Page 1

ARC FLASH SOLUTIONS

Electrical Engineering Services

OVERVIEW

Be Safe and Compliant

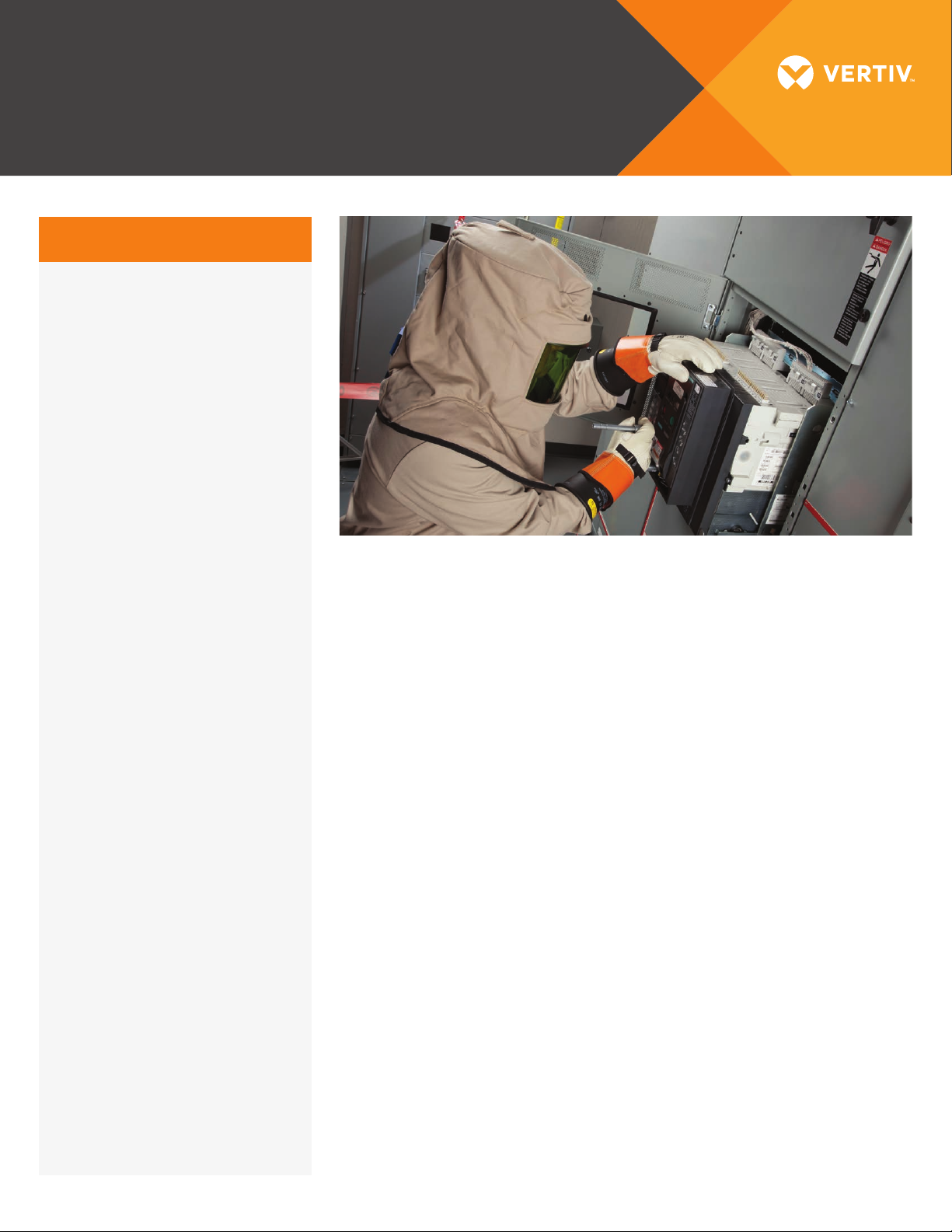

Arc flash is a serious hazard with

potentially devastating eects.

Ensuring worker safety and meeting

the challenges of the new arc flash

safety requirements can be a

diicult task.

Trust Vertiv's Electrical Reliability

Services (ERS) to deliver the most

complete solutions for arc flash

compliance. From risk assessment

and labeling to personal protective

equipment (PPE) and training, ERS will

provide you with the industry's best

safety programs, while reducing

your risk and ensuring

regulatory compliance.

Whether you require a complete

program or short-term assistance

with arc flash calculations, ERS has

a solution to fit your needs.

Benefits

y Ensure compliance with

regulatory requirements

y Avoid costly fines and higher

insurance costs

y Improve worker safety

y Reduce lost worker productivity

y Ensure optimum system

performance, safety

and eiciency

y Minimize threats to your critical

facility with solutions from a

single source

Electrical Reliability Services

Ensure worker safety and regulatory compliance with

comprehensive arc flash solutions

Electrical hazards, specifically shock, arc

flash and arc blast, can result in serious

injury or death to electrical workers.

Ensuring safety and meeting regulatory

requirements can be diicult to

accomplish in-house without the

assistance of resources familiar with

industry standards and recommended

practices. Consider the benefits of

partnering with ERS to help develop and

implement a complete, cost-eective,

single-point arc flash solution.

Our comprehensive portfolio of arc flash

solutions includes:

y Risk assessment

y Site review / compliance assessment

y Protective scheme design review

y Short circuit and coordination studies

y Single-line diagrams

y Arc flash analysis

y Hazard labeling plan

y Electrical safety program

review / development

y Training and performance evaluation

y PPE plan

y Preventive maintenance

y Documentation

y Optional annual re-certification

Risk Assessment

The National Fire Protection Association's

Standard for Electrical Safety in the

Workplace® (NFPA 70E) requires facility

owners to perform an arc flash risk

assessment prior to allowing a worker to

perform a task on or near energized

equipment. The risk assessment identifies

the presence and location of potential

hazards and provides recommendations

on PPE, boundaries for limited and

restricted approaches, flash protection,

shock protection and safe work practices.

To calculate the incident energy, all

technical data such as equipment type,

voltage, ratings, impedance, etc., is

collected and reviewed.

An eective way to conduct an

assessment is to utilize an outside

contractor trained in this procedure.

The technical sta of ERS is qualified

according to the National Electrical Code

definition. Our qualified electrical workers

have undergone specific training in the

hazards of working on energized

equipment, and the use and proper

application of PPE.

1

Page 2

ARC FLASH SOLUTIONS

To provide accurate results, state-of-the-art software (e.g., SKM, ETAP®, EasyPower®) is

utilized to perform arc flash calculations in accordance with the standards of NFPA and

the Institute of Electrical and Electronics Engineers (IEEE). These software packages

enable users to evaluate alternatives quickly and easily in order to establish optimal

protective schemes and device settings.

Hazard Labeling Plan

NFPA 70E mandates that electrical equipment such as switchboards, panelboards,

industrial control panels, and motor control centers, that are likely to require

maintenance while energized, must be field marked with a label. ERS can assist with

compliance during each phase of an arc flash risk assessment. Once the initial

assessment has been performed, ERS supplies the labels and can assist in applying the

appropriate hazard warning labels. As part of an ongoing labeling plan, updated labels

can be provided to accommodate equipment or system changes, or regulatory updates.

Site Review /

Compliance Assessment

The Occupational Safety and Health

Administration (OSHA) can and does

enforce its requirements. To ensure

compliance, ERS will determine the steps

needed to meet OSHA and NFPA

requirements. By conducting a

comprehensive assessment to identify

areas of risk and non-compliance, we will

formulate a plan to bring your facility into

compliance in the most eicient

way possible.

Protective Scheme Design Review

ERS’s technical sta can conduct a

protective scheme design review and

operational assessment of your electrical

distribution system to identify areas for

reducing potential arc flash hazards.

Several areas are evaluated including fault

current levels, arc exposure times,

operational procedures (such as remote

breaker control and remote racking), and

system grounding. Conducting a design

review is the most eective way to uncover

potential hazards, so options can be

evaluated and mitigation strategies can

be employed.

Page 3

"It was necessary for us to have one vendor for our arc flash, safety, and training programs. Based on our

previous experience with Vertiv's Electrical Reliability Services, we knew we would receive world-class

experience and solutions that would address all of our critical needs. We are very satisfied

with every phase of the program we received."

- Ramy Maharaj, Utility Maintenance Supervisor

Single-Line Diagrams

National Electrical Code (NEC)

requirements mandate accurate,

up-to-date single-line diagrams. These

schematics are essential for documenting,

troubleshooting, and communicating

information about your power systems. To

meet these requirements, ERS conducts a

comprehensive site survey that is

essential to developing or updating

existing single-line diagrams or

completing electrical system drawings.

Short Circuit and

Coordination Studies

To achieve the most accurate arc flash

hazard results, it is recommended that arc

flash calculations be completed in

conjunction with short circuit calculations

and protective device coordination. Short

circuit and coordination studies verify

protective device ratings, calculate

momentary and interrupting currents,

establish settings for all types of

protective devices, and coordinate

protective devices to minimize downtime.

ERS specializes in conducting these

studies which provide critical information

needed to ensure compliance with NFPA

and OSHA requirements.

Preventive Maintenance

NFPA 70E requires maintenance to be

performed on electrical equipment in

accordance with manufacturers’

instructions or industry consensus

standards. ERS can assist in developing a

preventive maintenance program to

specifically address arc flash hazards.

Our optimized preventive maintenance

program evaluates the equipment’s

condition and determines the most

cost-eective and manageable solution to

ensure your protective devices operate

properly, safely and reliably. Proper

maintenance will ensure that you are in

compliance with the NFPA 70E

requirements permitting "normal operation"

of equipment reducing hazards, thus often

allowing tasks to be accomplished safely

and without the need of extensive PPE.

Electrical Safety Program

Review / Development

OSHA requires every facility to establish

an electrical safety program. ERS can

assist in reviewing or developing a

comprehensive electrical safety

program that supports an overall site

safety program.

ERS can design an eective customized

program to provide training and create

awareness of potential electrical hazards.

This program will also identify hazard /

risk evaluation procedures, electrically

safe work procedures, tools and PPE

requirements, and risk mitigation

strategies. The electrical safety program

must be documented and audited at least

every three years. As part of the overall

safety program, we will assist you in

developing an eective safety audit

process, creating and maintaining a safety

manual, and planning and conducting

safety meetings.

Training and

Performance Evaluation

An eective electrical safety training

program should provide workers with the

knowledge and understanding of the

existence, nature, and causes of electrical

hazards, and methods for preventing them.

ERS’s arc flash training can include

sessions on building employee awareness

of the potential electrical hazards present,

identifying arc flash hazard and assessing

risk, understanding of quantities, selection,

and use of appropriate arc flash PPE,

reading and following hazard warning

labels, and reducing risk while working on

live exposed parts. Training can also cover

safety policy review and recommendations,

overview of applicable standards and

codes, and required documentation.

PPE Plan

PPE plans developed by ERS address all

relevant OSHA standards to ensure

compliance. Based on the findings of

the arc flash risk assessment, we will

provide incident energy information and

PPE recommendations, based on

calculated IE values. We can also assist in

the selection and supply of recommended

equipment on which workers will be

trained. Our team will address when

PPE is necessary and what equipment

is needed. ERS's approach can cover

how PPE should be worn, maintained,

and disposed of after the equipment life

has expired.

3

Page 4

ARC FLASH SOLUTIONS

Optional Annual Re-certification

Ongoing arc flash hazard research and

development will likely produce additions

to arc flash requirements. As modifications

or expansions to your electrical distribution

system are made, or as changes occur in

the electric utility system, it will be

necessary to update arc flash assessment

information on a regular basis.

In some cases it will be necessary to

update worker training on an annual basis.

ERS can provide annual follow-up site visits

to ensure continued compliance with

applicable arc flash standards, practices

and regulations. The audit includes a

written report of findings and

recommendations.

Documentation

Proper documentation will help you prove

compliance with OSHA and NFPA

standards, and facilitate an investigation

should an arc flash related injury occur.

Thorough documentation is one of ERS's

strengths. Our arc flash compliance plan

consists of a customized written report

that includes results of the arc flash risk

assessment, updated single-line drawings

of electrical systems, and signs and labels

on equipment and in hazardous areas.

Also included are the type, name/ID,

incident energy at working distances,

flash protection boundary, and other

pertinent information such as voltage,

available fault current, protective device

description and its trip time, arc gap, and

arc current.

Qualified Electrical Worker program

documentation can also be provided as

part of the safety and worker training

program, demonstrating compliance in

case of an audit.

Summary

Arc flash is a serious hazard with

potentially devastating eects.

NFPA 70E requirements aid users of

electricity in understanding how to

reduce the probability of injury in

case of an arc flash event.

Therefore, OSHA strictly enforces

these requirements. By complying,

your facility supports the goal of

reducing injuries and downtime.

However, you don’t have to do it

alone. Rely on the experts at ERS to

help you implement an arc flash

program. Whether you require a

comprehensive program or

short-term assistance with arc flash

calculations, we can help.

Establishing an eective arc flash

program will help reduce your risk,

provide required worker safety, and

ensure regulatory compliance.

Ordering Information

To learn more about this service

and other Electrical Reliability

Services solutions, please contact

your local sales representative oice

or visit ers.Vertiv.com. In the United

States, call 1-877-468-6384.

ers.Vertiv.com | Vertiv - Electrical Reliability Services, 1-877-468-6384

© 2019 Vertiv G roup Corp. All righ ts reserved. Ver tiv™ and the Vertiv log o are trademarks or re gistered trade marks of Vertiv Group C orp. While every p recaution has be en taken to ensure ac curacy and compl eteness herei n, Vertiv Group Cor p. assumes no res ponsibility, and d isclaims

all liabili ty, for damages res ulting from use of thi s information or for an y errors or omissi ons. Specifi cations are subje ct to change witho ut notice.

ES-02-557 (R05/19)

4

Loading...

Loading...