Page 1

Liebert® iCOM™

Installer/User Guide

Intelligent Communication and Monitoring for Liebert XDU

Page 2

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.Vertiv.com/en-us/support/ for additional assistance.

Vertiv | Liebert® iCOM™Instal ler/User Guid e

Page 3

TABLE OF CONTENTS

1 Getting Started with Liebert® iCOM™ 1

1.1 Touchscreen Display and User Interface 1

1.2 Touchscreen Status Dial 3

1.2.1 Dial Background Color Status Indication 4

1.3 Control Header 4

1.3.1 Powering On the Liebert® iCOM™ and Logging In/Unlocking Controls 5

1.3.2 Powering On the Thermal Management Unit 5

1.3.3 Powering Off the Thermal Management Unit 7

1.3.4 Logging Out 7

1.3.5 Setting the Date and Time 7

1.3.6 Searching 8

1.4 Using Context Sensitive Help 8

1.5 About Liebert®iCOM™ Version 8

1.6 Accessing the User, Service, and Advanced Menus 9

1.7 User Menu 9

1.7.1 User Menu Options 9

1.8 Service Menu 10

1.8.1 Service Menu Options 10

1.9 Advanced Menu 11

1.9.1 Advanced Menu Options 11

2 User Operation 13

2.1 Viewing and Editing Setpoints for the Cooling Unit 13

2.1.1 Editing Temperature Setpoints 13

2.2 Viewing Unit Alarms 14

2.2.1 To View Alarms 14

2.2.2 Silencing an Audible Alarm 15

2.2.3 Acknowledging Alarms 15

2.3 Viewing the Event Log 16

2.4 Viewing Sensor Data 16

2.5 Managing Run Hours for a Component 16

2.5.1 Setting Run Hours to Zero 16

3 Service Operation 17

3.1 Editing Setpoints for the Cooling Unit 17

3.1.1 Setpoints Options 17

3.2 Pump Control 17

3.2.1 Configuring Pump Setpoints 17

3.3 XDU Fan Control 18

3.3.1 Configuring Fan Setpoints 19

i

Page 4

3.4 XDU Pump Lead/Lag Control 20

3.5 XDU Pump Monitoring 20

3.6 XDU Loss of Flow Control 20

3.7 Setting General Thermal Management Unit Options 20

3.7.1 Setting Miscellaneous Options 21

3.8 XDU Quick Start 22

3.8.1 Configuring Quick Start 22

3.8.2 Setting Fan Options 23

4 Managing Events: Alarms,Warnings,andMessages 27

4.1 Event Properties 27

4.1.1 Alarms and Events Panel Fields 27

4.2 Enabling Events and EditingEventSettings 28

4.3 Selecting Event Type and SettingAlarm/WarningNotification 28

4.3.1 Notification Properties 29

4.4 Enabling the Audible Alarm Notification 31

4.5 Remote Alarm Device and Customer Input Events 31

4.5.1 Setting Up Customer Input Events 31

5 External Monitoring andBuilding ManagementSystems 33

5.1 BMS and IntelliSlot Settings 33

5.1.1 Configuring BMS Communication with Embedded Unity 33

5.1.2 Setting BMS Control Settings 34

5.1.3 Setting BMS Backup Setpoints 35

5.2 Communication Setup with Embedded Unity 35

5.2.1 Connecting to the BMS 36

5.2.2 Embedded Unity User and Password 38

5.2.3 Unity Restart and Restore Defaults 39

5.2.4 System Configuration 39

5.2.5 Local Users Configuration 41

5.2.6 Network Configuration 42

5.2.7 Web Server Configuration 45

5.2.8 Remote Services Configuration 47

5.2.9 Velocity Protocol Configuration 50

5.2.10 Messaging Configuration 51

5.2.11 BACnet Protocol Setup 56

5.2.12 Modbus Protocol Setup 59

5.2.13 SNMP Protocol Setup 61

5.3 Unity Status Readings 66

5.4 Unity Support Information 66

5.4.1 Support Folder Settings 66

5.4.2 Configuring Active Networking Settings 68

ii

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 5

6 Configuring Auxiliary Devices 71

6.1 Power Monitoring 71

6.1.1 To Setup Power Monitoring 71

7 Administering Firmware, Settings and Security 73

7.1 Liebert® iCOM™ Firmware Upgrades 73

7.2 iCOM Firmware Upgrades 73

7.2.1 Compatibility with Earlier Versions of Liebert®iCOM™ 73

7.2.2 Updating Liebert® iCOM™ Control Board Firmware 73

7.2.3 Reverting to Firmware in Dormant Partition 75

7.3 Backing Up and Restoring Control Board Settings 75

7.3.1 Control Board Back Up and Restore Options 76

7.4 Managing Access Permission and Passwords 76

8 Performing Diagnostics 77

8.1 Cooling Unit Status LED 77

8.2 Enabling Manual Mode for Diagnostics 77

8.2.1 Disabling Diagnostics Manual Mode 78

8.3 Diagnosing Evaporator Fan Issues 78

8.3.1 Diagnostics—Evaporator Fan Options 78

8.4 Diagnosing Digital Output Issues 79

8.4.1 Diagnostics—Digital Output Options 79

8.5 Diagnosing Analog Output Issues 79

8.5.1 Diagnostics—Analog Output Options 79

8.6 Diagnosing Customer Input Issues 80

8.6.1 Diagnostics—Customer Input Options 80

8.7 Diagnosing Water Leak Detection Issues 80

8.7.1 Diagnostics—Water Leak Detection Options 80

9 Customizing the Liebert® iCOM™ Display 81

9.1 Setting General Display Properties 81

9.1.1 Unit Display Options 81

9.2 Customizing Main Display Views 82

9.2.1 Moving Content 82

9.2.2 Resizing Content 82

9.2.3 Adding and Adjusting Content 83

9.2.4 Removing Content 84

9.3 Customizing Parameter and Field Labels 84

9.3.1 Exporting, Importing, and Customizing Labels Using a Text Editor 86

10 Hardware 89

10.1 Fluid Temperature Sensor 89

10.2 Inlet and Outlet Air Sensors 89

10.3 Liebert® Liqui-tect Leak Detection 89

iii

Page 6

10.3.1 Point Leak-Detention Sensor 89

10.3.2 Zone Leak-Detection Sensor 89

Appendices 91

Appendix A: Technical Support and Contacts 91

Appendix B: Setpoints and Alarm Settings by Line ID 93

iv

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 7

1 GETTING STARTED WITH LIEBERT® iCOM™

The Liebert® iCOM™ offers the highest capability for unit control, communication, and monitoring of Liebert® thermal

management units. It is available factory installed on new units and assemblies or may be retrofitted in existing units.

1.1 Touchscreen Display and User Interface

The Liebert iCOM touchscreen and user interface speeds set up and installation and simplifies control of Liebert® thermal

management units, literally putting cooling system monitoring and management at your fingertips.

• The resistive touchscreen is used with a firm touch, or consider using a stylus when interacting with the

touchscreen.

• User and service menus are password protected to prevent unauthorized changes to cooling unit operation.

• The touchscreen is back lit and auto-dims after a period on non-use, then turns off. Touch the screen to

illuminate the main screen.

• iCOM ships with default settings for efficient and effective operation of most cooling units and is easily

configured to meet any need.

• iCOM menus and displays are based on the options installed on the cooling units that it monitors and manages.

1

Page 8

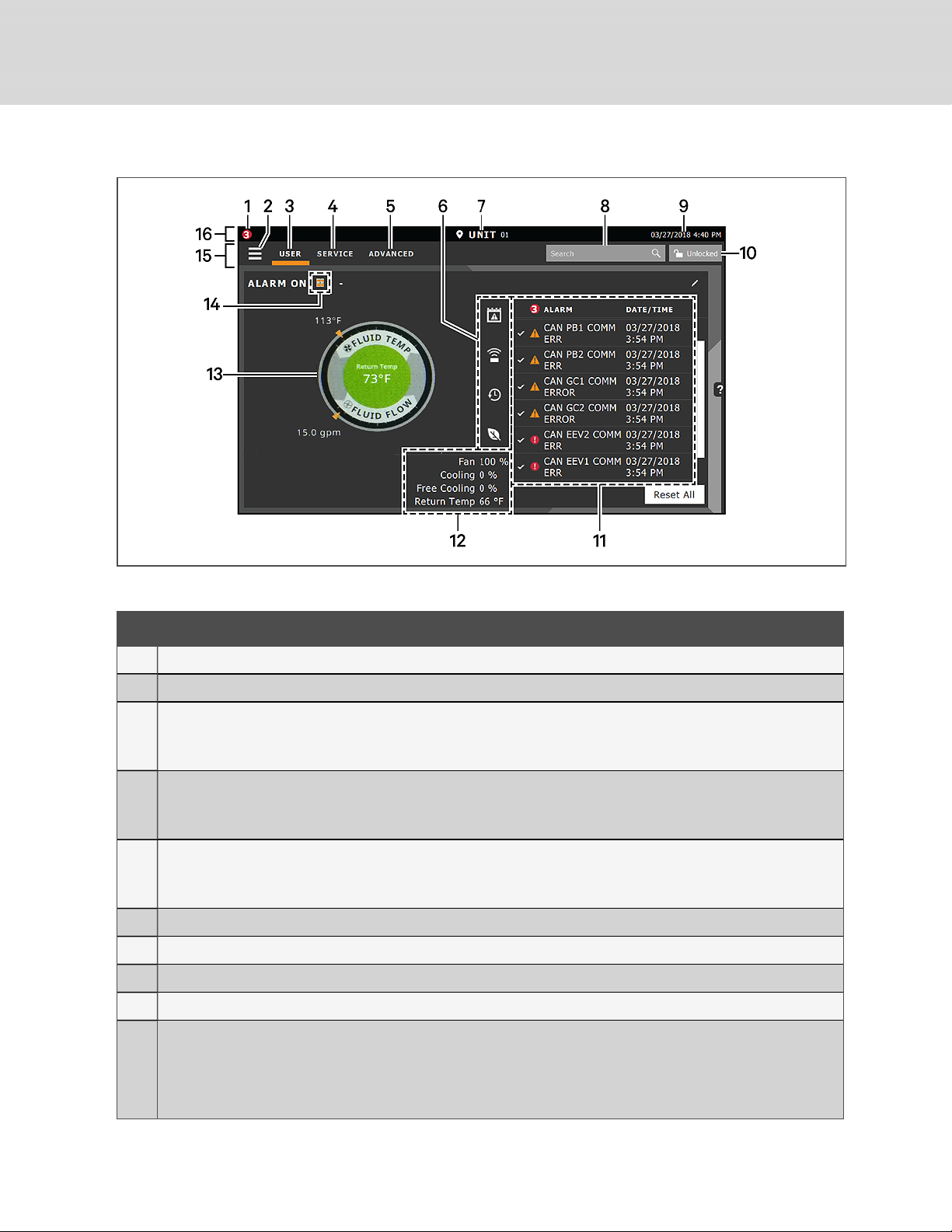

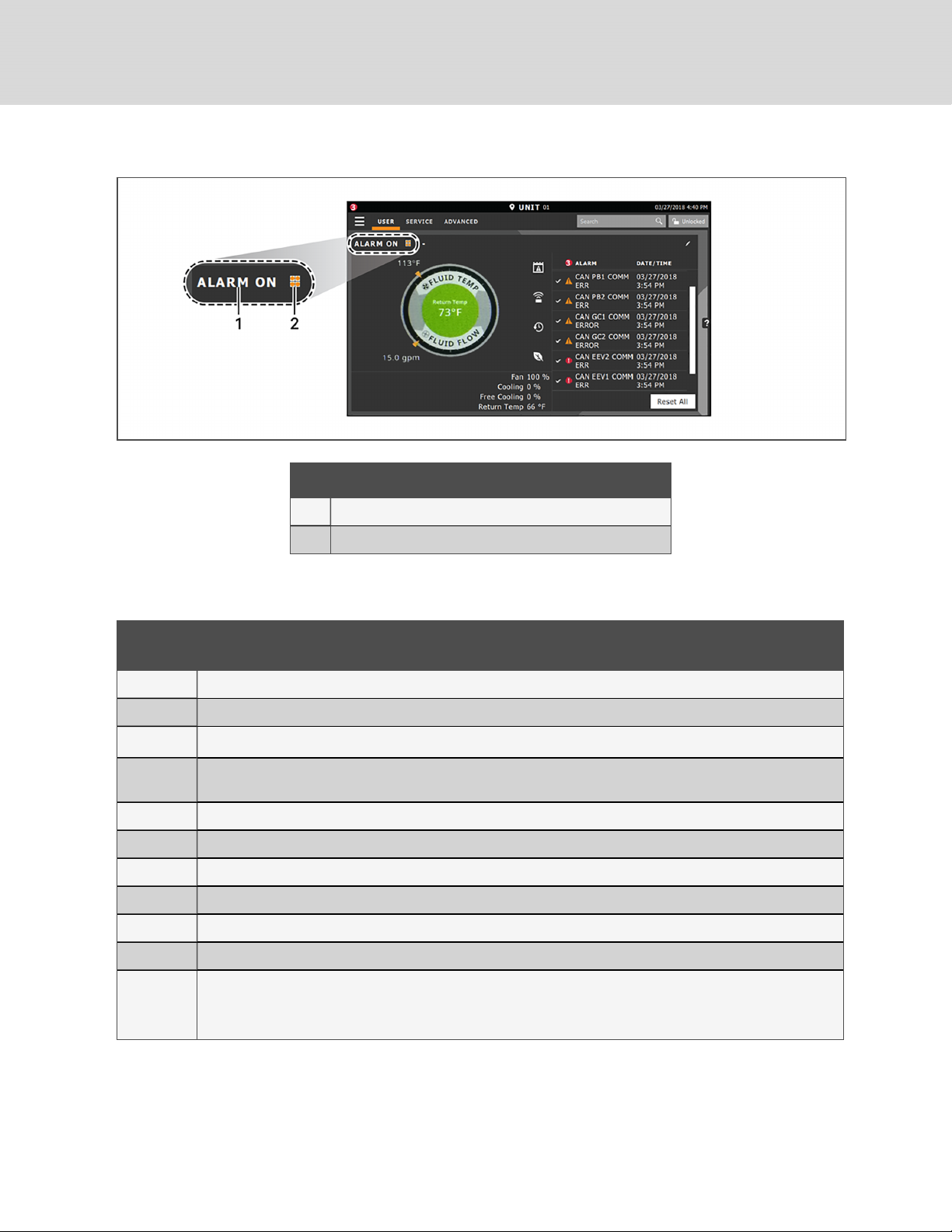

Figure 1.1 Liebert® iCOM™ Main Display

Table 1.1 Main Display Controls and Options

Item Description

1 Alarms present. Displays the number of active alarms.

2 Menu icon. When unlocked, displays a menu for user or service options depending on which icon is selected.

User icon. When selected, the user optionsare available on the m ain display and menu.

3

NOTE: You must unlock the display with the User PIN to acces s the menu and options.

See Powering On the Liebert® iCOM™and Logging In/Unlocking Controls on page5.

Service icon. When selected, the service options a re a vailable on the m ain display and menu.

4

NOTE: You must unlock the display with the Service PIN to access the menu and options.

See Powering On the Liebert® iCOM™and Logging In/Unlocking Controls on page5.

Advanced icon. When selected, the advanced optionsare available on the main display and menu.

5

NOTE: You must unlock the display with the Service PIN to access the menu and read-onlyoptions.

See Powering On the Liebert® iCOM™and Logging In/Unlocking Controls on page5.

6 Cooling unit parameters. Status display of selected system param eter settings. See Adding and Adjusting Content on page83

7 Unit Identification. You may customize the unit name up to six characters/numbers.

8 Search icon. O pen the keyboard to search for controls a nd setting loca tions. See Searching on page8.

9 Date/Time.

Lock/Unlock icon. Indicates whether or not the user and service optionsare accessible.

10

• Locked icon: display is read-only.

• Unlocked icon: user or service is logged in and options are accessible.

See PoweringOn the Liebert® iCOM™ and Logging In/Unlocking Controlson page5.

2

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 9

Table 1.1 Main Display Controls and Options (continued)

Item Description

11 Secondary content panel. When accessingsettings/configuration via the menus, the settings display in the right, secondary panel.

Summary of current unit function. You can customize to showfan speed, cooling, percentages from any installed device, and any physical

12

(sensor) values.

13 Status Dial. Circular display of setpointsand environmental conditions of the unit. See Touchscreen Status Dial below.

Teamwork mode icon. In a panel with Status content, the Teamwork Mode icon indicates the mode selec ted. For details and descriptions of the

14

teamwork controls, see Team work Modes.

15 Control header. Controls to access the user and service m enus. See Control Header on the next page.

16 Status Header. Displays the alarm status, unit identification, and the current date and time.

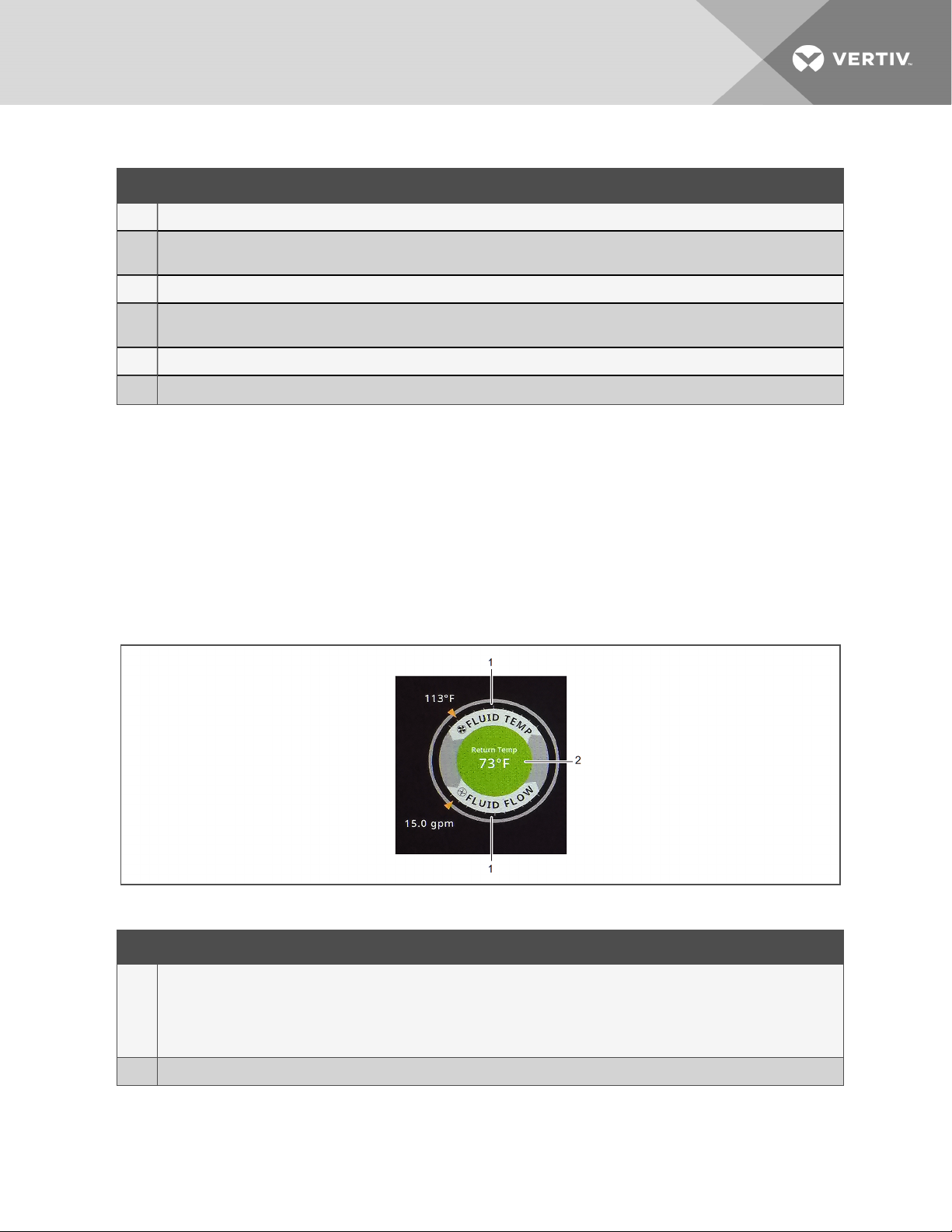

1.2 Touchscreen Status Dial

The dial in the primary control panel displays read-only control sensors, setpoints, and environmental conditions for unit

status at a glance. See Figure 1.2 below.

The center of the dial displays sensor readings and changes color according to alarm thresholds as the readings rise and

fall. See Dial Background Color Status Indication on the next page.

Touching the center of the dial cycles through a set of sensor settings, and you can select the readings displayed. See

Adding and Adjusting Content on page83.

Figure 1.2 Dial Sections

Table 1.2 Dial Sections

Item Description

Control sensor and its setpoint. The sensors and setpoints displayed depend on the configuration of y our unit.

You may see only temperature control, or if the unit includes humidity control, that displays on the dial as well.

1

If the sensor selected for fan control is the same as that selected for temperature control, the dial displays the fa n control sensor and setpoint, as

shownin Figure 1.2 above.

2 Single or multiple sensor readings. Cycle through readings by touching the displayed reading.

1 G ettin g Started with Liebert® iCOM™

3

Page 10

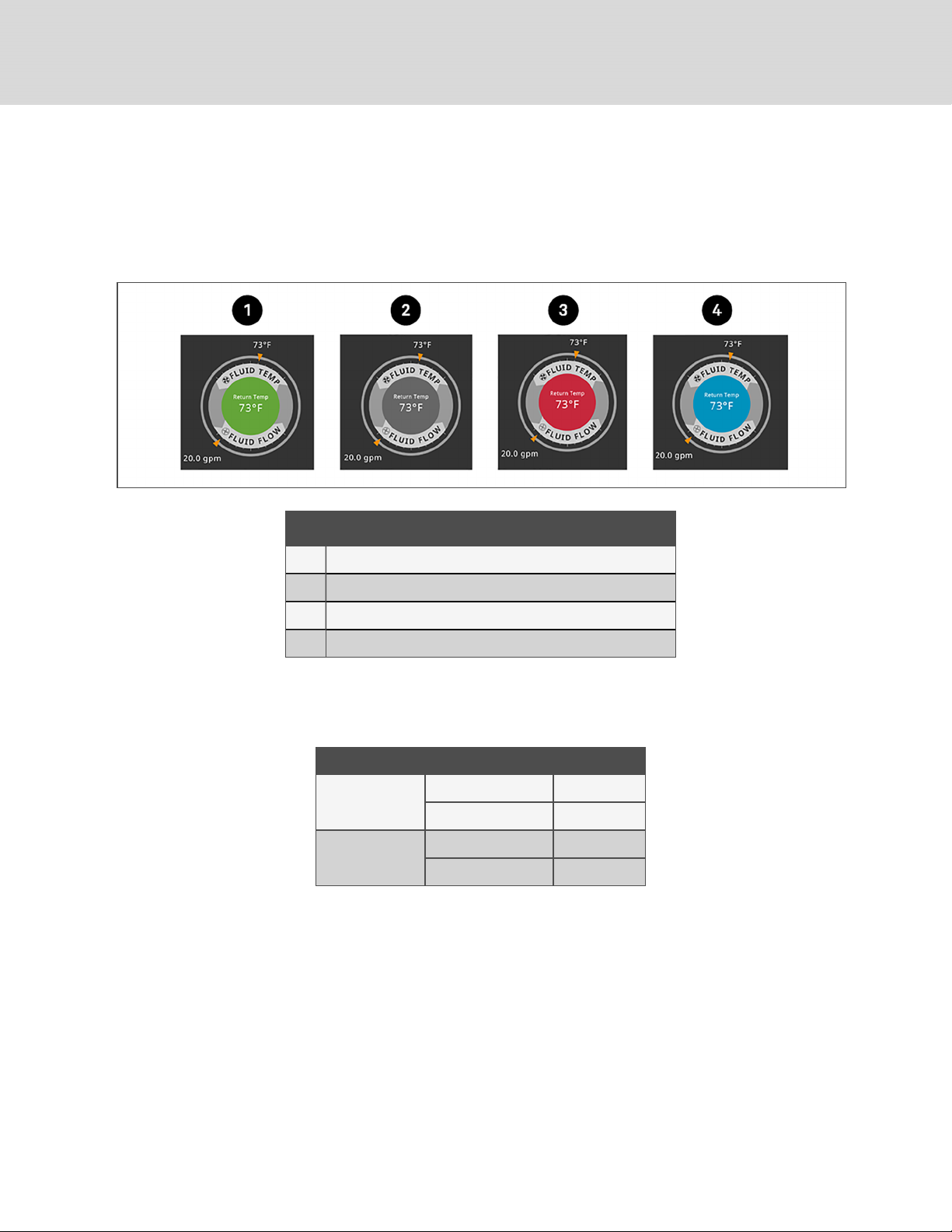

1.2.1 Dial Background Color Status Indication

The background color of the dial indicates whether or not the unit is powered on, and it also responds to threshold settings

of the control sensor reading. See Figure 1.3 below. Table 1.3 below describes the background color displayed if the

selected sensor reading has threshold limits set.

Figure 1.3 Dial Background Colors

Item Description

1 Sensor reading is within threshold limits..

2 Unit is powered off.

3 Sensorreading is above thresholdlimit or the unit is in an alarm condition.

4 Sensor reading is below threshold limit.

Table 1.3 Background Color Displayed by Selected

Value and Threshold Limit

Sensor/Value Selected Threshold Limit Backgroun d Colo r

Return Temp

Supply Temp

None Blue

High return temperature Red

Low supply temperature B lue

High supply temperature Red

1.3 Control Header

The control header contains the controls to access the user and service settings. The display is locked when started initially

and when restarted after a period of inactivity.

4

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 11

1.3.1 Powering On the Liebert® iCOM™ and Logging In/Unlocking Controls

Liebert® iCOM™ is powered on when power is switched on at the cooling unit’s disconnect switch and you activate the

display by touching it.

iCOM is locked when started and also locks after a period of inactivity to prevent unauthorized changes. A four- digit

password is required to access the user and service menus and options, and the advance menu displays as read-only when

logged in at the service level.

NOTE: The factory default inactivity period is one minute. To change the inactivity period, see Customizing Main

Display Views on page82.

NOTE: The factory default password for user and service log in are provided. We recommend you change passwords

as necessary to prevent unauthorized changes. See Managing Access Permission and Passwords on page76.

• Default user password: 1490

• Default service password: 5010

To unlock the controls:

1. On the header, touch .

The keypad opens.

2. Touch the numbers/characters for your password, then touch .

Depending on the password entered and your level of access, the User and/or Service options and view only

access to the Advanced menu are accessible. See Accessing the User, Service, and Advanced Menus on

page9.

1.3.2 Powering On the Thermal Management Unit

NOTE: Depending on the operating state, there are start and stop priority switches that may prevent the cooling unit

from operating even though power to the unit is switched on and you have turned it on via Liebert® iCOM™.

The cooling unit operates only when all switches are closed. For example, even though you have turned on the unit

through iCOM, if the BMS remote monitoring system is sending a command to turn off the unit, the cooling unit

remains off.

NOTE: You must be logged in to access the menu options. See Powering On the Liebert® iCOM™ and Logging

In/Unlocking Controls above.

To power on the unit:

1. Touch , then >Turn Unit On. The TURN UNIT ON dialog opens.

2. Touch Turn Unit On. The cooling unit starts and the operating status is displayed as shown in Figure 1.4 on the

next page.

1 G ettin g Started with Liebert® iCOM™

5

Page 12

Figure 1.4 Unit Status On Liebert® iCOM™ Display

Item Description

1 Current status of the unit. See Table 1.4 below.

2 Teamwork icon. See ViewingTeamwork, Standby, andCascade Status.

Table 1.4 Cooling Unit Statuses Displayed

Unit Status

Text

ALARM OFF An alarm forced the unit to turn off. See Viewing Unit Alarms on page14.

MANUAL Controlled by a service technician. See Enabling Manual Mode for Diagnostics on page77.

DISPLAY OFF

ALARM

STANDBY

STANDBY In standby because of service menu setting. See Assigning Cooling Units to Standby (Lead/Lag).

TIMER OFF Scheduled on a timer and is in sleep mode waitingfor the next start interval. See Scheduling Condenser and Cooling Unit Tasks.

UNIT ON O perating normally without alarms or warnings.

WARNING ON Active warning, but still operating. See ViewingUnitAlarms on page14.

ALARM ON Active a larm, but still operating. See Viewing Unit Alarms on page14.

TIMER Scheduled on a timer to operate, and is in operating mode. See Scheduling Condenser and Cooling Unit Tasks.

REMOTE OFF

Description

Unit is turned O ff at the iCOM display. See Powering On the Thermal Management Unit on the previous page.

In standby because of a n active alarm on the unit. See Viewing Unit Alarms on page14.

Turned off by remote shutdown terminal.

Occurs when a normally closed set of 24V contacts opens. The Rem ote On/Off and Display On/Off switches are in series, and the cooling

unit will only turn on if both switches are on/closed. If one is off/open, the unit turns off.

6

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 13

Table 1.4 Cooling Unit Statuses Displayed (continued)

Unit Status

Text

MONITORING

OFF

BACK-DRAFT Unit is non-operational, but EC fan is operating as a back-draft damper.

RESTART

DELAY

Description

Turned off by remote monitoring system.

Check the remote m onitoringdevice or call Vertiv technical support for assistance.

Not yet operational after a power c ycle because the restart delay timer is active.

1.3.3 Powering Off the Thermal Management Unit

NOTE: You must be logged in to access the menu options. See Powering On the Liebert® iCOM™ and Logging

In/Unlocking Controls on page5.

1. Touch , then >Turn Unit Off. The TURN UNIT OFF panel opens.

2. Touch Turn Unit Off. The unit begins a power off countdown and then powers off.

1.3.4 Logging Out

Log out occurs automatically when the display back light turns off for inactivity.

NOTE: The factory default inactivity period is one minute. To change the inactivity period, see Setting General Display

Properties on page81

• To log out manually, touch the lock icon. The icon indicates locked.

1.3.5 Setting the Date and Time

The correct date and time is critical for warnings, alarms, and scheduling.

1. Touch , then > Display Options > Display Properties > Date &Time.

2. Touch the date field, use the arrows to select the date, and touch OK.

– or –

Touch the time field, use the arrows to set the time, and touch OK.

3. Select the date and time format if necessary.

4. Touch Save.

1 G ettin g Started with Liebert® iCOM™

7

Page 14

1.3.6 Searching

When logged in, you can use the display search to find the location of settings options based on a term, service code, or

parameter. You can also search by the line ID used in the iCOM™ before the touchscreen model. For a listing of the line IDs,

see Setpoints and Alarm Settings by Line ID on page93.

NOTE: You must be logged in to access the display search. See Powering On the Liebert® iCOM™ and Logging

In/Unlocking Controls on page5.

1. In the control header, touch the search field. The keyboard opens.

2. Type the term and touch . A list of locations that contain the searched term opens.

3. To go to a listed location, touch an item, then touch Go. The panel for the selected location opens.

– or –

To view the service codes and parameter entries related to the searched term, touch View Parameter Directory

Entries (the number of related entries is included in the option). The Parameter Directory opens. You may

further refine the search in the directory.

1.4 Using Context Sensitive Help

Touching the Help icon, , on the right-hand side of the display opens the Help drawer with information about the

panel or dialog currently on the display.

You can use search and the topic index to find further information.

To close the Help drawer, touch the close arrow, .

1.5 About Liebert®iCOM™ Version

The version, build, and other firmware information for the Liebert® iCOM™ display board may be helpful when servicing or

troubleshooting. To locate the firmware version of the iCOM control board, see Updating Liebert® iCOM™ Control Board

Firmware on page73.

• Touch , then > About. The ABOUT panel opens.

8

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 15

1.6 Accessing the User, Service, and Advanced Menus

iCOM™ operating functions that monitor and control a cooling unit are accessed via the User and Service menus.

NOTE: You must be logged in to access the menu options. See Powering On the Liebert® iCOM™ and Logging

In/Unlocking Controls on page5.

1. To access a menu, touch the icon for the menu you want, , or , in the control header. See

Control Header on page4. The orange bar appears below the menu name when selected indicating that this is

the menu content that will be displayed.

2. Touch the menu icon, . The menu opens.

1.7 User Menu

The user menu lets you view system and unit statuses and edit some setpoints.

1.7.1 User Menu Options

Setpoints

Opens the SETPOINTS panel. See Viewing and Editing Setpoints for the Cooling Unit on page13.

Active Alarms

Opens the ALARMS panel. See Viewing Unit Alarms on page14.

Event Log

Opens the EVENT LOG panel. See Viewing the Event Log on page16.

Sensor Data

Opens the SENSOR DATA panel. See Viewing Sensor Data on page16.

Display Options

Opens the Display Options menu:

• Customize Layout: See Customizing Main Display Views on page82.

• Custom Labels: See Customizing Parameter and Field Labels on page84.

• Date & Time: See Setting the Date and Time on page7.

Total Run Hours

Opens the RUN HOURS panel. See Managing Run Hours for a Component.

1 G ettin g Started with Liebert® iCOM™

9

Page 16

About

Opens the ABOUT panel. See About Liebert®iCOM™ Version on page8.

Turn Unit On/Off

Depending on unit’s status, open the TURN UNIT ON or TURN UNIT OFF dialog. See Powering Off the Thermal

Management Unit on page7, or Powering Off the Thermal Management Unit on page7.

1.8 Service Menu

The service menu lets you view and edit setpoints and perform many other functions.

1.8.1 Service Menu Options

Setpoints

Opens the SETPOINTS panel. See Editing Setpoints for the Cooling Unit.

Diagnostic/Service

Opens the Diagnostic/Service menu:

• Diagnostics: See Performing Diagnostics.

• Technical Support: Contact information for the cooling unit andiCOM™ display.

Alarm/Event Setup

Opens the ALARMS & EVENTS panel. See Managing Events: Alarms,Warnings,andMessages.

BMS & Teamwork

Opens the BMS & Teamwork menu:

• U2U Setup: See Configuring U2U Network Settings.

• BMS Setup: See BMS and IntelliSlot Settings on page33

Scheduler

Opens the SCHEDULER panel. See Scheduling Condenser and Cooling Unit Tasks.

Options Setup

Opens the OPTIONS SETUP panel. See Setting General Thermal Management Unit Options on page20.

Auxiliary Device Setup

Opens the Auxiliary Device Setup menu:

• Sensors: See Wired Remote Sensors.

10

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 17

Backup & Security

Opens the Backup & Security menu:

• Display Backup and Restore: See Backing Up and Restoring Control Board Settings on page75.

• Control Backup and Restore: See Backing Up and Restoring Control Board Settings on page75

• Display Upgrade: See Updating Liebert® iCOM™ Control Board Firmware on page73.

• Control Upgrade: See Updating Liebert® iCOM™ Control Board Firmware on page73.

• Manage Permissions: See Managing Access Permission and Passwords.

Turn Unit On/Off

Depending on unit’s status, open the TURN UNIT ON or TURN UNIT OFF dialog. See Powering On the Thermal

Management Unit on page5, or Powering Off the Thermal Management Unit on page7.

1.9 Advanced Menu

The advanced menu provides a read-only view of the advanced set up and factory level settings.

1.9.1 Advanced Menu Options

Factory Settings

Unit code and configuration settings.

Diagnostics

Details about control and cooling operation.

Expert Settings

Parameters and settings for use by trained professionals only.

Runtime Monitoring

Details about component run times.

Control Override

Allows simulating events and override of analog outputs beyond normal limits.

Parameter Directory

A searchable list of all parameters in the user interface. See Setpoints and Alarm Settings by Line ID on page93.

1 G ettin g Started with Liebert® iCOM™

11

Page 18

This page intentionally left blank.

12

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 19

2 USER OPERATION

2.1 Viewing and Editing Setpoints for the Cooling Unit

NOTE: User level access allows viewing and editing only a limited number of setpoints. To view or adjust all setpoints,

you must have service level access. See Editing Setpoints for the Cooling Unit on page17.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

2.1.1 Editing Temperature Setpoints

1. Touch , then > Setpoints > Temperature Control.

The TEMPERATURE CONTROL secondary panel opens.

2. Refer to User Temperature Setpoint Options below, Temperature Control—TemperatureSetpointsandCooling

Operation, then touch Save.

The setpoint is updated.

• Touch Cancel to discard the changes.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

User Temperature Setpoint Options

2nd Temperature Setpoint

Alternate setpoint activated by customer input (remote alarm device). When customer input connection is 2nd

Setpoint, this value becomes the active temperature setpoint.

BMS Backup Temp Setpoint

Selects a temperature setpoint that activates in the event of a BMS timeout. The BMS timer must be configured for

this setpoint to activate. See Setting BMS Backup Setpoints on page35.

Temperature Setpoint Act

Read-only display of adjusted temperature setpoint when one of the following is active:

• Temperature compensation

• BMS backup temperature setpoint

• Customer input setpoint (remote alarm device)

Temperature Setpoint

Supply fluid temperature that the unit maintains via fan speed change.

2 U ser Operation

13

Page 20

2.2 Viewing Unit Alarms

The ALARMS panel lists active alarm and warning events. Table 2.1 below describes the type and state of the alarm

shown by indicator dots.

Table 2.1 Alarm Status and Type Indicators

Indicator Description

Yellow dot Warning event.

Red dot Alarm event.

Circle Event condition has clea red, but still must be acknowledged. See Acknowledging Alarms on the facing page.

2.2.1 To View Alarms

1. Touch , then > Alarms. The ALARMS panel opens.

2. Touch an alarm to display the ALARM DETAILS panel.

Alarm Fields

Alarm

Name of the event.

Date

Date event was logged.

Time

Time event was logged

Alarm Detail Fields

Alarm

Name of the event.

Alarm Type

Number representing the event type.

• 1 : Warning

• 2: Alarm

Date/Time

Date and time the event was logged.

14

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 21

Duration

Time elapsed since event was logged.

Threshold

Sensor reading at which an event is triggered.

Unit

Cooling unit to which the alarm applies.

Value

The current value to which the threshold is compared.

2.2.2 Silencing an Audible Alarm

Touch the screen to silence an audible alarm. If the alarm is non-latching, the alarm silences when the condition clears.

NOTE: The audible alarm must be enabled in display options to sound. See Enabling the Audible Alarm Notification on

page31.

2.2.3 Acknowledging Alarms

Depending on the notification settings, alarms and warnings must be acknowledged or reset. An event is active as long as it

is unacknowledged, with the exception of the network failure events described in Table 2.2 on the next page. Once

acknowledged, an event remains active until the situation that triggered the event is resolved, see Table 2.1 on the

previous page, for event status indicators. When an event is acknowledged and cleared, it is removed from the Alarms panel

and the LED stops flashing red.

NOTE: Acknowledging alarm events does not clear them. To clear an issue, it must be corrected, reset automatically

by the controller, or reset manually.

To Acknowledge Alarms

1. On the ALARMS panel, touch Acknowledge All. A check mark overlays the status indicator of the active alarms

and warnings, and these automatically clear when the condition is no longer present.

• If a critical event must be manually reset, the acknowledged items are listed with a Reset All button on

the ALARMS panel.

2. Touch Reset All to manually reset the condition.

2 U ser Operation

15

Page 22

2.3 Viewing the Event Log

The event log is a list by date/time of the last 400 events generated by iCOM™ for the thermal management unit.

• On the User menu, touch Event Log. The EVENT LOG for the cooling unit opens. Table 2.2 below describes

the color coded status for each event.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

Table 2.2 Event Status/Type Indicators

Indicator Description

Green dot Message.

Yellow dot Unacknowledged warning event. See Acknowledging Alarms on the previous page.

Red dot Unacknowledged alarm event. See Acknowledging Alarms on the previous page.

White dot withcheck-mark ov erlay Acknowledged event, the cause stillexists.

White circle Acknowledged event, the cause is cleared.

2.4 Viewing Sensor Data

The Sensor Data panel lists the standard and optional sensors monitored by iCOM™and the current reading of each sensor.

• Touch , then > Sensor Data. The SENSOR DATA panel opens.

A secondary panel displays the DAILY SENSOR READING SUMMARY, which shows temperature, humidity, and

dew point readings for the cooling unit.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, the options on your iCOM display may differ.

2.5 Managing Run Hours for a Component

You can view the run hours for components on a cooling unit, set the total run time limit, and reset total run hours to zero.

1. Touch , then > Total Run Hours. The RUN HOURS panel opens and the current hours for each

component are listed in the Total Run Hours column.

To reset the total run hours to zero, see Setting Run Hours to Zero below.

2. Use the slider to set the total run time limit for each component, then touch Save. The limits are set.

2.5.1 Setting Run Hours to Zero

1. On the RUN HOURS panel, touch to check each box in the Total Run Hours column next to the component(s) to

reset. The Set to Zero button becomes available.

2. Touch Set to Zero. The total run hours for the selected component(s) is set to zero.

16

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 23

3 SERVICE OPERATION

3.1 Editing Setpoints for the Cooling Unit

Setpoints are the means by which cooling unit operation is controlled.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

3.1.1 Setpoints Options

Fan Control

See Configuring Fan Setpoints on page19.

Pump Control

See Configuring Pump Setpoints below.

3.2 Pump Control

The Liebert® XDU shall utilize variable speed pumps to supply the maximum amount of fluid flow required by the server

configuration. The desired pump flow rate setpoint shall be determined by the end-user. XDU shall come with two variable

speed pumps, each pump operating via its own VFD. Pumps are 100% redundant of one another.

A flow meter shall monitor the actual XDU system flow rate. The flow rate value sensed by the flow meter shall be used to

control the actual pump speed to match the desired system flow rate setpoint. The flow meter is mounted on the discharge

(leaving) fluid line.

3.2.1 Configuring Pump Setpoints

Pump Control Options

Fluid Flow Rate @ Full Scale (%)

Flow rate corresponding to 20ma signal from the flow sensor (sensor output is 4-20ma) [Range 10-1000 lpm, default

115 lpm]

Fluid Flow Rate Setpoint (GPM)

Determines the speed output of the operating pump

Fluid Pump Initial Speed (%)

Pump speed at startup [Range 25-100%, default 25%]

Fluid Flow Proportional Band (GPM)

Value determines how aggressive the pump shall operate as flow rate deviates from fluid flow setpoint

Fluid Flow Dead Band (GPM)

3 S ervice Op eration

Defines the flow value where there will be no change in pump output as flow deviates from setpoint

17

Page 24

Fluid Flow Integration Time

Serves to push or pull the flow rate back in line with set point based on how long and how far away the measured

value is away from Set Point

Pump Transition Duration (sec)

Determines how long lead pump will operate while transitioning to lag pump

Pump Sequence

Determines which pump shall operate as the lead/lag. If set for Auto, pumps will operate based off run hours.

Pump Rotation Frequency (days)

Determines how often pumps will rotate from lead to lag [Range 0-30 Days, default 7 days]

Perform Pump Rotation

Forces the unit to perform a manual pump rotation

Loss of Flow Detection Delay (sec)

Delay time that must surpass in order to initiate ‘Loss of Flow’ alarm once loss of flow is detected

Fluid Check Speed Threshold

Defines how far the pump speed must change before ‘Check Fluid System’ notification is activated [Range 2-100%,

default 10%]

Expected Speed Reset

Resets the expected speed 60 second timer for the ‘Check Fluid System’ notification

Minimum Fluid Flow Volume

Determines the minimum flow the system can move

3.3 XDU Fan Control

The Liebert® XDU shall utilize two EC fans to provide the maximum rated airflow at 100% fan speed. Airflow shall help

determine the leaving fluid temperature from the discharge of the XDU. Both fans shall operate simultaneously at the same

speed to provide the airflow needed to maintain the control setpoint for the leaving fluid temperature. The fans are not

redundant of one another.

Each fan is self-monitoring and will provide a digital signal if the fan is powered but fails to operate. On the failure of one fan,

the remaining fan in operation shall continue to operate and increase speed to compensate for the failed fan.

18

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 25

3.3.1 Configuring Fan Setpoints

Configures fan speed control to operate independent of pumps loading (decoupled mode).

1. Touch , then > Setpoints > Fan Control. The FAN CONTROL secondary panel opens.

2. Adjust the setpoint options, then touch Save. The setpoint is updated.

• Touch Cancel to discard the changes.

Fan Control Options

Airflow Calibration

Maximum allowed fan output voltage.

Fluid T

Sensor monitoring the discharge fluid temperature will determine the fan speed output

Fan Control Sensor

Fluid T sensor monitoring the discharge fluid temperature will determine the fan speed output.

Fan Control Type

Selects the method of control for the fan motor.

• Proportional: Regulation based on the difference between the fan control sensor reading and the fan setpoint.

• PI: Regulation is based on proportional and integral terms. Provides best temperature control and helps avoid

fan speed oscillation.

• Adaptive PID: Auto-tuning PID control loop, can be set for cooling or fan speed.

Fan Speed Proportional Band

Adjusts the fan speed based on the deviation from the setpoint. A smaller number causes faster reaction to

temperature changes.

Fan Speed Integration

Adjusts fan speed based on time away from the setpoint to maintain accurate temperature control.

Maximum Fan Speed

Maximum percentage at which the fans will operate.

Minimum Fan Speed

Minimum percentage at which the fans will operate [15%, range 1.5 -10 v, default 1.5 v].

Proportional band adjusts fan speed activation point based on a deviation from setpoint by placing half of the

selected value on either side of the fan speed control setpoint. A smaller number causes a faster reaction in fan speed.

3 S ervice Op eration

19

Page 26

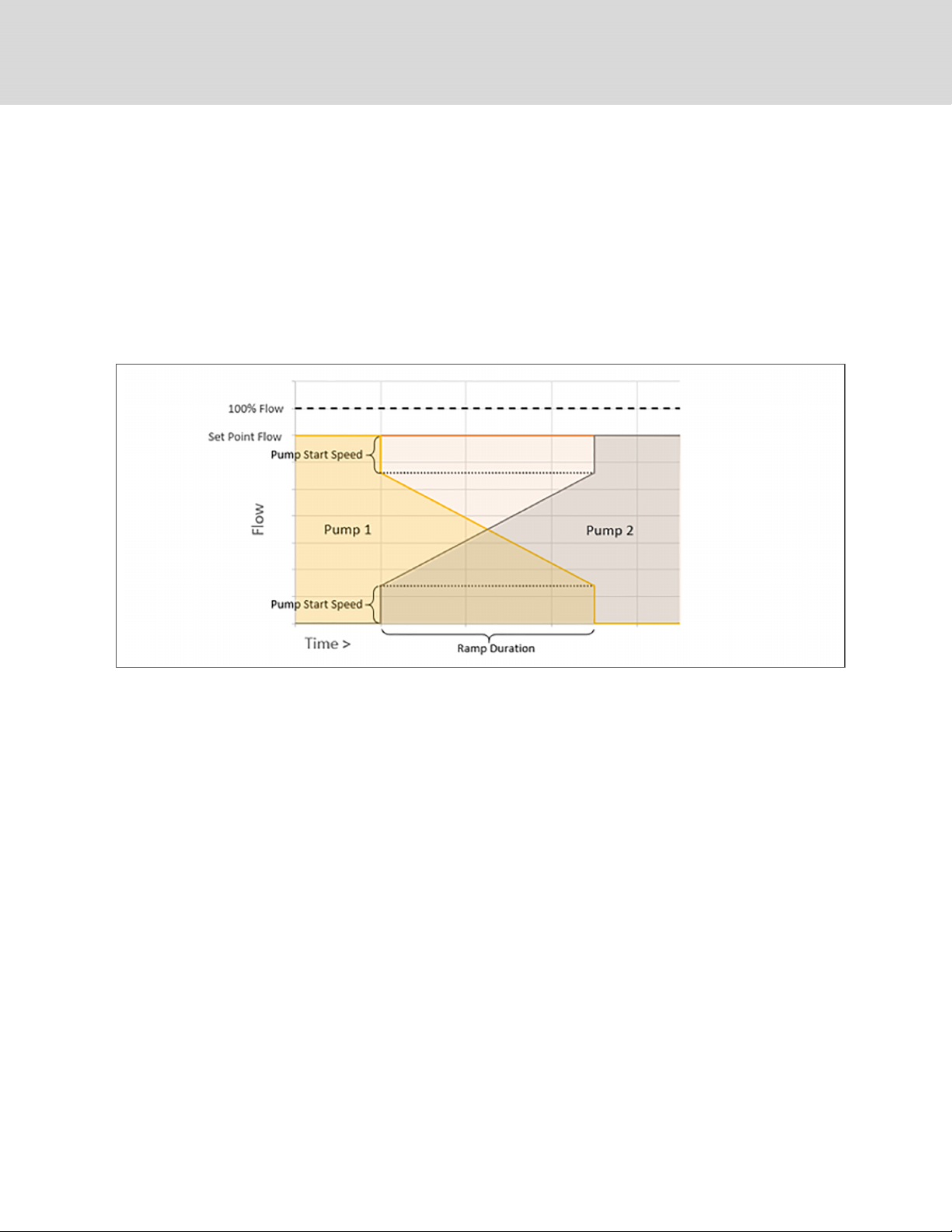

3.4 XDU Pump Lead/Lag Control

The two pumps in the Liebert XDU are lead/lag controlled to maintain equal runtime between the pumps, reduce corrosion,

and maintain the wetted seal surfaces of the lag pump. Only one pump shall operate at any given time to provide flow. The

lead/lag switchover of the two pumps is managed by the iCOM controller and shall switch operation of the pumps from lead

to lag without the interruption of flow. This is accomplished by first ramping down the operation of the lead pump while

simultaneously ramping up the speed of the lag pump. Pump lead/lag order can be manually switched via the iCOM

display. Pump lead/lag rotation is automatically switched after seven days of continuous pump operation by default. The

selectable range for pump rotation is 0 – 30 days. See Figure 3.1 below.

Figure 3.1 Pump Lead/Lag Control Chart

3.5 XDU Pump Monitoring

Each pump VFD shall receive a control signal that is used to monitor the health of the fluid system. After configuring the

flow rate setpoint via the iCOM display or remote communications and the pump speed signal reaches steady state, the

iCOM controller shall monitor the pump speed signal against the steady state value. In the event the pump speed signal

changes to a value outside (+/-) the range of the steady state value, a threshold warning shall annunciate letting the user

know to check the water system.

3.6 XDU Loss of Flow Control

Flow within the system is monitored by a unit mounted flow meter and pressure transducer pair across the pump . The two

measurements are required to identify the proper action to be taken and event to annunciate (loss of flow can be a result of

pump malfunction or strainer clog or valve closure). Switchover due to loss of flow shall result in a loss of flow alarm. Pump

switchover shall automatically occur if a pump is active but no flow is being detected.

3.7 Setting General Thermal Management Unit Options

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

20

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 27

3.7.1 Setting Miscellaneous Options

1. Touch , then > Options Setup > Misc Settings. The MISC SETTINGS panel displays.

2. Make adjustments as needed and click Save. The option settings are updated.

• Touch Cancel to discard the changes without saving.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

Miscellaneous Cooling Unit Settings Options

Auto Restart Enable

When enabled, the cooling unit returns to the status at which it was operating when input power returns after a power

failure. (ON if it was powered on and OFF if it was powered off before the failure.) See Automatic Restart after Power

Failure.

Cascade after Remote On

Upon a remote request for all units to start, selects whether or not the units start one after another by the Cascade

Units Delay set in Teamwork Modes, see the Teamwork Control Options.

K11 Active On

Selects the action of the activated K11 (warning) relay. Options are:

• Warning: A warning is active.

• Emergency Pwr: Emergency power is on.

Loss of Power Auto Reset Delay

Defines that amount of time that must surpass in order for the Loss of Power alarm to clear or auto-reset once power

has restored after power loss to the unit. When the delay time elapses, the event resets and is cleared automatically.

Operation at Temp Control Sensor Failure

Selects cooling unit operation in the event that the control temperature sensor fails.

• Shut Down: The unit shuts down on sensor failure.

• Cooling: The unit continues operation based on the select Temp Control Sensor Failure Cooling Mode.

3 S ervice Op eration

21

Page 28

Single Unit Auto Restart

Selects time elapsed (in seconds) before unit restarts when Auto Restart Enable is enabled.

Temp Control Sensor Failure Cooling Mode

Unit operation when Cooling is selected at control temperature sensor failure.

• Hold: Holds the last call for cooling. That is, continue operating at same capacity.

• Full: Activates full cooling, 100% capacity.

Warning Activates Alarm Relay

When enabled, a warning event activates the common alarm relay.

3.8 XDU Quick Start

3.8.1 Configuring Quick Start

In the event of a power interruption to the iCOM™ controller, the unit components and controls shut down. Normally, after

power is restored, the iCOM controller must fully boot, and no pump flow or air flow occurs until the controls have fully

booted. Quick Start lets you determine the fan and pump output that the unit will provide before the controller fully boots.

When configured, the unit can provide airflow and fluid flow within 10seconds after power is restored to the controller. Quick

Start can be applied to fan, chilled water, and pump functions. Quick Start operates only during iCOM™ application boot,

then normal controller operation resumes.

Configuring XDU Quick Start Options

QS: Use Remote Off Input

Enables/disables use of quick start feature.

Quick Start Delay (sec)

Delay time before quick start enables.

Fan Digital Output

Fan digital output status.

Fan Analog Output

Specifies the desired fan output percentage used during quick start.

Pump 1 Digital Output

Pump 1 digital output status.

Pump 1 Analog Output

Specifies the desired pump output percentage used during quick start.

22

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 29

Pump 2 Digital Output

Pump 2 digital output status.

Pump 2 Analog Output

Specifies the desired pump 2 output percentage used during quick start.

Quick Start Overlap Time

Amount of time quick start will continue to operate once iCOM controller has fully rebooted.

Last Quick Start Duration

Last quick start duration details.

To Configure Quick Start

1. Touch , then > Options Setup > XDU Quick Start Settings.

The QUICK START SETTINGS panel displays.

2. Refer to Configuring XDU Quick Start Options Configuring XDU Quick Start Options on the previous page, and

select the configuration options for your system.

3.8.2 Setting Fan Options

Air flow is adjustable via iCOM™ manually using a building management system (BMS) or automatically using locally

installed temperature sensors.

NOTE: Thermal management units ship with the factory setting Return Sensor for the temperature control sensor and

the fan speed control sensor.

1. Touch , then > Options Setup > Fan Settings. The FAN SETTINGS panel displays.

2. Make adjustments as needed and click Save. The option settings are updated.

• Touch Cancel to discard the changes without saving.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

Fan Settings Options

Airflow Calibration

Maximum allowed fan output voltage.

Fan Back Draft Mode

Enables/disables fan operation in back draft mode.

3 S ervice Op eration

23

Page 30

Fan Shutdown Delay Timer

Length of time that the fan continues to operate after the cooling unit is turned off via the display, local control or the

BMS.

The delay timer does not apply when the unit is turned off remotely.

Fanspeed at Unit Start

Speed at which the fans run on unit start up.

Fanspeed at Unit Start Timer

Length of time fans run at the speed selected in fan speed at unit start.

Fanspeed Filter at 0%

Decreases the rate at which the fan speed changes when close to or at the temperature setpoint to avoid

undershooting the setpoint.

Fanspeed Filter at 100%

Increases the rate at which the fan speed changes for a quicker reaction of fan speed at high temperatures.

Fanspeed Reposition Delay

Length of time before fan speed can decrease, allowing temperature to stabilize before the change occurs.

Fanspeed Reposition Mode

Sets a one time delay that allows the fan to maintain current speed when a call to increase or decrease is made to

allow the temperature to stabilize.

Fanspeed Transition Filter

Sets how quickly the fan speed changes between operating modes. Prevents an instant reaction when fans turn on or

off and prevents unstable operation.

Max Deceleration Rate

Selects the rate at which the fan speed changes during deceleration.

Maximum Fan Speed

Maximum speed at which the fan will operate.

MIN at CFC for EC Fan

Cooling deviation at which the fan will operate at minimum speed.

24

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 31

Minimum Fanspeed

Minimum speed at which the fan will operate (15%, range 1.5 -10 v, default 1.5 v).

No Power Fanspeed

Speed at which the fans operate when using emergency power.

3 S ervice Op eration

25

Page 32

This page intentionally left blank.

26

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 33

4 MANAGING EVENTS: ALARMS,WARNINGS,ANDMESSAGES

Events are notifications of operating status for the cooling unit, its components, and auxiliary devices. All events are

recorded in the Event Log, and alarm and warning events are also displayed on the Alarms panel (See Viewing the Event

Log on page16, and Viewing Unit Alarms on page14.)

In some cases, depending on configuration, an alarm event may power off the cooling unit, but not always. However, if a

standby unit is configured, all alarm events stop the faulty unit and start the standby unit. Message and warning events do

not.

4.1 Event Properties

The ALARMS & EVENTS panel lists all events available on the system. You can view and modify events and the criteria that

trigger visual/audible alarms including:

• Critical thresholds

• Time delays

• Enable/disable

• Event type

• Adding custom events

NOTE: Not all event properties may be adjusted, depending on the criticality of the event, whichisfactory set.

To open the panel:

Touch , then > Alarm/Event Setup.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

4.1.1 Alarms and Events Panel Fields

Property

Lists groups of events, expanding displays the events in each group. See Enabling Events and EditingEventSettings

on the next page.

Type

Event type. See Selecting Event Type and SettingAlarm/WarningNotification on the next page.

4 Managing Even ts: Alarms,Warnin gs,and Messages

27

Page 34

Ack

Indicates type of acknowledgment required. See Acknowledging Alarms on page15. This option is not available with

all alarm types.

• Auto: The alarm is acknowledged automatically. It goes away if the situation that triggered alarm event is no

longer true.

• Manual: The alarm goes away only when acknowledged, even if the situation that triggered the alarm event is

resolved/no longer true.

Reset

Indicates type of reset required for the event. This option is not available with all alarm types:

• Auto: The alarm resets automatically after acknowledgment.

• Manual: The alarm must be reset manually after acknowledgment. See Acknowledging Alarms on page15.

4.2 Enabling Events and EditingEventSettings

In the ALARMS & EVENTS panel, events are grouped into categories for easier management, for example, the factory set

remote sensor alarms and humidification/dehumidification events. In some cases, touch the group heading provides edit

options for the entire group, like thresholds, delays and enable/disable. Each event includes settings specific for that event

and the notification option where event type and alarm notifications are selected (See Selecting Event Type and

SettingAlarm/WarningNotification below).

1. Touch , then > Alarm/Event Setup. The ALARMS & EVENTS panel opens.

2. Scroll or search to find the event, touch the set’s heading to display theproperties and values for the entire set

in the EDIT panel.

– or –

Touch an individual alarm or event to display it’s specific values in the EDIT panel.

NOTE: To edit the event type and notification, see Selecting Event Type and SettingAlarm/WarningNotification

below.

3. Use the EDIT panel to adjust the settings for the selected event or group of events.

4.3 Selecting Event Type and SettingAlarm/WarningNotification

Setting notification delays and disabling visual notification prevents nuisance notifications. Customize to notify of critical

events on your cooling system.

NOTE: If the event includes a safety function, such as high pressure, low pressure, main fan overload, etc., the safety

function executes regardless of event type or notification setting. However, notification timing delays still apply.

To select event type and notification:

1. Touch , then > Alarm/Event Setup.

2. Scroll or search to find the event and touch the alarm or event.

28

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 35

3. On the EDIT panel, touch Notifications. The EDIT panel displays the notification properties.

4. Adjust the notification properties described in the Notification Properties below, then touch Save. The

notification is updated.

• Touch Cancel to discard the changes without saving.

4.3.1 Notification Properties

Delay

Time, in seconds, to delay notification after event trigger. Depending on the event, the delay may or may not be

adjusted. Table 4.2 on the next page, lists the delays and their default settings.

• If the notification delay for the event is greater than the delay set for the event group, the group’s delay

includes the event’s delay.

Enable

Enables/disables notification. Touch the switch to set On or Off.

• When disabled, events are not logged or displayed and visual/audible alarm notifications are not made.

Type

Logging and notification level of the event. Table 4.1 below, describes the event type and notification it generates.

Table 4.2 on the next page, lists the default types for events.

Table 4.1 Notification Types

Type Description

Message Stored in event log only. No visual or audible notification.

Warning

Alarm

Listedwith a yellow status dot on the ALARMS panel and the LED flashes.

See Table 8.1 on page77, and Viewing Unit Alarms on page14.

Listedwith a red status dot on the ALARMS panel, the LEDflashes, and the audible alarm sounds.

See Table 8.1 on page77, Viewing Unit Alarms on page14, and Enablingthe Audible Alarm Notification on page31.

Table 4.2 on the next page, lists the default settings for each event.

• Internal delay is factory set and not adjustable. It is the time delay after event trigger that notification is sent.

• Default delay may or may not be adjustable and is added to the internal delay of event notification.

• Type may be adjustable or may be fixed.

4 Managing Even ts: Alarms,Warnin gs,and Messages

29

Page 36

NOTE: Depending on customization, some events may not be available on your cooling unit.

Table 4.2 Event Notification Defaults

Event Internal Delay

MAIN FAN OVERLOAD 2 sec 5 sec/0 – 9999 * ALM

LOSS OF AIRFLOW 3 sec 3 sec/0 – 9999 * ALM

HIGH ROOM TEMP 1 min. after fa n on 30 sec/0 – 9999 Fixed to WRN

LOW ROOM TEMP 1 min. after fa n on 30 sec/0 – 9999 Fixed to WRN

HIGH ROOM HUM 1 min. after fa n on 30 sec/0 – 9999 Fixed to WRN

LOW ROOM HUM 1 min. after fa n on 30 sec/0 – 9999 Fixed to WRN

HIGH TEMP SENSOR A 1 min. after fa n on 30 sec/0 – 9999 Fixed to WRN

LOW TEMP SENSOR A 1 min. after fa n on 30 sec/0 – 9999 Fixed to WRN

WORKING HRS EXCEEDED 0 sec 0 sec/0 – 9999 Fixed to WRN

SMOKE DETECTED 2 sec 2 sec/0 – 9999 * ALM

WATER UNDER FLOOR 2 sec 2 sec/0 – 9999 * ALM

Default D elay/Range

for Adjustment

Type

LOSS OF FLOW

5 sec

Reset delay: 10 sec

2 sec/0 – 9999 * ALM

STANDBY UNIT ON 2 sec 2 sec/0 – 9999 * ALM

NO CON NECTION w/Unit1 Internal Calc. - WRN

UNIT X DISCONNECTED Internal Calc. - WRN

LOSS OF POWER 0 sec no ALM

CUSTOMER INPUT 1 2 sec 2 sec/0 – 9999 * ALM

CUSTOMER INPUT 2 2 sec 2 sec/0 – 9999 * ALM

CUSTOMER INPUT 3 2 sec 2 sec/0 – 9999 * ALM

CUSTOMER INPUT 4 2 sec 2 sec/0 – 9999* ALM

CALLSERVICE 2 sec 2 sec/0 – 9999 * MSG

HIGH TEMPERATURE 2 sec 2 sec/0 – 9999 * MSG

No Power 0 sec 0 sec/0 – 9999WRN

EC Fan Fault 0 sec 10 sec/0 – 9999 ALM

TEMP CTRL SENSOR FAIL 0 sec 3 sec/0 – 99999 ALM

HIGH REMOTE SENSOR 0 sec 30 sec/0 – 9999 WRN

POWER “A” FAILURE 0 sec 10 sec/0 – 9999 ALM

POWER “B” FAILURE 0 sec 10 sec/0 – 9999 ALM

AIRFLOW SENSOR FAILURE 0 sec 1 0 sec/0 – 9999 WRN

LOSS OF FLOW 0 sec 5 sec/0 – 9999 ALM

BMS DISCONNECTED 0 sec ENABLED/DIS - ENAB WRN

30

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 37

4.4 Enabling the Audible Alarm Notification

1. Touch , then > Display Options > Display Properties.

The UNIT DISPLAY panel opens.

2. Touch the Alarm Buzzer Pattern value, and select a pattern from the drop-down list.

• Selecting None disables the audible notification.

3. Touch Save to save the property settings.

• Touch Cancel to discard changes.

4.5 Remote Alarm Device and Customer Input Events

Remote alarm devices are various sensors and detectors outside the cooling unit that provide information about conditions

and situations that may affect operation. Remote alarm devices include smoke detectors, filter condition, valve status.

Included in the remote alarm devices (RAD) option are up to four customer input events depending on cooling unit

configuration. In some cases, two additional, optional customer-input events are available. See Setting Up Customer Input

Events below.

RAD and customer input notifications are set in the same way as other events. See Selecting Event Type and

SettingAlarm/WarningNotification on page28.

4.5.1 Setting Up Customer Input Events

Input devices must be wired to Terminal 24 through a dry contact to locations 50, 51, 55 and 56 for alarms 1 through 4

respectively (For the terminal location, refer to the cooling unit electrical schematic and installation manual). Table 4.3

below, maps the customer input to the remote alarm devices (RAD).

Table 4.3 Customer Input Terminals to Remote Alarm Device

Terminals

Custo mer Inp ut C ustom er Inpu t Terminal RAD Nu mber RAD Terminal

1 24 1 50

2 24 2 51

3 24 3 55

4 24 4 56

1. Touch , then > Alarm/Event Setup > Remote Alarm Device Input. The EDIT panel opens.

2. In Customer Input X (where X is the input number), select the input type that best describes the wired

device/input, see Table 4.4 on the next page.

3. In Customer Input X Active When, select whether the input is active (triggers events) when Opened or Closed.

4. Once input(s) are set, touch Save. The customer input settings are saved.

4 Managing Even ts: Alarms,Warnin gs,and Messages

31

Page 38

Customer Input Options

Customer Input X

Selects the customer wired input, where X is the input number. See Table 4.4 below, for a description of available

values.

Customer InputXActive When

Selects when the input triggers an event. Options are:

• Opened: Events are triggered when the contacts across the corresponding RAD terminal strip are open.

• Closed: Events are triggered when the contacts across the corresponding RAD terminal strip are closed.

NOTE: Depending on customization, some events listed in Table 4.4 below, may not be available with your system.

Table 4.4 Customer Input Options

Input Action/Description

Smoke Event only.

Water Alarm Event only.

Flow Alarm Event only.

Stdby Unit Event only.

C-Input 1 Event only.

C-Input 2 Event only.

C-Input 3 Event only.

C-Input 4 Event only.

Call Service Event only.

High Temp Event only.

Air Loss Event only.

Heater Alarm Event + Heaters off.

FIRE ALARM Event + Shuts down the unit.

2ND SETPOINT No event, but switches to the second setpoint.

Emergency Power Event + Disablesunit.

LSI Event + Activates humidifier-problem Alarm and stop filling bottle when full.

EC FAN FAULT Event + Set analog output to 10V.

POWER A Event only.

POWER B Event only.

32

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 39

5 EXTERNAL MONITORING ANDBUILDING MANAGEMENTSYSTEMS

Liebert® iCOM™-controlled cooling units are equipped with embedded Liebert® IS-Unity-DP software to communicate with

external monitoring systems including Building Management Systems (BMS), Network Monitoring Systems (NMS) and

Liebert® SiteScan™ Web.

Embedded Unity communicates with multiple third-party protocols to monitor and manage a range of parameters and

events. The Embedded Unity software delivers:

• Velocity Protocol for Trellis™, Liebert® SiteScan™ and Liebert® Nform.

• Embedded LIFE™ Technology for Remote Service Delivery.

• SNMP (v1/v2/v3) for NMS.

• HTTP/HTTPS for web page viewing.

• SMTP for e-mail.

• SMS for mobile messaging.

• Modbus RTU-Modbus Remote Terminal Unit communication protocol for BMS over an RS-485 serial

network (Modbus RTU RS-485).

• Modbus TCP-Modbus Transmission Control Protocol for BMS over Internet or LAN.

• BACnet IP—BACnet over Internet Protocol for BMS over Internet or LAN.

• BACnet MSTP—BACnet Master-Slave/Token-Passing communication protocol for BMS over an RS-485

serial network (Modbus MSTP RS-485).

5.1 BMS and IntelliSlot Settings

When communicating with a building management system (BMS) with an optional IntelliSlot Unity card or via embedded

Unity function, the BMS settings are identical and include:

• Disconnect fail safe

• Manual fan speed control

• Allowing the BMS to change fan speed

• Backup fan control

5.1.1 Configuring BMS Communication with Embedded Unity

By default, built-in Unity function is disabled. You must enable communication with the BMS via the IS-UNITY options in

iCOM.

To configure Modbus, BACnet, SNMP, SMS and HTTP communication, see Communication Setup with Embedded Unity on

page35.

To Enable Embedded Unity Function

1. Touch , then > BMS & Teamwork > BMS Setup.

The BMS SETUP panel opens.

5 Ext ernal Monitorin g and Buildin g Manag ementSys tems

33

Page 40

2. Select IntelliSlot Card Settings and one of the following in Monitoring Protocol:

• Embedded to use built-in Unity function.

• Embedded & IS V4 to use built-in Unity and and additional IntelliSlot card or SiteLink connection.

3. Touch Save & Restart (Unit Only).

Monitoring Address

Address used by an optional, installed IntelliSlot card. Factory default is 3.

• Do not modify the monitoring address unless directed to do so by Vertiv technical support.

Monitoring Protocol

Protocol used for communication with BMS. Options are:

• Velocity V3: Legacy Velocity communication card

• IGM: IGMNet communication cards

• Velocity V4: Liebert IS-UNITY card.

• Embedded: Embedded IS-UNITY function

• Embedded & IS V4 Both Embedded Unity function and Velocity V4 for an optionally installed IS-UNITY card

5.1.2 Setting BMS Control Settings

1. Touch , then > BMS & Teamwork > BMS Setup > Control Settings. The CONTROL SETTINGS

secondary panel opens.

2. Adjust the settings, and touch Save. The settings are configured.

NOTE: Use Configure Timeout to configure the setpoints used in the event of an outage and BMS takes control. See

Setting BMS Backup Setpoints on the facing page.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

BMS Control Settings Options

BMS is Connected To

• Velocity

• Analog Input 1-4

BMS Fan Speed Local Override

Enables/disables local override of the fan speed set via BMS.

Fan Control Sensor

Currently selected fan control sensor. Must be set to Manual for BMS control. See Configuring Fan Setpoints on

page19.

34

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 41

Handshake

Sets a time period, in minutes, in which communication between the BMS and iCOM™must occur.

Maximum Fan Speed

Current fan speed setting (set via fan setpoints or by BMS).

5.1.3 Setting BMS Backup Setpoints

1. Touch , then > BMS & Teamwork > BMS Setup > Configure Timeout button on the lower-right of the

panel. The CONFIGURE TIMEOUT secondary panel opens.

2. Adjust the values, and touch Save. The settings are configured.

NOTE: Depending on the type of thermal management unit, included components, and control settings of your

system, all of the options listed may not be available on your iCOM™ display.

BMS Timeout Settings Options

BMS Backup Fan Operation

Enables/disables BMS operation of the fans during back up operation. Options are:

• Disabled

• BMS Backup Spd

• Coupled

• BMS Backup Set

BMS Backup Temp Setpoint

Temperature that the cooling unit maintains during BMS back up operation.

5.2 Communication Setup with Embedded Unity

The following sections describe the configuration options for embedded Unity function including Modbus, BACnet, SNMP,

SMS, and HTTP communication.

NOTE: The Unity configuration is also accessible through the Unity web interface. For details on accessing and using

the web interface, refer to the Liebert® IntelliSlot™ Unity Card Installer/User Guide, available at www.vertiv.com.

5 Ext ernal Monitorin g and Buildin g Manag ementSys tems

35

Page 42

IS-UNITY setup includes the following options to configure Unity function and communication:

• Connection

• Connecting to the BMS below

• Embedded Unity User and Password on page38

• Troubleshooting Unity Connection and Set Up on the facing page

• Configuration

• System Configuration on page39

• Local Users Configuration on page41

• Network Configuration on page42

• Web Server Configuration on page45

• Remote Services Configuration on page47

• Velocity Protocol Configuration on page50

• Messaging Configuration on page51

• Protocols

• BACnet Protocol Setup on page56

• Modbus Protocol Setup on page59

• SNMP Protocol Setup on page61

• Unity Status Readings on page66

• Unity Support Information on page66

5.2.1 Connecting to the BMS

The embedded Unity software resides on the iCOM control board. There are two methods of connecting to a BMS, via

Ethernet or RS-485.

For a network connection, connect the Ethernet cable from the BMS to P74 on the iCOM control board. Figure 5.1 on the

facing page, shows the connector location.

For an RS-485 connection, connect the serial cable form the BMS to TB3 on the iCOM control board. Pin1 is the positive

terminal on the right in Figure 5.1 on the facing page.

36

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 43

Figure 5.1 Control Board Connections

No. Description

1 P74 Ethernet port

2 485 two wire terminal connector

Troubleshooting Unity Connection and Set Up

Table 5.1 on the next page, lists problems you may encounter with the Unity software and possible solutions.

5 Ext ernal Monitorin g and Buildin g Manag ementSys tems

37

Page 44

Table 5.1 Embedded Unity Troubleshooting

Problem Possible cause Sugg ested Remedy

Make sure the correct monitoring protocol is selected in BMS

Embedded Unity is not enabled.

Setup.

See Configuring BMS Comm unication with Embedded Unity on

page33.

Settingsa re not available

in local unit iCOM display, show as

"IS-Unity Service is Unavailable"

Ethernet to BMS network not

communicating or connecting

Unity software needs more time to boot up since

most recent iCOM c ontroller or Unity reboot.

The iCOM user and password for Unity are

incorrect.

Embedded Unity has crashed.

Unity configuration had becom e corrupt.

BMSEthernet drop is connected to the wrong

RJ-45 connector on the iCOM control board.

Ethernet c able is bad or incorrectly ma de.

Incorrect network settings.

Incorrect polarity.

Wait no more than 10minutes to give enough time to boot up.

Enter a valid user name and passwordfor the iCOM-to-Unity

connection.

See Embedded Unity User and Passwordbelow.

Restart, and wait at least 5minutes to fully boot up.

See Unity Restart and Restore Defaults on the facing page.

Restore to defaults, see Unity Restart and Restore Defaults on

the facing page.

NOTE: All customized Unity configuration settings will be lost .

Use this as a last r esort .

Make sure that the cable is connected to P74 on the iCOM

control board, and corrected if needed.

Use a cable tester that gives a quality rating and length (sends a

true data packet) to test the cable and correct as needed.

Correct the IPv4 network settings, see IPv4 a nd IPv6

Configuration on page43.

NOTE: If you adjust the settings, you must restart t he Unity

software for the changes to take effect.

Correct the polarity.

See Connectingto the BMS on page36.

Verify and correct the settings. Refer to the configuration

settingsthat apply to your system:

485twistedpair to BMS network

not com municating or connecting

Incorrect protocol settings.

Protocol settings have not been saved.

Save the settings, and restart Unity so the configuration is

authorized/applied.

See Unity Restart and Restore Defaults on the facing page.

• B ACnet Protocol Setup on page56.

• ModbusProtocol Setupon page59.

• SNMP Protocol Setup on page61.

5.2.2 Embedded Unity User and Password

Changes to the Unity configuration are authenticated with a user/password that is stored in iCOM. The stored user name

and password must match that of a user account in embedded Unity. See Local Users Configuration on page41, for a

description of the Unity accounts. By default, the user is Liebert and the password is Liebert (case sensitive).

If you are not using the default combination in Unity, then you must update iCOM with the matching username and

password.

1. Touch , then > BMS & Teamwork > IS-UnitySettings.

2. Adjust the Username and Password, and touch Save.

38

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 45

5.2.3 Unity Restart and Restore Defaults

Some types of configuration changes require a restart of the embedded Unity software to take effect. Using the Restart

IS-Unity option, does not affect the iCOM controller.

You also have the option of restoring the configuration to factory defaults if communication problems occur and cannot be

remedied with troubleshooting

To Restart Embedded Unity

1. Touch , then > BMS & Teamwork > IS-UnitySettings.

2. Touch Restart IS-Unity, then Save.

To Reset the Configuration to Factory Defaults

1. Touch , then > BMS & Teamwork > IS-UnitySettings.

2. Touch Default IS-Unity Setup, then Save.

5.2.4 System Configuration

System displays general information about the monitored and managed device. You can select the temperature units

displayed, which is Celsius by default.

To Update the System Settings

1. Touch , then > BMS & Teamwork > IS-UnitySetup > Configuration > System.

2. Adjust the information, and touch Save. The settings are configured.

Time Service Settings

1. Touch , then > BMS & Teamwork > IS-UnitySetup > Configuration > System > Time Service.

2. Adjust the settings, and touch Save.

Time Service Setting Options

External Time Source

The external source to use for time synchronization. Default is NTPServer.

Primary NTP Time Server

URL, Hostname, or IP address of the primary NTP time source. Has a 64 character maximum.

Backup NTP Time Server

URL, Hostname, or IP address of the back-up NTP time source. Has a 64 character maximum.

5 Ext ernal Monitorin g and Buildin g Manag ementSys tems

39

Page 46

NTP Time Sync Rate

The rate at which time will be synchronized with the network time protocol server, if NTP is the external time source.

Time Zone

Time zone where the device is located.

Enable Auto-Sync to Managed Device

Enable automatic writing time to the managed device.

Managed Device Auto-Sync Rate

Rate at which time will be written to the managed device, if an external time source has been selected.

40

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 47

5.2.5 Local Users Configuration

Local Users offers up to 10 users and three access levels described in Table 5.2 below.

The default password for all users is Liebert (case sensitive).

Table 5.2 User Access Levels

Level Name

No Access None The No Access lev el is enforced when Pa ssword Protected Site is enabled.

General User Read-only

Administrator Read/Write

Access/

Permission

Type

Description

Able to view all tabs, folders and sub-folders of the user interface.

A General User will only need to enter the a ssignedpassword if Password Protected Site is enabled, see Web Server

Configuration on page45.

By default, Local User [2] is User with the default password Liebert (both are case sensitive). The Authorization (access

type) for Local User [2] is General User.

Able to edit settings using the assigned password, which is a lways required to edit settings/configuration.

By default, Local User [1] is Liebertwiththe defa ult password Liebert (both are case sensitive). The Authorization(access

type) for Local User [1] is Administrator. Be sure that you always hav e one administratoruser, so you can acc ess and

modify configuration and other settings.

IMPORTANT! Record user names and passwords and save them in a secure place where they can be found if

forgotten. A lost password cannot be retrieved from the IS-UNITY card. If the administrator password is lost, the card

must be reset to factory defaults and reconfigured.

To Change the User Names and Passwords

NOTE: There is a 30 character maximum. All printable characters are valid except: \ : ’ < > ~ ? " #

1. Touch , then > BMS & Teamwork > IS-UnitySetup > Configuration > Users > User [n].

2. Enter a new user name and password.

3. Re-enter the password to confirm it.

4. In Authorization for User, select the type of access, see Table 5.2 above.

5. Touch Save.

5 Ext ernal Monitorin g and Buildin g Manag ementSys tems

41

Page 48

5.2.6 Network Configuration

1. Touch , then > BMS & Teamwork > IS-UnitySetup > Configuration > Network.

2. Adjust the settings, and touch Save.

Network Setting Options

Speed Duplex

Selects the speed and duplex configuration of the card’s Ethernet port. It is set to Auto by default. If it requires

changing, contact the system administrator for the proper settings.

Hostname

Identifies the network node. Default is UNITY-serial_number_of_card.

Domain Name Suffix List

Listing of domain name suffixes for resolution of host names. If it requires changing, contact the system administrator

for the proper setting.

Telnet Server

Enables/disables telnet access to the card to prevent unauthorized changes. The default setting disables telnet

access.

SSHv2 Server

Enables/disables SSHv2 (Secure Shell) access to the card to prevent unauthorized changes. The default setting

disables SSHv2 access.

42

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 49

IPv4 and IPv6 Configuration

The IPv4 and IPv6 settings determine which internet protocol will be used for communication over the network connected

to the Ethernet port. IPv4 and IPv6 networks will run in parallel (dual stack network), but the protocols are different. See

your network administrator to determine which protocol should be enabled and to determine the correct settings.

1. Touch , then > BMS & Teamwork > IS-UnitySetup > Configuration > Network > IPv4 or IPv6.

2. Adjust the settings, and touch Save.

IPv4 Settings

IPv4 Protocol

Enables IPv4 in the card.

IP Address Method

Mode the card boots into to be a network ready device (Static, DHCP, BootP). Defaultis DHCP.

Static IP Address

Network address for the interface.

Subnet Mask

Network mask for the interface which divides a network into manageable segments.

Default Gateway

IP address of the gateway for network traffic destined for other networks or subnets.

DNS Server Address Source

Source of DNS server identification (None, Automatic, Configured).

Primary DNS Server

Network address of the primary DNSserver.

Secondary DNS Server

Network address of the secondary DNS server.

IPv6 Settings

IPv6 Protocol

Enables IPv6 in the card.

5 Ext ernal Monitorin g and Buildin g Manag ementSys tems

43

Page 50

IP Address Method

Mode the card boots into to be a network ready device (Static, Auto). DefaultisAuto.

Static IP Address

Network address for the interface.

Prefix Length

Prefix length for the address that divides a network into manageable segments.

Default Gateway

IP address of the gateway for network traffic destined for other networks or subnets. Defaultis 64.

DNS Server Address Source

Source of DNS server identification (None, Automatic, Configured). DefaultisAutomatic.

Primary DNS Server

Primary DNS Server

Secondary DNS Server

Secondary DNS Server

Domain Name Server Test

The Domain Name Server (DNS) test checks key points of a DNS setup for a given domain.

1. Touch , then > BMS & Teamwork > IS-UnitySetup > Configuration > Network > DNSTest.

2. Adjust the settings, and touch Save.

DNS Test Settings

Last Query Response

Response from a DNS to the last query.

Example: gxtwebdemo.liebert.com resolved to 126.4.203.251

Type of Query

Type of DNS query. (Hostname, IP Address)

Query Value

Value for the domain name server (DNS) to resolve. Example: gxtwebdemo.liebert.com

44

Vertiv | Liebert® iCOM™Inst aller/User G uide

Page 51