Vertiv Liebert SmartAisle2 User Manual

Liebert® SmartAisle2

User manual

Copyright by Vertiv Co. Ltd.

The content in this document is subject to change without notice. All rights, including rights of

translation, reproduced by printing, copying or similar methods, and even of parts, are reserved.

Violators will be liable for damages. All rights, including rights deriving from patent license or

registration of a utility model or design, are reserved. No part of this document may be reproduced

or transmitted in any form or by any means without the prior written consent of Vertiv Co. Ltd.

Notice

The purchased products, services, and features are stipulated by the contract made between Vertiv

Co., and the customer. All or part of the products, services, and features described in this document

may not be within the purchasing scope or the usage scope. Unless otherwise specified in the

contract, all statements, information, and recommendations in this document are provided "AS IS"

without warranties, guarantees or representations of any kind, either express or implied. The

information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure the accuracy of the contents, but all statements,

information, and recommendations in this document do not constitute a warranty of any kind,

express or implied.

Vertiv Co., Ltd.

China

Website:www.vertivco.com

E-mail: support@Vertivco.com

Customer service hotline: 4008876510

Asia-Pacific

Homepage: www.vertivco.com

E-mail: overseas.support@Vertivco.com

For Technical Support, users may contact the nearest Vertiv Co. local sales office or service center.

Styling used in the Guide

The styles used in this manual are defined in the following table:

Situation

Description

Warning/Danger/Caution

The Warning/Danger/Caution note indicates a hazardous or

potentially harmful situation that can result in death or

injury. It also indicates instructions that need to be adhered

to, failing which may result in danger and safety issues,

thereby having an adverse effect on the reliability of the

device and security. Even for practices not related to physical

injury, the content under the Warning heading is used for

precautions which need to be taken which, otherwise, could

result in equipment damage, performance degradation, or

interruption in service.

Note

The Note section indicates additional and useful information,

including tips and tweaks. It also calls attention to best

practices and industry-best protocols that are standardized

and help make maximum utilization of the resources at

hand. Helpful information related to the mainstream content

also comes under the Note heading helping the users get to

grips with the definitions, concepts, and terminologies used

in the manual.

Version History

Issue

Revision Date

BOM

Changes

1.0

=

---

Safety Precautions & Measures

In this section, the safety measures related to the entire SmartCabinet™ unit will be explained in

detail.

Read the manual prior to installation and operation of the unit. Only qualified personnel

should move, install, or service this equipment.

The user reads and takes into account all the precautions, compliance, and safety measures

before working on the equipment. The unit control must be used exclusively for the purpose

which it is intended for; the manufacturer takes no liability for incorrect use or a

modification to the unit control.

Please read this manual carefully before installing, maintaining and troubleshooting;

especially the Warning/ Danger/ Caution information in the User Guide. Apart from the User

Guide, also pay attention to the warning labels on the unit and its components.

This manual is retained for the entire service life of the machine. The user must read all the

precautions, danger, warnings, and cautionary measures mentioned in the manual prior to carrying

out any operations on the machine.

Adhere to all the notes, warnings, cautions, potential dangers, and precautions mentioned in the

manual. Read this manual before carrying out any operation on the unit.

The Warnings/Danger/Cautions/Precautions/Notes do not represent the entire safety points to be

observed and only supplementary in nature. This product is tailored for industrial, commercial, or other

professional units (such as manufacturing, electrical, and instrumentation setups) and not meant for

purposes related wholly to individuals without the credentials. The purpose of the design is well defined

and therefore, the manufacturers do not assume any responsibility for any incorrect usage. Strict

adherence to the norms and usage should be observed. In case of any improper use or modifications,

the warranty will be void; handle with care, especially the key to the product must be allocated to the

service personnel responsible for maintenance.

General Safety Instructions

Use the tools with an insulation handle.

Wear rubber gloves and safety shoes.

Avoid placing tools and metal objects on the battery surface

Remove the watches, rings, or any metal objects.

Only after all the power is disconnected, operate on the inner components of the product.

Before operating on the inner components for any maintenance, you must switch off the

mains breaker and all UPS power.

After an alarm occurs through product monitoring platform, the need for timely find the

cause, treatment failure, to avoid more trouble, damage.

Risk of electric shock

There is a risk of an electric shock which may lead to personnel injury or death: To prevent or avoid

such a situation, the following points must be taken into account:

Disconnect the control box and remote power supplies prior to working on the product.

Local codes, regulations, and protocols may vary from region to region. Therefore, adhere

to all these local protocols and rules prior to installing, operating, or servicing of the

machine.

Read all the instructions, ensure that all the parts and components are included, and check

the nameplate to ascertain that the voltage matches the available mains; Proceed with the

installation, maintenance, troubleshooting, and operating on the machine only after going

through the preceding steps.

This product is suitable only for the TT and TN type power grid; it doesn’t apply to the IT

type power grid.

Finally, read all the labels on the unit and its components before operating on those

components during installation and maintenance. The warnings and cautionary measures

mentioned in this manual are supplementary and therefore, the measures listed on the

labels of the components and the unit must be considered strictly before any operation.

PART I

Introducing SmartAisle

1 Introduction

SmartAisle2 is an intelligent, integrated infrastructure in a self-contained line-up solution that is

easy to deploy and tailored for large data centers and computer rooms. All data centers have

distinct operation and business objectives. Balancing the data center practices for capacity, space

utilization, availability, and efficiency has been tedious owing to the ever-increasing demand in the

IT space.

Enter SmartAisle2 – an enclosed complete data center solution (referred to as SmartAisle) in an

indoor environment. With Precision cooling, UPS, power management, monitoring and control

technologies and fire suppression integrated into a holistic enclosed system, this smart solution is

ideally suited for environments where dedicated IT room improvements are neither practical nor

cost-effective. It is flexible as it can be placed unobtrusively into workspaces without the clutter or

bulk associated with these kinds of solutions. It is highly effective, economical, interoperable, and

makes use of the existing infrastructure or whitespace, avoids expensive room upgrades along with

the optional fire suppression system- all in one enclosed solution. This top-notch modular

enterprise-grade solution is unique and brings together industry-best practices and latest

technologies to enable streamlined management in a compact footprint.

It is an ideal solution tailored for 19” rack hardware device, including servers, voice data, the

internet network equipment, cabinets, closure assembly and power supply, cooling, monitoring

equipment, equipment for bearer cabinets and is best suited for large data centers.

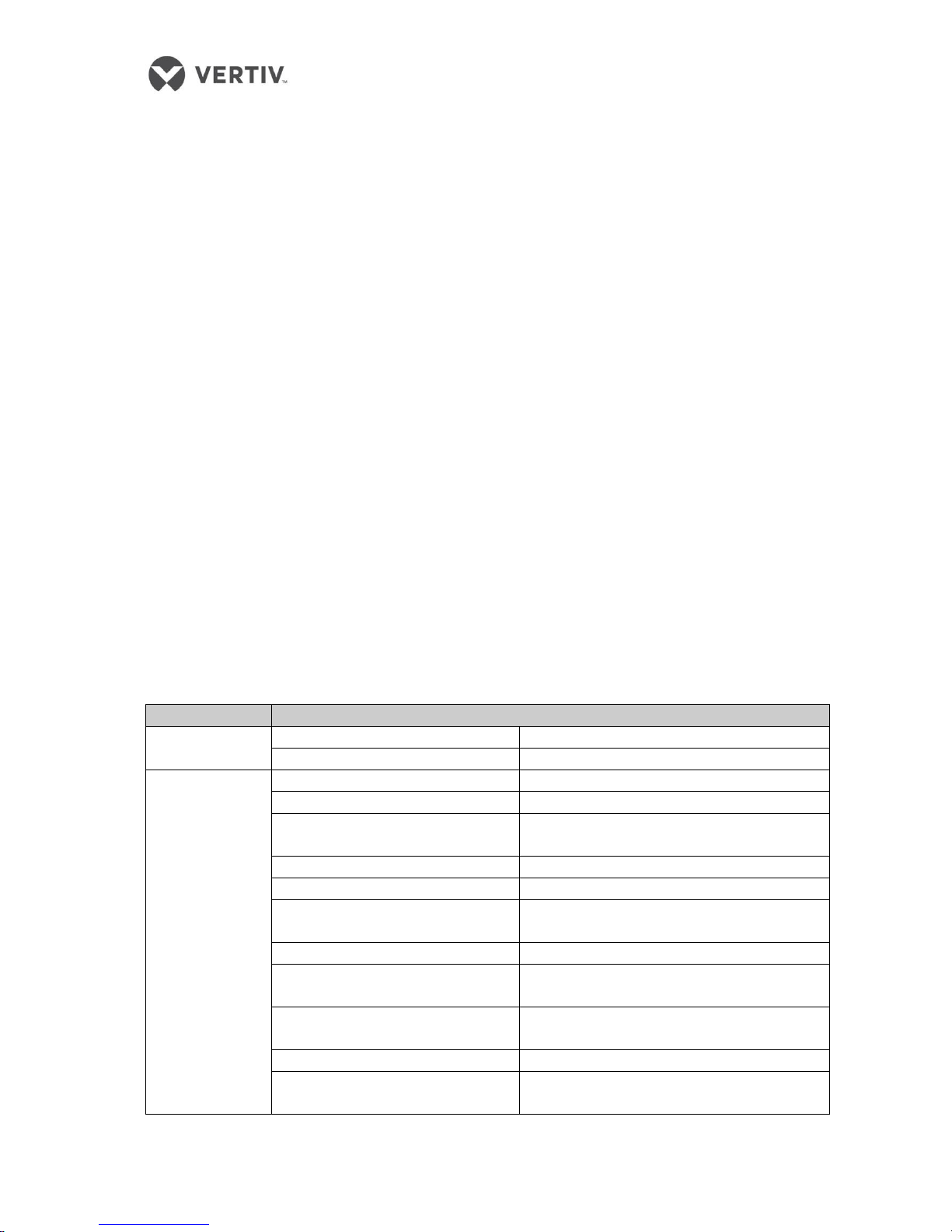

1.1 Configuration Specification for SmartAisle

The typical configuration of the SmartAisle solution is shown in Table 1-1.

Table 1-1 Configuration

Parameter

Specifications

Size

Corridor width

1200mm

Machine external dimensions

See Section 1.5.3

Overall key

indicators

Density levels

Low-density

Power Architecture

Centralized power supply

Cooling architecture

Air cooled DX based row cooling units,

independent cooling modules

Structured Cabling

Column header network wiring closet

Fire architecture

External fire, borrow building

The total number of U-bit single

module

966 (single cabinet 42U, including the

network cabinet)

Redundant power supply

2N

The average power consumption of

a single cabinet

4kW

IT power consumption single

module

92kW

Single refrigeration module

105kW

Altitude

Less than 1000m (air conditioning derating

more than 1000m)

Mounting

Raised floor or ground installation

Voltage

standard

Voltage

(380 ~ 415) Vac ± 10%, 3N ~

frequency

50Hz / 60Hz

Colour

Pantone 877C + RAL7021

1.2 Salient Features

SmartAisle has several distinct features that make it an outstanding utility for mid-tier and large

data centers.

Efficiency

Close control of precision air cooling with an exact match with the thermal load using a variable

capacity system that provides focussed cooling with high energy savings

Intelligent Monitoring

Enables supervision and management of the environment, equipment, electric doors, roof and

alarm linkage intelligent control system in a centralized manner for the administrator.

Convenient Operations & Maintenance

Use of electric door anti-pinch safety and access control systems improves the user comfort and

safety experience.

Security Management

Use of electric doors and roof-emergency response system that enables enhanced security

feature.

Intelligent Lighting

The integrated 3-color bright lights, set display, illumination and easy-to-understand interface

to facilate appropriate space lighting needs.

Human Machine Interface

A 15-inch large control panel which is quite intuitive and advanced enables administrators and

facility managers to visualize the entire system operation in real time

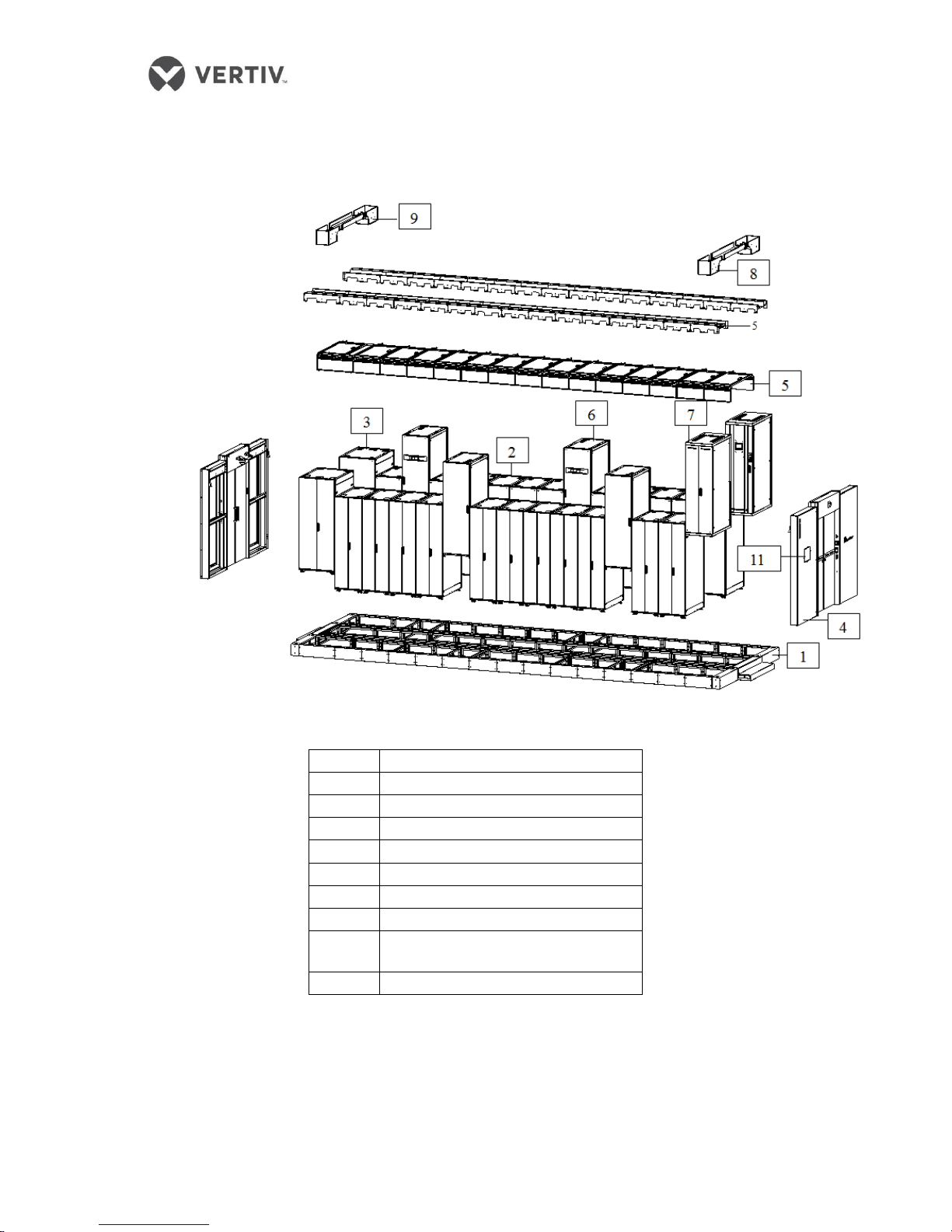

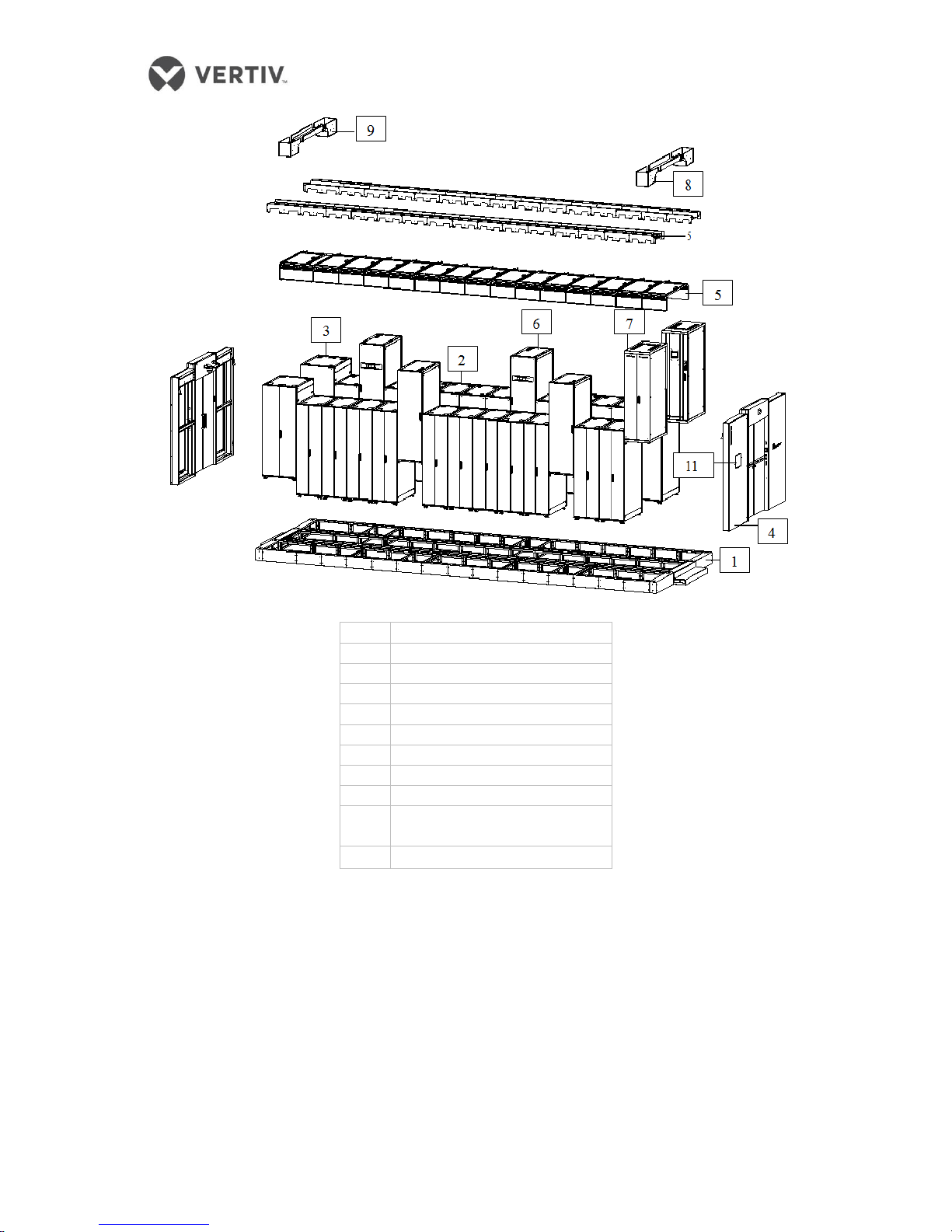

1.3 Appearance and Components

The bifurcation of all components that constitute the SmartAisle solution is depicted in the

following figure (Refer Figure 1-1);

Figure 1-1 SmartAisle layout diagram

1

Base

2

Server Cabinet

3

Network Cabinet

4

Access door

5

Top Plate

6

A/C Column

7

Distribution Cabinet

8

Strong wire passage groove

9

Power cable trunking; copper

and fibre cable tray

11

Control panel

Configuration of Components

The Base enables achieving a common ground to mount the entire machine equipment,

eliminating the need to set up static flooring and providing pipeline space.

The cabinet is an ideal utility for 19 "rack-mount hardware, including servers, voice, data,

Internet, and other network equipment.

Closure assembly (Access door & Roof) enables achieving closure of the hot and cold aisles,

personnel access control, and linkage opening function.

Lighting provides an environment within the channel display, operation, and maintenance

of lighting and warning prompts.

A Bridge from the distribution cabinet helps realize the connection related to the capacity

of the network cabinet to the circuit between the enclosure management functions.

Distribution cabinet power distribution equipment enables achieving the functionality to

provide 19” rack-mount hardware.

Refrigerant equipment helps realize a 19” rack mount hardware cooling.

Monitoring device enables achieving the USMS (meaning supervision of Power, Cooling

Temperature, Humidity, Water, and Leakage) equipment monitoring and control linkage.

Local Display helps administrators or the concerned facility managers by presenting

information to achieve the overall capacity, 2D and 3D temperature fields, alarms, and PUE

to name a few.

1.4 Environmental Requirements

1.4.1 Operating conditions

The installation site of the SmartAisle should be such that the product is away from heat and

environments where there is a presence of easy-to-produce sparks, direct sunlight, corrosive gases,

and organic solvents

Operation Conditions are shown in Table 1-2:

Table 1-2 Operation Conditions

Parameters

Values

Installation

location

The maximum deviation during the product installation at ground level must be less than

0.5mm/m; The maximum equivalent horizontal range of the Indoor and outdoor airconditioning is 50m. Height difference ΔH: -8m≤ΔH≤30m

Application

areas

Large data centers, Mid-size Data centers, Equipment & IT rooms

Ambient

temperature

Indoor: 0 °C ~ 40°C

Air Conditioners: -20 °C ~ + 45 °C, such as a cryogenic assembly; minimum outdoor working

temperature is -34 °C

Environment

humidity

5% RH ~ 90% RH (30 °C, no condensation)

Altitude

<1000m, greater than1000mDerating

Run power

range

(380 ~ 415) Vac ± 10%, 3N ~

Note:

[1]: For detailed installation techniques for the air conditioning and power distribution equipment along with

the requirements, refer to the product's user manual.

[2]: For the Air conditioning derating, contact the Vertiv local office;

for the cryogenic components, contact your local Vertiv office or the local dealer.

1.4.2 Storage Environment

The Product storage environment is shown in Table 1-3.

Table 1-3

Parameters

Values

Storage Environment

Room should be clean and clear of dust and debris

Environment humidity

5% RH ~ 95% RH (non-condensing)

Ambient temperature

-33 °C ~ + 70 °C

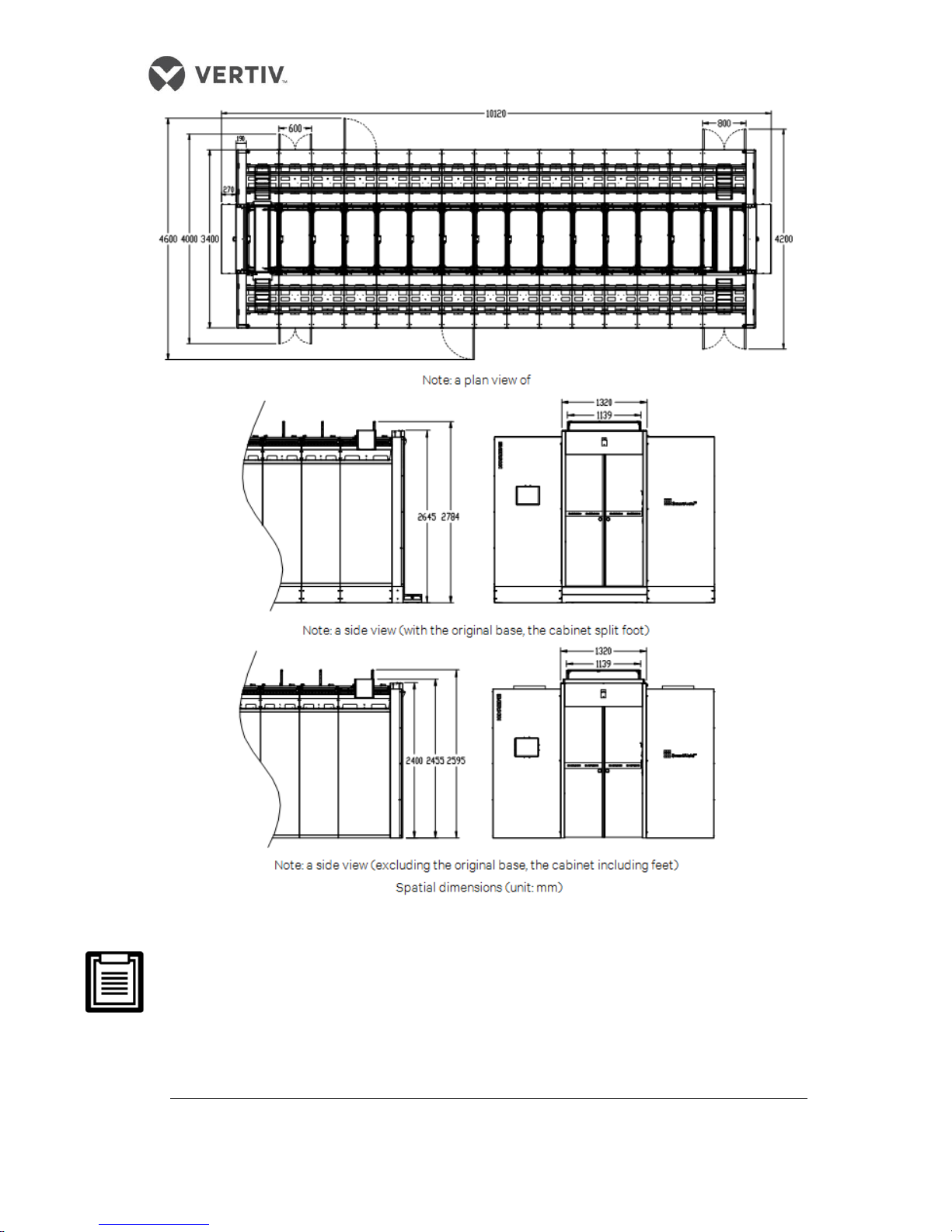

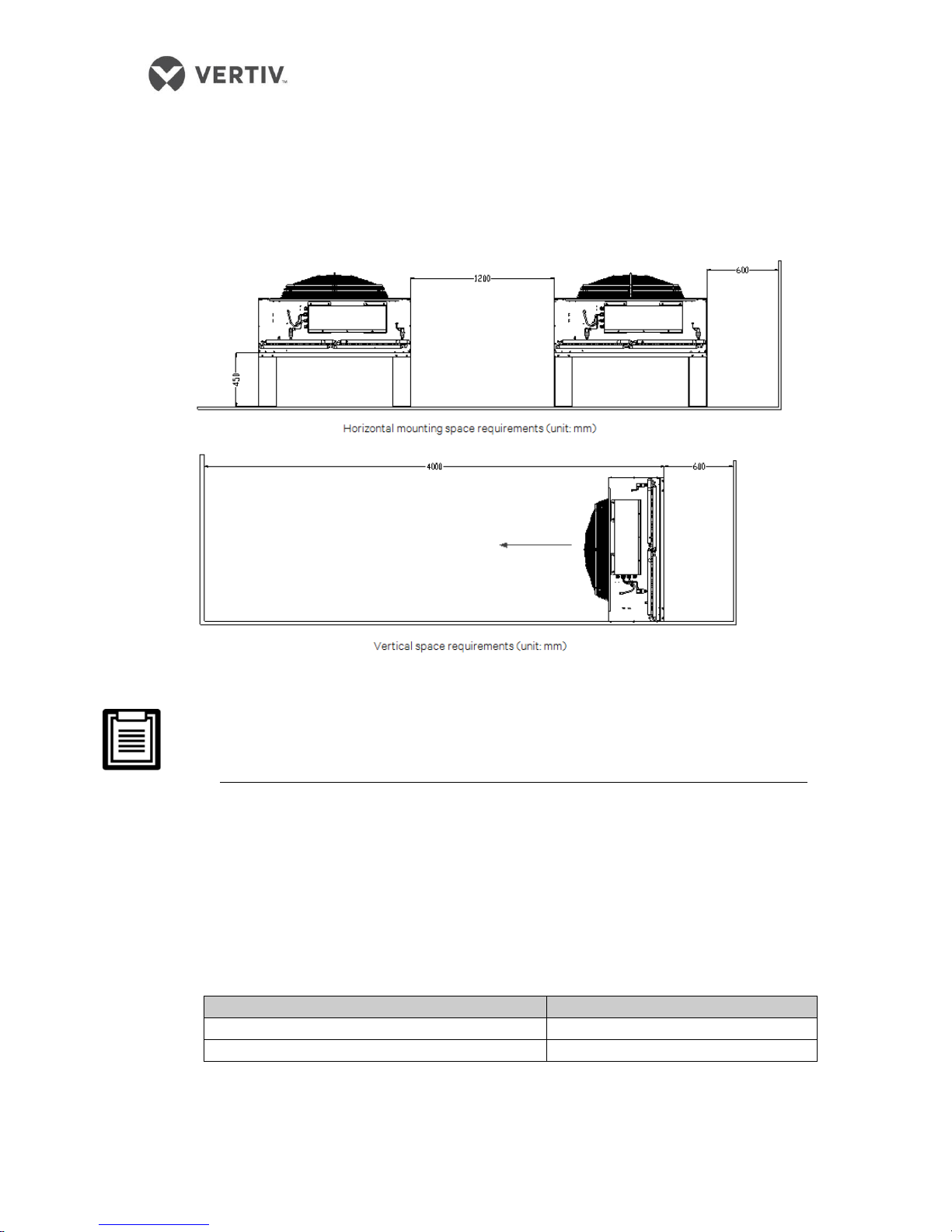

1.4.3 Space

Interior space side

Leave enough space for installation, maintenance, repairs and cooling; The space required

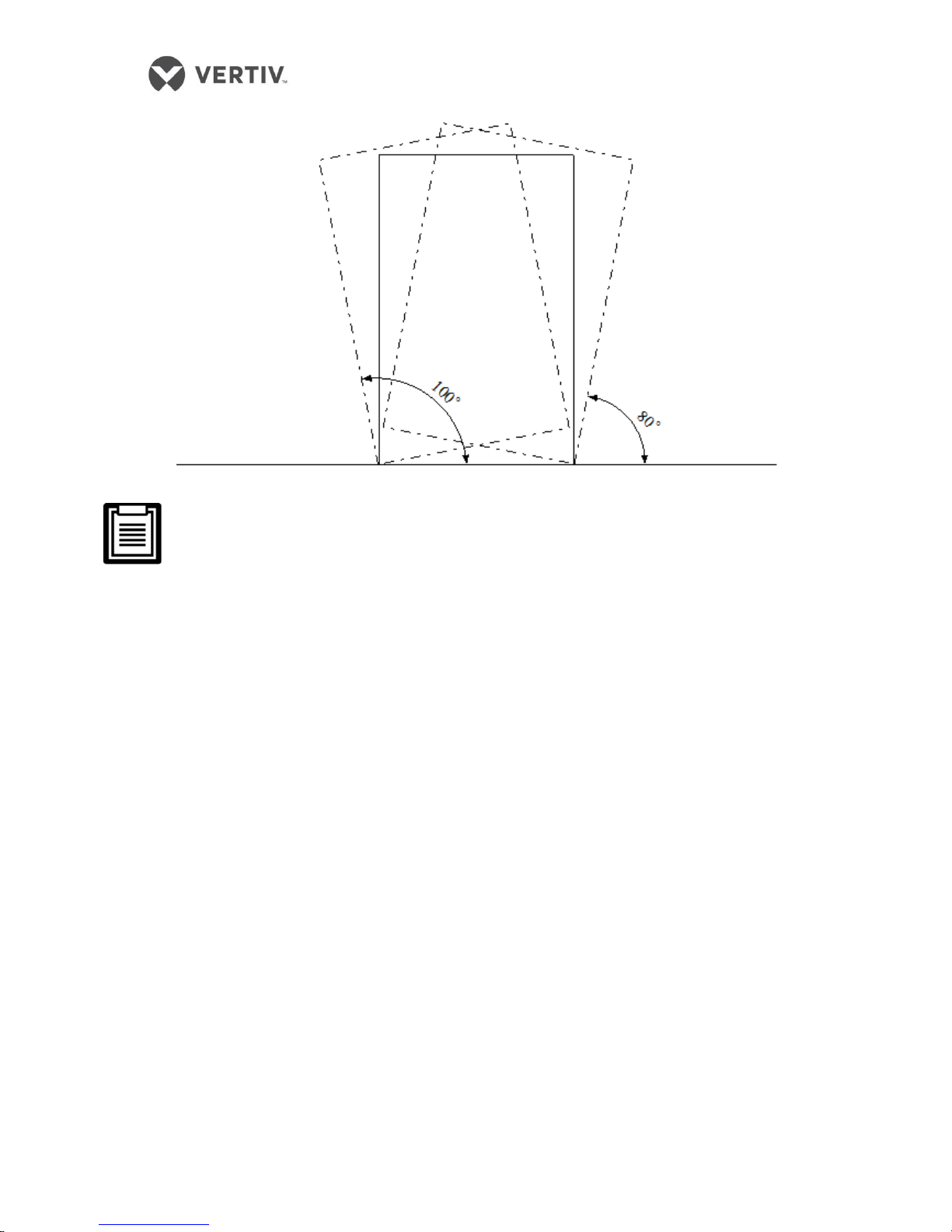

to open the door shown in Figure 1-2.

Figure 1-2 Interior Space side (Indoor)

Ensure to check the back door open space in front of the cabinet during product installation.

Always check and confirm the frame before mounting the product and the spacing between the

projecting outer enclosure level bridge.

Confirm the opening height space between the bridge, lighting, plumbing, and ceiling after the

roof opens prior to installation.

The rear cabinet door and the door from the wall end of the channel reservation must have an

appropriate distance between them to ensure easy access to equipment shelves for the

maintenance personnel.

Outdoor space

Maintain sufficient space for servicing and repairs around the condenser installation position.

The detailed space requirements are depicted in Figure 1-3.

Figure 1-3 Outdoor Space

Barrier free condenser outlet is 4000mm.

Keep a space of 600 mm from the front and rear sides of the condenser for maintenance

and repairs.

1.4.4 Indoor unit and outdoor unit distance

If the one way equivalent length is over 30m, or if the vertical height difference between the

indoor unit and outdoor unit exceeds the values shown in Table 1-4, contact the Vertiv local

office or office of the local dealer to ascertain the need for additional components to extend

the pipeline and other measures

Table 1-4: Perpendicular to the indoor unit and outdoor unit level difference

Relative position

Drop

The outdoor unit is higher than indoor unit

Maximum: + 30m

The outdoor unit is below the indoor unit

Maximum: -8m

1.4.5 Load-bearing

A typical configuration of the SmartAisle product is as follows: weight of about 9 tons, an

area of about 32.6 sq m, and heavy user equipment is considered the bearing capacity post

the installation

1.5 Configuration program

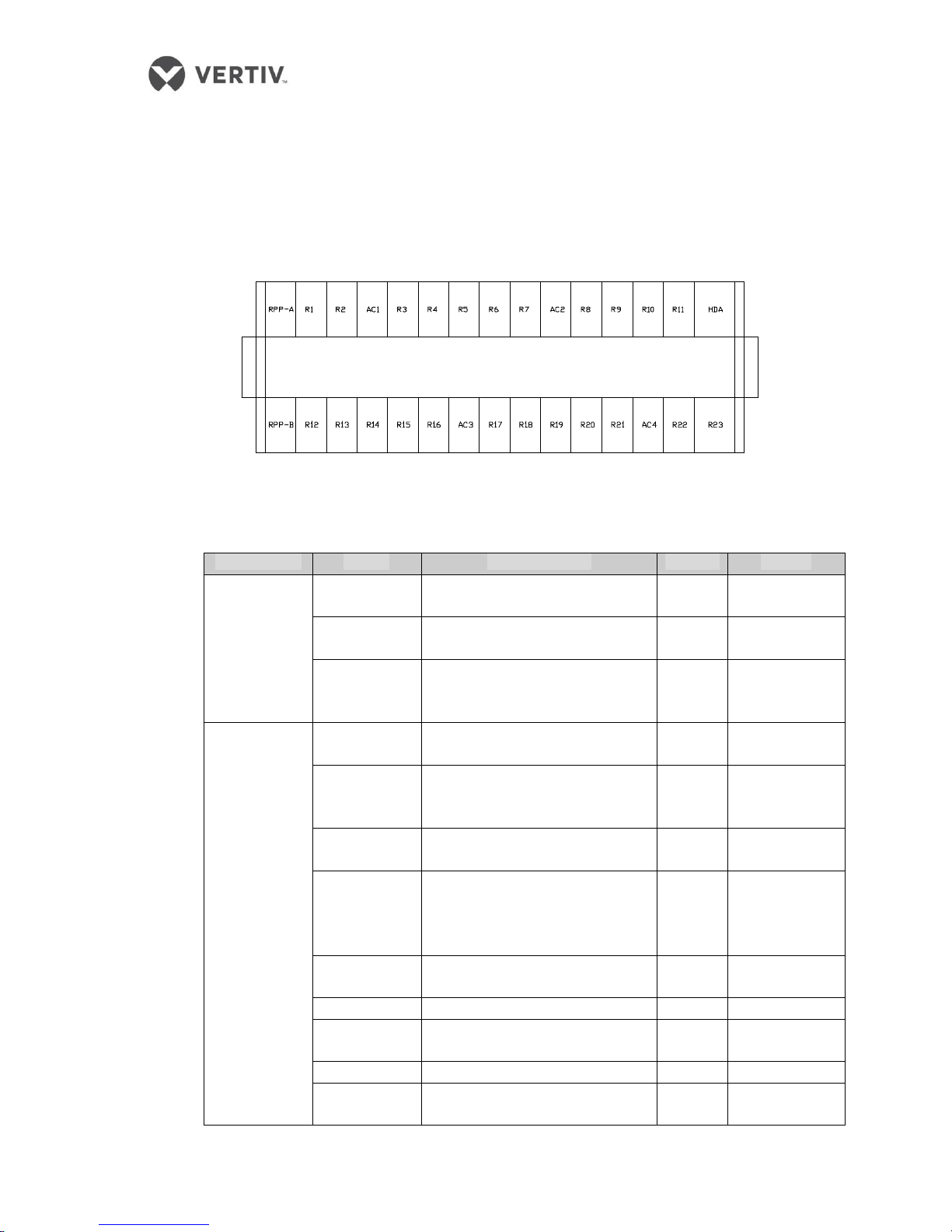

The layout typical configuration is shown in Figure 1-4.

Figure 1-4 Configuration Layout

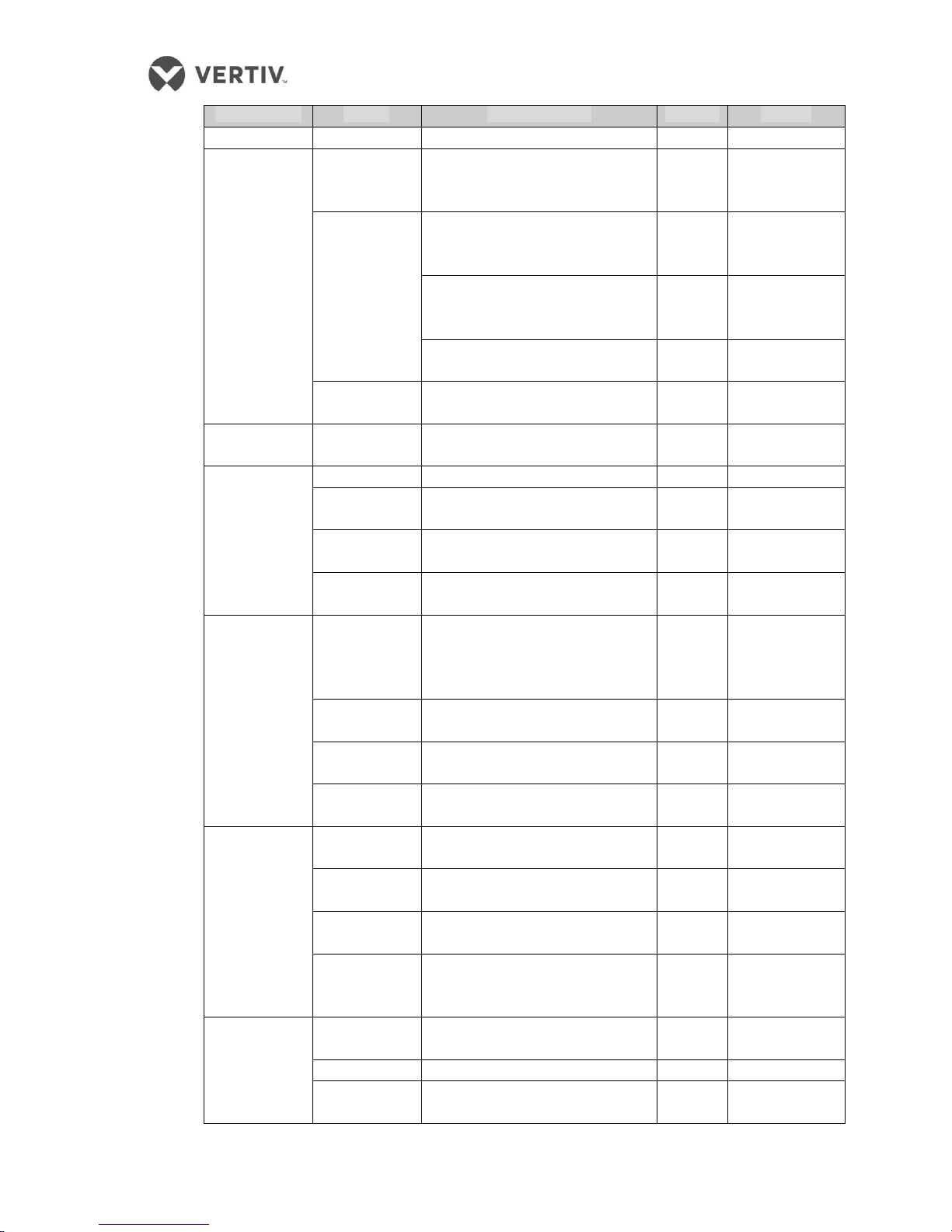

SmartAisle’s typical configuration list is described in Table 1-5.

Table 1-5 - Typical configuration list

Classification

Project

Product number

Quantity

Remark

Cabinets

600 wide

server cabinet

SR-E061120T

24 Nos

800 wide

server cabinet

SR-E081120T

1 set

800 wide

network

cabinet

SR-E081120T

1 set

Cabinet

Accessories

Cabinet side

panel

E-1120S

1 set

Vertical cable

management

panel

IRS-A-CV / E

12 sets

Windshield

side cabinet

/

2 sets

Rectangular

cable

management

unit

IRS-A-CR

16

Fixed light

load tray

IRS-A-SFL

24

1U Blind

IRS-A-B1

24 sets

2U blanking

plate

IRS-A-B2

24 sets

3U Blind

IRS-A-B3

24 sets

1U blind plate

with a brush

IRS-A-B1P

24 sets

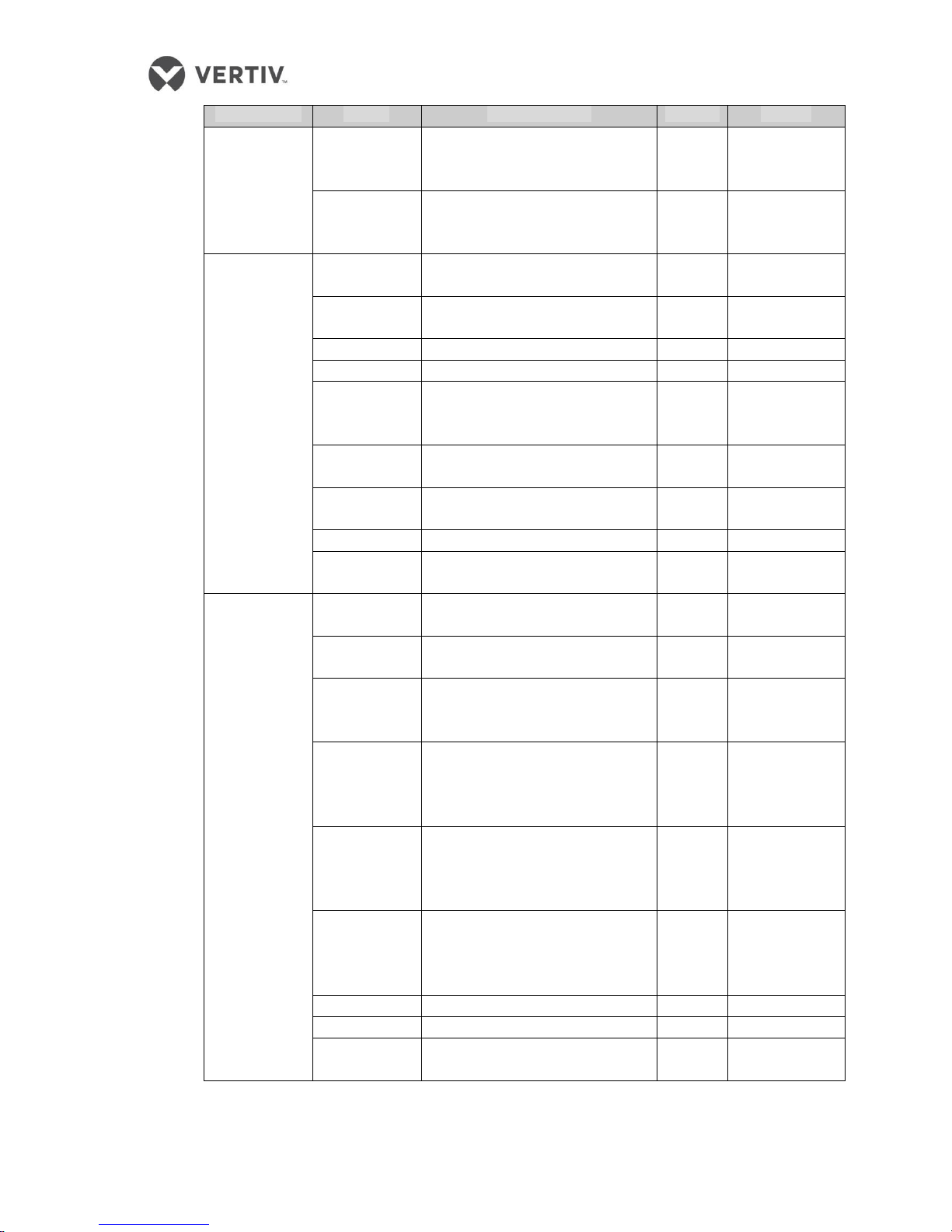

Classification

Project

Product number

Quantity

Remark

PDU

IRS-PL30NN32

46

Cooling

Indoor air

conditioning

unit

CR035RA138SS12E10000PV000

4

Air

Conditioners

LSF42-R3 – Option 1

4

Ambient

temperature

35 °C

LSF52-R3 – Option 2

4

Ambient

temperature

40 °C

LSF76-R3 – Option 3

4

45 °C ambient

temperature

Monitoring

Card

ES025RA SIC card assembly

4 pieces

Supply and

distribution

Distribution

Cabinet

/ 2

Channel

closed

Access door

SA-D1220SEY

1 set

600 open

skylight

SA-TR0612P

13

800 open

skylight

SA-TR0812P

1 item

SPM open

skylight

SA-TP0612P

1 item

The traces

Strong crosschannel

electrical

trunking

SA-WAQ121210

1 item

Weak trough

cross-channel

SA-WAR122610

1 item

Roof slot

width 600

SA-WR06103009

28

800 Roof

wide groove

SA-WR08103009

2 pieces

Base

600 wide

base

SA-SR061125

28

800 wide

base

SA-SR081125

2 pieces

The base

access door

SA-SD121125

1 set

Positioning

the base

member

SA-SF121125

6 pieces

Administration

Kit

Administration

Kit

SA-MP

1 set

Lighting Kit

SA-LP12C

1 set

Kit control

panel

SA-DP15

1 set

Classification

Project

Product number

Quantity

Remark

Management

and other

host

RDU-M

management

host

RDU-MI

1 set

Smart Device

Expansion

Card

IRM-4COM

1

Security

ID card

reader

CHD601S

2

IP Access

Controller

CHD806D2M3

1 set

ID card

RFID01A

10

Exit Button

EP68

2

ID card

dispenser

card

CHD603B-U

1

POE Network

HD IR Dome

ES-HND200-EI

2

Standard 8

NVR

ES-RN080201-C

1 set

2T hard disk

Seagate SV35.5-2T

2

POE Smart

Switch

H3C S2626-PWR

1 set

Engineering

materials (for

field)

Industrial

Connectors

IEC 60309 32A 1P

46 sets

Single phase

cables PDU

ZA-YJV

Several

Feeding rack

PDU

Air

conditioning

phase cable

ZA-YJV

Several

Air conditioning

power cable

Single-phase

power supply

line electric

door

ZA-YJV

Several

Electric gate

power cable

Cable

Cat6

Several

Communication

with the

monitoring

system

Control Cable

AWG

Several

Communication

with the

monitoring

system

Crystal Head

RJ-45

Several

Cable splicing

Cable tie

/

Several

Tie line with

Static flooring

600x600x32mm calcium sulfate

1 set

When there is

a base

Kit configuration management is described in Table 1-6.

Table 1-6

No.

product name

Product number

Quantity

1

Open controller

IRS-SA-CB

1

2

RDU-A G2

IRM-HOST2

1

3

8 digital / analog output expansion card

IRM-8DOAO

1

4

Temperature and humidity sensor

IRM-S02TH

6

5

Sound and light warning light

IRM-S01AN-B

2

6

Infrared Detectors

IRM-S01IN

1

7

Flooding tape - 10 m

IRM-S01W (10m)

2

8

4 digital input sensor

IRM-S04DI

1

9

Magnetic Roof state

IRM-S01DN-B

1

10

The top button open

IRS-CF-CS

2

11

The top button open the protective cover

IRS-CF-CC

2

12

Cable set top open

IRS-SA-SW

1

The Illumination configuration kit is described in Table 1-7.

Table 1-7 Illumination configuration kit

No.

product name

Product number

Quantity

1

Lighting Controller

IRS-SA-LB

1

2

Rocker

IRS-SA-LS

1

3

Lighting cable set

IRS-SA-LW

1

The Kit control panel configuration is shown in Table 1-8.

Table 1-8

No.

product name

Product number

Quantity

1

Control panel

IRS-SA-PN

1

2

Screen control cable set

IRS-SA-PW

1

Part II

Installation

2 Installation

In this section, info about installation tools, transportation, unpacking, inspection, installation

constraints and procedures will be explained in depth to enable users to get to grips with the

process.

The SmartAisle product is on the heavier side and there is a risk of severe injury if not

handled properly.

Read all the instructions carefully prior to unpacking, shifting, or installing the unit.

Wear sturdy safety helmets, gloves, shoes, and glasses while handling the equipment due to

sharp edges, objects, and buckles.

Prior to moving the equipment such as Cabinets, air conditioning, or the distribution utility,

measure the doorways, freight height, or the freight elevators to avoid damage to the stuff or

the building.

2.1 Installation Tools

Figure 2-1 shows the pictorial depiction of some of the generic installation tools.

Figure 2-1 Generic installation Tools

Table 2-1 Installation Tools

name

use

Utility Knife

Removing all kinds of packaging equipment

Phillips screwdriver

Tighten the screws when mounting the components

Small flat-blade

screwdriver

Install low-voltage terminal devices

Adjustable wrench

Adjust the various types of equipment feet

Socket wrench

Tighten the nut when installing the components

Level

Horizontal leveling control display

L Allen key

Hex bolts mounting the top plate

Line laser

Vertical projection, the level of the laser beam, verticalhorizontal adjustment device

Drill

Install the door frame on the ground

Rubber hammer

Structural parts mounting position fine adjustment tap

Pliers

Cutting the top plate rib hole modulus

ladder

Equipment installation height

2.2 Equipment handling, unpacking, inspection

Vertiv recommends rail or shipping for the product transportation. If road is the only option, choose

less bumpy roads to prevent equipment damage.

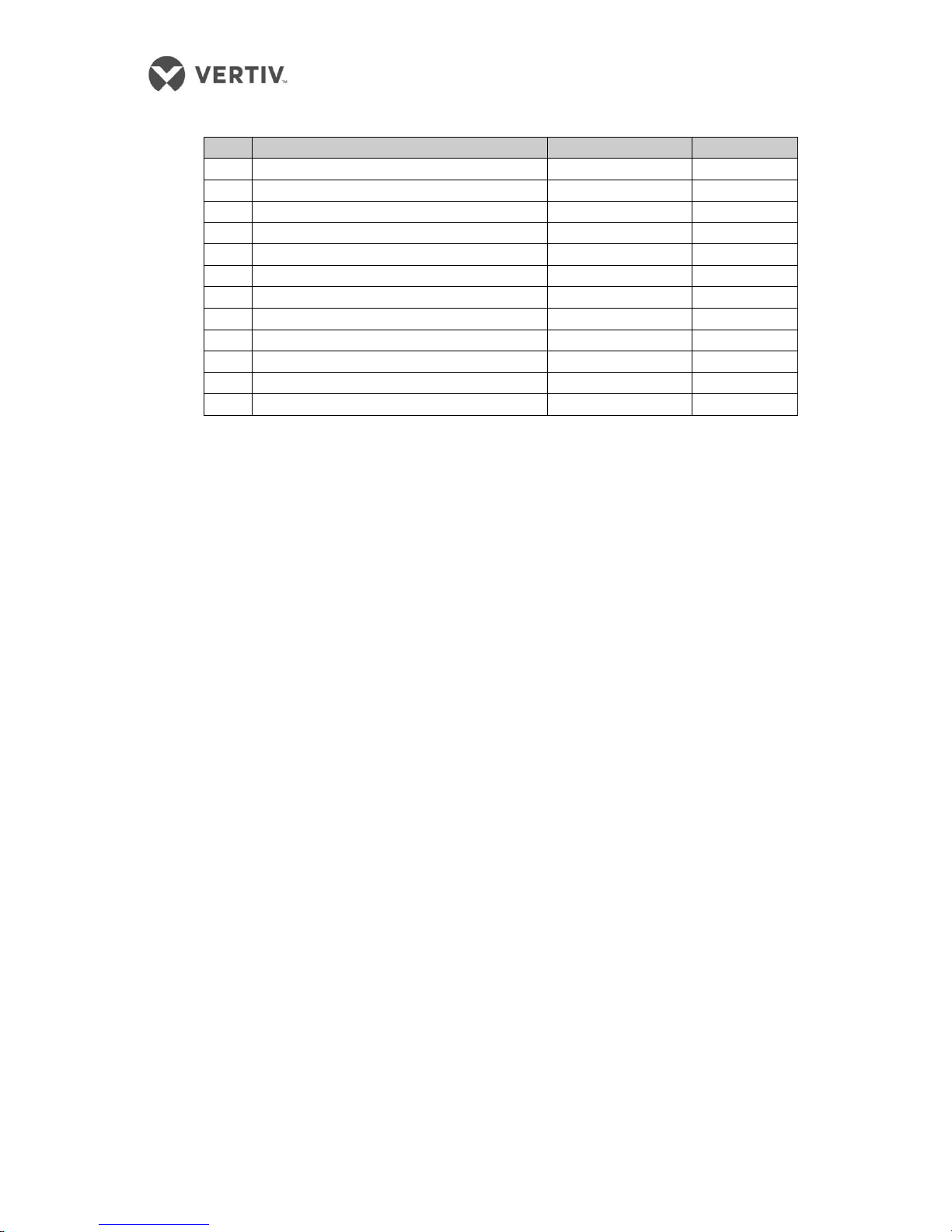

The size and weight of the package of each component is depicted in Table 2-2.

Table 2-2

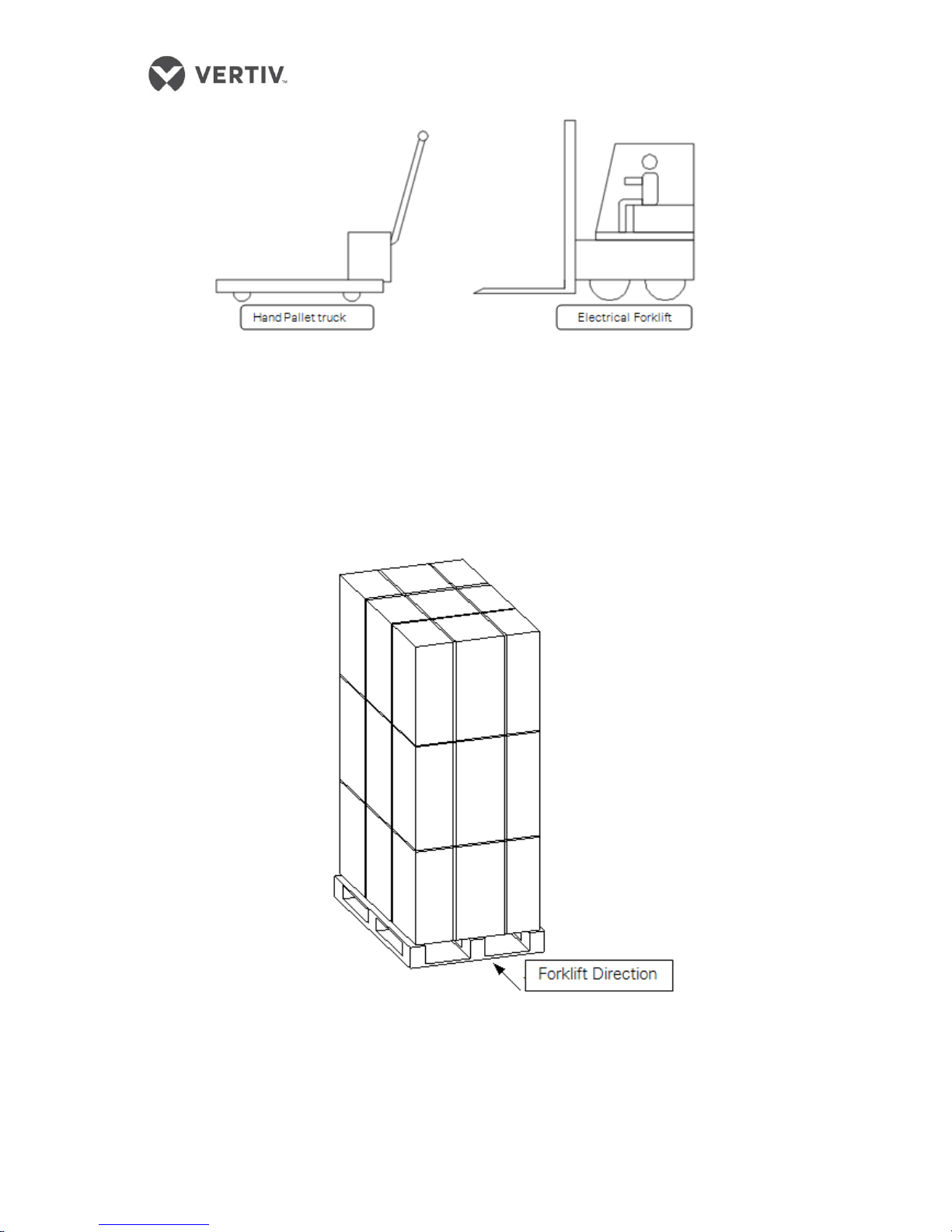

The components and parts need to be shipped to the vicinity of the installation site. Owing to the

heavy weight, use machines like a pallet jack or an electric forklift.

Figure 2-2 Forklift and hand pallet

While handling and unloading the equipment and cabinets, the center of gravity of the fork is to be

taken into consideration to prevent dumping or equipment damage.

Figure 2-3 Cross direction schematic view

While moving the components, the obliquity should be maintained at an angle of 80° to 100°

Figure 2-4 Inclination while transporting

The devices should remain upright; do not place the unit outdoors.

Use a forklift or a pallet jack with the adjustable fork arms open to the widest distance, so that

the device is placed just below the pallet. Further, ensure that the fork arm length matches the

length of the device.

Packaging material

All the material used in the packaging enclosure is re-cycleable. Either they can be retained for

future use or they can be disposed appropriately.

For China, the packaging is done in a carton box. For international locations, a wooden box is

utilized.

Following are the steps for unpacking the carton box:

The product package assembly should be done on an open, solid horizontal surface.

During disassembly, open the carton belt with a knife.

Remove the device carefully

Carefully, dismantle the film and packaging material on the product with a utility knife.

Following are the steps for unpacking the wooden box for international shipment:

The product package assembly should be done on an open, solid horizontal surface.

Using a hammer carefully and a screwdriver to dismantle the wooden packaging.

Remove the pallet

Carefully, dismantle the film and packaging material on the product with a utility knife.

Following the unpacking, confirm the parts and components by referring to the part checklist. If any

part is missing or damaged, it has to be immediately to the carrier. For concealed damage, inform

the local dealer or local Vertiv office immediately.

2.3 Installation Precautions

Following are the measures to be adhered prior to installation of the SmartAisle unit:

Close all the doors of the equipment and cabinets before using a forklift to lift the unit.

Measure and verify the installation site level prior to installation.

Confirm that charging operations are stalled and the installed power is disconnected before

installation.

For installation of indoor and outdoor air conditioning units, refer to the air conditioning

user manual

For installation of the distribution cabinet, refer to the specific user manual.

2.4 Installation Procedures

This section deals with the mechanical and electrical installation of the SmartAisle components.

Ensure that all the installation tools and accessories are in place before proceeding with the

installation process.

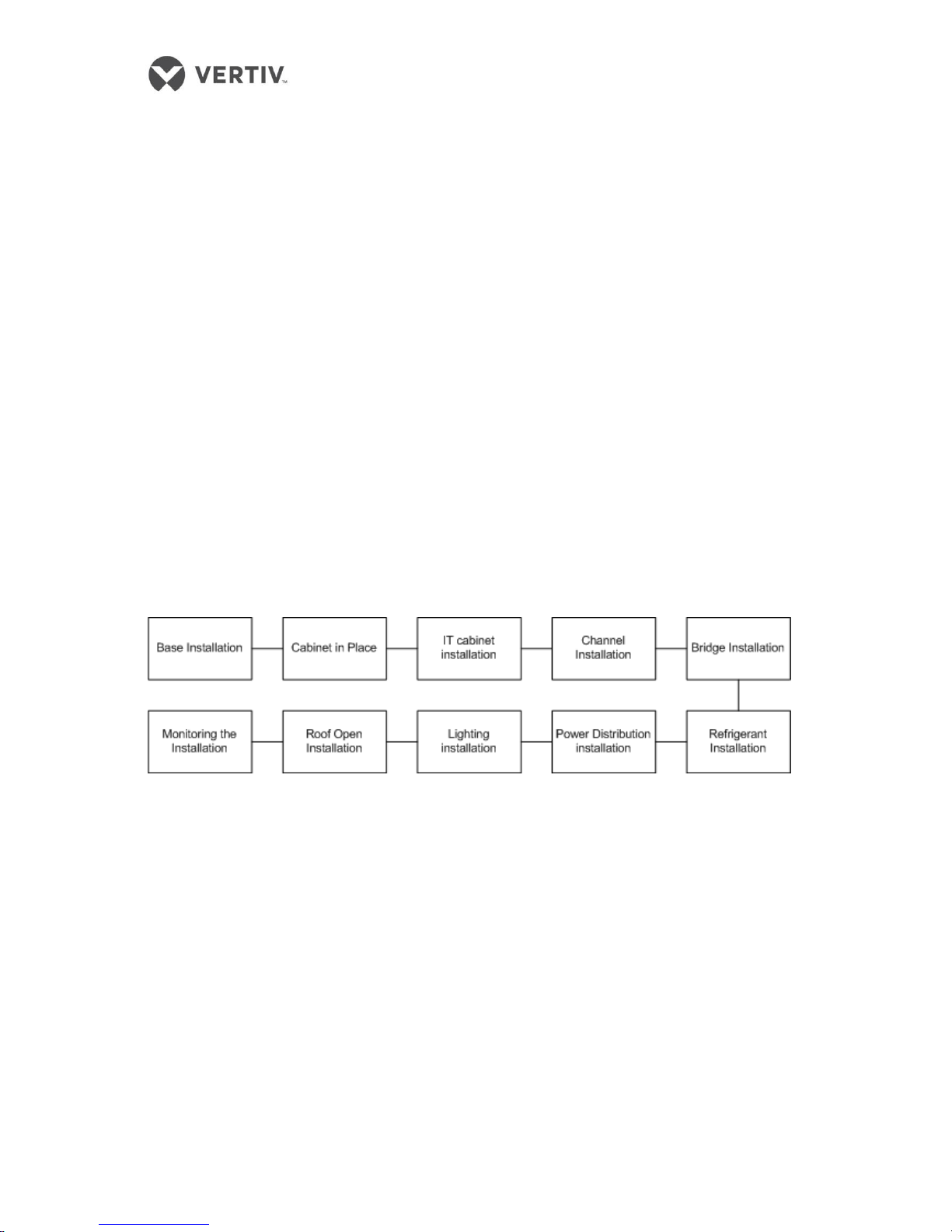

Following is the assembly flowchart for the installation process.

Figure 2-5 Assembly flowchart

S.No

Details of equipment

1

Base

2

Server Cabinet

3

Network Cabinet

4

Access door

5

Top Plate

6

A/C Column

7

Distribution Cabinet

8

Strong wire passage groove

9

Power cable trunking; copper

and fibre cable tray

11

Control panel

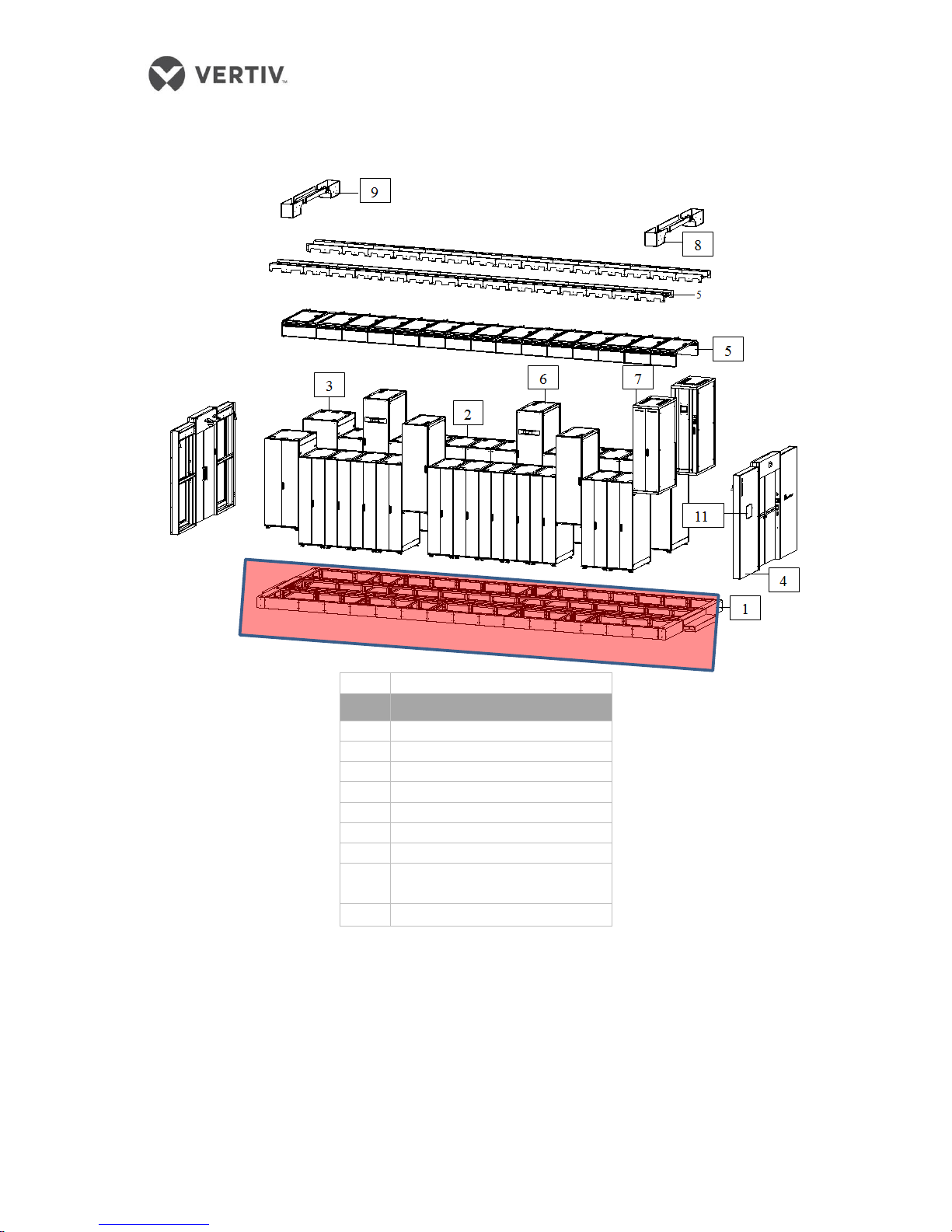

2.4.1 Installation of the base

If the base is already installed, then users can skip this section and goto section 2.4.2.

Splicing the base

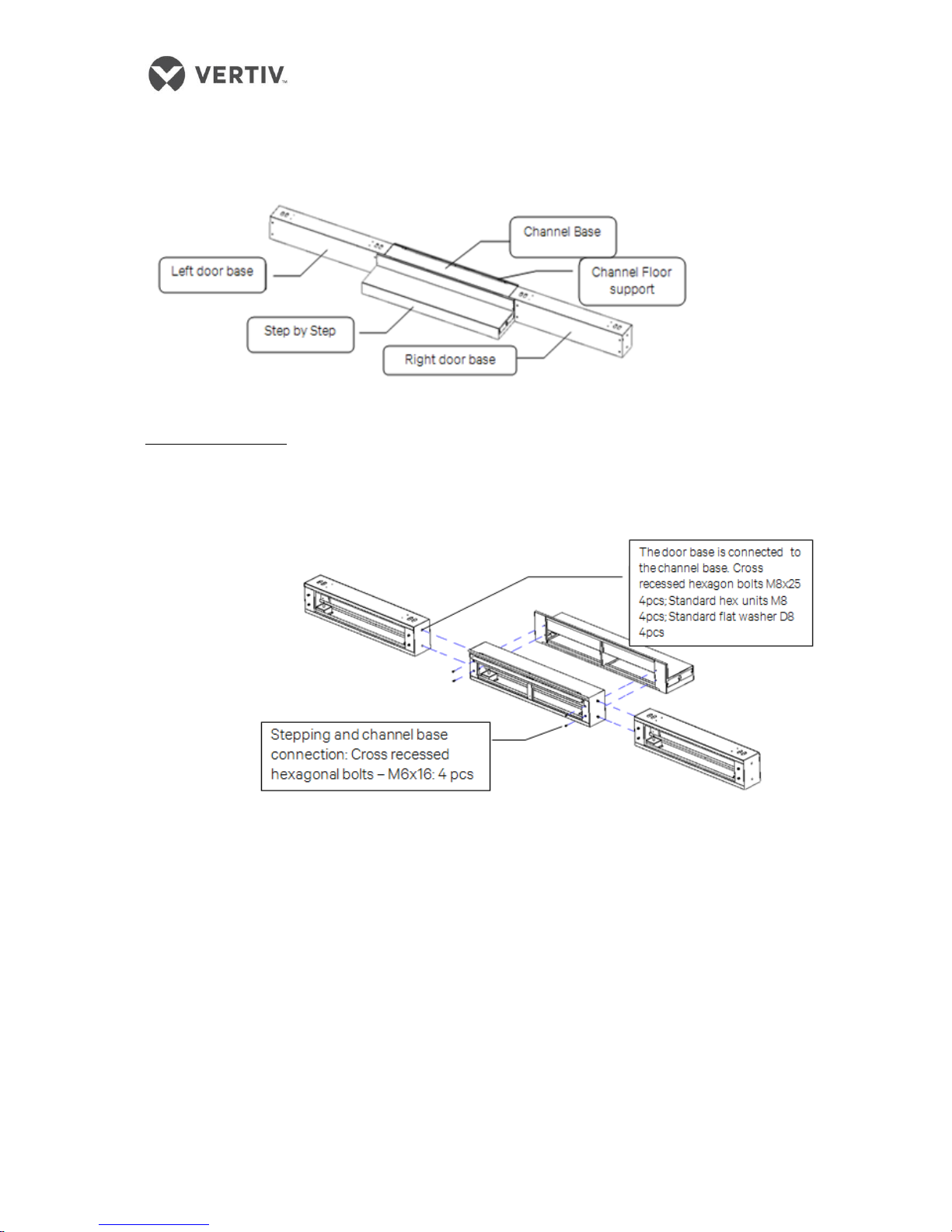

Figure 2-6 shows the base assembly, cabinet base, and the limiting position assembly process.

S.No

Details of equipment

1

Base

2

Server Cabinet

3

Network Cabinet

4

Access door

5

Top Plate

6

A/C Column

7

Distribution Cabinet

8

Strong wire passage groove

9

Power cable trunking; copper

and fibre cable tray

11

Control panel

Figure 2-6 Base schema

The three parts connected and coupled in steps are the door susceptor by a channel base and the

left and right channels of the base door as shown in Figure 2-7.

Figure 2-7 Door comprising the base

Door Assembly base

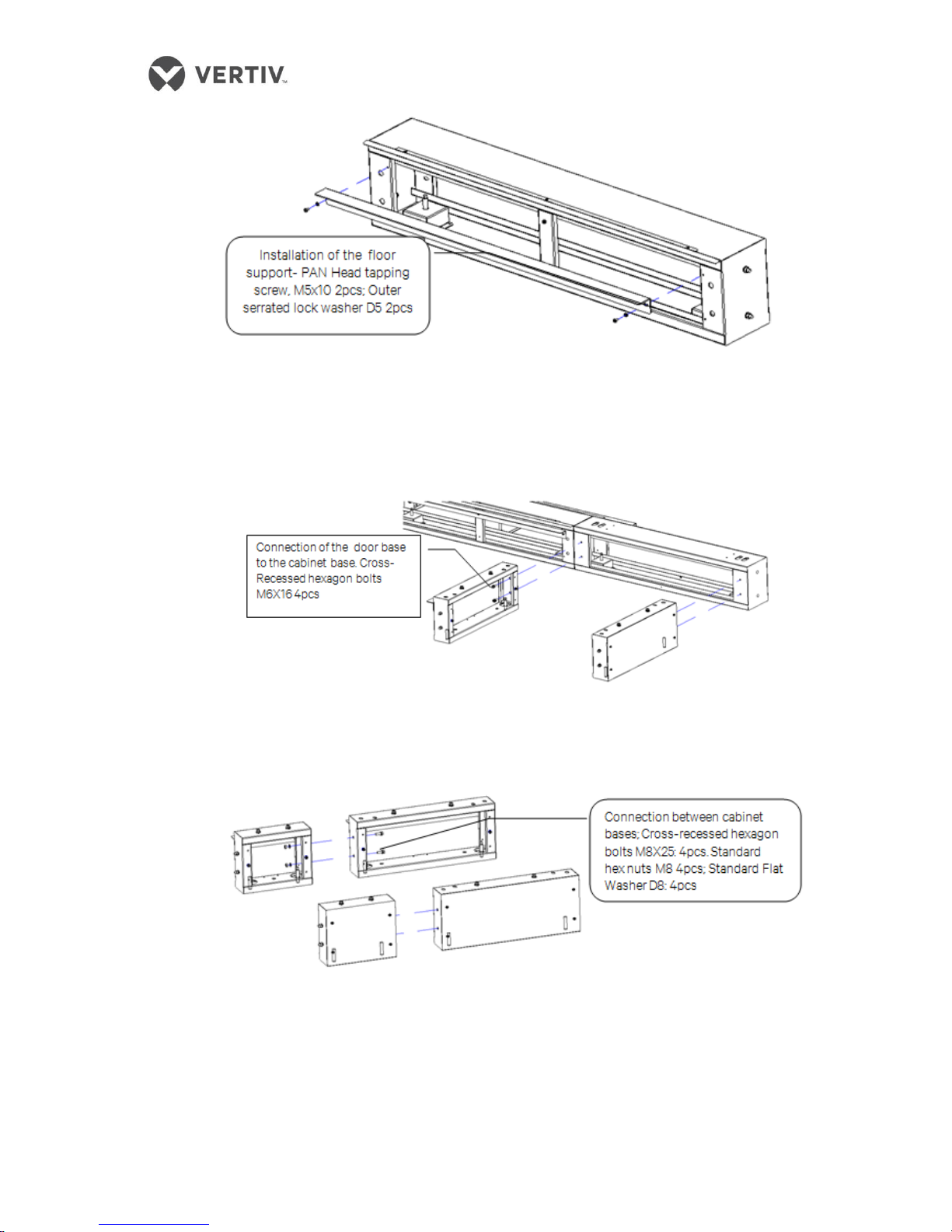

Figure 2-8 shows the base assembly with a door fastener.

Figure 2-8 Door assembly base

Base is mounted inside the channel floor support.

Figure 2-9 shows the support member mounted within the floor channel.

Figure 2-9 A support member mounted within the floor channel

The cabinet base is connected to the base of the door pocket and the channel base of the

cabinet is connected to the installed floor-side support member with the same base door.

Figure 2-10 Base connected to the base of the cabinet door

The connection between the base of the cabinet includes using bolts and nuts as shown in

Figure 2-11:

Figure 2-11 The connection between the base of the cabinet

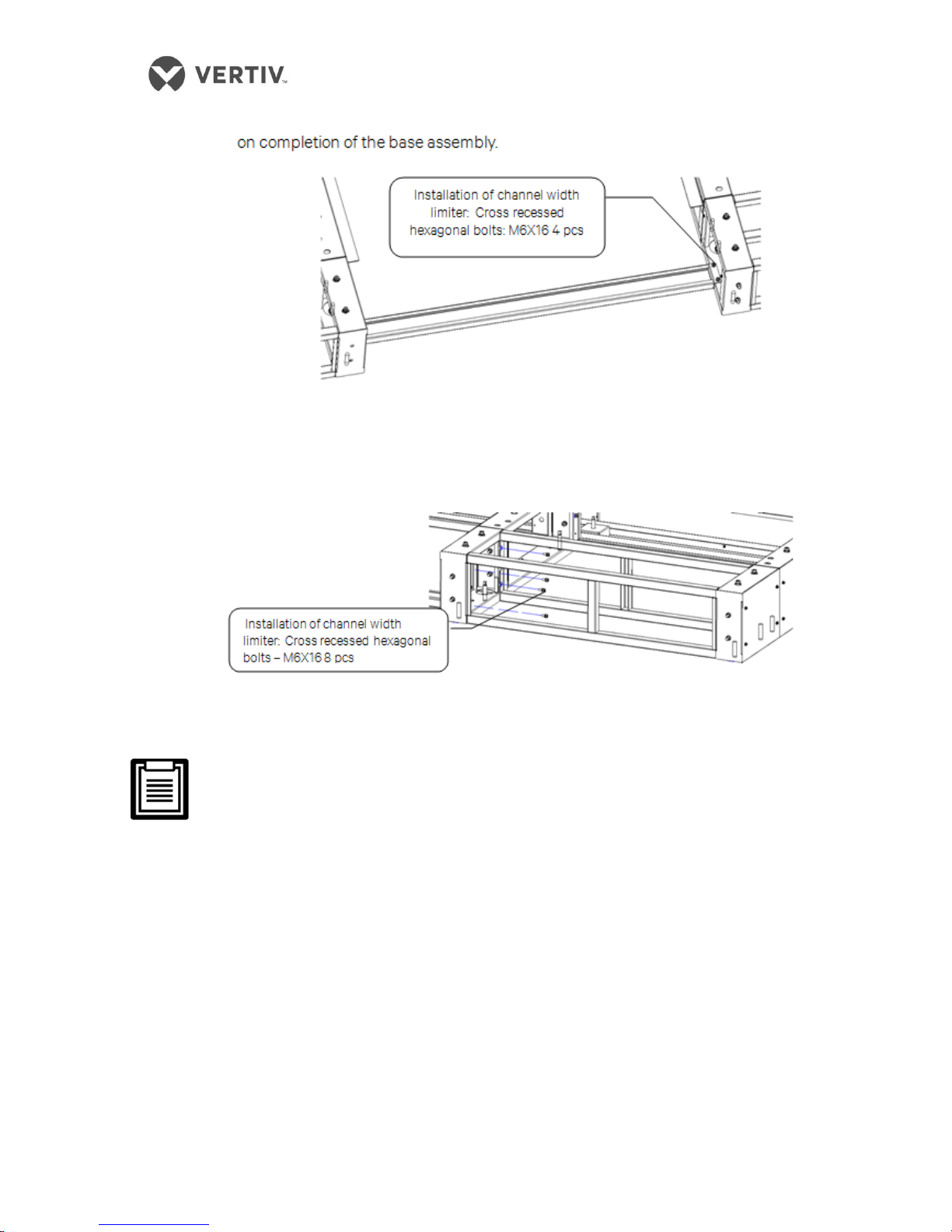

While mounting channel width of the stopper member, the channel width stopper base of

the cabinet in two rows ensure a pitch of 1200mm. The base of the cabinet is connected to

two rows of the stopper member as shown in Figure 2-12. Limit the equidistant positioning

member mounted in the base assembly as much as possible on completion of the base

assembly.

Figure 2-12 Mounting channel width of the stopper member

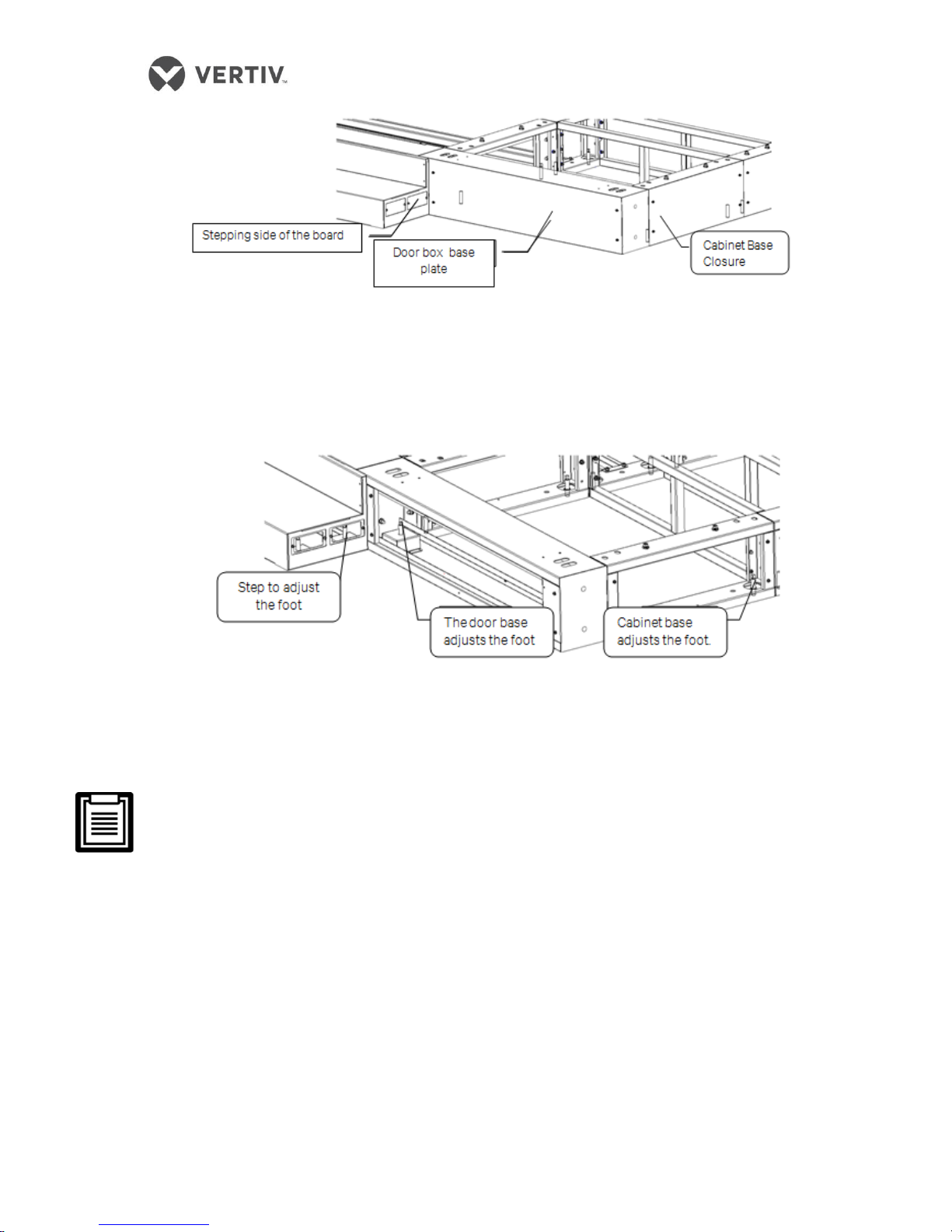

Installing the cabinet depth stop element is done to ensure consistency and depth of the

cabinet base is in the specified position with that of the cabinet depth.

Figure 2-13 Installation cabinet depth stop element

Stopper must be installed; if a stopper is not installed and that leads to quality issues,

the warranty is void as the customer is responsible for it.

Stopper must be installed at each distribution cabinet as well as the base of the air

conditioner to facilitate ease of installation

Fasteners are not consequential around the base.

2.4.2 Leveling the base

Figure 2-14 shows the removal of the outer base closure plate:

Figure 2-14 Leveling the base of the closure plate to be torn

Swing the wrench to the base leveling foot as shown in Figure 2-15:

Figure 2-15 Base tone flat feet

The nuts and bolts shall be protruding out at their maximum depth throughout the fastener

base

Levelling the base must be done using a line levelling laser and not on visual

inspection by the installation personnel

The base must be leveled to meet the cabinet and subsequent installation of a closed

system. If quality issues are caused due to uneven surface, the customer is

accountable as leveling is mandatory.

2.4.3 Fixing the base

A base is connected to ground through a fixed orifice. A predetermined ground base fixing hole and

ground connection is recommended if there are seismic requirements in the room.

2.4.4 Pre conduit arrangement

The layout diagram of the indoor air conditioning unit is prearranged within the base line and ample

length is allowed.

Loading...

Loading...