378. Vertiv

Services offers a complete range of start-up services, repair services, preventive maintenance plans and service

contracts.

For repair or maintenance service outside the 48 contiguous United States, contact Vertiv Services, if available in

your area. For areas not covered by Vertiv Services, the authorized distributor is responsible for providing

qualified, factory-authorized service.

For Vertiv Services to assist you promptly, have the following information available:

Part Numbers:

Serial Numbers:

Rating:

Date Purchased:

Date Installed:

Location:

Input Voltage/Frequency:

Output Voltage/Frequency:

Vertiv™| Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017

TABLE OF CONTENTS

CONTACTING VERTIV™ FOR SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . INSIDE FRONT COVER

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.0 UNPACKING AND INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 External Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Unloading and Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.1 Handling Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 Unit Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Internal Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 LOCATION CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Recommended Minimum Service Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Heat Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 LOCATING THE LIEBERT STS2/PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Anchoring the Unit to the Floor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Positioning the 250A Only Liebert STS2/PDU Without Anchoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.0 POWER AND CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Input and Output Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.2 System Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Control Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Remote Source Selection Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.0 OUTPUT POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.1 Customer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.0 OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Programmable Relay Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.2 Input Contact Isolator Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.3 Comms Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Liebert IntelliSlot™ Web/485 Card With Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.5 Remote Source Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.6 Key Lockout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.7 Static Switch Redundant Output Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.8 Inline Panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.9 I-Line Panelboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.10 Subfeed Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.11 K-Factor Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.12 Surge Suppression System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 i

7.0 INSTALLATION DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.0 INTRODUCTION TO LIEBERT STS2/PDU OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.1 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1.2 Reliability and Agency Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.1.3 Factory Backup and Service Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2.1 Normal (Preferred Source) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2.2 Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2.3 Transfer Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2.4 Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.3 Operator Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.0 THEORY OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

9.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1.1 Liebert Static Transfer Switch 2/Power Distribution Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

9.1.2 Source Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

9.1.3 Automatic Transfer/Retransfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

9.1.4 Emergency Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.5 Load Current Transfer Inhibit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.6 SCR Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.7 On/Off Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.2 Detailed Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.2.1 Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.2.2 Circuit Breakers and Non-Automatic Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2.3 SCRs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2.4 Logic Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2.5 Audible Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.2.6 RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.0 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.1 Normal System Turn-On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.2 Manual Transfer / Preferred Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3 Enabling Remote Source Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.4 Maintenance Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.4.1 Bypass Procedures for Source 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.4.2 Bypass Procedures for Source 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.5 Normal System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

10.5.1 Shutdown in Static Transfer Switch Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

10.5.2 Shutdown in Maintenance Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

11.0 ALARMS AND FAULTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.1 Event Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.2 Event and History Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.2.1 Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.2.2 History Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11.3 Alarm Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

11.4 List of Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 ii

12.0 COMMUNICATION INTERFACES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.1 Using the RS-232 Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.1.1 Connecting and Using a Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.1.2 Configuring the Liebert STS2/PDU via the Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.1.3 Setting Bitpacked Options With the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.1.4 Setting Event Masks with the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

13.0 TOUCHSCREEN DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

13.1 Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

13.2 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13.2.1 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

13.3 Mimic Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.4 Event Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.5 Event Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.6 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.7 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.7.1 Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.7.2 Source Transfers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.7.3 Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.7.4 Bypass Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.7.5 Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

13.7.6 Logo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

13.8 Cleaning the LCD Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

14.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

14.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14.1.1 Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14.1.2 Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

14.1.3 Output Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14.1.4 System Current Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14.1.5 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

14.1.6 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

14.1.7 Surge Suppression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

14.1.8 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

14.1.9 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 iii

14.2 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.2.1 Frame and Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.2.2 Casters - 250A only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.2.3 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.2.4 Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

14.2.5 Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

14.2.6 Cable Entrance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

14.2.7 Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

14.2.8 Color Graphical Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

14.2.9 RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

14.2.10 Terminal Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

14.2.11 RS-232 Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

14.2.12 Maintenance Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

14.2.13 Fuseless Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

14.2.14 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

15.0 EVENT MESSAGE HELP TEXT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

16.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

16.1 Proper Tightening of Nuts and Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

16.2 Testing the Liebert STS2/PDU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

16.3 Changing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

17.0 CUSTOMER SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

17.1 Programmable Relay Board Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

17.2 Input Contact Isolator Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

FIGURES

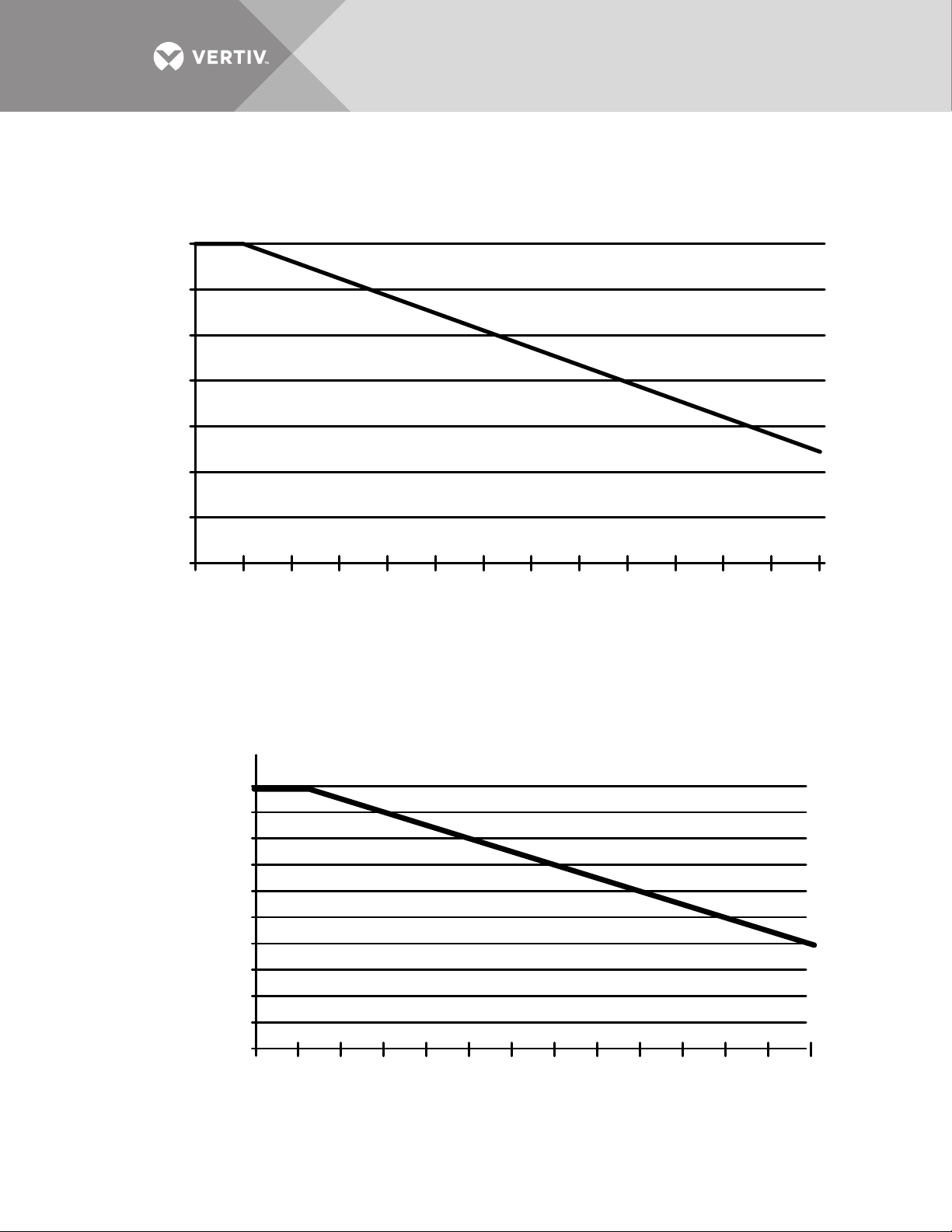

Figure 1 Recommended derating for high altitude operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

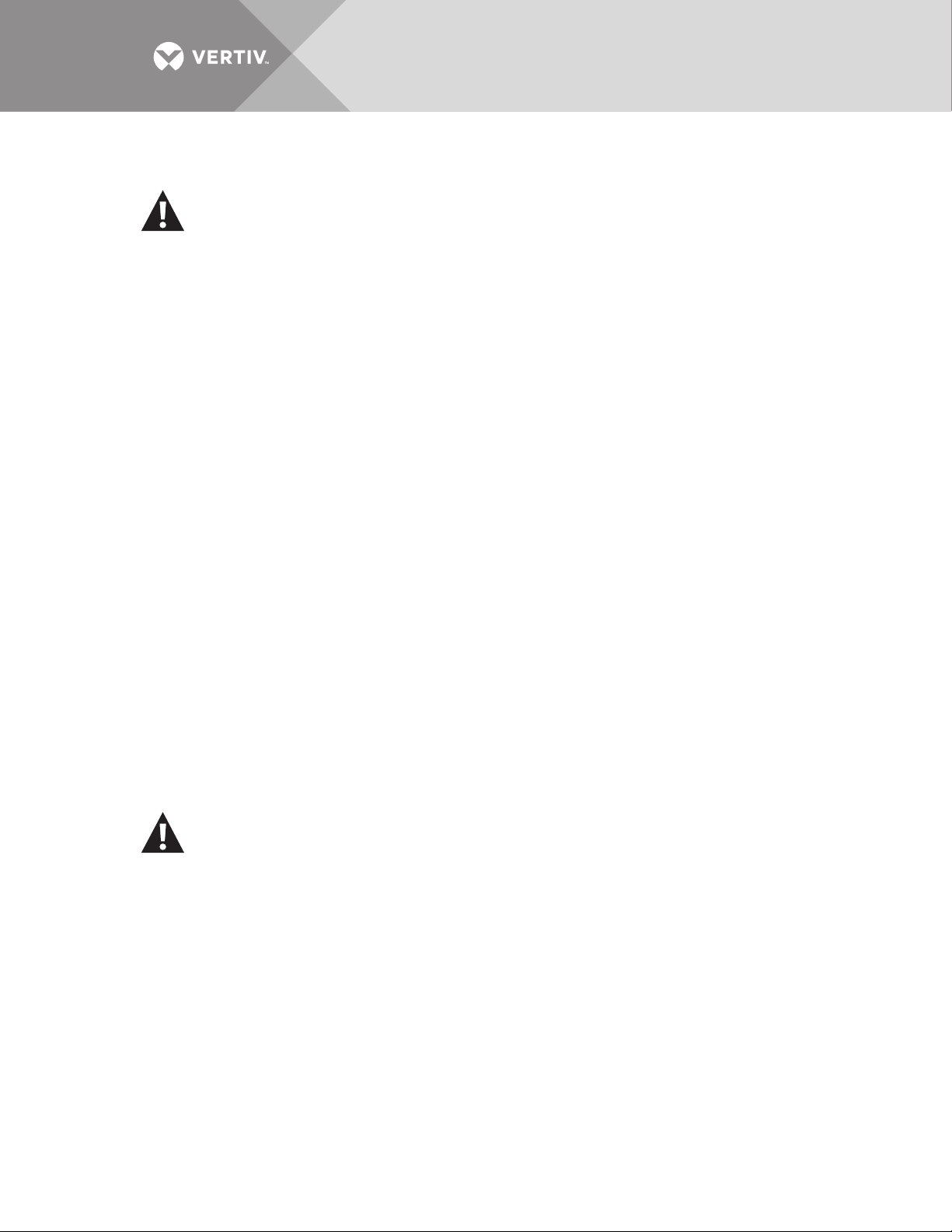

Figure 2 Maximum ambient temperature for full load operation at higher altitudes . . . . . . . . . . . . . . . . . . . . . . 6

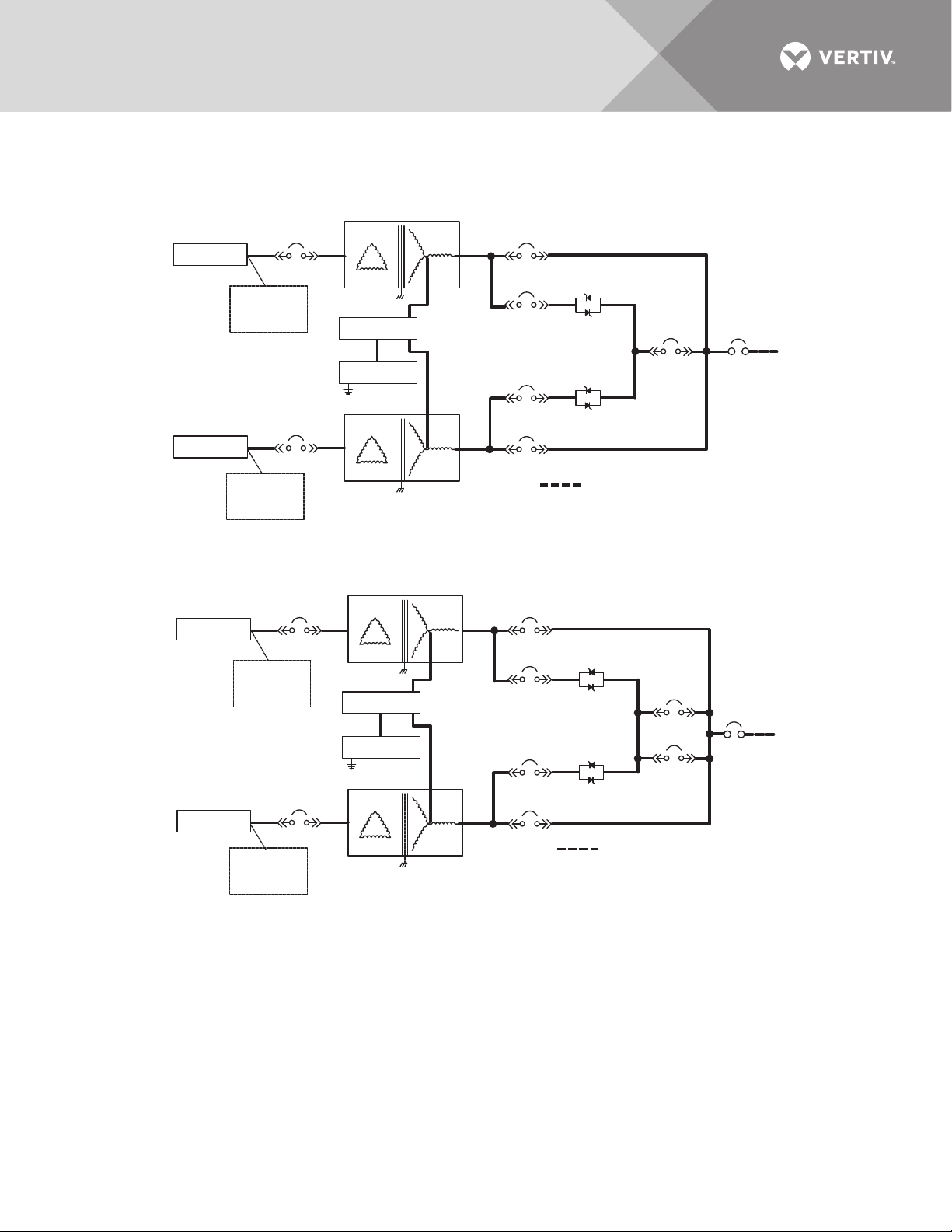

Figure 3 Typical Liebert STS2/PDU, one-line diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4 Typical Liebert STS2/PDU, one-line diagram, with dual static switch output circuit breakers

(not available on 250A units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

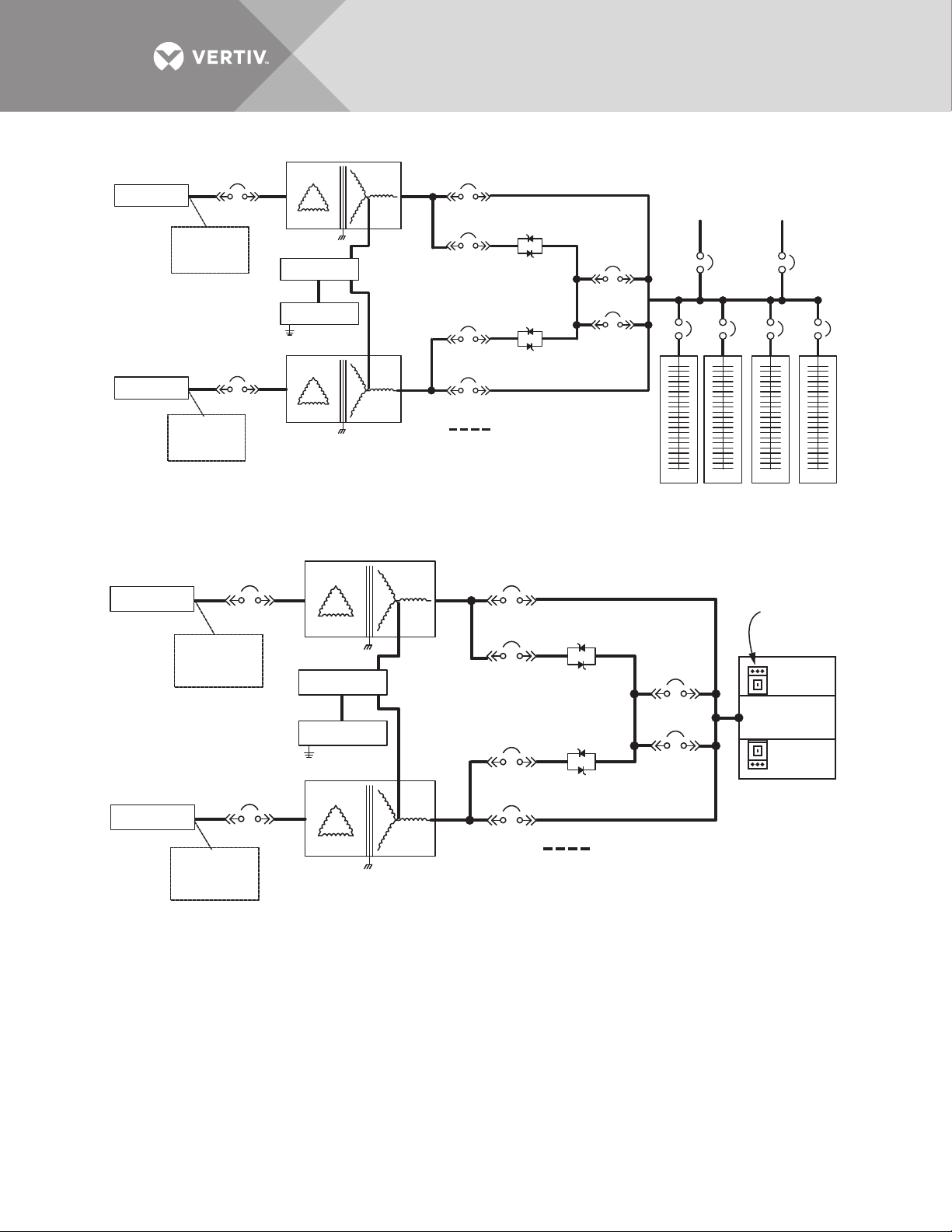

Figure 5 Typical Liebert STS2/PDU, one-line diagram, with inline distribution, dual static switch output

circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 6 Typical Liebert STS2/PDU, one-line diagram, with I-Line distribution, dual static switch output

circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

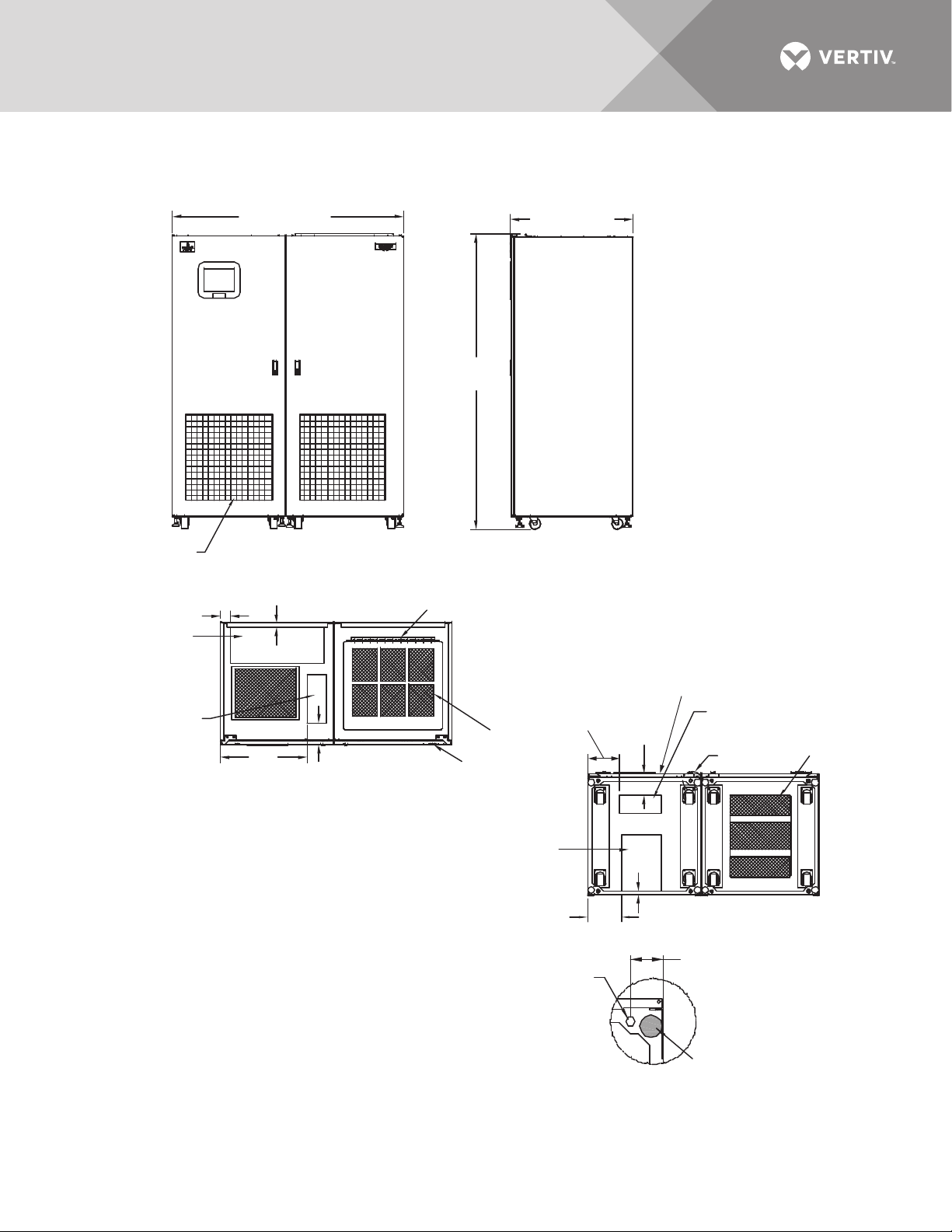

Figure 7 Outline drawing, 250A Liebert STS2/PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 8 Outline drawing, 250A Liebert STS2/PDU with right side I-Line distribution . . . . . . . . . . . . . . . . . . . .18

Figure 9 Outline drawing, 250A Liebert STS2/PDU with right side inline distribution. . . . . . . . . . . . . . . . . . . . .19

Figure 10 Outline drawing, 250A Liebert STS2/PDU with left side I-Line distribution. . . . . . . . . . . . . . . . . . . . . 20

Figure 11 Outline drawing, 250A Liebert STS2/PDU with left side Inline distribution . . . . . . . . . . . . . . . . . . . . . .21

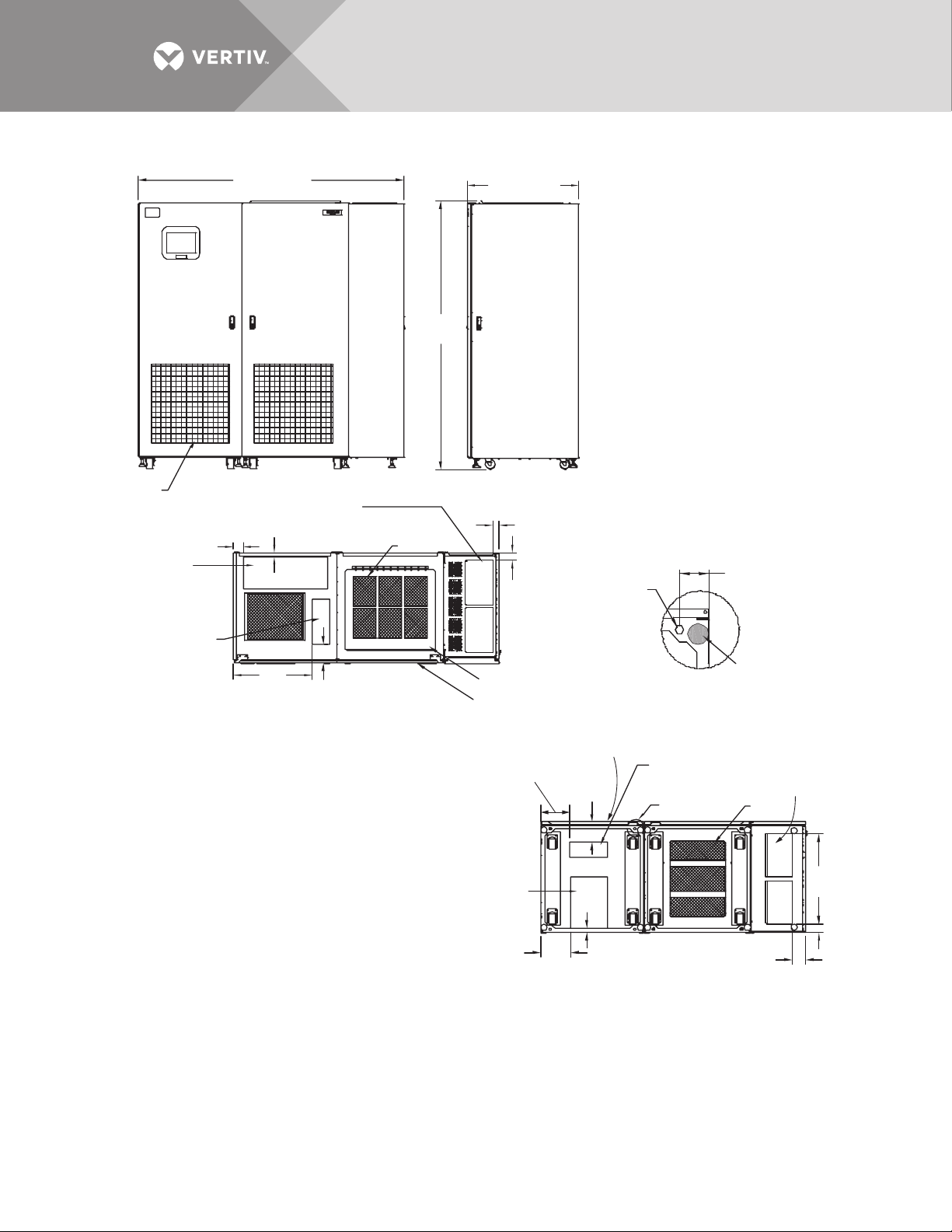

Figure 12 Outline drawing,400-600A Liebert STS2/PDU with right side inline distribution . . . . . . . . . . . . . . . 22

Figure 13 Outline drawing, 400-600A Liebert STS2/PDU with right side output breaker or I-Line

distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 14 Outline drawing, 400-600A Liebert STS2/PDU with left side inline distribution . . . . . . . . . . . . . . . . 24

Figure 15 Outline drawing, 400-600A Liebert STS2/PDU with left side output breaker or I-Line

distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 iv

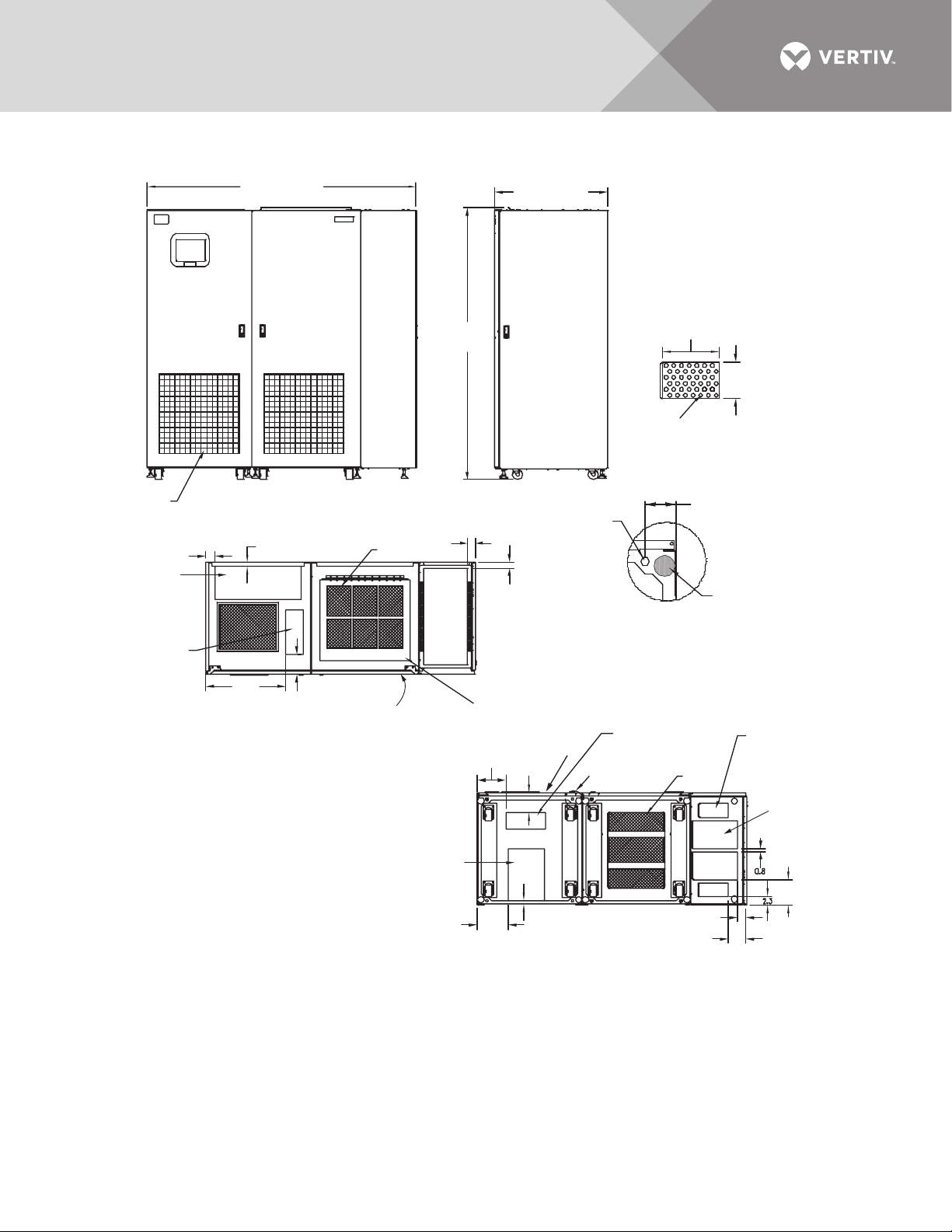

Figure 16 Outline drawing, 800A Liebert STS2/PDU with right side output breaker or I-Line

distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 17 Outline drawing, 800A Liebert STS2/PDU with right side inline distribution . . . . . . . . . . . . . . . . . . . 27

Figure 18 Outline drawing, 800A Liebert STS2/PDU with left side output breaker or I-Line

distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 19 Outline drawing, 800A Liebert STS2/PDU with left side inline distribution. . . . . . . . . . . . . . . . . . . . . 29

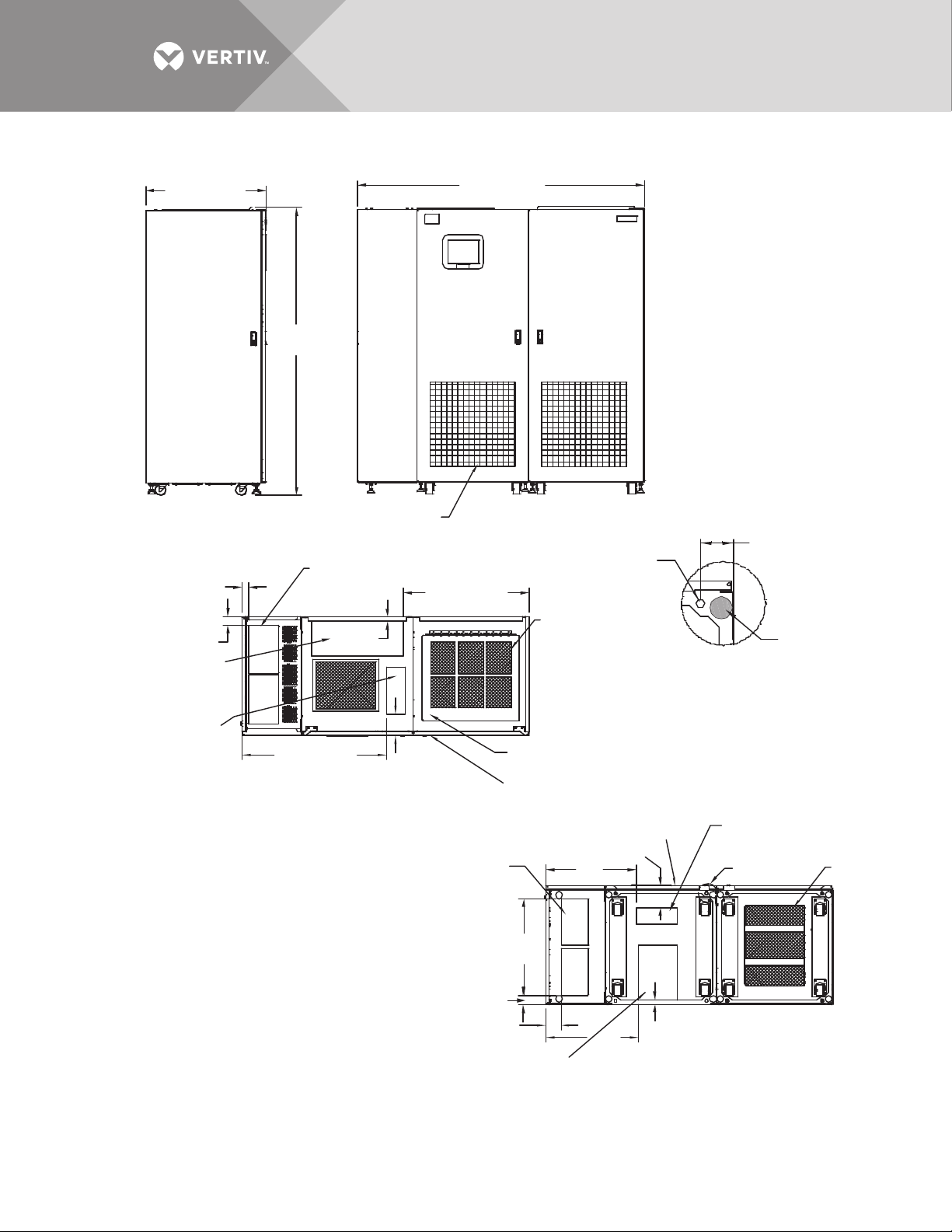

Figure 20 Outline drawing, 250A Liebert STS2/PDU with key lockout switch option. . . . . . . . . . . . . . . . . . . . . . 30

Figure 21 Outline drawing, 400-600A Liebert STS2/PDU, inline distribution, right side with key

lockout switch option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 22 Outline drawing, 800A Liebert STS2/PDU, inline distribution, right side with key lockout

switch option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 23 Electrical field connections, 250A Liebert STS2/PDU input/output with CB8. . . . . . . . . . . . . . . . . . . 33

Figure 24 Electrical field connections, 250A Liebert STS2/PDU input with CB3 . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 25 Electrical field connections, 250A Liebert STS2/PDU input with CB3 & CB3A . . . . . . . . . . . . . . . . . 35

Figure 26 Electrical field connections, 400-600A Liebert STS2/PDU input with CB3. . . . . . . . . . . . . . . . . . . . . 36

Figure 27 Electrical field connections, 400-600A Liebert STS2/PDU input with CB3 and CB3A . . . . . . . . . . 37

Figure 28 Electrical field connections, 800A Liebert STS2/PDU input with CB3. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 29 Electrical field connections, 800A Liebert STS2/PDU input with CB3 and CB3A . . . . . . . . . . . . . . . 39

Figure 30 Electrical field connections, 250A Liebert STS2/PDU output with inline panelboards. . . . . . . . . . . 40

Figure 31 Electrical field connections, 400-800A Liebert STS2/PDU output with inline panelboards . . . . . .41

Figure 32 Electrical field connections, Liebert STS2/PDU output with I-Line panelboard . . . . . . . . . . . . . . . . . 42

Figure 33 Electrical field connections, 400-600A Liebert STS2/PDU with right side output breaker . . . . . . 43

Figure 34 Electrical field connections, 400-600A Liebert STS2/PDU with left side output breaker . . . . . . . 44

Figure 35 Electrical field connections, 800A Liebert STS2/PDU with right side output breaker . . . . . . . . . . . 45

Figure 36 Electrical field connections, 8600A Liebert STS2/PDU with left side output breaker . . . . . . . . . . . 46

Figure 37 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring . . . . . . . . . . . . . . . . . . . . . 47

Figure 38 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, breaker section . . . . . 48

Figure 39 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, STS section . . . . . . . . 49

Figure 40 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, left side

distribution cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 41 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, left side one-line . . . . . 51

Figure 42 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, left side one-line

with CB3A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 43 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, right side

one-line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 44 Electrical field connections, 800A Liebert STS2/PDU interconnect wiring, right side

one-line with CB3A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 45 Control wiring, 800A Liebert STS2/PDU, left side distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 46 Control wiring, 800A Liebert STS2/PDU, right side distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 47 Control connection location, 250A Liebert STS2/PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 48 Control connection location, 400-800A Liebert STS2/PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 49 Control location drawing conduit box, top entry, 400-600A Liebert STS2/PDU . . . . . . . . . . . . . . . . 59

Figure 50 Control wiring for the programmable relay board option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 51 Control wiring for the input contact isolator board option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Figure 52 Control wiring for Comms board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 53 Control wiring for the Liebert IntelliSlot™ Web/485 Card With Adapter option. . . . . . . . . . . . . . . . . . 63

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 v

Figure 54 Control wiring for the RS-232 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 55 Control wiring for remote source selection option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 56 Color LCD touchscreen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 57 Liebert STS2/PDU touchscreen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 58 Liebert STS2/PDU touchscreen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 59 Source Transfer screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 60 Gate board viewing slot locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 61 Liebert STS2/PDU touchscreen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 62 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 63 Keyboard and keypad displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 64 Key lockout switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 65 Event Mask dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 66 User settings dialog box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Figure 67 Source setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 68 PDU setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 69 Comm options dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 70 Modem dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 71 Input Contact Isolator dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 72 Programmable relay board dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 73 System options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 74 PDU options button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 75 Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 76 History log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 vi

TABLES

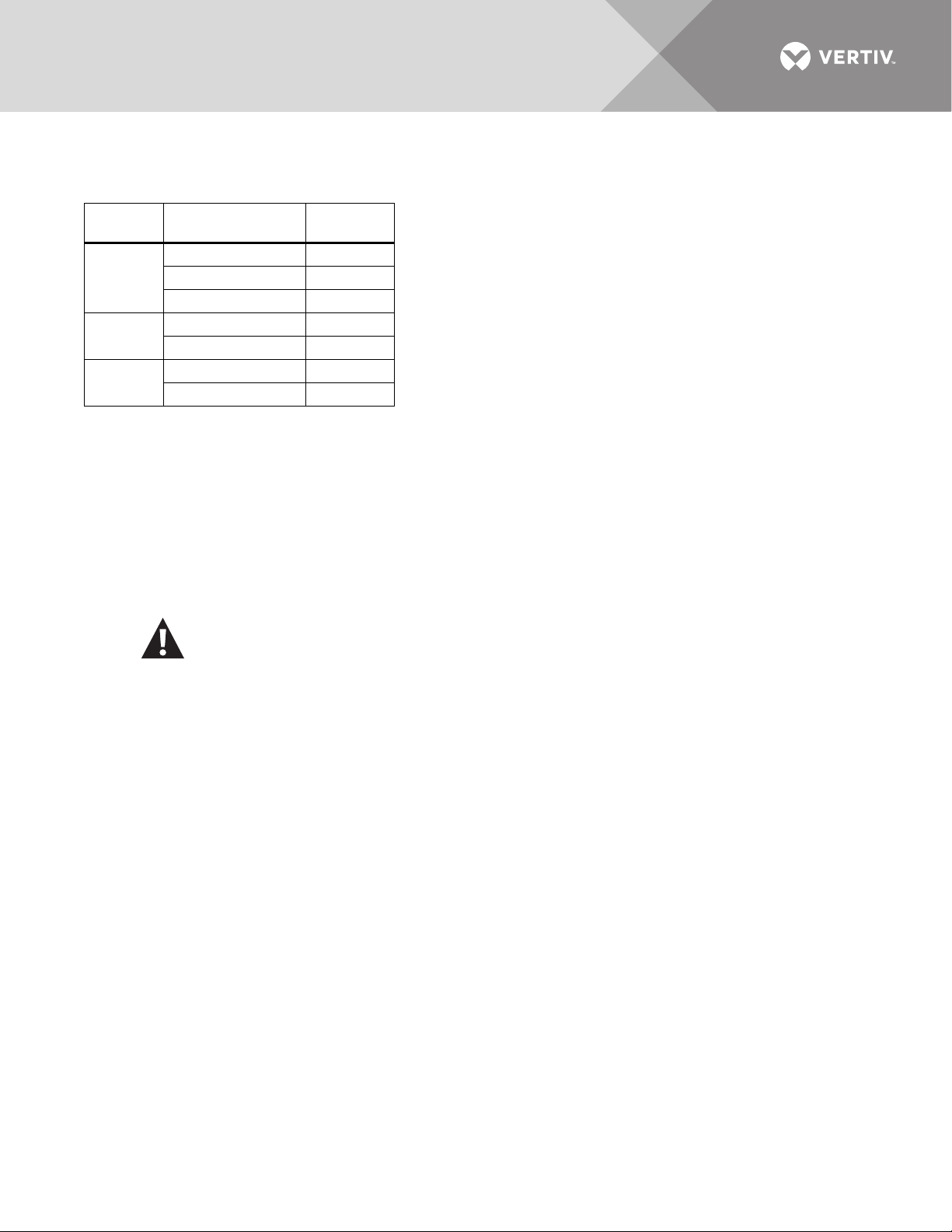

Table 1 Shipping weights (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

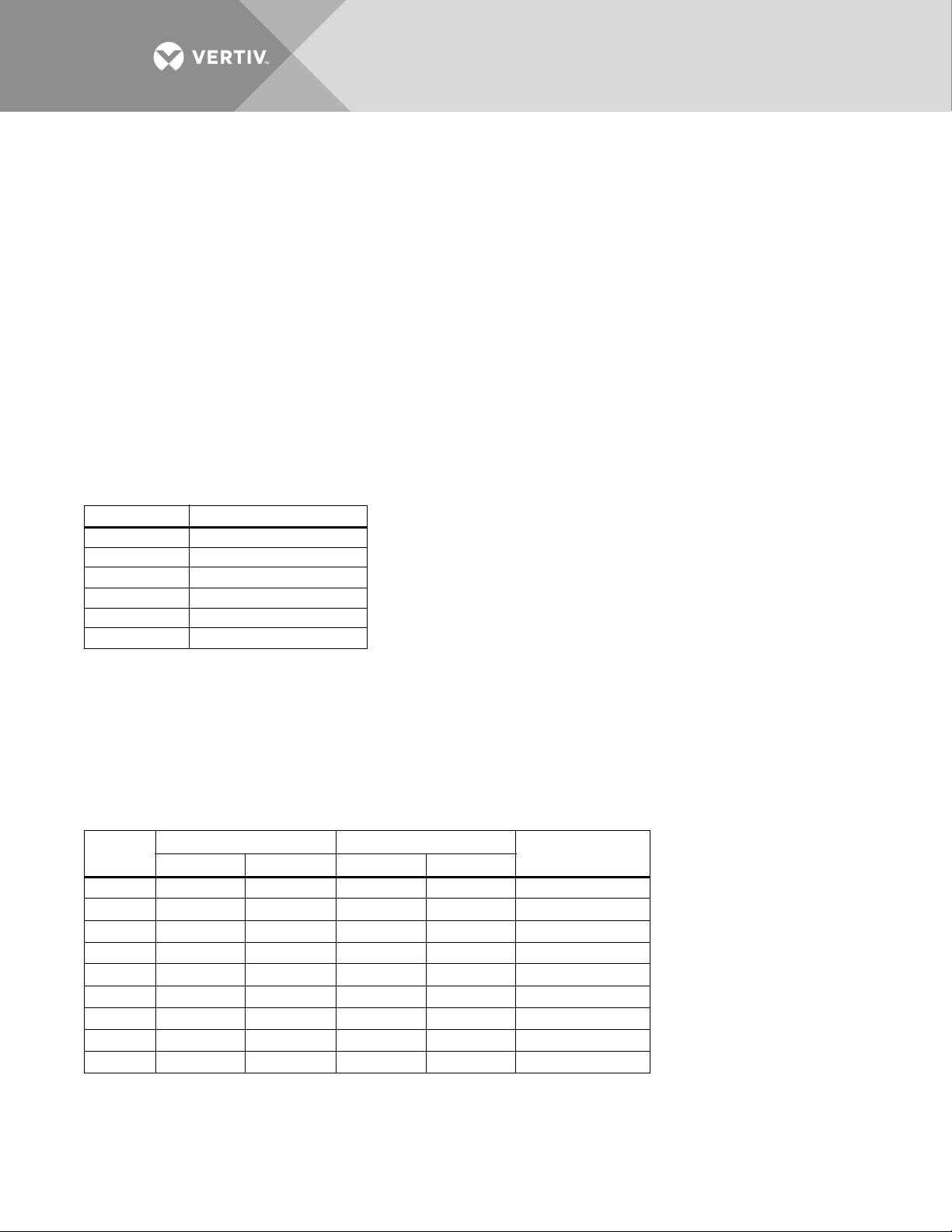

Table 2 Heat output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table 3 Input/output conduit plate specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4 Remote source selection terminal block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Table 5 Terminal block 1 and terminal block 2 wire connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6 Distribution configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

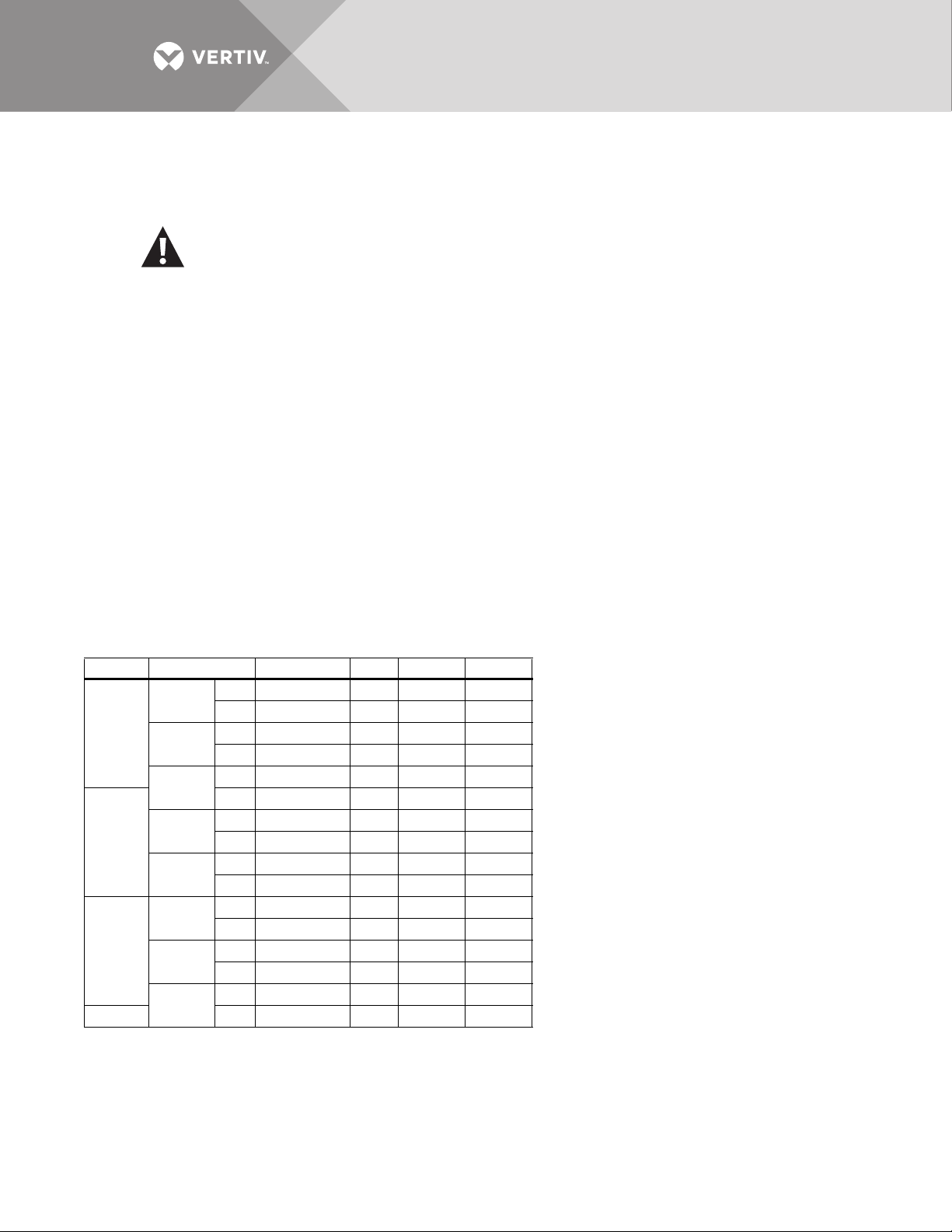

Table 7 Programmable relay board pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 8 Interconnection wiring, from STS section to breaker section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 9 Interconnection wiring from Breaker Section to Distribution Section . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 10 Input circuit breaker schedule, 250-800A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 11 Output circuit breaker schedule, 250-800A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 12 Non-automatic breaker schedule, 250-800A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 13 Event messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 14 Terminal commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 15 Value types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 16 Group settings and values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 17 Binary-hexadecimal conversions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 18 Setpoint parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 19 PDU setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Table 20 Standard settings for programmable relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 21 Input voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 22 Output voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 23 System current ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 24 Electrical requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 25 Unit short circuit withstand capability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Table 26 Frame sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 27 MTA plug pin-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 28 DB9 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 29 RS-232 settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Table 30 Torque tightening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Table 31 Branch circuit breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Table 32 Programmable relay board settings record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Table 33 Input contact isolator settings record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 vii

Vertiv | Liebert STS2/PDU User Manual | Rev. 6 | 10/17 viii

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during the installation and maintenance of

the Liebert Static Transfer Switch 2/Power Distribution Unit (Liebert STS2/PDU).

Read this manual thoroughly, paying special attention to the sections that apply to your installation, before

working with the Liebert STS2/PDU. Retain this manual for use by installing personnel.

Refer to 1.2.1 - Handling Considerations before attempting to move the unit.

WARNING

Risk of electric shock. Can cause injury or death.

Before proceeding with installation, read all instructions, verify that all the parts are included and check

the nameplate to be sure the voltage matches available utility power.

This unit is supplied by more than one power source. The unit contains hazardous voltages if any of the

input sources are on, even when the unit is in bypass. To isolate the unit, turn off and lock out all input

power sources.

Verify that all input power sources are de-energized and locked out before making connections inside

unit.

Lethal voltages exist inside the unit during normal operation. Only qualified service personnel should

perform maintenance on the Liebert STS2/PDU.

Installation and operation must comply with all national and local laws and regulations.

WARNING

Risk of electric shock. Can cause injury or death.

Under typical operation and with all Liebert STS2/PDU doors closed, only normal safety precautions are

necessary. The area around the Liebert STS2/PDU should be kept free of puddles of water, excessive

moisture, flammable liquids, gases, corrosive substances and debris.

Only properly trained personnel wearing appropriate safety headgear, gloves, shoes and glasses should

perform maintenance on the Liebert STS2/PDU. When performing maintenance on any part of the

equipment under power, service personnel and test equipment should be located on rubber mats. Service

personnel should wear insulating shoes for isolation from direct contact with the floor.

One person should never work alone, even if all power is disconnected from the equipment. A second

person should be standing by to assist and summon help in case of an accident.

NOTICE

Risk of damage from improper installation.

The input sources to the Liebert STS2/PDU must be grounded-wye sources. Input sources other than solidly grounded-

wye sources may cause damage to the switch.

Liebert neither recommends nor knowingly sells this product for use with life support or other FDA-designated

“critical” devices.

The Liebert STS2/PDU is suitable for indoor use only.

The unit is designed to operate from solidly grounded AC power sources only. Provide input over-current

protection in accordance with the unit ratings. Wire and ground the unit according to national and local electrical

safety codes. All wiring should be installed by a properly trained and qualified electrician.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 1

A thorough equipment inspection and supervised startup by qualified service personnel are strongly

recommended at these times:

1. Before unit is placed into service for the first time

2. After equipment relocation, and

3. After the unit has been de-energized for an extended period.

WARNING

Risk of heavy unit falling over. Can cause equipment damage, injury or death.

Locate the center of gravity symbols and determine the unit’s weight

before handling the cabinet.

Read all instructions before attempting to move the unit, lift it, remove packaging or prepare

the unit for installation.

NOTICE

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J of the FCC rules and

EN550022. These limits provide reasonable protection against harmful interference in a commercial environment. This

unit generates, uses and radiates radio frequency energy and, if not installed and used in accordance with this instruction

manual, may cause harmful interference to radio communications. Operating this unit in a residential area may cause

harmful interference that the user must correct at his own expense.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 2

1.0 UNPACKING AND INSPECTIONS

NOTE

Read the entire manual before beginning to install the Liebert STS2/PDU. Upon delivery of the Liebert

STS2/PDU, the installer should perform the following steps to ensure a high-quality installation.

A high-quality installation begins on the receiving dock. The Liebert STS2/PDU and its packaging should be

inspected when the unit is delivered. If the packaging is not damaged, unpack the unit and conduct an internal

inspection before beginning installation. This section discusses inspecting and unpacking the Liebert

STS2/PDU.

1.1 External Inspections

1. While the Liebert STS2/PDU is still on the truck, inspect the equipment and shipping container(s) for any signs of damage

or mishandling. Do not attempt to install the system if damage is apparent.

2. Upon receipt and before unpacking, inspect the shipping crate for damage or mishandling.

Check the Shock-Watch

• If the indicator is red, note the condition on shipper’s receipt and check for concealed damage.

• If any shipping damage is observed, file a damage claim with the shipper within 24 hours and contact your local Liebert

representative or Vertiv Services at 1-800-543-2378 to inform them of the damage claim and the condition of the

equipment.

3. Locate the bag containing the keys for the front access door. The bag is attached to the cabinet.

4. Compare the contents of the shipment with the bill of lading. Report any missing items to the carrier and to Vertiv Services

immediately.

5. Check the nameplate on the cabinets to verify that the model numbers correspond with the one specified. Record the

model numbers and serial numbers in the front of this installation manual. A record of this information is necessary should

servicing be required.

6. If unit is to be stored before installation, it is recommended to store the unit in a dry environment with temperatures in the

range of -40 to 176°F (-40 to 80°C). Use original packing materials or other suitable means to keep the unit clean. When

opening the shipping crate, use care not to puncture the container with sharp objects.

™

indicator.

1.2 Unloading and Handling

WARNING

Risk of heavy unit falling over. Can cause equipment damage, injury or death.

Locate the center of gravity symbols and determine the unit’s weight

before handling the cabinet.

Do not exceed a 15-degree tilt with the forklift. Read all instructions before attempting to

move the unit, lift it, remove packaging or prepare the unit for installation.

NOTICE

When moving the unit by forklift, lift the unit from the rear so as to protect the front panel.

Also, if moving the unit by forklift or pallet jack after it has been removed from the pallet, be aware of the location of the

casters and stabilizing feet (if the unit is so equipped) so as not to damage them.

Most Liebert STS2/PDU models are contained in one cabinet. The 800 amp units are contained in two cabinets,

shipped on two pallets and connected together in the field.

The unit can be moved by forklift or pallet jack. However, because the weight distribution in the cabinet is

uneven, use extreme care during handling and transporting.

See 1.2.2 - Unit Preparation for instructions on removing the Liebert STS2/PDU from the pallet.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 3

1.2.1 Handling Considerations

The Liebert STS2/PDU is bolted to a wood shipping pallet to allow handling by forklift or a pallet jack.

WARNING

Risk of heavy unit falling over. Can cause equipment damage, injury or death.

Exercise extreme care when handling Liebert STS2/PDU cabinets to avoid equipment damage or injury to

personnel.

The cabinet can be safely tilted 15 degrees in any direction by forklift. If moving the unit up a ramp on its

casters (if the unit is so equipped) or a pallet jack, ensure that the incline does not exceed 15 degrees.

Locate the center of gravity symbols and determine the unit’s weight before handling the cabinet.

Check the unit size and weight. Refer to the cabinet drawings furnished with the unit for size and weight. Typical

cabinet dimensions are shown in Figures 7 through 22. Typical unit crated weights are:

Table 1 Shipping weights (typical)

Model Weight, lb. (kg)

250A 3813 (1733)

400A 4808 (2185)

600A 5892 (2678)

800A Module A* 4180 (1900)

800A Module B* 4723 (2147)

*800A ships on two separate pallets

Plan the route. Review the route over which the unit will be transported to its installation location to ensure that

all passages are large enough to accommodate the unit and support the weight.

Check for any non-negotiable corners or offsets in hallways. Before moving the unit to the intended location,

review 2.0 - Location Considerations.

1.2.2 Unit Preparation

The unit can be removed from the pallet before it is moved to its location.

Complete the following steps to properly remove the Liebert STS2/PDU from the shipping pallet:

1. Set the pallet in a level area with enough room to maneuver and remove the unit.

2. Remove the bolts holding the unit to the shipping pallet (located in the base of the unit).

3. Remove the shipping blocks from under the frame of the unit.

4. Use a forklift to raise the unit off the pallet and onto the floor. On the 250A unit ensure that the forklift is clear of the unit's

casters and stabilizing feet. Lift the unit from the rear.

5. Conduct an internal inspection of the unit. See the list in 1.3 - Internal Inspection.

1.3 Internal Inspection

After the Liebert STS2/PDU has been unpacked, conduct an internal inspection:

1. Verify that all items have been received.

2. If spare parts were ordered, verify their arrival.

3. After the Liebert STS2/PDU has been removed from the pallet, open the door and remove cabinet panels to check for

shipping damage to internal components.

4. Check for loose connections or unsecured components in the cabinet(s).

5. Check for any unsafe condition that may be a potential safety hazard.

After the Liebert STS2/PDU has been inspected and no problems are found, the unit can be moved to its

installation location. If using a forklift, remember to lift the unit from the rear.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 4

2.0 LOCATION CONSIDERATIONS

The Liebert STS2/PDU should be placed in a clean, cool and dry location. The 250A unit without an output

cabinet requires only front access for installation and maintenance. Both front and side access are required for

installation and maintenance of 400-800A units and 250A units with output cabinet. The output cabinet comes

factory-installed or either the right or left side, depending on how it was ordered. It cannot be moved from one

side to the other in the field.

Adequate space is required above the unit for conduit (if configured as such) and cooling air flow. This section

provides specific information for these considerations.

The unit is designed with top and bottom cable terminations to allow maximum flexibility in its installation. Units

with output inline panelboards are bottom exit only. If bottom cable entry and exit is used, sufficient cable

bending space must be provided by a raised floor or a floor stand.

For dimensions of each unit, see Figures 7 through 22. If your unit is equipped with an optional key lockout

switch, see Figures 13 through 21 for the location of that switch.

2.1 Recommended Minimum Service Clearances

The recommended service clearances are at the front and side, if equipped with output cabinet. The minimum

service clearance required by the National Electrical Code (NEC) Article 110-26 is 36 in. (91cm) for units with

voltages up to 150V to ground and 42 in. (107cm) for units with voltages over 150V to ground. Clearance of at

least 18 in. (46cm) is required above the unit for cooling air flow.

2.2 Heat Output

The unit produces minimal heat during normal operation.

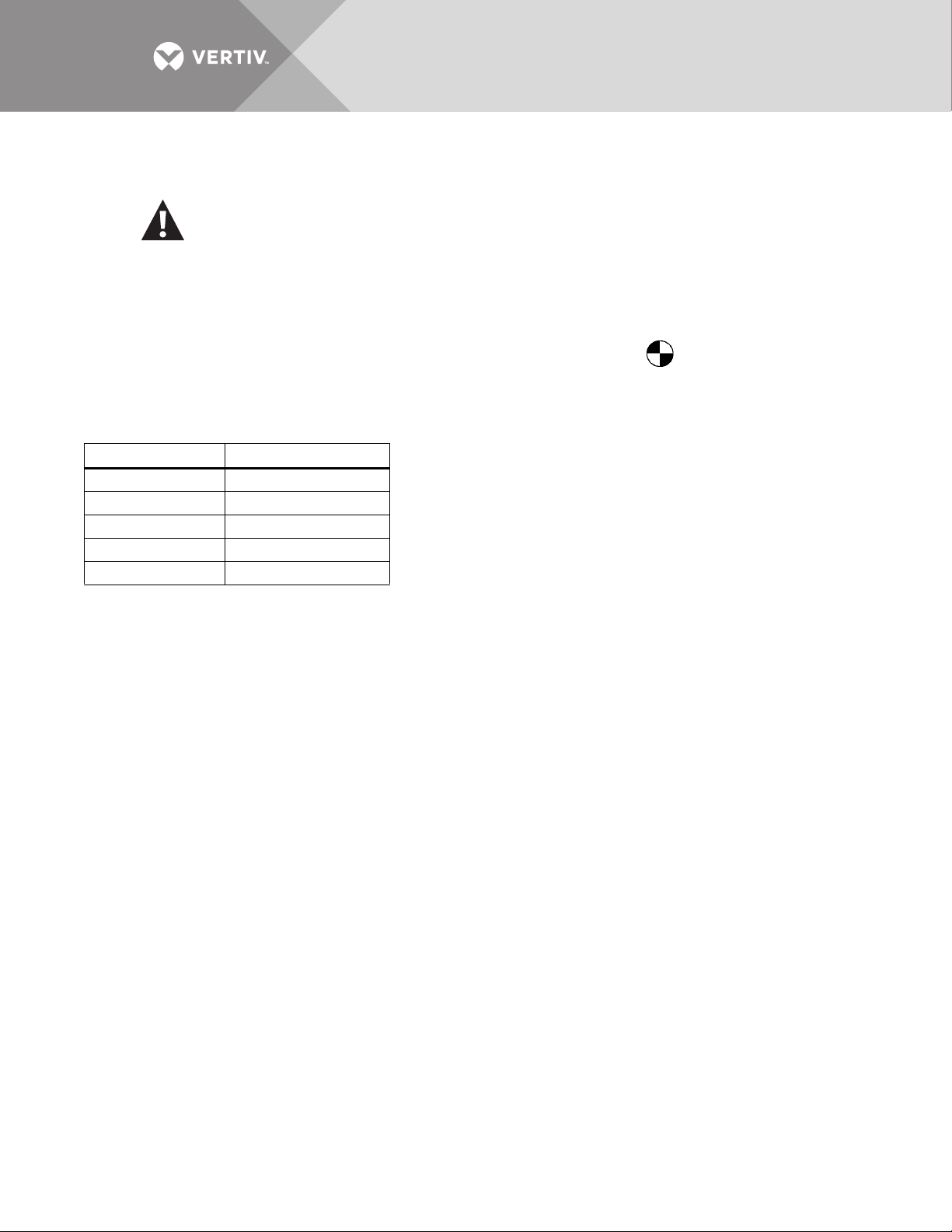

Table 2 Heat output

Switch Size

250A 11,737 (3.44)

400A 19,295 (5.66)

600A 29,238 (8.57)

800A 39,238 (11.50)

Heat Output

BTU/Hr (kW)

2.3 Operating Environment

The unit is designed to be installed indoors where the ambient air temperature is in the range of 32° to 104°F

(0°C - 40°C) with a relative humidity of 0% to 95% non-condensing, up to an altitude of 4000 feet (1200 meters).

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 5

2.4 Altitude

0

10,000

(3048)

9500

(2896)

9000

(2743)

8500

(2591)

8000

(2438)

7500

(2286)

6000

(1829)

5500

(1676)

7000

(2134)

6500

(1981)

5000

(1524)

4500

(1372)

4000

(1200)

100

86

88

90

92

94

96

98

Rating (%)

Altitude, Feet (M) Above Sea Level

0

10,000

(3048)

9500

(2896)

9000

(2743)

8500

(2591)

8000

(2438)

7500

(2286)

6000

(1829)

5500

(1676)

7000

(2134)

6500

(1981)

5000

(1524)

4500

(1372)

4000

(1200)

104.0 (40)

86.0 (30)

87.8 (31)

94.1 (33)

93.2 (34)

95.0 (35)

96.8 (36)

98.6 (37)

Maximum Ambient

Temperature, °F (°C)

Altitude, Feet (M) Above Sea Level

102.2 (39)

100.4 (38)

89.6 (32)

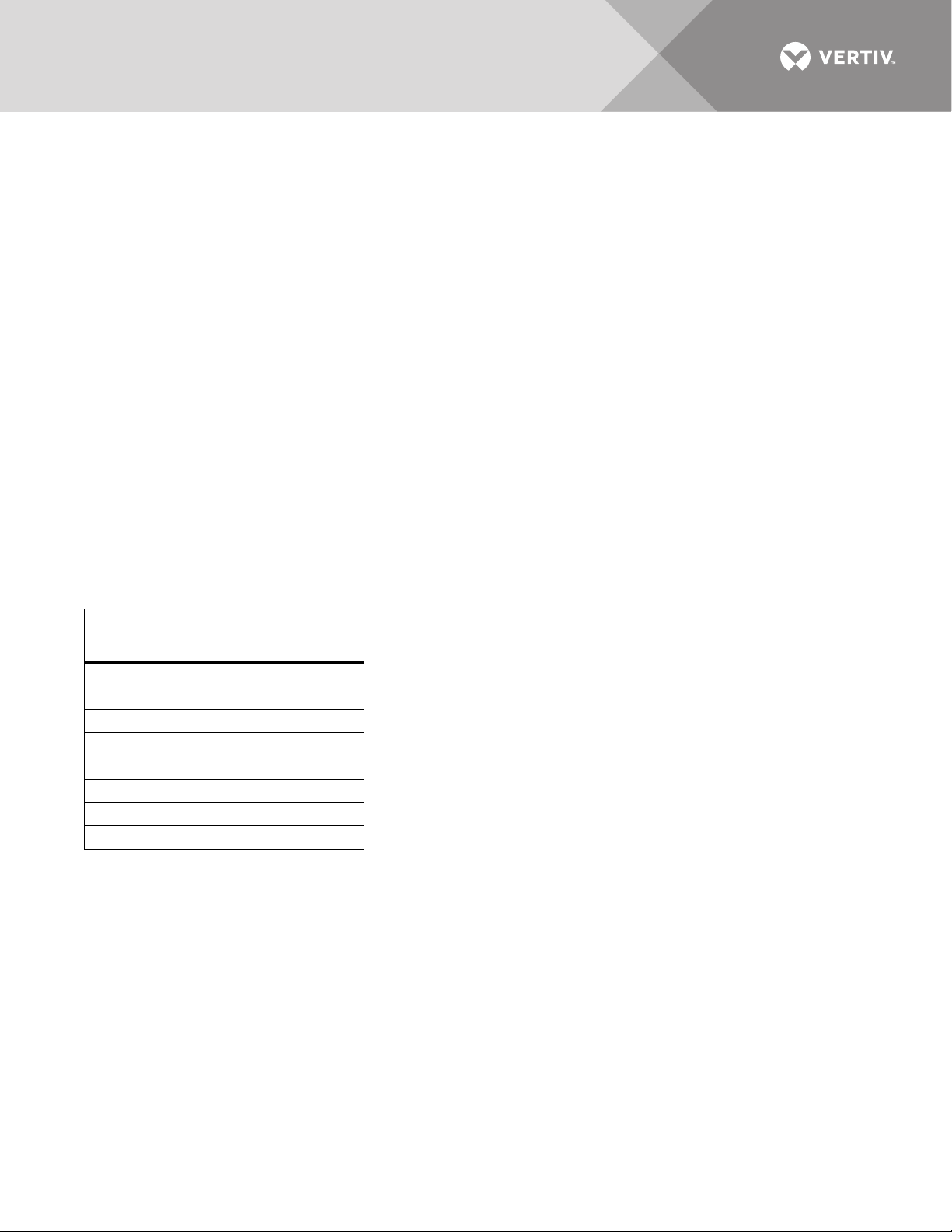

The standard units are designed for full load operation up to 4000 feet (1200m) above sea level. See Figure 1 for

recommended deratings for altitudes greater than 4000 feet (1200m).

Figure 1 Recommended derating for high altitude operation

Operation at full load at a higher altitude can be accommodated in ambient temperatures less than 104°F (40°C)

ambient. Figure 2 shows the maximum allowable ambient temperature for full load operation at altitudes above

4000 feet (1200m).

Figure 2 Maximum ambient temperature for full load operation at higher altitudes

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 6

3.0 LOCATING THE LIEBERT STS2/PDU

This section provides instructions for leveling the Liebert STS2/PDU and anchoring the unit to the floor, should

that be required.

3.1 Anchoring the Unit to the Floor

The Liebert STS2/PDU can be anchored to the concrete floor to ensure stability for the unit in the event of

seismic activity.

3.2 Positioning the 250A Only Liebert STS2/PDU Without Anchoring

The 250A Liebert STS2/PDU is furnished with casters and stabilizing feet. After final positioning of the unit,

adjust the stabilizing feet located in each corner of the frame base to stabilize the unit.

For stabilizing feet details, see Figures 7 through 11.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 7

4.0 POWER AND CONTROL WIRING

WARNING

Risk of electric shock. Can cause injury or death.

This unit is supplied by more than one power source. The unit contains hazardous voltages if any of the

input sources are on, even when the unit is in bypass. To isolate the unit, turn off and lock out all input

power sources.

Verify that all input power sources are de-energized and locked out before making connections inside

unit.

Lethal voltages exist inside the unit during normal operation. Only qualified service personnel should

perform maintenance on the Liebert STS2/PDU.

All power and control wiring must be installed by a licensed, properly trained and qualified electrician. All

power and control wiring must comply with the National Electrical Code and all applicable local codes.

The input power busbars are accessible through the front of the unit. Liebert’s 250A units have PEM nut inserts

designed to allow one-handed tightening. Busbars in the 400-800A units are supplied with holes to

accommodate two-hole lugs.

Cables can be installed through the top or bottom of the unit through removable conduits plates. Units with

output inline panelboards are bottom exit only for output cables.

Unless otherwise labeled, use the recommended tightening torque shown in Tab le 30.

See Figures 12 through 21 for wiring entrance locations.

4.1 Input and Output Power Connections

The input power connections are made to the busbars provided inside the unit (see Figures 26 through 31).

These busbars are accessible through the front of the unit.

Output power connections are handled two different ways, depending on the type of distribution used. Power

connections on standard units with an output breaker are made to the busbars inside the unit. These busbars

are accessible through the front on 250A units and on the side on 400-800A units. See Figures 26 through 31

for details on the busbars. Power connections on units with panelboard distribution are made directly to the

panelboard breakers. Busbars are provided in the output cabinet for ground and neutral connections.

WARNING

Risk of electric shock. Can cause injury or death.

Verify that all input power and control circuits are de-energized and locked out before making

connections inside unit.

The two input power feeds (sources) to the Liebert STS2/PDU should be from two independent sources to avoid

a common source failure.

To ensure proper operation of the Liebert STS2/PDU, the two input sources must be the same nominal voltage

level and phase rotation.

For uninterrupted automatic transfer, the two input sources should be synchronized within 15 degrees.

NOTICE

The input sources to the Liebert STS2/PDU must be grounded-wye sources. Input sources other than solidly groundedwye sources may cause damage to the switch.

The Liebert STS2/PDU is designed for operation with three-wire, solidly grounded sources only.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 8

See Figures 3 through 6 for typical one-line diagrams. Refer to Figures 26 through 31 for electrical field

connections on all units.

Figure 3 Typical Liebert STS2/PDU, one-line diagram

Source 1

Source 2

CB6

Surge

Suppression

Optional

CB7

Surge

Suppression

Optional

Transformer 1

Neutral

Ground

Transformer 2

CB4

CB1

CB2

CB5

SS1

CB3

SS2

Field-Supplied Wiring

PSP12006

Rev. 1

Figure 4 Typical Liebert STS2/PDU, one-line diagram, with dual static switch output circuit breakers

(not available on 250A units)

Source 1

CB6

Surge

Suppression

Optional

Transformer 1

Neutral

Ground

CB4

CB1

CB2

SS1

SS2

CB3

CB3A

Breaker

Output

Breaker

CB8

Output

CB8

Source 2

CB7

Surge

Suppression

Optional

Transformer 2

CB5

Field-Supplied Wiring

PSP12007

Rev. 1

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 9

Figure 5 Typical Liebert STS2/PDU, one-line diagram, with inline distribution, dual static switch output circuit breakers

Source 1

Source 2

CB6

Surge

Suppression

Optional

CB7

Surge

Suppression

Optional

Transformer 1

Neutral

Ground

Transformer 2

CB4

CB1

CB2

CB5

SS1

SS2

Field-Supplied Wiring

PSP12003

Rev. 3

CB3

CB3A

Subfeed 1

Optional

CB12

CB8 CB9 CB10 CB11

42-Pole Distribution

Panelboard, Typical

Subfeed 2

Optional

CB13

Figure 6 Typical Liebert STS2/PDU, one-line diagram, with I-Line distribution, dual static switch output circuit breakers

Source 1

CB6

Surge

Suppression

Optional

Transformer 1

Neutral

CB4

CB1

SS1

Output

Breaker(s)

CB3

CB3A

I-Line Panelboard

CB7

Ground

CB2

CB5

SS2

Source 2

Surge

Suppression

Optional

Transformer 2

Field-Supplied Wiring

PSP12001

Rev. 2

The input and output power wire size should be based on the overcurrent protection device, observing the NEC

and local codes.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 10

The Liebert STS2/PDU output power, ground and neutral busbars accommodate a wide range of wire sizes. The

Liebert STS2/PDU busbars accommodate standard two-hole lugs.

Table 3 Input/output conduit plate specifications

Rating

250A

400-600A

800A

Maximum Number

of Conduits Size, in.

12 2"

82-1/2"

63" or 3-1/2"

6 2"

4 2-1/2" or 3"

62-1/2"

53" or 3-1/2"

4.2 System Grounding

Equipment grounding—Grounding is primarily for equipment and personnel safety, although proper grounding

also enhances equipment performance.

All input and output power feeds must include an equipment grounding means as required by the NEC and local

codes.

An insulated equipment ground conductor is recommended to run with each input and output power feed. The

equipment ground conductors should be at least the minimum size conductor per the NEC based on the

upstream overcurrent protection device.

WARNING

Risk of electric shock. Can cause injury or death.

If conduit is used as a grounding means, adequate electrical continuity must be maintained at all conduit

connections. Using isolating bushings with a metal conduit can be a safety hazard.

4.3 Control Wiring Connections

No control wiring is needed on the standard Liebert STS2/PDU. Certain options and remote monitoring

configurations require external control wiring. See 6.0 - Options for details.

The customer must supply control wiring to the Liebert STS2/PDU for connection to any monitoring or

communication options. Top and bottom removable conduit plates are provided for control wiring conduit.

Control cables can be installed through the top or bottom of the unit through removable control conduit plates.

A top hat is provided on the 400-600A units for connecting the top entry control wiring conduits (see

Figures 13 through 21). The top hat is turned upside down and ships inside the unit. It must be removed from the

unit and flipped 180 degrees before being reinstalled (see Figure 49). The control wiring top hat does NOT

contain any knockouts for conduit. The installer must drill the appropriate-sized holes for the conduit before

attaching to the top of the Liebert STS2/PDU.

See Figures 47 and 48 for arrangement of optional cards.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 11

4.4 Remote Source Selection Wiring

An optional Remote Source Selection board may be installed in your Liebert STS2/PDU. This board is installed in the

same bay as the communications options. See Figures 47 and 48 for the location of these options. See Figure 55 for

information on the control wiring for the Remote Source Selection option.

The Remote Source Selection allows you choose the preferred input source from a remote location.

Terminal connections allow the customer to remotely select a source to be the preferred source in the same

process as the local source transfer selection.

If both the input contacts are closed, the current selected preferred source shall be retained. If the unit’s

preferred source selection and Remote Source Selection are active at the same time,

the Liebert STS2/PDU follows the last request for a preferred source change, regardless of whether it was from

the local or Remote Source Selection controls.

A six pin terminal block provides the Remote Source Selection connections. Two pairs of wires are used from the

switch to trigger the source selection. You can select the type of switch used for this remote control.

Connections are made to four of the connections, using Form A dry contacts. The contacts are numbered left to

right:

Table 4 Remote source selection terminal block

Contact

1Source 1

2 Isolated ground

3Source 2

4Isolated Ground

5 DO NOT USE

6 DO NOT USE

Connection

See 10.3 - Enabling Remote Source Selection for instructions on enabling the Remote Source Selection option.

4.5 Power Supply

The Liebert STS2/PDU is supplied with redundant power supplies that are designed to operate from a voltage

range of 200V to 600V. The unit is set at the factory to match the nameplate voltage. Field adjustments are not

necessary. If the unit needs to operate at a voltage other than what is listed on the nameplate, contact Vertiv

Services or your local Vertiv representative. Tab le 5 provides transformer tap information.

Table 5 Terminal block 1 and terminal block 2 wire connections

Connect Connect

Vol tag e

200 1 9 1 9 1-7

220 2 12 2 12 6-8

380 1 8 1 8 2-7

415 1 10 1 10 4-7

600 1 12 1 12 6-7

208 1 10 1 10 1-7

240111111 1-7

400 1 9 1 9 3-7

480 1 11 1 11 5-7

Jumper BetweenF1 TB1-XX F2 TB1-YY F3 TB2-XX F4 TB2-YY

NOTICE

Using Tab le 5 , ensure that the wiring for the control transformers matches the input voltage for the unit.

Improper wiring could result in blown fuses.

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 12

5.0 OUTPUT POWER WIRING

The Liebert STS2/PDU standard model is provided with a circuit breaker for connecting to the load or a remote

distribution cabinet. Other distribution configurations are available.

The three main types of distributions available for the Liebert STS2/PDU are:

•Output Breaker

• Inline Panelboards—two panelboards (84 poles) on 250A units and four panelboards (168 poles) on 400-800A units.

Square D

•SquareD I-Line

to 400A breakers are available on 800A units.

For other optional distribution methods, contact your local Liebert representative or call 1-800-LIEBERT.

The Liebert STS2/PDU distribution may be mounted on either the right or left side at the customer’s option.

Location of output conduit connections is affected by the location of the output cabinet. See

Figures 8, 9, 12, 13, 16 and 17 for wiring a right-side distribution configuration and Figures 10, 11, 14, 15, 18 and 19

for wiring a left-side distribution configuration. See Figures 23 through 44 for wiring.

See Table 6 for wiring the various output options.

5.1 Customer Connections

The customer is responsible for connections from the Liebert STS2/PDU distribution to the connected load,

either directly or through remote distribution cabinets.

Table 6 Distribution configurations

Distribution Type

Output Breaker

Inline Panelboards

I-Line (Square D) Figure 32

®

and General Electric panelboards are available to accommodate bolt-in or plug-in breakers.

®

Panelboard—designed to accommodate up to 10 plug-in breakers from 100A to 250A. Additionally, 300A

For Details See

Electrical Output

Field Connections

250A Figure 23

400-600A Figure 33

800A Figure 35

250A Figure 30

400-800A Figure 31

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 13

6.0 OPTIONS

This section discusses the options available for the Liebert STS2/PDU. The communications options are also

discussed in 12.0 - Communication Interfaces.

WARNING

Risk of electric shock. Can cause injury or death.

All options must be installed by Vertiv Services or Vertiv factory-authorized service provided by a Vertiv

distributor. The option area and customer control cable area contain hazardous voltages if any of the

input sources are on, even when the unit is in bypass. Turn Off all power sources before installing

customer control cables to any option.

6.1 Programmable Relay Board

The programmable relay board (PRB) provides a means to trigger an external device when an event occurs in

the Liebert STS2/PDU. Each PRB has 8 channels. Each channel has two sets of Form-C dry contacts, rated 1A @

30VDC or 250mA @ 125VAC.

Any alarm or event may be programmed to any channel or channels. Up to ten (10) events may be programmed

to a relay. If multiple events are grouped to one relay, group the events logically to simplify troubleshooting when

an event is triggered. The same alarm or event may be programmed to more than one channel. Up to two

programmable relay boards can be installed in the Liebert STS2/PDU for a total of 16 channels. Programming is

performed through the touchscreen.

See Configuring the Programmable Relay Board Settings on page 109 for default settings and instructions

for reconfiguring the relays. See Figures 47 and 48 for the location of the PRB. See Figure 50 for wiring details.

Table 7 provides the PRB pin-out.

Table 7 Programmable relay board pinout

Channel Pin No. C N.C. N.O.

CH1

TB1

TB2

TB3

TB4

Key: N.O. = Normally Open; N/C. = Normally Closed; C = Common

Note: Pin 16 not used on TB1, TB2 and TB3.

CH2

CH3

CH4

CH5

CH6

CH7

CH8

A1-3 12 3

B4-6 45 6

A7-9 78 9

B 10-12 10 11 12

A 13-15 13 14 15

B1-3 12 3

A4-6 45 6

B7-9 78 9

A 10-12 10 11 12

B 13-15 13 14 15

A1-3 12 3

B4-6 45 6

A7-9 78 9

B 10-12 10 11 12

A 13-15 13 14 15

B1-3 12 3

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 14

6.2 Input Contact Isolator Board

The Input Contact Isolator Board (ICI) provides a Liebert STS2/PDU module interface for up to eight external

user alarm or message inputs to be routed through the Liebert STS2/PDU’s alarm network. The eight contacts

are normally open dry contacts. When a contact closes, an event is triggered.

The Input Contact Isolator options are configured through the Input Contact Isolator dialog box, which is

accessed from the Comm Option dialog box on the touchscreen. You also can program the alarm messages

through this dialog box. See Configuring the Input Contact Isolator Settings on page 107 for instructions on

configuring the connections.

See Figures 47 and 48 for the location of the ICI. See Figure 51 for wiring details.

6.3 Comms Board

The Comms Board provides a communication interface to Liebert SiteScan®, site monitoring product and/or an

external modem. Liebert SiteLink®-12 or Liebert SiteLink®-4 is required for Liebert SiteScan to communicate with

the Liebert STS2/PDU.

The Comms Board is equipped with an RS-422 communication port for communication to a Liebert SiteScan

monitoring system using a 2-wire twisted pair for reliable communication up to 1000 meters (3281 feet).

Information available from the RS-422 port includes the present switch status information, all monitoring

parameters and all active alarms.

The Comms Board is equipped with a modem interface for remote reporting of the present switch status

information, alarm history information and the history of status screens that are triggered upon a major alarm

event. The monitoring system software also supports an auto-dial feature that allows the system to automatically

dial programmed phone numbers by way of a modem to report designated alarm conditions.

Programming the Comms Board is performed through the touchscreen. See Comm Options on page 105 for

details.

See Figures 47 and 48 for the location of the Comms Board. See Figure 52 for information on the control wiring.

6.4 Liebert IntelliSlot™ Web/485 Card With Adapter

A Liebert IntelliSlot Web/485 Card With Adapter (IS-WEB485ADPT) enables the Liebert STS2/PDU to

communicate to a network management system (NMS). The card provides the internal hardware and software to

communicate, via SNMP, to any I.P.-based Ethernet network through an RJ-45 connector using Category 5

cabling.

The Liebert IS-WEB485ADPT provides redundant paths for communications that make it possible to connect to

a Building Management System (BMS) using Modbus, while simultaneously communicating to a NMS through

SNMP. A terminal block provides the connection to Modbus.

See Figures 47 and 48 for the location of the Liebert IntelliSlot Web/485 Card With Adapter. See Figure 53 for

control wiring information.

If you have questions about the Liebert IS-WEB485ADPT, refer to the user guide SL-52615, available at Vertiv’s

Web site, www.vertivco.com

Vertiv™ | Liebert® STS2/PDU™ User Manual | Rev. 6 | 10/2017 15

6.5 Remote Source Selection

The Remote Source Selection allows the preferred input source to be chosen from a remote location. A user

supplied normally open dry contact allows the user to remotely select a source to be the preferred source in the

same process as the local source transfer selection.