Page 1

Liebert®

DSE ThermalManagementSystem

Installer/User Guide

Downflow, 250 kW (71 ton) and 265 kW (75 ton) Capacity, 50and60Hz

Page 2

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.Vertiv.com/en-us/support/ for additional assistance.

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 1

2 Nomenclature and Components 7

2.1 Liebert® DSE Model Number Nomenclature 7

2.2 Component Location 9

3 Pre-installation PreparationandGuidelines 11

3.1 Planning Dimensions 11

3.2 Connections and System Setup 12

3.3 Operating Conditions 12

3.3.1 Humidification Control 12

3.4 Shipping Dimensions and Unit Weights 12

4 Equipment Inspection and Handling 15

4.1 Packaging Material 15

4.2 Handling the Unit while Packaged 16

4.3 Unpacking the Unit 16

4.4 Removing the Unit from the Skid 17

4.5 Unpacking and Handling the Fan Section 20

5 Electrical Field Connections 21

6 Piping and Refrigerant Requirements 23

6.1 Drain Fluid Piping 24

6.1.1 Field Installed, Gravity Fed Drain Line Requirements 24

6.1.2 Condensate Pump Drain Line Requirements 26

6.2 Refrigerant Piping and Charging 26

6.2.1 Refrigerant Piping Guidelines forAir CooledSystems 27

6.2.2 Piping Layout and Condenser Positioning 28

6.2.3 Refrigerant Line Sizes and Equivalent Lengths 28

6.2.4 Refrigerant Charge Requirements for Air Cooled Systems 29

6.2.5 Additional Oil Requirements forScrollandDigital ScrollCompressors 30

6.2.6 Evacuation, Leak Testing, and Charging Air Cooled Systems 32

7 Checklist for Completed Installation 37

7.1 Moving and Placing Equipment 37

7.2 Electrical Installation Checks 37

7.3 Piping Installation Checks 37

7.4 Other Installation Checks 37

8 Initial Startup Checks andCommissioningProcedure forWarrantyInspection 41

9 Maintenance 43

9.1 Filters 44

9.1.1 Replacing the Filters 44

9.2 Fan Maintenance 45

9.2.1 Fan Assembly Troubleshooting 45

9.2.2 Fan Impellers 46

Vertiv | Liebert® DSE Thermal Management System Installer/User Guide | i

Page 4

9.2.3 Blower Motor Lubrication 46

9.2.4 Removing Fan Assembly 46

9.3 Condensate Drain and Condensate Pump System Maintenance 46

9.3.1 Condensate Drain 46

9.3.2 Condensate Pump 46

9.4 Electronic Expansion Valve (EEV) Maintenance 47

9.5 Compressor Maintenance 47

9.5.1 Compressor Oil 47

9.5.2 Replacement Compressors 48

9.5.3 Rotalock Valve on Digital Scroll Compressors 48

9.5.4 Unloading Solenoid(s) on a Digital Scroll Compressor 48

9.5.5 Compressor Electrical Failure (Motor Burnout) 49

9.5.6 Replacing a Compressor with Electrical Failure (MotorBurnout) 49

9.5.7 Compressor Mechanical Failure 49

9.5.8 Replacing a Compressor with Mechanical Failure 50

9.6 Evaporator Coil 50

9.7 Air Cooled Condenser Maintenance 51

10 Preventive Maintenance Checklist 53

Appendices 59

Appendix A: Technical Support and Contacts 59

Appendix B: Submittal Drawings 61

Vertiv | Liebert® DSE Thermal Management System Installer/User Guide | ii

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and maintenance of the

Liebert® DSE. Read this manual thoroughly before attempting to install or operate this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit and in this manual.

Follow all installation, operation and maintenance instructions and all applicable national and local building, electrical and

plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory supplied disconnect switch is inside the

unit. The line side of this switch contains live high voltage. The only way to ensure that there is NO voltage

inside the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all

local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

WARNING! Risk of electric shock. Can cause serious injury or death. Open all local and remote electric power

supply disconnect switches and verify with a voltmeter that power is off before working within the fan motor

electric connection enclosures. Fan motor controls can maintain an electric charge for 10 minutes after power

is disconnected. Wait 10 minutes after power is verified as off before working within the VFD electric

control/connection enclosures. Use only fully trained and qualified HVAC technicians to perform

maintenance on the fans.

WARNING! Risk of electric shock. Can cause injury or death. Open all local and remote electric power supply

disconnect switches and verify that power is Off with a voltmeter before working within the condensate

pump electrical connection enclosure. The Liebert® iCOM™ does not isolate power from the unit, even in the

Unit Off mode. Some internal components require and receive power even during the Unit Off mode of the

Liebert®iCOM™.

1 Importan t Safety Ins tructions

1

Page 6

WARNING! Risk of electric shock. Can cause serious injury or death. The Liebert® iCOM™ microprocessor

does not isolate power from the unit, even in the Unit Off mode. Some internal components require and

receive power even during the Unit Off mode of the Liebert® iCOM™ control. Open all local and remote electric

power disconnect switches and verify with a voltmeter that power is Off before working on any component of

the system.

WARNING! Risk of electric shock. Can cause serious injury or death. Open all local and remote electric power

supply disconnect switches and verify with a voltmeter that power is off before opening the fan motor

electric connection enclosure. Use only fully trained and qualified HVAC technicians to replace or perform

maintenance on the EC fans.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive discharge of high

pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage, injury or death. This

unit contains fluids and gases under high pressure. Use extreme caution when charging the refrigerant

system. Do not pressurize the system higher than the design pressure marked on the unit's nameplate.

WARNING! Risk of very heavy 350 lb. (56.7kg) fan modules dropping downward suddenly. Can cause injury or

death. Support fan modules before removing mounting hardware. Use caution to keep body parts out of the

fan modules pathway during repositioning. Only properly trained and qualified personnel should work on

this equipment.

WARNING! Risk of improper moving. Can cause equipment damage, injury or death. Use only lifting

equipment that is rated for the unit weight by an OSHA-certified rating organization. The center of gravity

varies depending on the unit size and selected options. The slings must be equally spaced on either side of

the center of gravity indicator. Unit weights are listed in Shipping Dimensions and Unit Weights.

WARNING! Risk of contact with high speed rotating fan blades. Can cause serious injury or death. Open all

local and remote electric power supply disconnect switches, verify with a voltmeter that power is off, and

verify that all fan blades have stopped rotating before working in the unit cabinet or on the fan assembly. If

control voltage is applied, the fan motor can restart without warning after a power failure. Do not operate the

unit with any or all cabinet panels removed.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment damage,

serious injury or death. Installation and service of this equipment should be done only by qualified personnel

who have been specially trained in the installation of air conditioning equipment and who are wearing

appropriate, OSHA-approved PPE.

2

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 7

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of top heavy unit falling over. Improper handling can cause equipment damage, injury or

death. Read all of the following instructions and verify that all lifting and moving equipment is rated for the

weight of the unit before attempting to move, lift, remove packaging from or prepare the unit for installation.

WARNING! Risk of wiring damage, short circuits and electric shock. Can cause overheated wiring, smoke, fire,

activation of fire suppression systems and EMS personnel and equipment, building and equipment damage,

injury or death. Insert CSA certified or UL listed bushings into holes and or knockouts used to route wiring

through metal panels to protect the wire insulation from contact with sheet metal edges.

CAUTION: Risk of explosive discharge of high pressure refrigerant. Can cause serious injury. Neutral and

service ports on the rotalock valve do not have a valve core. Front seat the service valves and relieve pressure

from the compressor before loosening a part or a component attached to the service valve. Follow local codes

to properly reclaim refrigerant.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of contact with hot surfaces. Can cause injury. The compressor, refrigerant discharge lines,

fan motor, and some electrical components are extremely hot during unit operation. Allow sufficient time for

them to cool to a touch safe temperature before working within the unit cabinet. Use extreme caution and

wear appropriate, OSHA-approved PPE when working on or near hot components.

CAUTION: Risk of handling heavy and lengthy parts. Can cause personal injury and equipment damage.

Cabinet panels can exceed 5 ft. (1.5 m) in length and weigh more than 35 lb. (15.9 kg). Follow relevant OSHA

lifting recommendations and consider using a two person lift for safe and comfortable removal and

installation of cabinet panels. Only properly trained and qualified personnel wearing appropriate, OSHAapproved PPE should attempt to remove or install cabinet panels.

CAUTION: Risk of exposure to harmful noise levels. Can cause hearing injury or loss. Depending on the

installation and operating conditions, a sound pressure level greater than 70dB(A) may arise. Take

appropriate technical safety measures. Operating personnel must wear appropriate, OSHA-approved PPE

and observe all appropriate hearing protection safety requirements.

1 Importan t Safety Ins tructions

3

Page 8

NOTICE

NOTICE

CAUTION: Risk of excessive refrigerant line pressure. Can cause tubing and component rupture resulting in

equipment damage and personal injury. Do not close off the refrigerant-line isolation valve for repairs unless

a pressure relief valve is field installed in the line between the isolation valve and the check valve. The

pressure relief valve must be rated 5% to 10% higher than the system design pressure. An increase in

ambient temperature can cause the pressure of the isolated refrigerant to rise and exceed the system design

pressure rating (marked on the unit nameplate).

Risk of improper power supply connection. Can cause equipment damage and loss of warranty coverage.

Prior to connecting any equipment to a main or alternate power source (for example: backup generator

systems) for startup, commissioning, testing, or normal operation, ensure that these sources are correctly

adjusted to the nameplate voltage and frequency of all equipment to be connected. In general, power source

voltages should be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure

that no three phase sources are single phased at any time.

Risk of oil contamination with water. Can cause equipment damage.

Liebert®DSE systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster rate

when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration system,

extreme care must be used when opening systems during installation or service. If water is absorbed into the

POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If the oil

is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent in a

refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to bring

any foreign matter back to the compressor.

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into air cooled compressorized systems before they are started. Starting

digital scroll compressors without proper refrigerant charging can cause the compressors to operate at less

than 5°F (–15°C) evaporator temperature and at less than 52psig(358kPa). Operation for extended periods at

less than 52psig(358kPa) can cause premature compressor failure.

4

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 9

NOTICE

NOTICE

NOTICE

Risk of clogged or leaking drain lines and leaking water supply lines. Can cause equipment and building

damage.

This unit requires a water drain connection. Drain lines must be inspected at startup and periodically, and

maintenance must be performed to ensure that drain water runs freely through the drain system and that lines

are clear and free of obstructions and in good condition with no visible sign of damage or leaks. This unit may

also require an external water supply to operate.

Improper installation, application and service practices can result in water leakage from the unit. Water

leakage can result in catastrophic and expensive building and equipment damage and loss of critical data

center equipment.

Do not locate unit directly above any equipment that could sustain water damage.

We recommend installing a monitored fluid detection system to immediately discover and report coolant-fluid

system and condensate drain line leaks.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet.

Installation of a second trap will prevent drain water flow and will cause the water to overflow the drain pan.

Sagging condensate drain lines may inadvertently cause an external trap.

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may be too large to fit

through a doorway or hallway while on the skid. Measure the unit and passageway dimensions, and refer to the

installation plans prior to moving the unit to verify clearances.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and contact damage.

NOTE: The Liebert® indoor cooling unit has a factory installed, high pressure safety switch in the high side

refrigerant circuit. Each refrigerant receiver contains a fusible plug for fire safety purposes. Consult your local

building code to determine whether the refrigerant piping will require additional, field provided pressure relief

devices.

1 Importan t Safety Ins tructions

5

Page 10

This page intentionally left blank

6

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 11

2 NOMENCLATURE AND COMPONENTS

This section describes the model number for Liebert® DSE units and components.

2.1 Liebert® DSE Model Number Nomenclature

Table 2.2 below describes each digit of the model number.

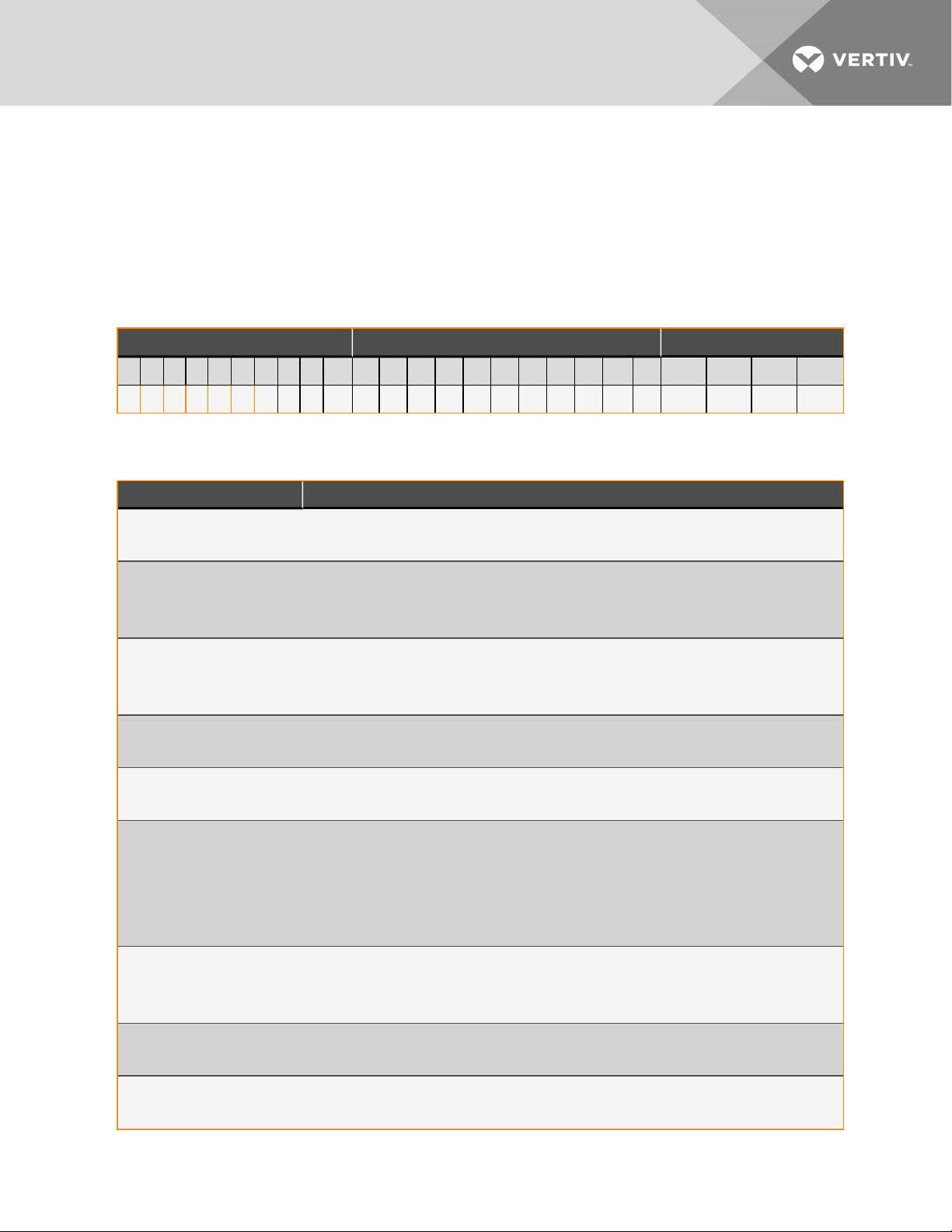

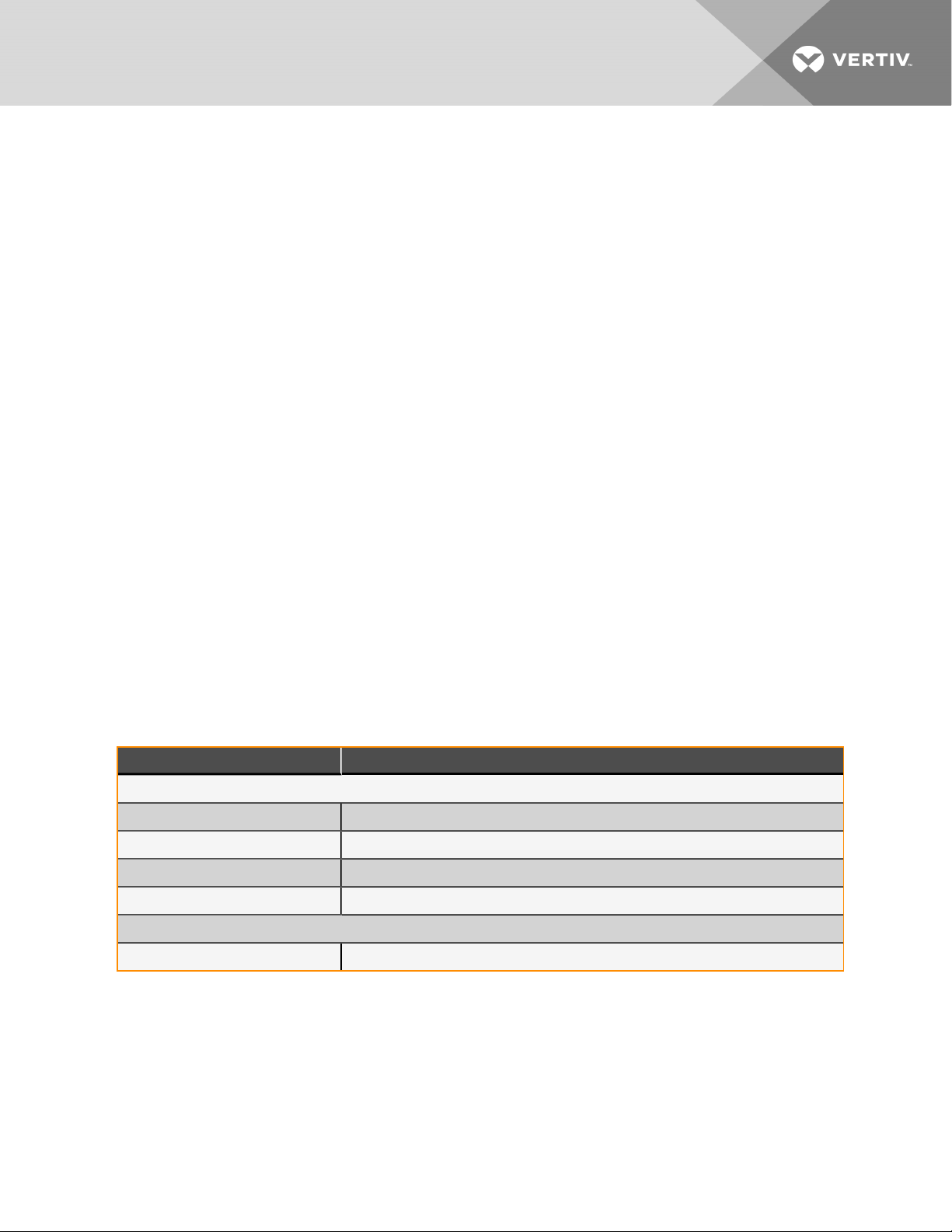

Table 2.1 DSE Model Number

ModelNumber Digits 1 to 10 ModelDetails ModelNumber Digits 1 1 t o 14

1 2 3 4 5 6 7 8 9 10 11 12 1 3 14 15 1 6 17 18 1 9 20 21 22 23 24 25

D A 2 5 0 D P 3 A T 0 2 0 8 1 1 L 0 B 0 P 1 2 3 S

Table 2.2 DSE Model Number Digit Definitions

Digit Description

Digits 1 and 2 = Product Family

DA = Liebert®DSE

Digit3, 4, 5 = Nominal Cooling Capacity, kW

250 = 250 kW

265 = 265 kW

Digit6 = Air Discharge

D = Downflow, bottom discharge

H = Downflow, horizontal discharge

Digit7 = System Type

P = Air cooled, Econ-O-Phase ready

Digit8 = Airflow (Fan Type)

3 = Direct-drive + VFD (plenum)

Digit9 = Voltage

A = 460V - 3ph - 60Hz

B = 575V - 3ph - 60Hz

G = 415 V - 3ph - 50Hz

*For applications that require less than 400V/3ph/50Hz, please consult your loca l sales office for assistance.

Digit10 = Cooling System

T = Tandem with digital scroll, R-410A

P = Ta ndem with digital scroll, R-410A with Power Factor Correction

Digit11 = Humidifier

0 = N o humidifier

Digit12 = Display

2 = Liebert® iCOM™ (High Definition)

2 Nomenclature and Components

7

Page 12

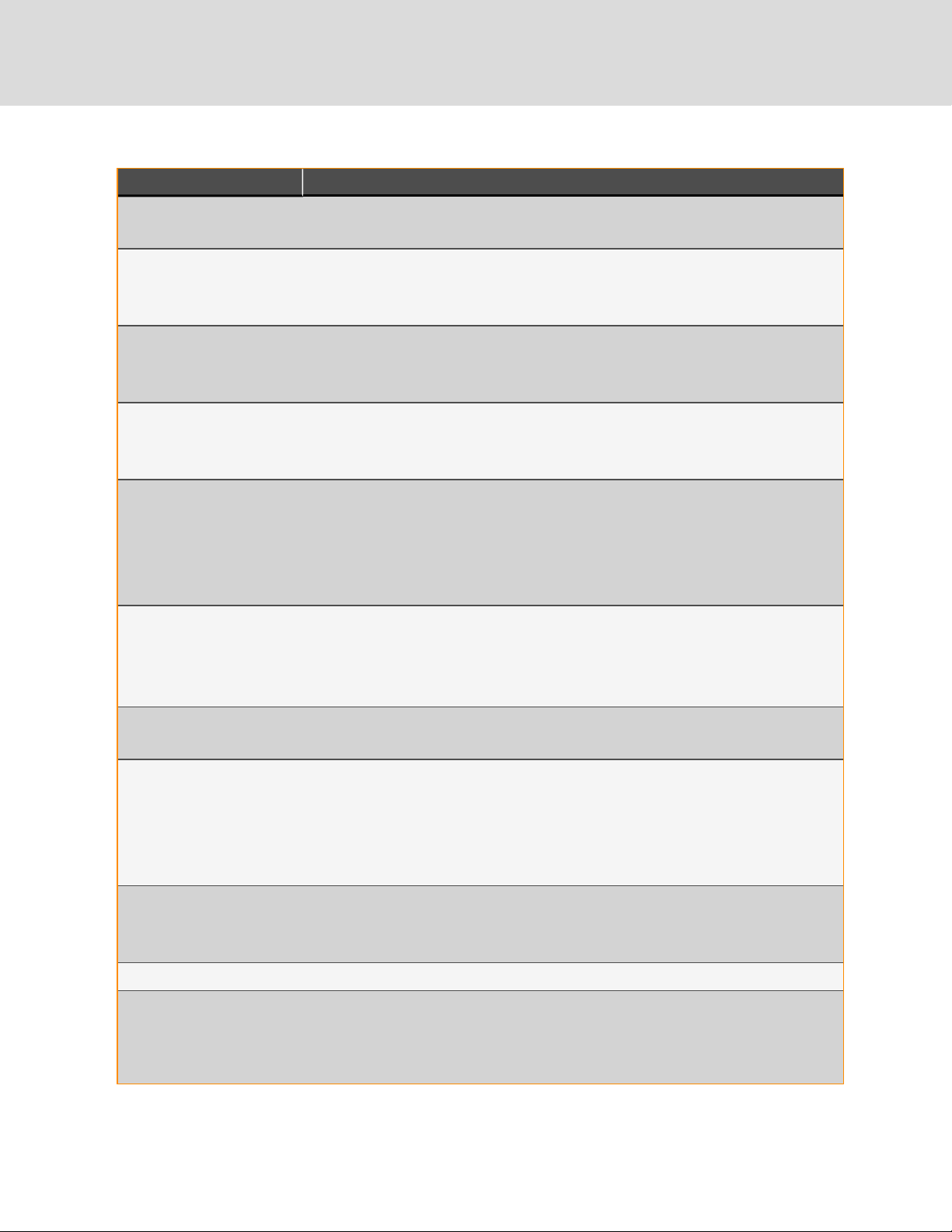

Table 2.2 DSE Model Number Digit Definitions (continued)

Digit Description

Digit13 = Reheat

0 = N one

Digit14 = Air Filter

8 = MERV 8, 4 in .

9 = MERV 11, 4 in .

Digit15 = Coil Option

1 = Non-coated coil, indoor unit

2 = Coated coil, indoor unit

Digit16 = Enclosure Option

1 = Color standard

2 = Color optional

Digit17 = High voltage option

L = Locking disconnect

5 = Locking disconnect, with condensate pump

S = Dual locking disconnect with reversing starter and condenser subfeed

9 = Dual locking disconnect with reversing starter with condensate pump and condenser subfeed

Digit18 = Option packages

0 = N one

L = Option package #1 - low voltage terminal package contact

D = Low Voltage Terminal Package and Remote Humidifier Contact

Digit19 = Monitoring

B = Base comms and connectivity

Digit20 = Sensors

0 = N one

H = High Temperature Sensor

S = Smoke Sensor

F = Smoke Sensor and High Temperature Sensor

Digit21 = Pa ckaging

P = Domestic

C = Export

Digit22-24 = Factory Configuration Number

Digit25 = Configuration Code

A = No SFAs (Any alpha letter except S)

S = Special fea ture authorization (SFA). A non-standard configuration or feature of the product that requires the local factory

representative to work directly with the fa ctory.

8

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 13

2.2 Component Location

The unit component locations are described in the submittal documents included in the Submittal Drawings.

The following table lists the relevant documents by number and title.

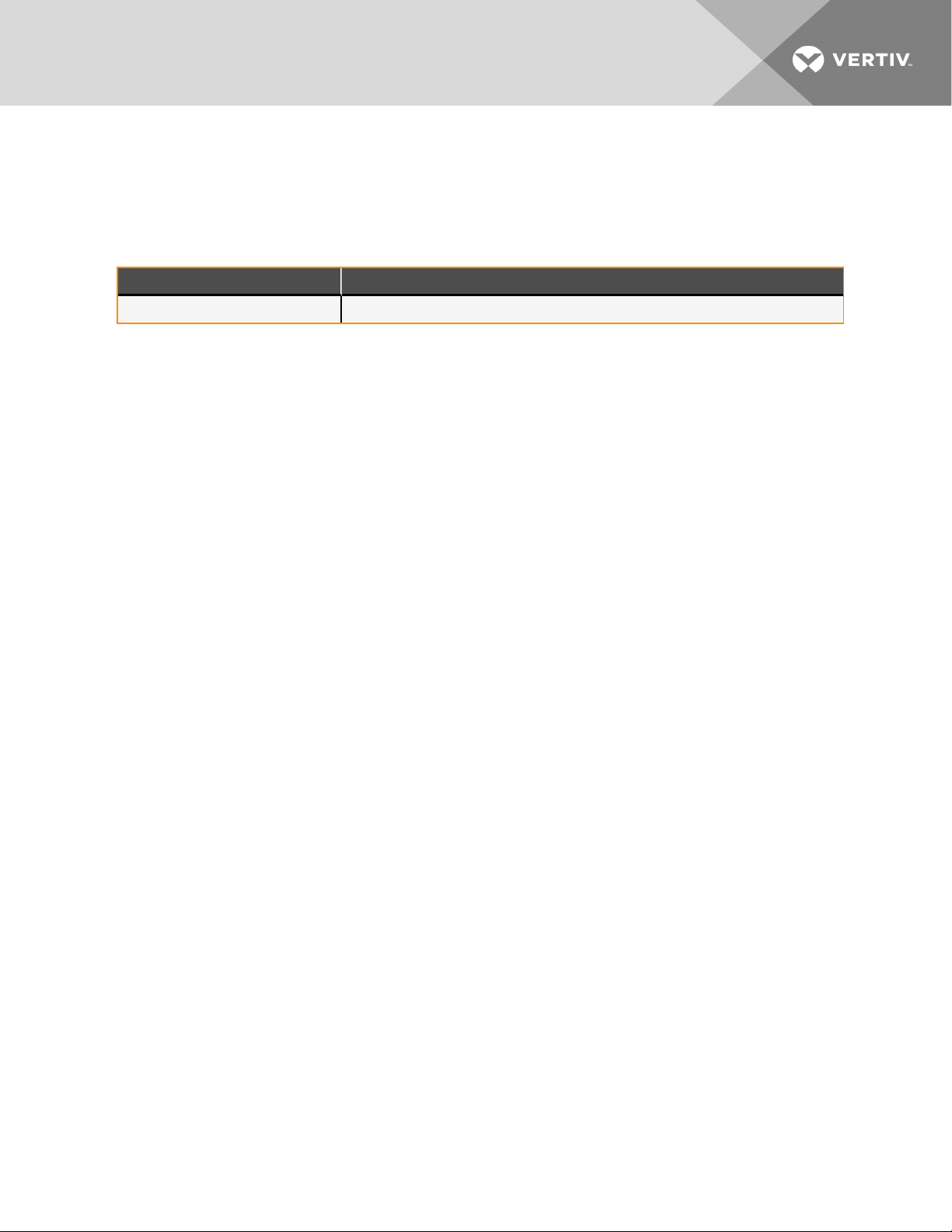

Table 2.3 Component Location Drawings

Docu ment Num ber Title

DPN004368 Liebert®DSECabinet Dimension Data DA250, DA265 with Horizontal Discharge

2 Nomenclature and Components

9

Page 14

This page intentionally left blank

10

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 15

3 PRE-INSTALLATION PREPARATIONANDGUIDELINES

NOTE: Before installing unit, determine whether any building alterations are required to run piping, wiring and duct

work. Follow all unit dimensional drawings and refer to the submittal engineering dimensional drawings of individual

units for proper clearances.

Refer to DSE Model Number Digit Definitions, and submittal drawings to determine the type of system being installed and

anticipate building alterations, piping and duct work needed.

The unit dimensions, pipe connection locations, and piping schematics are described in the submittal documents included

in the Submittal Drawings.

• Verify that the floor is level, solid and sufficient to support the unit. See Shipping Dimensions and Unit Weights

on the next page for unit weights.

• Confirm that the room is properly insulated and has a sealed vapor barrier.

• For proper humidity control, keep outside or fresh air to an absolute minimum (less than 5% of total air

circulated in the room).

• Do not install a Liebert® DSE in an alcove or at the end of a long, narrow room.

• Install the units as close as possible to the largest heat load.

• Allow at least the minimum recommended clearances for maintenance and service. See the appropriate

submittal drawings for dimensions.

We recommend installing an under floor water detection system. Contact your Vertiv representative for information.

3.1 Planning Dimensions

The unit, floor stand, and plenum dimensions are described in the submittal documents included in the Submittal Drawings.

The following table lists the relevant documents by number and title.

Table 3.1 Dimension Planning Drawings

Docu ment Num ber Title

Downflow Units

DPN004366 Liebert®DSE Cabinet Dimensional Data DA250, DA265 with Horizontal Discharge

DPN004516 Liebert® DSE Cabinet Dimensional Data DA250, DA265 with Bottom Discharge

DPN004514 Liebert® DSE Installation and Service Clearance Data DA250, DA265

DPN004581 Liebert® DSE Floor Planning for Adjacent DA250, DA265 Units

Floor Stands

DPN004511 Liebert®DSE Floor Stand Dimensional Data DA250, DA265

3 Pr e-installation PreparationandG uidelin es

11

Page 16

3.2 Connections and System Setup

• The unit requires a drain, which must comply with all applicable codes. See Connections and System Setup

above, for details.

• If seismic requirements apply, consult your Vertiv representative for information about a seismic rated floor

stand.

NOTE: Seal openings around electrical connection to prevent air leakage. Failure to do so could reduce the unit’s

cooling performance.

The Liebert® DSE controls superheat with an electronic expansion valve (EEV). The EEV controller adjusts the orifice based

on suction pressure and temperature. The EEV control will drive the valve to maintain the superheat setpoint, set in the

Liebert® iCOM™, using a Proportional, Integral, Derivative (PID) routine. The PID control values are set at the factory for

most applications. These default values PID will allow stable superheat control of the unit.

3.3 Operating Conditions

The Liebert® DSE must be operated in a conditioned space within the operating envelope that ASHRAE recommends for

data centers. Operating the DSE outside of this envelope can decrease equipment reliability. Refer to ASHRAE’s

publication, “Thermal Guidelines for Data Processing Environments.”

The recommended maximum for return air temperature is 105°F (40°C) and maximum dew point is 59°F (15°C). The

recommended minimum return air temperature setpoint for the DSE is 85°F(29.4°C).

3.3.1 Humidification Control

The humidifier option is not available on the DA250 or DA265. A remote humidifier contact is available for a standalone

humidifier.

3.4 Shipping Dimensions and Unit Weights

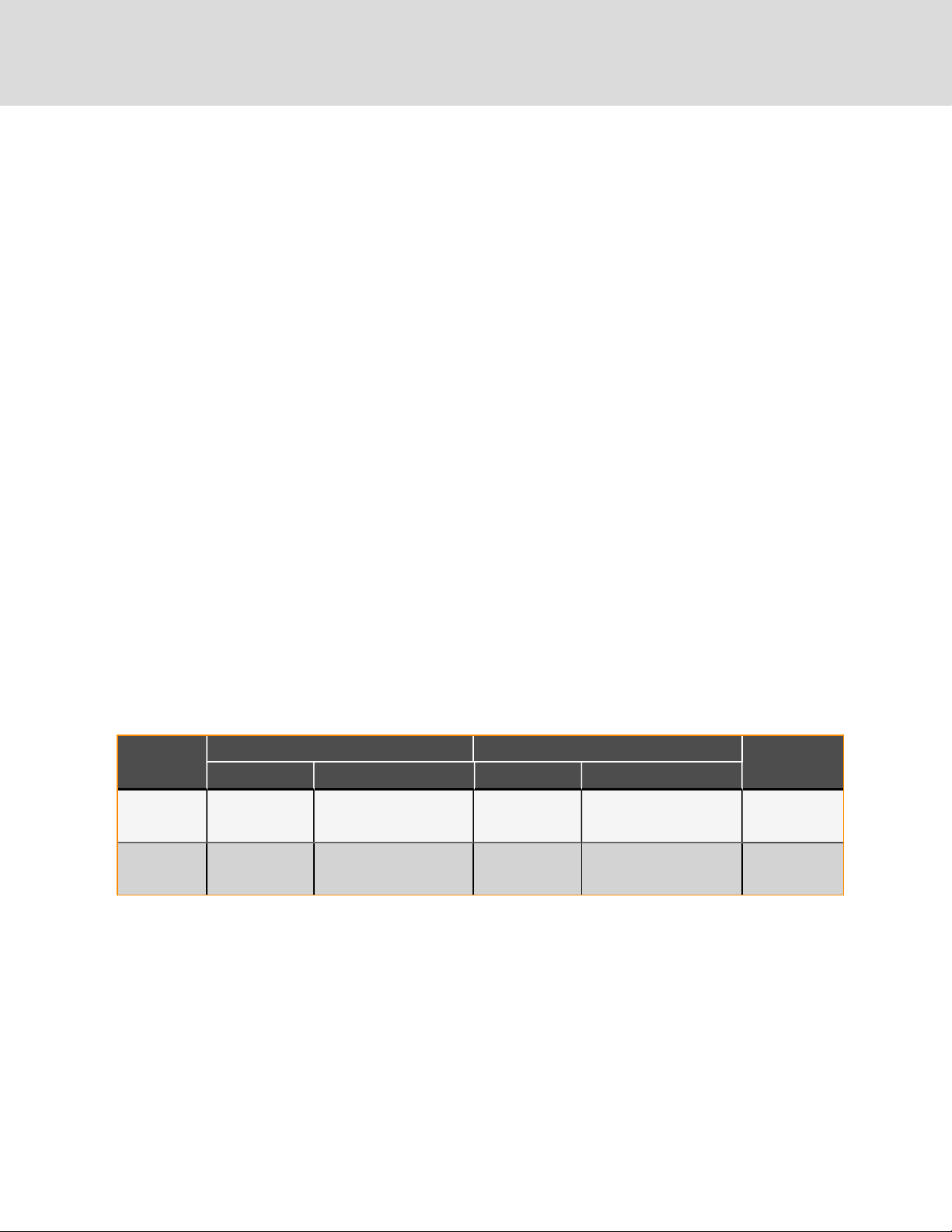

Table 3.2 Downflow Unit Domestic and Export Shipping Dimensions and Weights

Model #

DA250, DA265

Fan section

Ship Weight, lb(kg) Shippin g Dim ensions, in.(mm ) Ship Weight, lb(kg) Shipping Dimensio ns, in.(mm)

6,160

(2,794)

3,281

(1,488)

Dom estic Packaging Export Packaging

90 x 128 x 97

(2,286 x 3, 251 x 2,464)

90 x 128 x 54

(2,286 x 3, 251 x 1,37 2)

6,540 (2,966)

3,676 (1,667)

90.5 x 1,28.5 x 99

(2,299 x 3,264 x 2,515)

90.5 x 1,28.5 x 99

(2,299 x 3,264 x 2,515)

Dry Weight, lb(kg)

4,761

(2,159)

2325

(1,055)

12

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 17

Table 3.3 Liebert® MCV Condenser Unit Domestic and Export Shipping Dimensions and Weights

Dom estic Packaging Export Packaging

Model #

Ship Weight, lb

(kg)

Shippin g

dimension s, ft

(mm)

Ship Weight, lb

(kg)

Shippin g

dimension s, ft

(mm)

Dry Weight, lb

(kg)

Max. Operation

Weight, lb(kg)

1

MCV440

(singleskid)

8-fan+PR250

2

MCV440

(dual skid)

16-fan+PR250

(qty.2)

1

Deduct 120 lbs. (55kg) if no receivers

2

Deduct 220 lbs. (100kg) if no receivers.

5,900

(2,676)

11,580

(5,252)

8ft 6 in. x 14 ft 6

in. x 9ft6in.

(2,591 x 4,420 x

2,896)

8ft 6 in. x 29ft x

9ft6in.

(2,591 x 8,839 x

2,896)

6,200

(2,812)

11,580

(5,252)

9ft 5 in. x 14ft

9in. x 9ft6in.

(2,870 x 4,496 x

28,96)

9ft 5 in. x 29ft

4in. x 9ft6in.

(2,870 x 8,941 x

2,896)

5,800

(2,667)

11,560

(5,243)

5,940

(2,694)

11,880

(5,388)

3 Pr e-installation PreparationandG uidelin es

13

Page 18

This page intentionally left blank

14

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 19

4 EQUIPMENT INSPECTION AND HANDLING

WARNING! Risk of top heavy unit falling over. Improper handling can cause equipment damage, injury or

death. Read all of the following instructions and verify that all lifting and moving equipment is rated for the

weight of the unit before attempting to move, lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of passageway interference. Can cause unit and/or structure damage. The unit may be too large to fit

through a passageway while on or off the skid. Measure the unit and passageway dimensions, and refer to the

installation plans prior to moving the unit to verify clearances.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Keep the unit upright, indoors and protected from dampness, freezing temperatures

and contact damage.

Upon arrival of the unit and before unpacking:

• Verify that the labeled equipment matches the bill of lading.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv or to your sales

representative.

Equipment Recommended for Handling the Unit:

• Forklift

• Slings

• Spreader bars

• Beam trolleys

• Chain hoists

• Gantries

4.1 Packaging Material

All material used to package this unit is recyclable. Please save for future use or dispose of the material appropriately.

4 Equipment Inspection and Hand lin g

15

Page 20

4.2 Handling the Unit while Packaged

If possible, transport the unit with a forklift

When using a forklift:

• Make sure that the lift has adjustable forks, and are spread to the widest allowable distance to still fit under the

skid.

• Make sure that the fork length is suitable for the skid length. Skid length is 128in. (3251mm).

• If the unit must be lifted higher than 2in.(51mm) to 4in. (102 mm), all personnel not directly involved in

moving the unit must be 20ft. (5m) or farther from the unit.

4.3 Unpacking the Unit

Remove exterior package material from around, and on top of the unit.

Figure 4.1 Unpacking the Unit

16

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 21

4.4 Removing the Unit from the Skid

NOTE: If you do not follow these steps, damage could occur to the panels and base of the unit.

1. Referring to Figure 4.2 below, use a 9/16 in. socket driver to remove the lag screws (24 total) from the four

corner brackets to detach the unit from the skid.

Figure 4.2 Remove Corner Brackets

4 Equipment Inspection and Hand lin g

17

Page 22

2. Open the door indicated in Figure 4.3 below, and locate the rigging fastener kit that is secured to the bottom

base inside the door.

3. Using the instructions included in the kit, install the rigging hardware for lifting the unit from the skid. Figure 4.3

below, shows an example of one of the eye nuts installed.

Figure 4.3 Locate the Rigging Fastener Hardware Kit

18

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 23

4. Attach the recommended rigging equipment to the eye nuts installed in Step 3.

5. Using the rigging equipment, lift the unit from the skid, and remove the skid from under the unit, see Figure 4.4

below.

Figure 4.4 Lifting Unit and Removing Skid

4 Equipment Inspection and Hand lin g

19

Page 24

6. Use the rigging equipment to move the unit to the final installation location, see Figure 4.5 below.

Figure 4.5 Moving the Unit with Rigging

4.5 Unpacking and Handling the Fan Section

Refer to drawing number 336511 "Instructions Handling/Installation of Fan Section CW/DSE" that is included in the fan

plenum packaging for instructions on uncrating and handling the fan section.

20

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 25

5 ELECTRICAL FIELD CONNECTIONS

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory supplied disconnect switch is inside the

unit. The line side of this switch contains live high voltage. The only way to ensure that there is NO voltage

inside the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all

local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

NOTICE

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of wiring damage, short circuits and electric shock. Can cause overheated wiring, smoke, fire,

activation of fire suppression systems and EMS personnel and equipment, building and equipment damage,

injury or death. Insert CSA certified or UL listed bushings into holes and or knockouts used to route wiring

through metal panels to protect the wire insulation from contact with sheet metal edges.

Risk of improper electrical connection of three phase input power. Can cause backward compressor rotation

and unit damage. Service technicians should use a gauge set on the system during the initial startup to verify

that the three phase power is connected properly. Three phase power must be connected to the unit line

voltage terminals in the proper sequence so that the compressors rotate in the proper direction. Incoming

power must be properly phased to prevent compressors from running backward. We recommend checking the

unit’s phasing with proper instrumentation to ensure that power connections were made correctly. We also

recommend verifying discharge and suction pressures during startup to ensure that the compressors are

running in the correct direction.

5 Electrical Field Connections

21

Page 26

NOTICE

Risk of improper power supply connection. Can cause equipment damage and loss of warranty coverage.

Prior to connecting any equipment to a main or alternate power source (for example: backup generator

systems) for startup, commissioning, testing, or normal operation, ensure that these sources are correctly

adjusted to the nameplate voltage and frequency of all equipment to be connected. In general, power source

voltages should be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure

that no three phase sources are single phased at any time.

See transformer label for primary tap connections. Installer will need to change transformer primary taps if

applied unit voltage is other than pre-wired tap voltage.

NOTE: Seal openings around piping and electrical connection to prevent air leakage. Failure to do so could reduce the

unit’s cooling performance.

Three phase electrical service is required for all models. Electrical service must conform to national and local electrical

codes. Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer the appropriate

submittal drawing, listed in Table 5.1 below, for electrical service entrances into unit

• Liebert® DSE voltage should be verified with available power supply before installation. Refer to the unit’s

electrical schematic and serial tag for specific electrical requirements. Line voltage electrical service is also

required for all condensers at the location of the condenser.

• For the most reliable operation of the system, the indoor unit and the Liebert® MCV condenser should be on the

same power source. The Liebert® DSE system offers an option for a power feed from the active source on the

indoor unit to the outdoor condenser. This configuration provides the greatest reliability and fastest recovery

during power loss or source change.

• When powering the outdoor condenser from the indoor unit, there is a breaker/fuse on the indoor unit.

• A unit disconnect is standard on the Liebert® MCV skid. However, a site disconnect may be required per local

code to isolate the unit for maintenance. Refer to the unit’s serial tag for specific condenser electrical

requirements.

• Route the supply power to the site disconnect switch and then to a factory provided high voltage enclosure

located on the MCV heat rejection skid.

• A manual electrical disconnect switch should be installed in accordance with local codes and distribution

system. Consult local codes for external disconnect requirements.

The electrical and unit to unit connections are described in the submittal documents included in the Submittal Drawings.

The following table lists the relevant documents by number and title.

Table 5.1 Electrical Field Connection Drawings

Docu ment Num ber Title

DPN004797 Liebert®DSE Electrical Field Connections DA250, DA265 Downflow Models

DPN003886

Unit to Unit Networking

DPN004351

22

Liebert®Heat Rejection Skid CANbus and Interlock Connections Liebert®MCV and Liebert®MCV

EconoPhase and Base Assembly

Liebert®iCOM™ Unit to Unit Network Connections (Liebert® CW, Liebert® CWA, Liebert® DS, Liebert® DSE,

Liebert®P DX, Liebert® PCW

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 27

6 PIPING AND REFRIGERANT REQUIREMENTS

All fluid and refrigeration connections to the unit are sweat copper. Factory installed piping brackets must not be removed.

Field installed piping must be installed in accordance with local codes and must be properly assembled, supported,

isolated and insulated. Avoid piping runs through noise sensitive areas, such as office walls and conference rooms.

Refer to specific text and detailed diagrams in this manual for other unit specific piping requirements.

All piping below the elevated floor must be located so that it offers the least resistance to air flow. Careful planning of the

piping layout under the raised floor is required to prevent the air flow from being blocked. When installing piping on the

subfloor, we recommend that the pipes be mounted in a horizontal plane rather than stacked one above the other. Whenever

possible, the pipes should be run parallel to the air flow.

The following pipe connections are required:

• A drain line from the unit.

• A drain line from the secondary drain pan (if applicable).

• Refrigerant piping connections between the evaporator unit and the MCV440 heat rejection skid. See

Refrigerant Piping and Charging on page26.

The pipe connection locations, piping general arrangement and schematics are described in the submittal documents

included in the Submittal Drawings.

The following tables list the relevant documents by number and title.

Table 6.1 Piping General Arrangment Drawings

Docu ment Num ber Title

DPN004476 Piping Schematic, DA125, DA150, DA165 & DA250 with Liebert®MCV

DPN005206 Piping Schem atic, DA265 with Liebert®MCV

Piping Arrangement - Liebert®MCVCondenser and EconoPhase Pump Locations

DPN003965 Liebert® DSEAir Cooled Piping Schematic Liebert®MCV Mounted above Liebert®DA125-250

DPN005207 Liebert® DSE Air Cooled P iping Schematic Liebert® MCV Mounted above DA265

Table 6.2 Piping Connection Drawings

Docu ment Num ber Title

DPN004208 Liebert®DSE Connection Locations, DA250, DA265

6 Pip ing and Refrigerant Requirements

23

Page 28

6.1 Drain Fluid Piping

NOTICE

Risk of water leakage. Can cause severe property damage and loss of critical data center equipment.

The Liebert®DSE requires a water drain connection. Improper installation, application and service practices

can result in water leakage from the unit.

Do not locate the unit directly above any equipment that could sustain water damage.

We recommend installing monitored leak detection equipment for the water supply lines and the internal unit

water lines.

6.1.1 Field Installed, Gravity Fed Drain Line Requirements

NOTICE

Risk of water backing up in the drain line. Leaking and overflowing water can cause equipment and building

damage.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet.

Installation of a second trap will prevent drain water flow and will cause the water to overflow the drain pan.

Sagging condensate drain lines may inadvertently create an external trap.

Observe the following requirements when installing and routing the drain line:

• The drain line must be sized for 2 gpm (7.6 l/m) flow.

• The drain line must be located so it will not be exposed to freezing temperatures.

• The drain should be the full size of the drain connection.

• The drain line must slope continuously away from the unit. Pitch drain line toward drain a minimum of 1/8in.

(3mm) per 1ft (305mm) of length.

• Drain is trapped internally. Do not externally trap the drain line.

• The drain line must be rigid enough that it does not sag between supports, which unintentionally creates traps.

• The drain line must comply with all applicable codes.

• We recommend installing monitored, under floor leak detection equipment.

24

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 29

Figure 6.1 Correct and Incorrect Gravity Drains for Downflow Units

Table 6.3 Gravity Fed Drain Line Figure Descriptions

Item D escription

1 Correct drain installation.

2 Incorrect drain installation.

3 DSEunit.

4 Internal drain.

5 External drain.

6 Continuous downwardslope

7 External trap. Do not trap externally..

8 External trap, although unintentional. Lines must be rigid enough to not bow ov er the top of other objects.

6 Pip ing and Refrigerant Requirements

25

Page 30

6.1.2 Condensate Pump Drain Line Requirements

NOTICE

Risk of water backing up in the drain line. Leaking and overflowing water can cause equipment and building

damage.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet.

Installation of a second trap will prevent drain water flow and will cause the water to overflow the drain pan.

Sagging condensate drain lines may inadvertently create an external trap.

Observe the following requirements when installing and routing the drain line:

• The drain line must be located so it will not be exposed to freezing temperatures.

• Size the piping based on the available condensate head.

• Drain is trapped internally. Do not externally trap the drain line.

• The drain line must be rigid enough that it does not sag between supports, which unintentionally creates traps.

• We recommend installing monitored, under floor leak detection equipment.

Factory Installed Condensate Pump

If your unit includes an optional condensate pump, the pump is factory installed inside the unit and a 3/4 in. copper sweat

connection is provided on the unit.

6.2 Refrigerant Piping and Charging

WARNING! Risk of over pressurization of the refrigeration system. Can cause explosive discharge of high

pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage, injury, or death. This

unit contains fluids and gases under high pressure. Use extreme caution when charging the refrigerant

system. Do not pressurize the system higher than the design pressure marked on the unit's nameplate.

CAUTION: Risk of excessive refrigerant line pressure. Can cause equipment damage or injury resulting from

tubing and component rupture. Do not close off the refrigerant-line isolation valve for repairs unless a

pressure relief valve is field installed in the line between the isolation valve and the check valve. The

pressure relief valve must be rated 5% to 10% higher than the system design pressure. An increase in

ambient temperature can cause the pressure of the isolated refrigerant to rise and exceed the system design

pressure rating (marked on the unit nameplate).

Consult local building and plumbing codes for installation requirements of additional pressure relief devices when isolation

valves are field installed. Do not isolate any refrigerant circuits from over pressurization protection.

Table 6.4 System Refrigerant Pressures

Maximum Design O perating Pressure (High Side) 530 psig 3655 kPa Noted on the unit serial tag

High Pressure Cut Out Safety Switch 580 psig 4000 kP a Nominal

26

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 31

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

Liebert®DSE systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster rate

when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration system,

extreme care must be used when opening systems during installation or service. If water is absorbed into the

POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If the oil

is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent in a

refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to bring

any foreign matter back to the compressor.

6.2.1 Refrigerant Piping Guidelines forAir CooledSystems

• Field installed interconnecting piping should be properly selected based on local codes and unit labeling.

• Air cooled units ship with a nitrogen holding charge. Do not vent the charge until all refrigerant piping is in

place, ready for connection to the unit and condenser.

• Use copper piping with a brazing alloy with a minimum temperature of 1350°F (732°C), such as Sil-Fos. Avoid

soft solders, such as 50/50 or 95/5.

• Use a flow of dry nitrogen through the piping during brazing to prevent formation of copper oxide scale inside

the piping. When copper is heated in the presence of air, copper oxide forms. POE oils will dissolve these

oxides from inside the copper pipes and deposit them throughout the system, clogging filter driers and

affecting other system components.

• A pure dry nitrogen flow of 1-3 ft3/min (0.5-1.5 l/s) inside the pipe during brazing is sufficient to displace the air.

Control the flow using a suitable measuring device.

• Ensure that the tubing surfaces to be brazed are clean and that all burrs have been removed from the ends of

the tubes.

• Ensure that all loose material has been cleaned from inside the tubing before brazing.

• Protect all refrigerant line components within 18in. (460mm) of the brazing site by wrapping them with a wet

cloth or with a suitable heat sink compound.

• Isolate piping from building using vibration isolating supports.

• The Liebert® MCV heat rejection skid cannot be installed below the evaporator.

• The DA250 is used with a Liebert® MCV heat rejection skid with receiver tanks. For this system, the outlet of

the receivers on the outdoor Liebert® MCV heat rejection skid must be higher than the elevation of the

electronic expansion valves (EEVs) inside of the indoor unit. If the vertical height of the receiver outlet is

greater than 60 ft. (18.3m) above the EEV, consult the factory. Refer to DPN003965 in Submittal Drawings on

page61.

• The DA265 is used with a Liebert® MCV heat rejection skid with without receiver tanks. For this system, the

bottom of the condenser coil on the outdoor Liebert® MCV heat rejection skid must be higher than the

elevation of the EEV inside of the indoor unit. If the vertical height between the condenser coil bottom and the

EEV is greater than 60 ft. (18.3m), consult the factory. Refer to DPN005207 in Submittal Drawings on page61

• Install traps on hot gas (discharge) lines at the base of vertical risers over 5ft.(1.5m) and then for vertical rises

over 25 ft. (7.6 m), install a trap in 20 ft (6 m) increments or evenly-divided over the vertical rise. The DA250

with piping out the top of the unit has internally installed traps on the hot gas lines.

• Pitch horizontal hot gas piping down at a minimum rate of 1/2in.per 10ft. (42mm per 10m) so that gravity will

aid in moving oil in the direction of refrigerant/oil flow.

• Consult factory if piping run exceeds 200ft. (61m) linear length or 300ft.(91m) equivalent length.

6 Pip ing and Refrigerant Requirements

27

Page 32

• Keep piping clean and dry, especially on units with R-410A refrigerant.

• Avoid piping runs through noise-sensitive areas.

• Do not run piping directly in front of discharge air stream.

• Refrigerant oil – do not mix oil types (see Compressor Oil).

Refer to ASHRAE Refrigeration Handbook for general, good-practice refrigeration piping. The indoor cooling unit has a

factory installed high pressure safety switch in the high side refrigerant circuit. A fusible plug is installed in each Liebert®

DSE receiver.

NOTE: All indoor and outdoor field refrigerant piping must be insulated 1/2 in. minimum. All outdoor insulation must

be UV and ozone resistant.

• Refer to Refrigerant Line Sizes and Equivalent Lengths below, for recommended refrigerant piping sizes based

on equivalent pipe lengths.

• Refer to Refrigerant Charge Requirements for Air Cooled Systems on the facing page, for the refrigerant-charge

requirements of the system.

• Refer to Charging DA250 Air Cooled Systems (Liebert® MCV440 with Receivers) on page33, for charging

information.

6.2.2 Piping Layout and Condenser Positioning

The piping layout and condenser positioning is detailed in the submittal documents included in the Submittal Drawings.

The following table lists the relevant documents by number and title.

Table 6.5 Refrigeration Piping Layout and Condenser Positioning Drawings

Docu ment Num ber Title

DPN003965 Liebert®DSE Air Cooled Piping Schematic Liebert® MCV Mounted above Liebert® DA125-250

DPN005207 Liebert® DSEAir Cooled Piping Schematic Liebert®MCV Mounted above DA265

6.2.3 Refrigerant Line Sizes and Equivalent Lengths

Table 6.6 Recommended Refrigerant Line Sizes, OD Copper

Model

Equivalent Length Hot Gas Line, in. Liquid Line, in.

50 ft. (15 m) 1-5/8 1-3/8

100 ft. (30 m) 1-5/8 1-3/8

150 ft. (45 m ) 1-5/8* 1-3/8*

300 ft. (91 m) 1-5/8* 1-3/8*

*The DA250 and DA265 units can be extended to a maximum 200 ft (61m) linear or 300 ft (91m) equivalent length.

Source: DPN000788 Rev. 13

DA250

DA265

NOTE: See the piping schematics for your system in Submittal Drawings. For installations using pre-fabricated heat

rejection skids, included piping must be factored into total equivalent length calculation. Please consult factory for

details.

28

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 33

6.2.4 Refrigerant Charge Requirements for Air Cooled Systems

The following tables provide the refrigerant charge requirements for the Liebert® DSE, connected piping, and condenser

options.

Table 6.7 Indoor Unit Approximate Refrigerant Charge for R-410A Per Circuit

Indoo r Unit Type Model Circuit 1 (Outercircuit), lb(kg) Circuit 2 (In nercircuit), lb(kg)

Air cooled DA250 25 (11. 3) 25 (11. 3)

Air cooled DA265 25 (11 .3) 35 (15.9)

*System Charge: Indoor unit, MCV440 heat rejection skid with EconoPhase (PRE)and refrigerant lines.

For system charges over 200 lb. (90.7kg), consult your Vertiv representative.

See Table 9.3 on page47 for the recommended oil for the system.

The values in this table a nd in the following tables are needed in order to calculate the full system charge:

• Ta ble 6.8 below

• Ta ble 6.9 below

Table 6.8 MCV Heat Rejection Skid Refrigerant Charge for R-410A per Circuit Including PRE

Heat Rejection Skid* System # Circuit Number

Charge per Circuit, lb (kg) (With or

Without Receivers)

MCV440 Single skid with (1) PRE

unit

MCV440 Dual skid with (2) PRE units

*The heat rejection skid contains Liebert® MCV condenser(s), Liebert® DSE receiver(s)when used with a DA250 system, Liebert®EconoPhase PRE units(s),

and all internal piping. Liebert® DSE receivers are not used with a DA265 system.

1

1

2

1 62 (28.1)

2 62 (28.1)

1 62 (28.1)

2 62 (28.1)

1 62 (28.1)

2 62 (28.1)

Table 6.9 Interconnecting Piping Refrigerant Charge for R-410A, lb per 100ft (kg per 30m)

Line Size, OD, in. Liquid Line Hot Gas Line

1-3/8 51.5 (23.0) 5.9 (2.6)

1-5/8 — 8.4 (3.7)

Source: DPN003099, Rev. 1

6 Pip ing and Refrigerant Requirements

29

Page 34

6.2.5 Additional Oil Requirements forScrollandDigital ScrollCompressors

NOTICE

Risk of improper compressor lubrication. Can cause compressor and refrigerant system damage.

Failure to use oil types, viscosities and quantities recommended by the compressor manufacturer may reduce

compressor life and void the compressor warranty. See Compressor Oil Types for R-410A Refrigerant, for the

recommended oil for the system.

• Do not mix polyolester (POE) and mineral-based oils.

• Do not mix oils of different viscosities.

• Consult your Vertiv sales representative, visit https://www.Vertiv.com/en-us/support/, or contact the

compressor manufacturer if questions arise.

See 6.2.5 above, for the amount required for various system charge levels.

In addition to oil added based on system charge, additional oil is required for discharge line field installed traps. Standard

formed tube traps are required, see Figure 6.2 below, and Table 6.11 on page32, because straight tubes and fittings used

as traps require much more oil and the length of the straight tube can vary.

After the system has been fully charged with refrigerant, use a hand pump to add the additional oil at the suction side of the

system while the system is running.

The amount of oil added by field service must be recorded on the tag marked “Oil Added Field Service Record,” attached

to each compressor. The date of oil addition must be included as well.

Figure 6.2 Standard Formed Tube Trap Versus Straight Tubes and Fittings Trap

Item Description

1 Standard forme d t ube tr ap

2 Stra ight t ubes and fit ti ngs t rap

30

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 35

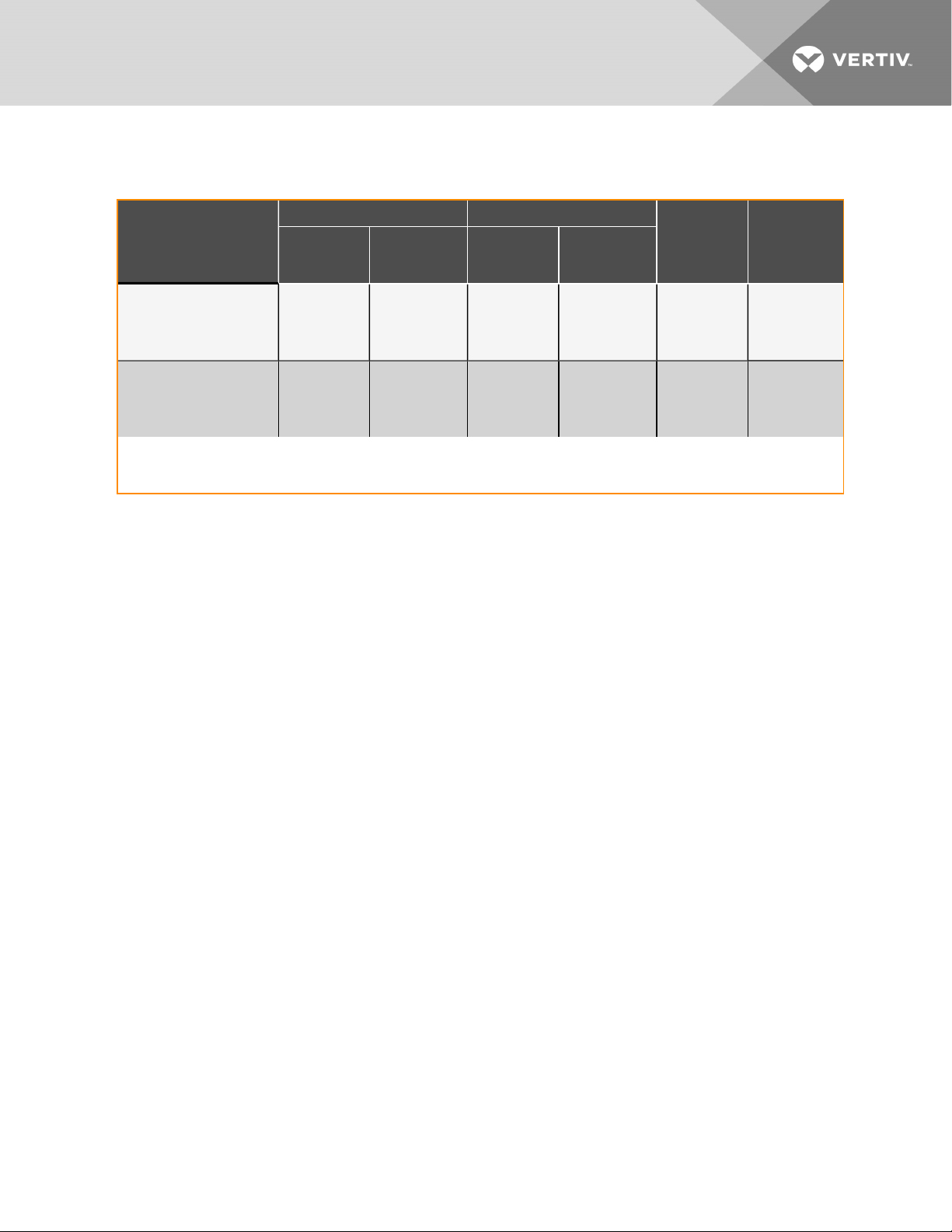

Table 6.10 Additional Oil Required per Refrigerant Charge

Refrigerant System C harge

Per Circuit, lb (kg) *

< 40 (18. 1) 0

40 (18.1) 10 (300)

50 (22.7) 1 8 (530)

60 (27.2) 26 (770)

70 (31. 8) 34 (1010)

80 (36.3) 42 (1240)

90 (40.8) 50 (1480)

100 (45.4) 58 (1720)

110 (49.9) 66 (1950)

120 (54.4) 74 (2190)

130 (59.0) 82 (2430)

140 (63.5) 90 (2660)

150 (68.0) 98 (2900)

Model

DA250, DA265

Additional Oil Required Per Circuit, oz (ml)

160 (72. 6) 106 (3130)

170 (77. 1) 11 4 (3370)

180 (81.6) 1 22 (3610)

190 (86.2) 130 (3840)

200 (90.7 ) 138 (4080)

System Charge: indoor unit, MCV heat rejection skid, refrigerant lines. Calculated per circuit.

For system charges over 200 lb. (90.7kg), c onsult your Vertiv representative.

See Compressor Oil Types for R-410A Refrigerant, for the recommended oil for the system.

Source:DPN003950 Rev. 6

6 Pip ing and Refrigerant Requirements

31

Page 36

Table 6.11 Volume of Oil in Standard Form Trap by Pipe Diameter

Pipe d iameter, in. Oil volume, oz (ml)

1/2 0.2 (5.9)

5/8 0.4 (11.8)

3/4 0.6 (17.7 )

7/8 0.9 (26.6)

1-1/8 1.8 (53.2)

1-3/8 3.3 (97.6)

1-5/8 5.5 (162. 7)

Source: DPN003950, Rev. 6

6.2.6 Evacuation, Leak Testing, and Charging Air Cooled Systems

Two discharge lines and two liquid linesmust be field installed between the indoor unit and the outdoor condenser.

NOTE: Keep the evaporator unit, receiver (if equipped), and condenser closed with their factory charge of dry

nitrogen while all field piping is installed. Keep the field piping clean and dry during installation. Do not allow it to

stand open to the atmosphere. When all the field interconnecting piping is in place, vent each outdoor unit’s dry

nitrogen charge and connect to the field piping. Finally, vent the evaporator unit's dry nitrogen charge and make its

piping connection last. Follow all proper brazing practices, including a dry nitrogen purge to maintain system

cleanliness. The condenser connection pipes must be wrapped with a wet cloth to keep the pressure and temperature

sensors cool during any brazing.

Evacuation and Leak Testing Air Cooled Systems

For proper leak check and evacuation, you must open all system valves and account for all check valves.

NOTE: The system includes a factory installed check valve and an additional downstream Schrader valve with core in

the compressor discharge line. Proper evacuation of the condenser side of the compressor can be accomplished only

using the downstream Schrader valve. See the appropriate piping schematic for your system in Submittal Drawings.

1. Starting with Circuit #1, open the service valves and place a 150 PSIG (1034kPa) of dry nitrogen with a tracer

of refrigerant. Check the system for leaks with a suitable leak detector.

2. With pressure still in Circuit #1, open the compressor service valves in Circuit#2.

• If pressure increases in Circuit#2, the system is cross-circuited and must be re-checked for proper

piping.

• If there is no pressure increase, repeat step1 on Circuit#2.

3. After completion of leak testing, release the test pressure, (observe local code) and pull an initial deep vacuum

of 500microns on the system with a suitable pump.

4. After fourhours, check the pressure readings and, if they have not changed, break vacuum with dry nitrogen.

Pull a second and third vacuum to 500 microns or less. Re-check the pressure after twohours.

When the three checks are complete, remove the jumper hose from the service valve fitting and the condenser,

and proceed to Charging DA250 Air Cooled Systems (Liebert® MCV440 with Receivers) on the facing page.

32

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 37

Charging DA250 Air Cooled Systems (Liebert® MCV440 with Receivers)

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

R-410A is a blended refrigerant and must be introduced and charged from the cylinder only as a liquid.

When adding liquid refrigerant to an operating system, it may be necessary to add the refrigerant through the

compressor suction service valve. Care must be exercised to avoid damage to the compressor. We recommend

connecting a sight glass between the charging hose and the compressor suction service valve. This will permit

adjustment of the cylinder hand valve so that liquid can leave the cylinder while allowing vapor to enter the

compressor.

NOTICE

Risk of improper operation. Can cause compressor failure.

Operating the unit with the EEV closed can cause compressor failure. The reheat and humidifier are disabled. A

minimum of 20 psig (138 kPa) must be established and maintained for the compressor to operate. The

charging function can be reset as many times as required to complete

To charge the system:

1. Check the nameplate on the indoor unit for refrigerant type to be used. Unit control configurations differ

depending on refrigerant type.

2. The unit must be operating during charging, refer to Checklist for Completed Installation on page37

3. Calculate the amount of charge for the system. See Refrigerant Charge Requirements for Air Cooled Systems

on page29.

4. Accurately weigh in as much of the system charge as possible before starting the unit. Do not exceed the

calculated charge by more than 0.5lb(0.37kg).

5. Close the MVC heat rejection skid disconnect switch.

• We recommend charging the unit with the return air setpoint between 75°F and 85°F (24°C and 29°C).

• The return air temperature to the unit being charged must be stable and must be maintained greater

than 65°F(18°C). If this is not possible due to lack of heat load, then the load banks must be used to offset

the cooling load during startup. See Target Refrigerant Level in Sight Glasses at Outdoor Temperatures

on the next page.

6. Close the Liebert® DSE disconnect switch.

6 Pip ing and Refrigerant Requirements

33

Page 38

7. In the Service menu of the Liebert® iCOM™ controller, select Diagnostics/Service > Diagnostics:

a. Enable Manual Mode.

NOTE: Manual Mode will time out after 30 minutes.

b. In the search box, enter E177 and press Enter.

Two parameters appear in the Parameter Directory (E177.1 and E177.2).

Press the Gear icon in the upper right corner.

Select Make Writeable.

Change E177.1 and E177.2 from 15 minutes to 2 minutes.

This reduces the superheat setpoint from 24°F (13.3 °C) to 13°F (7.2°C) in two minutes.

c. In Evaporator Fan options set Motors to On to operate the fan during Manual Mode.

d. In Compressor Circuit 1 options, set Compressor Mode to Charge to operate Compressors 1A and 1B at

full capacity. Turn Compressor 1A and 1B to On. The EEV will modulate to control superheat setpoint

e. Reset the charge function as many times as needed to complete unit charging.

NOTE: You must establish and maintain a minimum 20psig (138kPa) for the compressor to operate.

f. Repeat step 7 for Compressor Circuit 2.

8. Check the refrigerant level in the refrigerant level sight glasses on each receiver after the unit has been

operating for at least 15minutes.

NOTE: Each receiver at the condenser has two sight glasses and the refrigerant level varies with outside temperature.

9. Adjust the refrigerant level in each circuit to meet the level shown in Target Refrigerant Level in Sight Glasses

at Outdoor Temperatures below.

10. After adjusting the refrigerant, allow the system to operate an additional 15minutes before checking for the

need of further adjustment.

11. Repeat the procedure for the second circuit.

NOTE: A digital scroll compressor can have a clear unit sight glass on the liquid line only when operating at 100%

capacity. When operating with a receiver, the unit sight glass might not become clear even when operating at 100%

capacity. When operating below 100%, the unit sight glass may show bubbles with each 15 second unloading cycle.

Target Refrigerant Level in Sight Glasses at Outdoor Temperatures

• 40°F (4.5°C) and lower—bottom sight glass is 3/4 full

• 40°F (4.5°C) and higher—bottom sight glass is full

If the return air temperature cannot be maintained between 75°F and 85°F (24°C and 29°C) due to lack of load, then the

liquid level receiver must be adjusted to the following if return air is between 65°F and 75°F (18°C and 24°C):

• 40°F (4.5°C) and lower—Charge to the bottom of the top sight glass.

• 40°F (4.5°C) and higher—Top sight glass is 1/4 full.

34

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 39

Charging DA265 Air Cooled Systems (Liebert® DA265 without Receivers)

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

R-410A is a blended refrigerant and must be introduced and charged from the cylinder only as a liquid.

When adding liquid refrigerant to an operating system, it may be necessary to add the refrigerant through the

compressor suction service valve. Care must be exercised to avoid damage to the compressor. We recommend

connecting a sight glass between the charging hose and the compressor suction service valve. This will permit

adjustment of the cylinder hand valve so that liquid can leave the cylinder while allowing vapor to enter the

compressor.

NOTICE

Risk of improper operation. Can cause compressor failure.

Operating the unit with the EEV closed can cause compressor failure. The reheat and humidifier are disabled. A

minimum of 20 psig (138 kPa) must be established and maintained for the compressor to operate. The

charging function can be reset as many times as required to complete.

To charge the system:

1. Check the nameplate on the indoor unit for the refrigerant type to be used. Unit control configurations differ

depending upon the refrigerant type.

2. The unit must be operating during charging. Refer to Checklist for Completed Installation on page37

3. Calculate the amount of charge for the system. See Refrigerant Charge Requirements for Air Cooled Systems

on page29.

4. Accurately weigh in as much of the system charge as possible before starting the unit. Do not exceed the

calculated charge by more than 0.5 lb (0.37 kg).

5. Close the Liebert® MCV heat rejection skid disconnect switch.

• Unit must be charged with the return air within +/- 10°F (5.5° C) of the operating point.

• If the operating point changes, the charge may need to be adjusted according to the new operating

point.

• The return air temperature to the unit being charged must be stable. If this is not possible due to the lack

of heat load, then the load banks must be used to offset the cooling load during startup.

6. Close the Liebert® DSE disconnect switch.

7. In the Service menu of the Liebert® iCOM™ controller, select Diagnostics/Service > Diagnostics.

a. Enable Manual Mode.

NOTE: Manual mode will time out after 30 minutes.

b. In the Search Box type E177 and press Enter.

6 Pip ing and Refrigerant Requirements

Two parameters appear in the Parameter Directory (E177.1 and E177.2).

Press the Gear icon in the upper right corner.

Select Make Writeable.

Change E177.1 and E177.2 from 15 minutes to 2 minutes.

This will reduce the superheat setpoint from 24°F (13.3° C) to 13°F (7.2° C) degrees in two minutes.

35

Page 40

c. In the Evaporator Fan options, set Motors to On to operate the fan during Manual Mode.

d. In Compressor Circuit 1 options, set the Compressor Mode to Charge to operate Compressors 1A and 1B

at full capacity. Turn Compressor 1A and 1B to On. The EEV will modulate to control superheat setpoint.

e. Reset the charge function as many times as needed to complete unit charging.

NOTE: You must establish and maintain a minimum 20 psig (138 kPa) for the compressor to operate.

8. Check out the subcooling using the Schrader port on the liquid line just before the expansion valve. Superheat

should be around 13°F (7.2°C) before verifying subcooling.

9. Adjust the refrigerant level to meet the subcooling shown in Table 6.12 below

10. After adjusting the refrigerant, allow the system to operate an additional 15 minutes before checking the need

of further adjustment.

NOTE: A digital scroll compressor can have a clear unit sight glass on the liquid line only when operating at 100%

capacity. When operating below 100% capacity, the unit sight glass may show bubbles with each 15 second unloading

cycle.

Table 6.12 Target Subcooling at Outdoor Temperature

Outdo or Ambient Subco oling

°F °C °F °C

-30 -34.4 10 5.5

-15 -26.1 10 5.5

0 -17. 8 10 5.5

15 -9.4 1 0 5.5

30 -1.1 1 0 5.5

45 7.2 1 0 5.5

60 15.6 10 5.5

75 2 3.9 10 5.5

85 29.4 1 0 5.5

95 35 10 5.5

105 40.6 12 6.7

115 46.1 14 7.8

Subcoolingshould be within ± 3°F (1. 7°C)

11. Repeat steps 7 through 10 for Compressor Circuit 2.

12. Change E177.1 and E177.2 back to 15 minutes after both circuits are charged.

36

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 41

7 CHECKLIST FOR COMPLETED INSTALLATION

7.1 Moving and Placing Equipment

1. Unpack and check received material.

2. Make sure that proper clearance for service access has been maintained around the equipment.

3. Check that equipment is level and mounting fasteners are tight.

7.2 Electrical Installation Checks

1. Check that supply voltage and phase matches equipment nameplate.

2. Check that power wiring connections completed to the disconnect switch, evaporator unit and heat rejection

equipment.

3. Check that power line circuit breakers or fuses have proper ratings for equipment installed.

4. Control wiring connections completed between indoor evaporator and heat rejection equipment.

5. Ensure that all internal and external high and low voltage wiring connections are tight.

6. Confirm that unit is properly grounded to an earth ground.

7. Check that control transformer setting matches incoming power.

8. Confirm that electrical service conforms to national and local codes.

9. Check blowers and compressors for proper rotation.

7.3 Piping Installation Checks

1. Check that piping is completed to refrigerant loop.

2. Confirm that piping has been leak checked.

3. Check that additional oil has been added for system charges over 40 pounds (18.1kg) per circuit. See

Additional Oil Requirements forScrollandDigital ScrollCompressors on page30.

4. Check that piping is properly sized, sloped and trapped as shown in the piping schematics.

5. Check piping inside and outside of equipment for proper support and adequate spacing to prevent rub

through.

6. Ensure that factory clamps have been reinstalled.

7. Confirm that the drain line is connected, not obstructed, and pitched per local code.

7.4 Other Installation Checks

1. Make sure that ducting or plenum assembly complete (if required), maintain access to filters.

2. Check that filters are installed.

3. Check fasteners that secure motors—some may have become loose during shipment.

4. Verify water detection is properly installed around all units (recommended).

5. Confirm that blower drive system rotates freely.

6. Check all fans are free of debris.

7. Set fan airflow calibration voltage. Refer to Table 7.1 on the next page, for values. The values are set in the

iCOM™ Service menu > Setpoints > Fan.

7 Checklist for Completed Installation

37

Page 42

Table 7.1 Airflow Calibration Voltage DA250

Air Flow* at 0.1in.(25Pa) ESP Air Flow C alibration Vo ltage

CFM CMH 60 Hz 50 Hz

25,0 00 42480 4.66 5.57

26,000 44179 4.83 5.78

27, 000 45878 5. 00 5.98

28,000 47578 5. 17 6.19

29,000 49277 5.34 6.39

30,000 50976 5.52 6.60

31,000 52675 5.69 6.81

32,000 54374 5.86 7. 01

33,000 56074 6.03 7. 22

34,000 57773 6.20 7.42

35,000 59472 6.38 7. 63

36,000 61171 6.55 7.83

37,000 62870 6.72 8.04

38,000 64570 6.89 8.24

39,000 66269 7.06 8.45

40,000 67968 7.23 8.65

41,000 69667 7.41 8.86

42,000 71366 7.58 9.07

43,000 73066 7.75 9.27

44,000 74765 7.92 9.48

*Maximum air flow calibration voltage must be adjusted based on the required air flow.

38

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 43

Table 7.2 Air Flow Calibration Voltage DA265

Air Flow* at 0.1in.(25Pa) ESP Air Flow C alibration Vo ltage

CFM CMH 60 Hz 50 Hz

25000 42,475 5.42 6.49

26,000 44,174 5.61 6.71

27, 000 45,873 5.80 6.94

28,000 47,572 5.99 7.1 7

29,000 49,271 6.18 7.40

30,000 50,970 6.37 7.62

31,000 52669 6.56 7 .85

32,000 54368 6.75 8.08

33,000 56,067 6.94 8.31

34,000 57,766 7. 13 8.54

35,000 59,465 7.32 8.76

36,000 61, 164 7.52 8.99

37,000 62,863 7.7 1 9.22

38,000 64,562 7. 90 9.45

39,000 66,261 8.09 9.67

40,000 67,960 8.28 9.90

41,000 69,659 8.47 -

42,000 7 1358 8.66 -

43,000 73,057 8.85 -

44,000 74,756 9.04 -

45000 76,455 9.23 -

46000 78,154 9.42 -

47000 79,853 9.61 -

48000 81,552 9.80 -

49000 83,251 9.99 -

*Maximum air flow calibration voltage must be adjusted based on the required air flow.

7 Checklist for Completed Installation

39

Page 44

This page intentionally left blank

40

Vertiv | Liebert ® DSE Thermal Management S ystem In staller/User Guide

Page 45

8 INITIAL STARTUP CHECKS ANDCOMMISSIONINGPROCEDURE

FORWARRANTYINSPECTION

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory supplied disconnect switch is inside the

unit. The line side of this switch contains live high voltage. The only way to ensure that there is NO voltage

inside the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all

local codes.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment damage,

serious injury or death. Installation and service of this equipment should be done only by qualified personnel

who have been specially trained in the installation of air conditioning equipment and who are wearing

appropriate, OSHA-approved PPE.

NOTICE